Sinovo SD300-4T-0.7G, SD300-2T-1.5G, SD300-2T-2.2G, SD300-4T-1.5G, SD300-4T-2.2G User Manual

...

SD300 D rive Us e Manua l (Ver sion: 2 .4)

Open/Close Vector Control Inverter

SD

003

AC DRIVE

User Manual

SHENZHEN SINOVO ELECTRIC TECHNOLOGY CO.,LTD

Add :

5th F loor, No . D Build ing, Hu afeng I ntern ation al Robo t

Ind ustry P ark, Xi xiang S treet ,Hang cheng R oad, Ba oan

Dis trict , Shenz hen Cit y

Tel 075 5 29 78487 0

: ( )

Fax : (0755 )2978 4969

Tech su ppor: 4 00-88 1-868 9

htt p://w ww.sin ovo-v fd.co m

Version: 2.4

SD300 User Manual

Preface

Preface

Thank y ou for pu rchas ing the S D300 se ries AC d rive developed b y Our com pany.

SD300 s eries A C drive is a gen eral- purpo se high -perf orman ce vect or cont rol AC

drive , and it i s mai nly u sed f or co ntrol ling and r egula ting the s peed and t orque of t he

three -phas e AC as ynchr onous motor . It is a ne w ge nerat ion of AC Dri ve with la test

techn ology . SD 300 serie s is c harac teriz ed i n the high- perfo rmanc e current v ector

contr ol tec hnolo gy, hi gh tor que ou tput at lo w freq uency and st rong ove rload capac ity.

It po ssess go od stabili ty, dyna mic perf orman ce, commun icati on bus functi ons, ric h

power ful and stable perf ormance, and suppor ts for multi -PG car ds, wit h per fect an ti-

tripp ing con trol and the abil ity to adapt to bad powe r grid. It i s used to driv e var ious

autom atic pr oduct ion equip ments involv ing the indust ry of tex tile, paperm aking , wire

drawi ng, mac hine to ols, pa ckagi ng, food, fans and pumps an d so on.

SD300 Series AC drive Features

Multiple Control Modes:

ªSuppo rts mul tiple c ontro l modes : vecto r V/F con trol, s ensor less vector speed c ontro l,

senso rless v ector t orque c ontro l, sens or vect or spee d contr ol and sensor vecto r torqu e

contr ol .

Advanced Vector Control Algorithm:

ªThe op timiz ed VF c ontro l and s ensor less v ector contr ol is m ore st able a t low s peed,

more powerf ul in the abilit y of low fr equen cy tor que ou tput and with bett er dyn amic

respo nse and both the sens orles s vecto r an d se nsor v ector m ode suppo rt s peed

contr ol and to rque co ntrol .

Small and Compact Volume:

ªIn t he f ull power ran ge, the sam e po wer type c ompar ed to the old produ cts EH600 , it

reduc es th e vol ume of 20%~40 %. As the volume is red uced, the optimize d the rmal

desig n ensur es the favor able te mpera ture ri se of t he whol e AC driv e.

The op timiz ed VF cont rol an d sens orles s ve ctor contro l is more stable at low spe ed,

more powerf ul in the abi lity of low freque ncy to rque output and wit h bett er dyn amic

respo nse and bot h the senso rless v ector a nd s ensor v ector mod e suppo rt spee d co ntrol

and tor que con trol.

Unpacking Inspection Cautions

Every AC Drive hav e been te sted strictly in facto ry pri or to shipm ent. U pon unpa cking ,

check :

Preface

SD300 User Manual

ªWheth er the pr oduct i s damag ed;

ªWheth er the na mepla te of mod el and AC d rive ra tings are consis tent wi th your o rder.

ªWheth er the box contai ns the AC drive , ce rtifi cate of confo rmity , us er manu al and

warra nty car d. If you f ind any o mission or damag e, cont act Our c ompan y or your s uppli er

immed iatel y.

First-time Use

For the use rs who us e th is prod uct for t he f irst ti me, rea d the manua l caref ully. I f in d oubt

conce rning some f uncti ons or perfo rmanc es, contact the techn ical s uppor t pers onnel of

Our com pany to e nsure c orrec t use.

SD300 series AC drives have passed CE test and also meet the requirements of following International Standard.

ªIEC/E N 6180 0-5-1 :2003 S afety r equir ement s for a djust able speed elec tric d rive

syste ms.

ªIEC/E N 61800 -3:20 04 adju stabl e speed elec tric dr ive sys tems: (The third par)th e

elect romag netic c ompat ibili ty stan dard of the produc t and its s pecif ic test m ethod .

ªIE C/EN 61 000-2-1 ,2 -2 ,3-2,3- 3, 4- 2, 4-3,4 -4 ,4 -5 ,4-6: EM C Int er na ti onal an d E U

Stand ards.

The i nstru ction s are s ubjec t to chan ge, w ithou t notic e, d ue to produc t u pgrad e,

speci ficat ion modif icati on as well as e ffort s to i ncrea se the accu racy an d conve nienc e of

the man ual.

-2-

SD300 User Manual

Contents

Contents

Preface.......................................................................................................................................01

Contents....................................................................................................................................03

Chapter 1 Safety and Cautions.........................................................................................07

1.1 Safet y an d Ca ution s De finit ion

1.2 Sa fety C autio ns

1.3 Cauti ons

..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..08

..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..10

Chapter 2 Product Information.........................................................................................15

2.1 Chapter of Thi s Conte nt... ..... ..... ..... ..... ..... ..... ..... ..... ..... . .... ..... ..... .

2.2 Ba sic P rinci ple.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .....

2.3 Na ming Rule s.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .....

2.4 N amepl ate.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .

2.5 SD300 Ser ies of A C drive ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .

2.6 Techn ical Sp ecifi catio ns... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .....

2.7 St ructu re Di agram ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..

2.8 Pe ripheral El ectri cal Compo nents Sys tem Struc ture. ..... ..... ..... ..... ...

2.9 SD300 O ption al Part s.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ....

2.10 Conn ectio n M ethod s.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...

..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .07

. 15

15

17

17

18

19

22

27

30

33

Chapter 3 Mechanical and Electrical Installation........................................................35

3.1 Chapter of Thi s Conte nt... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..35

3.2 Me chani cal I nstal latio n.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .36

3.3 Stand ard Wir ing.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ....4 1

3.4 La yout Prote ction ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...51

Chapter 4 Operation, Display and Application Examples.........................................53

4.1 Chapter of thi s Conte nt... ..... ..... ..... ..... ..... ... ..... ..... ..... ..... ..53

4.2 In trodu ction of the Keyp ad... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...54

4.3 Disp lay of K eypad ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...56

4.4 Ke ypad Oper ation ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...57

..... ..... ...

Chapter 5 Function Parameter Table..............................................................................59

5.1 Chapter of thi s Conte nt... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...59

5.2 Fun ction Param eter T able. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... 60

-3-

Contents

SD300 User Manual

Chapter 6 Parameter Description.....................................................................................93

Group F00 : Ba sic Fun ction Gro up... ..... ..... ..... ..... .... ..... ..... ..... ..... ..... ...94

Group F01 : St art-s top Con trol Grou p.... ..... ..... ..... ..... ..... ..... ..... ..... ..... 101

Group F02: Motor 1 Pa ramet er Gro up... ..... ..... ..... ..... ..... ..... ..... ..... ..... .107

Group F0 3: Vecto r Cont rol Grou p.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .111

Group F0 4: V/Fco ntrol Gr oup.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ....1 15

Group F0 5: Input Termi nal Grou p.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .121

Group F06 : Outp ut T ermin al G roup. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..129

Group F 07: HMI Gro up... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...13 5

Group F08: Stre ngthe n th e Fu nctio nal Gr oups. ..... ..... ..... ..... ..... ..... ..... .141

Group F 09: PID Con trol Gr oup.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ...14 8

Group F0A:W obble , Le ngth, Count and Timin g Pa ramet er Gro up... ..... ..159

Group F0B: Simp le PLC and Multi -spee d Co ntrol Group ..... ..... ..... ..... ...16 2

Group F0C : Pr otect ion Par amete r Gr oup.. ..... ..... ..... ..... ..... ..... ..... ..... ...16 6

Group F0D : Mo tor 2 Pa ramet er G roup. ..... ..... ..... ..... ..... ..... ..... ..... ..... ...17 1

Group F0E: Serial Co mmuni catio n Func tion G roup. ..... ..... ..... ..... ..... ....1 76

A00: Torq ue C ontrol and Limi t Fu nctio nal Group ..... ..... ..... ..... ..... ..... ....1 78

A01: A 1 Cu rve Setti ng F unction Gro up... ..... ..... ..... ..... ..... ..... ..... ..... ..... 182

A02: S tatus Ch eck Fu nctio n Grou p.... ..... ..... ..... ..... ..... ..... ..... ..... ..... ....1 84

A03 : DP Par a met e r G rou p ... . ... . .. . ... . ... . ... . ... . .. . ... . ... . ... . ... . ... . .. . 185

..

Chapter 7 EMC.....................................................................................................................197

7.1 Definition o f Relat ed Term s.... ..... ..... ..... ..... ..... ..... ..... ..... .. .. ..... ...19 8

7.2 EMC Stand ard Intro ducti on... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... 198

7.3 Selec tion of Per ipher al EMC Devi ces.. ..... ..... ..... ..... ..... ..... ..... ..... ..199

7.4 Shi elded Cable ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... 203

7.5 Req uirement for Lea kage Cu rrent ..... ..... ..... ..... ..... ..... ..... ..... ..... ....2 05

7.6 Sol ution s to Common E MC Inte rfere nce Pro blems . ..... ..... ..... ..... ...20 6

..

Chapter 8 Troubleshooting and Maintenance...........................................................207

8.1 Daily R epair a nd Mainte nance ... ..... . ..... ..... .208

8.2 War ranty Ag reeme nt... ..... ..... ..... ..... ..... ..... ................................. .209

8.3 Cont ents o f Th is Cha pter. ..... ..... ..... ............................ ..... ..... ..... ..209

8.4 Ala rm and Fault In ducti ons.. ..... ..... ..... ................................. ..... ...21 0

8.5 Fault Res et... ..... ..... ..... ..... ................................. ..... ..... ..... ..... ..... 210

8.6 Fault Hi story ..... ..... ..... ..... ..... ..... ..... ..... ................................. ..... .210

8.7 Fault I nstru ction a nd Solution... ............................ ..... ..... ..... ..... ....2 10

8.8 Comm on F ault A nalys is... ..... ..... ..... ..... ..... ..... ..... ..... ....................215

..... ..... ..... ..... ..... ..... .. ..

-4-

SD300 User Manual

Contents

Chapter 9 Communication Protocol.............................................................................221

9.1 Netw orkin g Mode ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... .221

9.2 In terfa ce Mo de... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..222

9.3 Pr otoco l Frame For mat.. ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..222

9.4 Funct ion Pro tocol ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..223

9.5 Co mmuni catio n Param eters Add ress. ..... ..... ..... ..... ..... ..... ..... ..... ...22 6

..... .

-5-

Chapter 1

Safety and Cautions

1.1 Safety and Cautions Definition

Read this man ual care fully so that you hav e a thor ough und ersta nding . Installa tion,

commi ssion ing or m ainte nance ma y b e p erfor med in conj uncti on with this cha pter. Ou r

compa ny w ill ass ume no abil ity and r espon sibil ity for any i njury or los s ca used by

impro per ope ratio n.

Danger

Opera tions whi ch are not perfor med compl y with the requ ireme nts may cause sev ere

hurt or e ven dea th.

Note

Opera tions w hich are not perf ormed comply with requ ireme nts may caus e perso nal

injur y or prop erty da mage.

-7-

Chapter 1 Safety and Cautions

1.2 Safety Cautions

SD300 User Manual

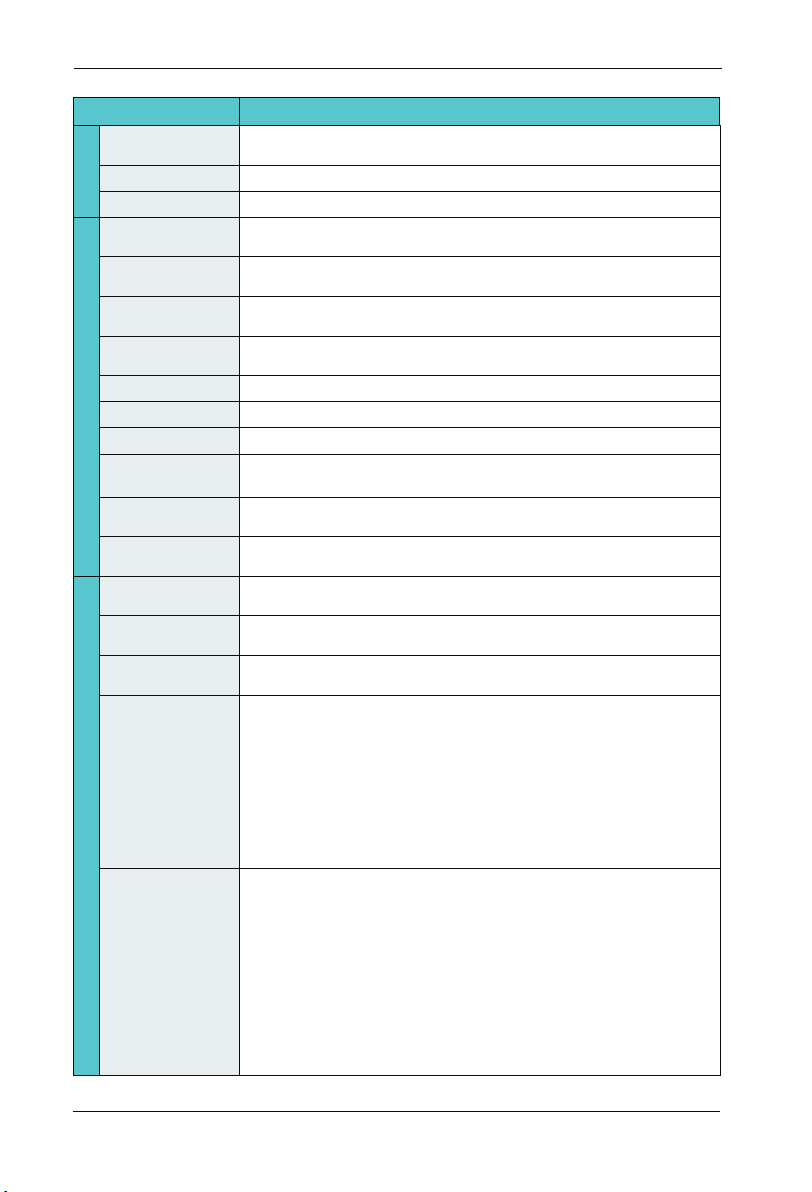

Use Stage Safety Grade

Danger

Befor e

Insta llati on

Danger

Danger

Durin g

Insta llati on

Note

At wiri ng

Danger

Precautions

Do not in stall t he equi pment i f you fin d water seepage,

ª

compo nent mi ssing o r damag e upon unpacking.

Do not in stall t he equi pment i f the pac king list does not

ª

confo rm to the p roduc t you rec eived .

Handl e the equ ipmen t with ca re duri ng transportat ion

ª

to prev ent dam age to th e equip ment.

Do not us e the equ ipmen t if any co mpone nt is damaged

ª

or miss ing. Fa ilure t o compl y will re sult in personal

injur y.

Do not to uch the c ompon ents wi th your h ands. F ailure

ª

to comp ly will r esult i n stati c elect ricit y damage.

Insta ll the eq uipme nt on inc ombus tible objects such as

ª

metal , and kee p it away f rom com busti ble mat erials.

Failu res to co mply ma y resul t in a fire .

Do not lo osen th e fixed s crews o f the com ponen ts,

ª

espec ially t he scre ws with e red mar ks.

Do not dr op wire e nd or scr ew into t he AC dri ve. Fai lure

ª

it will r esult i n damag e to the AC d rive.

Insta ll the AC d rive in p laces f ree of vi brati on and direct

ª

sunli ght.

When tw o AC driv es are la id in the s ame cab inet

ª

,arra nge the i nstal latio n posit ions properly to ensure

the coo ling ef fect.

A circu it brea ker mus t be used t o isola te the po wer

ª

suppl y and the A C drive . Failu re to com ply may r esult a

fire.

Ensur e that th e power s upply i s cut off b efore w iring .

ª

Failu re to com ply may r esult i n elect ric sho ck.

Never c onnec t the pow er cabl es to the o utput

ª

termi nals( U,V,W ) of the AC d rive. P ay atte ntion t o the

marks o f the wir ing ter minal s and ens ure correct

wirin g. Fail ure to co mply ma y resul t in damage to the

AC driv e.

Ensur e that th e main ca ble lin e compl y with th e

ª

stand ard, th e line me ets the E MC requ ireme nts and

the are a safet y stand ard. Fa ilure t o compl y may res ult

in risk o r accid ent.

Never c onnec t the pow er cabl es the br aking resistor

ª

betwe en the DC b us term inals P +, P-. Fa ilure t o

compl y may res ult in a fi re.

-8-

SD300 User Manual

Chapter 1 Safety and Cautions

Use Stage Safety Grade

At wiri ng

Befor e

Power -on

After

Power -on

Danger

Danger

Danger

Danger

Durin g

Opera tion

Danger

Precautions

Use a shi elded c able fo r the enc oder, and ensure that

ª

the shi eldin g layer i s relia bly grounded.

Pleas e confi rm the pe riphe ral equ ipment and cable

ª

conve rter is c onfig ured in t his man ual of th e

recom mende d model , all the c onfig uration line in

accor dance w ith the c onnec tion me thod of the manual

provi des the c orrec t wirin g. Fail ure to co mply will result

in acci dents .

Check t hat the v oltag e class o f the pow er supp ly is

ª

consi stent w ith the r ated vo ltage c lass of t he AC dri ve.

Do not op en the AC d rive’ s cover a fter po wer-o n.

ª

Failu re to com ply may r esult i n elect ric sho ck.

Do not to uch the o perat ion of AC d rive du ring th e

ª

hands i s wet. Fa ilure t o compl y will re sult in a ccident.

Do not to uch any I /O term inal of t he AC dri ve. Fai lure

ª

to comp ly may re sult in e lectr ic shoc k.

Do not ch ange th e defau lt sett ings of t he AC dri ve.

ª

Failu re to com ply wil l resul t in dama ge to the AC drive.

Do not to uch the r otati ng part o f the mot or duri ng the

ª

motor a uto-t uning o r runni ng. Fai lure to c omply will

resul t in acci dent.

Signa l detec tion mu st be per forme d only by q ualified

ª

perso nnel du ring op erati on. Fai lure to comply wil l

resul t in pers onal in jury or d amage t o the AC drive.

Do not to uch the f an or the d ischa rging r esist or to

ª

check t he temp eratu re. Fai lure to c omply w ill result in

perso nal bur nt.

Avoid o bject s falli ng into t he AC dri ve when it is

ª

runni ng. Fai lure to c omply w ill res ult in damage to the

AC driv e.

Do not st art or st op the AC d rive by t urnin g the

ª

conta ctor ON /OFF. F ailur e to comp ly will r esult i n

damag e to the AC d rive.

After

Power -on

Danger

Do not re pair or m ainta in the AC d rive at p ower-on.

ª

Failu re to com ply wil l resul t in elec tric shock.

Ensur e that th e AC driv e is disc onnec ted fro m all

ª

power s uppli ers bef ore sta ring re pair or maintena nce

on the AC d rive.

Repai r or main tenan ce of the A C drive m ay be

ª

perfo rmed on ly by qua lifie d perso nnel. Failure to

compl y will re sult in p erson al injury or damage to the

AC driv e.

-9-

Chapter 1 Safety and Cautions

SD300 User Manual

Use Stage Safety Grade

After

Power -on

Danger

Set and c heck th e param eters a gain af ter the A C drive

ª

is repl aced.

Precautions

1.3 Cautions

1.3.1 Requirement on Residual Current Device(RCD)

The AC dr ive gene rates high lea kage c urren t d uring runni ng, whic h flow s earthi ng (PE )

condu ctor. Th us insta ll a t ype-B RC D a t t he trans ient and st eady- state le akage cu rrent

to gro und that may b e ge nerat ed at star tup and du ring runn ing of the AC dri ve. You ca n

selec t a sp ecial ized RC D with th e funct ion of su ppressing high harmon ics or ge neral -

purpo se RCD wi th rela tivel y large r esidual curren t.

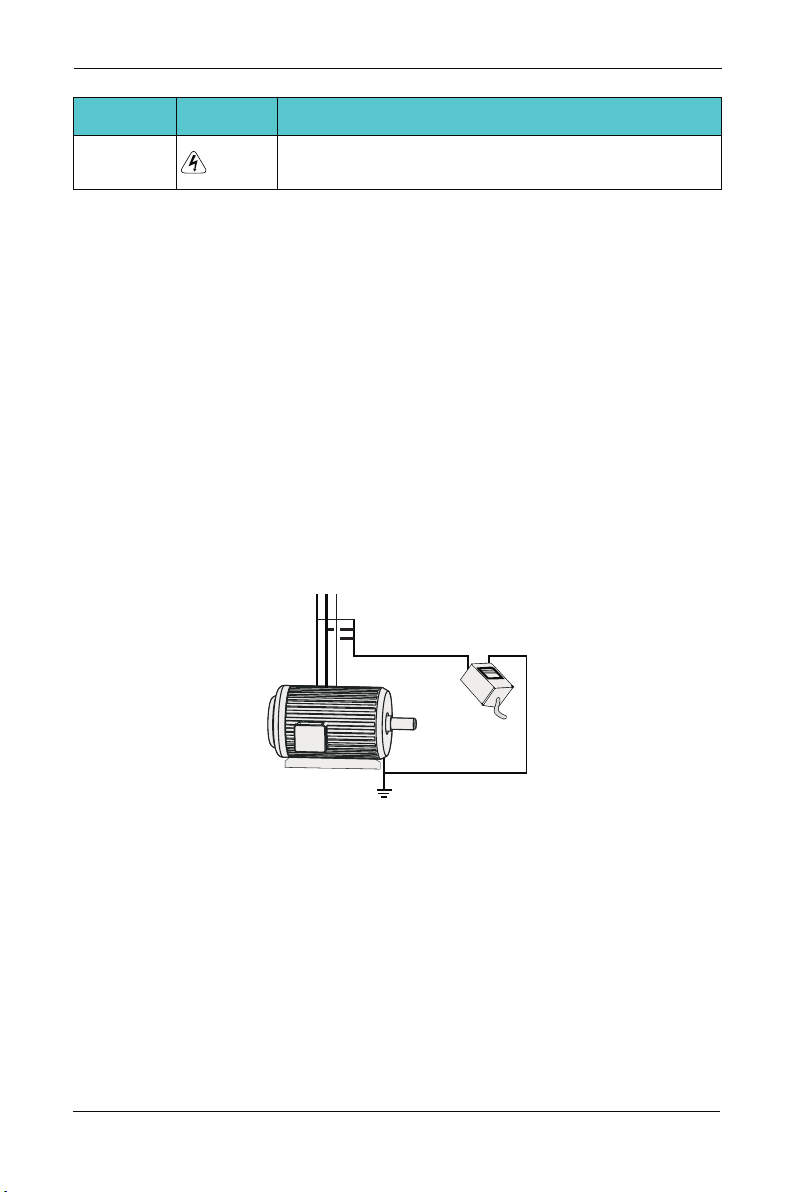

1.3.2 Motor Insulation Test

Perfo rm the insul ation test when the mo tor is used for t he fir st tim e, o r when it is reused

after be ing stor ed for a lo ng time, or in a reg ular che ck-up , i n o rder to pre vent the po or

insul ation of mo tor windi ngs fro m damag ing the AC driv e durin g the insul ation test. A

500-V meg a-Ohm m eter is rec ommen ded for t he t est. Th e insul ation res istan ce must not

be less t han 5 MΩ.

UVW

Input termina ls of the motor

Megger

Ground

1.3.3 Thermal Protection of Motort

If t he s elect ed A C drive doe s no t ma tch the rat ed c apaci ty o f the motor , espec ially w hen

the rated p ower of t he AC drive i s highe r than that o f the mot or, adjus t the par amete rs for

motor p rotec tion in t he AC dri ve or to in stall t hermal relay to protect the moto r .

1.3.4 Running Below and Above Rated Frequency

The AC dri ve pr ovide s fre quenc y out put of 0 to 600.00 Hz. When the us ers use the

frequ ency in verte r for a long ti me, ple ase pay attent ion to th e motor coolin g or use of

varia ble fre quenc y mot or. If the A C drive is req uired to r un at o ver 50H z, co nside r the

capac ity of th e machi ne.

-10-

SD300 User Manual

Chapter 1 Safety and Cautions

1.3.5 Vibration of mechanical device

The AC dr ive may e ncoun ter the m echan ical resonance p oint at s ome out put fre quenc ies,

which c an be avo ided by s ettin g the ski p frequency. If the operating fr equen cy of the c us-

tomer c oinci de with t he reso nant fr equency please modify t he oper ating f reque ncy or

chang e the inh erent r esona nce fre quency of the mechanica l syste m.

1.3.6 Motor heat and noise

The ou tput of the AC dri ve i s puls e wi dth modulat ion (PWM) wav e with cer tain harm onic

frequ encie s, and there fore, the motor t emper ature , noi se, and vibr ation are sligh tly

great er than t hose wh en the AC d rive ru ns at pow er frequency (50 Hz).

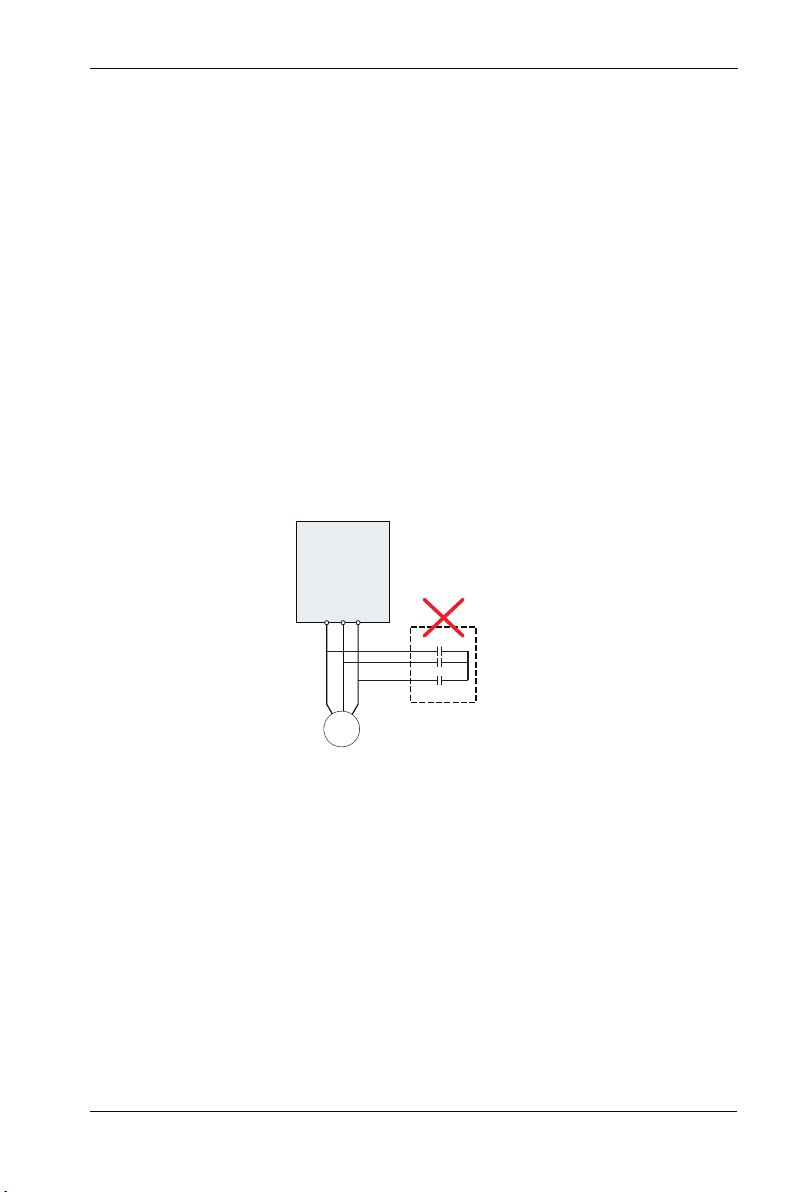

1.3.7 Voltage-sensitive device or capacitor on output side of the AC drive

Do not in stall t he capa citor f or impr oving p ower factor or lig htnin g prote ction v oltag esen-

sitiv e resis tor on th e outpu t side of the AC dri ve beca use the outp ut of the AC drive is

PWM w ave. Ot herwi se, t he AC d rive ma y suffe r trans ient ov ercur rent or even

bedam aged.

AC Driver

W

U V

Capacitor or

M

voltage-sensitive resi stor

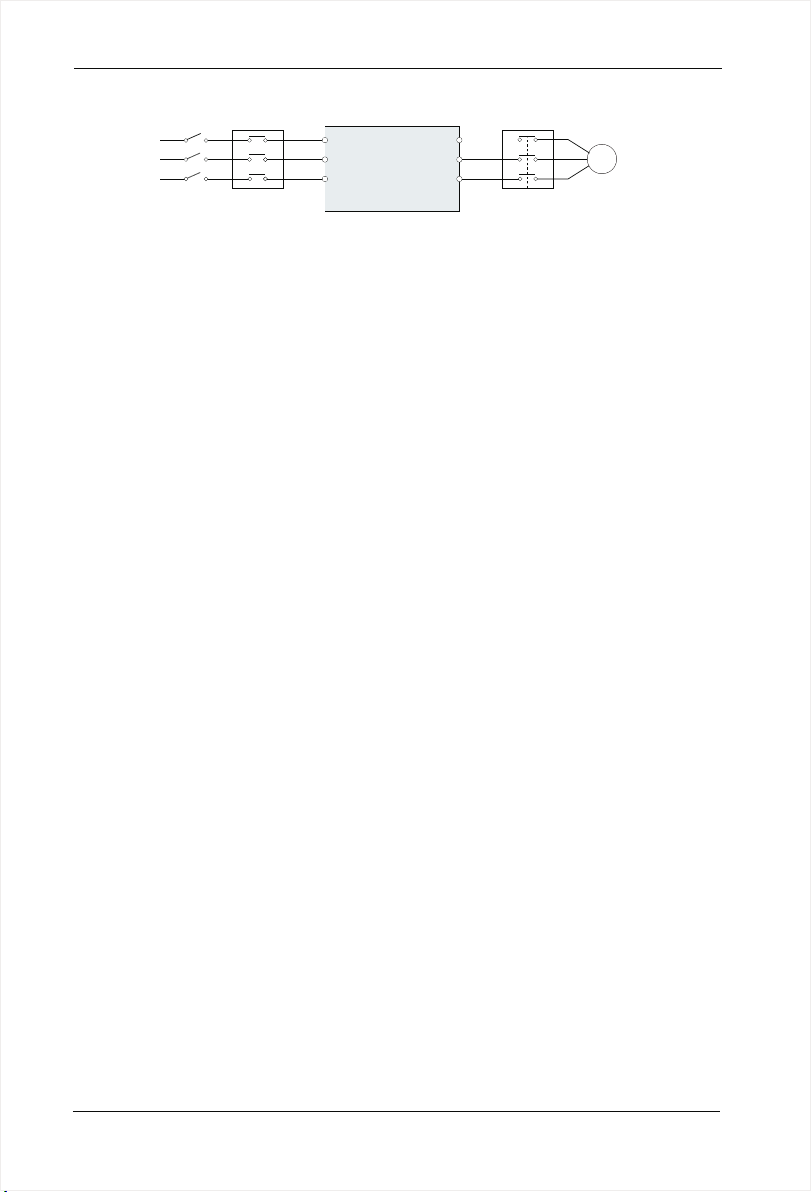

1.3.8 Contactor at the I/O terminal of the AC drive

When a co ntact or is ins talle d betw een the input side of th e AC driv e and the power

suppl y, the AC driv e must not be star ted or sto pped by sw itchi ng t he c ontac tor on or off.

If the AC d rive ha s to b e opera ted by th e conta ctor, e nsure t hat the t ime int erval b etwee n

switc hing is at le ast one ho ur since freq uent charg e and di schar ge wi ll short en th e

servi ce life o f the cap acito r insid e the AC dr ive.

When a co ntact or is ins talle d b etwee n the out put si de of the AC drive and the m otor, do

not tu rn o ff t he c ontac tor wh en t he A C dr ive is act ive. Othe rwise , mo dules insid e th e AC

drive m ay be dam aged.

-11-

Chapter 1 Safety and Cautions

SD300 User Manual

Contactor KM

380Vac

50/60Hz

Do n ot start/stop the AC drive by

switching the contactor on/off. If

the AC drive has to be operated

by the contact or, ensure that the

tiome interval is at least one hour.

R

S

AC Driver

T

Cont actor KM or

offer switche s

U

V

W

Turn on / off the contactor when

the A C d rive h as no ou tput.

Other wise,m odifies inside the AC

drive ma y be damaged.

M

1.3.9 The Use Occasion of the External Voltage Out of Rated Voltage Rage

The AC drive must not be used outsi de the all owabl e volt age ra nge sp ecifi ed in this

manua l. Other wise, th e AC driv e’s comp onent s may be dam aged. If re quire d, use a

corre spond ing vol tage st ep[-u p or step -down device.

1.3.10 The Above Derating of the Default

Diffe rent pow er gra de frequency i nvert er has it s defa ult ca rrier fr equen cy, whe n to ru n

at a high er carr ier fre quenc y, the AC D rive mu st to red uce the amount when runni ng.

1.3.11 Change Three Phase Input into Two Phase Input

It is no t allo wed to chang e the three pha se AC d rive i nto tw o phas e o ne . Ot herwi se , it

may cau se it may c ause fa ult or da mage th e AC driv e.

1.3.12 The Protection of the Lighting Impulse

Although t he AC d riv e has equipped wi th li ghtning overv olt age, overcurr ent device, whi ch

has a certain pro tec tion function f or th e induction lig hti ning. For the lightn ing prone areas ,

the user is neces sar y to in stall ligh tni ng protection d evi ce at the front of the AC drive ,

which will bene fit to the service lif e of th e tra nsducer.

1.3.13 Ambient Temperature and De-rating

Th e normal us e of th e frequency i nv er te r ambient t em pe ra tu re is -1 0℃ ~4 0℃ .

Te mp er at ur e exc ee ds 40 ℃, the equipment need to red uc e the am ou nt of use. The

am bi en t te mp er at ur e of ea ch inc re as e is reduced by 1.5 %, the maximum use of the

am bi en t te mp er at ur e is 5 0℃ .

1.3.14 Altitude and Derating

In p la ce s where the a lt it ud e is a bo ve 1000m and th e co ol in g effect reduces du e to t hi n

ai ri t is necessary to d e- ra te t he A C drive. Contact Ou r co mp an y for technical s up po rt .

1.3.15 Some Special Usages

If w ri ti ng that is no t de sc ri be d in this manual, s uc h as common DC bu s is a pp li ed , cont-

ac t th e agent or Ou r co mp an y fo r technical support.

-12-

SD300 User Manual

Chapter 1 Safety and Cautions

1.3.16 The Cautious of the AC drive Disposal

The electr olytic capaci tors on the main circu its and PCB may exp lor e when they are bur nt.

Poisonou s gas is generate d whe n the plasti c par ts ar e burn. Trea t the m as or dinary ind u-

strial ref er to r elevant na tio nal laws and regu lations.

1.3.17 Adaptable Motor

1. The stan dard par ameters of the adaptable motor is ada pta ble four -squirre l-cage

asynchro nous in duction motor or PMSM . For other t ype s of motor, select a pro per AC

drive acco rding to the rate d mot or cu rrent.

2. The cooling fan and rot or shaft of gene ral AC Drive are coaxial , which results in

reduced cooling e ffect w hen the ro tational speed decl ines. I f variabl e speed is

required , add a more powerf ul fa n or re place.

3. The standard par ameters of the adapt able motor have been con figured insi de t he A C

drive. It is st ill n ecessary to perfor m mot or au to-tunin g or modif y the defa ult valu es

based o n act ual condit ions. Othe rwi se, the runn ing result a nd protect ion p erforman ce

will be affe cte d.

4. The AC dr ive may ala rm or even be damaged whe n s hort-cir cuit exists on cables or

inside the m otor. Therefor e, per form i nsulation short-c ircuit test when t he mot or and

cables ar e newl y in stalled o r during r outine ma intenanc e. During the test, make sure

that the AC drive i s dis connecte d fro m the tested part s.

-13-

Chapter 2

Product Information

2.1 Chapter of This Content

This ch apter b riefl y intro duces t he operation principl e, prod uct fea tures , layou t, name pl-

ate, an d type of i nstru ction .

2.2 Basic Principle

SD300 i s a kind of A C drive u sed to co ntrol a synch ronous AC induct ion mot or.

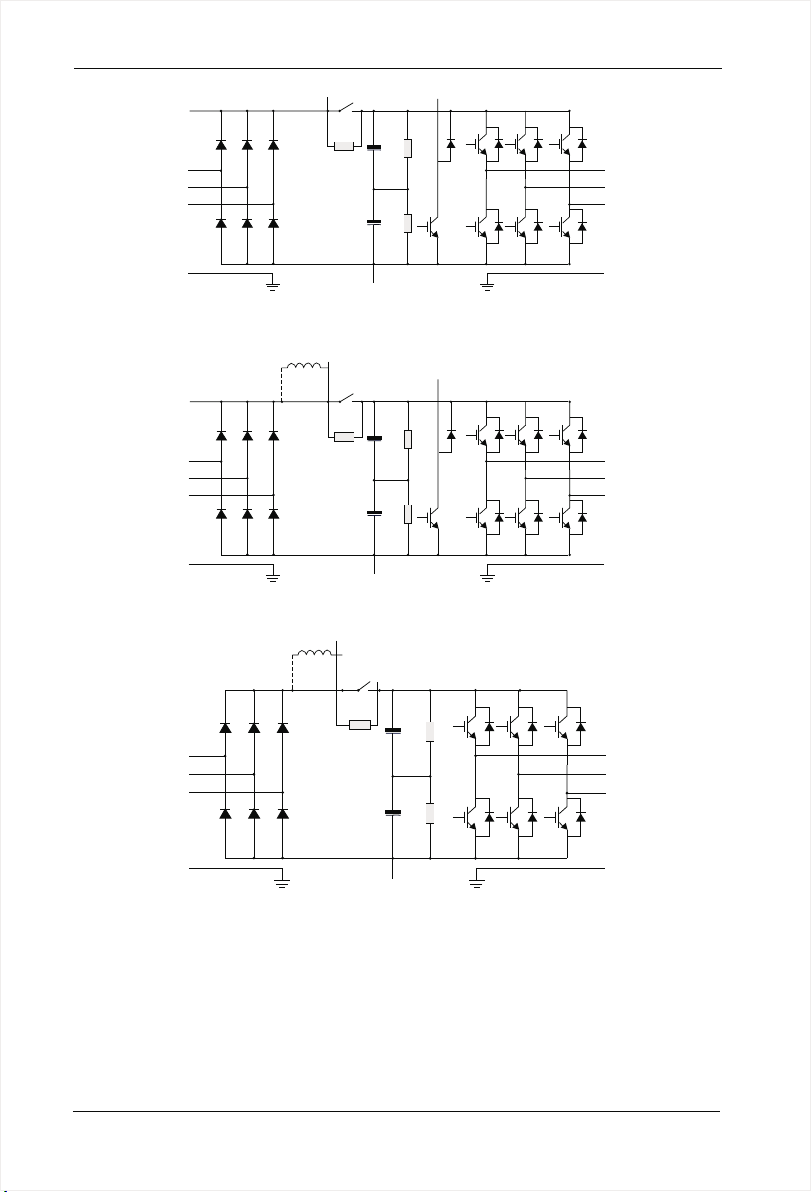

The follo wing figu re s hows the AC drive mai n circuit d iagra m. R ectif ie m ake three -phas e

AC voltage i nto DC v oltag e. Capacitor grou ps of inte rmedi ate c ircui t sta biliz e the DC

volta ge .Th e AC dr ive converts o f the D C volt age to AC vol tage f or AC m otor u se. Wh en

the vol tage in the ci rcuit exceed s the m aximu m limit , the brakin g pipe wi ll co nnect an

exter nal bra king re sisto r to the in terme diate DC circuit to consu me the fe edbac k energ y.

-15-

Chapter 2 Product Information

SD300 User Manual

R

S

T

PE

P+

P-

PB

PE

Figur e 2-1 M ain Cir cui t Diagram( l ess t han 18. 5 kw (i ncluding ))

DC react or

R

S

T

PE

P+

P

P-

PB

PE

Figur e 2-2 M ain Cir cui t Diagram (2 2kw ~30kw )

DC reactor

P+

U

V

W

U

V

W

P

R

S

T

PE

P-

U

V

W

PE

Figur e 2-3 M ain Cir cui t Diagram (o ver 3 7kw)

Note:

Higher th an 2 2kw AC driv e (i ncluding ) su pport for exte rnal DC react or, b efore

1.

connecti ng, it need to take down t he br onze betwe en P an d P +. 1.

2. Low er than 30k w AC dri ve (inc luding) supp ort for ext ernal braking resis tor, hi gher

than 37kw AC d riv e (includi ng) s upport for exte rnal braking un it , br aking resi sto r.

-16-

SD300 User Manual

Chapter 2 Product Information

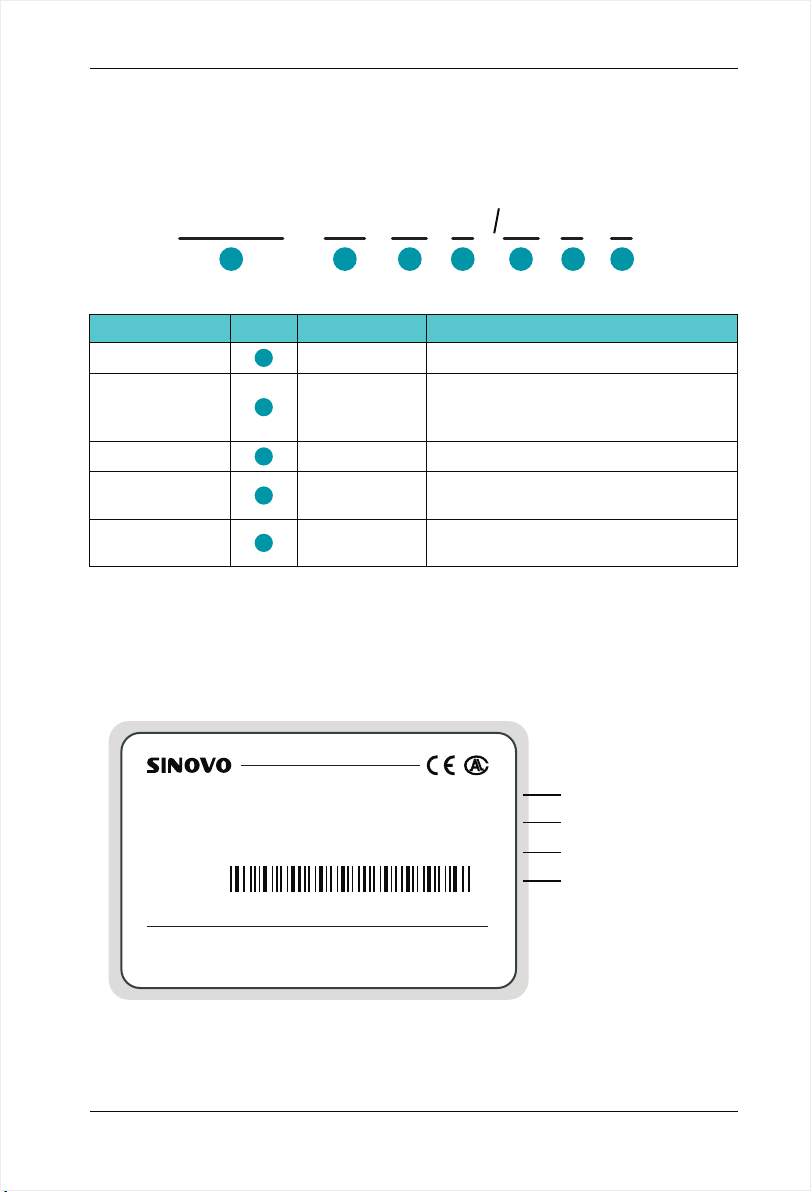

2.3 Naming Rules

In the mo del cod e conta ins the p roduc t information Users can find the c ode fro m the

trans ducer and sim ple nam eplat e.

SD300

Field Mark

Ac driv e ser ies

Volta ge Le vel

Adapt ive P ower

Funct ion T ype

braki ng Un it

1

1

2

3

4

5

4T

-

2 4

Explanation

Ac driv e ser ies

Volta ge Le vel

Adapt ive P ower

Funct ion T ype

braki ng Un it

Figur e 2-4 N ame Des ign ation Rule s

2.4 Nameplate

MODEL : SD300 -4T-5.5G/7.5P C

INPUT : AC3PH 3 80V 50/ 60Hz 14.6A/20.5A

OUTPU T: AC3P H 380V 0~600Hz 1 3A/17 A

S/N: FD LAGCA 0A040

SHENZHEN SINOVO ELECTRIC TECHNOLOGIES CO.,LTD.

G

11

3 3

Sinod riv e200 ab bre viated SD3 00

2S:si ngl e-pha se 22 0V

2T:Th ree -phas e 220 V

4T:Th ree -phas e 380 V

0.7KW ~50 0KW

G:Gen era l

P:Fan pum p

Null

C:

Only br aki ng unit

MADE IN CHINA

15

:None

C

P

5

4

Content

Model of the AC drive

Rated input voltage,

frequency and current

Rated output voltage,

frequency and current

Bar cod e

Figur e 2-4 N ame Des ign ation Rule s

-17-

Chapter 2 Product Information

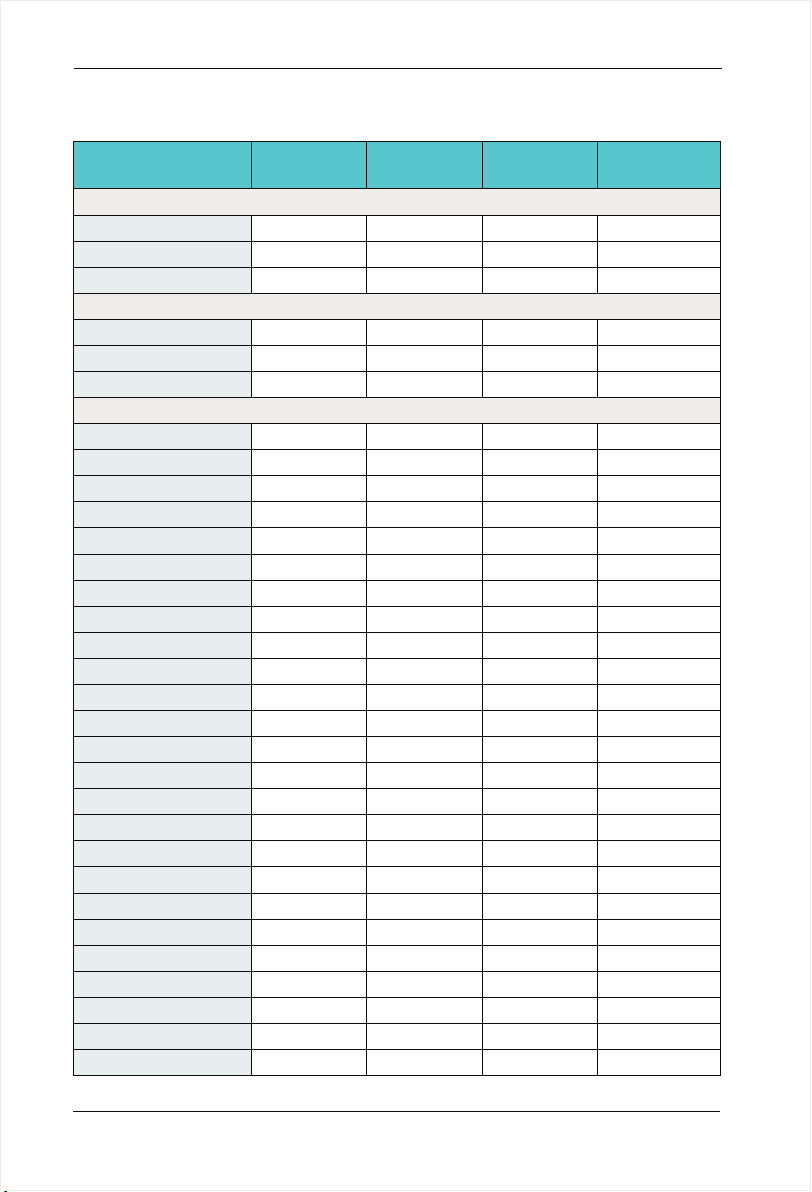

2.5 SD300 Series of AC drive

SD300 User Manual

Model

SD 300 -2S -0. 7G

SD 300 - - 1.52S G

SD 300 - - 2.22S G

SD 300 -2T -0. 7G

SD 300 - - 1.52 T G

SD 300 - - 2.22 T G

SD 300 -4T -0. 7G

SD 300 -4T -1. 5G

SD 300 -4T -2. 2G

SD 300 -4T -4. 0G

SD 300 -4T -5. 5G

SD 300 -4T -7. 5G

SD 300 -4T -11 G

SD 300 -4T -15 G

SD 300 -4T -18 .5G

SD 300 -4T -22 G

SD 300 -4T -30 G

SD 300 -4T -37 G

SD 300 -4T -45 G

SD 300 -4T -55 G

SD 300 -4T -75 G

SD 300 -4T -90 G

SD 300 -4T -11 0G

SD 300 -4T -13 2G

SD 300 -4T -16 0G

SD 300 -4T -18 5G

SD 300 -4T -20 0G

SD 300 -4T -22 0G

SD 300 -4T -25 0G

SD 300 -4T -28 0G

SD 300 -4T -31 5G

Power Capacity

(KVA)

single-p hase 220V Ra nge:-15%~20 %

1. 5

3. 0

4. 0

Three-ph ase 220V Ran ge:-15%~20%

1. 5

3. 0

4. 0

Three-ph ase 380V Ran ge:-15%~20%

1. 5

3. 0

4. 0

5. 9

8. 9

11

17

21

24

30

40

57

69

85

11 4

13 4

16 0

19 2

23 1

25 5

28 7

31 1

35 5

39 6

43 9

Input Current

(A)

8. 2 0.7 54.7 0.7 5

14 .0 7.5

23 .0

5. 5 0.7 54.7 0.7 5

7. 7 7. 5

12 .0

3. 4 0. 752. 3 0. 75

5. 0 3. 7

5. 8

10 .5 8. 5 4. 0

14 .6 13

20 .5

26 .0 25 11

35 .0 32

38 .5 37 18 .5

46 .5 45

62 .5 60 3 0

76 .0

92 .0 91 4 5

11 3

15 7

18 0 176 90

21 4

25 6 253 13 2

30 7 304 16 0

33 3 330 18 5

38 0 377 20 0

42 9 426 220

47 0 465 25 0

52 5 520 28 0

60 5 600 31 5

Output Current

Adaptable Motor

(A)

10 .0

10 .0

5. 1

17 7. 5

75

11 2

15 0

21 0 11 0

(KW)

1. 5

2. 2

1. 5

2. 2

1. 5

2. 2

5. 5

15

22

37

55

75

-18-

SD300 User Manual

Chapter 2 Product Information

Model

SD 300 -4T -40 0G

SD 300 -4T -45 0G

SD 300 -4T -50 0G

Power Capacity

(KVA)

47 9

53 0

60 0

66 0

Input Current

(A)

66 5 660 35 0SD 300 -4T -35 0G

73 0 725 40 0

82 5 820 45 0

91 0 900 50 0

Output Current

(A)

Adaptable Motor

(KW)

Note:

1. 0.75 ~ 315 kw AC dri ve in put current is th e mea sured resu lts , which under the c ond ition

of input vol tag e 380V, and witho ut DC reactor as we ll as i npu t and output reac tor;

2. 350 ~ 500 kw AC driv e inp ut cu rrent is the meas ured resul ts, w hich under the co ndi tion

of input vol tag e 380V, and equip ped with input re act or;

3. Rated out put c urrent is defin ed as t he output curre nt of the output vo lta ge 380V.

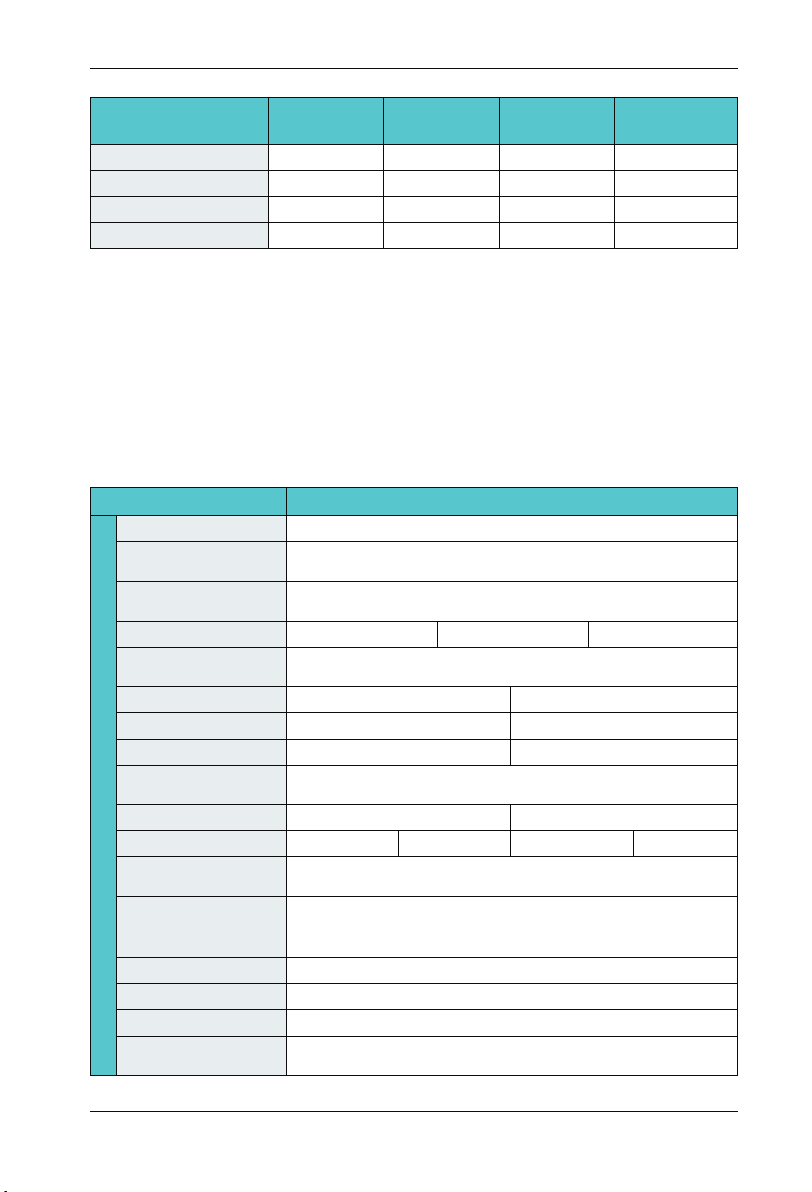

2.6 Technical Specifications

Item

Maximum frequency

Carrier frequency

Input frequency

resolution

Startup torque

Speed range

Speed stability accuracy

Basic Function

Torque control accuracy

Overload capacity

Torque boost

V/F curve

Accelerate/

Decelerate curve

DC braking

Jog contro l

Sim ple PLC Multi-speed

Onboard PI D

Auto voltage

regulation (AVR)

0~600Hz

1.0kHz~10kHz;The carrier frequency is automatically adjusted

based on the load features.

Digital setting:0.01Hz

Analog setting : Maximum frequency x 0.025%

G Type:0.5Hz/150%(SVC) 0Hz/180%(FVC)

P Type:0.5Hz/110%

G type:150% rated current for 60s

P type: 110% rated current for 60s

Line or S-curve Acc/Dec mode, four kinds of Acc/Dec time Range of

Acc/Dec time 0.0~6000.0s

DC braking frequency : 0.00Hz to Maximum frequency

braking time: 0.0 to 100.0s

braking current : 0.0 to 150%

Jog fre que ncy ran ge:0. 00Hz~Max imu m frequ enc y

16-speed o perating t hrough built- in PLC or cont rol terminal

It real ize s process-con troll ed cl osed loop co ntr ol syst em ea sily.

Jog fre que ncy ran ge:0. 00Hz~Max imu m frequ enc y

Specification

V/F

1:100(SVC)

±0.5%(SVC)

±10%(SVC)

Auto torque boost

Line

Multi-point

SVC FVC Control mode

1:1000(FVC)

±0.02%(FVC)

±5%(FVC)

Manual torque boost: 0.1%~20.0%

Square V/F curve

VF separation

-19-

Chapter 2 Product Information

SD300 User Manual

Item

Overvoltage/overc-

Function

Basic

urrent stall control

Rapid current limit

Torque control

High performance

Non stop function

Speed tracking start

Rapid current limit

Freatures

Virtual IO

Timing Control

Multi-motor switch

Bus Support

Motor overheating

protection

Multi-encoder

support

Command source

Frequency source

Auxiliary frequency

source

Input terminal

Running

Output terminal

Specification

The current and voltage are limited automatically during the running

process so as to avoid frequent tripping due to overvoltage/over-current.

It helps to av oid freque nt over- curren t faults of th e AC drive.

Open /c los ed-lo op ve ctor model c an re alize t orq ue control

High-performance current vector control technology to achieve a threephase AC induction motor control

Load feedback energy compens ates the voltage reduction so that the

AC drive can continue to r un in a short time in c ase of power interruption.

Identify the speed of rapidly rotating motor to realize a smooth start

without any rush.

Rapid software and hardware current limiting technology helps to avoid

frequent over-current fault.

Five sets of virtual DIDO enables easy logic control.

Timing control: set the time range 0.0Min~6500.0Min

Two independen t motor parameters enable two motors switching control

Two independent Modbus co mmunication, one CAN communication,

Profibus-DP

Optional IO expansion card 1, analog input AI3 acceptable the input of

motor temperature sensor .(PT100,PT1000)

Support differential, open colle ctor optical encoders, resolvers speed

sensor.

Given the control panel, control terminal, serial communication port

given. It can be switched by a variety of ways.

11 frequency sources: digital setting, analog voltage setting, analog current

setting, pulse setting and serial port. It can be switched by a variety of ways.

11 auxiliary frequency source. Flexible implementation of auxiliary

frequency tuning, frequency synthesis.

Standard:

. Six digital input terminals, one of which support to 50kHz high-speed

pulse input

. Three analog input terminals, two of which supports -10V~10V voltage

input

. One support 0 ~ 10V voltage input or 0 ~ 20mA current input Expansion

capability:

. Two digital inputs

. One analog input terminal, support -10V ~ 10V voltage input, and

supports PT100 / Pt1000

Standard:

. One high-speed pulse output terminal (optional open collector type),

support of 0 ~ 50kHz square wave signal output

. One digital output terminal

. Two relay output terminals

. Two analog output terminals, support 0~20mA current output or 0~10V

voltage output

Expansion capability:

. One digital output terminal

. One relay output terminal

. One analog output terminal, support 0~20mA current output or 0~10V

voltage output.

-20-

SD300 User Manual

Chapter 2 Product Information

Item

LED display

The key lock and

Display and

function selection

operation

Protection function

Accessories

Application

environment

Environment

Altitude

Ambient temperature

Humidity

Vibration

Storage temperature

Specification

Display each parameter of function code group

Achieve some or all of the keys locked and define the scope of partial

keys to prevent misuse.

Powered motor short circuit test; Input/output phase failure protection;

Over current protection; voltage protection; Under voltage protection;

Over heat protection ; Overload protection; braking resistor fault protection.

Braking assembly, simple IO expansion cards, multi-IO expansion card,

RS485 communication card, CAN communication card, differential input

PG card, resolver PG card, OC input PG card.

In-door, free from direct sunlight, dust, corrosive gas, combustible ga , oil

mist, steam , water drop and salt .

Lower than 1000m (1000m-3000m for derated use)

-10℃+40℃ (derated use in the ambient temperature of 40℃ to 50 ℃ )

Less than 95%RH, without condensation

Less than 5.9m/s(0.6g)

-20℃~+60℃

-21-

Chapter 2 Product Information

SD300 User Manual

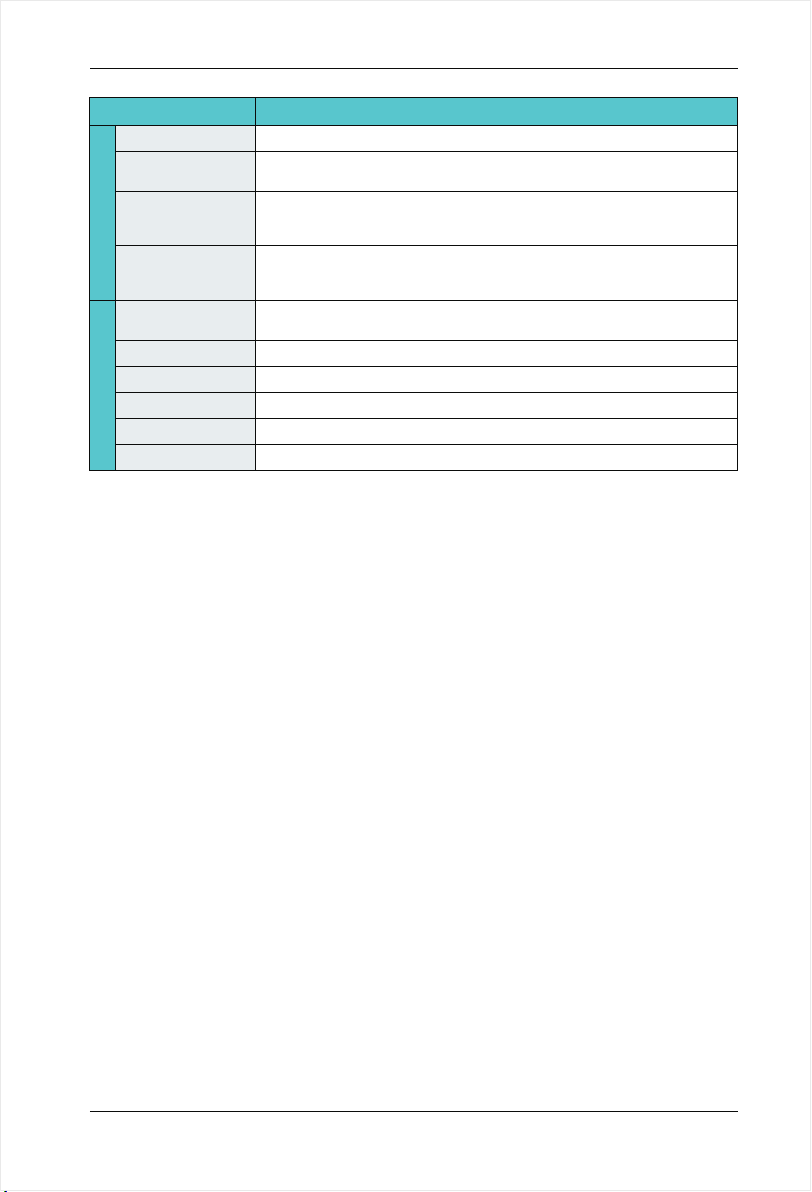

2.7 Structure diagram

2.7.1 The following figure shows the layout of the AC drive ( 7.5KW,for example).

1

8

9

10

11

12

No

1

2

3

4

5

6

7

8

9

10

11

12

Keypad interface

Control terminals

Main circuit terminals

Name

Fan-cover

Cooling fan

Vents-cover

Nameplate

Keypad

Cabinet-cover

Series Label

Apron

Lower-cover

2

3

4

5

6

7

Figur e 2-6 P roduc t str ucture dia gra m

Description

Protection fan.

Refer to 8.1 " Definition of Related Terms."

It is used to connect the Keypad.

Optional. with the vents-cover installed, the protection level will

increase and the AC drive internal temperature will increase as

well so please derating use the AC drive.

Refer to 2.4 "Nameplate"

Refer to 3.3 "Standard Wiring."

."

Refer to 3.3 "Standard Wiring."

Refer to chapter4 "Operation, Display and Application Examples."

Protect the internal components.

Refer to 2.3 "Naming Rules".

Convenient input and output wiring.

Protect the internal components.

-22-

SD300 User Manual

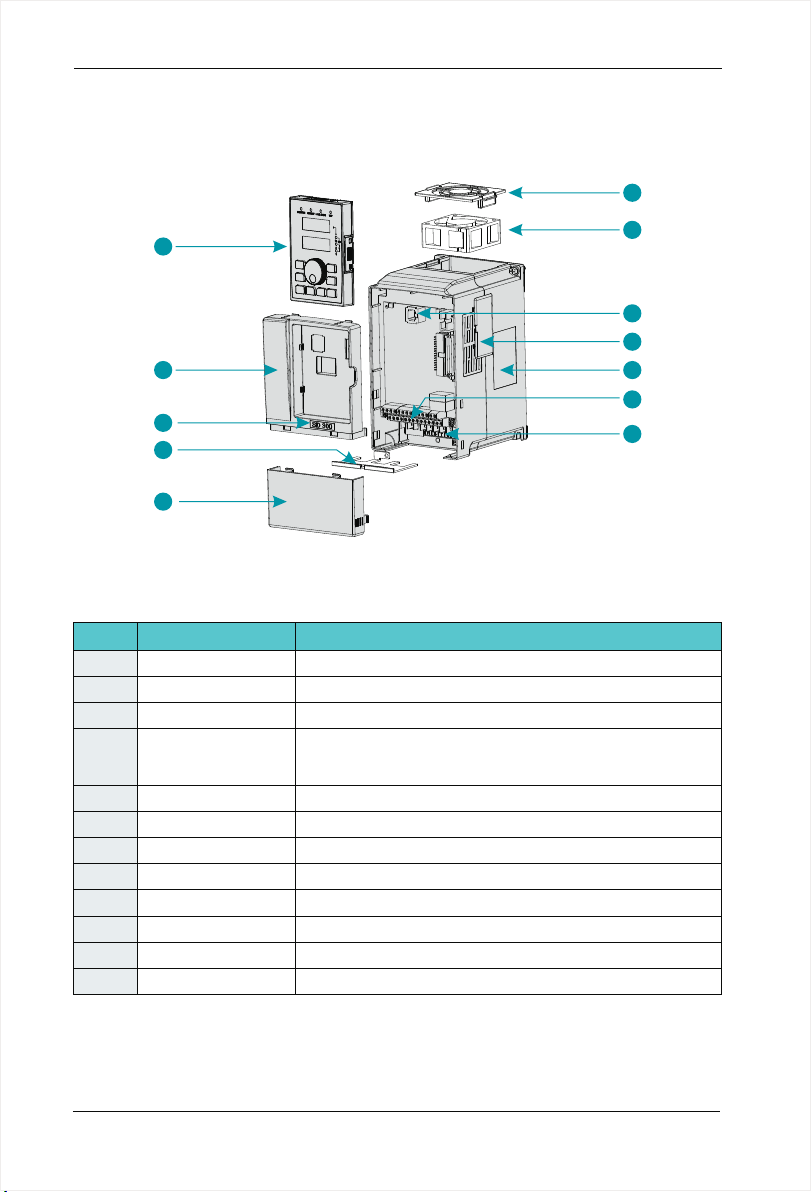

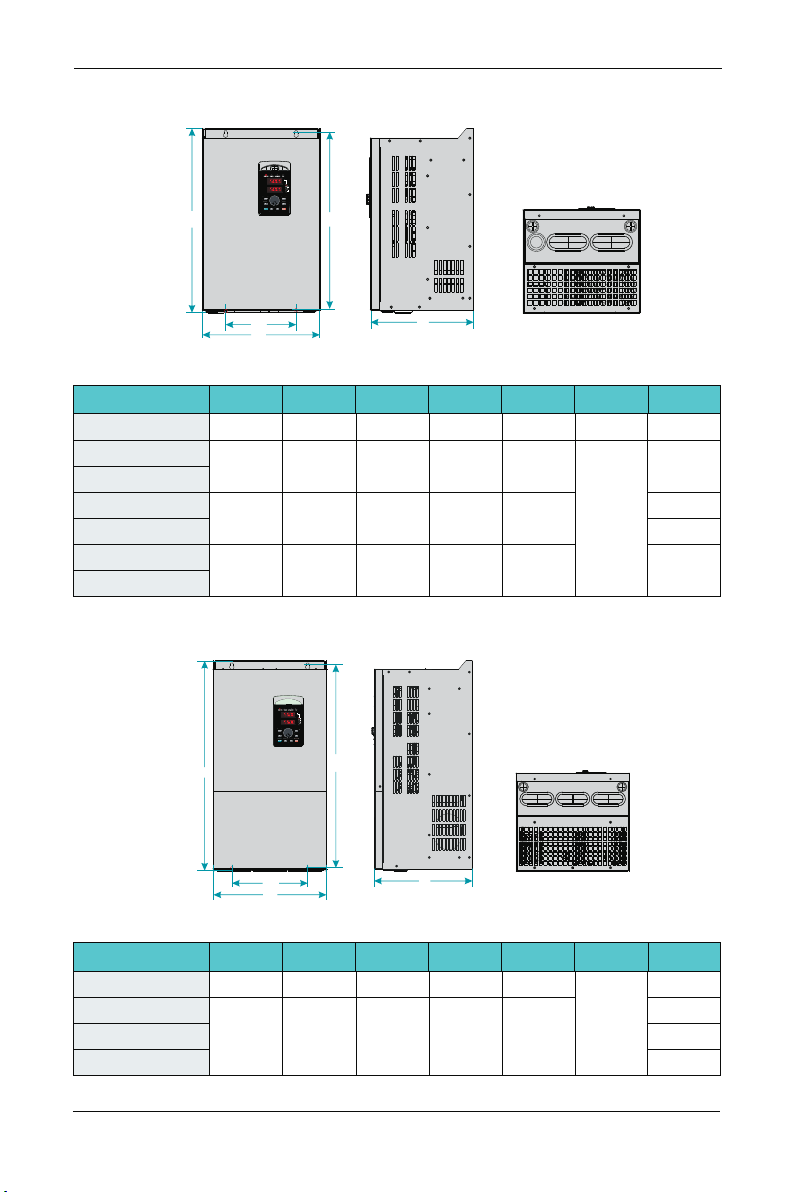

2.7.2 Product Outline, Installation Hole Size

2.7.2.1 SD300 series less than7.5KW (including 7.5KW)

Ø

H

H1

Chapter 2 Product Information

W1

W

D

Figur e 2-7 L ess tha n 7.5 K W AC drive ins tal latio n dim ensions an d ins talla tio n size

AC driv e mo del

H(mm) W(mm) D(mm)

H1(mm ) W1 (mm)

D

SD 300 -2S -0. 7G

SD 300 -2 -1 .5S G

19 0 11 0 15 0 17 8 98

SD 300 -2 -2 .2S G

SD 300 -2T -0. 7G

SD 300 -2T -1. 5G

19 0 11 0 15 0 17 8 98

SD 300 -2T -2. 2G

SD 300 -4T -0. 7G

SD 300 -4T -1. 5G

19 0 11 0 15 0 17 8 98

SD 300 -4T -2. 2G

SD 300 -4T -4. 0G

SD 300 -4T -5. 5G

SD 300 -4T -7. 5G

21 0 13 0 16 0 19 8 11 8

25 0

15 5

17 6 23 6

14 1

iameter

(mm)

Ø5

Ø5

Ø5

Ø5

Ø5

GW(kg)

2. 4

2. 4

2. 4

3. 5

4. 5

-23-

Chapter 2 Product Information

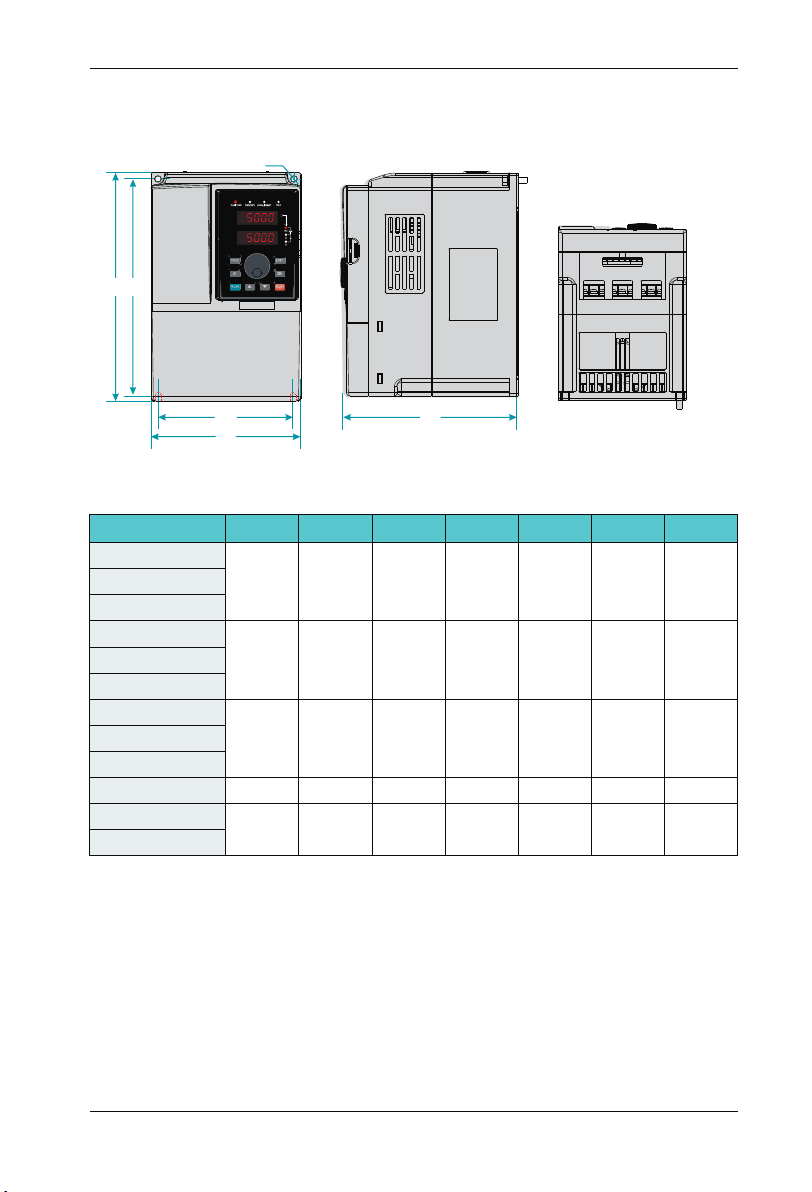

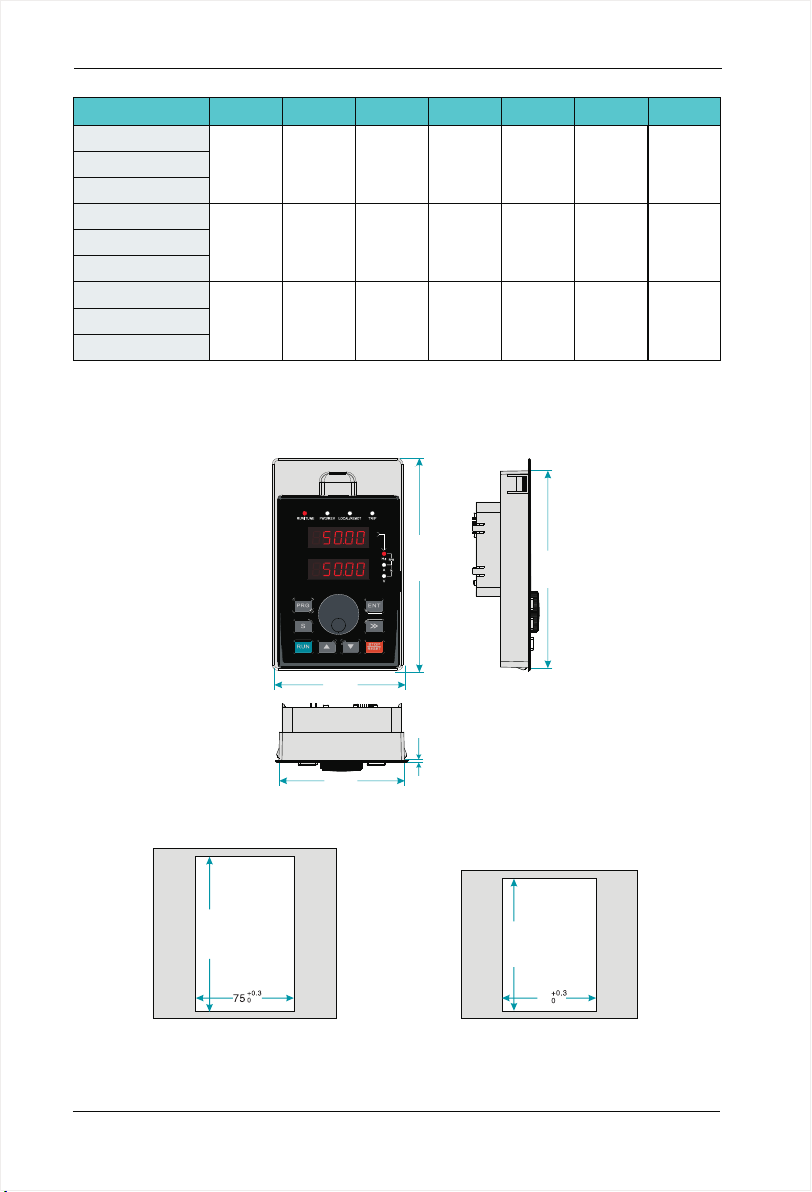

2.7.2.2 SD300 Series 11KW~45KW

SD300 User Manual

H

W1

W

Figur e 2-8 1 1kw~4 5kw A C drive inst all ation d ime nsion s and i nst allat ion s ize

AC driv e mo del

SD 300 -4T -11 G

SD 300 -4T -15 G

SD 300 -4T -18 .5G

SD 300 -4T -22 G

SD 300 -4T -30 G

SD 300 -4T -37 G

SD 300 -4T -45 G

H(mm) W(mm) D(mm)

28 5

33 2

38 7

17 0 16 2 27 0

22 0

25 0 22 0 37 3

27 0 25 2 42 6 2544 0

2.7.2.3 SD300 Series 55KW~110KW

H

H1

D

iameter

13 5

14 0

15 0

D

(mm)

Ø6

Ø7

GW(kg)

5. 1

9. 3

14

19

H1(mm ) W1 (mm)

21 4

31 8

18 0

H1

Fig 2-9 5 5~1 10KW AC d riv e installa tio n dimen sio ns and insta lla tion si ze

AC driv e mo del

SD 300 -4T -5 G5

SD 300 -4T -75 G

SD 300 -4T -90 G

SD 300 -4T -11 0G

W1

W

H(mm) W(mm) D(mm)

30 0 25 8 53 4 20 0

65 0

37 0 28 2 62 5 25 0

-24-

D

H1(mm ) W1 (mm)

D

iameter

(mm)

Ø9

GW(kg)

3255 0

52

55

58

SD300 User Manual

2.7.2.4 SD300 Series 132KW~185KW

H

H1

Chapter 2 Product Information

W1

W

D

Figur e 2-1 0 132KW ~18 5KW AC drive i nst allat ion d imension s and i nstal lat ion siz e

AC driv e mo del

H(mm) W(mm) D(mm)

H1(mm ) W1 (mm)

SD 300 -4T -13 2G

88 0 48 5 31 0 86 0 32 0

SD 300 -4T -18 5G

2.7.2.5 SD300 Series 200KW~500KW

H1

H

D

iameter

(mm)

Ø1 3

GW(kg)

99SD 300 -4T -16 0G

W1

W

D

Figur e 2-1 1 200KW ~50 0KW AC drive i nst allat ion d imension s and i nstal lat ion siz e

-25-

Chapter 2 Product Information

AC driv e mo del

H(mm) W(mm) D(mm)

SD 300 -4T -20 0G

SD 300 -4T -22 0G

12 50 50 0 40 0 100 0 440

SD 300 -4T -25 0G

SD 300 -4T -28 0G

SD 300 -4T -31 5G

13 50 65 0 40 0 110 5 513

SD 300 -4T -35 0G

SD 300 -4T -40 0G

SD 300 -4T -45 0G

18 10 85 0 40 5 141 0 513

SD 300 -4T -50 0G

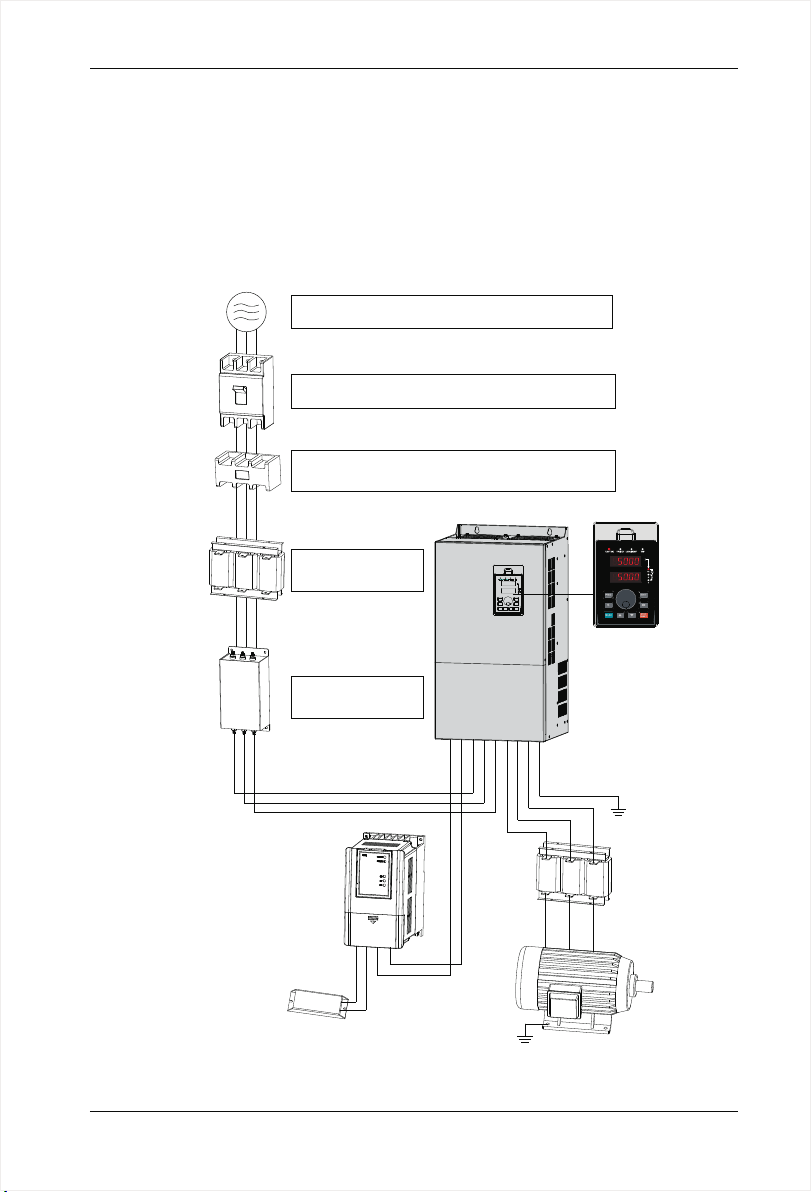

2.7.3 External Keypad Installation Dimensions

H1(mm ) W1 (mm)

SD300 User Manual

D

iameter

(mm)

Ø1 3

Ø1 3

Ø1 3

GW(kg)

16 7

20 6

41 5

79.00

74.80

Figur e 2-1 2 Keypa d Ins tallatio n dim ensio ns

+0. 3

0

119 .5

Figur e 2-1 3

Openi ng di mensi on di agram

for key pad w ith bas e

-26-

128.20

1.50

Openi ng di mensi on di agram

for key pad w ithou t bas e

119.00

+0. 3

0

100

70

Figur e 2-1 4

SD300 User Manual

Chapter 2 Product Information

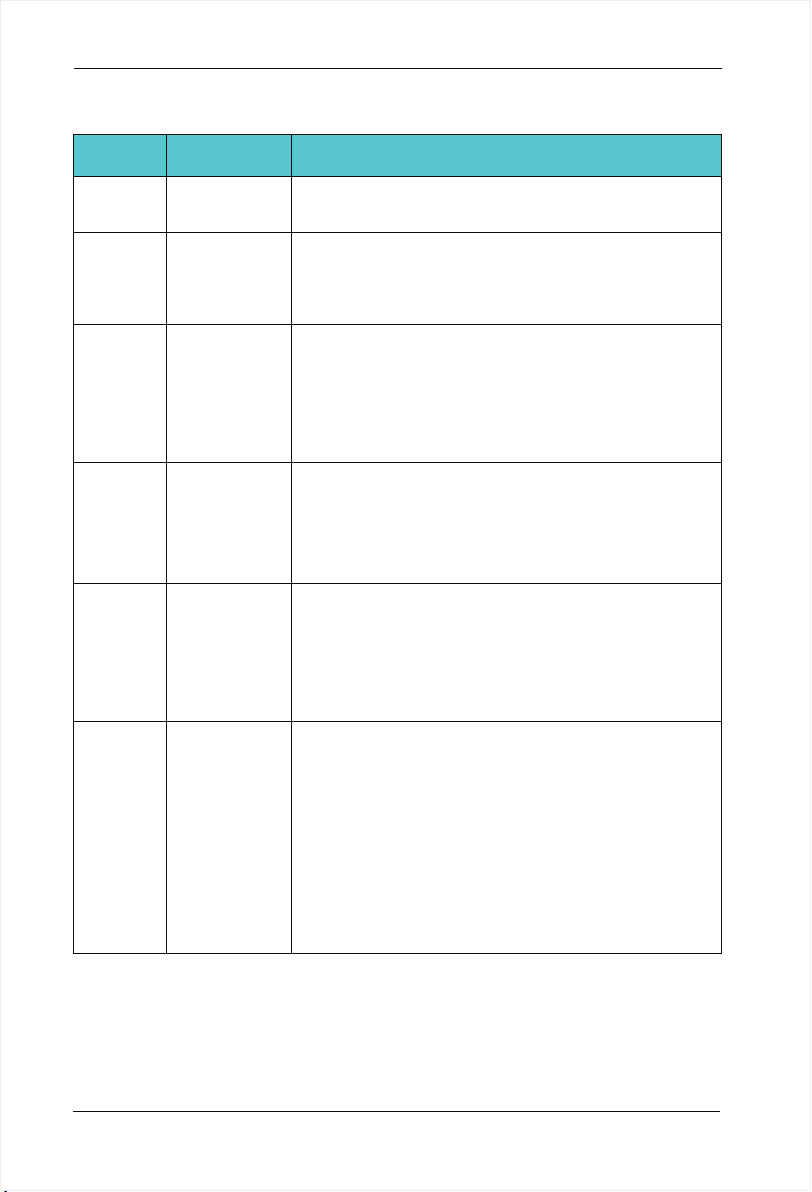

2.8 Peripheral Electrical Components System Structure

When usi ng SD300 serie s A C d rive t o c ontro l a synch ronou s moto r s ystem , you hav e t o

insta ll va rious elec trica l com ponents on the si de of inpu t and outp ut of the AC dr ive t o

guara ntee the stab ility and safe ty o f sy stem. In a dditi on, SD300 s eries A C drive is

equip ped w ith a va riety of o ption al accessories and expa nsion card to achi eve v ariou s

funct ions. Mor e th an 37kw ser ies three -phas e 38 0v syst em struct ure as show n in the

figur e below (The fi gure AC d rive te rminal refer to 55~110K W):

3-phas e AC

power su ppl y

Moulde d cas e

circui t bre ake ror

earth le aka ge

circui t bre ake rs

Electr oma gne tic

contac tor

AC re act or

Inp ut si de EM C

fil ter

Use with in th e all owa ble p ower supp ly sp eci fic ati on

of th e AC dr ive

Select a proper b reaker t o resistlarge in- rush cur rent

that fl ows into t he AC driv e at power-on

To guarantee sa fety, us e an electromagne tic cont actor.

Do not use it to star t or stop th e AC drive because su ch

operation red uces the s ervice life of the AC d rive

Suppress the hi gh

order harmoni c to

improve power f actor

AC Driver

Reduce the elec tromagnetic inter ferenc e

on the input side .

Bre ak un it

P

P+

R

P-

S

T

U

V

W

PE

Gro und

Out put r eac tor s

PB

P

P+

Brakin g res ist or

BR

P+

P-

Gro und

Motor

Figur e 2-1 5 Under 3 7 kw se ries 3-pha se 38 0 V syste m str ucture dia gra m

-27-

Chapter 2 Product Information

2.8.1 Peripheral Electrical Components Description

SD300 User Manual

Accessory

Name

MCCB

Conta ctor

AC input

reactor

EMC input

filter

DC reactor

AC output

reactor

Installation

position

Power

receiving side

Between MCCB

and the AC drive

input side

AC drive

input side

AC drive

input side

SD300 series

AC drive of

30G and above

configured

with DC reactor

as standard

Between the AC

drive output side

and the motor,

close to the AC

drive

Function Description

Inter rupt th e power s upply w hen ove rcurr ent occurs

ª

on down strea m devic es.

Start and stop the AC drive.Do not start and stop the AC

ª

drive frequently by switching the contactor on and off

(less than twice per minute) nor use it to directly start

the AC drive.

Improve the power factor of the input side;

ª

Eliminate the higher harmonics of the input side effecti-

ª

vely and prevent other devices from being damaged due

to distortion of the voltage waveform;

Eliminate the input current unbalance due to unbalance

ª

between the power phases;

Reduce the external conduction and radiation interfere-

ª

nce of the AC drive;

Decrease the conduction interference flowing from the

ª

power end to the AC drive and improve the anti-interfe rence capacity of the AC drive.

Improve the input power factor;

ª

Improve the efficiency and thermal stability of the AC

ª

drive;

Eliminate the impact of higher harmonics of the AC drive

ª

input side and reduce the external conduction and

radiation interference.

The output side of the AC drive generally has much

ª

higher harmonics. When the motor is far from the AC

drive, there is much distributed capacitance in the circuit

and certain harmonics may cause resonance in the

circuit, bringing about the following two impacts:

a.Degrade the motor insulation performance and damage

the motor in the long run.

b.Generate large leakage current and cause frequent AC

drive protection trips.

If the distance between the AC drive and the motor is

ª

greater than 100 m, install an AC output reactor.

-28-

SD300 User Manual

Chapter 2 Product Information

Note:

Do not install capacitor or surge su ppressor on the out put side of the AC drive.

1.

Otherwis e, it may ca use fa ults to the AC drive or damage to the capaci tor an d s urge

suppress or;

2. I nput/out put (main circ uit ) o f t he AC dri ve include har monic componen ts, which may

interfer e with the AC drive att achment commun ica tions equ ipment. Theref ore , inst all

an anti-al iasing filter t o min imize the inter ference;

3. Details o f per ipherals a nd op tions refer to Ch apt er 2 selecti on of p eripheral dev ices.

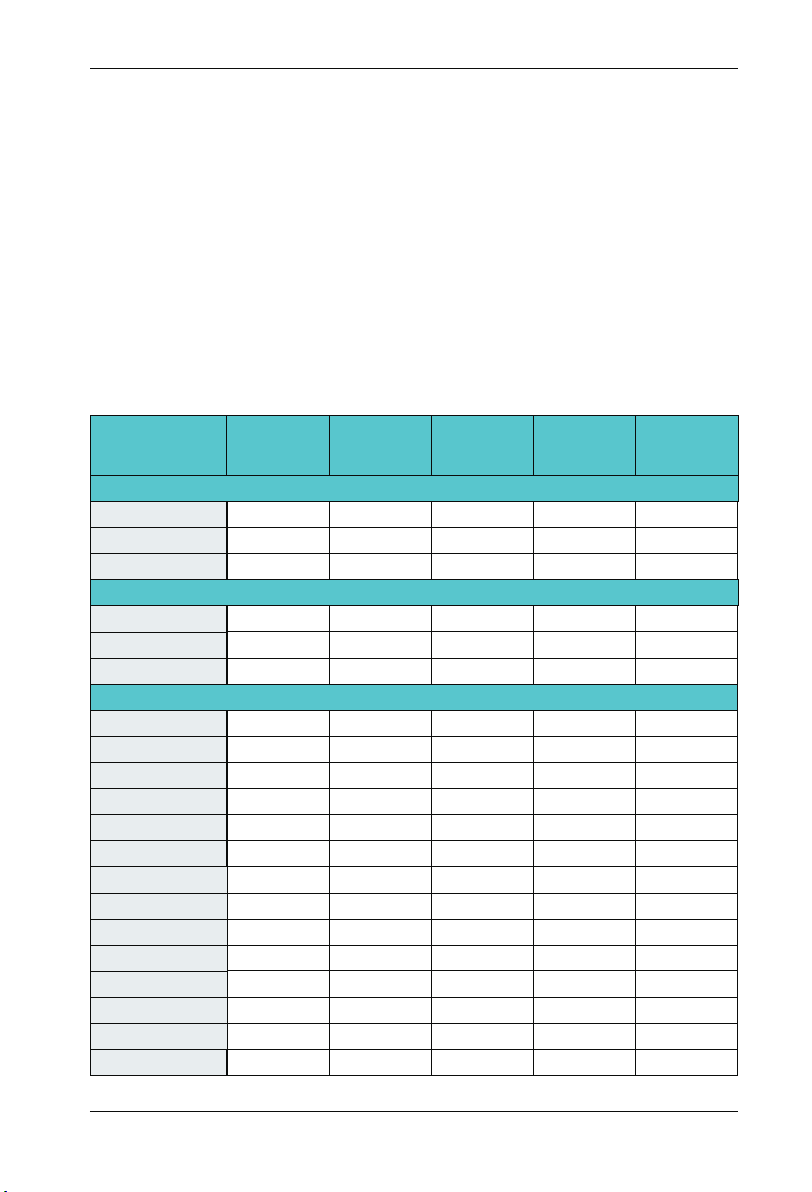

2.8.2 Peripheral electrical components selection guidance

AC Drive mod el

SD 300 -2S -0. 7G

SD 300 -2 -1 .5S G

SD 300 -2 -2 .2S G

SD 300 -2T -0. 7G

SD 300 -2T -1. 5G

SD 300 -2T -2. 2G

SD 300 -4T -0. 7G

SD 300 -4T -1. 5G

SD 300 -4T -2. 2G

SD 300 -4T -4. 0G

SD 300 -4T -5. 5G

SD 300 -4T -7. 5G

SD 300 -4T -11 G

SD 300 -4T -15 G

SD 300 -4T -18 .5G

SD 300 -4T -22 G

SD 300 -4T -30 G

SD 300 -4T -37 G

SD 300 -4T -45 G

SD 300 -4T -5 G5

MCCB(A)

Recommended

contactor

Recommended

input side main

circuit wire mm2

Recommended

output side main

circuit wire mm2

Single pha se 220V

16

20

32

16

25

25

10

16

20

Three phas e 220V

10

16

16

2. 5

4. 0

6. 0

2. 5

4. 0

4. 0

2. 5

2. 5

4. 0

2. 5

2. 5

4. 0

380VThree phas e

10

16

16

25 16 4. 0 4. 0 1.0

32 25 4. 0 4. 0 1.0

40 30 4. 0 6. 0 1.0

63

63

10 0

10 0

12 5

16 0

20 0

25 0

6

10

10

40

40

63

63

10 0

10 0

12 5

16 0

2. 5

2. 5

2. 5

4. 0

6. 0

10

16

16

25

50

2. 5

2. 5

2. 5

6. 0

10

6

10

10

16

25

25

35

Recommended

control loop

wire mm2

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 0

1. 5

1. 5

1. 5

1. 5

1. 5

1. 5

-29-

Loading...

Loading...