Form

#

Date

ZCE701

5-02JA

Operator

ManufacturerBuppIier

Sioux

250

P.0.

Murpb,

U.S.A.

Tel

Product Net

-Recommended

Maximum

Tools,

Snapon

sox

1596

NC

No.

828-835-9765

5-10

2.32

Instructions

lnc.

Drive

28906

Weight

I&

kg

Working

,

Fax

Recommended

Air

Pressure

62

6.2

No.

Wancer

-bar

bar

828-835-9635

Use

Or

Support

NO

90

90

Of

PSI

PSI

accessible

Product

Low

Air

Mcdel %/Nos

plack

Type

VI

bdon

Hammer

Serial

No-

-

Recornmded

Size

916

Noise

Level:

Tesi

Method:

test

code

Wbration

Test

Method:

standards

Hose

-

Minimum

ins

Sound

Sound

Tested

PNBNTCI

Level

Tested

8662

8

Farl

m

Bore

Pressure

Power

Level

in

accordance

and

IS0

9.56

in

accordance

I

Recommended

Hose

Length

30Ft

Level

Standard

Meters

943

106.6

with

3744

1

S&

with

IOM

Pneump

IS0

Max.

dB(A)

dB(A)

Safety

rules

when

using

a

5276

Hammer

-Always

-

-Read

-

-

-

-Use only compressed air

-If the toot appears

-

-When opefating lhe

wear

saw

flying

akqeck.

Prolonged exposure to vibration

all

instructions before using this tool. All

operalots must be

these safety rules.

Do

not exceed the maximum working air pressure.

Use personal

Some

dust created

drilling, and other construction actjvities contains

&@mi&

reproduhe

conditions.

remove from use immediately

arrange

not

sewice,

to

warning note

If

other suspension device, ensure that

the tool is firmly

suspensiontsupport device.

the

away from the working attachment

knmn

br

practical to

then

the

tool

tool is to

body

and

and

be

goggles

fully

protectii

by

to

cause

harm-

sewice and repair- If it is

remove

shul

off

write

and

attach it to the

used with a balancer

attached

pariicularly

as

trained

equipment

per

snchg,

mer,

to

malfunction,

tool from

rhe air supply

or

haw-writlen

tool.

always

the

use

of

tool

may

cause

in

its use and aware

as

recommended-

sawing,

birih

defects

at

the

recommended

7

and

a

tool.

or

to the

keep

hands

Recomrnendd

may

cause

injury-

grhding,

and

.kttlsuikkl~

T0MaiUaii~

Air

of

other

to

fixed

-

The

-Always when

-Use

-

Air

Supply

the tool-

tool is not electrically insulated,

if

there is

electricity.

position

any

wok.

repair.

Major

by person$ trained to

Do

position.

return to

any

and grip

reaction

Do not overgrip.

only

Do

servicing

not

lock,

The

the

System

chance of coming into

using

the

td, adopt a firm footing andtor

the

tool

sufkienlly only

forces

that

may

correct spa?e

not improvise or

and

tape,

WggerAever,

'OW

parts

repairs should

do

so.

wire,

ek.

etc.

position when released.

Never

wntacl

result

from

the tool doing

for maintenance

make

temporary

only

be

the

'0n/Off'

must

always

we

the tool

with

to

uverme

repairs.

carried

valve

in

be

free to

Fgure

live

and

out

'On'

1

-Always

-

-Check

-

shut

'0n/Off'

before

attachment

Before

has

known

the

been

1001

valve

figing,

using

and

can

hose

Take

care

the

td

w-Wi

off

the

air

10

exhaust

removing

filted

to

the

he

td,

fitted

to

the

easily

accessible

be

&ut

off

and

fitlings

against entangtement

cbthing,

jewelry, watches, bracelets,

body

of

parts

of

the

contact

with

the

moving

very

dangerous.

-It

is

expected

praclices

and

that

observe

legal requirements

maintaining

-Take care

any

be

contaminated

a

1001

not

surfaces

-Never

has

-

Men

press

tool is

disconnect

room

the

-If

inexperienced

passed

-

Do

where

governors,

-WMrever

,

vise,

work

stfetch

-

Try

a

tml

in

doubL

-In general

undewater

seek

-Try

the

possible;

skrtjng

-Always

working

maximum

the

tool.

that

the

other

person

or

if

the

tool

allow

the

exhaust

or

flames.

Iay

the

tool

stopped

fnm*ng-

ttw

tool

is

the

triggernever to

not

10

be

from Ar

used

tertyeralure

tool is

passed

user,

with

not

the

reme

fitted,

etc.

any

i-e.,

possible,

etc-

to

make

operation. Keep

or

overreach.

to

match

tfw

that

is

too

seek

adGce.

terms,

use

advice

from

to

make

task

try

work.

use

sure

to

to

air

work

pressure

working

exhaust

or

by

exhaust

down

nat

environment.

tool.

wheel

it

rigid

tml

light

or use

mndaclurer.

that

be

clear

hose

preGre

supply

to

the

tool

and

the

air

or

adjusting

from

the

the

press

feed

working

W.

mike

sure that

air

supply

in

an

regularly

hair,

ties,

etc-

body

to

parts

users

will

all

local, rdimal

when

air

material

oil

droplets.

has

air to

until

in

use,

shut

drain

for

a

period

supply

and

from

mab

sure

manufacturer

guards.

secure

so

it

good

balance at

to

the

work

or

heavy

this

tool

in

explm*ve

the

work

a

line

and

so

that the

emergency.

for

wear-

of

the

moving

cleaning

This

could

be

drawn towards

of

the

tool

adopt

installing,

does

not

or

substance

When

a

high

come

the

wor!4ng

off

the

the

supply line. If

of

time,

store

in a dry

one

user

these

atid

safety

workpiece

does

not

operalion.

for

the

work

is

not

e~mnments

area

is

shut

off

the

positim

air

supply

park

rags, rings,

cause

and

could

safe

working

and

country

using

point towards

that

first

lubricating

oil

content,

near

very

attachment

air

supply

first

lubricate,

average

to

a

instructions

safely

trigger,

with

clamps,

mwe

during

all

times.

Do

operation.

suitable

clear

to

performed safely. If practical

unnecessary

and couplings

ratings

obsmctim

at least

raling

of

1

the

with

1/2

W.

minimum

times

the

hose

device

to

the

and

be

could

do

h.ot

and

the

new

are

d-

speed

the

Do

rmt

not

use

enable

and

bbt9

is

of

in

or

or

a

If

for

-

?he

.

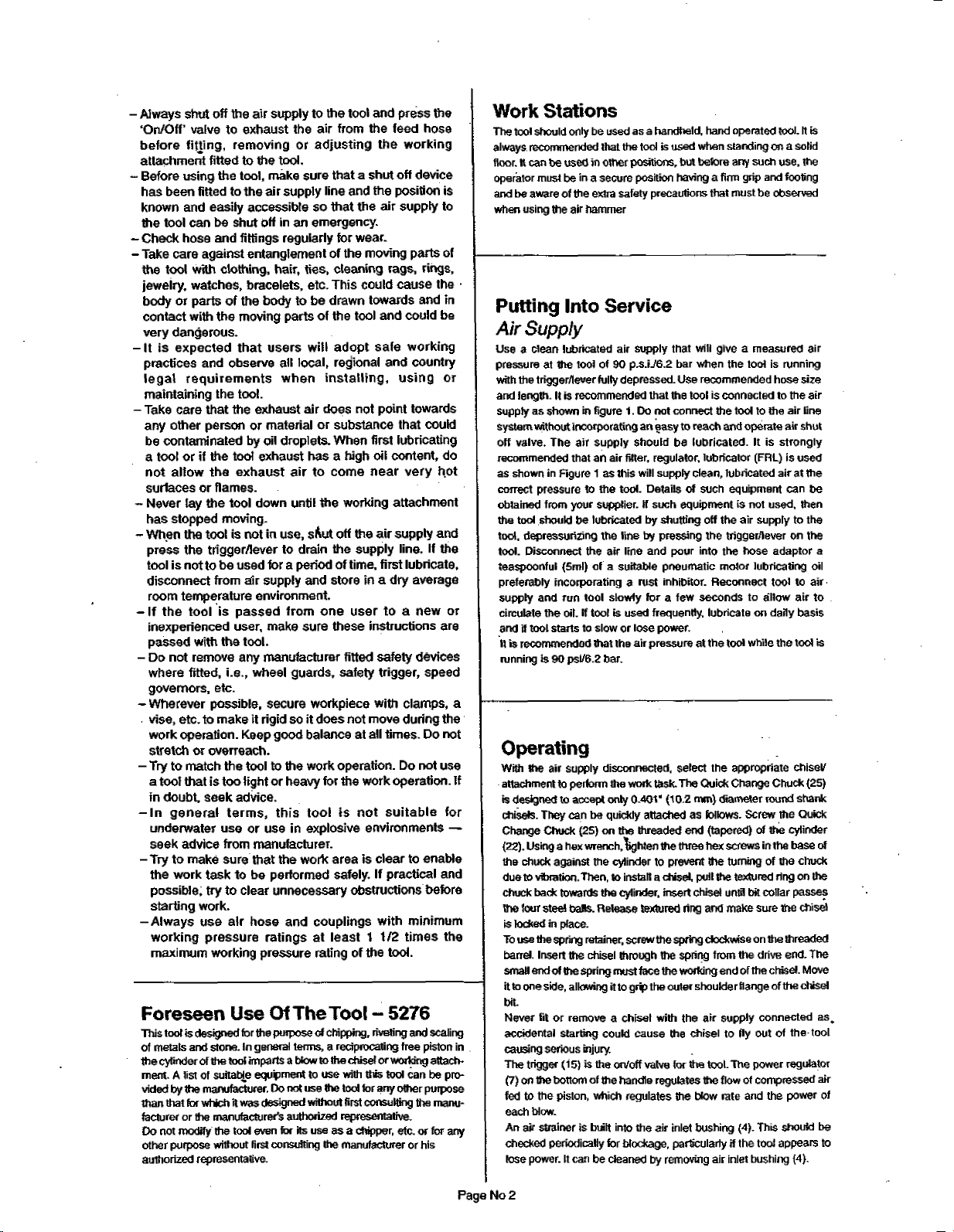

Putting

Air

Suppiy

Use

a

p~re

with

lhe

and

Ie+.

supplyasshw~~

system

off

valve.

rmrnaed

as

shown

correct

obtained

the

tod

tad,

dq~essurizMg

W.

Disconnect

teaspmnful

preferably iworpraiing

supply

circulate

and

il

11

is

rwmmded

wnniq

Into

dmn

lubiiated

at

t-erAever

It

is

without

The

in

F~ure

~essure

from

your

shu!d

(5ml)

and

run

the

oil-

tool

starts

is

90

psU6.2

Service

air supply that

tool

d90

ps.iJ6.2

fully

depressed.

rmmndd

mQure

I.

Oa

ifmporating

air

that

to

be

lubmted

the

of

tool

If

&I

to

an

supply

should

an

air Mer, regulator.

I

as

Wis will

the

tod.

s-ier.

lf

the

I'm

air

line

a

suitable

a

net

slowly

is

used

slow

or

I-

-1

tbe

a~

bar.

will

bar

hen

Use

mmmemd

that

the

tool

notmnmct

isy

to

reach

be

lubricated.

lubricator

supply

clean,

Details

d

swh

by

tq

and

for

frequenw.

such

equipment

&urn

ofl

p&ng

the

pour into the

pneumatic

inh'#)iior.

a

few

seconds

lubricate

power.

pressure

at

the

give

a

measured

the

too4

is

connected

the

tool

to

and

operate

It

(FRL)

lubrbted

equipment

is

not

the

air

supply

biggerfiever

We

motor

lubmliq

Reconnect

to

cn

tool

while

is mning

hose

to

me

4he

air

air

is

strongly

is

air

at

mn

used,

to

on

adaptor

td

to

allow

air

daiiy

the

td

air

size

air

Gne

shut

used

me

be

lhen

the

the

a

oil

air

lo

basis

is

Foreseen

Use

Uf

TheToot

-

5276

Page

No

2

Loading...

Loading...