MaxiMixer

MODEL 2050

OPERATION AND

MAINTENANCE MANUAL

877 1st. AVE. NW Sioux Center, IA. 51250 Iowa 1-712-722-1488

www.siouxautomation.com MON600127

12/7/04 $15

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL

IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR

PERSONAL SAFETY AND THE SAFETY OF OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS

- ATTENTION!

- BECOME ALERT!

- YOUR SAFETY IS INVOLVED!

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate Signal word for

each has been selected using the following

guidelines:

DANGER: Indicates an imminently

hazardous situation that, if not avoided, will

result in death or serious injury. This signal

word is limited to the most extreme situations

typically for machine components that cannot

be guarded for functional purposes.

WARNING: Indicates a potentially

hazardous situation that, if not avoided, could

result in death or serious injury, and includes

hazards that are exposed when guards are

removed. It may also be used to alert against

unsafe practices.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

If you have any questions not answered in this manual or require additional copies or the manual is

damaged, please contact your dealer or Sioux Automation Center, Inc., 877 1st Avenue N.W., Sioux

Center, IA, 51250. (Telephone) 712-722-3711, (Fax) 712-722-3706.

SAFETY ALERT SYMBOL

− THE SAFETY ALERT SYMBOL IS USED TO PINPOINT

CHARACTERISTICS WHICH IF NOT PROPERLY FOLLOWED

CAN CREATE A SAFETY HAZARD.

− WHEN YOU SEE THIS SYMBOL IN THIS MANUAL OR ON

THE UNIT ITSELF, YOU ARE REMINDED TO:

BE ALERT!

YOUR PERSONAL SAFETY IS INVOLVED!

SAFETY FIRST

FARM AND INDUSTRIAL EQUIPMENT INSTITUTE SAFETY ALERT SYMBOL.

This symbol is used preceding all CAUTION (a general safety

reminder), WARNING (denotes a potential hazard), and DANGER

(denotes a potential injury) notices!

Most farm accidents, like industrial, home, and highway accidents are caused by the failure of some

individuals to observe simple and fundamental safety rules or precautions. For this reason, farm

accidents, just as other types of accidents, can be prevented by recognising the causes of accidents and

doing something about them before an accident occurs.

Regardless of the care used in the design and construction of farm equipment, there are many points

that cannot be completely safeguarded without interfering with accessibility and efficient operation.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN ACCIDENT

The complete observance of one simple rule would prevent many thousand serious injuries each year.

That rule is "NEVER ATTEMPT TO CLEAN, OIL, OR ADJUST A MACHINE WHILE IN

MOTION".

NATIONAL SAFETY COUNCIL

BEFORE ATTEMPTING TO OPERATE YOUR NEW MACHINE, BE SURE TO READ

THIS OWNERS MANUAL AND FAMILIARIZE YOURSELF WITH THE MACHINE!!

OBSERVE THE FOLLOWING PRECAUTIONS FOR SAFE OPERATIONS OF THIS

MACHINE!!

SAFETY TIPS:

1. Keep Hands, Feet, and Clothing away from PTO Shaft!

2. DO NOT Climb on or enter Machine while in operation.

3. DO NOT Make High Speed Maneuvers with the machine.

4. Disengage PTO and remove Keys before servicing.

5. Keep ALL Shields in place.

6. DO NOT allow riders on outside of vehicle.

7. DO NOT attempt to clean, oil or adjust machine while in motion.

8. DO NOT exceed rated PTO RPM speed.

TABLE OF CONTENTS

PAGE

INTRODUCTION 2

SET-UP 3 - 4

OPERATION 5 -7

MAINTENANCE 8 - 9

Chains

Power Take Off Shafts

Augers

LUBRICATION SCHEDULE MON600122

DECAL LOCATIONS MON600123

ASSEMBLY PRINTS

FINAL ASSEMBLY MON900386

BASE ASSEMBLY MON900382

TOP AUGER ASSEMBLY MON900394

BOTTOM AUGER ASSEMBLY MON900380

8” CHAIN TIGHTENER ASSEMBLY MON900383

17” CHAIN TIGHTENER ASSEMBLY MON900373

23” CHAIN TIGHTENER ASSEMBLY MON900374

SHEAR SPROCKET ASSEMBLY MON900381

120 MM BEARING ASSEMBLY MON900377

POWER TAKE OFF MON700424

DRIVELINE POWER TAKE OFF SAC75756

4 FUNCTION HYDRAULIC ASSEMBLY MON900388

SWITCHBOX ASSEMBLY SCA170076

2” CYLINDER ASSEMBLY MON100437

DISCHARGE ASSEMBLYS

4052 MON900340 & MON900364

4062 MON900341 & MON900361

4074 MON900342 & MON900362

4080 MON900343 & MON900363

DRIVE ASSEMBLY MON700231

DRIVE COUPLING ASSEMBLY MON700143

FLIP CHUTE CYLINDER ASSEMBLY MON700230

FLIP CHUTE ASSEMBLY MON900335

TRUCK MOUNT C BAR ASSEMBLY MON900173

GENERAL SPECIFICATIONS 2050

INTRODUCTION

Thank you for purchasing a

give the agricultural industry the ability to incorporate long stem roughage into the total mixed

ration without additional grinders or processors. We have built the

standards and a high level of quality that will give you many years of dependable service if properly

used, maintained and serviced.

Along with the purchase of your new

family of agricultural equipment, and a fully equipped and knowledgeable service staff that can

help you with all y our needs.

In addition to reading and completely understanding this owner's manual, please take the

time to fill out the warranty registration sheet so that we may process your warranty, as well as

anticipate your future needs.

2050 MaxiMixer

MaxiMixer

. The purpose of the

MaxiMixer

you have also become part of a fine

MaxiMixer

to very exacting

is to

MODEL NO: 2050 SERIAL NO

DATE:_____________

Please have these ready when phoning in for service.

Sioux Automation Center Inc.

877 1ST AVE NW

SIOUX CENTER IA 51250

(712) 722-1488

www.siouxautomation.com

2

__________________

USING YOUR

MaxiMixer

READ CAREFULLY

SETUP

1. When you are delivered your new

to check the machine for bearing lubrication or chain tightness, as these items have been factory

serviced. It is recommended to walk around the machine and familiarize yourself with the

location of all moving parts, caution decals, the general operating dimensions, and the basic

working features of the

2. All lubrication has been completed at the factory prior to delivery and will not be immediately

necessary. For Lubrication intervals and specifications see the enclosed Lubrication Schedule.

IMPORTANT! DO NOT OVER GREASE BEARINGS, SEAL FAILURE AND

SUBSEQUENT PREMATURE BEARING FAILURE COULD RESULT.

3. When you receive your

source for the solenoid that switches power between the hydraulic functions (if so equipped).

The switch box is supplied with a lead that has 1 white wire and 1 black wire. The white wire

is to be hooked to positive and the black is to be hooked to ground. It is recommended to hook

these leads into a switched power source such as a keyed ignition. This will eliminate the

possibility of draining the battery if the switch is left on. When not in use, be sure to turn unit

off.

IMPORTANT: ALWAYS KEEP POWER CONNECTIONS TIGHT, NEAT AND FREE

FROM DIRT AND CORROSION! DO NOT HOOK THE LEADS FOR THE SWITCH

BOX INTO THE MIXER MOUNTED BATTER Y THA T SUP PLIES THE SCALE!

The leads for the switch box have been supplied with and inline fuse holder that holds a 10 amp

fuse.

MaxiMixer

MaxiMixer

CAUTION!

UNDERSTAND THIS OWNER'S MANUAL AND ALL CAUTION,

WARNING, AND DANGER SYMBOLS LOCATED ON THE

MACHINE AND IN THIS MANUAL.

MaxiMixer

.

BEFORE OPERATING THIS MACHINE, READ AND

, it will be first necessary for you to hook up the power

from the factory, it is not immediately necessary

CAUTION!

HIGHER RATING!

3

DO NOT REPLACE A BLOWN FUSE WITH A FUSE OF A

4. The

MaxiMixer

understand the scale manual and familiarize yourself with its different functions. The scale

indicator needs to be connected to a power source. Connect the scale indicators power cord

directly to the solenoid operated hydraulic valve (if so equipped) or to the battery either on the

mixer or the tractor. The leads are supplied with 1 white wire and 1 black wire. The white wire

is to be connected to the positive and the black is to be connected to the ground. By having the

scale connected to a constant power source, it will save warm up time between feedings. It is

recommended to run the scale wires separately from other power lines to keep electrical

interference to a minimum. A 10 amp inline fuse a lso prote cts the sc ale indic ator .

IMPORTANT

ANY SERVICE WORK SUCH AS WELDING!

DRAWBAR.

has also been supplied to you with a complete scale system. Read and

! ALWAYS DISCONNECT SCALE LEADS BEFORE PERFORMING

DANGER!

OFF PTO, TURN OFF ENGINE AND PULL THE KEY, SET

PARKING BRAKE, AND WAIT FOR ALL MOTION TO STOP

BEFORE ADJUSTING PTO LENGTH AND WORKING ON THE

TO PREVENT SERIOUS INJURY OR DEATH, TURN

4

OPERATION

1. Before attempting to fill the mixer, make sure that the discharge door is completely closed, the

chute is in the up position, and the mixing chamber is free of any foreign objects.

IMPORTANT! IF THE DISCHARGE DOOR IS LEFT OPEN DURING MIXING,

FEED MAY BECOME TIGHTLY PLUGGED AGAINST THE CONVEYOR AND

DAMAGE IT.

2. Refer to the Owner's Manual of the truck before operating the mixer, to ensure proper PTO

engagement.

including small grains, corn, concentrates and premixes, cotton seed, corn and hay silage etc.

The

MaxiMixer

recommended that wrapped and ensiled round bales be processed in the

IMPORTANT! THE MIXER SHOULD ALWAYS STAND LEVEL WHEN MIXING!

4. Due to the nature of mixing and cutting long stem hay, pin shearing is something that can be

expected. The shear pin is designed to be the weakest li nk in the drive train and i ts shearing is

to prevent damage to critical components. Therefore never replace shear pins with a higher

tensile strength or grade pin. If a machine is regularly shearing pins, the operator should first

look for mechanical problems such as worn knives or a bearing failure, then evaluate loading

procedures and lastly, call for technical assistance.

5. If a

MaxiMixer

(counter clockwise from the front) will not resolve the problem, it will be necessary to reverse

the mixer. This can safely be done by first turning off all power sources, setting the parking

brake and waiting for all motion to stop before removing the PTO from the input shaft end.

Then fit the supplied T handle to the input shaft, and then turn the T handle (facing the mixer)

clockwise to loosen the plugged material.

CAUTION:

could cause the shear pin to shear or damage the drive system.

3. The

DANGER! TO PREVENT SERIOUS INJURY OR DEATH, DO NOT

ENTER THE MIXING CHAMBER!

MaxiMixer

is also capable of processing dry long stem hay into your ration. It is not

does become plugged or jammed to the point where normal mixing rotation

Avoid high speed engagement of the

will effectively mix all ingredients in a Total Mixed Ration

MaxiMixer

MaxiMixer

as it

.

5

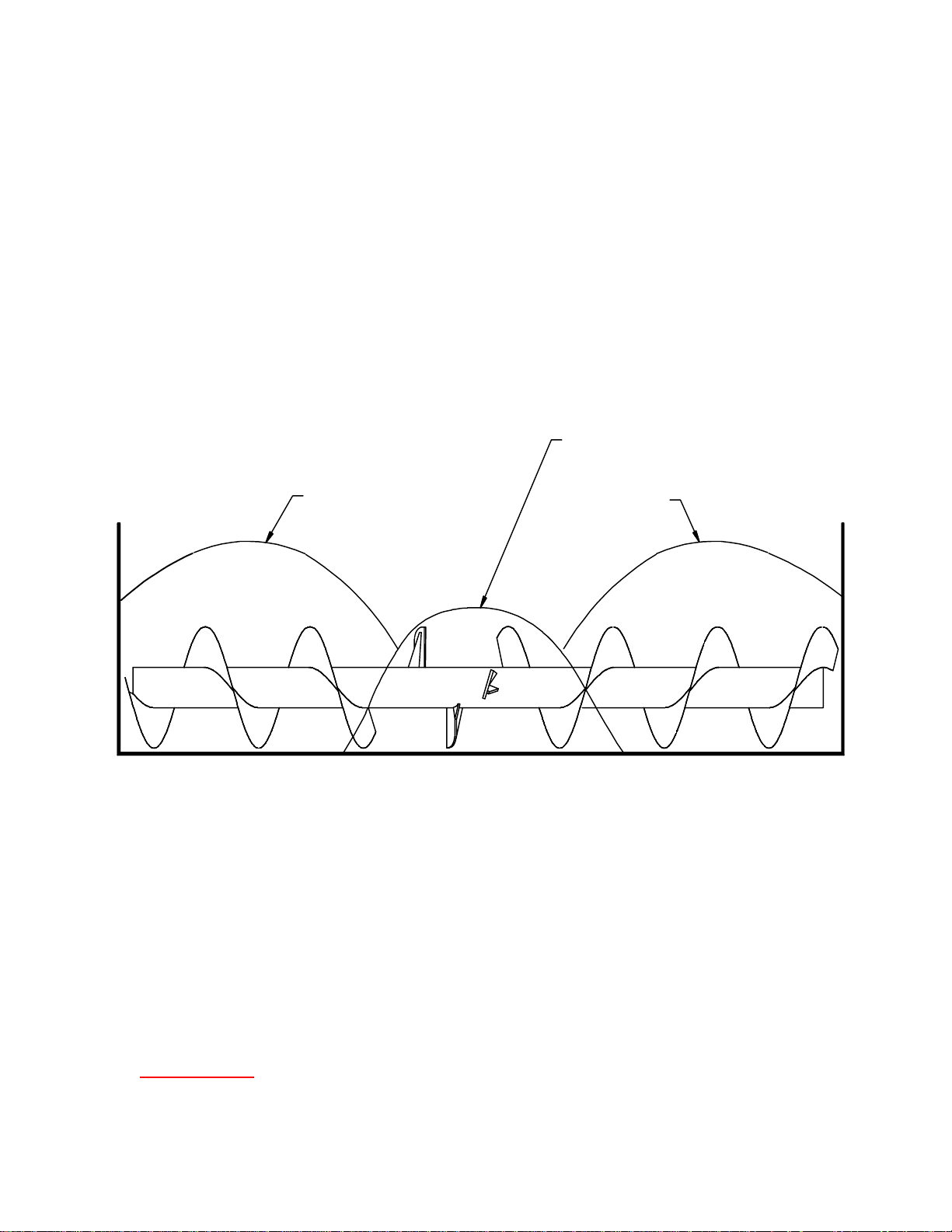

6. Proper loading procedure involves loading smaller quantity ingredients in the center of the

mixer first, to cover up the mixing paddles. This will prevent the aggressive paddles from

grabbing too much hay before it can be first adequately processed by the knives on the auger

flighting. Loading long stem hay in the center of the mixer increases the chances of shearing

pins. If not happy with the resulting ration, some sequencing changes may need to be made. If

sequencing changes do not fix your ration problems, see the factory for further assistance. Do

not be concerned about the appearance of the ration in the mixer; the appearance and evenness

of the ration is determined only in the bunk.

SMALL INGREDIENTS

HAY HAY

7. To discharge feed from the

MaxiMixer

it is necessary to first start the conveyor (either self

contained hydraulics, or tractor supplied) and then open the discharge door. The conveyor and

the door operate on two different hydraulic circuits and can be operated independently. The rate

of ration flowing from the

MaxiMixer

can be controlled by the door position. The higher the

door is raised, the more feed it will allow out, and vice versa.

IMPORTANT! ALWAYS START THE DISCHARGE BEFORE OPENING THE

DOOR TO PREVENT JAMMING FEED AGAINST THE CONVEYOR!

6

8. Normal mixing time is form 1 to 2 minutes after the last ingredient has been added. It is

necessary to run the

long stem hay or ensilage. It is not necessary to run the machine while loading. Strive for the

shortest mixing time possible, as over-mixing will decrease the value of the ration and will

cause unnecessary wear on the machine.

9. Proper mixing patterns are achieved when two cavities are visible in the mixer, one in the front

and one in the rear. Feed must be able to tumble from the top to the bottom of the mixer to

obtain maximum mixing potential. A mixer that is struck level full will not mix properly and

will put undue stress on moving parts.

10. Do not leave partially mixed loads in the machine for long periods of time such as during the

day or overnight. Acids from the feed will react with the steel and will cause premature

deterioration of the machine. It is better to mix two small loads, than one large load.

MaxiMixer

at 1600 ENGINE RPM during mixing of ingredients such as

7

MAINTENANCE

Your MaxiMixer will be delivered, fully lubricated and set up to all drive component installation

specifications. During the break in of your new MaxiMixer, it is recommended that a complete

daily inspection of all drive components be carried out. Throughout the life of your Maximixer, a

complete inspection of all drive components, fasteners, auger knives and shields should be

carried out during scheduled lubrication times. Wore or damaged parts must be replaced, loose or

misaligned parts must be adjusted and tightened to assure proper operation and life of

components.

WARNING: Always shut off engine, set parking brake, remove the key and

wait for all motion to stop before attempting to adjust, lubricate, service or

setup this machine!

CHAINS

Discharge Conveyor Chain

A. The conveyor chain will loosen up some during the first few hours of operation and over the

life of the discharge. Lift a flight near the center of the table. It should move about an inch

off the floor. Remember when tightening the chain to move both take ups the same distance

so the conveyor chain runs straight along the length of the discharge.

Oil bath Roller Chain and Sprockets

Chain Tension

B. Be sure it is tensioned adequately to prevent tooth jumping (ratcheting) under the most severe

load conditions, which the drive will encounter during operation.

C. Adjust spring tightener, to eliminate any slack in roller chain, by moving S-hook along

tightening chain to increase tension on spring.

Drive Alignment

D. Any degree of sprocket misalignment will result in some reduction of chain life.

Misalignment of all roller chain sprocket drives should not exceed 1/4 degree or 1/16” per

foot of linear distance. Misalignment should be checked with a good, straight edge tool. The

tool should be applied from the driver to driven, and then from the driven to driver sprockets

so that the total effect of parallel and angular misalignment is taken into account.

E. Drive misalignment can cause premature sprocket and chain wear. Extreme case may result

binding of chain and drive failure. Alignment of sprockets, using shims and the adjusting

screw on the jackshaft, is critical for proper operation of your MaxiMixer.

Upper Auger Shear Sprocket

8

F. The shear sprocket uses one 5/8 X 3-1/2” NF grade 8 bolt. Any change from this

specification will void warranty.

POWER TAKE OFF SHAFTS

G. Keep PTO shaft covers in place at all times. Keep universal joints greased. The PTO shear

uses a 5/16 x 2" NF grade 5 bolt. Any change from this specification will void warranty.

AUGERS

Knives

H. Auger Knives should be checked regularly for lose or damaged knives and tightened or

replaced as required. A minimum of grade 5 carriage bolts and lock nuts should be used

because of wear.

I. Rotating knives from high wear areas (middle of auger) to low wear areas (end of auger) will

increase the life of the knife set and maintain a high level of cutting action. Knifes wore past

the tungsten coating and are not effective for cutting should be replaced. Knifes should be set

as close as possible to stainless steel bars on the belly, but must not hit.

Bushings

J. Both augers run on oil impregnated nylon bushings at the front of the mixer. This assembly is

designed to make a metal rubbing metal squealing sound when bushing is wore and needs

replacement. Prolong use at this stage, without replacing bushing, will cause damage to both

the stub shaft and auger sleeve.

K. To change the bushing: - support the auger in the mixer

- remove the stub shaft from the front of the mixer

- remove the wore bushing from the auger sleeve

- tap new bushing into auger sleeve using wooden block

- grease stub shaft and reinstall

- remove auger support and any foreign objects from inside mixer

9

DWG NO.

8

MON600123

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE CHKBY

1

REV

D

D

9

C

6

12

10

C

6

7

ITEM NO . QTY. PART NO. DESCRIPTION

1

B

1

1

6

A

1

3

12

9

1

7

5

8

2

8

7

11

6

DRAWN

JL

CHECKED

SCALE

1:30

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

.020 ANGULAR 1

2 PLACE

MATERIAL

AS NOTED

456

ITEM NO . QTY. PART NO. DESCRIPTION

1 6 DEC102 DECAL,G RS , GUN,P ICTURE

1 6 DEC102 DECAL,G RS , GUN,P ICTURE

2 1 DEC106 DE CA L, CAUTION,MA N,O WNE R,5,6

2 1 DEC106 DE CA L, CAUTION,MA N,O WNE R,5,6

3 1 DEC107 DECAL,WA RNING,CHAIN,EXPOS ED

3 1 DEC107 DECAL,WA RNING,CHAIN,EXPOS ED

4 1 DEC108 DE CA L, WA RNING,PA RT,M OVING,4,4

4 1 DEC108 DE CA L, WA RNING,PA RT,M OVING,4,4

5 1 DEC109 DECAL,CAUTION,WLD,3,3

5 1 DEC109 DECAL,CAUTION,WLD,3,3

6 4 DEC111 DECAL,DA NG E R,A UG E R, 5,6

6 4 DEC111 DECAL,DA NG E R,A UG E R, 5,6

7 1 DEC114 DECAL,M O NO, GA,DOOR

7 1 DEC114 DECAL,M O NO, GA,DOOR

8 2 DEC128 DECAL,SAC,LOGO,NEW,3,5.66

8 2 DEC128 DECAL,SAC,LOGO,NEW,3,5.66

9 2 DEC154 DECAL,SAC,LO G O, NEW , 20.5H,24W

9 2 DEC154 DECAL,SAC,LO G O, NEW , 20.5H,24W

10 1 DEC158 DECAL,2030,6,108,RH

10 1 DEC158 DECAL,2030,6,108,RH

11 1 DE C 1 59 DECAL,2 03 0,6,10 8

11 1 DE C 1 59 DECAL,2 03 0,6,10 8

12 2 DEC163 DE CA L,M AXI,2050,BLACK

12 2 DEC163 DE CA L,M AXI,2050,BLACK

13 1 DEC161 DECAL,MAXI,GA,DOOR

13 1 DEC161 DECAL,MAXI,GA,DOOR

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

DECAL LOCATIONS

SIZE

DWG NO.

B

MON600123

B

REV

SHEET

OF

1

123

1

DWG NO.

8

MON600122

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE CHKBY

1

REV

-

D

WARNING

IF WORK MUST BE PREFORMED INSIDE

MIXER A PROTECTIVE COVER MUST BE

PLACED OVER KNIVES TO AVOID INJURY

OR DEATH.

ALWAYS STOP MIXER AND TURN OFF

MOTOR BEFORE LUBRICATING, ADJUSTING

OR SERVICING THIS MACHINE.

D

SERVICE NOTES:

C

2

4

5

5

6

2

4

B

3

1

A

8

7

ALL BEARINGS, SHAFTS, SPROCKETS, CHAINS, BELT AND FASTENERS

MUST BE VISUALY INSPECTED, WHEN LUBRICATING MIXER.

WORE OR DAMAGED PARTS MUST BE REPLACED

LOOSE OR MISALIGNED PART MUST BE ADJUSTED AND TIGHTENED

TO ASURE PROPER OPERATION AND LIFE OF CONPONENTS.

DISCHARGE

6

5

4

3

2

1

POINT

DRAWN

JL

CHECKED

SCALE

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

CHAIN

DISCHARGE

BEARINGS

FRONT AUGER

BUSHING

ALL DRIVE LINE

BEARINGS

POWER TAKE OFF

REAR DRIVE

OILBATH

ITEM LUBRICATION

1:30

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

.020 ANGULAR 1

AS NOTED

456

DATE

07-01

DATE

BREAK ALL EDGES

.03 X 45

LIGHT WEIGHT OIL

STANDARD ALL PURPOSE

GUN GREASE

STANDARD ALL PURPOSE

GUN GREASE

STANDARD ALL PURPOSE

GUN GREASE

STANDARD ALL PURPOSE

GUN GREASE

LIGHT WEIGHT OIL

FILL TO COVER CHAIN ON

BOTTOM OF LOWEST SPROCKET

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

LUBRICATION SCHEDULE

SIZE

DWG NO.

B

MON600122

BRUSH ON LIGHTLY EVERY

40 HOURS OF OPERATION

EVERY40 HOURS

OF OPERATION

EVERY40 HOURS

OF OPERATION

EVERY40 HOURS

OF OPERATION

EVERY40 HOURS

OF OPERATION

CHECK EVERY40 HOURS

OF OPERATION

CHANGE YEARLY

INTERVAL

REV

SHEET

123

C

B

-

OF

1

1

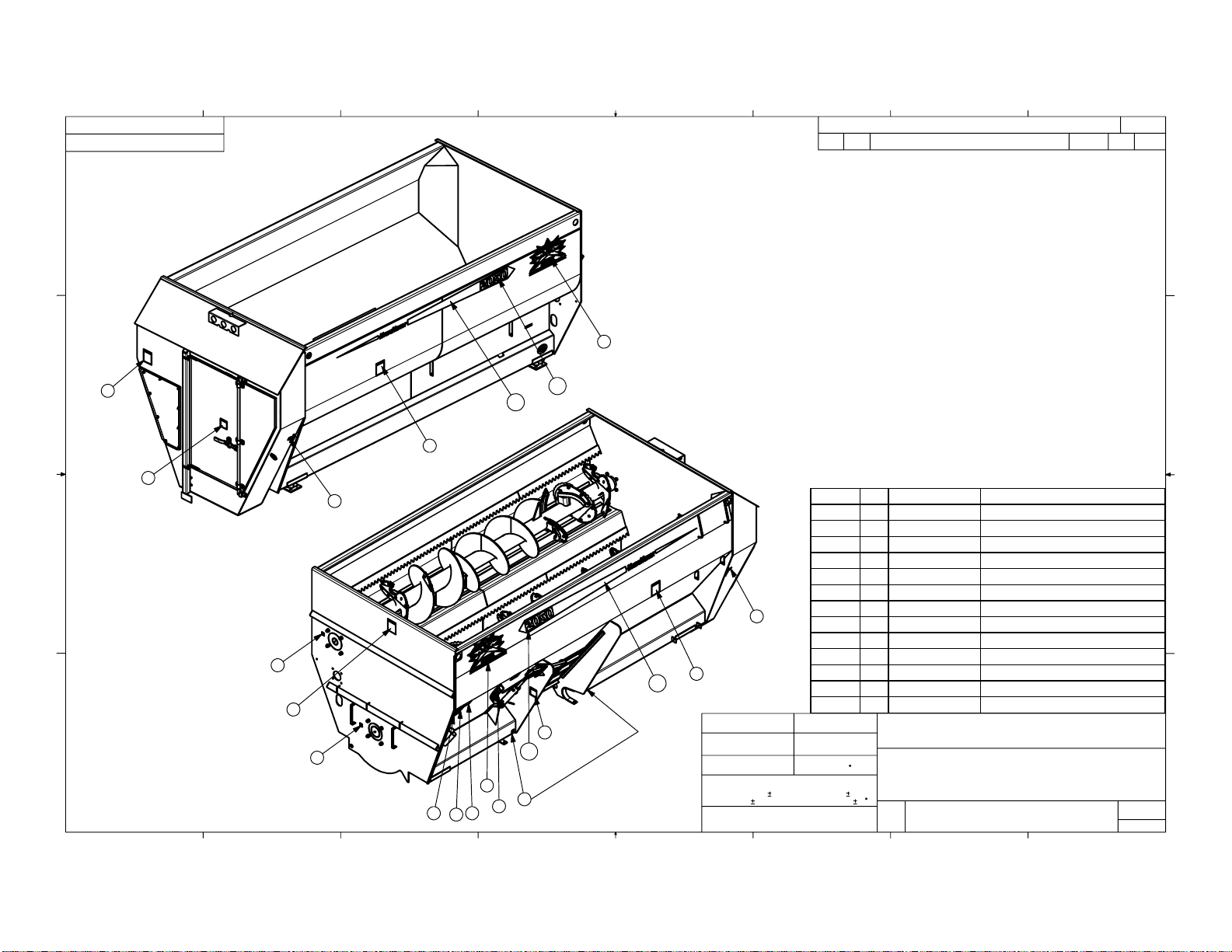

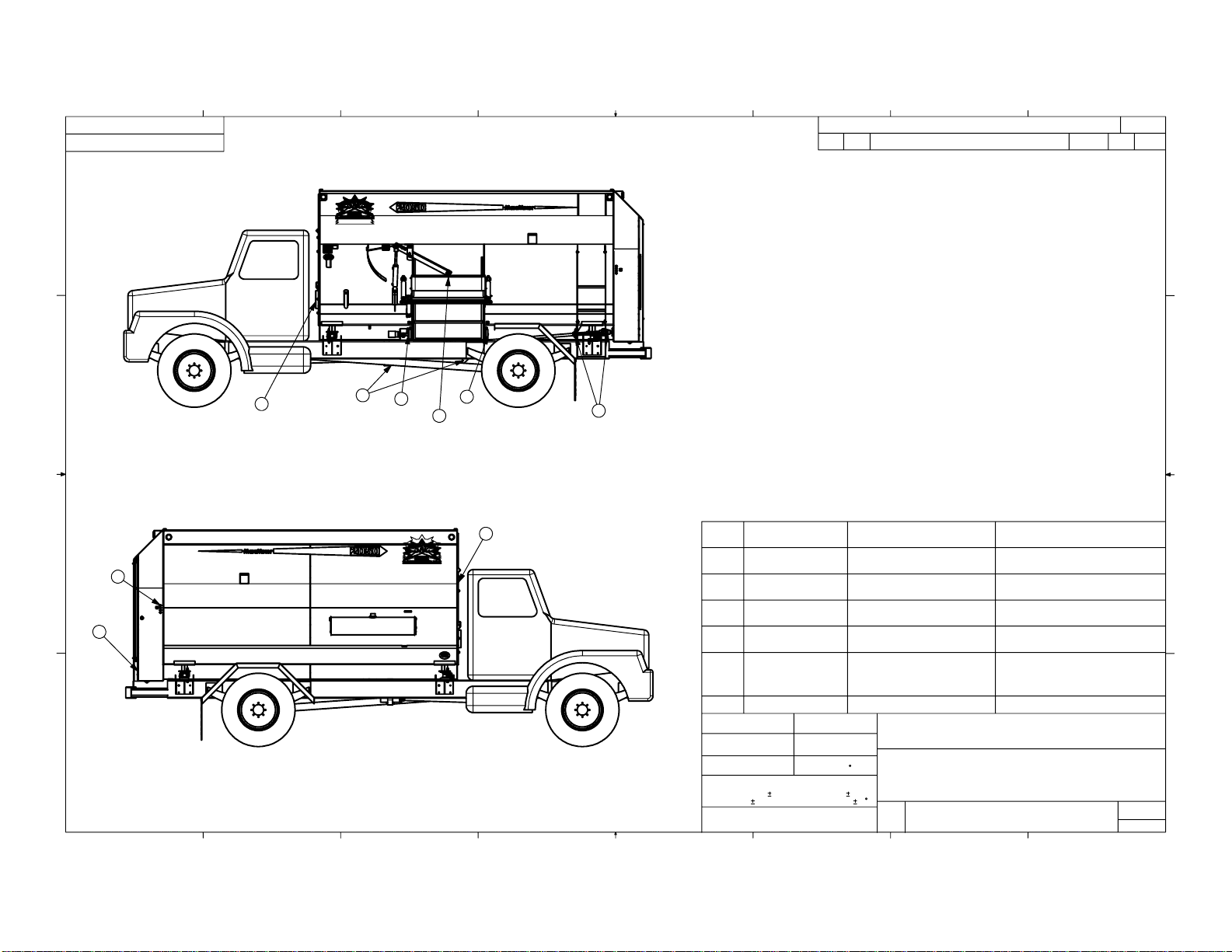

MaxiMixer

Model 2050 Truck Mount

Assembly Prints

DWG NO.

MON900386

8

DO NOT SCALE DRAWING

ITEM # QTY

1

2

D

3

4

5

6

7

8

9

10

11

12

13

14

15

C

16

17

18

19

20

21

22

23

24

25

26

27

28

29

B

30

31

32

33

34

35

36

37

38

39

40

41

42

A

43 *

44

45

46

47

48

49

1

6

16

8

2

8

32

2

1 KN136362 SHAFT,INPUT,1.375,109"

1

2

2

*

1

2

2

1

1

1

1

22

2

8

8

32

2

4

1

1

2

2

1

1

1

2

4

4

4

1

50

100

2

1

1

22

8

8

32

8

(PTO SPEC PER TRUCK)

BLT12X112NC

BLT12X134NC

BLT38X1NC

BLT38X712NC

BLT516X114NC

BLT58X212NC

BRGRCJ138

MON100321

MON100908

MON101238

MON600100

MON700424

MON700593

MON700594

MON700609

MON900382

MON900388

MON900389

NUT12NC

NUT38LOCKNC

NUT38NC

NUT516NC

NUT58NC

PTO3-4-613

PTO3-94-18X

PTO5-178X

SAC35333

SAC35528

SAC56009

SAC60546

SAC60547

SAC75756

SACFLAP24X24

SCA170031

SCAOMS30K

SP14X1TS

SP2:1GEARBOX

SPCABLETIEHVY

SPCABLETIEMED

SPCP316X2

TRKFRAME

TWHL43A

TWKIT#3

WSH12LOCK

WSH38LOCK

WSH516LOCK

WSH58LOCK

PART #

7

PTO,HOT,SHIFT,111%

6

DESCRIPTION

5

4

3 2

REVISIONS

ECN REV. DESCRIPTION DATE

2948

A

ADD:SPCABLETIEMED,SPCABLETIEHVY,

TWHL43A,TWKIT#3,SACFLAP24X24,SAC56009,

BLT516X114NC,NUT516NC, & WSH516LOCK

DEL:MON100437

06-04 CM

1

REV

BY CK

A

BLT,HEX,1/2,1-1/2,NC,G5

BLT,HEX,1/2,1-3/4,NC,G5

D

BLT,HEX,3/8,1,NC,G5

BLT,HEX,3/8,7-1/2,NC,G5

BLT,HEX,5/16,1-1/4,NC,G5

BLT58X212NC

BRG,FLG,4BLT,1.38

ROD,LIFT,DIS,40

WRM38TEPIPE,6.12

WRM5CHANNEL,29

DIS,ROLLER,OPTIONS

PTO,W2400,25.2,WALTERSCHEID

MOUNT,BODY,TRK

MOUNT,BODY,TRK,WEDGE

LADDER,16,62

C

2050,TRK,BASE,ASSY

HYD,ASSY,2050,TRKMNT

LIGHT,2050,TRK,ASSY

NUT,HEX,1/2,NC,G5

NUT,LOCK,3/8,NC,G5

NUT,HEX,3/8,NC,G5

NUT,HEX,5/16,NC,G5

NUT,HEX,5/8,NC,G5

YOKE,RND,1.38,AUTO

BLT,U,PTO,CROSS,OSW837227

CROSS,1.88,AUTO

BUMPER,TRK,RR,830804

SUPPORT,BUMPER,TRK,RR,830804

B

STRAP,FLAT,MUD

MOUNT,GEARBOX,TRK,ANGLE,FR

MOUNT,GEARBOX,TRK,ANGLE,RR

DRVLN,PTO,HANGER,KN

FLAP,MUD,.38,24,24

MOUNT,LDCLL,ASSY

LDCLL,30K,.10%,OMNI

SCREW,HEX,1/4,1,DRLLNG

GEARBOX,2:1,200,DI

TIE,CABLE,HVY,#175

TIE,CABLE,MED,#30-50

PIN,COTTER,3/16,2

TRK,10' CAB TO AXLE

DRAWN

JL

CHECKED

DATE

DATE

07-01

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250877 FIRST AVE NW SIOUX CENTER, IA 51250

FENDER,TRK,POLY,SINGLE,AXLE,PR

HARDWARE,MOUNTING,FENDER,SNGL

WSH,LOCK,1/2

WSH,LOCK,3/8

WSH,LOCK,5/16

WSH,LOCK,5/8

SCALE

MATERIAL

1:30

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

7

456

BREAK ALL EDGES

.03 X 45

B

SIZE

2050,TRK,FINAL,ASSY

DWG NO.

MON900386

REV

A

SHEET

OF

1

123

4

DWG NO.

MON900386

8

DO NOT SCALE DRAWING

7

6

5

4

3 2

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

A

CHKBY

D

D

3

172.00

120.00

16

15

30

12

29

12

46

21

30

C

6

C

48

24

31

35

45

44

B

TYP. ALL

B

REAR BUMPER

.25

24.00

COMPONENTS

NOTE:

1.) DRILL HOLES IN TRUCK FRAME TO SUIT FOR

MOUNTING FENDERS AND MIXER MOUNTS.

13.44

149.00

106.56

C

MOUNT

L

A

8

7

C

MOUNT

L

DRAWN

JL

CHECKED

SCALE

MATERIAL

1:50

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

456

DATE

07-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,FINAL,ASSY

REV

MON900386

123

SHEET

A

2

OF

4

DWG NO.

MON900386

8

DO NOT SCALE DRAWING

7

6

5

4

3 2

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

A

CHKBY

D

C

SEE NOTE #2

46

18

D

C

33

32

47

23

4

17

34

39

14

19

36

7

2

49

25

SEE NOTE #1

37

8

9

B

B

13

NOTE:

1.) LOAD CELL MOUNTS MUST ALL MOUNT

WITH STABILIZER BARS AT 90 TO EACH OTHER.

REAR LEFT AND FRONT RIGHT TO RUN FROM FRONT

TO BACK. REAR RIGHT AND FRONT LEFT TO RUN

FROM SIDE TO SIDE.

2.) ADD 1.50 SPACER TO REAR OF GEARBOX

MOUNT BRACKET BEFORE ATTACHING TO RAIL

DRAWN

JL

A

CHECKED

SCALE

MATERIAL

1:40

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

8

7

456

DATE

07-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,FINAL,ASSY

REV

MON900386

123

SHEET

A

3

OF

4

DWG NO.

MON900386

8

DO NOT SCALE DRAWING

7

6

5

4

3 2

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

A

CHKBY

D

C

D

C

OF

B

4

B

A

8

7

19

DRAWN

JL

CHECKED

SCALE

MATERIAL

1:30

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

456

DATE

07-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.

SIOUX AUTOMATION CENTER INC.SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250

877 FIRST AVE NW SIOUX CENTER, IA 51250877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,FINAL,ASSY

REV

MON900386

123

SHEET

A

4

DWG NO.

MON900382

DO NOT SCALE DRAWING

7

6

5

4

32

1

ITEM NO. QTY . PART NO. DESC R IPTION

1 1 MON700592 BODY,2050,TRK,WLD

D

2 1 MON100437 CYL,HYD,2,10,PAINTED

3 2 MON100450 ARM,LINKAGE,DOOR

4 1 MON100831 GA,DOOR,ROD,500,TRK

5 1 MON700013 DOOR,DIS,PIVOT,WLD,40

6 1 MON700471 LEVER,ASSY,DOOR,TRK

7 6 SPCP14X2 PIN,COTTER,1/4,2

8 3 HYDSC003 PIN,CYL,CLEVIS,1,3

9 4 WSH1FLAT WSH,FLAT,1

10 1 MON700595 SHAFT,FLG,WLD,5.5,10,8.75,TRK

11 1 MON700636 SHAFT,FLG,3.5,10,6.5,TRK,PNT

12 8 BLT34X2NC BLT,HEX,3/4,2,NC,G5

C

13 20 WSH34LOCK WSH,LOCK,3/4

14 18 NUT34NC NUT,HEX,3/4,NC,G5

15 1 SPGZRK613 ZRK,GRS,1/8,MALE,PIPE,90DEG

16 1 SPGZRK610 ZRK,GRS,1/8,MALE,PIPE,STR

ITEM NO. QTY. PART NO. DES C R IPTION

40 2 MON101141 FLG,RND,9.5,7.88,5,.81,1

41 1 MON101139 SPACER,RND,3.5,3.07,3.41

42 1 SPASNC38X1 SCREW,ALLEN,3/8,1,NC

43 2 MON101066 SHIM,BRGPB22440H,10GA

44 1 BRGPB22440H BRG,PILLOW,2.5,ROLLER

45 1 BRGFCB22440H BRG,FLG,4BLT,2.5,CART

46 1 MON101135 WRM212SPRD,13.75

47 1 MON700632 SPK,160A13,120A54,2.5,WLD

48 1 MON700582 SPK,160,56,120mm,WLD

49 1 MON101149 SPK,120,18,120mm,SPLINED

50 1 MON101144 SPACER,RND,5.5,4.73,1.5

51 1 MON900380 AUGER,BOT,2050,25DEG,ASSY

52 1 MON900394 AUGER,TOP,BLADE,2050,ASSY

53 1 MON101173 SPACER,RND,5.5,4.73,2.25

54 1 MON900377 BRG,FLG,6BLT,120mm,ASSY

55 1 KN180630 TUBE,GREASE,.18,109,ID

ITEM NO. QTY . PART NO. DESC R IPTION

79 2 MON101207 TIGHTNR,BRG,.5,5.88

80 2 BLT12X212NC BLT,HEX,1/2,2-1/2,NC,G5

81 2 BLT12X2NC BLT,HEX,1/2,2,NC,G5

82 2 BLT38X212FTNC BLT,HEX,3/8,2-1/2,NC,G5,FT

83 2 RP090005 KEY38X38,2.5,KIT

84 1 SELCR13536 SEAL,OIL,1.38,1.835,.25

85 1 MON101201 RTNR,SEAL,1.38,PLATE

86 1 MON101314 SHAFT,INPUT,1.38,17

87 1 HUBQ1138 HUB,Q1,1.38

88 1 SPK100Q14 SPK100,Q1,14

89 2 BRGRCJ138 BRG,FLG,4BLT,1.38

90 1 MON100866 KEY516X516,2.5

91 1 MON900383 TIGHTNR,CHAIN,100,8,ASSY

92 1 MON101318aa DOOR,OILBATH,LH,2050,TRK

93 9 NUT38WING NUT,WING,3/8

94 25 WSH38FLAT WSH,FLAT,3/8

D

C

17 1 RC160HCON LINK,CONN,160H

18 2 RC120HCON LINK,CONN,120H

19 1 MON101673 CHAIN,ROLLER,160-H,77P,154

20 1 MON101178 CHAIN,ROLLER,120-H,85P,127.5

21 1 MON101196 CHAIN,ROLLER,120-H,73P,109.5

22 16 KN172822 FTTNG,GREASE,LINE

23 13 NUT12NC NUT,HEX,1/2,NC,G5

B

24 16 WSH12LOCK WSH,LOCK,1/2

25 6 BLT12X112NC BLT,HEX,1/2,1-1/2,NC,G5

26 2 WSH58LOCK WSH,LOCK,5/8

27 2 NUT58NC NUT,HEX,5/8,NC,G5

28 4 WSH58FLAT WSH,FLAT,5/8

29 4 BLT58X312NC BLT,HEX,5/8,3-1/2,NC,G5

30 2 BLT34X112NF BLT,HEX,3/4,1-1/2,NF,G8

31 6 BLT34X512NC BLT,HEX,3/4,5-1/2,NC,G5

32 4 BLT34X412NC BLT,HEX,3/4,4-1/2,NC,G5

33 1 MON101174 SPACER,RND,5.56,4.81,.06

34 1 MON101175 DISK,6.25,.81,.5

A

35 1 BURN12000305 DISK,4.5,.81,.5

36 1 MON900381 SPK,120,38,3,SHEAR,ASSY

37 2 SPBUS3WR14G BUSHING,MACH,3,WR,14GA

38 1 MON101140 SPACER,RND,3.5,3.07,2.25

39 1 BRGFB22448H BRG,FLG,4BLT,3

8

56 9 BLT12X134NC BLT,HEX,1/2,1-3/4,NC,G5

57 2 NUT58LOCKNC NUT,LOCK,5/8,NC,G5

58 2 MON900374 TIGHTNR,CHAIN,23,ASSY

59 3 OSW830848 WTHRSTRP,SEAL,DOOR

60 1 PFPL2PLUG PLUG,2,PL

61 6 WSH12FLAT WSH,FLAT,1/2

62 1 MON700589 DOOR,OILBATH,2050,W LD

63 1 MON700590 LOCK,DOOR,CAM,57,WLD,ASSY

64 4 BLT38X1FNC BLT,FLG,3/8,1,NC,G2

65 12 WSH38LOCK WSH,LOCK,3/8

66 14 NUT38NC NUT,HEX,3/8,NC,G5

67 8 BLT38X1NC BLT,HEX,3/8,1,NC,G5

68 2 NUT12LOCKNC NUT,LOCK,1/2,NC,G5

69 1 MON101202 CHAIN,ROLLER,100-H,79P,98.75

70 1 RC100HCON LINK,CONN,100H

71 1 PFBL112PLUG PLUG,1-1/2,BLK

72 1 MON101197 JCKSHFT,SEC,1.75,12.5

73 1 BRGPB900134 BRG,PILLOW,1.75,DBL

74 1 BRGRAK134 BRG,PILLOW,1.75

75 2 HUBQ1134 HUB,Q1,1.75

76 1 SPK120Q14 SPK120,A,15,4.625

77 1 SPK100Q35 SPK100,Q1,35

78 1 MON101206 SHIM,BRGRAK134,14GA

95 8 SPGZRK618 ZRK,GREASE,1/8,FEM,PIPE,STR

96 1 MON101393 OILER,ANGLE,CHAIN

97 2 BLT516X1NC BLT,HEX,5/16,1,NC,G5

98 2 WSH516LOCK WSH,LOCK,5/16

99 2 NUT516NC NUT,HEX,5/16,NC,G5

2948

2513

1449

ECN

DRAWN

JL

CHECKED

SCALE

1:24

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

AS NOTED

C

B

A

REV.

DEL:MON101352,MON700577 & RC140HCON

ADD:MON700632,MON101393,BLT516X1NC,

& WSH516LOCK NUT516NC

DEL: MON700596/ADD MON700636

SEE ECN FOR CHANGES

DESCRIPTION

REVISIONS

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,BASE,ASSY

SIZE

DWG NO.

B

MON900382

06-04

12-03

12-01

DATE

1237

CM

CM

AP

BY CHK

REV

C

REV

C

SHEET

OF

1

B

4

DWG NO.

MON900382

8

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

C

CHKBY

D

C

1

94

95

22

55

D

C

B

5

B

3

6

3

9

7

8

4

A

2

8

7

DRAWN

JL

CHECKED

SCALE

MATERIAL

1:20

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

456

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,BASE,ASSY

REV

MON900382

123

SHEET

C

2

OF

4

DWG NO.

MON900382

8

DO NOT SCALE DRAWING

D

7

6

5

52

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

C

CHKBY

41

40

39 22

D

14 13 32

SEE NOTE 1

25 24 23

42

38

SEE NOTE 3

37

18

21

C

51

14

13

31

22

54

50

33

46

58

4522

11

29 28 26 27

19 17

5623

58

36

35

C

13

30

16

53

47

75

83

76

20 18

44 22

79

121314

24

8266

22

61

73

B

15

10

80

85

84

72

49

43

SEE NOTE 2

34

B

13

30

24

23

48

56

121314

86

75

REAR

83

77

87

91

90

88

8922

NOTE:

1.) CUT GREASE TUBE LENGTH TO SUIT AND

A

FRONT

RUN TUBING TO THE EIGHT BEARI NGS INSIDE

THE OILBATH AT ASSEMBLY.

GREASE ZERKS ON BEARINGS TO BE REPLACED

WITH PART # KN172822

2.) SHIM AS REQUI RED, USING SHIMS MON101066

AND MON101067.

3.) SHIM AS REQUIRED

8

7

DRAWN

JL

CHECKED

SCALE

MATERIAL

1:18

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

456

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

2050,TRK,BASE,ASSY

69 70

79

82 66

78

74 22

56 24 23

877 FIRST AVE NW SIOUX CENTER, IA 51250

MON900382

81 24 61

REV

C

SHEET

OF

3

123

4

DWG NO.

MON900382

8

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE

1

REV

C

CHKBY

D

D

APPLY WEATHER STRIP ALL

AROUND DOOR OPENINGS

59

C

C

256168

OF

B

4

B

DRAWN

A

63

2957

71

60

676566

646566

JL

CHECKED

SCALE

MATERIAL

1:20

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

8

7

456

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIZE

DWG NO.

B

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

2050,TRK,BASE,ASSY

REV

MON900382

123

SHEET

C

4

DWG NO.

8

MON900394

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE CHKBY

1

REV

D

AUGER ROTATION

FROM REAR

3

7

4 5 6

C

FLIGHTING KNIFE DETAIL

TYP. AT 20 LOCATIONS

DETAIL SCALE

SCALE 1 : 5

WARNING!

IF WORK MUST BE PREFORMED INSIDE

MIXER, A PROTECTIVE COVER MUST

BE PLACAED OVER KNIVES TO AVOID

INJURY OR DEATH.

ALWAYS STOP MIXER AND DISCONNECT

POWER BEFORE LUBRICATING, ADJUSTING

OR SERVICING THIS MACHINE.

NOTE:

ALL KNIVES TO BE ON PRODUCT FLOW

SIDE OF FLIGHTING.

D

-REAR-

3

C

8 5 6

9

7

B

1

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 MON700613 AUGER,TOP,2050,WLD

2 1 MON101006 BUSHING,PLNYOIL,4.5,3.5,4

B

3 14 MONP100170 KNIFE,AUGER,LH,TUNGSTEN,TIPPED

4 40 BLT716X114CG5 BLT,CARR,7/16,114,NC,G5

5 100 WSH716FLAT WSH,FLAT,7/16

6 100 NUT716LOCKNC NUT,LOCK,7/16,NC,G5

7 18 MONP100171 KNIFE,AUGER,RH,TUNGSTEN,TIPPED

8 60 BLT716X112CG5 BLT,CARR,7/16,112,NC,G5

DRAWN

A

2

9

7

3

JL

CHECKED

SCALE

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

AS NOTED

8

7

456

9 12 MONP100172 KNIFE,AUGER,PADDLE,TUNGSTEN

DATE

08-01

DATE

1:10

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

.020 ANGULAR 1

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

AUGER,TOP,BLADE,2050,ASSY

SIZE

DWG NO.

B

MON900394

REV

SHEET

OF

1

123

1

DWG NO.

8

MON900380

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE CHKBY

1

REV

D

C

3

B

6 8 7

5

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 MON700586 AUGER,BOT,2050,25DEG.,WLD

WARNING

IF WORK MUST BE PREFORMED INSIDE

MIXER, A PROTECTIVE COVER MUST

BE PLACED OVER KNIVES TO AVOID

INJURY OR DEATH.

ALWAYS STOP MIXER AND DISCONNECT

POWER BEFORE LUBRICATING, ADJUSTING

OR SERVICING THIS MACHINE.

NOTE:

ALL KNIVES TO BE ON PRODUCT FLOW

SIDE OF BLADES AND PADDLES.

D

C

B

2 1 MON101005 BUSHING,PLNYOIL,5.5,6.25,6.13

3 20 MONP100170 KNIFE,AUGER,LH,TUNGSTEN,TIPPED

1

4

4 16 MONP100171 KNIFE,AUGER,RH,TUNGSTEN,TIPPED

5 22 MONP100172 KNIFE,AUGER,PADDLE,TUNGSTEN

6 138 BLT716X112CG5 BLT,CARR,7/16,112,NC,G5

7 138 WSH716FLAT WSH,FLAT,7/16

2

A

8

7

DRAWN

JL

CHECKED

SCALE

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

456

8 138 NUT716LOCKNC NUT,LOCK,7/16,NC,G5

DATE

04-01

DATE

1:12

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

.020 ANGULAR 1

BREAK ALL EDGES

.03 X 45

AS NOTED

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

AUGER,BOT,2050,25DEG,ASSY

SIZE

DWG NO.

B

MON900380

REV

SHEET

OF

1

123

1

DWG NO.

8

MON900383

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

2313

REV.

DEL: MON101070,BLT12X312NC,SPRLK38

A

ADD: BLT12X4NC,WSH12FLAT,NUT12LOCKNC

DESCRIPTION

DATE CHKBY

1

REV

A

CM08-03

D

5

7

D

3

10

5

C

1

3

10

9

C

6

2

4

ITEM NO. QTY. PART NO. DESCRIPTION

B

1 1 MON700597 TIGHTNR,CHAIN,8

B

2 1 MON100932 TIGHTNR,NYL,CHAIN,100

3 2 NUT12LOCKNC NUT,LOCK,1/2,NC,G5

8

4 1 BLT12X4NC BLT,HEX,1/2,4,NC,G5

5 2 WSH58FLAT WSH,FLAT,5/8

6 1 BLT58X412NC BLT,HEX,5/8,4-1/2,NC,G5

7 1 NUT58LOCKNC NUT,LOCK,5/8,NC,G5

8 1 OSW840253 SPRING,EXPNSN

9 1 SPEE38 TRNBCKL,3/8,EYE,EYE

DRAWN

JL

A

NOTE:

1.) TENSION ON TIGHTENER SHOULD BE JUST ENOUGH

TO PRODUCE SMOOTH TRAVEL OF CHAIN. OVER TIGHTENING

WILL REDUCE TIGHTENER AND CHAIN LIFE.

CHECKED

SCALE

1:4

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

DATE

05-01

DATE

BREAK ALL EDGES

.03 X 45

.020 ANGULAR 1

AS SHOWN

8

7

456

10 2 WSH12FLAT WSH,FLAT,1/2

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

TIGHTNR,CHAIN,100,8,ASSY

SIZE

DWG NO.

B

MON900383

REV

A

SHEET

OF

1

123

1

DWG NO.

8

MON900373

DO NOT SCALE DRAWING

D

7

6

5

7

4

32

REVISIONS

ECN

1371

2313

REV.

DELETED: OSW830843, ADDED: NUT38NC, OSW840253,

A

SPEE38, CHG'D: RPP100036 QTY 2 WAS QTY 1

B

DESCRIPTION

SEE ECN

DATE CHKBY

10-01

08-03

1

REV

B

JL

CM

D

5

13

3

5

1

10

6

C

13

12

SEE NOTE 2

NOTE:

1.) TENSION ON TIGHTENER SHOULD BE JUST ENOUGH

TO PRODUCE SMOOTH TRAVEL OF CHAIN. OVER TIGHTENING

WILL REDUCE TIGHTENER AND CHAIN LIFE.

2.) TIGHTEN NUT AGAINST TURNBUCKLE AFTER PROPER

TENSION ADJUSTMENT IS MADE.

C

3

2

4

11

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 MON700559 TIGHTNR,CHAIN,17

2 1 MON101036 TIGHTNR,NYL,CHAIN,120,140

3 2 NUT12LOCKNC NUT,LOCK,1/2,NC,G5

B

9

4 1 BLT12X4NC BLT,HEX,1/2,4,NC,G5

5 2 WSH58FLAT WSH,FLAT,5/8

B

6 1 BLT58X412NC BLT,HEX,5/8,4-1/2,NC,G5

7 1 NUT58LOCKNC NUT,LOCK,5/8,NC,G5

8 1 OSW840253 SPRING,EXPNSN

9 1 RP100547 CHA316PC,15.25

10 1 SPEE38 TRNBCKL,3/8,EYE,EYE

11 1 RPP100036 HOOK,S,ROPE

12 1 NUT38NC NUT,HEX,3/8,NC,G5

DRAWN

A

8

JL

CHECKED

SCALE

1:5

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

DATE

DATE

.020 ANGULAR 1

AS SHOWN

8

7

456

13 2 WSH12FLAT WSH,FLAT,1/2

11-00

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

TIGHTNR,CHAIN,17,ASSY

SIZE

DWG NO.

B

MON900373

REV

B

SHEET

OF

1

123

1

DWG NO.

8

MON900374

DO NOT SCALE DRAWING

D

7

6

7

5

11

4

32

REVISIONS

ECN

1498

2313

REV.

DEL: OSW830843, RPP100036, RP100547

A

ADD: OSW840253, SPRLK38, NUT38NC

DEL: MON101070,BLT12X312NC,SPRLK38,NUT58LOCKNF

B

ADD: BLT12X4NC,WSH12FLAT,NUT12LOCKNC,NUT58LOCKNC

DESCRIPTION

DATE CHKBY

01-02

08-03

1

REV

B

JL

CM

D

7

1

C

10

5

2

9

9

6

NOTE:

1.) TENSION ON TIGHTENER SHOULD BE JUST ENOUGH

TO PRODUCE SMOOTH TRAVEL OF CHAIN. OVER TIGHTENING

WILL REDUCE TIGHTENER AND CHAIN LIFE.

2.) TIGHTEN NUT AGAINST TURNBUCKLE AFTER PROPER

TENSION ADJUSTMENT IS MADE.

C

5

ITEM NO. QTY. PART NO. DESCRIPTION

B

8

1 1 MON700552 TIGHTNR,CHAIN,23

2 1 MON101036 TIGHTNR,NYL,CHAIN,120,140

B

3 1 OSW840253 SPRING,EXPNSN

4

SEE NOTE 2

4 1 SPEE38 TRNBCKL,3/8,EYE,EYE

5 2 NUT12LOCKNC NUT,LOCK,1/2,NC,G5

6 1 BLT12X4NC BLT,HEX,1/2,4,NC,G5

7 2 WSH58FLAT WSH,FLAT,5/8

8 1 NUT38NC NUT,HEX,3/8,NC,G5

9 2 WSH12FLAT WSH,FLAT,1/2

10 1 BLT58X412NC BLT,HEX,5/8,4-1/2,NC,G5

3

A

DRAWN

JL

CHECKED

SCALE

1:5

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

DATE

DATE

.020 ANGULAR 1

AS SHOWN

8

7

456

11 1 NUT58LOCKNC NUT,LOCK,5/8,NC,G5

10-00

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

TIGHTNR,CHAIN,23,ASSY

SIZE

DWG NO.

B

MON900374

REV

B

SHEET

OF

1

123

1

DWG NO.

8

MON900381

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

1316

REV.

DEL; BLT58X312NC - QTY 1, NUT58LOCKNC - QTY 1

A

ADD; BLT58X312NF - QTY 1, NUT58LOCKNF - QTY 1

DESCRIPTION

DATE CHKBY

09-01

1

REV

A

JL

D

1

6

D

SEE NOTE 1

5

C

NOTE:

1.) APPLY A THIN FILM OF GEASE BETWEEN

THE SHEAR HUB AND SPROCKET AT ASSY.

2.) THE BRONZE BUSHING IS TO BE PRESS FIT

INTO THE SPROCKET.

3.) ONLY ONE GRADE 8 SHEAR BOLT IS TO BE

USED IN ASSEMBLY. ANY ADDITION TO THIS

WILL CAUSE DAMAGE TO MIXER.

C

7

SEE NOTE 2

2

B

B

3

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 MON700580 HUB,SHEAR,SPK,SPLINED,3,WLD

2 1 MON101079 BRG,BUSHING,4.5,4,.92,BRZ

3 1 MON101080 DISK,5.5,4.03,10GA

4 1 KN171989 RING,SNAP,OUTSIDE,4

5 1 MON700591 SPK,120,A,38,4.5,SHEAR,WLD

4

DRAWN

JL

A

CHECKED

SCALE

1:3

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

.020 ANGULAR 1

2 PLACE

MATERIAL

AS SHOWN

8

7

456

6 1 BLT58X312NF BLT,HEX,5/8,3-1/2,NF,G8

7 1 NUT58LOCKNF NUT,LOCK,5/8,NF,G8

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

SPK,120,38,3,SHEAR,ASSY

SIZE

DWG NO.

B

MON900381

REV

A

SHEET

OF

1

123

1

DWG NO.

8

MON900377

DO NOT SCALE DRAWING

7

6

5

4

32

REVISIONS

ECN

REV.

DESCRIPTION

DATE CHKBY

1

REV

-

D

C

D

C

1

B

4

B

3

ITEM NO. QTY. PART NO. DESCRIPTION

4

1 1 MON101142 HOUSING,BRG22224CJ

2 1 MON101143 CAP,BRG22224CJ

3 1 BRG22224CJ BRG,ROLLER,120MM,215MM,SPHER

DRAWN

JL

A

2

CHECKED

SCALE

1:4

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

.020 ANGULAR 1

2 PLACE

MATERIAL

AS NOTED

8

7

456

4 2 SELNA417254 SEAL,OIL,5.5,6,5,.56

DATE

04-01

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

BRG,FLG,6BLT,120mm,ASSY

SIZE

DWG NO.

B

MON900377

REV

-

SHEET

OF

1

123

1

DWG NO.

SCA170079

8

DO NOT S CALE DRAWING

7

6

5

4

32

REVISIONS

ECN REV. DESCRIPTION DATE BY CK

4677 A

4841 B

4864 C

DEL: 1 SCA170080, CHG: JES422005 QTY 3 WAS 4,

SCACORD185 QTY 82 WAS 96 ADD: 1 SCA170089

CHG RED PUMP RUN WIRE FROM RED TO WHITE/BLK

ADD: STI610809 QTY 1

1

REV

1-07 JK

5-07 CM

5-07 SZ

C

D

D

17

15

C

12

C

15

6

9

15

B

10

11

A

14

18

ITEM QTY. PART # DESCRIPTION

1 1 DEC278 DECAL,FACE,CNTRL,JYSTK,BOTEC

2 2 JES3AG10A FUSE,10AMP,GLASS,.25,1.25 (NOT SHOWN)

8

1

3 3 JES422005 CONN,BUTT,BLUE,16-14

4 1 JES452145 TRMNL,R I N G , B L UE,.25

5 15 JES461065 TRMNL,FORK,RED

6 1 JES6624 CONN,COR D ,F L E X,3/4, R OME X

7 1 JESYELFEMALEI TRMNL,SPADE,FEM,INSUL,YELLOW

8 1 SCA170078 COVER,BOX,CNTRL,JYSTK

B

16

9 1 SCA170089 SWITCH,JYSTK,DPDT,LOWPRO,WLD

10 300 SCAC2412 CORD,BULK,18,12COND

11 82 SCACORD185 CORD,BULK,18,5

12 1 SCADPDTMOM SWITCH,TOGG L E,DPDT,SC

13 2 SCAINLINE HOLDER,FUSE,INLINE

14

1 SCAL50171 LED,LAMP,1 2VDC

15 3 SCASPSTSC SWITCH,TOGGLE,SPST,ON/OF F

16 4 SPMB832X34SSP SCREW,MACH,8-32,3/4,SS

17 1 STI200109 BOX,CNTRL, ELEC

18 1 STI610809 GASKET,REMOTE,3.19,5.19

19 33 STIWIRE14PR02 WIRE,PRIMARY,14GA,RED

DRAWN

CM

CHECKED

DATE

DATE

06-05

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

SCALE

MATERIAL

1:4

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR

AS NOTED

8

7

456

BREAK ALL EDGES

.03 X 45

SWTCHBOX,JYSTK,5SW TCH, AS SY

1

SIZE

DWG NO.

B

SCA170079

REV

C

SHEET

OF

1

123

2

DWG NO.

SCA170079

8

DO NOT S CALE DRAWING

7

6

5

4

32

1

REV

C

D

C

D

C

OF

B

2

B

DRAWN

CM

A

NOTE: BOTTOM VIEW OF SWITCHES

8

7

CHECKED

SCALE

MATERIAL

1:5

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE .020 ANGULAR 1

AS NOTED

456

DATE

06-05

DATE

BREAK ALL EDGES

.03 X 45

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

SWTCHBOX,JYSTK,5SWTCH,ASSY

REV

SHEET

123

B

SIZE

DWG NO.

SCA170079

C

2

8

DWG. NO.

MON700143

DO NOT SCALE DRAWING

D

567

4

ECN REV

AECN

1964 B

3

REVISIONS

DESCRIPTION

MON800158 WAS MON800112

ADD: SPASNC14X12 QTY2

12

DATE BY

VM10-98

12-02 CV

REV

B

CHK

D

1

2

C

5

3

C

4

B

4

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 MON100846 RC402,18P,9IN

B

2 1 MON800158 SPK,40,B,18,1

3 1 RC402CON LINK,CONN,40-2

4 2 SPASNC14X12 SCREW,ALLEN,1/4,1/2,NC

DRAWN BY

BM

CHECKED

A

SCALE

1:1.5

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

.020 ANGULAR 1

MATERIAL

DATE

4-94

DATE

BREAK ALL EDGES

.03 X 45

AS NOTED

8

7

456

5 1 SPK40B18X114 SPK,40,B,18,1.25

PROPERTY OF:

SIOUX AUTOMATION CENTER INC

877 FIRST AVE NW SIOUX CENTER, IA 51250

CHAIN,COUP,DIS

SIZE

A

DWG. NO.

MON700143

3

2

REV.

SHEET

1

B

A

OF

1

1

DWG NO.

8

MON700230

DO NOT SCALE DRAWING

D

C

7

6

5

4

7

32

REVISIONS

ECN

744

REV.

A

MON100955 WAS MON100251

B

HYD6801-6-6 WAS HYD6400-6-8

DESCRIPTION

DATE CHKBY

2-95MON700253 WAS MON700189

12-00

1

REV

B

VM

JL

D

4

10

5

6

11

11

2

C

8

1

3

9

9

B

7

1 1 MON100393 BRKT,RAM,CLY,CHUTE

2 1 MON100955 CYL,HYD,2,8,W/CNTRBAL,PAINTED

B

3 1 NUT34JAMNF NUT,HEX,JAM,3/4,NF,G8

4 2 BLT38X1CNC BLT,CARR,3/8,1,NC,G2

5 2 WSH38LOCK WSH,LOCK,3/8

6 2 NUT38NC NUT,HEX,3/8,NC,G5

7 2 SPCP316X112 PIN,COTTER,3/16,1-1/2

8 1 SPBUS58NR14G BUSHING,MACH,.625,NR,14GA

9 2 MON700253 HOSE,HYD,3/8,62

10 1 MON700171 BRKT,CHUTE,FLIP

ITEM NO. QTY. PART NO. DESCRIPTION

DRAWN

JL

A

CHECKED

SCALE

1:3

DIMENSIONS ARE IN INCHES

TOLERENCES UNLESS SPECIFIED

FRACTIONAL 1/32 3 PLACE .005

2 PLACE

MATERIAL

AS SHOWN

8

7

456

11 2 HYD6801-6-6 ADPT,ELBOW,06,MJIC,06,MORG,90D

DATE

12-00

DATE

BREAK ALL EDGES

.03 X 45

.020 ANGULAR 1

PROPERTY OF

SIOUX AUTOMATION CENTER INC.

877 FIRST AVE NW SIOUX CENTER, IA 51250

CHUTE,FLIP,CYL,ASSY

SIZE

DWG NO.

B

MON700230

REV

B

SHEET

OF

1

123

1

GENERAL SPECIFICATIONS 2050 TRUCK MOUNT

WIDTH: MIXING CHAMBER...........................86” (218 cm)

OVERALL..................................87” (221 cm)

LENGTH: MIXING CHAM BER .........................168” (427 cm)

OVERALL (BOX ONLY)................................249” (632 cm)

HEIGHT: (DETERMINED BY TIRE SIZE)...............124” (315 cm)

CAPACITY: .................................508 CU/FT (14.38 m3)

(STRUCK LEVEL)……………….406 BUSHELS

UNIT WEIGHT: (BOX ONLY)…….......................13500 LBS (6123 Kg)

BOTTOM SECTION: ............. 5/16 STEEL PLATE WITH STAINLESS

LINER AND WEAR BARS

UPPER SIDES: ...................... 3/16 STEEL PLATE

FRONT/REAR: .......................5/16 STEEL PLATE

DISCHARGE: .........................40" DISCHARGE WITH BOTH STANDARD AND

EXTENDED LENGTHS HYDRAULICALLY

DRIVEN; ON LEFT SIDE OF MIXER

DRIVE: ............................BELT and CHAIN

MINIMUM HORSEPOWER REQUIREMENT: ...............90 HP (67 Kw)

Loading...

Loading...