SH79F085/SH79F165 Application Note

SH79F085/SH79F165 Application Note

1 Introduction

SH79F085/SH79F165 is an 8051 compatible micro-controller with a redesigned CPU of high efficiency and high

performance. The device provides high-endurance Flash program memory to store user’s code. In circuit programming

and debugging is offered to facilitate testing and debugging the systems using SH79F085/SH79F165 without removing the

circuit from the board.

The Sinowealth 8051 JET51 Driver is intended to provide the product development engineer with a complete

microcontroller design tool set for Sinowealth 8 bit microcontrollers. Software control of the JET51 Driver is advanced by

the Keil µ vision Integrated Development Environment via a JTAG interface, which allows editing, building, downloading

and source debugging from a single environment.

1.1 Package

SH79F165: SOP24/SOP28 package

SH79F085: TSSOP20 package

2 Using Target Board

2.1 Software Installation

Steps

1) Install Keil c uvision2 (V2.34 or above) or uvision3。

2)

Install JET51_Keil_Vxxx.exe (Vxxx means version), the device library for Sinowealth 8-bit microcontrollers, to the

Keil C directory.

Connect the JET51emluator to the PC via a USB cable. The red power LED and green USB LED will turn on if the

3)

installation is successful.

2.2 Target Board

Set up the target board as follows:

1) Connect the flat cable from the SH79F085/SH79F165 target board to the JET51emluator via JTAG

2) Connect C pin with external 47uF capacitor to GND.

3) The JTAG pins of the SH79F085/SH79F165 cannot be used as I/O function when downloading and debugging .

To communicate successfully with the emulator, make sure the JTAG pins are connected with no loads.

1/27

V 1.0

SH79F085/SH79F165 Application Note

4) Make sure the selected options (Oscillator option, Power option, etc) on the Setting dialog are the same as what

target board actually selects.

5) The capacitance between VDD and GND cannot be greater than 220µF; otherwise communication error may

occur.

S

H

7

9

F

0

8

5

/

S

H

7

9

F

1

6

5

USB

PWR

USB

JET51

VDD

GND

GND

TCK

TDI

TMS

TDO

GND

10

PINs

10

PINs

VDD

TCK

TDI

TMS

TDO

GND

Target Board

When designing user’s own board, 5 jumpers connecting JTAG pins with application circuit are recommended. To

program the device or run the device in emulation mode, the jumpers should be disconnected.

SH79F085/

SH79F165

VDD

TCK

TDI

TMS

TDO

GND

JET 51

To Application

Circuit

Jumper

2/27

V 1.0

SH79F085/SH79F165 Application Note

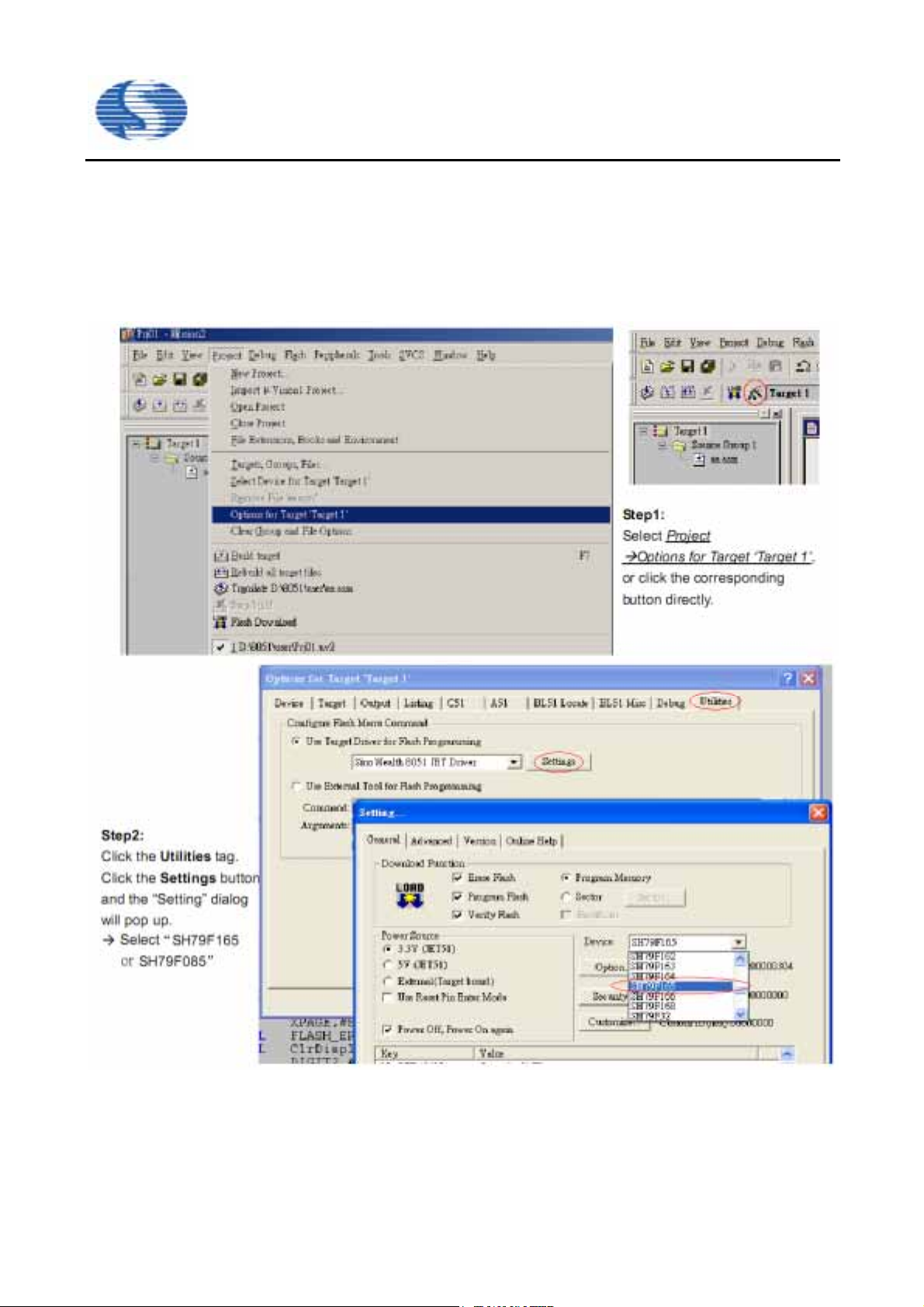

2.3 Creating a Project

The following steps describe how to create a new project.

Note: The source file – aa.asm located in ...\user directory.

3/27

V 1.0

SH79F085/SH79F165 Application Note

An empty project has been created, then setting the attribute as follow.

4/27

V 1.0

SH79F085/SH79F165 Application Note

The attribute of project is now finished, and then the program will be added to the project as follow.

5/27

V 1.0

SH79F085/SH79F165 Application Note

p

Step12:

步骤 12:将鼠标移至程序开

Right click the blank space at the

始处,按鼠标右键,选择头文

program file star, which a pop-up menu

comes up. Select the head file of menu

件, 头文件自动加入程序

item, and add head file to program.

中。

Right click the head file to open a

头文件加入后, 将鼠标移至头

pop-up menu. Select the menu

文件处,按鼠标右键,可以打开

item ”Open document <SH79F165.H>”

头文件。

to o

en the head file in a new window.

6/27

V 1.0

SH79F085/SH79F165 Application Note

2.4 Building a Project and Downloading to the Flash Memory

2.4.1 Building a Project

Select Project->Build target or click the corresponding button to build the source files. If no compilation error

and linking error are found, OBJ and HEX files will generate. The generated files can be found in the directory

\user.

7/27

V 1.0

SH79F085/SH79F165 Application Note

2.4.2 Downloading to the Flash Program Memory

2.4.2.1 Setting for Downloading

Before downloading the code, some options, including programming device, device’s code option and power supply

source, must be determined. Since the options will save automatically each time you set them, this step can be skipped

once you did before.

8/27

V 1.0

SH79F085/SH79F165 Application Note

9/27

V 1.0

SH79F085/SH79F165 Application Note

Note: Two ways are available to power up the target board, which can be determined by Step3.

1) Type 1: Power supply from JET51

Please select “3.3V (JET51)” or “5V (JET51)” for power source option. Check Power Off, Power On again option, which

means that each time the Download or Debug button has been clicked, JET51 will power off the target board before it

powers up the target board again. Use this way if debugging code is in process or downloading error is found.

In this case, the JET51 driver powers up the target board when downloading and debugging the program. Since the power

is used from JET51 driver, any external voltage should not be applied to the target board. Type 1 is recommended if the

current consumption of the target board is less than 20mA.

2) Type 2: Power supply from your own external voltage.

Select “External (Target board)” for power source option. In this case, an external voltage should be applied to the target

board. Please strictly follow the steps below to power on successfully.

Step1: Power off the target board

Step2: Connect JET51emluator with the target board

Step3: Connect the USB cable from JET51emluator to PC. The red power LED and green USB LED will turn on if the

connection is successful.

Step4: Apply external voltage to the target board.

Once the target board has been set up as previously described, you can download and debug the application program

repeatedly without powering off and reconnecting the target board again

2.4.2.2 Downloading to the Flash Memory

10/27

V 1.0

SH79F085/SH79F165 Application Note

2.5 Debugging Source Code

Select the menu item Debug->Start/Stop Debug Session or click the corresponding button to enter the debugging mode of

the device. Once the device enters into its debugging mode, a yellow arrow will point to 0000H location and the SP register

in left pane read 07H. the feature of in circuit debugging enable the designer to develop and debug source code by setting

breakpoints, single stepping and watching variables, and CPU status and peripheral registers. Running at full speed

enable testing hardware and applications in read time.

Note:

1) The instruction at the breakpoint location has been executed when the device breaks.

2) The next statement of ACALL or LCALL statement will execute when step over command executes.

3) The emluator supports total 7 breakpoints. If more than 7 breakpoints have been set, the last 7 breakpoints work and

the others are ignored.

4) power off the device and disconnect it from JET51 driver.

5) To run the device in normal mode, Apply external voltage to the target board again, and the device will operate under

11/27

V 1.0

SH79F085/SH79F165 Application Note

3 Design Tips

3.1 CPU

The SH79F085/SH79F165 is an 8051 compatible microcontroller with an enhanced CPU core. The CPU function is

intensified in the following aspects:

3.1.1 The SH79F085/SH79F165 CPU machine cycle is the same as its oscillator clock, while the traditional 8051 CPU

machine cycle is composed of 12 oscillator clock cycles. When the same oscillator frequency is selected, the

SH79F085/SH79F165 devices run almost 10 times faster than the traditional 8051 devices. See the SH79F085/

SH79F165 datasheet for the detail instruction execution cycles.

3.1.2 The SH79F085/SH79F165 has implemented enhanced multiplication and division instructions, where 16bit×8bit

and16bit÷8bit operations are supported by introducing an AUXC register. Set the MUL and DIV bits of the INSCON

register to perform the 16bit operation. Please clear these two bits when the 16bit operation is terminated.

3.1.3 The SH79F085/SH79F165 has implemented dual data pointers (DPTR and DPTR1). It is convenient for the user to

branch table and move data using two data pointers. Configure the DPS bit the INSCON register to select the

corresponding data pointer. Please clear the DPS bit when the DPTR1 operation is complete.

3.1.4 The SH79F085/SH79F165 provides XPAGE to represent the high byte address of RAM and only with indirect

instruction MOVX @Ri, A or MOVX A, @Ri to access external RAM above 256 bytes. it is recommended to clear

XPAGE when operation is complete.

3.1.5 The SH79F085/SH79F165 resets when a required low pulse is applied on the RESET pin, while the traditional

8051 devices require a high pulse to reset.

3.1.6 The SH79F085/SH79F165 can distinguish whether to access FLASH ROM or to access information EEPROM

block by FAC bit. It is recommended to clear FAC bite when operation is complete.

3.1.7 The SH79F085/SH79F165 provides SFR addressed 80H~FFH with page control bits BKS1, BKS0. It is

recommended to clear these two bits when page operation is complete.

For more detail description please refers to the DATASHEET.

3.2 FLASH Program Memory

3.2.1

The SH79F165 contains 16K bytes Flash program memory organized in 16 sectors of 1024 bytes, The SH79F085

contains 8K bytes Flash program memory organized in 8 sectors of 1024 bytes, Every two sectors can be encrypted.

When the security bits are not set, each sector could be erased by the user’s code in the other sectors. Mass erase

operation could erase all the sectors including the last sector (by Flash programmer only).

3.2.2 The Flash program memory also could be used as EEPROM. Flash memory could be programmed and erased by

the user’s code (SSP mode). The bits of the Flash memory could be programmed from 0 to 1 directly, but when to be

programmed from 1 to 0, the Flash memory should do Sector Erase. The program time for 1 byte FLASH ROM is related

with system clock. but will not longer than 50us for programming 1 byte and will not longer than 30ms for erasing 1 sector.

3.2.3 Using a Flash programmer, in circuit programming (ICP) operation could be used to download application code

without removing the device from the user’s application circuit board. Note that capacitance loads should not be

12/27

V 1.0

SH79F085/SH79F165 Application Note

connected to the JTAG pins, and the capacitance between VDD and GND should not be more than 220µF;

otherwise the downloading operation may be fail.

3.2.4 Programming the Flash Memory in SSP Mode

3.2.4.1 The following steps describe how to program Flash memory bytes:

1) Clear the global interrupt enable bit. Although all pending interrupts would be ignored during programming

operation, the interrupt flag bits would also be set. If an interrupt flag were set during programming operation, the

execution would branch to the interrupt service routine when the programming operation is completed and the

interrupt is enabled again.

2) Clearing FAC bit as 0 if operation location is at program block;

Setting FAC bit as 1 if operation location is at information block or EEPROM like block.

3) Write the XPAGE, IB_OFFSET registers. These two registers denote the programming location, where the

IB_OFFSET register maps to the lower address of the byte to be programmed and the XPAGE register

corresponds to the higher address of the byte to be programmed.

4) Write the IB_DATA register. The data of this register will be programmed to the specified byte of the Flash memory.

5) Configure the IB_CON1~IB_CON5 registers consecutively. Write these registers the following values:

IB_CON1Æ #6EH ; 6EH denotes programming operation

IB_CON2Æ #05H

IB_CON3Æ #0AH

IB_CON4Æ #09H

IB_CON5Æ #06H

Note: Load the registers with the above values in the exact order above. Once the programming operation is completed,

these five registers will be cleared automatically to avoid undesired programming. Reload these five registers to start

another programming operation.

Write the IB_CON5 register to initiate the programming action, which makes the device enter IDLE mode. The

6)

device will be waked up automatically when the programming operation is done. This step is taken automatically

by hardware without user’s assistance.

4 NOP instructions follow, which ensures CPU to wake up from IDLE mode correctly and stably when

7)

programming process is finished.

8) Go to step3 for the next programming operation, if necessary.

9) Clear the XPAGE register. Set the global interrupt enable bit if needed. Set FAC bit as 1 or 0 if needed.

10) Sample:

CLR EA ;Step1

ORL FLASHCON,#01H ; Step2, Writing EEPROM like block

MOV XPAGE,#00H ; Step3

MOV IB_OFFSET,#00H

MOV IB_DATA,#05H ; Step4

MOV IB_CON1,#6EH ; Step5

MOV IB_CON2,#05H

MOV IB_CON3,#0AH

MOV IB_CON4,#09H

MOV IB_CON5,#06H ; Step6

NOP ; Step7

13/27

V 1.0

SH79F085/SH79F165 Application Note

NOP

NOP

NOP

MOV XPAGE,#00H ; Step8

ANL FLASHCON,#0FEH ; Step9

SETB EA

Note: Replace the data with your when developing your own application.

3.2.4.2 Erasing the Flash Memory in SSP Mode

Perform the erase operation as follows

1) Clear the global interrupt enable bit. Although all pending interrupts would be ignored during programming

operation, the interrupt flag bits would also be set. If an interrupt flag were set during programming operation, the

execution would branch to the interrupt service routine when the programming operation is completed and the

interrupt is enabled again.

2) Clearing FAC bit as 0 if operation location is at program block.

Setting FAC bit as 1 if operation location is at information block or EEPROM like block.

3) Load the XPAGE register with appropriate sector number which wanted to erase, The SH79F165 contains 16K

bytes Flash program memory organized in 16 sectors of 1024 bytes. The Bit7 to bit6 in the XPAGE register is

reserved. Bit5 to bit2 denote the erasing sector number. The SH79F085 contains 8K bytes Flash program memory

organized in 8 sectors of 1024 bytes. The Bit7 to bit5 in the XPAGE register is reserved. Bit4 to bit2 denote the

erasing sector number. Bit1~bit0 have no effect on the operation. The IB_OFFSET register is not used in this

situation.

4) Configure the IB_CON1~IB_CON5 registers with the following values:

IB_CON1----Æ #0E6H ; 0E6H denotes erasing operation

IB_CON2 ---Æ #05H

IB_CON3----Æ #0AH

IB_CON4 ----Æ #09H

IB_CON5 ----Æ #06H

Note: Load the registers with the above values in the exact order above. Once the erasing operation is complete,

these five registers will be cleared automatically to avoid undesired erasure. Reload these five registers to start

another erasing operation.

5) Write the IB_CON5 register to initiate the erasing action, which makes the device enter IDLE mode. The device

will be waked up automatically when the erasing process terminates. This step is completed by hardware without

software assistance.

6) 4 NOP instructions follow, which ensures CPU to wake up from IDLE mode correctly and stably when

programming process is finished.

7) Go to step3 for the next erasing operation, if necessary.

8) Clear the XPAGE register. Set the global interrupt enable bit if needed.

Set FAC bit as 1 or 0 if needed.

14/27

V 1.0

SH79F085/SH79F165 Application Note

9) Sample:

CLR EA ; Step1

ORL FLASHCON,#01H ; Step2, Erase EEPROM sector

MOV XPAGE,#00H ; Step3

MOV IB_CON1,#0E6H ; Step4

MOV IB_CON2,#05H

MOV IB_CON3,#0AH

MOV IB_CON4,#09H

MOV IB_CON5,#06H

NOP ; Step6

NOP

NOP

NOP

MOV XPAGE,#00H ; Step7

ANL FLASHCON,#0FEH ; Step8

SETB EA

3.3 RAM

3.3.1 SH79F085/SH79F165 provides 256 bytes internal RAM and 256 bytes external RAM.

3.3.2 The Internal RAM addressed from 00H~FFH can be accessed by direct instructions or indirect instructions.

The internal RAM addressed from 80H~FFH only can be accessed by indirect instructions, and the SFR location will

be accessed by direct instruction.

3.3.3 The external RAM is addressed from 00H~FFH. User can access external RAM from 00H~FFH with MOVX A, @Ri

instruction

3.4 System Clock and Oscillator

The SH79F085/SH79F165 oscillator clock from one of the five oscillator types (32.768kHz crystal, crystal oscillator,

ceramic oscillator, Internal 128kHz RC or Internal 16.6M RC)

3.4.1 The SH79F085/SH79F165 is two clocks for system at the same time. The two Clocks contain low frequency

oscillator and high frequency oscillator. Low frequency oscillator is selected as system clock prescaler when power

on. If select high frequency oscillator is use as system clock prescaler input (OSCSCLK), need set corresponding

register.

3.4.2 The system clock changed from low-frequency (Internal 128kHz RC or 32.768kHz crystal) to high-frequency

(Internal 16.6MHz RC or crystal/ceramic oscillator), the steps below must be done in sequence:

Step1: Set HFON=1, turn on high frequency oscillator;

Step2: Wait at least 2ms; (note)

Step3: Set FS=1, select high frequency oscillator as OSCSCLK.

Note: Different types of high-frequency oscillator need wait for different start-up time.

Internal 16.6MHz RC: about 30us;

High-frequency crystal oscillator: about 2ms + 213T

High-frequency ceramic oscillator: about 100us + 29T

15/27

OSC

OSC

V 1.0

SH79F085/SH79F165 Application Note

3.4.3 The system clock changed from high-frequency (Internal 16.6MHz RC or crystal/ceramic oscillator) to

low-frequency (Internal 128kHz RC or 32.768kHz crystal), Refer to following step:

Step1: Clearing FS bit, select low frequency oscillator as OSCSCLK;

Step2: Delay one NOP instruction;

Step3: Clearing HFON bit, turn off high-frequency oscillator.

3.4.4 When system power on, CLKS[1:0]=11, The default is 1/12 of system clock prescaler (If code option

OP_OSC=1010, External 32.768kHz crystal is not effect as system clock prescaler. This means that prescaler is invalid).

3.4.5 When code option OP_OSC is 1010, the 32.768kHz oscillator speed up control bit (32K_SPDUP) is set by

hardware automatically in all kinds of RESET such as Power on reset, watch dog reset etc. to speed up the

32.768kHz oscillator, shorten the 32.768kHz oscillator start-oscillating time. And this bit also can be set or cleared

by software if necessary. Such as set before entering Power-Down mode and cleared when Power-Down mode

wake up. It should be noticed that turning off 32.768kHz oscillator speed up (clear this bit) could reduce the system

power consumption.

3.5 Idle & Power-down

Three NOP instructions after the power-managed instruction are required to allow the CPU to prepare for execution when

leaving IDLE mode or Power-down mode. An example is shown below for your reference.

MOV 8EH, #55H

ORL PCON,#01H ;idle mode (or #02H: Power-down mode)

NOP ; Three NOP instructions are required

NOP ;

NOP ;

…… ; Breakpoint should be set after the third NOP instructions when watching

; wake up of IDLE mode or Power-down mode.

Note:To reduce the start up time of oscillator, set the 32K_SPDUP bit in the CLKCON register by software before entering

Power-down.

3.6 External Interrupt

3.6.1

When the I/O pin is used as the external interrupt input, only the pin configured as input can cause the interrupt to

occur. Turn on the internal pull-up resistors by software. The pull-up resistance is about 30 kΩ. When the I/O pin outputs

low just before it is configured as the external interrupt input and low-level trigger is selected at the same time, an interrupt

request would happen in respect that a low level, remaining on the pin for the capacitance loads and slow internal pulling

up, was detected by the built-in low level detecting circuitry. After turning on the internal pull-up resistor, a delay, for

example 5 NOP instructions, is recommended to eliminate the undetermined state before enabling the interrupt.

3.6.2 Before switching from the external interrupt input to a second function of the I/O pin, clear the EXx (x=0~2) bits to

turn off the external interrupts, or the execution would vector to the external interrupt service routine if the requirements of

the interrupt is met for changing the port function.

3.6.3 The following steps illustrate how to configure an I/O pin to an external interrupt input (INT0/P1.4 is taken for

example):

16/27

V 1.0

SH79F085/SH79F165 Application Note

1) Clear the POCR.4 bit to select input mode, and set the P0PCR.4 bit to turn on the internal pull up resistor.

2) 5 NOP instructions

3) Configure the IT0 bit of the TCON register to select the trigger mode, and clear the IE0 bit to remove the possible

generated interrupt flag.

4) Set the EX0 bit in the IEN0 register to enable the external interrupt 0, and set the EA bit to enable the global interrupt.

3.6.4 Follow the steps below to wake up IDLE and Power-down mode correctly (INT0/P1.4 is taken for example):

1) Configure the P1.4 pin as described above. Once, according to the selected trigger mode, the CPU detected a falling

edge or a low level, it will exit from IDLE and Power-Down mode.

2) The execution would resume from the interrupt service routine of the external interrupt 0 immediately after the

waking-up of the CPU. Return to the main program by RETI instruction.

3) The instructions after the 3 NOP instructions will execute later.

3.7 ADC&PGA

3.7.1 The SH79F085/SH79F165 includes a full-differential 20-bit Σ-∆ analog to digital converter. The ADC module can

work in IDLE mode and the ADC interrupt will wake up the IDLE mode if interrupt is enabled. The module is

disabled in Power-Down mode. But user can wake up in Power-Down with timer3 interrupt.

3.7.2 The SH79F085/SH79F165 built-in regulator of 2.7V for ADC module. Before using the ADC module must set

REGEN bit in REGCON register to enable regulator. This regulator maximum output current is 15mA, enough used

in sensors of electronic scales. VDDR pin is regulator output port of 2.7V. Recommended to be connected 47 uF

electrolytic capacitor and 104 ceramic capacitor to AGND.

3.7.3 The GND pin is digital power ground. The AGND pin is analog power ground. So PCB layout need connect GND to

AGND.

3.7.4 The ADC module pins may be shared as I/O function, Corresponding input channels will be selected when set

CH[2:0] bits in ADCH register. The VREF pin is use as ADC reference voltage function port when setting P27OS bit

in ADCH register.

3.7.5 The VREF pin is use as reference voltage whether internal or external function. This pin can’t be used as I/O port

and connect a 104 capacitor to AGND.

3.7.6 VIN+/VIN- pins are PGA positive/negative output port. A 104 capacitor must be connected between VIN+ and VIN-

in order to enhance the anti-noise performance of ADC. This port can’t use as O/I when The ADC module is

enabled.

3.7.7 AIN+/AIN- pins are differential analog positive/negative input port. Both ports are input front-end of PGA. Therefore,

it can be calculated by input-output relationship: (AINx+/-)*Gain=VIN+/- .

3.7.8 Common-input voltage range of AIN+/AIN- pins is 0.4V~2.0V. To improve the ADC’s effective accuracy,

recommended that user adopt common-input voltage of about 1.35V at analog input port.

3.7.9 To improve the anti-noise performance of system, In PCB layout, digital and analog power supply traces should be

separated and not overlapping, digital ground and analog ground adopt single-point connection. Analog ground should be

17/27

V 1.0

SH79F085/SH79F165 Application Note

large area coated with copper, making noise and interference source in the shortest path back to the input source of power.

If it is double-sided PCB board, analog ground should not be many via hole. The spacing of hole generally is 1cm~2cm.

3.7.10 To improve the anti-noise performance of system, recommended that the bead or resistor of 1000Ω should be

connected of series each differential input channel, then connect a 104 capacitor between positive and negative. In

PCB layout, line of trace width generally is more 20 mil and parallel trace. Analog device must close chip pin of mcu

such as sensor, resistors and capacitors. Refer to following application circuit schematic.

3.7.11 To improve the anti-noise performance of system, recommended that power supply of sensor connects to T-type

filter and filter must close chip pin. Refer to following application circuit schematic.

3.7.12 The SH79F085/SH79F165 provides a low noise programmable gain amplifier. This PGA provides amplification

setting of 12.5, 25, 50, 75, 100, 125, 150 and 200 for ADC analog input. The actual gain of PGA will possible lower

of 3%~7%, but doesn’t affect application. A chopper function is included, which can be use for eliminate offset of

PGA. Work clock of 1kHz is recommended. Chopper must be enabled when PGA is enabled. Otherwise accuracy

of ADC should be affected.

18/27

V 1.0

SH79F085/SH79F165 Application Note

3.7.13 Application Circuit Schematic:

JP1

JTAG

VDD

1

TCK

2

TDI

3

TMS

4

TDO

5

6

JTAG Interface

VDD

JP2

5V

2

1

POWER

U1

1

FLT/P0.2

2

T3/P0.3

3

BUZ/P1.0

4

TDO/RXD/P1.1

5

TMS /TXD/P1.2

6

RST/P0.4

7

XTAL1/T0/P0.5

8

XTAL2/T1/P0.6

9

TDI/T2/P1.3

10

TCK/T2EX/INT0/P1.4

11

AIN1+/INT1/P1.5

12

AIN1-/IN T2/P1.6

13

P1.7

14

P2.0

SH79F165

P0.1/PWMN

P0.0/PWMP

P2.7/V REF

P2.6/AIN0-

P2.5/AIN0+

P2.4/VIN-

P2.3/V IN+

P2.2/AIN2-

P2.1/AIN2+

J2

0

J1

1

2

3

4

Sensor

GND

VDD

VDDR

AGND

AGND

28

27

26

25

C

24

23

22

21

20

19

18

17

16

15

AIN+

AIN-

Analog Circuit

R21KR3

C1

47uF/16V

104

C4

C6

104

1K

C7

104

AGND

VDDR

C5

104

AGND

R1

10

R4

10

C2

104

C8

47uF/16V

VDDR

VDD

C3

104

Note: in application circuit, the R2 and R3 is the bead to improve the effect which will be better than the resistor

19/27

V 1.0

SH79F085/SH79F165 Application Note

3.7.14 Example:(the ADC conversion data send PC with UART)

#include"SH79F165.H"

ORG 0000H

LJMP START

ORG 0033H

LJMP ADC_IRQ

ORG 0100H

START:

;SYSCLK from low-frequency to high-frequency

MOV CLKCON,#08H

CALL DELAY_2ms ;Delay 2ms

MOV CLKCON,#0CH

;ADC Module Initialization

MOV REGCON, #01H ;2.7V output

MOV ADCON, #02H ;AIN2

MOV ADT, #0ADH ;ADC Sample Freq = 25Hz

MOV ADCH, #0EFH ; Internal REF=0.8V

MOV PGAM, #0C4H ;PGA Gain=100,CHOP=1K

ORL ADCON, #80H ;ADC Enable

;Timer1/UART Initialization

MOV SCON, #40H

MOV TCON, #00H

MOV TCON1, #0CH

MOV TMOD, #21H

MOV TL1, #0caH

MOV TH1, #0caH ;Baud Rate=9600Hz

SETB TR1 ;Enable Timer1

ADC_WAIT:

MOV A,ADCON

NOP

JNB ACC.6, ADC_WAIT ;Wait for AD Conversion

ANL ADCON, #0BFH ;Clear ADCIF Flag

MOV R0,ADDL

MOV R1,ADDM

MOV R2,ADDH

MOV SBUF,#0A3H

JNB TI,$

CLR TI

MOV SBUF,R0

JNB TI,$

CLR TI

MOV SBUF,R1

JNB TI,$

CLR TI

MOV SBUF,R2

JNB TI,$

CLR TI

LJMP ADC_WAIT

20/27

V 1.0

SH79F085/SH79F165 Application Note

3.8 Watch Dog Timer

3.8.1 The SH79F085/SH79F165 builds in a watchdog timer (WDT). The WDT time-out period is from 1ms to 4 seconds.

A WDT reset will occur if WDT is time out. WDT reset will set the WDOF bit in the RSTSTAT register. To prevent

WDT from overflowing, access (read or write) the WDT register RSTSTAT at a given period according to the

time-out period.

3.8.2 The WDT consumes 1-2uA current during operation. If the WDT is still enabled in the Power-down mode by

OPTION, the WDT will reset CPU to leave the Power-down mode.

3.8.3 The WDT can be enabled or disabled by the code option OP_WDT permanently (See section 2.4.2.1 step3).

3.9 UART

3.9.1 The TXD/RXD pin may be shared as I/O function, the RXD pin will be configured as input-pull up automatically

when REN bit is set as 1. But the TXD pin is used as UART function only when users write data to SBUF register,

and goes back to I/O function automatically when UART transmission is over. So it is recommend to configure the

TXD pin as output high level before UART transmission which can avoid that the receiver get error information.

3.9.2 Both Timer1 and Timer2 can be selected as baud rate clock source of UART controlled by TCLK and RCLK bits.

If set TCLK or RCLK bit as logic 0, Timer1 acts as the baud rate clock source, if set TCLK or RCLK bit as logic 1,

Timer2 acts as the baud rate clock source. This shows that UART can use deferent baud rate in transmission and

reception.

3.9.3 The maximum tolerance of UART reception baud rate is ±4%.

3.10 PWM

3.10.1 The SH79F165 has one PWM module, which can provide two complementary outputs. The output polarity that is

if high active or low active is controlled by PWMS bit, each output has independent control bit, note that it is

complementary output with dead time control if the two outputs are all active, regardless polarity setting.

3.10.2

3.10.3

PWM provides interrupt function on every period overflow.

PWM has 12-bit control register, when writing PWMPH/L, PWMDH/L registers, low byte first, then high byte to

update the whole registers. The internal register value can’t be changed if only writing low byte.

3.10.4 PWM dead time register only can be set when PWMEN bit is 0 (that is PWM block disable), and make sure that

any time when PWM is disabled, before enable PWM again, dead time register must be clear to 0 at first, and

then set to proper value.

3.10.5 Set PWMLO register to 0x55 before writing the PWM registers, otherwise the PWM registers can’t be changed.

21/27

V 1.0

SH79F085/SH79F165 Application Note

3.11 Timer3

3.11.1 Timer 3 is a 16-bit auto-reload timer. When writing to TH3 and TL3, they are used as timer load register. When

reading from TH3 and TL3, they are used as timer counter register.

3.11.2 Read or write operation to TH3 and TL3 should follow these steps.

Write operation: Low nibble first, High nibble to update the counter.

Read operation: High nibble first, Low nibble followed.

3.11.3 Timer 3 can operate even in Power-Down mode. System clock must be high-frequency oscillator before timer3

entering Power-Down mode, and timer3 clock source must select low frequency oscillator, such as 32.768kHz

crystal and internal 128kHz RC. That is T3CLKS[1:0]=10.

3.11.4 Timer3 control and reload/counter register is placed to Bank1. When user operate timer, need set BKS0 bit in

INSCON register. But clear BKS0 is as 0 after operating complete.

3.11.5 Example:(Timer3 wake up in Power-Down mode)

#include"SH79F165.H"

ORG 0000H

LJMP START

ORG 005BH

LJMP Timer3_IRQ

ORG 0100H

START:

;SYSCLK from low-frequency to high-frequency

MOV CLKCON,#08H

CALL DELAY_2ms ;Delay 2ms

MOV CLKCON,#0CH

;Set timer3 Register

MOV INSCON,#40H ; Bank1

MOV T3CON,#02H

MOV TL3,#080H

MOV TH3,#0FFH

SETB TR3

MOV INSCON,#00H ; Bank0

MOV IEN1,#10H ;Enable Timer3 Interrupt

SETB EA

PD_Mode:

;Entering Power-Down mode

MOV SUSLO,#55H

ORL PCON,#02H

NOP

NOP

NOP

SJMP PD_Mode

Timer3_IRQ: ;Timer3 Interrupt Subroutine

NOP

RETI

22/27

V 1.0

SH79F085/SH79F165 Application Note

3.12 Application Circuit

3.12.1 Electronic Weighing Scale

- VIN+/VIN-/VREF as ADC pin

- SH79F085 built-in digital circuit regulator. It can output stable voltage of 1.8V for core and peripherals.

- SH79F085 built-in analog circuit regulator. It can output stable voltage of 2.7V for analog devices.

- SH79F085 built-in measure voltage of V

sample point. If SCH[2:0]≠100

,

This resistor will be disconnected.

channel, an internal 80kΩ resistor will connect VDD with GND to provide

DD

Battery

SENSOR

GND

VDDR

AGND

VDD

0

47uF

3.0V~5.5V

GND

AGND

104

51K

10K

51K

104

104

47uF

47uF

104

VDD

GND

VDD

GND

C

VDDR

AGND

VREF

VIN+

VIN-

AIN2-

AIN2+

AIN0+

AIN0-

SH79F085

P0.4

P0.5

P0.6

P0.6

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P2.0

P1.0

CS

SDA

SCK

LED/LCD

DRIVER

VDD

GND

1K

GND

23/27

V 1.0

SH79F085/SH79F165 Application Note

3.12.2 Industry Temperature Controller

- VIN+/VIN-/VREF as ADC pin

- SH79F165 built-in digital circuit regulator. It can output stable voltage of 1.8V for core and peripherals.

- SH79F165 built-in analog circuit regulator. It can output stable voltage of 2.7V for analog devices.

- SH79F165 built-in measure voltage of V

sample point. If SCH[2:0]≠100

,

This resistor will be disconnected.

channel, an internal 80kΩ resistor will connect VDD with GND to provide

DD

Input Voltage

0.6V

AGND

LM7805

GND

GND

REF2.5V

AGND

104

Thermistor

47u

0

AGND

Thermocouple

PT100

REF2.5V

5.0V

47uF

47uF

REF0.8V

REF2.5V

REF2.5V

104

104

104

AGND

VDD

GND

C

VDDR

AGND

VIN+

VIN-

VREF

AIN0+

AIN0-

AIN1+

AIN1-

AIN2+

AIN2-

SH79F165

P0.4

P0.5

P0.6

P0.5

P0.6

P1.4

P1.7

PWMP

RXD

TXD

P1.0

P0.1

P0.2

P0.3

P2.0

CS

SDA

SCK

T2

set

up

down

enter

LED/LCD

DRIVER

GND

RS485

Interface

VDD

VDD

Frequency Input

PWM output

DC12V

GND

DC12V

OUT12

OUT11

OUT1

OUT22

OUT21

OUT2

AGND

Input Voltage

Input Voltage

ADR431

GND

LM7812

GND

47uF

100u

24/27

104

DC12V

REF2.5V

GND

104

REF0.8V

VDD

VDD

GND

DC12V

GND

DC12V

GND

OUT32

OUT31

OUT3

OUT42

OUT41

OUT4

V 1.0

SH79F085/SH79F165 Application Note

Appendix1:

Target Board Circuit Schematic

MCU_VD D

RESET

MCU OSC

J1

DC12V

U2 7805

3

2

1

100uF/25V

R3

10k

K1

RESET

1

C2

C1

104

J3

2

1

D3

VDD

1N4001

J2

2

1

GND

C5

103

C6

12pF

Y1

16M

C7

12pF

3

Vin

Vout

GND

C3

2

104

R1

470

D1

1N4001

VDD

D2

1N4001

C4

47uF/16V

JP1

MCU_VDD

2

R2

1

470

IDD_TEST

Power

D4

S1

RESET

S2

XTAL1

S3

XTAL2

MCU_VD D

J7

1

2

AIN0

VDD

J4

1 2

3 4

5 6

7 8

9 10

JTAG

JTAG

1

P02

2

P03

3

P10

4

P11

5

P12

6

P04

7

P05

8

AIN2+

AIN2-

AIN1+

AIN1-

P06

9

P13

10

P14

11

AIN1+

12

AIN1-

13

P17

14

P20

VDDR

R19

R20

0

0

C11

104

AGND

VDDR

R14

50K

J8

R16

10K

AIN1

C13

104

R18

15K

AGND

P04

P05

P06

R13

50K

AIN0+

R15

C12

10K

104

AIN0-

R17

15K

Sensor Input

TDI

TMS

TDO

U1

FLT/P 0. 2

T3/P0.3

BUZ/ P1. 0

TDO/RXD/P1.1

TMS/TXD/P1.2

RST/P 0. 4

XTAL1/T0/P 0.5

XTAL2/T1/P 0.6

TDI/T2/P1 .3

TCK/T2EX/INT0/P1.4

AIN1+/ INT1/P1 .5

AIN1-/INT2/P1.6

P1.7

P2.0

SH79F165

J6

1

2

3

4

AIN2

1

2

3

4

P14TCK

P13

P12

P11

MCU_VDD

C8

104

P0.1/PWMN

P0.0/PWMP

VDDR

AGND

P2.7/VREF

P2.6/AIN0-

P2.5/AIN0+

P2.4/VIN-

P2.3/VIN+

P2.2/AIN2-

P2.1/AIN2+

C9

GND

C

VDD

104

100uF/16V

VDDR

C16

AGND

28

27

26

25

24

23

22

21

20

19

18

17

16

15

R4

R5

R6

R7

R12

MCU_VDD

0

0

0

0

0

VREF

AIN0AIN0+

VINVIN+

AIN2AIN2+

AGND

I/O PORT

P01

P00

C

C14

104

C10

104

VIN+

P23

VINP24

AIN0+

P25

AIN0P26

VREF

P27

FLT/P 0. 2

T3/P0.3

BUZ/ P1. 0

TDO/RXD/P1.1

TMS/TXD/P1.2

RST/P 0. 4

VDDR

XTAL1/T0/P0.5

AGND

XTAL2/T1/P0.6

TDI/T2/P1 .3

TCK/T2EX/INT0/P1.4

AIN1+/INT1/P 1.5

AIN1-/INT2/P1.6

P1.7

P2.0

C

VREF

VIN+

VIN-

AIN1+

P15

AIN1P16

AIN2+

P21

AIN2P22

C15

47uF/16V

R21

0

AGND

R8

0

R9

0

R10

0

R11

0

P02

P03

P10

P11

P12

P13

P14

P15

P16

P17

P20

J5

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

PORT

MCU_VDD

P01

P00

C

VDD

VDDR

AGND

P27

P26

P25

P24

P23

P22

P21

P0.1/PWMN

P0.0/PWMP

GND

C

VDDR

AGND

P2.7/VREF

P2.6/AIN0P2.5/AIN0+

P2.4/VINP2.3/VIN+

P2.2/AIN2P2.1/AIN2+

25/27

V 1.0

SH79F085/SH79F165 Application Note

Appendix2:

Target Board

A target board is provides to help user to familiar with the SH79F085/SH79F165.

SH79F165 Target Board (SOP28)

Function blocks on the board

A. Power LED

B. Pin Reset Key

C. Emulator Interface (JTAG Interface)

The emulator interface communicates with the JET51emluator via a 10-pin cable. The power supply can also be

provided from VDD pin of the emulator interface when the JET51 emulator is connected to PC.

D. Power Supply Interface1 (VDD/GND)

The power supply interface1 supplies the power of SH79F085/SH79F165, where the user determines the voltage

level.

E. Power Supply Interface2

The Power supply interface2 is a DC power jack (Outer to GND Inner to 9~12V). A fixed voltage (5V), regulated by

U2 components, will be applied to the device.

Note: The power source of target board can be selected among power supply interface 1, power supply interface 2 and

emulator interface. Whichever option is chosen, the applied voltage can be measured through power supply interface 1.

F. Current test interface.

26/27

V 1.0

SH79F085/SH79F165 Application Note

4. Revision History

version Content Date

1.0

original

Jul. 2011

27/27

V 1.0

Loading...

Loading...