Model

5203

Form

#

Z551

Date 4-99IA

318"

b

-----

II

Read

these instructions carefully before installing, operating, servicing or repairing this

tool.

Keep

these instructions in a safe accessible place,

SAFETY

Use

-

Safety

Use - Safety

Use

-

Safety

Use

-

Breathing

Use

-

Ear

-

Use may produce flying objects. Always use safety

goggles.

-

Use accessories rated at above

-

Prolonged exposure to vibration may cause injury.

-

Read

all

be fully trained in

-

Do not exceed the maximum working air pressure.

-

Use personal protection equipment as recommended.

-

Use compressed air only at the recommended

conditions.

-

If

the

immediately and arrange for service and repair. If it is not

practical to remove tool from service, then shut off the air

supply to the tool and write or have written a warning

note and attach

-

If

tool is to be used with a balancer or other suspension

device, ensure that the tool is firmly attached to the

suspension/support device.

-

When operating the tool, always keep the body and

particularly the hands away from the working attachment

fixed to the tool.

-

The tool is not electrically insulated. Never use the tool if

there is any chance of coming into contact with live

electricity.

-

Always when using the

position and grip the tool sufficiently only to overcome

any reaction forces that may result from the tool doing

work. Do not overgrip.

-

Use only correct spare parts for maintenance and repair,

Do not improvise or make temporary repairs. Major

servicing and repairs should only be

carried out bv oersons trained to do

-

DO

not lock, tape, wire, etc. the 4~n/~ff1

valve in 'On' position. The throttle

trigger1 lever, etc. must always be free

to return to the 'Off' position when

released.

-

Always shut off the air supply to the tool

and press the

the air from the feed hose before

fitting, removing or adjusting the

working attachment fitted to the tool.

-

Before using the tool, make sure that a

hut o device has bee fitted to the

supply line and the position is known

MESSAGES

Personal

Safety

Equipment

Glasses YES

Gloves

Boots

Masks

Protectors

YES

Safety

1,550

instructions before using this tool. All operators must

its

use and aware of these safety rules.

tool aooears

it

to the tool.

'On/Off'

to

malfunction, remove from

tool,

adopt a firm footing andlor

valve to exhaust

A

@

@

@

dh

rules

RPM.

so.

7

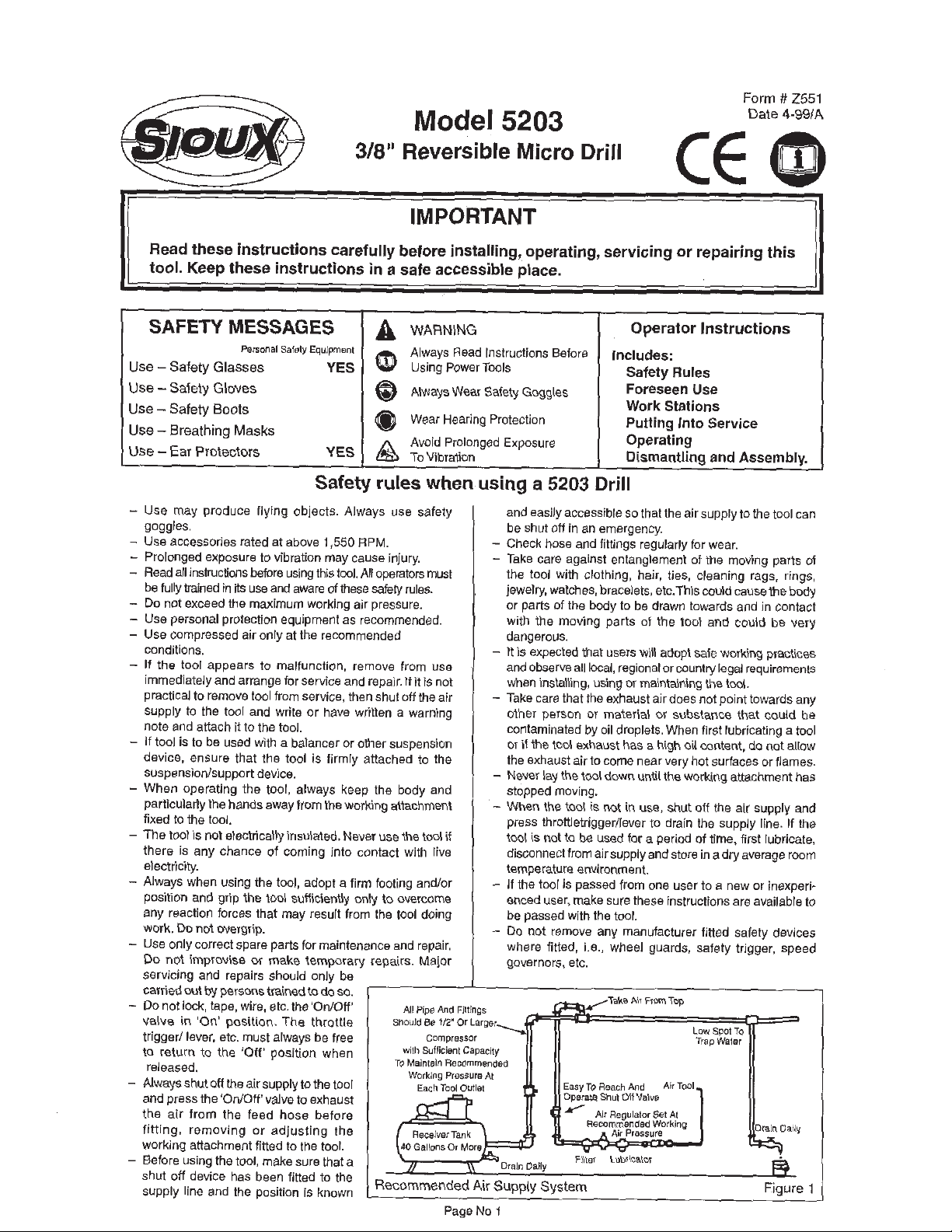

Recommended

Reversible

Micro

IMPORTANT

WARNING

Always Read Instructions Before

Using Power Tools

Always Wear Safety Goggles

Wear Hearing Protection

Avoid Prolonged Exposure

T

o Vibration

when using

use

AII

Pipe

And

ShouldBe

Fillings

112"

Or Larger

Page No

Air

a

5203

and easily accessible so that the air supply

be shut off in an emergency.

-

Check hose and fittings regularly for wear.

-

Take care against entanglement of the moving parts of

the tool with clothing, hair, ties, cleaning rags, rings,

jewelry, watches, bracelets, etc.This could cause the body

or parts of the body to be drawn towards and in contact

with the moving parts of the tool and could be very

dangerous.

-

It is expected that users will adopt safe working practices

and

observe all local, regional or country legal

when installing, using or maintaining the tool.

-

Take care that the exhaust air does not point towards any

other person or material or substance that could be

contaminated by oil droplets. When first lubricating a tool

or if the tool exhaust has a high oil content, do not allow

the exhaust air to come near very hot surfaces or flames.

-

Never lay the tool down until the working attachment has

stopped moving.

-

When the tool is not in use, shut off the air supply and

press throttletriggerllever to drain the supply line.

tool is not to be used for a period of

disconnect from air supply and store in a dry average room

temperature environment.

-

If the tool is passed from one user to a new or inexperienced user, make sure these instructions are available to

be passed with the tool.

-

Do not remove any manufacturer fitted safety devices

where fitted, i.e., wheel guards, safety trigger, speed

governors, etc.

Supply

System

1

Drill

Includes:

Drill

C?

Operator Instructions

Safetv

Rules

ores seen

Work

Putting Into Service

Operating

Dismantling and

Use

Stations

time,

0

Assembly.

to

the tool

requirements

first lubricate,

Figure

If

can

the

I

I

1

Loading...

Loading...