Sinovo SP200-2S-0.7, SP200-4T-3.7, SP200-4T-2.2, SP200-2S-2.2, SP200-4T-5.5 User Manual

...Page 1

SP200 Drive User Manual (Version: 2.0)

SP200 SERIES

PV PUMP CONTROLLER

User Manual

SHENZHEN SINOVO ELECTRIC TECHNOLOGY CO.,LTD

Add: 5 th Floo r,No. D Build ing,H uafen g Inter natio nal Rob ot

Indu stry Pa rk,Xi xiang S treet ,Hang cheng R oad,B aoan

Dist rict, Shenz hen Cit y

Tel 0755 2978 4870: ( )

F 0755 2978 4969ax: ( )

Tech s uppor : 400-88 1-868 9

http : //www .sino vo.cn

Version: 2.0

Page 2

SP200 Manual

Preface

Preface

Thank you for purchasing the SP200 series PV Pump controller developed by our

company.

This manual introduce how to use SP200 series in correct manner. Please read it carefully

before application, operation, maintenance and inspection.

Please apply this series after fully understand the safety cautions of this products.

Unpacking Inspection Cautions:

1.Whether the product is damaged during shipping, whether the parts is damaging or

falling, whether the main part is crashed.

2.Whether the nameplate of model and controller ratings are consistent with your order.

SINOVO is very strict in quality control in the producing and packing, in case any fault

occcurs, please contact us or your own supplier ASAP.

Note

For the details of illustrating products, the diagram of this manual is sometimes in the

ª

status of removing the cover or safety cover. To use this product, please make sure

install the cover or housing as required and operate in accordance with manual

instructions.

The diagrams in this manual is only for illustration, it may have sightly difference with

ª

the product that you ordered.

This instructions are subject to change, without notice, due to product upgrade,

ª

specification as well as efforts to increase the accuracy and convenience of the

manual.

Please contact district agent or all SINOVO customer service center directly for the

ª

damaged or missing parts and need to order the Manuals.

If you have any confusion when refering the manual during operation, please contact

ª

SINOVO Customer Service Center.

Customer Service: 400-8818-689

ª

-1 -

Page 3

Contents

SP200 Manual

Contents

Preface.................................................................................................................01

Contents...............................................................................................................02

Chapter 1 Safety and Cautions..........................................................................05

Safety Definition.....................................................................................................05

1.1 Safety Cautions................................................................................................06

1.2 Cautions.... ................................................................................................08.......

Chapter 2 Basic principle...................................................................................11

2.1 Basic principle.... ............................................. ........... ....

2.2 Functions.................................................................................... .

Chapter 3 Product Information.........................................................................15

3.1 Inspection... .. ............................................................................. ......... ...... ...... 16

3.2 Instroductions and Feature....... ..................................................... ...... ........... 16

3.3 Protection function..... .......................................................................... ....... .... 16

3.4 Naming rules............... ................................................................................... .17

3.5 SP200 PV Pump Controller input/output parameter................. ......... ............. . 17

3.6 Nameplate...................... ........................................................... ..................... . 21

3.7 SP200 PV pump controller Size....... .... .......................................................... . 21

............. . ...................

....................

11

13

Chapter 4 Mechanical and Electrical Installation.............................................25

4.1 Controller Installation and Operation Environment........ ..............................26....

4.2 Controller Installation Spacing............ ............................................ ...........27.. ...

4.3 Install and Remove the Cover........ .......................................... ..............27....... ..

4.4 Wiring......................... .... .....................................28...................................... ......

Chapter 5 Operation..........................................................................................35

5.1 Operation Panel Description... .................. .......................................36 .. .............

5.2 Operation Procedure............ ............ ...................38 ........ ....................................

5.3 Commissioning Process..................................................................................40

5.4 Panel Displays Parameters in Running State.................. ... ...................40....... ..

-2 -

Page 4

SP200 Manual

Contents

Chapter 6 Function Parameter Table...............................................................41

F00 Basic Function Group.................... ........................ .............................42........... ..

F01 Startup and Stop Control........ .............................................................42............

F02 Motor parameter............... ......... .............. ..................................................... .. . 42

F03 Solar Water Pump Special Parameters... ....................................... .... ........ ... .. 42

F05 Input Terminal Group................. ........................... . ............... ......................... .. 43

F07 HMI&Fault parameters....................................................................................43

Chapter 7 Troubleshooting...............................................................................47

7.1 Fault Instruction and Solution..................................................... . .........48.......... .

7.2 Common Faults and Solutions......................................................... .......51.........

7.3 Controller Overcurrent, Overload Fault (OC1/2/3/OL1/2)................................52

Chapter 8 Maintenance.....................................................................................53

8.1 Controller........ ........................... . .........54............................. .............................. .

8.2 Pump.............. .............................................. .......56................................... .........

8.3 Solar Array.......................................................................................................56

8.2 Electric Wire and Cable..................................................................................56

Chapter 9 Spare AC power use........................................................................57

-3 -

Page 5

-4 -

Page 6

Chapter 1

Safety and Cautions

Safety Definition

Read this manual carefully so that you have a thorough understanding.

Installation,commissioning or maintenance may be performed in conjunction with this

chapter. Our company will assume no ability and responsibility for any injury or loss caused

by improper operation.

Danger

Operations which are not performed comply with the requirements may cause severe hurt

or even death.

Note

Operations which are not performed comply with requirements may cause personal injury

or property damage.

-5 -

Page 7

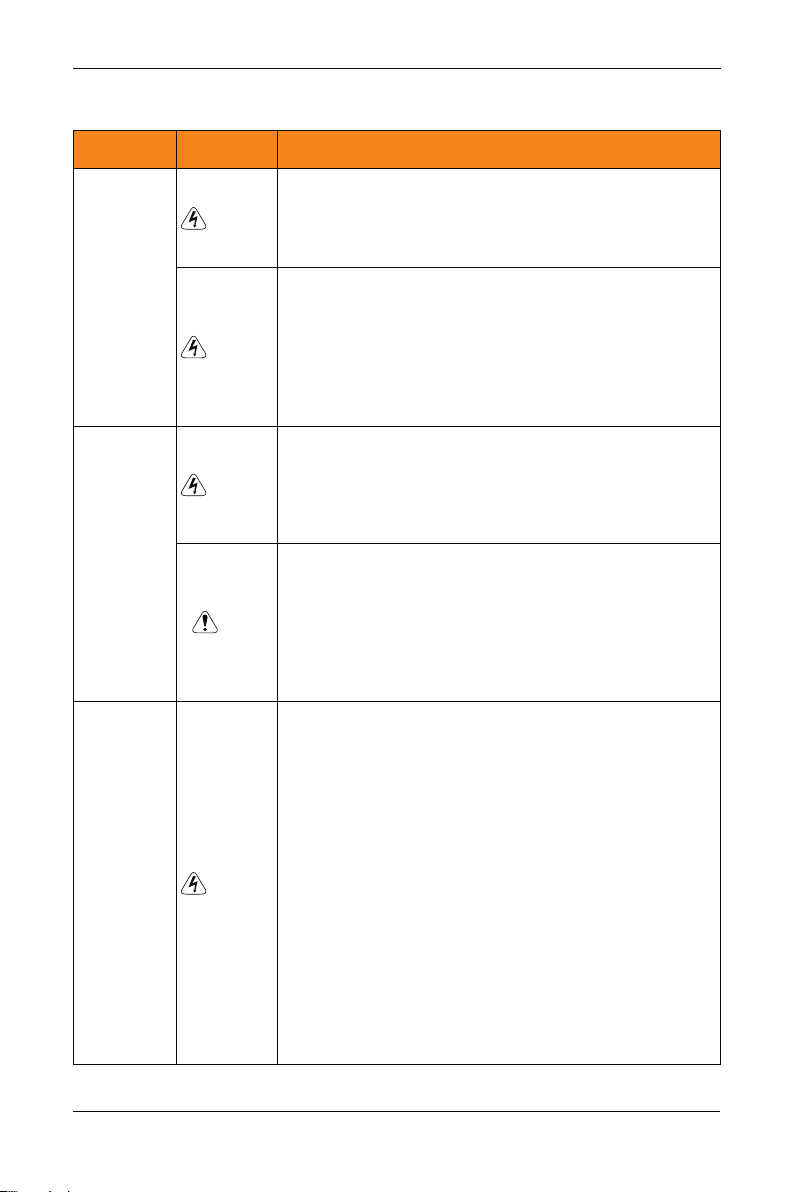

Chapter1 Safety and cautions

1.1 Safety Cautions

SP200 Manual

Use Stage Safety Grade

Danger

Before

Installation

Danger

Danger

During

Installation

Note

At wiring

Danger

Precautions

Do not install the equipment if you find water seepage,

ª

component missing or damage upon unpacking.

Do not install the equipment if the packing list does not

ª

conform to the product you received.

Handle the equipment with care during transportation to

ª

prevent damage to the equipment.

Do not use the equipment if any component is damaged or

ª

missing. Failure to comply will result in personal injury.

Do not touch the components with your hands. Failure to

ª

comply will result in static electricity damage.

Install the equipment on incombustible objects such as

ª

metal, and keep it away from combustible materials.

Failures to comply may result in a fire.

Do not loosen the fixed screws of the components,

ª

especially the screws withe red marks.

Do not drop wire end or screw into the controller. Failure it

ª

will result in damage to the controller.

Install the controller in places free of vibration and direct

ª

sunlight.

When two controller are laid in the same cabinet ,arrange the

ª

installation positions properly to ensure the cooling effect.

A circuit breaker must be used to isolate the power supply

ª

and the controller. Failure to comply may result a fire.

Ensure that the power supply is cut off before wiring. Failure

ª

to comply may result in electric shock.

Never connect the power cables to the output

ª

terminals(U,V,W) of the controller. Pay attention to the

marks of the wiring terminals and ensure correct wiring.

Failure to comply may result in damage to the controller.

Ensure that the main cable line comply with the standard,

ª

the line meets the EMC requirements and the area safety

standard. Failure to comply may result in risk or accident.

Never connect the power cables the braking resistor

ª

between the DC bus terminals P+, P-. Failure to comply

may result in a fire.

-6 -

Page 8

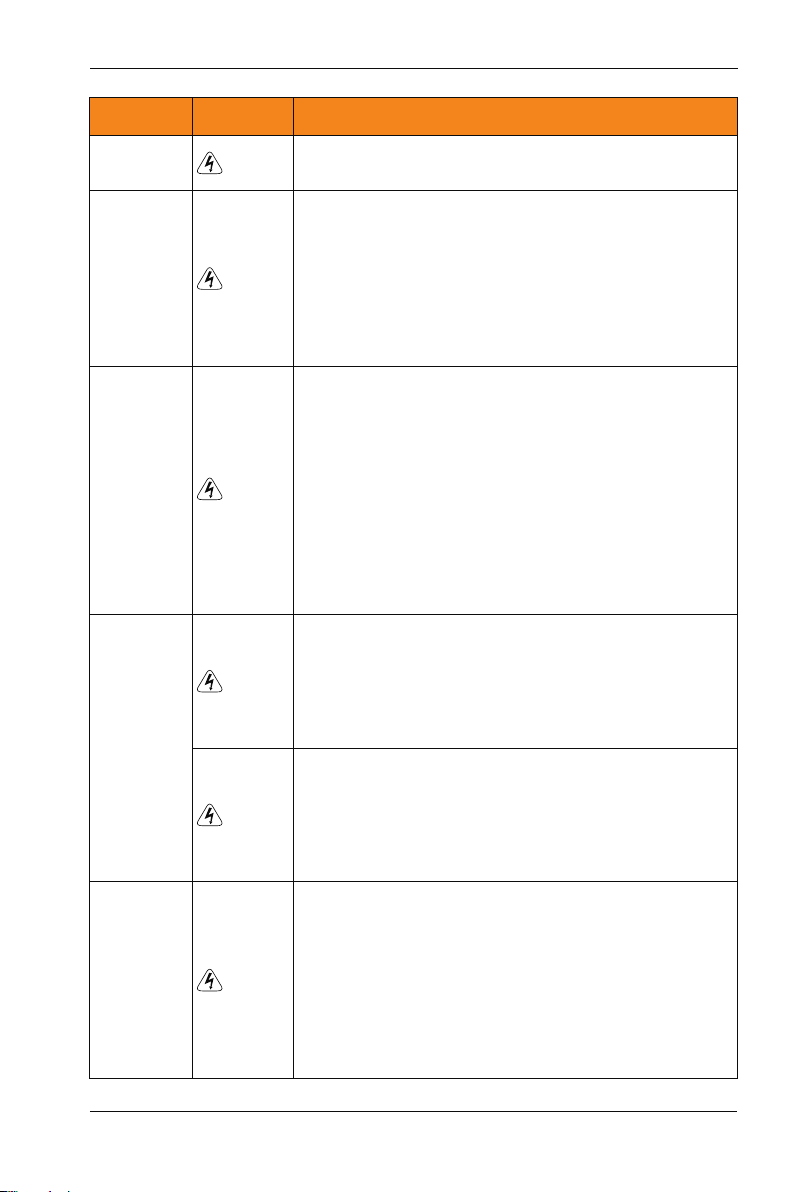

SP200 Manual

Chapter1 Safety and cautions

Use Stage Safety Grade

At wiring

Before

Power-on

After

Power-on

Danger

Danger

Danger

Danger

During

Operation

Danger

Precautions

Use a shielded cable for the encoder, and ensure that the

ª

shielding layer is reliably grounded.

Please confirm the peripheral equipment and cable converter

ª

is configured in this manual of the recommended model, all

the configuration line in accordance with the connection

method of the manual provides the correct wiring. Failure to

comply will result in accidents.

Check that the voltage class of the power supply is consistent

ª

with the rated voltage class of the controller.

Do not open the controller’s cover after power-on. Failure to

ª

comply may result in electric shock.

Do not touch the operation of controller during the hands is

ª

wet. Failure to comply will result in accident.

Do not touch any I/O terminal of the controller. Failure to

ª

comply may result in electric shock.

Do not change the default settings of the controller. Failure to

ª

comply will result in damage to the controller.

Do not touch the rotating part of the motor during the motor

ª

auto-tuning or running. Failure to comply will result in

accident.

Signal detection must be performed only by qualified

ª

personnel during operation. Failure to comply will result in

personal injury or damage to the controller.

Do not touch the fan or the discharging resistor to check the

ª

temperature. Failure to comply will result in personal burnt.

Avoid objects falling into the controller when it is running.

ª

Failure to comply will result in damage to the controller.

Do not start or stop the controller by turning the contactor

ª

ON/OFF. Failure to comply will result in damage to the

controller.

After

Power-on

Danger

Do not repair or maintain the controller at power-on. Failure

ª

to comply will result in electric shock.

Ensure that the controller is disconnected from all power

ª

suppliers before staring repair or maintenance on the

controller.

Repair or maintenance of the controller may be performed

ª

only by qualified personnel. Failure to comply will result in

personal injury or damage to the controller.

-7 -

Page 9

Chapter1 Safety and cautions

SP200 Manual

Use Stage Safety Grade

After

Power-on

Danger

Set and check the parameters again after the controller is

ª

replaced.

Precautions

1.2 Cautions

1.2.1 Motor Insulation Test

Perform the insulation test when the motor is used for the first time, or when it is reused

after being stored for a long time, or in a regular check-up, in order to prevent the poor

insulation of motor windings from damaging the controller during the insulation test. A 500V mega-Ohm meter is recommended for the test. The insulation resistance must not be

less than 5 MΩ.

1.2.2 Thermal Protection of Motort

If the selected controller does not match the rated capacity of the motor , especially when

the rated power of the controller is higher than that of the motor, adjust the parameters for

motor protection in the controller or to install thermal relay to protect the motor .

1.2.3 Running Above Rated Frequency

The controller provides frequency output of 0 to 600.00Hz. If the controller is required to

run at over 50Hz, please consider the capacity of the machine.

1.2.4 Vibration of mechanical device

The controller may encounter the mechanical resonance point at some output frequenc-ies,

which can be avoided by setting the skip frequency. If the operating frequency of the

customer coincide with the resonant frequency please modify the operating frequency or

change the inherent resonance frequency of the mechanical system.

1.2.5 Motor heat and noise

The output of the controller is pulse width modulation (PWM) wave with certain harmonic

frequencies, and therefore, the motor temperature, noise, and vibration are slightly greater

than those when the controller runs at power frequency (50 Hz).

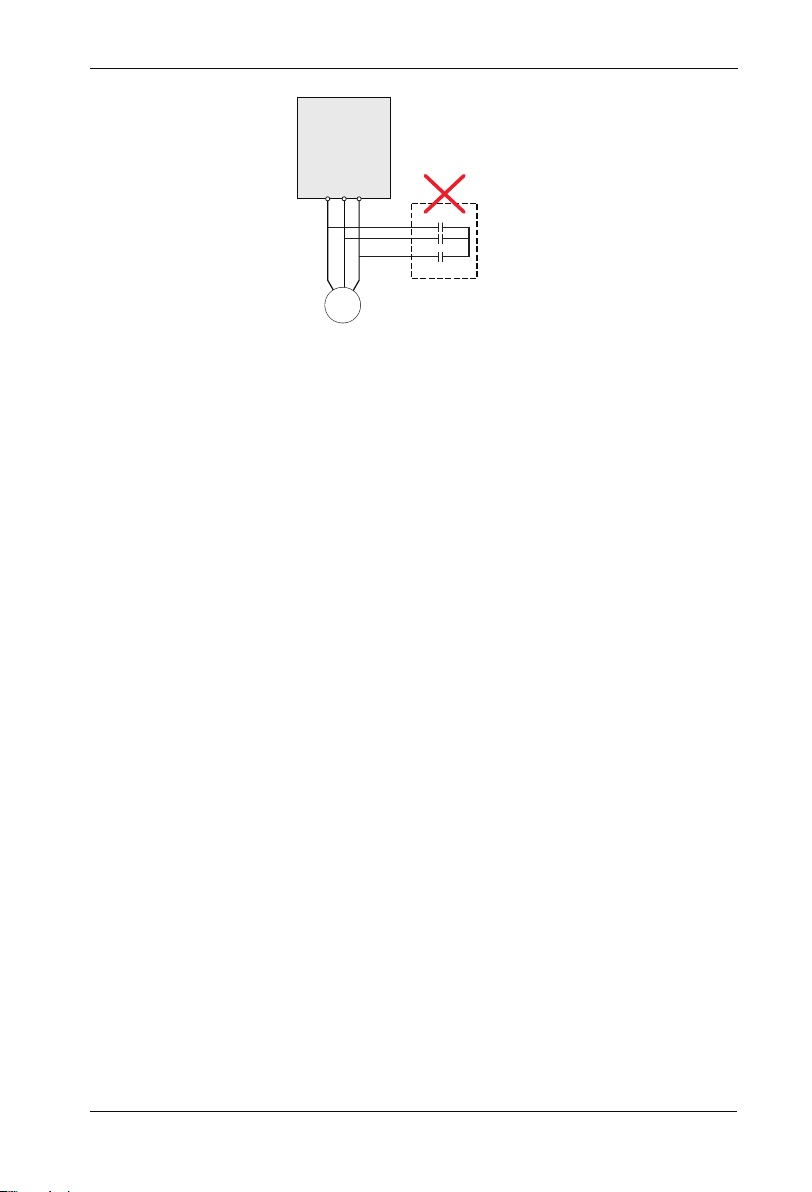

1.2.6 Voltage-sensitive device or capacitor on output side of the controller

Do not install the capacitor for improving power factor or lightning protection voltagesensitive resistor on the output side of the controller because the output of the controller is

PWM wave. Otherwise, the controller may suffer transient overcurrent or even

bedamaged.

-8 -

Page 10

SP200 Manual

SP200

controller

W

U V

Capacitor or

voltage-sensitive resistor

M

1.2.7 Contactor at the I/O terminal of the controller

When a contactor is installed between the input side of the controller and the power supply,

the controller must not be started or stopped by switching the contactor on or off. If the

controller has to be operated by the contactor, ensure that the time interval between

switching is at least one hour since frequent charge and discharge will shorten the service

life of the capacitor inside the controller.

When a contactor is installed between the output side of the controller and the motor,do not

turn off the contactor when the controller is active. Otherwise, modules inside the controller

may be damaged.

1.2.8 The Use Occasion of the External Voltage Out of Rated Voltage Rage

The controller must not be used outside the allowable voltage range specified in this

manual. Otherwise, the controller’s components may be damaged. If required, use a

corresponding voltage step[-up or step-down device.

Chapter1 Safety and cautions

1.2.9 Change Three Phase Input into Two Phase Input

It is not allowed to change the three phase controller into two phase one . Otherwise , it

may cause it may cause fault or damage the controller.

1.2.10 The Protection of the Lighting Impulse

Although the controller has equipped with lightning overvoltage, overcurrent device, which

has a certain protection function for the induction lightining. For the lightning prone areas,

the user is necessary to install lightning protection device at the front of the controller,

which will benefit to the service life of the transducer.

1.2.11 Altitude and Derating

In places where the altitude is above 1000m and the cooling effect reduces due to thin airit

is necessary to de-rate the controller. Contact Our company for technical support.

-9 -

Page 11

Chapter1 Safety and cautions

SP200 Manual

1.2.12 Some Special Usages

If writing that is not described in this manual, such as common DC bus is applied, contact the agent or Our company for technical support.

1.2.13 The Cautious of the controller Disposal

The electrolytic capacitors on the main circuits and PCB may explore when they are burnt.

Poisonous gas is generated when the plastic parts are burn. Treat them as ordinary indu-

strial refer to relevant national laws and regulations.

1.2.14 Adaptable Motor

1. The standard parameters of the adaptable motor is adaptable four-squirrel-cage

asynchronous induction motor or PMSM. For other types of motor, select a proper

controller according to the rated motor current.

2. The cooling fan and rotor shaft of general controller are coaxial, which results in reduced

cooling effect when the rotational speed declines. If variable speed is required, add a

more powerful fan or replace.

3. The standard parameters of the adaptable motor have been configured inside the

controller. It is still necessary to perform motor auto-tuning or modify the default values

based on actual conditions. Otherwise, the running result and protection performance

will be affected.

4. The controller may alarm or even be damaged when short-circuit exists on cables or

inside the motor. Therefore, perform insulation short-circuit test when the motor and

cables are newly installed or during routine maintenance. During the test, make sure

that the controller is disconnected from the tested parts.

-1 0-

Page 12

Chapter 2

Basic principle

2.1 Basic principle

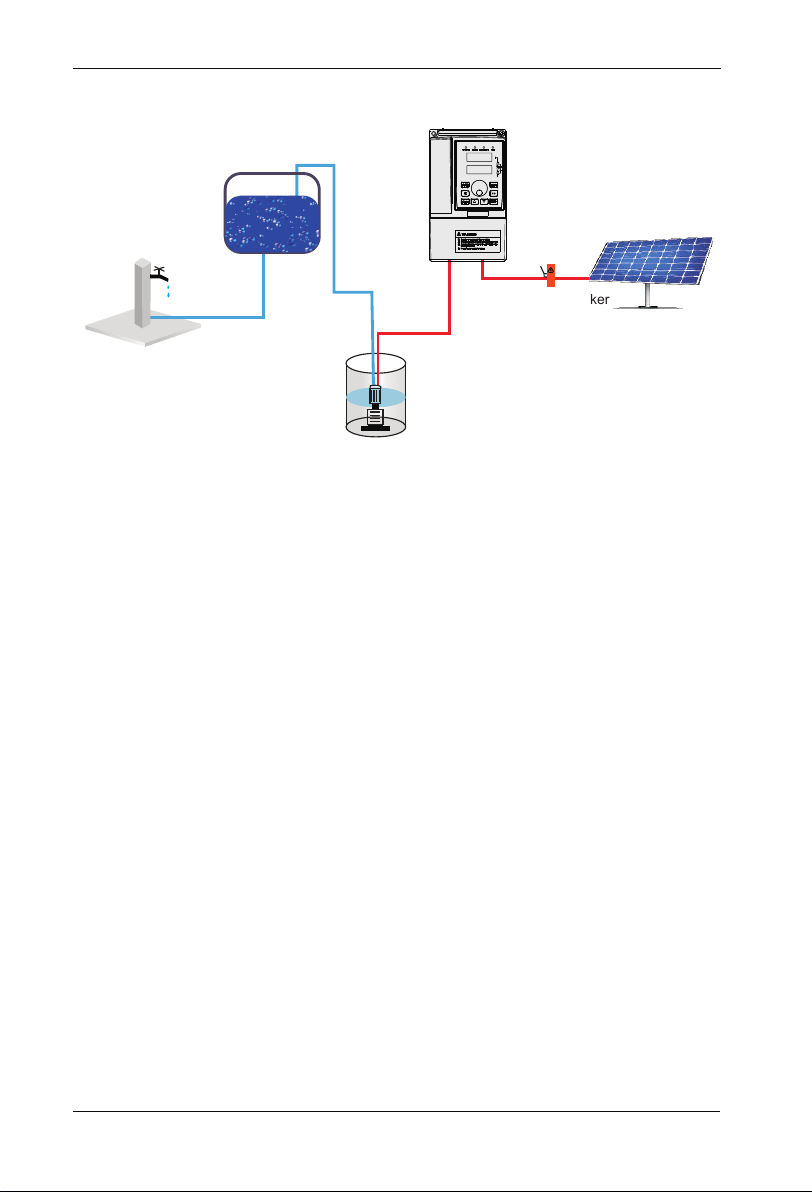

SP 200 solar pumping system can provide water for remote areas lacking of electricity or

places where the electricity supply is unstable. PV pump controller can convert the DC

power from solar panels to AC power so to drive various kinds of pumps.System enables

continiously pumping when in good weather. System is not equipped with strorage battery

devices, it is suggested that pumping the water to conservation pool for future use.Water

source could come from river, lake,well,or other natural water source or special

soucre.System enables application of floating switch in the conservation pool or water

tower to control the operation of pumps. Low water level probes can be installed in the

well to detect the water level of the well in order to stop the pumps when the well in low

water level. Diagram 1 is a typical SP200 PV pumping system. The main parts and

compenents of this system is after diagram 1.

-11 -

Page 13

Chapter2 Basic principle

SP200 Manual

C.SP200 PV pump controller

F.Storage tank

A.solar panels

B.DC circuit braker

E. well water

level switch

2-1 SP200 PV pumping system

D.pump

SP200 PV pumping system is composed of following parts:

A: Solar panels

:

B DC circuit braker or disconnector

:

C SP200 PV pump controller

:

D Pump

:

E well water level switch(optional)

:

F water tower water level switch(optional)

P

S 200 PV pump controller can start the pump softly and is consistent with the electricity

coming from the changes providing by solar panels. The advantage of soft starting is avoid

surge or power surges when the pump or motor are in the process of starting,whi-ch

reduce the loss of motor and pumping system.

Requirements of pump check valve:

Note: To ensure the best reliability of the system and water supply, check valves is required

to be installed in the output pipe. The first check valves must be installed in the outlet of

pumps, the rest check valves should be installed in the vertical direction of the pipes of

every 30 meters(100 feet) behind the pump.

-1 2-

Page 14

SP200 Manual

Chapter2 Basic principle

2.2 Functions

System diagnostics

SP200 PV pump controller continuously monitor the system performance and can detect a

variety of abnormal circumstance. In most cases, controller provide compensations as

required to keep the non-stop operation of the system. If there is a damage, controller will

protect the system and display fault state. If possible, controller will restart after the fault

status is gone. Fault codes and correction information please refer to the chapter of

Detecting and troubleshooting.

Motor soft-starter

Generally speaking, S 200pv pump controller will operate when there is water requirement or electricity is available.Everytime SP200 PV Pump Controller detect the water

requirement, the rotating speed is always improved slowly and at the same time add motor

voltage gradually.Compared to traditional water supply system, solar pumping sytem's

motor temperature and starting current is much lower. Controller with soft starting function

has no damage to the motor.

Overheating monitoring

P

S 200 PV pump controller can run at full power when the ambient temperature reaches

45℃ For temperature above 45℃, controller will keep on running by reducing output

power. When the controller temperature cooled to safety point, it will run at full power

output.

P

Water level float switch

P

S 200 PV pump controller can connect 2 water level detecting switch to detect pump

running by remote control. Water level switch is optional to the controller, it is not required.

SP200 PV pump controller's input power terminals can be switched to spare AC power

supply manually.

Spare AC power supply switch

Note: Based on different models, SP200 input power could be 220v AC single power, or

380V AC 3 phase power. For more information, please contact SINOVO or certified agent.

When the system is running by spare AC power, please check the DC power every 30 mins.

If the AC power is applicable, then stop the controller and switch to the AC power and try to

run the pump at the AC power driving way.

-1 3-

Page 15

Chapter2 Basic principle

SP200 Manual

Note:

DC circuit switching and generator power switch installation are required and both switches

should be mutually locked to prevent they were connected at the same time which lead to

the solar panels and generator connect SP200 controller simultaneously. Please check if

the design meets electrical specifications of relative country and area.

-1 4-

Page 16

Chapter 3

Product Information

200 PV pump controller is adjustable speed motor controller designed in accordance

SP

with any IEC standard 3 phase asynchronous motor。 SP200 PV pumping system convert

the high voltage DC power of solar array into AC power to drive an standard 3 phase

asynchronous motor thus provide water for remote areas. When the solar power is not

enough, controller can be switched manually to spare single or 3 phase AC power, such as

generator. This controller is functioned with fault detection, motor soft-starting, and speed

control.SP200 PV Pump Controller is designed with the function of plug-and-play and easy

to install.SP200 PV Pump Controller is a product of stable performance and high standard.

In weak light condition, controller will try to drive pump for water lifting, but if the light is

becoming weaker, then controller will reduce the speed of pump to protect the system

components from damaged and shut down during some extreme circumanstances.When

the special circumanstances is gone, controller will restart driving the pump.

-1 5-

Page 17

Chapter3 Product Information

SP200 Manual

3.1 Inspection

Before using, please check the SP200 PV pump controller components firstly. Please make

sure the components serial number is correct and if the product is damaged during

shipping.

3.2 Instroductions and Feature

SP200 PV Pump Controller monitor the system performance continiously and with

integrated protection of multi-function pump system. When fault occurs, SP200 PV Pump

Controller will display the type of faults by LED screen in the front of the controller and will

automatically reset routine fault.

Internal Diagnostics allows lower input voltage.

Whenever possible, the controller will maximize the use of the solar array output to drive

the pump.

To provide users with an easy interface, enhanced configurability and realize remote

monitoring system.

3.3 Protection Function

Electronic monitoring enables the controller to monitor systems and automaticlly shut down

in following circumanstances:

1. Wells is short of water- Low liquild level swtiches;

2. Pump locked rotor overload protection;

3. High voltage surge;

4. Low output voltage;

5. Motor lack phase;

6. Short circuit;

7. Over heating.

Note:

the controller protect the motor by limiting load running when the motor current exceeds the

rated current at the time of low water leve.The controller does not provide high motor

temperature detection.

-1 6-

Page 18

SP200 Manual

Chapter3 Product Information

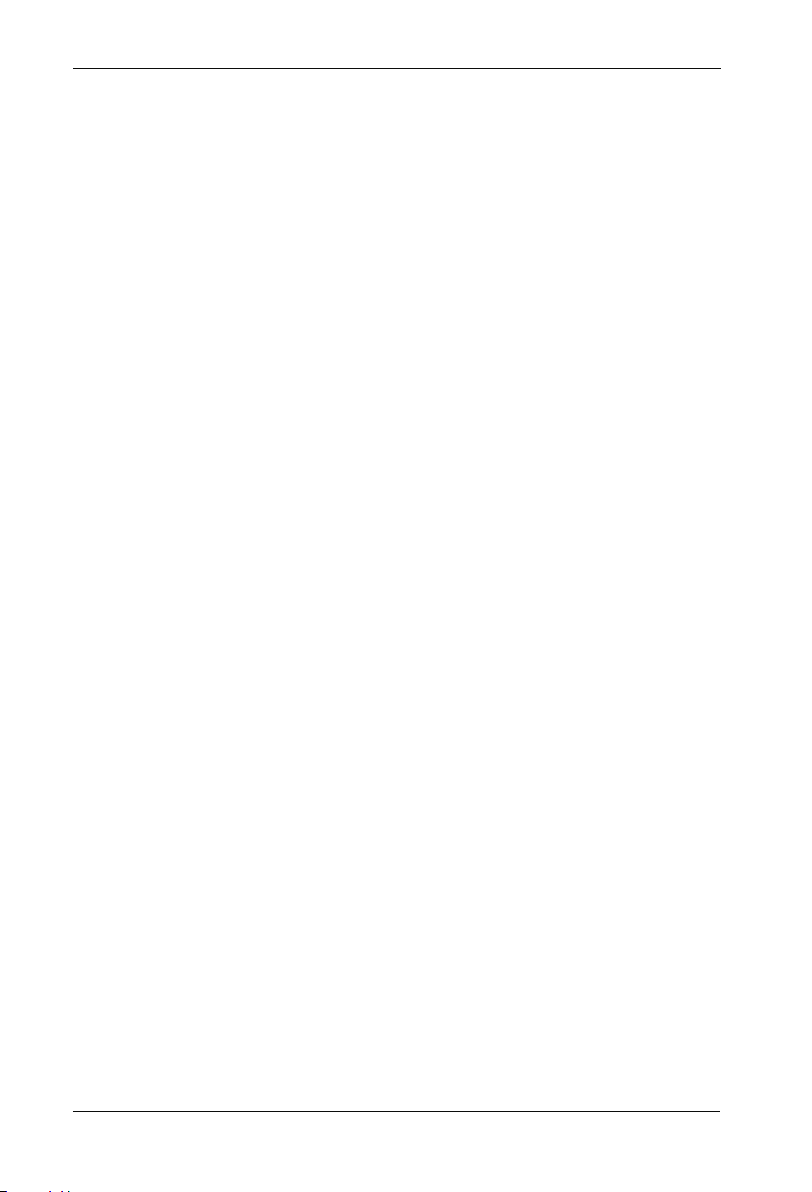

3.4 Naming Rules

In the model code contains the product information Users can find the code from the

transducerand simple nameplate.

SP

Field Mark

controller series

Series number

Voltage Level

voltage range

Pump rated power

200

1

1

2

3

4

5

2

Solar water pump controller

Series second generation

2: Three-phase 220V

4 Three-phase 380V:

S Rated voltage310VDC,Recommended voltage range

(MTTP)180VDC~360VDC

T: : Rated voltage540VDC,Recommended voltage range

(MTTP)500VDC~600VDC

2.2: 2.2KW

Figure 3-1 Name Designation Rules

-

4

3

Content

T

4

2.2

5

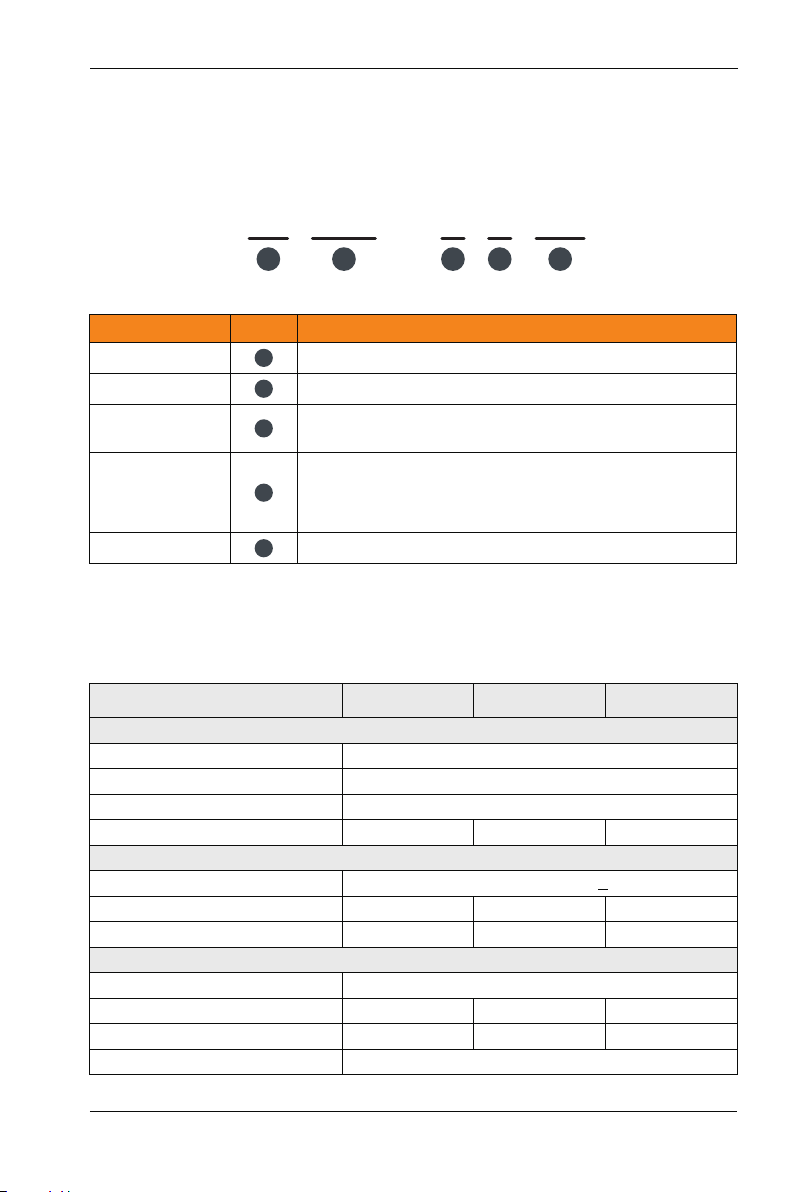

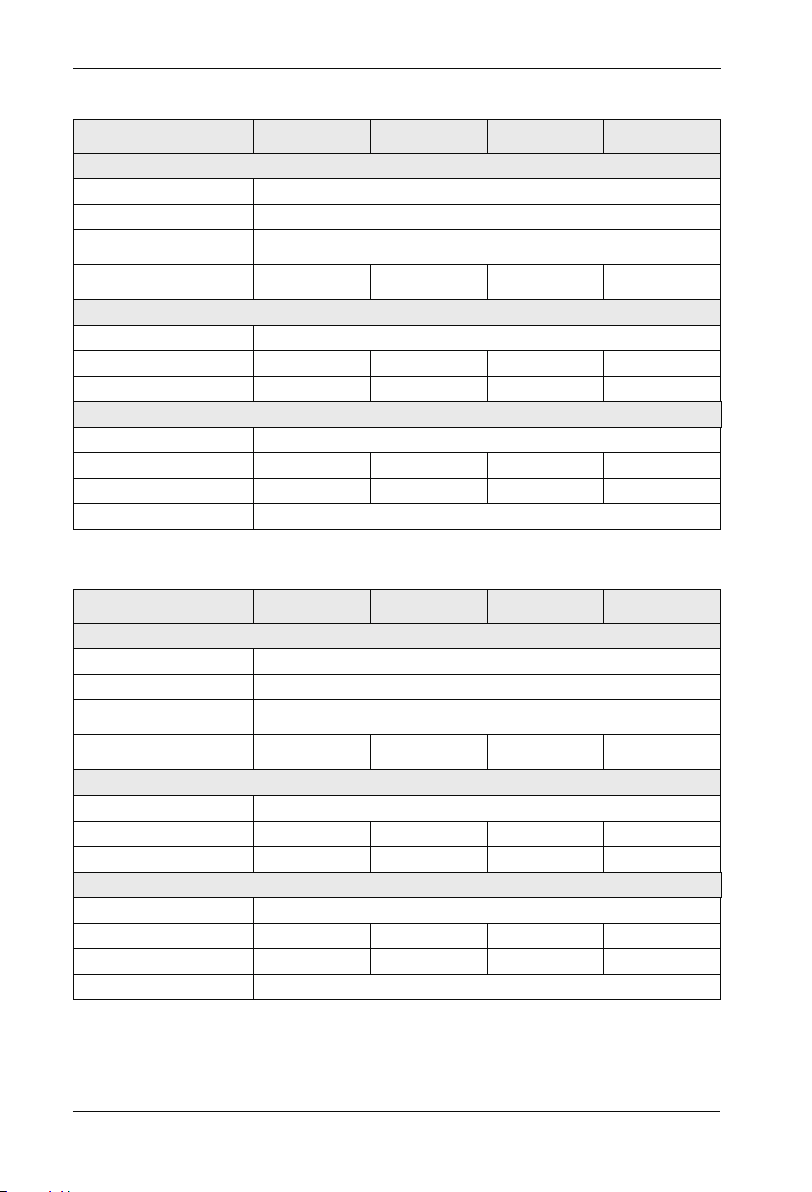

3.5 SP200 PV Pump Controller input/output parameter

SP200-2SXXX

Model

PV array input parameter

Max voltage V ( )input

Min input voltage V ( )

Recommended voltage mpp)(

Recommended PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

0.9 1.2~

Spare AC generator

Singel phase AC 200-240(+10%)

8.2

1.5

Output parameter

4.7

0.75

DC 450V

DC 180V

DC 280~360V

1.8~2.4

14

3

3-phase AC 200-240V

7.5

1.5

0~50Hz/60Hz

SP200-2S-2.2SP200-2S-0.7 SP200-2S-1.5

2.7 3.5~

23

4

10

2.2

-1 7-

Page 19

Chapter3 Product Information

SP200-4TXXX Input/output parameter

Model

PV array input parameter

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage(mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

2.7 3.5~

Spare AC generator

5.8

4

Output parameter

5.1

2.2

SP200-4T-5.5SP200-4T-2.2 SP200-4T-3.7

DC 800V

DC 350V

DC 500~600V

4.8~6.4

3-phase AC 380/400/415/440V(+15%)

10.5

5.9

3-phase AC 380/400/415/440V(+15%)

9

3.7

0~50Hz/60Hz

6.6~8.8

14.6

8.9

13

5.5

SP200 Manual

SP200-4T-7.5

9~12

20.5

11

17

7.5

Model

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage(mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

PV array input parameter

13.2~17.6

Spare AC generator

3-phase AC 380/400/415/440V(+15%)

26

17

Output parameter

3-phase AC 380/400/415/440V(+15%)

25

11

-1 8-

DC 500~600V

18~24

35

21

32

15

0~50Hz/60Hz

SP200-4T-18.5SP200-4T-11 SP200-4T-15

DC 800V

DC 350V

22.2~29.6

38.5

24

37

18.5

SP200-4T-22

26.4~35.2

46.5

30

45

22

Page 20

SP200 Manual

Chapter3 Product Information

Model

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage( mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

Model

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage( mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

PV array input parameter

36~48

Spare AC generator

62

40

Output parameter

60

30

PV array input parameter

90~120

Spare AC generator

157

114

Output parameter

150

75

44~59.2

3-phase AC 380/400/415/440V(+15%)

3-phase AC 380/400/415/440V(+15%)

44~59.2

3-phase AC 380/400/415/440V(+15%)

3-phase AC 380/400/415/440V(+15%)

DC 800V

DC 350V

DC 500~600V

76

57

75

37

0~50Hz/60Hz

DC 800V

DC 350V

DC 500~600V

180

134

176

90

0~50Hz/60Hz

SP200-4T-45SP200-4T-30 SP200-4T-37

SP200-4T-110SP200-4T-75 SP200-4T-90

54~72

92

69

91

45

132~176

214

160

210

110

SP200-4T-55

66~88

113

85

112

55

SP200-4T-132

159~211

256

192

253

132

-1 9-

Page 21

Chapter3 Product Information

SP200 Manual

Model

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage( mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

Model

Max voltage V ( )input

Min input voltage V ( )

Recommended

voltage( mpp)

Recommended

PV power(Kw)

Input voltage(V)

Max current A ( )

Generator capacity kVA ( )

Rated output voltage

Max current A( )

Rated output power kW( )

Output frequency

PV array input parameter

192~256

Spare AC generator

307

231

Output parameter

304

160

PV array input parameter

192~256

Spare AC generator

525

396

Output parameter

520

280

240~320

3-phase AC 380/400/415/440V(+15%)

3-phase AC 380/400/415/440V(+15%)

378~504

3-phase AC 380/400/415/440V(+15%)

3-phase AC 380/400/415/440V(+15%)

DC 800V

DC 350V

DC 500~600V

385

250

377

200

0~50Hz/60Hz

DC 800V

DC 350V

DC 500~600V

590

445

585

315

0~50Hz/60Hz

SP200-4T-220SP200-4T-160 SP200-4T-200

SP200-4T-355SP200-4T-280 SP200-4T-315

264~352

430

280

426

220

426~568

665

500

650

355

SP200-4T-250

300~400

468

355

465

250

SP200-4T-400

480~640

785

565

725

400

Note:

According to the different illumination in different regions, recommended PV array power is

1.2 to 1.6 times of the controller power.

-2 0-

Page 22

SP200 Manual

3.6 Nameplate

Chapter3 Product Information

MODEL: SP200-4T-7.5

INPUT: DC500~600V 9~12KW

AC3PH 380V 50/60Hz 20.5A

OUTPUT: AC3PH 380V 50/60Hz 17A

S/N: FDLAGCA1A042

SHENZHEN SINOVO ELECTRIC TECHNOLOGIES CO.,LTD.

MADE IN CHINA

Figure 3-2 Name Designation Rules

3.7 SP200 PV Pump Controller Size

Ø

H

H1

Model of the controller

Rated input voltage,

frequency and current

Rated output voltage,

frequency and current

Bar code

W1

W

7.5KW Less than 7.5KW Controller installation dimensions and installation size

D

-2 1-

Page 23

Chapter3 Product Information

3.7.1 Installation Hole Size

Controller Model

SP200-2S-0.7

SP200 S-2 -1.5

SP200 S-2 -2.2

SP200-2T-0.7

SP200-2T-1.5

SP200-2T-2.2

SP200-4T-0.7

SP200-4T-1.5

SP200-4T-2.2

SP200-4T-4.0

SP200-4T-5.5

SP200-4T-7.5

SP200-4T-11

SP200-4T-15

SP200-4T-18.5

SP200-4T-22

SP200-4T-30

SP200-4T-37

SP200-4T-45

SP200-4T-55

SP200-4T-75

SP200-4T-90

SP200-4T-110

SP200-4T-132

SP200-4T-160

SP200-4T-185

SP200-4T-200

SP200-4T-220

SP200-4T-250

SP200-4T-280

SP200-4T-315

SP200-4T-350

SP200-4T-400

SP200-4T-450

SP200-4T-500

H(mm) W(mm) D(mm)

190 110 150 178 98

190 110 150 178 98

190 110 150 178 98

210 130 160 198 118

250

285

332

387

650

880 485 310 860 320

1250 500 400 1000 440

1350 650 400 1105 513

1810 850 405 1410 513

H1(mm) W1(mm)

155

170 162 270

220

250 220 373

270 252 426 25440

300 258 534 200

370 282 625 250

176 236

214

318

141

135

140

150

180

D

iameter

(mm)

Ø5

Ø5

Ø5

Ø5

Ø5

Ø6

Ø7

Ø9

Ø13

Ø13

Ø13

Ø13

SP200 Manual

GW(kg)

2.4

2.4

2.4

3.5

4.5

5.1

9.3

14

19

32550

52

55

58

99

167

206

415

-2 2-

Page 24

SP200 Manual

3.7.2 External Keypad Installation Dimensions

Chapter3 Product Information

+0. 3

0

119.5

128.20

79.00

1.50

74.80

Figure 3-3 Keypad Installation dimensions

+0.3

119.00

0

100

Opening dim en si on d iagram

Figure 3-4

for keypad wi th b as e

-2 3-

70

Opening dim en si on d iagram

Figure 3-5

for keypad wi th ou t ba se

Page 25

-2 4-

Page 26

Chapter 4

Mechanical and Electrical Installation

Danger

Only those who are trained and qualified professionals can operate the work described

ª

in this chapter. Please operate according to the section of "pay attention to security

matters", failure to these may cause personal injury or damage to equipment.

Connect the input power lines tightly and permanently. And ground the device with

ª

proper techniques.

Even when the controller is stopped, dangerous voltage is present at the terminals:

ª

-Power terminals: R,S,T,P,P+,P-, PB

- Motor connection terminals: U,V and W

Wait for 10 minutes to let the controller discharge and then begin the installation.

ª

Minimum cross-sectional areas of the grounding conductor should be equal to or

ª

greater than the power supply cable cross-sectional area.

-2 5-

Page 27

Chapter4 Mechanical and Electrical Installation

SP200 Manual

Note

Lift the controller by its base other than the keypad or the cover. The dropping of the

ª

main part may cause personal injury.

ª

Install the equipment on incombustible objects such as metal, and keep it away from

ª

combustible materials. Failure to comply may result in a fire.

ª

If motor than two controller are installed in a cabinet, the temperature should be

ª

lower than 45℃ by means of a cooling fan. Failure it will result in damage to the

controller.

4.1 Controller Installation and Operation Environment

4.1.1 Thermal Protection

If installed outdoors, the controller should be installed inside the control box with waterproof function, and the control box there should be vents.

And control box mounted vertically in a well ventilated place, avoid direct sunlight and

rainwater.The best installation location can be mounted directly beneath the solar array to

prevent the device from overheating and performance degradation.Particularly in places of

extreme high temperature, the controller may shut down to protect themselves.For best

performance, avoid placing solar panels around any obstacle where there are cast

shadows and will reduce the sunlight to these arrays.It is recommended to use a conduit to

protect the wire from wildlife and natural weathering and the conduit should be buried

underground for extra protection.If there is no use conduit, higher quality outdoor cable

should be used.

4.1.2 Installation Location

SP200 PV Pump Controller applies to the site where the ambient temperature ups to 60

degrees.It is recommended to install the controller in the shadow position to avoid

overheating fault.

SP200 PV Pump Controller must be installed in the control cabinet. The control cabinet has

a such enclosure to avoid direct sunlight and it has functions of rain-proof, dustproof,

moisture-proof, anti-animals and so on. Control cabinet should have a sealed bottom plate

for mounting wire cable or conduit. Refer to Figure 4-2 below to determine the size of the

control cabinet.

-2 6-

Page 28

SP200 Manual

4.2 Controller Installation Spacing

Chapter4 Mechanical and Electrical Installation

Fan exhaust

More than

50mm

Figure 4-1 Installation distance

More than 100mm

controllerr controllerr

More than 100mm

Figure 4-2 Installation of multiple controller

Upper row and lower row installation for two controller, A guide plate should be added

between the two controller.

4.3 Install and Remove the Cover

Hook

Lower cover

Hook slot

Figure 4-3 Install and remove the plastic lower cover

Note:

Remove the lower cover by pushing the hook of the lower cover inward symmetrically.

-2 7-

Page 29

Chapter4 Mechanical and Electrical Installation

SP200 Manual

4.4 Wiring

Danger

Only qualified electricians are allowed to operate on the safe running of the controller.

ª

Never carry out any insulation or voltage withstand tests on the cables connecting with

ª

the controller.

Even if the controller is stopped, dangerous voltage is present at the input power lines,

ª

DC circuit terminals and motor terminals. Wait for 10 minutes even when the

controller is switched off until the CHARGE light is off before operation.

Ground the grounding terminals of the controller with proper techniques.

ª

220V resistor should be 100Ω or less than it

400V resistor should be 10Ω or less than it

690V resistor should be 5Ω or less than it

Otherwise there is danger of electric shock and fire.

Please ensure the right connection between the power supply wires and motor wires.

ª

Connect the power supply to the R,S and T terminals and connect motor wires to U,V

and W terminals.

Never do wiring or other operation on the controller with wet hands. Otherwise there is

ª

danger of electric shock.

Note

Verity that the rated voltage of the controller equals to the voltage of the AC power

ª

supply.

The power wires and motor wires must be permanently fastened and connected.

ª

-2 8-

Page 30

SP200 Manual

4.4.1 Typical Wiring Diagram

A.solar panels

DC310V

/540V

MCCB

R

S

T

3-phase380V/480V

Input power 50/60Hz

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

High-speed pulse input

3

DC:0~10V/0~20mA

2

1kΩ 5kΩ~

1

DC:-10V~10V

DC:-10V~10V

P-

R

S

T

SP200

Main circuit

+24V

OPEN

DI1

DI2

DI3

DI4

DI5

HDI1

COM

Analog input

reference voltage

+10V

Analog input 1

AI1

AI2

AI3

GND

PE(connect cabinet)

J9

V

I

Analog input 2

Analog input 3

T

S

Chapter4 Mechanical and Electrical Installation

P+

PB

U

V

W

DISP1

J7

485

ON

OFF

A

B

A

B

J3

AO1

V

I

J4

AO2

V

I

GND

HDO1

CME

DO1

CME

T1C

T1B

T1A

T2C

T2A

M

Keypad interface

Expansion card interface

485 communication interface

Analog output AO 1,AO2

0V-10V/0mA-20mA

Open collector output 1

(High-speed pulse output)

Open collector output2

Relay output1

Relay output2

Control circuit

Figure 4-4 Wiring diagram of Control Circuit

-2 9-

Page 31

Chapter4 Mechanical and Electrical Installation

4.4.2 Terminal Diagram

4.4.2.1 Main Circuit Terminal

PBP-P+

R

S

SP200 Manual

U

T

V

E W

DC input

Figure 4-5 Suitable for SP200-4T-22G/30P or less than 22KW machines

3-phase input power

Figure 4-6 Suitable for SP200-4T-30G/37P or more than 37KW machines

3-phase input power

SR

T

P

Shorting bar

DC Reactor

P+

DC input

Motor

U

P-

V

Motor

The main circuit terminals function description is as follows:

Terminal Name

R、 S、 T

P(+)

P(-)

P(+)、 P(-)

P(+)、 PB

U、 V、 W

E

External braking unit reserve terminals

External braking resistor reserve terminals

Function Description

Three-phase power input terminals

DC positive bus output terminal

DC negative bus output terminal

Three-phase AC output terminals

Ground terminal

Ground

W

E

Ground

4.4.2.2 Control Circuit Terminal

DI1 DI2

Low water

level probe

DI3

DI4

NO

Remote float switch

COM

Figure 4-7 Control circuit terminals

-3 0-

NC

DI5

COM

Page 32

SP200 Manual

Chapter4 Mechanical and Electrical Installation

4.4.3 Terminal Diagram

For solar pumping system, Dual DC circuit breaker must be installed between PV array and

SP200 PV Pump Controller.Connect the cable of the bottom part of dual DC breaker

marked as "+" and "-" to SP200 PV Pump Controller wiring terminals "+" and "-".

Note:

R、 S、 T terminals has the feature of protection against reverse polarity, DC power can

connect to R、 S、 T terminals, and don't need to consider the phase sequence.

Note

Before connecting the DC wires, follow the steps belowing to prevent dangerous

ª

electrical shock resulting in serious injury or equipment burned down.

Ensure the external DC isolation switch is turned off。

ª

Ensure that the polarity of the solar array cable must be properly connected with the

ª

controller +, - polarity, otherwise may damage the controller.

Ensure that the AC power is disconnected (if AC power as an alternate power

ª

source, AC and DC power supplies cannot enter the controller at the same time,

otherwise it will damage the controller).

4.4.4 Junction box connection

If the solar panels series parallels is too many, then junction box is required to converge the

current of the solar array. Junction box is required to install fuse, surge protector, DC

switch within it. Fuse and DC switch is helpful to protect from short circuit, surge protector

has the effect of lighting protection along DC side. Junction box must be sealed and

waterproof.

4.4.5 Ground connection

The ground terminal on the controller (E) is marked as an icon, please connect to ground, if

motor fails, proper grounding helps eliminate electric shock risk.

4.4.6 Motor wiring

Connect the 4 wires of the cable to controller's U,V,W,E terminals from the motor.Motor

international wiring diagram is as following 9. Check the motor wiring to make sure the

installation is correct.

Note:

If the pump reverse, then please reverse any 2 wires.

USA Standard

International Standard

Black BLK( ) Red RED( ) Yellow YEL( ) Ground E( )

Grey GRY( ) Black BLK( ) Brown BRN( ) Ground E( )

-3 1-

Page 33

Chapter4 Mechanical and Electrical Installation

SP200 Manual

4.4.7 Well low water level probe wire (optional)

To avoid the damage of the pump due to pumping in dry condition, well probe can be

connected to the control terminals of SP200 PV Pump Controller to detect the well water

level, the length of the well probe should not exceeds 50m.If there is no well probe to

detect the water level, please keep the 2 terminals of the controller shorted( It is shorted

before leaving factory). The well water level aslo can be detected by the built-in water

shortage detecting software of the controller, please refer to Chapter F03 Group

parameters.

4.4.8 Water tower water level floating ball wiring (optional)

We suggest use one floating ball switch to prevent the overflow of the reservoir, pump will

shut down once the reservoir is full.Pum will restart when it is in lower water level. In this

way, unnessary pump damage is reduced. SP200 controller enable small termial wire to

connect to the remote floating ball switch even if the reservoirs location is far away.

Sealed cable

Pump stop location

Pumping area

Pump start location

Floating ball switch requirements:

1.terminals wiring is required

2. Minimum wire diameter is 1mm², longest distance is 600m

3. If applied in long distance transmission, shielding wire is must be used, shields near the

controller need to be grounded, where near the floating ball switch don't need to be

grounded.

If don't apply floating ball switch, then DI5 has to be short with COM.

-3 2-

Page 34

SP200 Manual

Remote floating

ball switch terminal

NO

NC

COM

M5

M6 COM

If the cable is shielding wire

only need to be grounded here

Chapter4 Mechanical and Electrical Installation

NO

NC

COM

Floating

ball switch

Up: OFF

Down:ON

Noramal: ON

4.4.9 Electrical Conduit application

When the system is installed in outdoor, electrical conduit is required to use to protect the

outdoor cable from the influences of weather, human activity, chewing animals. If no

application of electrical conduit, please use high quality outdoor cables.

-3 3-

Page 35

-3 4-

Page 36

Chapter 5

Operation

-3 5-

Page 37

Chapter5 Operation

5.1 Operation Panel Description

5.1.1 Panel Diagram

SP200 Manual

1

3

4

5

Figure 5-1 SP200 KBA keypad diagram

5.1.2 Button Function Descriptions

NameNo.

LED off means that the controller is in the stopping state;

LED blinking means the controller is in the parameter

autotuning state;

LED on means the controller is in the running state.

OFF means the controller is in the forward rotation state

ON means the controller is in the reverse rotation state.

○ FF LOCAL/REMOT: O

● LOCAL/REMOT: PN

○ LOCAL/REMOT: Flash

LED for faults

LED on when the controller is in the fault state;

LED off in normal state

LED blinking means the controller is in the pre-alarm state.

1

Status

indicator

RUN/TUNE

FWD/REV

LOCAL/

REMOT

TRIP

2

Instructions

Operation panel control

Terminal control

Communication control

-3 6-

Page 38

SP200 Manual

Chapter5 Operation

2

3

NameNo.

Unit

indicator

Code

Display

Zone

Instructions

It represents the current display of the Keypad

Hz

Hz

Hz

Hz

Hz

%

RPM

A

%

RPM

A

%

RPM

A

%

RPM

A

%

RPM

Hz

V

A

V

V

V

RPM

V

%

Frequency unit

Current unit

Voltage unit

Speed unit

Percentage

V

A

5-figure LED display displays various monitoring data and alarm code

such as set frequency and output frequency.

Display

letter

Correspo-

nding letter

0

3

6

9

C

F

L

o

S

v

Display

letter

Correspo-

nding letter

1

4

7

A

d

H

N

P

t

.

Display

letter

Correspo-

nding letter

2

5

8

b

E

I

n

r

U

-

4

5

Digital

potent-

iometer

Keypad

button

zone

When the frequency source A or B is set to 1, the setting of the frequency source is determined by the analog potentiometer input voltage .

The maximum output voltage corresponding to the maximum frequency,

minimum voltage corresponding to 0 Hz

Program key

Entry key

Up key

Down key

Enter or escape from the first level menu and

remove the parameter quickly

Enter the menu step-by-step confirm parameters

Increase data or function code progressively

Decrease data or function code progressively

Move right to select the displaying parameter

Right-Shift

key

circularly in stopping and running mode. Select

the parameter modifying digit during the para-

meter modification

-3 7-

Page 39

Chapter5 Operation

No.

Name

Run key

Instructions

The key is used to operate on the controller in key

operation mode

This key is used to stop in running state; This key

5

Keypad

button

zone

Stop/Reset

S Key

is used to reset all control modes in the fault

alarm state..

F07.01=0 without function

F07.01=1 jog running

F07.01=2 shift key to change the display state

F07.01=3 switch between forward and reverse

F07.01=4 clear UP/DOWN setting

F07.01=5 coast to stop

5.2 Operation Procedure

5.2.1 Parameter Setting

The controller has three-level menus, they are:

1.Group number of function code(first-level menu)

2.Tab of function code(second-level menu)

3.Set value of function code(third-level menu)

Operation procedure on the operation panel:

SP200 Manual

50.00 F00

Display par amete r

interface

PRG

ENT

F00.03 F00.04

ENT

50.00

PRG

PRG

return

return

ENT

PRG

(modify sto rage)

return

level 1 menu

level 2 menu

level 3 menu

Press / modify parameters

Figure 5-2 Schematic editing diagram

Note:

Press both the "PRG" and the "ENT" key to return to level2 menu from the level3 menu.

The difference is: pressing "ENT" will save the set parameters into the control panel, and

then return to the level2 menu with shifting to the next function code automatically; while

pressing "PRG" will directly return to the level 2 menu without saving the parameters, and

keep staying at the current function code.

-3 8-

Page 40

SP200 Manual

Chapter5 Operation

In Level 3 menu, if the parameter has no blinking digit, it means that the parameter cannot

be modified. This may be because:

a. Such a function code is only readable, such as, controller model, actually detected

parameter and running record parameter;

b. Such a function code cannot be modified in the running state and can only be

changed at stop.

Example: Set function code F0C.02 from 10.00Hz to 15Hhz.

PRG

50.00

PRG

F00

PRG

F0C F0C.03

Figure 5-3 Mo di fy in g parameters di ag ra m

F0C

ENT

15.00 10.00

ENT

F0C 00.

10.00

F0C 02.

ENT

5.2.2 Password Setting

SP200 series controller provide password protection function to users. Set F07.00 to gain

the password and the password protection becomes valid instantly after quitting from the

function code editing state. Press "PRG" again to the function code editing

state,“0.0.0.0.0”will be displayed. Unless using the correct password, the operators cannot

enter it.

Set F07.00 to 0 to cancel password protection function.

The password protection becomes effective instantly after retreating form the function code

editing state. Press "PRG" again to the function code editing state, “0.0.0.0.0”will be

displayed. Unless using the correct password, the operators cannot enter it.

PRG

50.00 F00 F07

PRG

PRG

F07 F07.01

Figure 5-4 Password setting diagram

ENT

X X X X X. . . .

ENT

F07 00.

ENT

0 0 0 0 0. . . .

5.2.3 How to watch the controller state through function codes

SP200 series control ler provide gr oupA02 as the sate in spectio n group. Users can

enter into A02 directly to watch the state. Operations procedure as follows:

ENT

A02 00.

ENT

A02 05.

50.00

PRG

A02

PRG

PRG

F00

A02.06

A02

ENT

1400

Figure 5-5 Motor speed diagram

-3 9-

Page 41

Chapter5 Operation

SP200 Manual

5.3 Commissioning Process

1: Check and confirm the wiring is correct.

2: Using high a megger to test the insulation of the motor and cable if needed.

3: Use a multimeter to test whether the open circuit voltage of the DC switch solar modules

meet the requirements.

4: Close the DC switch to power up the controller

Modify and set the parameters of the motor if needed.

For example, if the motor's rated power is 60Hz, the following parameters need to be

modified:

Running frequency upper limit F00.03=60.00 F00.04=60.00

Other related parameters: Motor rated power F02.02, motor rated frequency F02.05,

motor rated speed F02.06,

motor rated voltage F02.03, motor rated current F02.04.

Note:

Default motor rated frequency is set to 50Hz.

Slow start to check the direction

Start the motor slowly by pressing the RUN/STOP key,check whether the pump is correct.

If the pump run in dry condition,the maximum running time less than 15s Failure to comply

will result in damage to the pump. Turn off the DC switch if water pump rotates in a wrong

direction. And swap any two wires of the motor in accordance with the section of the Water

Pump or Motor Connection.

After the above steps are completed, you can try to run the system.

Check the water supply capacity when the system work for one hour.

Finish commissioning.

When there is insufficient light, the output power of solar modules is reduced, so the speed

of the pump will be very slow until it stops.The controller will try to start once every 120 s,

during the trial run, the running indicator light has been lit.When a shadow through the

battery array suddenly , the controller will lose track of the input voltage, and the pump will

stop working. The controller will try to restart the pump rather than display the fault.

5.4 Panel Displays Parameters in Running State

Display

H Hz

V

A A

V

Name

Running frequency

Output voltage

Running current

Input voltage

Description

Current running frequency

Output voltage of controller

Actual output current of controller

DC input voltage

-4 0-

Unit

V

V

Page 42

Chapter 6

Function Parameter Table

User-defined Parameters

“ ”means the set value of the parameter can be modified on stop and running state;

○

“ ”means the set value of the parameter can not be modified on the running state;

◎

“●”means the value of the parameter is the real detection value which can not be modified.

-4 1-

Page 43

Chapter6 Function Parameter Table

Function

code

F00.01

Name

Run command

channel

Group F00 Basic Function Group

0: Keypad run command channel(LED is OFF)

1: Terminal command channel / Keypad STOP

disabled(LED is ON)

2: Terminal command channel / Keypad STOP

enable(LED is ON)

3:Terminal command channel / Keypad

Setup range

SP200 Manual

Default

Value

STOP disabled(LED is flashes)

4:Terminal command channel / Keypad

STOP enabled(LED is flashes)

Max output frequency

Upper limit frequency

F00.04 50.00Hz

F00.04~600.00HzF00.03 50.00Hz

F00.05~F00.03(Maximum frequency)

Modifi-

cation

1

○

◎

◎

Lower limit frequency

F00.05 0.00Hz

Acc-time 1

Dec-time 1

F00.18 0

F01.08

F01.18

F01.19

F02.02

F02.03

F03.07

Function restore

parameter

Stop Mode

Select restart

after power failure

Restart waiting time

Rated power of

motor 1

Rated voltage of

motor 1

Rated current of

motor 1

Rated frequency

of motor 1

Rated speed of

motor1

The lowest operating fr-

equency of water outlet

0.00Hz~F00.04(Operating frequency upper limit)

0.0~6000.0sF00.12

0.0~6000.0sF00.13

0:No operation

1:Restore the default value

2:Cancel the fault record

Group F01 Startup and stop Control

0: Decelerate to stop

1 Coast to stop:

0 prohibit restart

:

1 allow restart

:

0.0~6000.0s(F01.18 equal to1is valid)

Group F02 Motor Parameter Group

0.1~1000.0kW

0~1200V

0.8~6000.0AF02.04

0.01Hz~F00.03(Maximum)F02.05 50.00Hz

1~36000rpmF02.06

Group F03 Solar Water Pump Special Parameters

0~50.00Hz 20.00Hz

Depend

on

model

Depend

on

model

0

0

1.0s

Depend

on

model

Depend

on

model

Depend

on

model

Depend

on

model

◎

○

○

◎

○

○

○

◎

◎

◎

○

○

◎

-4 2-

Page 44

SP200 Manual

Function

code

F03.08

The lowest operating

frequency of water outlet

Name

0~6553.5s

Setup range

Chapter6 Function Parameter Table

Default

Modifi-

Value

cation

10.0s

◎

F03.09

F03.10

F03.11

F03.12

F03.13

F03.14

F03.15

F05.01

F05.02

F05.03

F05.04 13

F05.05 47

F05.17 0.000~50.000s

Wake detection time 1

Wake up voltage

detected increases in

Wake detection time 2

Water shortage

underload alarm selection

Underload detection point

Underload detection time

Water shortage

detection interval

DI1 terminals

function selection

DI2 terminals

function selection

DI3 terminals

function selection

DI4 terminals

function selection

DI5 terminals

function selection

Low water level

switch closing delay

0~F3.11s

0~6553.5V

0~6553.5s

111

0~100.0%

0~60.0s

0~60000Min 20.0Min

Group F05 Input Terminal Group

0: No function

1: Forward rotation operation

2: Reverse rotation operation

3: Three-wire control operation

6: Coast to stop

7: Fault reset

13: Shift between A setting and B setting

46: Liquid level switch input

47:Floating ball switch input

120.0s

10.0V

600.0s

000

30%

10.0s

1.000s

◎

◎

◎

◎

◎

◎

◎

◎

1

0

◎

46

◎

◎

◎

○

F05.21 0.000~50.000s

F07.00 0

F07.02

F07.04

F07.18

F07.19

Remote floating ball

switch closing delay

User’s password

Display parameters for

~

running/stopping state

Current fault type

The 1 times

before fault type

Group F07 HMI and Fault Parameters

0~65535

0x0000~0xFFFF

See Chapter Seven 7.1 Fault

Information and Troubleshooting

1.000s

0x03FF

-4 3-

----

----

○

○

○

●

●

Page 45

Chapter6 Function Parameter Table

Function

code

F07.20

F07.21

F07.22

F07.23

Name

The 2 times

before fault type

The 3 times

before fault type

The 4 times

before fault type

The 5 times

before fault type

Setup range

See Chapter Seven 7.1 Fault

Information and Troubleshooting

SP200 Manual

Default

Modifi-

Value

cation

----

●

----

●

----

●

----

●

F07.24

F07.25

F07.26 0V

F07.27 0.0A

F07.28 0.0V

F07.29 0.0

F07.30 0

F07.31 0

F07.32

F07.33

F07.34 0V

F07.35 0.0A

F07.36 0.0V

F07.37

F07.38 0

F07.39 0

F07.40 0.0A

Running frequency

at current fault

Ramp reference

frequency at current fault

output voltage

at the current fault

output current

at current fault

Bus voltage at current fault

The Max. temperature

at current fault

Input terminals state

at current fault

Output terminals state

at current fault

Running frequency

at previous fault

Ramp reference frequency

at previous fault

Output voltage

at previous fault

The output current

at previous fault

Bus voltage

at previous fault

The Max. temperature

at previous fault

Input terminals state

at previous fault

Output terminals

state at previous fault

Running frequency

at previous 2 fault

----

----

----

----

----

----

----

----

----

----

----

----

----

----

----

----

----

0.00Hz

0.00Hz

0.00Hz

0.00Hz

0.0℃

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

-4 4-

Page 46

SP200 Manual

Function

code

Ramp reference frequency

F07.41 0.0V

F07.42

F07.43 0

F07.44 0

F07.45

F07.46 0

F07.47 0

Name

at previous 2 fault

Output voltage

at previous 2 faults

Output current

at previous 2 fault

Bus voltage

at previous 2 fault

The Max. temprature

at previous 2 fault

Input terminals state

at previous 2 fault

Output terminals state

at previous 2 fault

----

----

----

----

----

----

----

Setup range

Chapter6 Function Parameter Table

Default

Modifi-

Value

cation

●

0.0℃

0.0℃

●

●

●

●

●

●

Parameter Explanation:

F03.07 The lowest operating frequency of water outlet: the controller real time detects the

output power of solar panel and reduces frequency when there is insufficient light. The

controller stop and tips E.Sun error if frequency is lower than F03.07 running time and

greater than F3.08. Tip into the weak illumination.

F03.09 Wake up detaction time: The controller jugdes voltage every F03.09. Start the

controller when voltage is higher than the last time and the enter the weak light bus voltage

F3.10. Forced to restart the controller when detection time unable to achieve voltage

condition cumulative time F3.11.

F3.14 Water shortage detection time: When applied to deep-well pump and do not use

water level detection probe to detect water shortage, water detection can be done via the

water detection function of built-in controller. When the Tens change into 1, the function of

alarm is valid.

The working principle of software water shortage detection: When the current detection

level lower than F03.13% and last the time of F03.14, E.LL water shortage underload fault

will appear. This failure can be run automatically after F03.15 delay.

If no shortage of water, the E.LL failure occurs, it may be false positives, just reduces the

value of F03.13.

F07.00 User's password: the user can set the 5-digit password, when the setup is

completed and confirmed, the password will be valid for one minute.

-4 5-

Page 47

Chapter6 Function Parameter Table

Warning:

Do not touch any part inside the SP200 PV Pump controller when power on.If you want to use

the controller in other areas, please disconnect all the power supply, and wait for 5 minutes

before operate.In general, for the selection of SP200 PV pump controller, the controller and the

pump power can be matched.However, controller Please enlarge a document if you are driving

a submersible pump.It's uneccessary to enlarge while driving a ground pump. Install output

reactors if the wiring length is greater than 100 meters.

For example, for a 50-meter deep water well, the 4KW motor matches a 5.5KW controller.

SP200 Manual

-4 6-

Page 48

Chapter 7

Troubleshooting

SP200 PV pump controller attempts to drive water pumps to lift water even in severe

weather conditions. In order to ensure reliable service life, it must to be protected all

system components stay away from some factors that could damage the device. When

there is a bad situation, if necessary, the controller will reduce the output, continue to water

delivery as much as possible, and close in extreme cases. Once the severe situation is

slowed down, the controller will automatically try to resume operation.

SP200 PV pump controller possess 20 alarm information and protection functions, once

occur abnormal,protective function, controller stop output and fault relay contact, display

fault codes on the controller display panel. Using the information given in this chapter, most

alarm and fault cause can be identified and corrected. If not, contact with our company.

-4 7-

Page 49

Chapter7 Troubleshooting

7.1 Fault Instruction and Solution

SP200 Manual

Code Cause

E.out 1

1

E.out 2

2

E.out 3

3

E.oc 1

4

5

E.oc 2

6 E.oc 3

7

E.ou 1

8 E.ou 2

9 E.ou 3

E.LU

10

E. ol 1

11

FaultNo.

IGBT U phase

protection

IGBT V phase

protection

IGBT W phase

protection

Accelerating

overcurrent

Accelerating

overcurrent

Accelerating

overcurrent

Accelerating

overvoltage

Decelerating

overvoltage

Constant

overvoltage

Bus under-

voltage fault

Motor overload

The acceleration is too fast .

♦

♦ There is damage to the intern-

al to IGBT of the phase.

♦ The connection of the driving

wires and the grounding is

not good.

The acceleration or deceleration

♦

is too fast.

♦ The voltage of the grid is too low.

♦ The power of the controller is too

low.

♦ The load transient or abnormal.

♦ The grounding is short circuited

or the output is phase loss.

♦ There is strong external

interference.

♦

The input voltage is abnormal.

♦ There is large energy feedback.

♦

The voltage of the power supply

is too low.

The voltage of the power supply

♦

is too low.

Solution

Increase Acc time.

♦

♦ Change the power unit.

♦ Check the driving wires.

♦ Check if there is strong

interference to the

external equipment

Increase the Acc time.

♦

♦ Check the input power.

♦ Select the controller with a

large power.

♦ Check if the load is short

circuited(the grounding

short circuited) or the

rotation is not smooth.

♦ Check the output configur ation.

♦ Check if there is strong

interference.

Check the input power.

♦

♦ Check if the DEC time of

the load is too short or the

controller starts during the

rotation of the motor or it

needs to increase the

energy consumption com ponents.

♦

Check the input power of

the supply line.

Check the input power of

♦

the supply line.

Increase the Acc time.

♦

The acceleration is too fast.

♦

E. ol 2

12

13

E.SPI

E.SPO

14

E,OH1

15

Invertor

overload

Input

phase loss

Output

phase loss

Rectifying

module

overheated

♦ Reset the rotating motor.

♦The voltage of the power supply

is too low.

♦ The load is too heavy.

♦

Phase loss or fluctuation of input

R,S,T.

U,V,W phase loss input

♦

(or serious asymmetrical three

phase of the load)

♦ Air duct jam or fan damage.

♦ Avoid the restarting after

stopping.

♦ Check the power of the

supply line,

♦ Select an controller with

bigger power,

♦ Select a proper motor.

♦ Check input power

♦ Check input power

♦ Check input power

-4 8-

Page 50

SP200 Manual

Chapter7 Troubleshooting

Code Cause

E,OH2

16

E.EF

17

18

E.CF

19

E.LCE

E.TUE

20

19

E.LCE

E.TUE

20

E.EEP

21

E.PID

22

23

E.BRE

E.End

24

FaultNo.

IGBT

overheated

External fault

485

communication

fault

Current-

detecting fault

Motor-

autotuning

fault

Current-

detecting fault

Motor-

autotuning fault

EEPROM

operation fault

PID feedback

outline fault

Braking

circuit fault

Running

time arrival

♦

Ambient temperature is too high.

♦ The time of overload running is

too long

♦

SI external fault input terminals

action.

The baud rate setting is incorrect.

♦

♦ Fault occurs to the communica tion wiring.

♦ The communication address is

wrong.

♦ There is strong interference to

the communication.

♦

The connection of the control

board is not good.

♦ Hoare components is broken

♦ The modifying circuit is abnormal.

The motor capacity does not com-

♦

ply with the controller capability.

♦ The rated parameter of the motor

does not set correctly.

♦ The offset between the paramet-

ers from autotune and the stand ard parameter is huge.

♦Autotune overtime.

The connection of the control

♦

board is not good.

♦ Hoare components is broken

♦ The modifying circuit is abnormal.

The motor capacity does not co-

♦

mply with the controller capability.

♦ The rated parameter of the motor

does not set correctly.

♦ The offset between the paramet-

ers from autotune and the stand ard parameter is huge.

♦ Autotune overtime.

Error of controlling the write and

♦

read of the parameters.

♦ Damage to EEPROM.

♦

PID feedback offline.

♦ PID feedback source disappear.

Braking circuit fault or damage to

♦

the braking popes.

♦ The external braking resistor is

not sufficient.

♦

The actual running time of the AC

drive is above the internal setting

running time.

Solution

♦ Check input power

♦ Check input power

♦

Set proper baud rate.

♦ Check the communication

connection distribution.

♦ Set proper communication

address.

♦ Change or replace the

connection distribution or

improve the anti-interfere nce capability.

♦

Check the connector and

repatch.

♦ Change the hoare.

♦ Change the main panel.

Check the connector and

♦

repatch.

♦ Change the hoare.

♦ Change the main panel.

Check the connector and

♦

repatch.

♦ Change the hoare.

♦ Change the main panel.

♦ Change the controller

mode.

♦ Set the rated parameter

according to the motor

name plate.

♦ Empty the motor load and

reindentify.

♦ Check the motor connec tion and set the parameter.

Press STOP/RESET to

♦

reset.

♦ Change the main control

panel.

Check the PID feedback

♦

signal.

♦ Check the PID feedback

source.

Check the braking unit and

♦

change new braking pipe.

♦ Increase the braking

resistor.

♦

Ask for the supplier and

adjust the setting running

time.

-4 9-

Page 51

Chapter7 Troubleshooting

SP200 Manual

Code Cause

25 E.oL3

26

E.PCE

E.UPE

27

28

E.DnE

29

E.ErH1

30

E.ErH2

E.dEu

31

32

E.STo

33 E.Esd1

FaultNo.

Electronic

overload fault

Keypad

communication

fault

Parameters

uploading fault

Parameters

downloading

fault

Grounding

shortcut fault 1

Grounding

shortcut fault 2

Speed

deviation fault

Maladjustment

fault

Encoder

disconnect fault

The controller will report the over-

♦