Sioux Tools 5550 User Manual

Read

11

tool.

I

SAFETY

1

Use

Use

Use

Use

Use

-

these

Keep

-

Safety

-

Safety

-

Safety

-

Breathing

-

Ear

Protectors

instructions

these

instructions

MESSAGES

PeoonalSafetyEqucment

Glasses

Gloves

Boots

Masks

1/2"

carefully

in

1

A

@

@

YES

A

Model

Sq.

Drive Pistol

.

Impact

IMPORTANT

before

a

safe

installing,

accessible

WARNING

Always

Read

Using

PowerTwls

Always

Wear

Wear

Hearingprotection

Avoid

Prolonged

T o Vibration

Safety

5550

Tool

operating,

place.

Instructions

Goggles

Exposure

Grip

servicing

1

1

Operator

includes:

Safety

Foreseen

Work

Stations

Putting

Operating

Dismantling

Form

#

Date

1

C?

or

repairing

@

this

Instructions

Ruk

Use

Into

Service

and

Assembly.

Z470

-WA

I

I

Safety

-

Use

only

impact

sockets

etc.,

rated

as

-

Prcibqed

.-

ReadaBjnstrucfionsbeforetKhgltfetoot.AIoperatorsmust

beMytrainedinitsuseandawareoftiesesafety

-

Do

not

-

Use

personal

-

WcofnpressedsironlyattÈrecornnerxledconcflions

-

If

the

immed"lately

practical

supply

note

and

-

If

tool

device,

suspension/support

-

When

being

exposure

exceed

the

protection

tool

appears

and

toremovetoolfromsewh,

to

the

too!

attach

is

to

be

used

ensure

operating

the

hands

suitable

to

maximum

to

arrange

and

it

to

the

wtt)

that

the

device.

the

tori,

away

and

vibration

equipment

malfunction,

for

write

tod.

a

baiancer

too)

rules

extensions,

for

use

with

may

working

&

service

and

thanshutofftheair

or

have

or

is

firmly

always

keep

from

the

woriang

when

universal

impact

cause

air

recommerKled-

remove

written

other

tools.

injury.

rules.

pressure.

from

-r.

ti

a

suspension

attached

the

body

attachment

it

warning

KExw.

Theiwlisnoteiectri

there

is

any

electricity.

-

Always

posHion

any

reaction

work.

-

Use

only

Do

not

servicing

personstrainedtodoso.

-

Do

not

position.'me

to

return

On/W

before

mentfittedtothetool.

-

Beforeusinothatool.makesurethata

shutoffdeucehasbeenfittedtothe

supply

andeasilyaccessiblesothattheair

supply

emergency.

-

Check

-

Takecareagainstentanglementofthe

movtrgpartedttwtoolwithdoÈwg,hair

fes,deaningrags.rings,jewafry.watrfres.

bracelets,ete.'nrecotAJcauseftebody

orpartsoftktbodytobedrawnfcwaids

axiricortactwflhihemovingpartsofSw

toolandcouldbevarydangerous.

-

itisexpectedthatuserswiladoptsafe

working

local,

chance

when

using

p

and

e

Do

fitting,

tine

to

hoseandfitSngs

ces

not

ororgrip.

correct

spare

improvise

and

repairs

lock,

tape,

tfvotfte

to

lhe

"Off" positron

shutofftheairsupplytoVnetootandpressthe

valve

to

removing

and

the

thetoolcanbeshutoff

practices

regional

insulated.Neveruseftatoolif

cany

o

the

too[,

the

tool

that

may

parts

or

make

should

wire,

trigger/tever,

exhaust

or

position

reoularty

and

or

country

into

adopt

sufficiently

result

for

maintenance

temporary

only

etc.

the

'On/Off

etc.

when

the

air

adjusting

is

known

inan

fcfwear.

observe

legal

contact

a

firm

arty

from

be

must

released.

from

the

all

w'h

footing

to

overcome

the

tool

and

repairs-

carried

out

valve

in

ahvays

be

the

feed

working

attach-

.

To

Maintain

Recommended

jointe,

use

is

not

to

the

and

li

and/or

doing

repair.

Major

by

"On'

free

hose

using

-

-

-

-

-

-

-

-

-

-

FteconnnenitKt

Air

Supply

Pager401

a

5550

requirements

Take

other

contaminated

or

the

Never

stopped-moving-

When

press

tool

dsconnectfroman-supplyandstoreinadryaverage

temperature

If

enced

be

Do

where

go-,

Wherever

etc.tomate

operation.

or

Try

tod

doubt, seek

in

use

manufacturer.

Tvtomakesurethattheworkareaisdeartoenablethe

work

possible,

starting

Always

ing

working

ImpactTool

care

W#e

person

if

the

tool

exhaust

lay

the

the

tool

Ihrotfle

is

not

to

the

fool

is

user.

passed

withthetool.

not

remove

fitted,

etc-

p-e,

Keep

overreach.

to

match

that

is

too

general

terms,

or

use

in

task

b'y

work.

use

pressure

pressure

System

when

instaihng,

exhaust

or

material

by

oil

droplets.

exhaust

air

passed

make

advice.

to

air

has

to

come

too!

is

frioaerfiever

be

environment

i.e.,

itngtd

the

light

explosive

be

to

ratings

near

down

until

not

in

use,

used

for

from

sure

these

any

manufacturer

wheel

secure

soçtdoesno

good

balance

tool

to

(he

or

heavy

this

tool

envirmrnente-seek

performed

ctear

unnecessary

hose

and

at

least

rating

of

a

using

air

does

or

substance

When

a

high

oil

very

the

working

shut

to

drain

period

one

user

instructions

guards,

workpiece

at

aU

work

operation.

for

the

is

not

suitabie

safely.

couplings

1

1/2

the

tooL

or

maintaining

not

point

towante

that

first

lubricating

content,

hot

off

the

of

to

fitted

safety trigger.

moveduring

surfaces

the

supply

time,

a

new

with

times.

work

do

attachment

air

supply

first

or

are

available

safety

clamps,

Do

Do

operation.

for

underwater

advice

If

practical

obstructions

with

minimum

times

the

the

tool.

any

could

be

a

tool

not

allow

or

flames.

has

and

line.

If

the

lubricate,

room

inexperi-

devices

speed

a

vise,

the

work

not

stretch

not

use

If

from

and

before

work-

maximum

Figure

to

a

in

1

Foreseen Use

The Impact tool

should only

Die Impact

It

is

allowed

the female square drive of

Do

not

use

supplier. To do

Never use an impact tool as a hammer to dislodge or straighten cross threaded fasteners. Never attempt to modify the tool for other uses

and

never

Of

The Tool

is

designed for the tightening and loosening of threaded fastener within the range

be

used

in

conjunction with suitable impact

-

5550

as

type

112" square female drive nut running sockets. Only use sockets which are of

specified

by

the manufacturer. It

type.

to use suitable extension bars, universal joints and socket adaptors between

the tool for any other purpose than that specified without consulting the manufacturer or the manufacturer's authorized

so

modify the tool for even its recommended use as a nutrunner.

the

socket.

may be dangerous.

the

square output drive of the impact tool and

Work

Stations

The

tool should only be

floor.

It

can be used in other positions,

be

aware that when loosening fasteners the tool can move quite quickly away from the fastener being undone.

and

always be

made

used

asa handheld,

for

this

rearward movement so as to avoid the possibility of handlarmhmdy entrapment.

hand

but

operated toot.# Isalways ~~~OInmended that the tool is used when standing on a solid

before any such use, the operator must be in a secure position having a firm grip and footing

Putting Into Service

Air

Supply

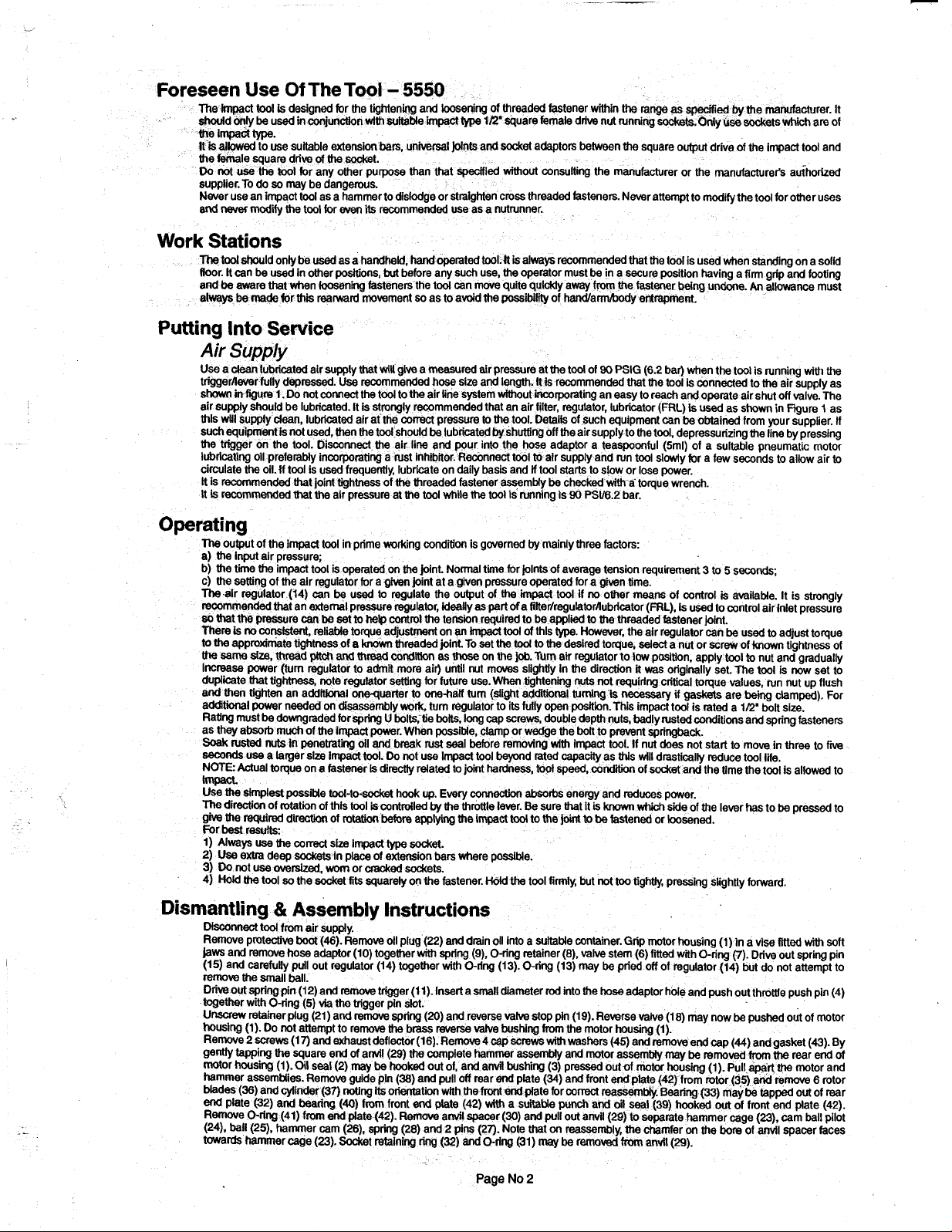

Use a

clean

triggerhever fully depressed. Use recommended hose size and length. It is recommended that the tool is connected to the air suoolv as

shown

air supply should be lubricated. It Is strongly recommended that an air filter, regulator, lubricator (FRL) is used as shown in Figure 1 as

thls will supply dean, lubricated air at the correct pressure to the tool. Details of such equipment can beobtained from your supplier. If

such

the trigger on the tool. Disconnect the air line and pour into the hose adaptor a teaspoonful (5ml) of a suitable pneumatic motor

lubricating oil preferably incorporating a rust inhibitor. Reconnect tool

circulate the oil.

It

is recommended that joint tightness of

It is

lubricated air supply that will give a measured air pressure at

In

figure 1. Do not

equipment is not used, then the tool should be lubricated

recommended

connect

the tool to the air line system without incorporating an easy to reach and operate air shut off vake.The

tf

tool Is used frequently, lubricate on daily basis and

that

the air pressure at the tool while

the

threaded fastener assembly be checked with a toque wench.

the

by

tool is running is

the

tool of

90

PSIQ (6.2 bar) when the tool is running

shutting off the air supply to the tool, depressurizing the line by pressing

to

air supply and run tool slowly for a few seconds to allow air to

If

tool starts to slow or lose power.

90

PSI/6.2

bar.

Operating

The

output of the impact tool in prime working condition is governed

a) the Input air pressure;

b)

the time the impact tool is operated on the joint. Normal time for joints of average tension requirement 3 to 5 seconds;

c) the setting of the air regulator for

The

air regulator (14) can

recommended that an external pressure regulator. Ideally as part

so

that

the pressure can

There

is

no consistent, reliable toque adjustment on

to

the

approximate tightness of a

the

same

size,

increase power (turn regulator to admit more aio until nut moves slightly In the direction

duplicate that tightness, note regulator setting for future use.

and then tighten an additional onequarter to one-half tum (slight additional turning is

additional power needed

Rating must be downgraded for spring U bolts, tie bolts, long cap screws, double depth nuts, badly rusted conditions and spring fasteners

as they absoib much of the impact power. When possible, clamp or wedge the bolt to prevent springback.

Soak

Seconds

NOTE:

impact.

Use

the

The

direction of rotation of this tool

give

the

best

For

1) Always

2)

Use

3)

Do

4) Hold

thread

rusted

nuts

use a larger size Impact tool.

Actual toque on a fastener

simplest possible tool-to-socket hook up. Every connection absorbs energy and reduces power.

required

results:

use the correct size impact

extra deep

not use

oversized,

the

tool

be

pitch

on

in penetrating oil

direction

sockets

worn

so

the socket fits squarely on the fastener. Hold

a

given

be

used

set to

known

and thread condition as

disassembly work, turn regulator to its fully open posWton. This impact tool is rated a 1/2" bolt size.

of

rotation

in place of extension bars where possible.

or cracked sockets.

joint at a given pressure operated for a given time.

to

regulate the output of the impact tool if no other

help

control

the

tension required to be applied to the threaded fastener joint.

an

threaded joint To set

Impact tool of thls

those

and

break

rust

Do

Is

directly related

is

controlled

before

type

seal before removing with impact tool. If nut does not start to move

not use Impact tool beyond rated capacity as this will drastically reduce tool life.

to

joint hardness,

by

the

applying the impact tool to the joint to be fastened or loosened.

socket.

throttle lever. Be sure that it is

the

on the

When

by

mainly three factors:

means

of

a

filterlregulator~lubricator

type.

tool to

job.

Turn air regulator to

tightening

However, the air regulator can

the

desired toque,

nuts

not requiring critical toque values, run nut up flush

of control

(FRL),

select

a nut or screw of

low

position, apply tool

it

was

originally set. The tool is now set to

necessary if

too)

speed, condition of socket and the time the tool is allowed to

known

which

side of the lever has to

the

tool firmly, but

not

too tightly, pressing slightly forward.

is

is

gaskets

available. It is strongly

used to control air inlet pressure

be

are

used to adjust toque

being

An

allowance must

with

known

tightness of

to

nut and gradually

clamped). For

in

three to five

be

pressed to

the

Dismantling & Assembly Instructions

DiSC~nnect

Remove protective

jaws and remove hose adaptor (10) together

(15) and carefully pull out regulator (14) together with O-ring (13). O-ring (13) may

remove the small ball.

Drive out spring pin (12) and

together with O-ring (5) via

Unscrew

housing

Remove 2 screws

gently tapping

motor housing

hammer assemblies. Remove guide pin

blades

end

Remove O-ring (41) from

(24). ball (251, hammer cam

towards hammer cage (23). Socket retaining ring

tool from air supply.

boot

(46).

Remove oil plug

remove

trigger (1 1). Insert a small diameter

the

retainer plug (21) and remove spring

(1).

Do not attempt to remove the brass reverse

(17)

the

square end

(1).

Oil seal (2)

(36)

and cylinder (37) noting

plate (32) and bearing

trigger pin slot.

and exhaust deflector (16). Remove 4

of

anvil

may

be hooked out of, and anvil bushing (3) pressed out of motor housing (1). Pull apart

its

(40)

from front

end

plate442). Remove anvil spacer

(26).

spm

(22)

and

with

drain oil into a suitable container. Grip motor housing

spring (9), O-ring retainer

(20)

and reverse valve stop pin (19). Reverse valve (18) may now

valve

bushing

cap

(29)

the complete hammer assembly and motor assembly

(38)

and pull

off

rear

orientation with the

end

plate (42)

(28) and 2 pins

(32)

end

front

end

with

(30)

(27).

Note that on reassembly, the chamfer on the bore of anvil spacer faces

and

O-ring (31)

Page

(1)

(8),

valve stem

rod

into the

from

screws with washers (45) and remove end cap

plate

a suitable punch and oil seal (39) hooked

No

the motor housing (1).

(34)

and front end plate (42) from rotor (35) and remove 6 rotor

plate for correct reassembly. Bearing

and pull out anvil (29) to separate hammer cage (a), cam ball pilot

may

be removed

2

(6)

be

hose

fitted with O-ring

pried off of regulator (14) but do not attempt to

adaptor hole and push out throttle push pin (4)

may

be

from

anvil

(29).

in a vise fitted

(7).

Drive out spring pin

be

pushed out of motor

(44)

removed

(33)

and gasket (43). By

from

may

be

out

of front end plate (42).

with

the

rear end

the

motor and

tapped out of rear

soft

of

Loading...

Loading...