Sioux Tools 5558A User Manual

I

PCiOOLtd

--

Ai^w

Jepues

esn

IOU

Oa

-

esn

)ou

OQ

-

-

'

.

-

-

-

-

,

-

IOU

od

sfe~iv

PESY

8sau

jou

asn

'6u!l~~p

asn

pa6uQaiid

~a0ieisd0

pnp

^M^/A~w

oe-t

%I

LC1

saw

E

S@

JSSM

.israu

Alepzs

peeoxa

[euos~ad

pue

'~9p~y6

aua~kdlod

sapme3:)e

4aps

01

WlsorfYB

SYOiptuiSUf

%sjw

q

uo@w~o~d

Aq

mean

J@U$O

1tw0~~t~)eaaiatp

uai^w

-sped

patw

we

5856606

liogaiqy

83048q

~unuiveui

~0Mod

PSPU9UIIll~Y

ON

e

hi=

i

ewe

e

@#V32

few

~!SB

Ès

si!

U!

JÈI

fiunuo~

SB

)ueuid!nbe

'Buptm

uo!iotu1suoo

^Qm("i

mtoi~auej89

VW9S

w<ty

000'0

-itsew

6ufui8e~q

-&ti@!

#$Y

+jOOl

$iW

33-

pUe

.wn^s&~d

'p8pU~WO3al

m

'BuipuyG

suf?iuo9

~aw

'(Suwe~

settifttlo~

^Èa[wtfliiqro~estwo

-

-

-

-

-

, , ,-

au

11

A0

Aq

oa

m!&IJS

..-..-

UW

&emwed

01

pwi

~UW

s!

fw^

si

QJ9W

'Ayaiiiiaaia

USYM

dettiv

wl!ç0(

-WM

Wft

Aluo

~sr>

OQ

¥J(~È~

x~@w

suos~ad

'1(001101,1

~IU.-UOQ!SO<*

Suge)s<to

SIB

am

iou

he

6tt!m

da5

w

KM

on

33a~ioo

iou

pue

6up!i\~&s

peuiw

'eedei

1

%IOQsOHi^puautuioosH

iynuÈui^-$2;t

-8

'Wt

9^

WJI

KKWS

SMIEU

-loot

6u!uoo

'100)

i~a

-pai~insfi

id0W

Ajlmppa~a

$0

saueya

844

6t8

-du&i=

101

swd

&reds

em

JO

&S!AOJ~W!

op

01

'am

'iamj/jaSSt~i

mjedai

ws

am

"w

-a^

pinoqs

&SOH

-YOâ

d->s

cut

olu!

UUy

zz

A&u&iagiris

AIUO

,YOPO,

isw

win

^poq

eig

BUMJCMH

sift

asn

J&AaN

L)~!M

isqnoa

SUROOJ

at

Aim

e3UEUe$U!Bul

Ai~~oduist

aq

u!

aAim

aq

sfem@

wyipapuaaayo3$y

NO1

pue

-t~peue

1004

1

/PUB

-.ma

loolwa~aans~Aeu;i^m^aKaucaaeeiAwaaca

pue

"wfeda~

iw

pa!Jjeo

.UQ,

oj

aais

return

to

the

'Off'

-Always

*On/Off'

before

attachment

-Before

has

been

known

shut

off

vatro

Bang,

fitted

using

tha

fitted

and

easily

position

the

to

'exhaust

f-ng

to

too),

to

the

when

air

supply

thÃ

or

the

tool.

make

sure

air

supply

accessible

released.

to

the

toot

air

from

adjusting

that

a.

fine

and

so

that

the

and

the

the

shut

the

air

press

feed

hose

working

off

device

position

stippiy

tha

is

to

ihetootcanfeeshuEoffI#anç(ne^e~~y

-Check

-Take

care

the

tool

jewelry,

ho^e

and

against

wHh

watches,

tittings

entanglement

clothing,

b,-ac6tebr

reguSarty

hair.

ties,

etc.

for

wear.

of

the

moving

cleaning

This

could

lags,

cause

parts'

rings,

of

the

bodyorpartsof8abodytob&drawntowaRisanstIn

contact

very

-It

practices

tegat

raatntainittQ

-Take

-Never

-When

with

dangerous.

is

expected

and

requirements

care

any

other parson

be

contaminated

a

toot

or

not

surfaces

has

if

allow

or

lay

stopped

the

toot

ihe

observe

the

that

the

ttw

toot

the

flames.

the

tool

moving.

is

moving

that

users

tod,

exhaust

or

material

by

oil

exhaust

exhaust

down

not

in

parts

of

wilt

all

local,

when

instaiting,

air

does

or

droplets.

has

air

to

until

the

use,

shirt

the

toof

and

adopt

safe

regional

not

and

point

substance

When

first

3

high

oil

come near

worWng

oft

ttÈ

air

46

be

worxing

country

using

or

towardte

that

could

lubricating

content,

very

do

ftoi

attachment

supply

and

pressthetrigg&^!~wto<facanfeesupptytine.BBte

tool

is

not

to

be

used

for

Ã

period

of

time,

first

disconnect

room

temperature

-If the

tool

inexperienced

from

is

passed

user,

air

supply

environment.

frm

make

and

one

sure

store

user

these

iubricate,

\r\

a

dry

average

to

a

new

(nstrucSons

w

are

passedwiththatoot

-Do

not

remove

any

manufacturer

where

fitted,

i-e.,

wheel

governors?,

-Wherever

viss,etc.tomaisait

work

stretch

-

Try

a

loot

in

doubt

-In

underwater

seek

-Try

the

possifcis.

starting

-Always

working

maximum

Foreseen

This

toot

vanetaoffnataffetstaaistfeawtai,wswt.sSasfessateiais,^C.

TtÈdualrotaryofbttatacCortwSwasttwamurtoisbrssiv

EpncNng

can

be

abrasive

so#

adhesive

Dowstusemtoriferanyot&er~tothaifarw^ahas

(wen

possible,

opefaSon.

or

overreach.

to

match

thai

is

sesk

genera.)

advice

to

make

work

task

try

workuse

pressure

is

&signed

mites

used

discs

ç

designed

etc.

Keep

the

too)

too

light

advice.

terms,

use

from

sure

to

to

clear

ah

working

Use

and

hence

wfth

a

whichr

VefctoA$atiiwf,

and

use

guards,

secure

rig(<iisoSdoesRotwwe&RngW

good

to

the

or

heavy

this

or

use

in

manufacturer.

that

the

be

performed

unnecessary

hose

and

ratings

pressure

Of

The~ool

tor

the

purpose

Is

primarily

variety

of

grades

according

only

abrasive

fitted

safety

workpiice

balance

work

operation.

for

the

toot

is

wpbsive

work

area

safeiy-

couplings

at

least

rating

of

cisam

a

finishifig

of

to

pad

fitted

discs

safety

trigger,

with

clampst

at

a11

times.

Do

work

operalion.

not

suitable

wivlronmente

is

clear

to

if

practical

obst(uc8ons

with

minimum

1

112

Ihe

toot.

-

5558A

or

sanding

mm

to

the

as

clesenbed.

times

sanding

(6'

tori,

of

150

devices

speed

Do

not

notuse

for

-

enable

ansi

before

the

at

toot.

diameter)

can

be

Work

The

isawieewtsaartdgdSateÈioofisasedtAessteBicfeaw

solaftw-&can

use,

and

using

Putting

Air

Use

piesswe

wflhtne{Bg3e-la8sf<iepresse<f.Use;'ee6ffHwffite<itosestzs

and

supply

systtsm

off

recwiffien(fed

as

coffeet

obtained

the

tool,

tool

ie.tsp(Ènhi

profBmMy

supply

circulate

and

KisteeMwtentisi!8*attfeeairpressa#at8iatwi¥sitsiteiheto<^E

furwiw

Stations

too;

sfwutsi

on!y

operator

and

sander.

tÃ

must

be

the

tooting

the

Into

Supply

a

dean

lubricated air

at

the

tool

SstPQ'&i.

ti

is

reaanffiewieti

as

shown

incorporating

The

air

iftat

in

Ffgare

pressure

from

your

should

be

&m!$

incorporating

and

run

the

oil.

starts

fe

60

y6iS42

in

to

IiÃ

tool

if

to

without

valve.

stiow>

tool

depressuriang

Clfeeonnact

if

tool

be

used

as

a

handheld,

u$&insawpositions.

be

ft)

a

secure

aware

of

the

safety

position

rules

Service

supply

that

o<

SO

fiaure

1.

supply

an

ate

fatar,

3

as

ftis

the

toot.

supplier.

IiAhted

ths

fine

ak iine

of

a

suitafcfe

a

slowly

too)

is

used

stow

or

bar.

p.aiJ4.2

Do

an

should

wB

Details

If

by

by

ansi

fust

lor

tose

bat

that

the

toot

not

connect

easy

to

reach

be

lubricated.

rsguiator,

s^rfy

aft,

&

such

equipment

shuttimi

pressing

Wdsafe

mhibftor.

a

few

frequently.

power,

will

when

lubffcaiar

such

ffiio

seconds

hand

but

give

is

the

off

the

Reconnect

lubricate

Operating

Setectasiat^xaabi^arodisc<seeSaefen'F<ws^nUteaotTooT)

amtatsAftsweftatBisteedssxwstftothetool.Conwcttos~

air

sufifty

as

Appty

wLTate

a

toaw4dthecfiscsna~~i.e.thediscmay

ssspwcwUSsssSiSy^cwedwhichwScausettÈtoottote*fe^

hati&-

breathing

hazarcfous

Ctwck

If

leva!,theactualsandfcw~ass~isauseanoisel&such~r

earcratectefswl!feefcauirad.ESwearesfsTpwsaonShe

mteiiatixSag

Do

not

win

unnecessarilyhighfcrcostothetoot.

DorwtusawxiasiradorfHwsizedmtSscs.TBe<i6scshouki

&emfflt~e8Èat1/4'iamis(iiafnaerSwiaÈ{arfand#staff

ttanttropad.hairwgutalorlever(42)tehxaiedm(heisxteofttÈ

bo~(16).Itcanbeusedtovarythevolume<rfcompressed~rfedto

the

AnairstrainerisinowporatediitintetbuSt&w.TWsstioutd

pef*xttea9tf*rSetrfartyiffhstoo!sfewsorlosespowervItcanbe

eas%çteanrfwTOSaciwq&iat3tHi#Èfc?miia(Èdte(58)."ntespBt

lock

drtve

mounting

a

It

balance

L

Dismantling

DisewiTOCt

RUto*&Èif!sm>eiwBiafceifeie(ito;atÈtioffi&a(ancew<1tl.Pre

the

Side

move

reconnmeoded.

8Ã

saoder

great

care

It

!s

&ways

mask.

dust

before

using

sanctet!"

cortinue

make

the

sanding

motor

which

can

be

set

washer

(5)

shaft

pCTrades a

too!

We

dimpie

Of

mounting

the

instruction

lightly

to

ttie

when

sand"mg

ifacof~resfldd

The

sanding

which

may

the

tool.

safety

to

use

atwastve

process

wilt

vary

the

to

provute

ptate

h

untB

(9)

for

titoat

when

&

Assembly

from

air

supply.

on

drive

pad

shah

telbof

work

around sharp

of

require

Even

ffews

dim

heffteiwit

speed

eittiw

Die

rotary

which

washer

(9)

and

fixed

to

aftd

allow

to

use

certain

ma\

9

tte

machine

Wts

recomerKieA

that

of

the

rotary or

point

falters

action.

fiwas

(5)

to

unscrew

the

random

bebroughttoanabrupt

safely

materials

are

and

saoder.

orbital

engage

operated

beforeany

having

to

be

a

9w

connected

tod

and

itj&iteitefi

equipment

IS

the

air

triggetAewr

me

msiw

the

edges

breathing

worn

the

the

The

a

smooth,

toot.

-suctt

a

finn

is

wnning

to

to

the atr

(S

strongly

(FRL}

aif

used,

supply

adaptor

loot

allow

on

daily

and

surfaces

may

create

equipment.

dogged.

need

becheewct

in

swirt-iree

when

the

air

useti

at*

can

to

on

to

air

basis

doc

and

to

Slide

the

grip

line

shut

then

the

noise

Ttife

apply

obsysd

measured

too*

operate

I1

rtot

Rose

(liBncating

to

abtasiw

gtaasfis

has a bw

or

action.

races-s

counterweight

It

air

air

be

the

s

041

air

to

to

a

a

the

pad

Instructions

the

hots

in

Carefully

bwtv

(1

the

re-

11

pad

[I).

balance

Page

No

2

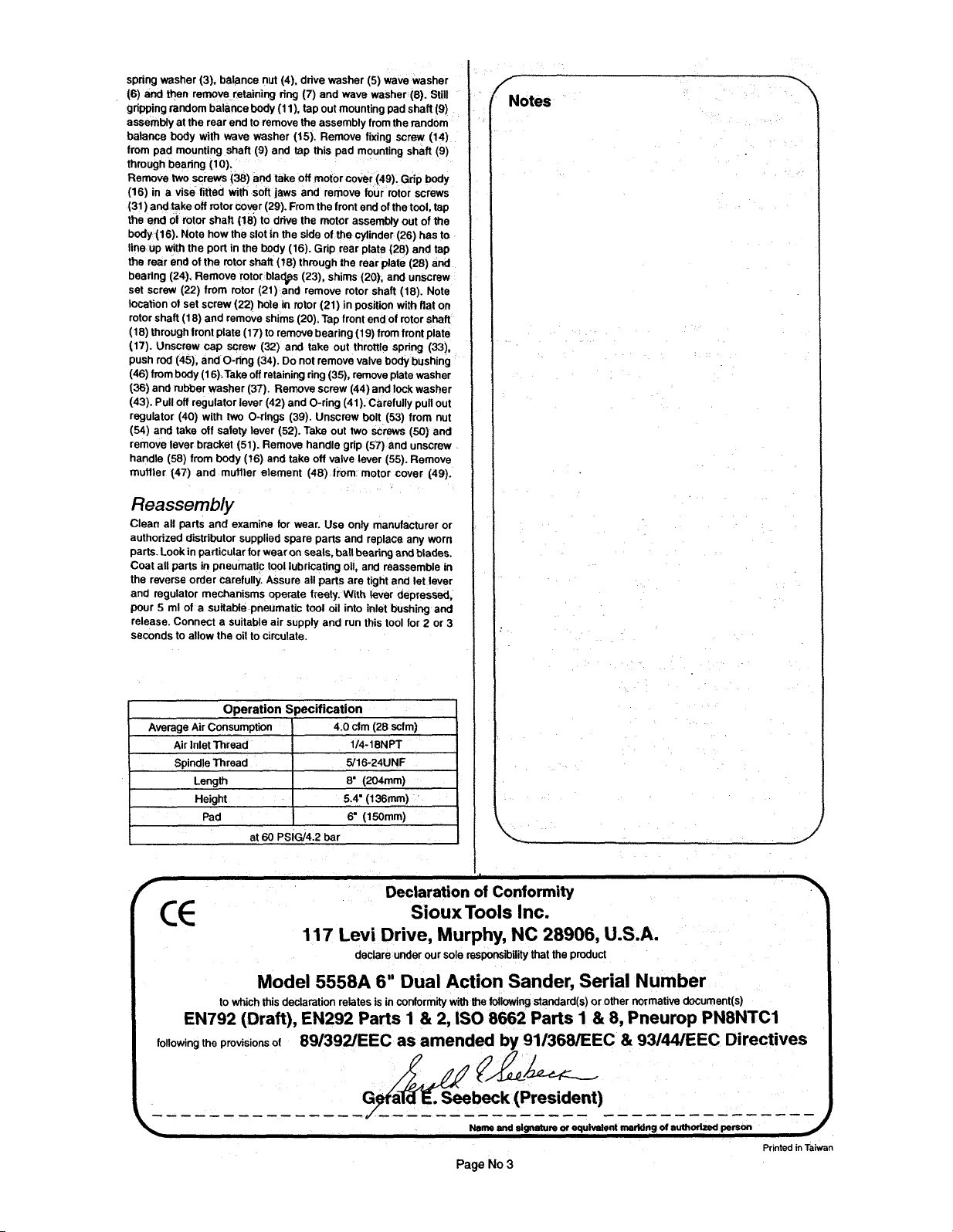

spring washer (3). balance nut (4). drive washer

(6)

and

then remove retaining ring (7) and wave washer

gripping random balance body (1

assembly at the rear end to remove the assembly from the random

balance body with wave washer

from pad mounting shaft (9) and tap this pad mounting shaft

through bearing (10).

Remove

two

screws

in a vise fitted with soft jaws and remove four rotor screws

(16)

(31) and take off rotor cover (29). From the front end of the tool, tap

the

end

of rotor shaft (18) to drive the motor assembly out of the

body (16). Note how the slot in the side of the cylindei(26) has to

line up with the port in the body (16). Grip rear plate (28) and tap

the rear end

bearing (24). Remove rotor blades (23), shims (20). and unscrew

set screw (22) from rotor (21) and remove rotor shaft (18). Note

location of set screw (22) hole

rotor shaft (18) and remove shims (20). Tap front end of rotor shaft

(18) through front plate (17) to remove bearing (19) fromfront plate

(17).

Unscrew cap screw (32) and take out throttle spring

push rod (45). and O-ring (34). Do not remove valve body bushing

(46) from body (16).Take off retaining ring (35), remove plate washer

(36)

and rubber washer (37). Remove screw (44) and lock washer

(43). Pull off regulator lever (42) and O-ring (41). Carefully pull out

regulator (40) with

(54)

and take off safety lever (52). Take out two

remove lever bracket (51). Remove handle grip

handle (58) from body (16) and take off valve lever (55). Remove

muffler (47) and muffler element (48) trom motor cover (49).

(38)

of the rotor shaft

two

l),

tap out mounting pad shaft (9)

(15).

and take off motor cover

(18)

through the rear plate (28) and

in

rotor (21) in position with flat on

O-rings (39). Unscrew bolt

(5)

Remove fixing

(49).

screws

(57)

wave washer

(8).

Still

screw

(14)

(9)

Grip

body

(33).

(53)

from nut

(50)

and

and unscrew

Reassembly

Clean all parts and examine for wear. Use only manufacturer or

authorized distributor supplied spare parts and replace any worn

parts. Look in particular for wear on seals,

Coat all parts in pneumatic tool lubricating oil, and reassemble in

the reverse order carefully. Assure all parts are tight and let lever

and regulator mechanisms operate freely. With (ever depressed,

5

mi of a suitable pneumatic

pour

release. Connect a suitable air supply and run this tool for

seconds to allow the oil to circulate.

ball

bearing and blades.

tool

oil into inlet bushing and

2

or

Notes

3

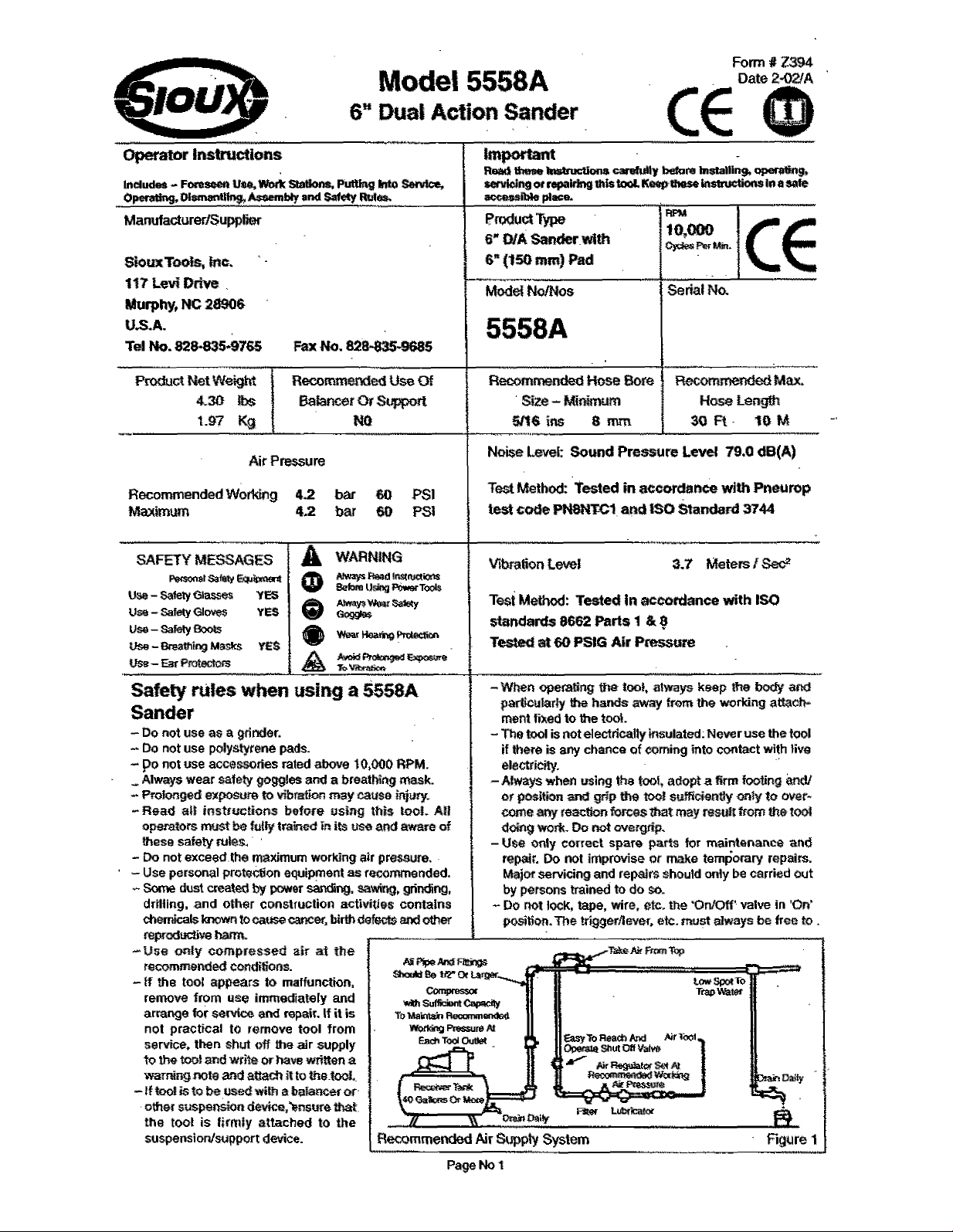

Operation Specification

Average Air Consumption

Air Inlet Thread 114-18NPT

Spindle Thread 511 6-24UNF

t

I

Length

Height 5.4" (1 36mm)

Pad

at

60

PSIGl4.2 bar

r

cc

Model 5558A

to which this declaration relates is in conformity

EN792 (Draft), EN292 Parts

following the provisions of

89139ZEEC as amended

4.0

dm

(28 scfm)

8"

(204mm)

6"

(150mm)

Declaration of Conformity

Sioux Tools Inc.

117

Levi Drive, Murphy,

declare under our sole responsibility that the product

6"

Dual Action Sander, Serial Number

1

&

&

G a

1

I.

NC

28906,

with

the following standard(s) or other normative document(s)

2,

IS0 8662 Parts

by

91/368/EEC & 93144fEEC Directives

U.S.A.

1

&

8, Pneurop PN8NTC1

fAL

.

Seebeck (President)

Page

No

3

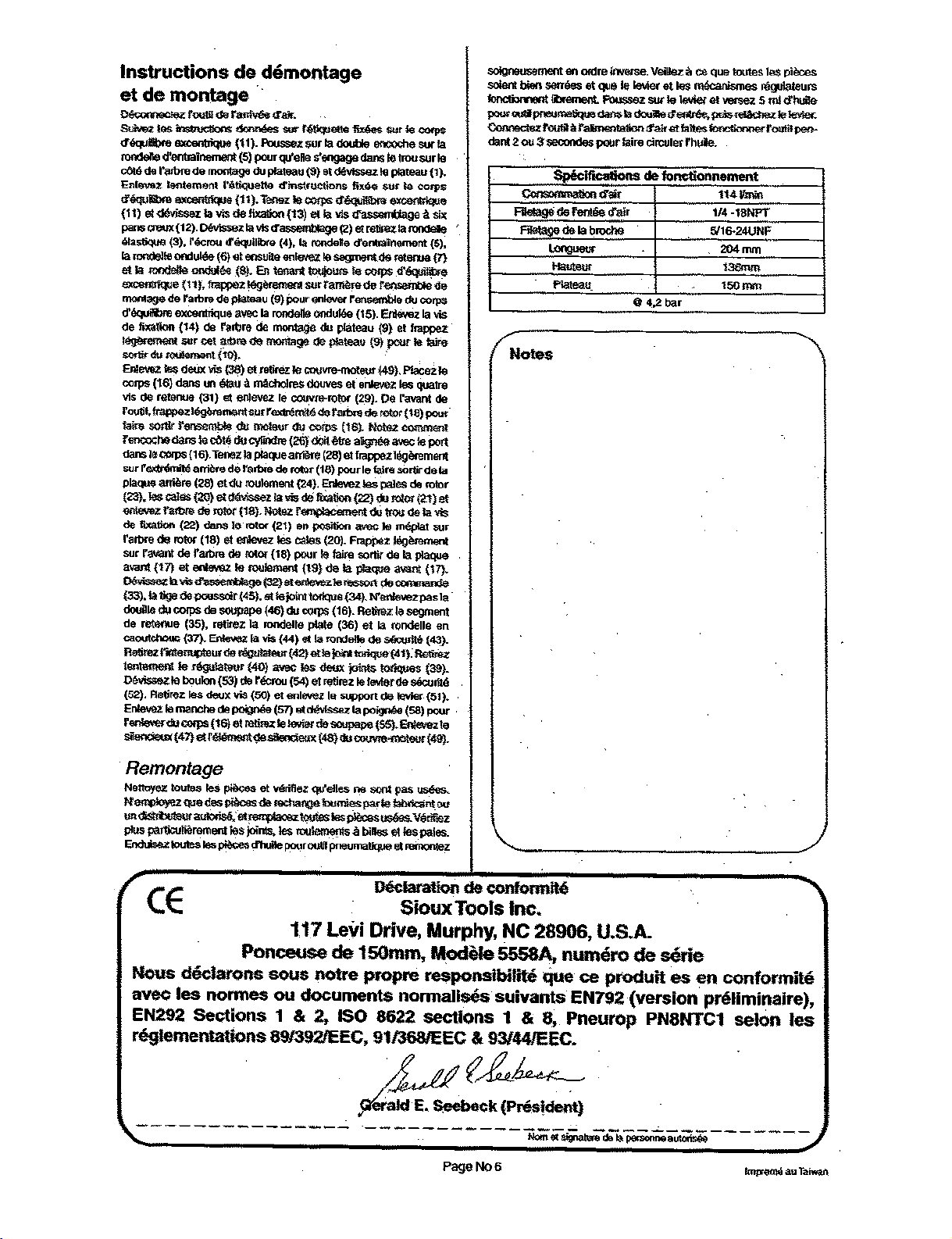

Modhle

Fonceuse

de

5558A

a

action

150

mm

Important

Usez

foncttoniw,

Type

double

atlefitivenwnl

d'Bfltretenir

de

produit

ces

Instructions

ou

de

-rer

avant

Tours

d'instalk,

cet

outil.

par

He

Gardez

faire

ces

Sioux

Tools, Inc.

117

Levi

Drive

Murphy,

US.

Tel

Poids

De

NC

28906

A.

No.

828-835-9765

net

du

1,97

-

fonctionnement

recornmand6e

Maximum

produit

kg

Fax No.

Emploi

diitif

d'un

Pression

conseille

d'6quilibrage

support.

(fair

828-835-9685

(fun

-

4,2

4,2

NON

bar

bar

ou

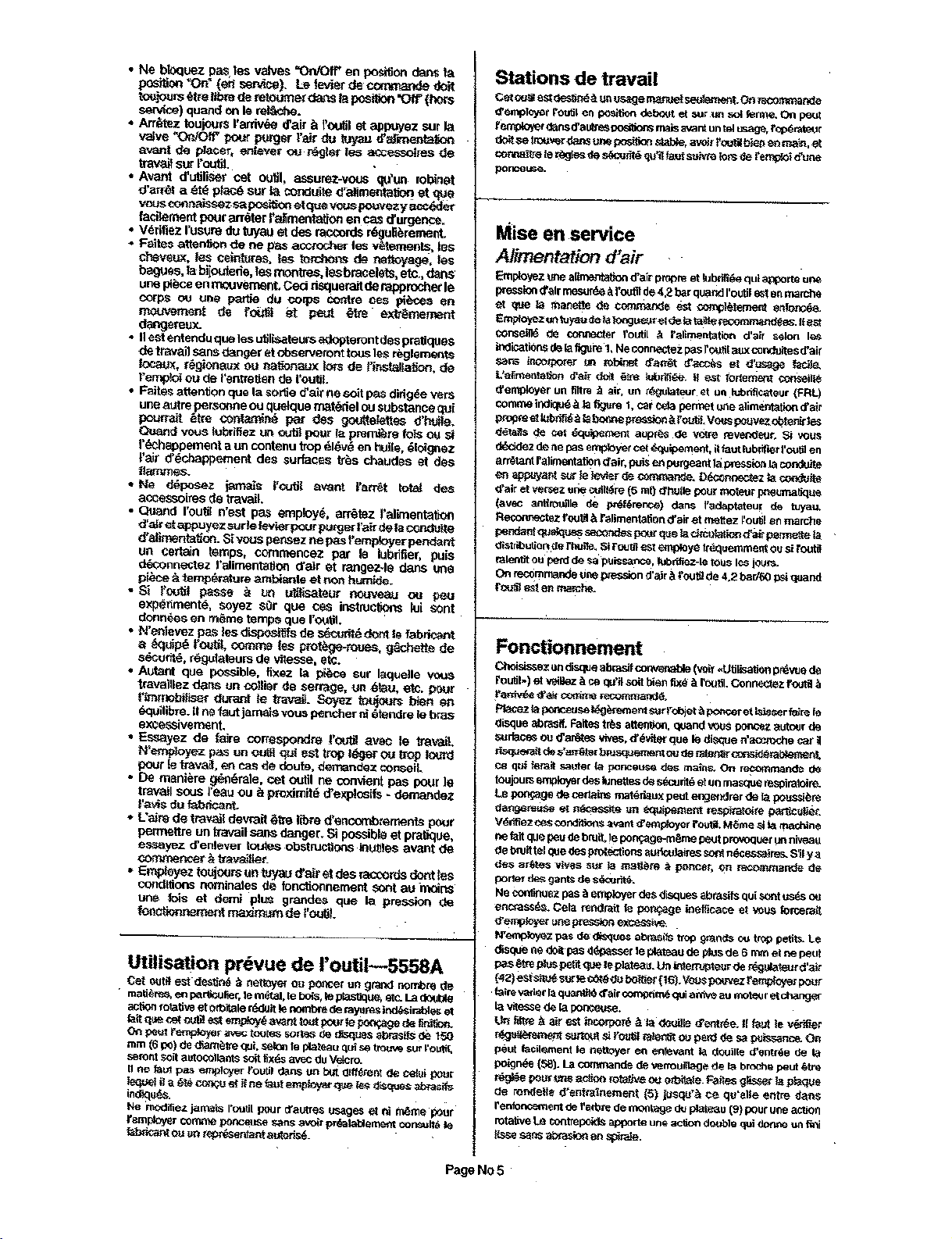

Ponceuse 3 action

double

kge

Niveau

de

de

Taille

sonore:

150

fuyau

fecornmandd

minimum

8

mm

-

mm

Niveau

M6thode

Pneurop

Niieau

M^thode

8662,

Test6

St

ou

i'out1

da

de

test:

PN8NTC1

de

vibrations

de

test

sections

sous

line

doit

6tre

suspension,

de

pression

Test6

selon

et

la

norme

test4

selon

1

&

8

pression

employe

#air

avec

assurez-vous

t/rnm

Longueur

tuyau

-

sonore

Ie

code

IS0

3,7

les

normes

de

4,2

un

cfisposftif

oue

I'outjt

c?

maximum

recommand&

10

m

79,O

de

3744.

m/s2

bar

d'huilibrage

esi

hen

dB

test

IS0

fixa

de

(A)

ace

N'empkye~

-

N'erndwez

nominalesup6fteure

11

hut

to-

respiratoire.

Une

exposition

Measures.

Usez

tes

operateurs

ponqage,

percage

activites

des

produits

comme

anomalies

troubles

Ernployez seufement

dans

les

SiFouBsembtematfoncSonnar,an-etez

.

.

immeciatementsonempfaietfailes-te

de

ptateaux

oue

des

porter

des

p(Olong6e

instructions

ddw?

connaHre

Ie sciage.

pneumatique

de

construction

chimiqms

provoquant

cong6nitales

reproductifs.

conditions

recqmadh

en

accessoires

a

10.000

lunettes

awevibrations

avant

demployer

pariaftemenl

Ie

meulage, Ie

et

d'autres

contiennent

qui

sort

Ie

cancer,

et

de

Pair

compreno

polystyrene.

d'une

trAnin.

de

security

cet

connus

des

d'airtres

puissance

et

m

masque

peut

causer

des

outiL

Tous

son

uliBsation

Toufktuyauxetoccoids

çltwHitavoirindBio6tr

ffw

moms

Svstefne

Q~ICI

mains & I'Acart

Cot

jamais

l'6tectridt6.

Quad

Ie

et

r&ction

de

Employe2

pour

fSparaBons

dotvent

1.27

tin

(t/y)

tfalimentation

Page

No

4

vous

oulil

cet

vous

tenez

I'outit.

rentretien

&tre

{fair

employe2

des

n'est

pas

od

si

vous

employez

bien

I'otitil

qui

pourraient

Ne

sqez

settlement

et

tsmporaires.

effectuees

recommand4

routi~,

ten&

accessoires de

+&6

61ectriquement.

risquez

d'entrer

cet

outil,

pour

&tre

pas

des

tes

Prise

prenez

compenser

musees

trop

fort

pieces

reparations.

L'entretien

que

par

du

Cair

an

met

toutours

travail

en

contact

une

toutes

par!%

dans

fonctionnement

les

de

recbange

NVimprovisez

et

les

personnel

~e

corps

et

fix&

a

foutd.

N'employez

avec

position

ierrne

forces

mains.

correctes

pas

reparations

qualie.

Fmure

18s

de

de

de

ne

1

Loading...

Loading...