Sinovo SD200-4T-0.7G, SD200-2T-1.5G, SD200-2S-0.7G, SD200-2T-2.2G, SD200-2S-1.5G User Manual

...Page 1

Preface

SD200 User Manual

Preface

Thank you for purchasing the SD200 series AC drive developed by Our company.

SD200 series AC drive is a general-purpose high-performance vector control AC drive,

and it is mainly used for controlling and regulating the speed of the three-phase AC

asynchronous motor. It is a new generation of AC Drive with latest technology. SD200

series is characterized in the high-performance V/F control and Vector control 0

Algorithm technology, high torque output at low frequency and strong overload capacity.

It possess good stability, dynamic performance, communication bus functions, rich

powerful and stable performance, with perfect anti-tripping control and the ability to

adapt to bad power grid. It is used to drive various automatic produc tion equipments

involving the industry of textile, papermaking, wire drawing, machine tools, packa ging,

food, fans and pumps and so on.

SD200 Series AC drive Features

Advanced Vector Control Algorithm.

ªVector c on trol 0 Algori th m with low speed stability, high torque output a t low

frequency an d dy namic performance.

ªsmaller, com pa ct volume.

ªIn the full power range, the same power type compared to the old series products, it

reduces the volume of 20%~40%. As the vol ume is reduced, the optimized thermal

design ensur es t he favorable temperature rise of the whole AC drive.

ª485 Communication , externa l high precisi on PID, multi-stag e speed and simple PIC,

swing freque nc y, length and counting value functions.

Stronger functions:

Unpacking Inspection Cautions

The op timized VF control and sensorless vec to r control is more st ab le at low speed,

more powerful in the ability of low frequency torque output and w ith better dynamic

response and both the sensorless ve ctor and sensor vector mode support speed control

and torque con tr ol.

Every AC Drive have been tes te d strictly in factory prior to shipment. Upon u npacking,

check:

ªWhether the pr od uct is damaged;

ªWhether the na me plate of model and AC drive ratings are consistent with your order.

Page 2

-2 -

SD200 User Manual

Preface

First-time Use

For th e users who use this product for the first time, read the manual carefully. If in doubt

concerning some functi on s or performan ce s, co nt act t he tech ni cal s up port pe rsonnel of

Our company to e ns ure correct use.

SD200 series AC drives have passed CE test and also meet the requirements of following International Standard.

ªIEC/EN 6180 0- 5-1:2003 Sa fety re qu irements fo r adjus ta ble spe ed el ectric dr ive

systems.

ªIEC/EN 61800-3:2004 adjustable speed electric drive systems:(The third par)the

electromag ne tic compatibility standard of the product and its specific test method.

ªIEC/EN 610 00- 2-1 ,2-2,3-2,3 -3, 4-2 ,4-3,4- 4,4 -5, 4-6:EMC Intern ati onal an d EU

Standards.

The instruction s are subject to change, without notice , due to product upgrade,

specificat io n modification as well as efforts to increase the accuracy and convenience of

the manual.

ªWhether the box contains the AC drive, certificate of conformity, user manual and

warranty car d. I f you find any omission or damage, contact Our company or your supplier

immediatel y.

Page 3

Contents

SD200 User Manual

Contents

Preface.......................................................................................................................................01

Contents....................................................................................................................................03

Chapter 1 Safety and Cautions.........................................................................................07

1.1 Safety and Cautions De finition

1.2 Safety Cauti on s

1.3 Precautio ns

............ .. .. ........................................07

............ .. .. .............................................................08

............ .. .. ..................................................................10

Chapter 2 Product Information.........................................................................................15

2.1 Ch ap te r of This Content................................................ . ...............

2.2 Basic Principle............................................. .. ..............................

2.3 Naming Rules.................................................... .. .. .......................

2.4 Nameplate.................................................... .. .............................

2.5 SD200 Series of AC d rive.............................................................

2.6 Te ch nical Specifications......................................... .. .. ..................

2.7 Structure Diagram......................................... .. .. ...........................

2.8 Per ip heral Electrical Components System Structure............... .. .. .....

2.9 SD 20 0 Optional Parts................................................. .. .. ...............

2.10 Connection Methods............................................ .. .. ...................

. 15

15

17

17

18

19

22

27

29

31

Chapter 3 Mechanical and Electrical Installation........................................................33

3.1 Ch ap te r of This Content................................................ .. .. .............33

3.2 Mechanical Installation..................................... .. .. ........................34

3.3 Standard Wiring.................................................... .. .. ....................39

3.4 Layout Protection............................................. .. .. ........................49

Chapter 4 Operation, Display and Application Examples.........................................51

4.1 Ch ap te r of this Content............................... ............ .. .. ......51

4.2 Introduction of the Keypad............................................. .. .. ............52

4.3 D is play of Keypad.................................................. .. .. ...................54

4.4 Keypad Operation.................................................... .. .. .................55

............ .

Chapter 5 Function Parameter Table..............................................................................57

5.1 Ch ap te r of this Content.................................................. .. .. ............57

5.2 Fu nction Parameter Table....................................... .. .. ..................58

-3 -

Page 4

SD200 User Manual

Contents

-4 -

Chapter 6 Parameter Description.....................................................................................83

Group F00: Basic Func ti on Group........................... ............ .. .. ............84

Group F 01 : Start-stop Control Group.................................. .. .. ..............91

Group F 04 : V/Fcontrol Group......................................... .. .. ..................99

Group F05: Input T er minal Group..................................... .. .. ..............105

Group F06: Output Terminal Group......................................... .. .. ........113

Group F0 7: H MI Group..................................................... .. .. ..............119

Group F08: Strengthen th e Functional Groups................................. .. .. 125

Group F0 9: P ID Control Group............................................... .. .. .........132

Group F0A:Wobble, Length, Count and Ti mi ng Parameter Group..........142

Group F0B: Simple PLC and Multi-sp ee d Control Group....................... 14 5

Group F0C: Protection P arameter Group................................... .. .. ......149

Group F0D: Motor 2 Parameter Group....................................... .. .. ......154

Group F0E : Serial Communication Function Group...................... .. .. ....156

A01: A1 Curve Settin g Function Group...................................... .. .. ......159

A02: Stat us Check Function Group....................................... .. .. ..........161

..

Chapter 7 EMC.....................................................................................................................163

7.1 ............ .. .. .............................. ..........16 4

7.2 EMC Standard Introduction............................................. .. .. .........164

7.3 Selection of Peripheral EMC Devices................................... .. .. .....165

7.4 Shielded Cable.................................................. .. .. .....................169

7.5 Requ ir ement for Leakage Current........................................ .. .. .....171

7.6 Solutions to Common EMC Inter fe re nce Problems....................... .. 17 2

Definition o f Related Terms ..

Chapter 8 Troubleshooting and Maintenance...........................................................173

8.1 ...... .. ...... .. .. ..174

8.2 Warranty Agreement............................................ .. .. ...................175

8.3 Contents of This Chapter............................................ .. .. .............175

8.4 Al ar m and Fault Inductions........................................ .. .. ..............176

8.5 Fault Reset........................................................ .. .. .....................176

8.6 Fault History................................................... .. .. ........................176

8.7 Faul t Instruction and Solution........................................... .. .. ........176

8.8 C ommon Fault Analysis............................................ .. .. ...............181

Daily Re pa ir a nd Maintenance ............ .. .. ................ ..

Page 5

Chapter 9 Communication Protocol.............................................................................187

9.1 Networking Mode.................................................. .. .. ...... ......187

9.2 Interface Mode................................................ .. .. .......................188

9.3 Protocol Fram e Format............................................. .. .. ...............188

9.4 Fu nction Protocol.................................................. .. .. ..................189

9.5 Communication P ar ameters Address................................ .. .. ........192

......

SD200 User Manual

Contents

-5 -

Page 6

Page 7

Chapter 1

Safety and Cautions

1.1 Safety and Cautions Definition

Read this manual carefully so that you have a thorough understanding. Installat io n,

commission in g or maintenance ma y be performed in conjunction with this chapter. Our

company will assume no ability an d responsibility for any in ju ry or loss caused by

improper ope ra tion.

Danger

Note

Operations which are not performed comply with the requirements may cause severe

hurt or even dea th .

Operations which are not perf or med comply with requirements may caus e personal

injury or prop er ty damage.

-7 -

Page 8

SD200 User Manual

Chapter 1 Safety and Cautions

-8 -

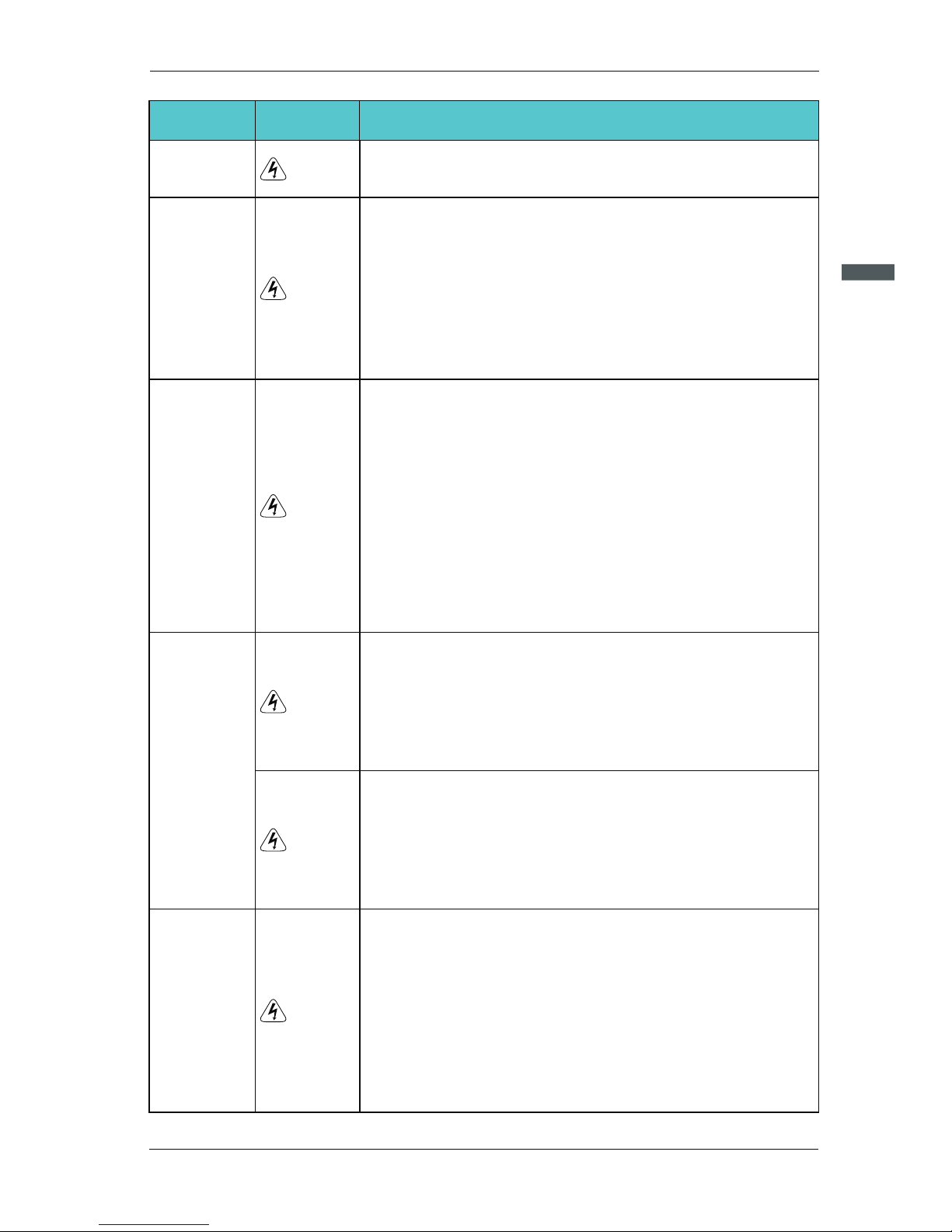

1.2 Safety Cautions

1

Use Stage Safety Grade

Precautions

Danger

Before

Installati on

Do not install t he e quipment if you find water seepage,

ª

component mi ss ing or damage upon unpacking.

Do not install t he e quipment if the packing list does not

ª

conform to the p ro duct you received.

Danger

Handle the e qu ip ment with care during transportation

ª

to prevent dam ag e to the equipment.

Do not use the equ ip ment if any component is damaged

ª

or missing. Fa il ure to comply will result in personal

injury.

Do not touch the c om ponents with your hands. Failure

ª

to comply will r es ult in static electricity damage.

Danger

During

Installati on

Install the eq ui pment on incombustible objects such as

ª

metal, and kee p it a way from combustible materials.

Failures to co mp ly may result in a fire.

Do not loosen th e fi xed screws of the components,

ª

especial ly t he s crews withe red marks.

Do not drop wire e nd o r screw into the AC drive. Failure

ª

it will result i n da mage to the AC drive.

Install the AC d ri ve in places free of vibration and direct

ª

sunlight.

When two AC driv es a re laid in the same cabinet

ª

,arrange the i ns tallation positions properly to ensure

the cooling ef fe ct.

Danger

At wiring

A circuit brea ke r must be used to isolate the power

ª

supply and the A C dr ive. Failure to comply may result a

fire.

Ensure that th e po wer supply is cut off before wiring.

ª

Failure to com pl y may result in electric shock.

Never connec t th e power cables to the output

ª

terminals( U, V,W) of the AC drive. Pay attention to the

marks of the wir in g terminals and ensure correct

wiring. Fail ur e to comply may result in damage to the

AC drive.

Ensure that th e ma in cable line comply with the

ª

standard, th e li ne meets the EMC requirements and

the area safet y st andard. Failure to comply may result

in risk or accid en t.

Never connec t th e power cables the braking resistor

ª

between the DC b us t erminals P+, P-. Failure to

comply may res ul t in a fire.

Note

Page 9

1

-9 -

SD200 User Manual

Chapter 1 Safety and Cautions

Use Stage Safety Grade

Precautions

Danger

At wiring

Use a shield ed c ab le for the encoder, and ensure that

ª

the shieldin g la yer is reliably grounded.

Danger

Before

Power-on

Please confi rm t he peripheral equipment and cable

ª

converter is c on figured in this manual of the

recommende d mo del, all the configuration line in

accordance w it h the connection method of the manual

provides the c or rect wiring. Failure to comply will result

in acciden ts .

Check that the v ol tage class of the power supply is

ª

consistent w it h the rated voltage class of the AC drive.

Danger

After

Power-on

Do not open the AC d ri ve’s cover after power-on.

ª

Failure to com pl y may result in electric shock.

Do not touch the o pe ration of AC drive during the

ª

hands is wet. Fa il ure to comply will result in accident.

Do not touch any I /O t er minal of the AC drive. Failure

ª

to comply may re su lt in electric shock.

Do not change th e de fault settings of the AC drive.

ª

Failure to com pl y will result in damage to the AC drive.

Do not touch the r ot ating part of the motor during the

ª

motor auto-t un ing or running. Failure to comply will

result in acci de nt.

Danger

During

Operation

Signal detec ti on must be performed only by qualified

ª

personnel du ri ng operation. Failure to comply will

result in pers on al injury or damage to the AC drive.

Do not touch the f an o r th e discharging resistor to

ª

check the temp er ature. Failure to comply will result in

personal bur nt .

Danger

Avoid obje ct s fa lling into the AC drive when it is

ª

running. Fai lu re to comply will result in damage to the

AC drive.

Do not start or st op t he A C drive by turning the

ª

contactor ON /O FF . Failure to comply will result in

damage to the AC d ri ve.

Danger

After

Power-on

Do not repair or m ai ntain the AC drive at power-on.

ª

Failure to com pl y will result in electric shock.

Ensure that th e AC d rive is disconnected from all

ª

power suppli er s before staring repair or maintenance

on the AC drive.

Repair or main te nance of the AC drive may be

ª

performed on ly b y qualified personnel. Failure to

comply will re su lt in personal injury or damage to the

AC drive.

Page 10

Danger

After

Power-on

Set and check th e pa rameters again after the AC drive

ª

is replaced.

Use Stage Safety Grade

Precautions

SD200 User Manual

Chapter 1 Safety and Cautions

-1 0-

1

1.3 Cautions

1.3.1 Requirement on Residual Current Device(RCD)

The AC drive generates high leakage current d uring running, which f lows earthing (PE)

conductor. Thus i nstall a type-B RCD at the transient and steady-state leakage current

to ground that may be generated at st artup and during running of the AC dri ve . You can

select a special iz ed RCD with the function of suppre ss in g high harmonics o r general-

purpose RCD wi th r elatively large residual current.

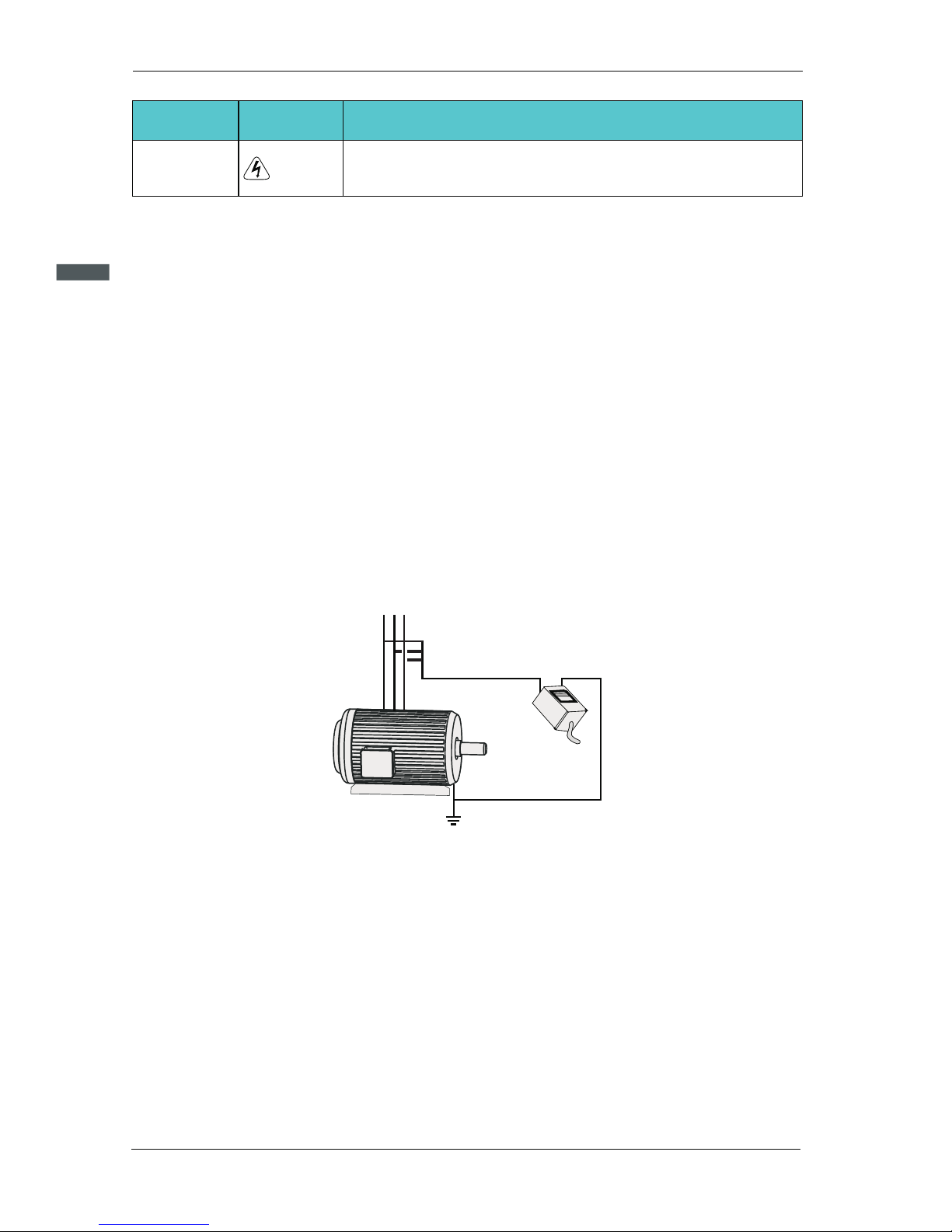

1.3.2 Motor Insulation Test

Perform the insulation test when the motor is used for the first time, or when i t is reused

after being stored for a long time, o r in a regular check-up, i n order to prevent the p oo r

insulation of motor wind in gs from damaging the AC drive during the insulatio n test. A

500-V mega-Ohm meter is recommended for the test. The insula ti on resistance must not

be less than 5 MΩ.

UVW

Input terminals of the motor

Megger

Ground

1.3.3 Thermal Protection of Motort

If the selected AC drive doe s not match the rated capacity of the motor , especially when

the ra te d power of the AC drive is higher than that of the motor, adjust the parameters for

motor protec ti on in the AC drive or to install thermal relay to protect the motor .

1.3.4 Running Below and Above Rated Frequency

The AC drive provides frequency output of 0 to 60 0.00Hz. When th e users use the

frequency converter for a long time, please pay attention to the motor cooling o r use o f

variable fr eq ue ncy motor. If the AC drive is required to run at over 50Hz, consid er th e

capacity of th e ma chine.

Page 11

1

-1 1-

SD200 User Manual

Chapter 1 Safety and Cautions

1.3.5 Vibration of mechanical device

The AC drive may e nc ounter the mechanical resonance point at some output frequencies,

which can be avo id ed by setting the skip frequency. If the operating frequency of the cus-

tomer coinci de w ith the resonant frequency please modify the operating frequency or

change the inh er ent resonance frequency of the mechanical system.

1.3.6 Motor heat and noise

The output of th e AC drive is pulse width modulation (PWM) wav e with certain harmonic

frequencie s, and therefore, the motor temperature, noise, and vibration are sli ghtly

greater than t ho se when the AC drive runs at power frequency (50 Hz).

1.3.7 Voltage-sensitive device or capacitor on output side of the AC drive

Do not install t he c apacitor for improving power factor or lightning protection voltagesen-

sitive resistor on the output side of th e AC dr ive because the output of the AC drive is

PWM wave. Otherwise, the AC drive may suffer tr ansient overcurrent o r even

bedamage d.

1.3.8 Contactor at the I/O terminal of the AC drive

When a contactor is installed between t he input side of the AC drive and the power

supply, the AC dri ve must not be started or stopped by switching the contactor on or off.

If the AC driv e has to be operated by the contactor, ensure that the time interval betw ee n

switching is at le as t one hour since frequent charge and discharge will shorten the

service life o f th e capacitor inside the AC drive.

When a contactor is i ns talled between the o ut put side of the AC drive and the motor,do

not turn off the contactor when the AC drive is active. Otherwise, modules inside the AC

drive may be dam ag ed.

M

U V

W

AC Driver

Capacitor or

voltage-sensitive resistor

Page 12

SD200 User Manual

Chapter 1 Safety and Cautions

-1 2-

1

M

380Vac

50/60Hz

R

S

T

U

V

W

Contactor KM

Do not start/stop the AC drive by

switching the contactor on/off. If

the AC drive has to be operated

by the contactor, ensure that the

tiome interval is at least one hour.

Contactor KM or

offer switches

AC Driver

Turn on /off the contactor when

the AC drive has no output.

Otherwise,modifies inside the AC

drive may be damaged.

1.3.9 The Use Occasion of the External Voltage Out of Rated Voltage Rage

The AC drive must not be used outside the allowable voltage range specified in th is

manual. Otherwise, the AC drive’s components may be damaged . If required, use a

correspond in g voltage step[-up or step-down device.

1.3.10 The Above Derating of the Default

Different power grade frequenc y converter has its default carrier frequenc y, when to

run at a higher ca rr ier frequency, the AC Drive must to reduce the amount when running.

1.3.11 Change Three Phase Input into Two Phase Input

It is not allowed to change the three ph as e AC drive into two phase one . O th er wise , it

may cause it may c au se fault or damage the AC drive.

1.3.12 The Protection of the Lighting Impulse

Although the AC drive has equipped with lightning overvoltage, overcurrent device, which

has a certain protection function for the induction lightining. For the lightning prone areas,

the user is necessary to install lightning protection device at the front of the AC drive,

which will benefit to the service life of the transducer.

1.3.13 Ambient Temperature and De-rating

The nor mal use o f the fre quency con verter amb ient te mpe rature is -10℃~40 ℃.

Tempe rat ure exce eds 40℃, the e quipment ne ed t o reduce t he a mou nt o f use. The

ambie nt tem perature of e ach inc rease is reduced by 1.5%, the maximum use of the

ambie nt te mperatur e is 50 ℃.

1.3.14 Altitude and Derating

In places where the altitude is a bove 1000m an d the c ool ing e ffe ct re duces due to th in

airit is necessary to de-rat e the AC d rive. Contact Our company for t echnical supp ort .

1.3.15 Some Special Usages

If writing that is n ot de scribed in th is ma nual, su ch as comm on DC bus is ap plied, cont-

act the agent o r Our comp any f or te chn ical support.

Page 13

SD200 User Manual

Chapter 1 Safety and Cautions

1.3.16 The Cautious of the AC drive Disposal

The electrolytic capacitors on the main circuits and PCB may explore when they are burnt.

Poisonous gas is generated when the plastic parts are burn. Treat them as ordinary indu-

strial refer to relevant national laws and regulations.

1.3.17 Adaptable Motor

1. The standard parameters of the adaptable motor is adaptable four-squirrel-cage

asynchronous induction motor or PMSM. For other types of motor, select a proper AC

drive according to the rated motor current.

2. The cooling fan and rotor shaft of general AC Drive are coaxial, which results in

reduced cooling effect when the rotational speed declines. If variable speed is

required, add a more powerful fan or replace.

3. The standard parameters of the adaptable motor have been configured inside the AC

drive. It is still necessary to perform motor auto-tuning or modify the default values

based on actual conditions. Otherwise, the running result and protection performance

will be affected.

4. The AC drive may alarm or even be damaged when short-circuit exists on cables or

inside the motor. Therefore, perform insulation short-circuit test when the motor and

cables are newly installed or during routine maintenance. During the test, make sure

that the AC drive is disconnected from the tested parts.

1

-1 3-

Page 14

Page 15

Chapter 2

Product Information

2.1 Chapter of This Content

This chapter b ri efly introduces the operation principle, product features, layout, namepl -

ate, and type of i ns tr uction.

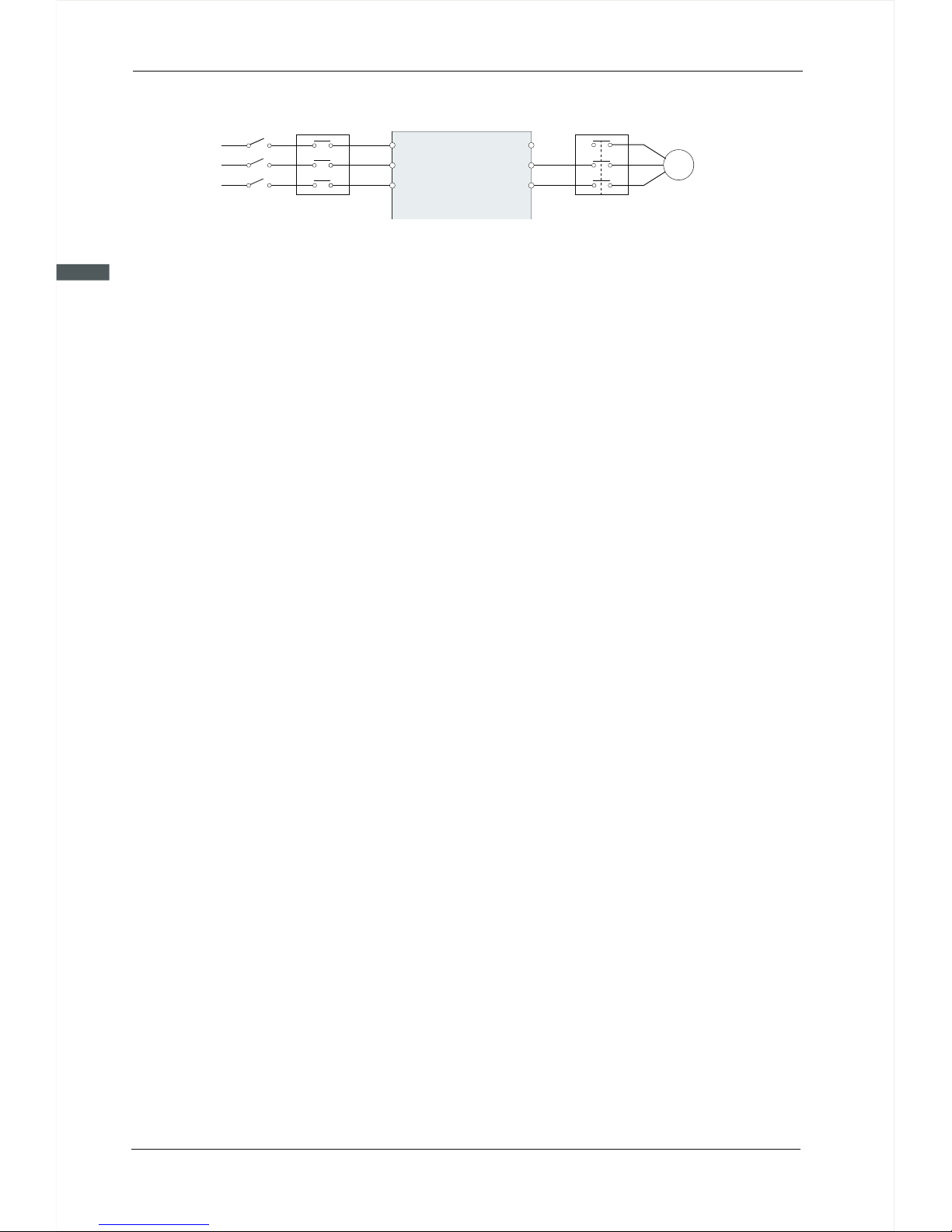

2.2 Basic Principle

SD200 is a kind of A C dr ive used to control asynchronous AC induction motor.

The following figure shows the AC drive main circuit diagram. R ec ti fie make th ree-phase

AC v ol ta ge into DC voltage. Capacitor groups of i nt ermediate circuit stabilize the D C

voltage . Th e AC drive converts of the DC voltage to AC voltage for AC mot or use. When

the voltage in the circuit e xceeds the maxi mu m limit, the braking pipe will connect an

external bra ki ng resistor to the intermediate DC circuit to consume the feedback energy.

-1 5-

Page 16

Figure 2-1 Main Circu it Diagram( less than 1 8.5 kw (including))

P+

R

S

T

U

V

W

PE

PE

PB

P-

Figure 2-2 Main Circu it Diagram (22kw~30 kw)

R

S

T

U

V

W

PE

PE

PB

P-

DC reactor

P

P+

Figure 2-3 Main Circu it Diagram (over 30kw )

DC reactor

P

R

S

T

U

V

W

PE

PE

P+

P-

2

SD200 User Manual

Chapter 2 Product Information

-1 6-

Note:

1.

connecting, it need to take down the bronze between P and P +. 1.

2. Lower than 30kw AC drive (including) support for external braking resistor, higher

than 37kw AC drive (including) support for external braking unit , braking resistor.

Higher than 22kw AC drive (including) support for external DC reactor, before

Page 17

2

SD200 User Manual

Chapter 2 Product Information

-1 7-

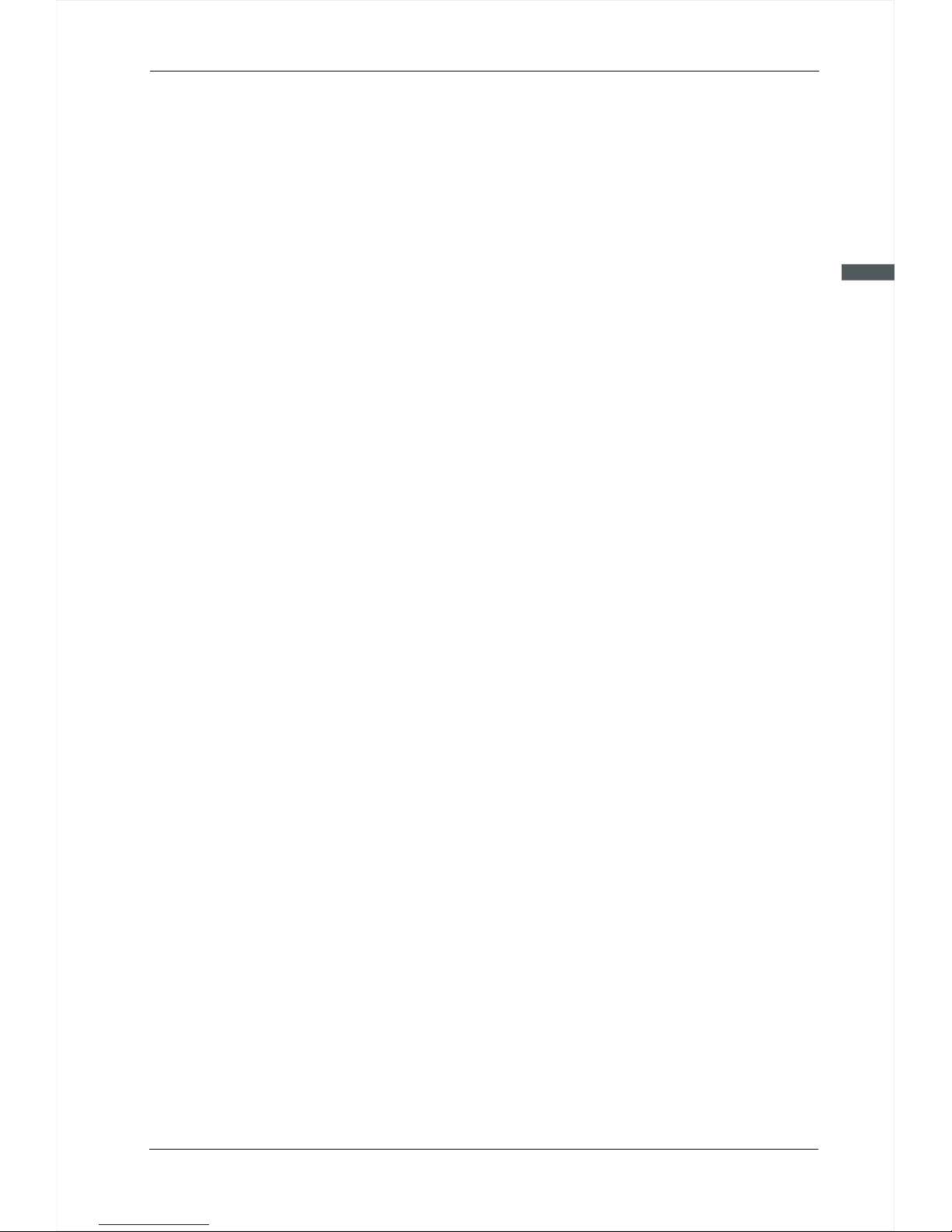

2.3 Naming Rules

In the model cod e co ntains the product information Users can find the code from the

transducer an d simple nameplate.

-

SD200

4T

11

G

P

15

1

2 4

5

C

3 3

4

Field M ark

Content

Explanation

Sinodrive200 abbr eviated SD200

Ac drive series

2S:single-phase 2 20V

2T:Three-phase 22 0V

4T:Three-phase 38 0V

Voltage Level

Adaptive Power

Null

C:

:None

Only braking unit

braking Unit

0.7KW~500KW

G:General

P:Fan pump

Function Type

Ac drive series

Voltage Level

Adaptive Pow er

braking Unit

Function Type

2

4

3

5

1

Figure 2-4 Name Desig nation Rules

Figure 2-4 Name Desig nation Rules

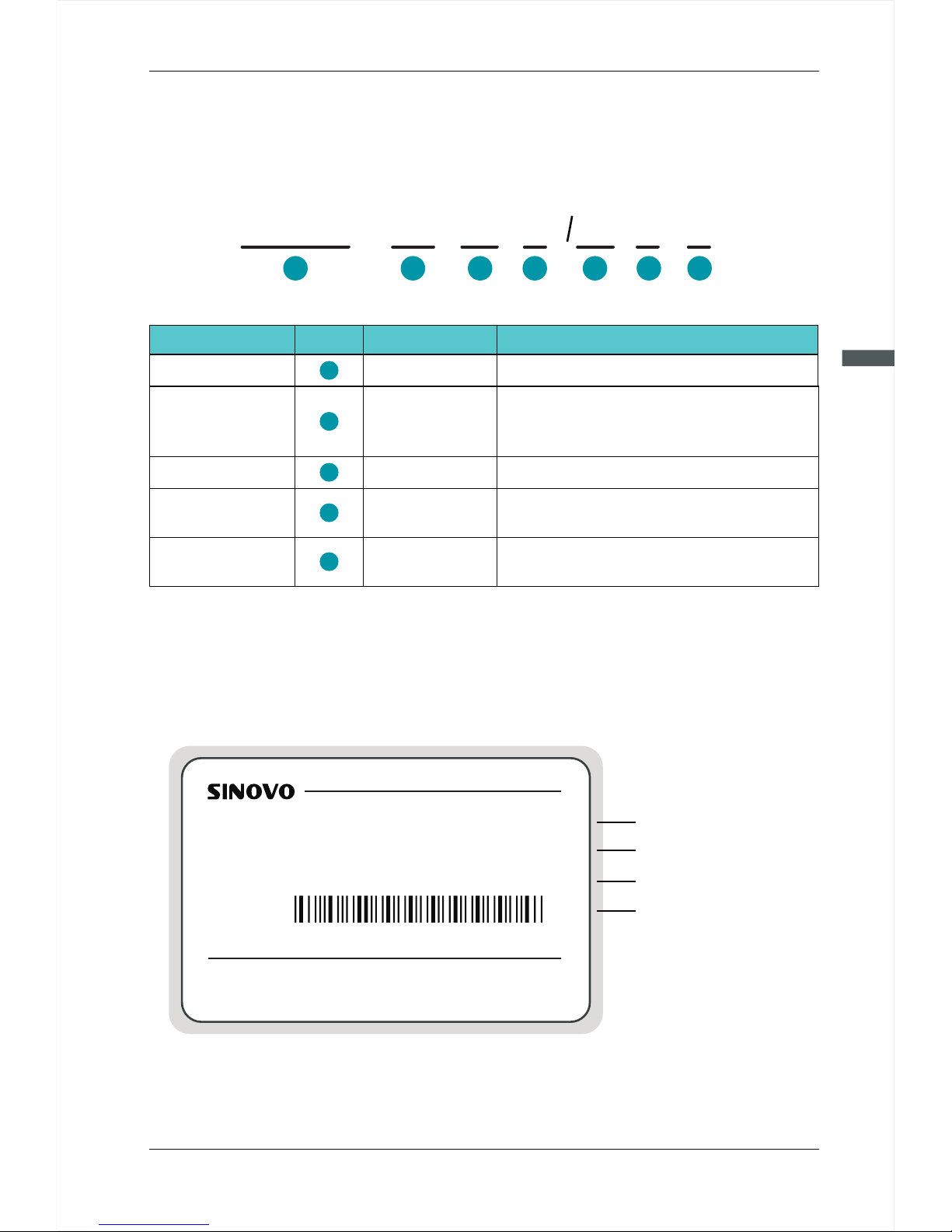

2.4 Nameplate

SHENZHEN SINOVO ELECTRIC TECHNOLOGIES CO.,LTD.

MODEL: SD200-4T-5.5G/7.5P C

INPUT: AC3PH 380V 50/60Hz 14.6A/20.5A

OUTPUT: AC3PH 380V 0~600Hz 13A/17A

S/N: FDLAGCA0A040

MADE IN CHI NA

Model of the AC drive

Rated input voltage,

frequency and current

Bar code

Rated output voltage,

frequency and current

Page 18

2

SD200 User Manual

Chapter 2 Product Information

-1 8-

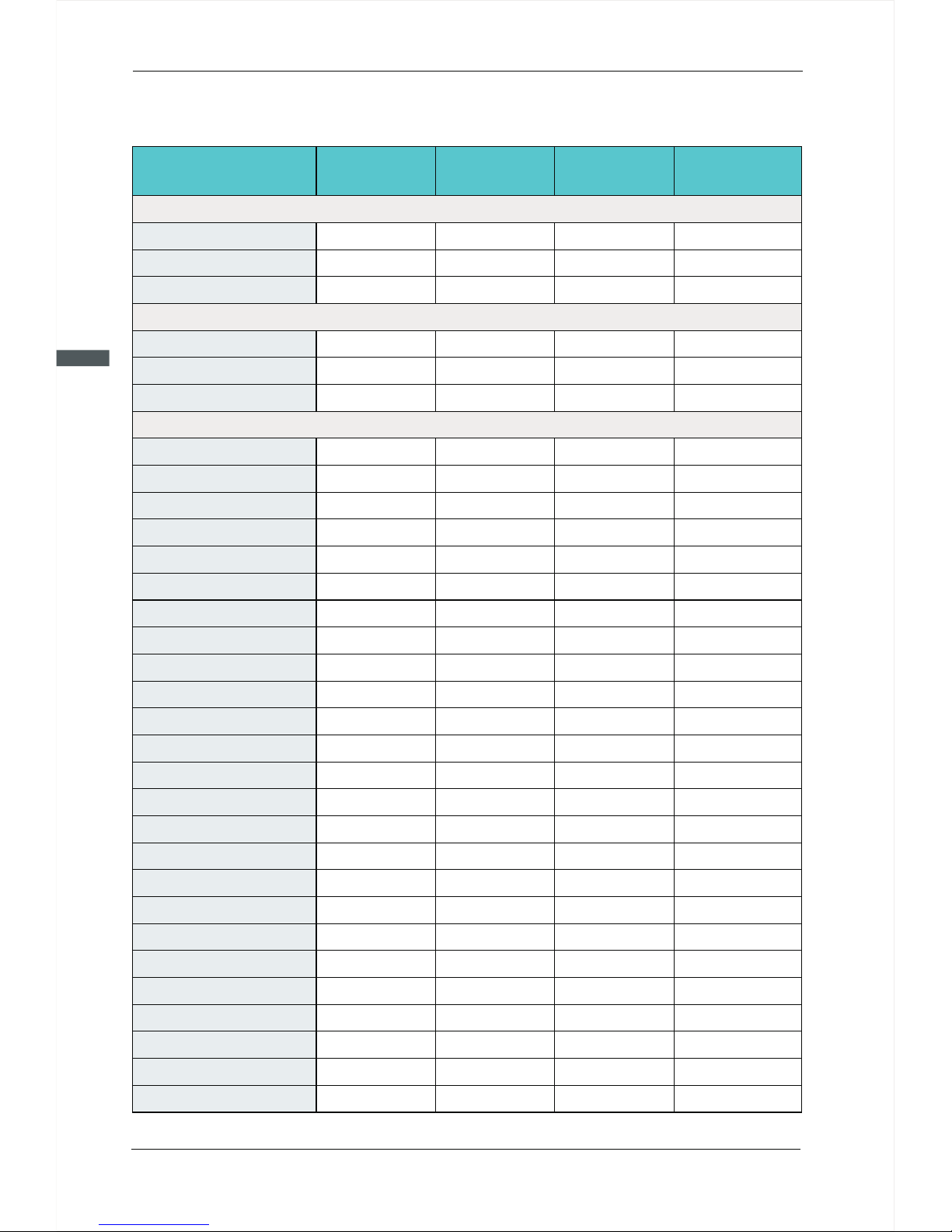

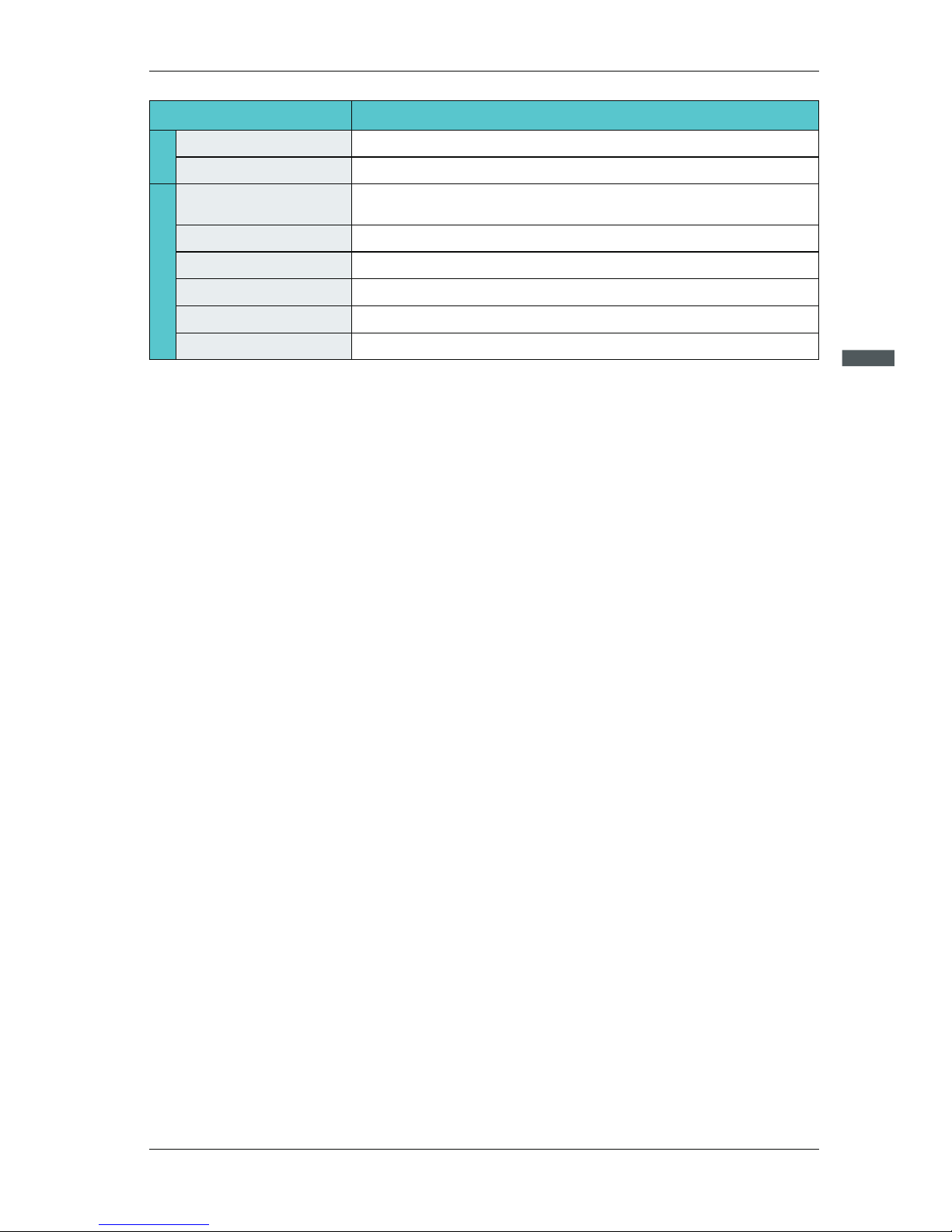

2.5 SD200 Series of AC drive

Model

Power Capacity

(KVA)

1. 5

Input Current

(A)

Output Current

(A)

Adaptable Motor

(KW)

3. 4 0. 752. 3 0. 75

Three-phase 380V Range:-15%~20%

3. 0

4. 0

5. 9

8. 9

11

40

57

69

85

11 4

13 4

16 0

19 2

17

21

24

30

23 1

35 5

25 5

39 6

28 7

43 9

31 1

5. 0 3. 7

1. 5

5. 8

5. 1

2. 2

10 .5 8. 5 4. 0

14 .6 13

5. 5

20 .5

17 7. 5

62 .5 60 30

76 .0

75

37

92 .0 91 45

11 3

11 2

55

15 7

15 0

75

18 0 176 90

21 4

21 0 110

25 6 253 1 32

26 .0 25 11

35 .0 32

15

38 .5 37 18.5

46 .5 45

22

30 7 304 16 0

47 0 465 25 0

33 3 330 18 5

52 5 520 28 0

38 0 377 20 0

60 5 600 31 5

42 9 426 220

SD 200-4 T-55G

SD 200-4 T-75G

SD 200-4 T-90G

SD 200-4 T-110G

SD 200-4 T-132G

SD 200-4 T-160G

SD 200-4 T-185G

SD 200-4 T-200G

SD 200-4 T-220G

SD 200-4 T-250G

SD 200-4 T-280G

SD 200-4 T-315G

SD 200-4 T-0.7G

SD 200-4 T-1.5G

SD 200-4 T-2.2G

SD 200-4 T-4.0G

SD 200-4 T-5.5G

SD 200-4 T-7.5G

SD 200-4 T-11G

SD 200-4 T-15G

SD 200-4 T-18.5G

SD 200-4 T-22G

SD 200-4 T-30G

SD 200-4 T-37G

SD 200-4 T-45G

1. 5

8. 2 0.754.7 0.75

single-phase 220V Range:-15%~20%

3. 0

4. 0

14 .0 7.5

1. 5

23 .0

10 .0

2. 2

SD 200-2 S-0.7G

SD 200- -1 .52S G

SD 200- -2 .22S G

1. 5

5. 5 0.754.7 0.75

Three-phase 220V Range:-15%~20%

3. 0

4. 0

7. 7 7. 5

1. 5

12 .0

10 .0

2. 2

SD 200-2 T-0.7G

SD 200- -1. 52T G

SD 200- -2. 22T G

Page 19

2

SD200 User Manual

Chapter 2 Product Information

-1 9-

53 0

60 0

66 0

47 9

73 0 725 40 0

82 5 820 45 0

91 0 900 50 0

66 5 660 35 0SD 200-4 T-350G

SD 200-4 T-400G

SD 200-4 T-450G

SD 200-4 T-500G

Model

Power Capacit

(KVA)

Input Current

(A)

Output Current

(A)

Adaptable Motor

(KW)

Note:

1. 0.75 ~ 315 kw AC drive input current is the measured results, which under the condition

of input voltage 380V, and without DC reactor as well as input and output reactor;

2. 350 ~ 500 kw AC drive input current is the measured results, which under the condition

of input voltage 380V, and equipped with input reactor;

3. Rated output current is defined as the output current of the output voltage 380V.

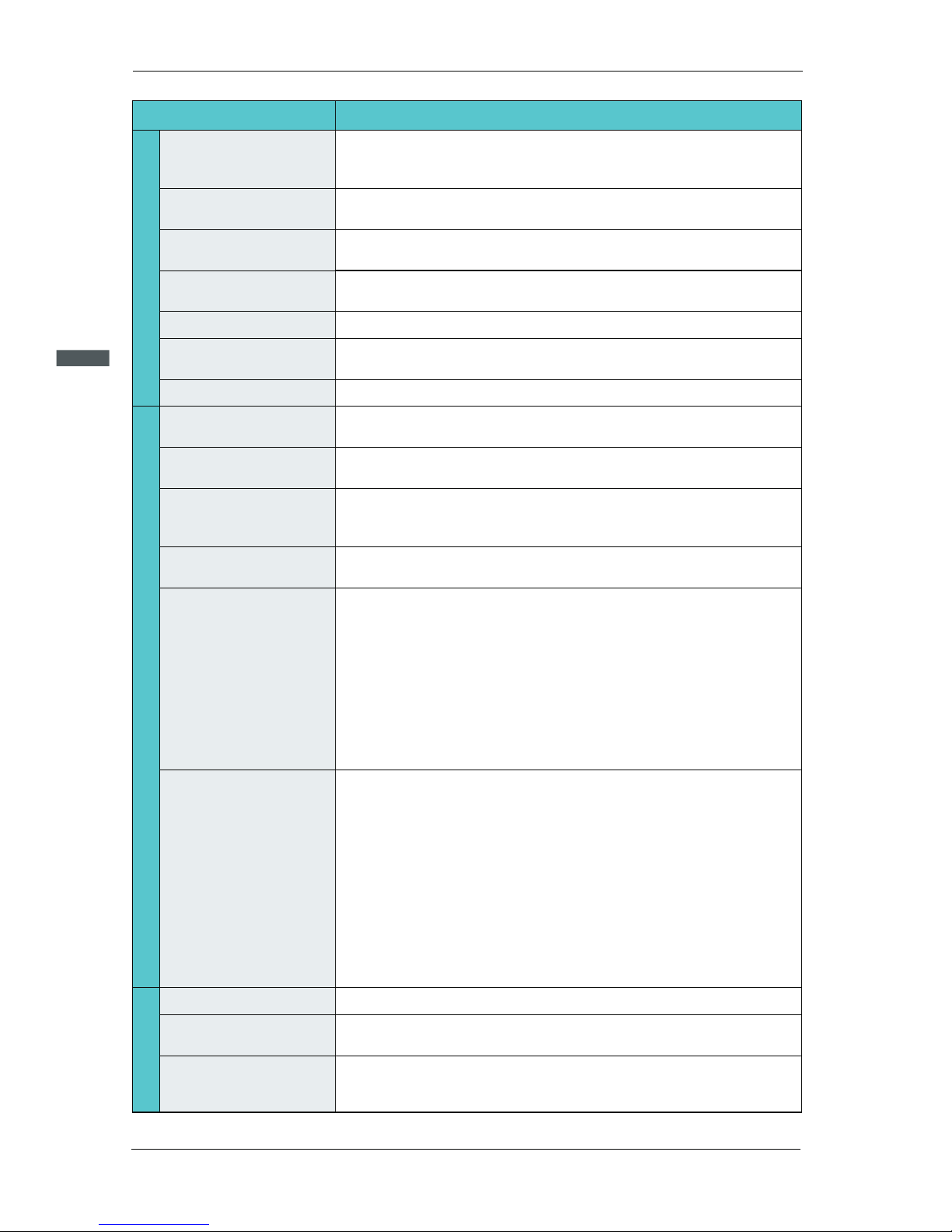

2.6 Technical Specifications

Item

Specification

0~600Hz

2.0kHz~10kHz; The carrier frequency is automatically adjusted

based on the load features.

1:50(vector control 0 mode)

1HZ/150% Rated troque

G type:150% rated current for 60s

Auto torque boost

Line or S-curve Acc/Dec mode, four kinds of Acc/Dec time Range of

Acc/Dec time 0.0~6000.0s

DC braking frequency : 0.00Hz to Maximum frequency

braking time: 0.0 to 100.0s

braking current : 0.0 to 150%

16-speed operatin g through built-in PL C or control terminal

It realizes proce ss-controlled clo sed loop control syst em e asily.

Jog frequency range:0 .00Hz~Maximum fre quency

The current and voltage are limited automatically during

the running process so as to avoid frequent tripping due to

overvoltage/overcurrent.

It helps to avoid frequ ent over- current fau lts of the AC drive.

P type: 110% rated current for 60s

Manual torque boost: 0.1%~20.0%

Maximum frequency

Carrier frequency

Input frequency

resolution

Overload capacity

Torque boost

V/F curve

Accelerate/

Decelerate curve

DC braking

Simple PLC Multi-speed

Onboard PID

Auto voltage

regulation (AVR)

Overvoltage/overcurrent

stall control

Rapid current limit

Jog frequency range:0 .00Hz~F00.03Max imum frequency

Jog control

Digital setting:0.01Hz

Analog setting : Maximum frequency x 0.025%

Basic Function

0:V/F control

1:Vector control 0 mode

Control mode

Speed range

Line

Multi-point

Square V/F curve

VF separation

Page 20

2

SD200 User Manual

Chapter 2 Product Information

-2 0-

Item

Specification

Freatures

Identify the speed of rapidly rotating motor to realize a smooth start

without any rush.

Load feedback energy compensates the voltage reduction so that

the AC drive can continue to run in a short time in case of power

interruption.

Speed tracking start

Non stop function

Rapid software and hardware current limiting technology helps to

avoid frequent over-current fault.

Rapid current limit

Four sets of virtual DO, five groups of virtual DI, enables easy logic

control.

Virtual IO

Timing Control

Two independent motor parameters enable two motors switching

control

Multi-motor switch

Timing control: set the time range 0.0Min~6500.0Min

Bus Support

Two independent Modbus communication, profibus-DP

Optional IO expansion card 1, analog input AI5 acceptable the input

of motor temperature sensor .(PT100,PT1000)

Motor overheating

protection

Running

Given the control panel, control terminal, serial communication port

given. It can be switched by a variety of ways.

Frequency source

Command source

11 frequency sources: digital setting, analog voltage setting, analog

current setting, pulse setting and serial port. It can be switched by a

variety of ways.

11 auxiliary frequency source. Flexible implementation of auxiliary

frequency tuning, frequency synthesis.

Auxiliary frequency

source

Standard:

. Six digital input terminals, one of which support to 50kHz high speed pulse input

. Three analog input terminals, two of which supports -10V~10V

voltage input

. One support 0 ~ 10V voltage input or 0 ~ 20mA current input

Expansion capability:

. Two digital inputs

. One analog input terminal, support -10V ~ 10V voltage input, and

supports PT100 / Pt1000

Input terminal

Standard:

. One high-speed pulse output terminal (optional open collector

type), support of 0 ~ 50kHz square wave signal output

. One digital output terminal

. Two relay output terminals

. Two analog output terminals, support 0~20mA current output or

0~10V voltage output

Expansion capability:

. One digital output terminal

. One relay output terminal

. One analog output terminal, support 0~20mA current output or

0~10V voltage output.

Output terminal

Display each parameter of function code group

LED display

Achieve some or all of the keys locked and define the scope of

partial keys to prevent misuse.

The key lock and

function selection

Display and

operation

Protection function

Powered motor short circuit test; Input/output phase failure protection; Over current protection; voltage protection; Under voltage protection; Over heat protection ; Overload protection; braking resis-

Page 21

2

SD200 User Manual

Chapter 2 Product Information

-2 1-

Item

Specification

Protection function

tor fault protection.

Display each parameter of function code group

Accessories

In-door, free from direct sunlight, dust, corrosive gas, combustible

ga , oil mist, steam , water drop and salt .

Application environment

Altitude

Lower than 1000m (1000m-3000m for derated use)

Environment

Ambient temperature

-10℃+40℃ (derated use in the ambient temperature of 40℃ to 50 ℃ )

Humidity

Less than 95%RH, without condensation

Vibration

Less than 5.9m/s(0.6g)

Storage temperature

-20℃~+60℃

Page 22

2

SD200 User Manual

Chapter 2 Product Information

-2 2-

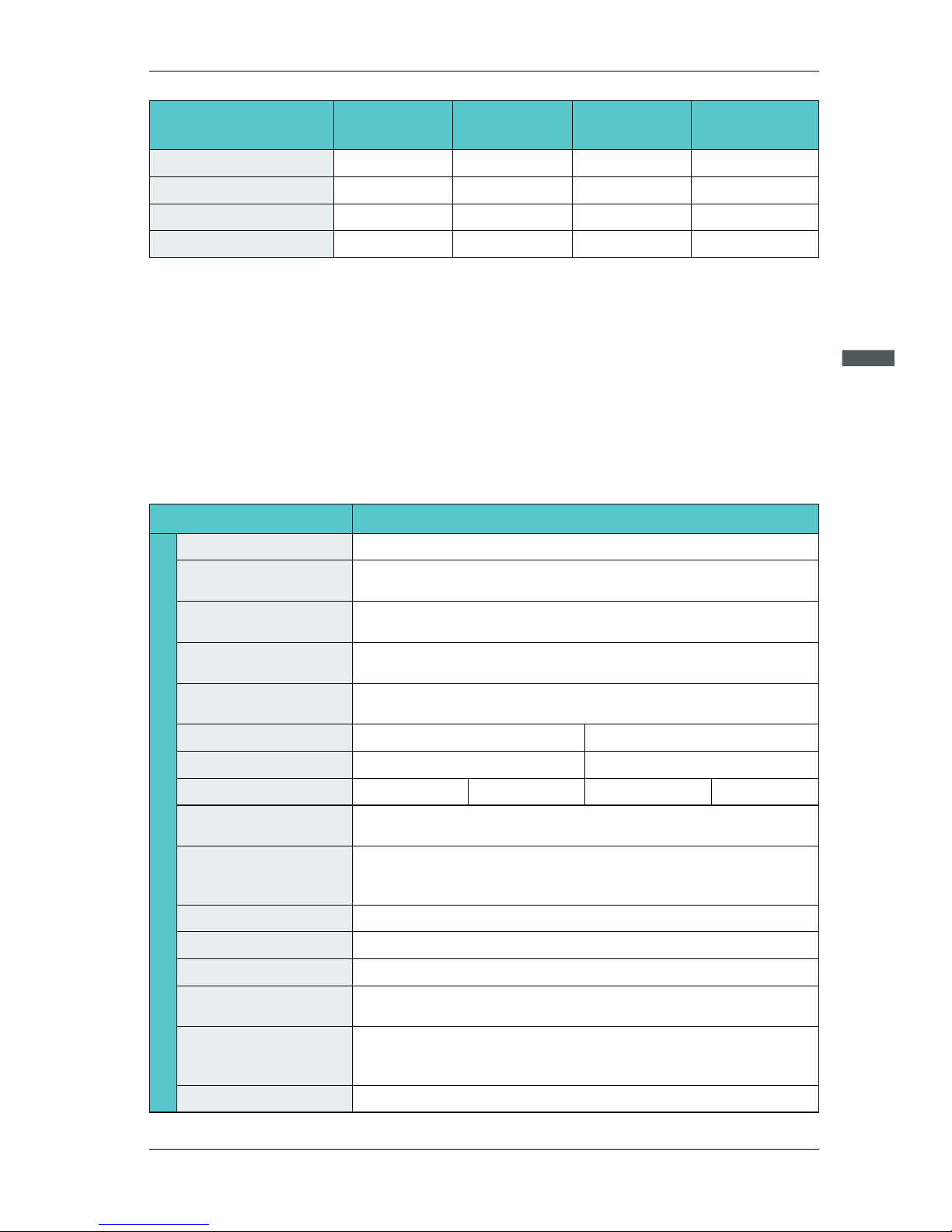

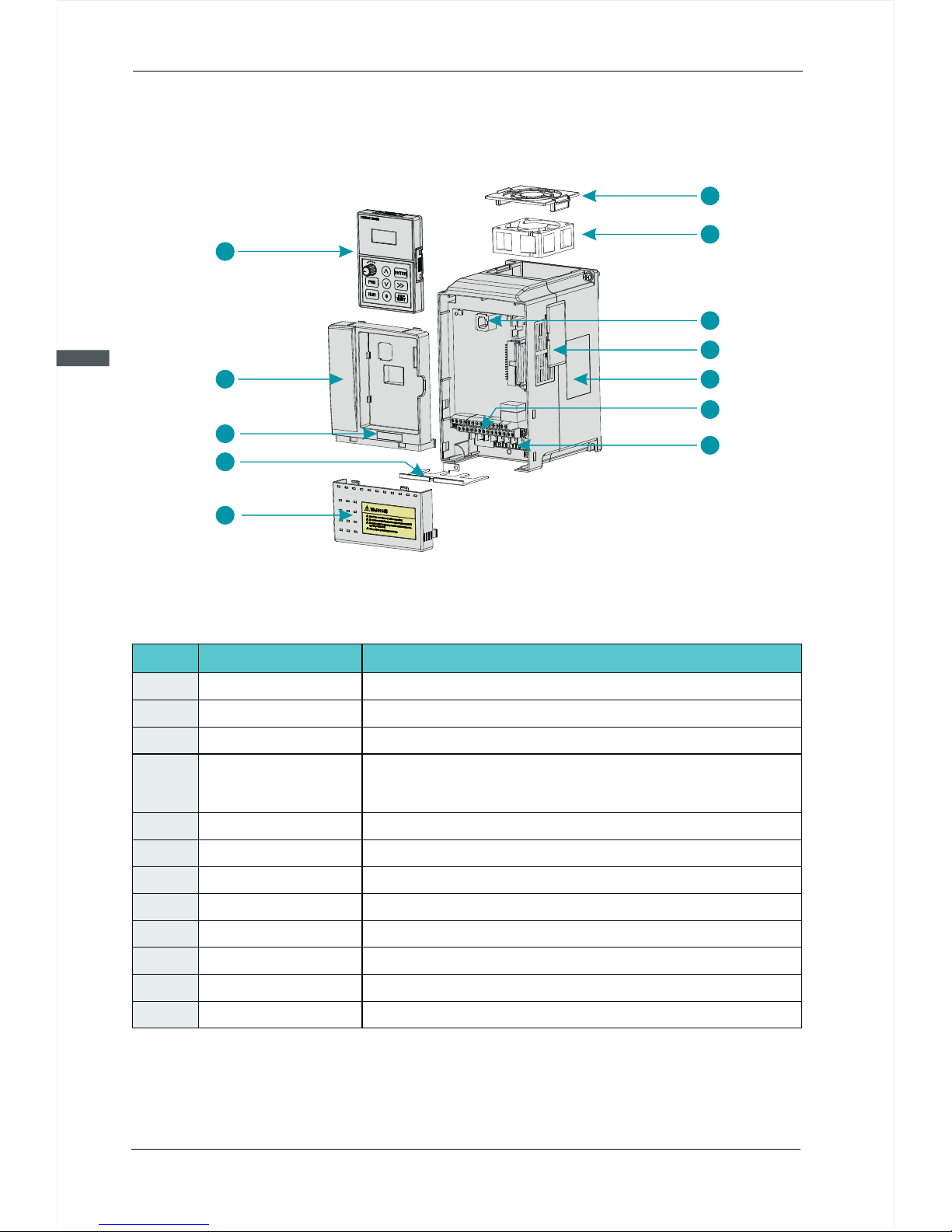

2.7 Structure diagram

2.7.1 The following figure shows the layout of the AC drive ( 7.5KW,for example).

1

2

3

4

5

6

7

8

9

10

11

12

Figure 2-6 Product st ructure diagram

Name

Description

1

No

2

3

4

5

6

7

8

9

10

11

12

Fan-cover

Protection fan.

Refer to 8.1 "Maintenance and hardware diagnostics."

It is used to connect the Keypad.

Optional. with the vents-cover installed, the protection level will

increase and the AC drive internal temperature will increase as

well so please derating use the AC drive.

Refer to 2.4 "Operating principle and Product Overview."

Refer to 3.3 "Electrical Installation."

Refer to 3.3 "Electrical Installation."

Refer to chapter4 "Keypad operating procedures."

Protect the internal components.

Refer to 2.3 "Naming Rules".

Convenient input and output wiring.

Protect the internal components.

Cooling fan

Keypad interface

Vents-cover

Nameplate

Control terminals

Main circuit terminals

Keypad

Cabinet-cover

Lower-cover

Series Label

Apron

Page 23

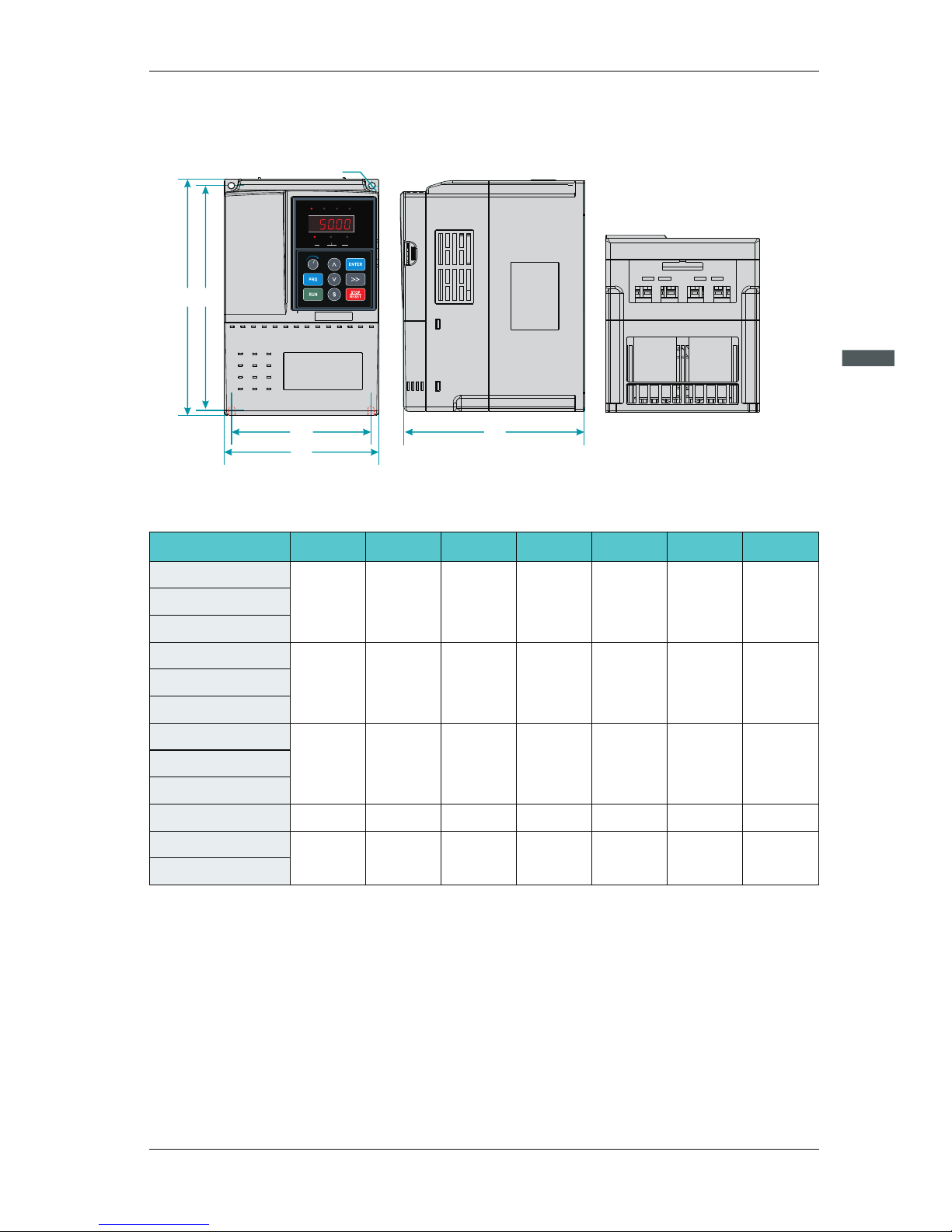

Figure 2-7 Less than 7. 5 KW AC drive installat ion dimensions and in st allation size

D

H

W

W1

H1

Ø

DIGI TAL PAN EL

DIGI TAL PAN EL

Hz

A

V

RPM

%

FWDREV/RUNTUNE/ LOCALREMOT/ TRIP

2

SD200 User Manual

Chapter 2 Product Information

-2 3-

2.7.2.1 SD200 series less than7.5KW (including 7.5KW)

2.7.2 Product Outline, Installation Hole Size

AC drive model

H(mm) W(mm) D(mm)

H1(mm) W1(mm)

D

(mm)

iameter

GW(kg)

SD 200-4 T-0.7G

SD 200-4 T-1.5G

SD 200-4 T-2.2G

SD 200-4 T-4.0G

SD 200-4 T-5.5G

SD 200-4 T-7.5G

19 0 11 0 15 0 17 8 98

Ø5

2. 4

21 0 13 0 16 0 19 8 11 8

Ø5

3. 5

25 0

15 5

17 6 23 6

14 1

Ø5

4. 5

SD 200-2 S-0.7G

SD 200-2 -1.5S G

SD 200-2 -2.2S G

SD 200-2 T-0.7G

SD 200-2 T-1.5G

SD 200-2 T-2.2G

19 0 11 0 15 0 17 8 98

Ø5

2. 4

19 0 11 0 15 0 17 8 98

Ø5

2. 4

Page 24

2

SD200 User Manual

Chapter 2 Product Information

-2 4-

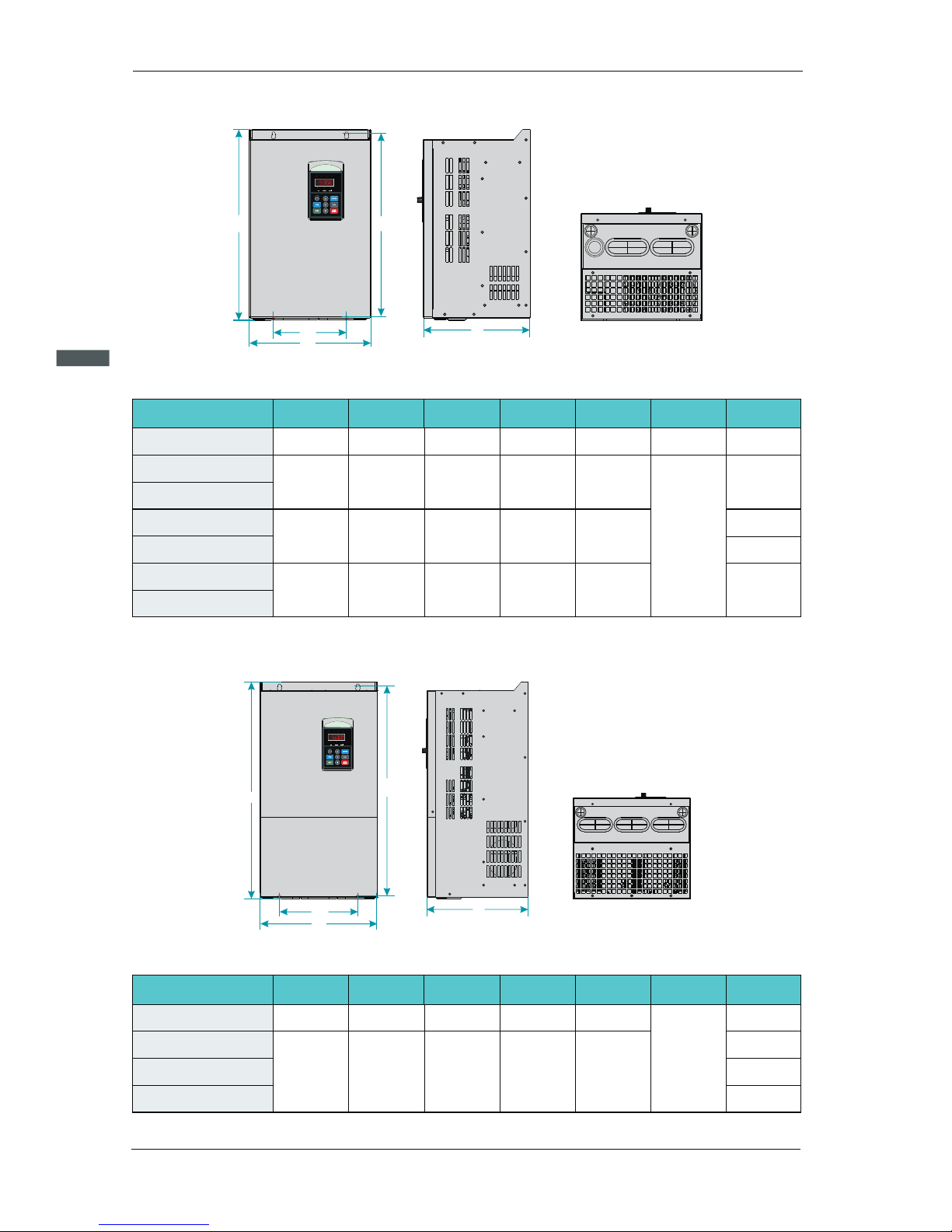

2.7.2.2 SD200 Series 11KW~45KW

D

H

W

W1

H1

DIGITAL PANEL

DIGITAL PANEL

Hz

A

V

RPM

%

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Figure 2-8 11kw~45k w AC drive installati on dimensions and insta llation size

17 0 16 2 27 0

Ø6

22 0

21 4

31 8

Ø7

25 0 22 0 37 3

5. 1

9. 3

19

28 5

33 2

38 7

27 0 25 2 42 6 2544 0

13 5

14 0

15 0

18 0

SD 200-4 T-11G

SD 200-4 T-15G

SD 200-4 T-18.5G

SD 200-4 T-22G

SD 200-4 T-30G

SD 200-4 T-37G

SD 200-4 T-45G

14

AC drive model

H(mm) W(mm) D(mm)

H1(mm) W1(mm)

D

(mm)

iameter

GW(kg)

D

H

H1

W1

DIGITAL PANEL

DIGITAL PANEL

Hz

A

V

RPM

%

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

W

2.7.2.3 SD200 Series 55KW~110KW

Fig 2-9 55~110KW AC dri ve installation dim ensions and installat ion size

30 0 25 8 53 4 20 0

37 0 28 2 62 5 25 0

Ø9

3255 0

65 0

52

55

58

SD 200-4 T-5 G5

SD 200-4 T-75G

SD 200-4 T-90G

SD 200-4 T-110G

AC drive model

H(mm) W(mm) D(mm)

H1(mm) W1(mm)

D

(mm)

iameter

GW(kg)

Page 25

2

SD200 User Manual

Chapter 2 Product Information

-2 5-

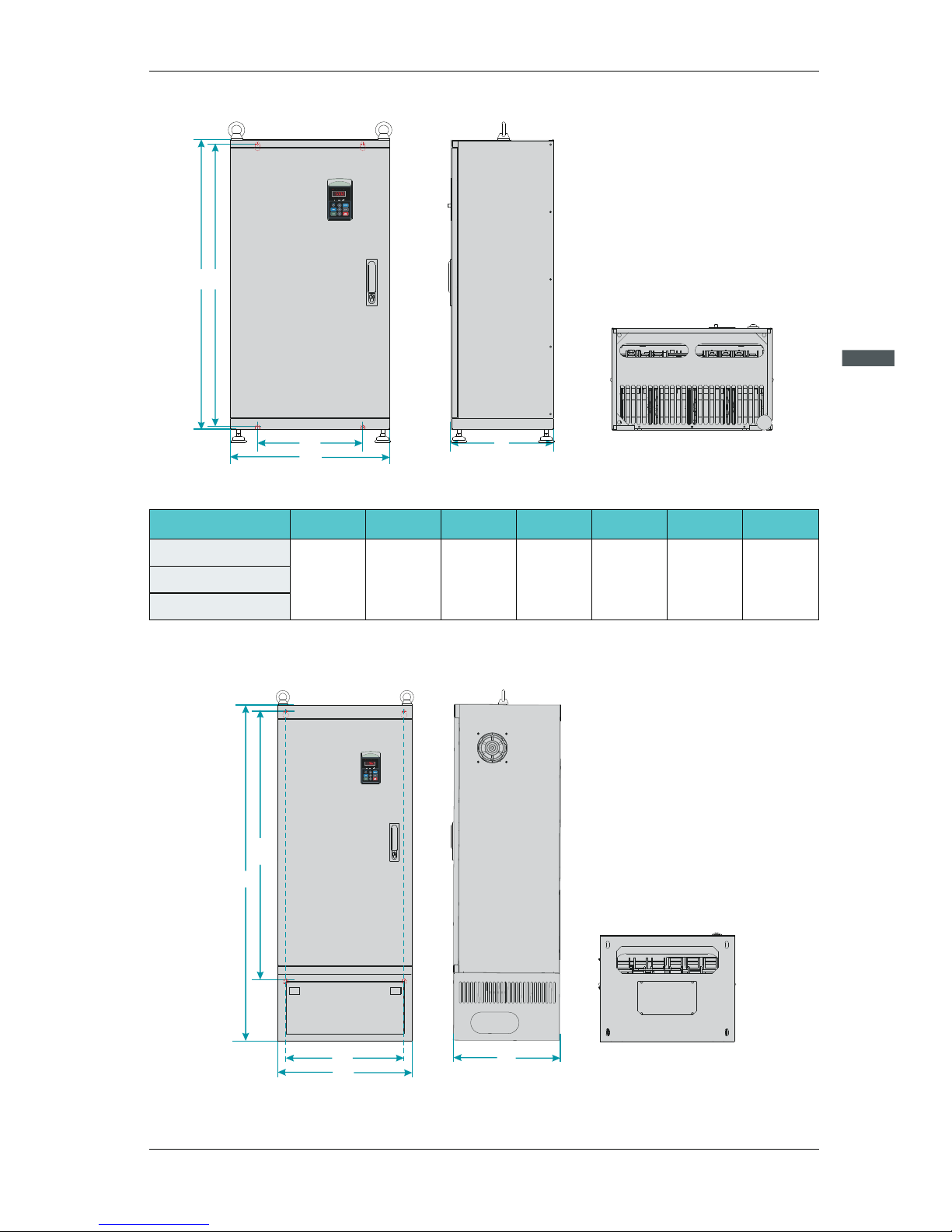

SD 200-4 T-132G

88 0 48 5 31 0 86 0 32 0

Ø1 3

99SD 200-4 T-160G

SD 200-4 T-185G

AC drive model

H(mm) W(mm) D(mm)

H1(mm) W1(mm)

D

(mm)

iameter

GW(kg)

2.7.2.4 SD200 Series 132KW~185KW

H

H1

W

W1

DIGITAL PANEL

DIGITAL PANEL

Hz

A

V

RPM

%

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

D

Figure 2-10 132KW~1 85KW AC drive install ation dimensions and in stallation size

2.7.2.5 SD200 Series 200KW~500KW

H

H1

W1

DIGITAL PANEL

DIGITAL PANEL

Hz

A

V

RPM

%

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

W

D

Figure 2-11 200KW~5 00KW AC drive install ation dimensions and in stallation size

Page 26

2

SD200 User Manual

Chapter 2 Product Information

-2 6-

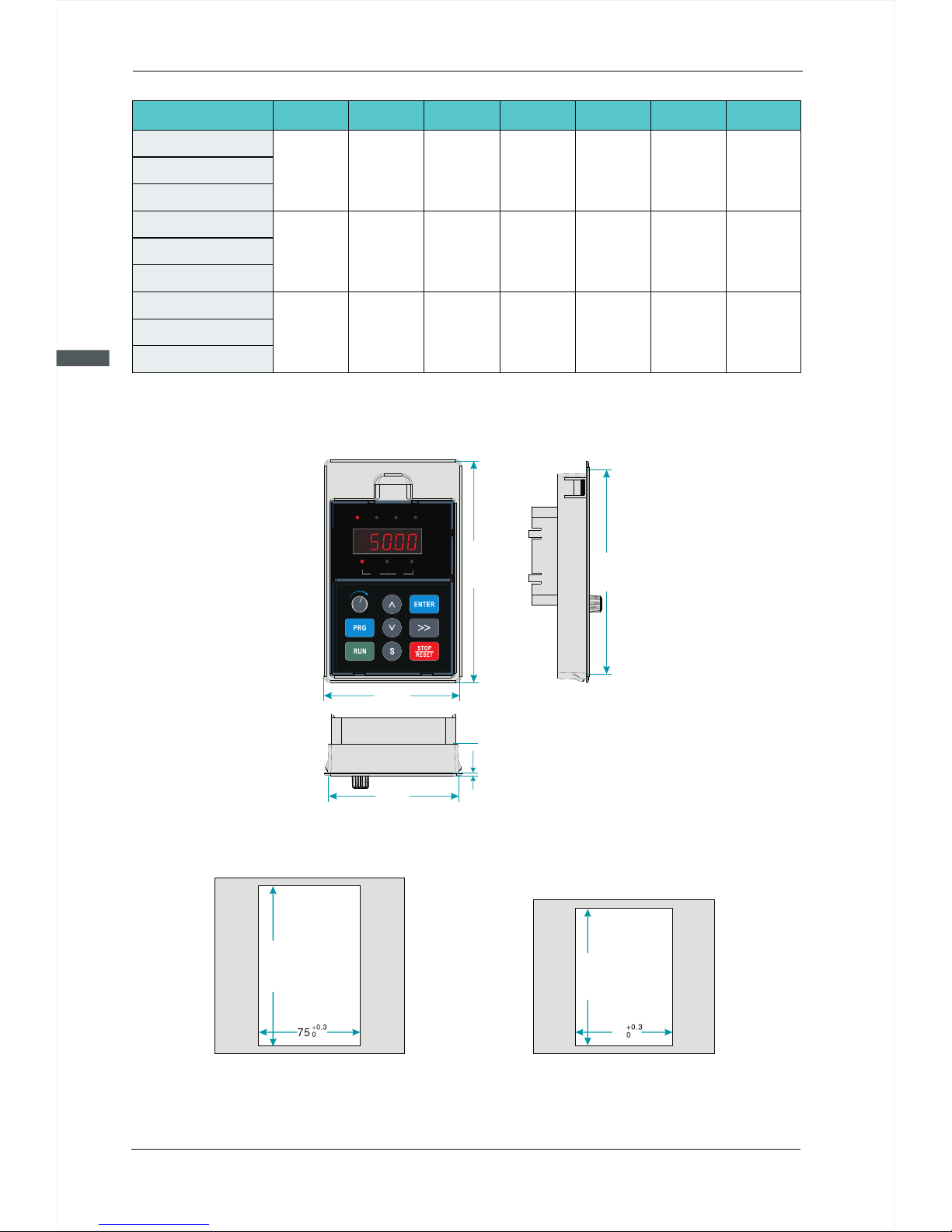

2.7.3 External Keypad Installation Dimensions

Figure 2-12 Keypad In stallation dimens ions

119.00

128.20

79.00

DIG ITAL PA NELDIG ITAL PA NEL

Hz

A

V

RPM

%

FWDREV/RUNTUNE/ LOCALREMOT/ TRIP

74.80

1.50

AC drive model

H(mm) W(mm) D(mm)

H1(mm) W1(mm)

D

(mm)

iameter

GW(kg)

SD 200-4 T-200G

SD 200-4 T-220G

SD 200-4 T-250G

SD 200-4 T-280G

12 50 50 0 40 0 100 0 440

Ø1 3

16 7

SD 200-4 T-315G

SD 200-4 T-350G

SD 200-4 T-400G

SD 200-4 T-450G

SD 200-4 T-500G

13 50 65 0 40 0 110 5 513

Ø1 3

20 6

18 10 85 0 40 5 141 0 513

Ø1 3

41 5

Figure 2-14

Opening dimension d iagram

for keypad without ba se

Figure 2-13

Opening dimension d iagram

for keypad with base

11 9.5

+0. 3

0

10 0

+0. 3

0

70

Page 27

2

SD200 User Manual

Chapter 2 Product Information

-2 7-

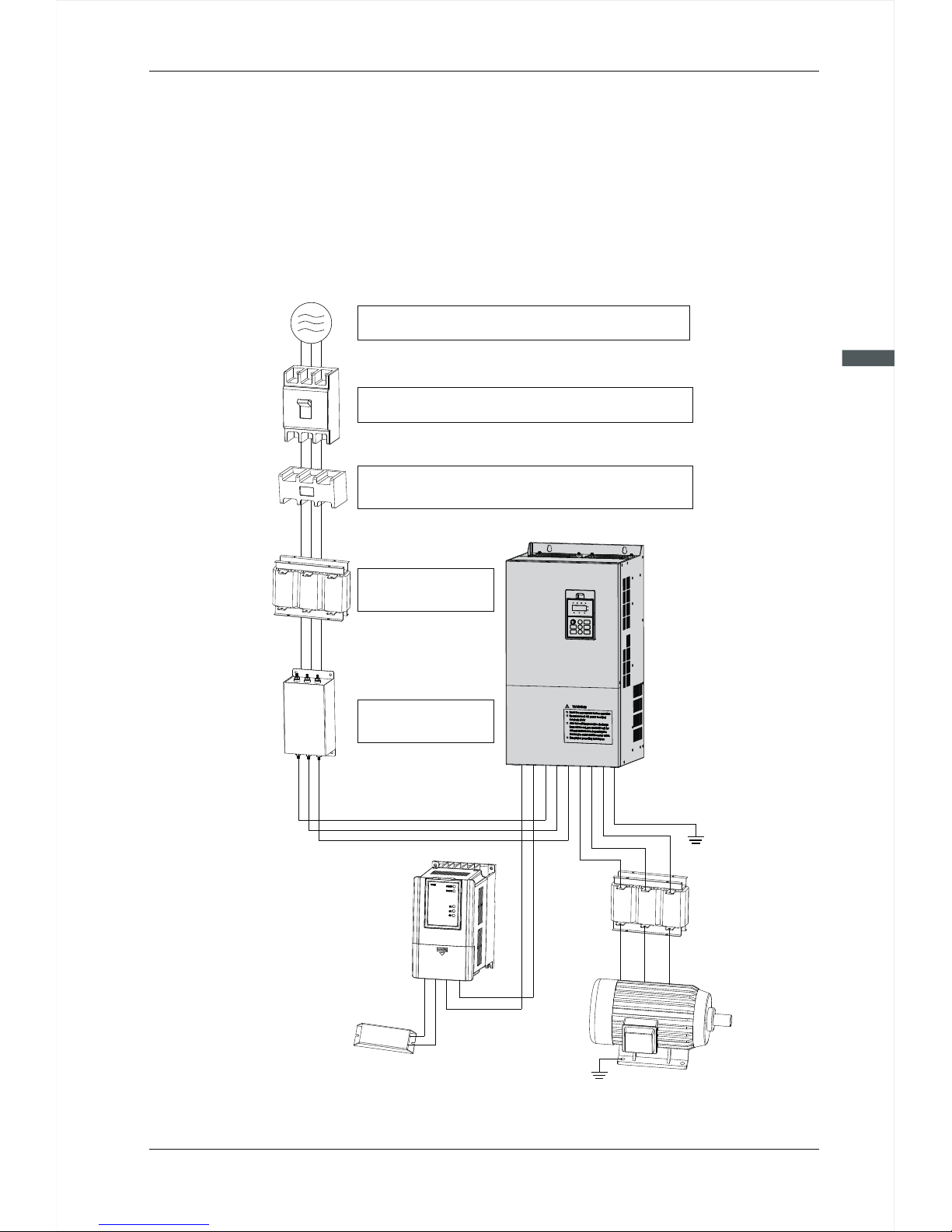

When using SD200 s eries AC drive to control a sy nchronous motor syste m, you have to

install va ri ous electrical components on the side of input and output o f the AC drive to

guarantee the stabili ty and safety of s ys te m.In addition, SD200 series AC drive is

equipped with a variety of optional accessories and expansion card to achieve various

functions. More than 37kw series three-phase 380v system structure as sh ow n in the

figure below (T he figure AC drive terminal refer to 55~110KW):

2.8 Peripheral Electrical Components System Structure

Figure 2-15 Under 37 kw s eries 3-phase 380 V sys tem structure diagr am

T

S

R

P-

P+

P

PB

P+

BR

PE

W

V

U

P

P-

P+

3-phase AC

power supply

Use within the allowable power supply specif icati on

of the AC d rive

Moulded case

circuit breakeror

earth leakage

circuit breakers

Select a proper breaker to resistlarge in-rush current

that flows into the AC drive at power-on

To guarantee safety, use an electromagnetic contactor.

Do not use it to start or stop the AC drive because such

operation reduces the service life of the AC drive

Suppress the high

order harmonic to

improve power factor

Electromagnetic

contactor

AC reactor

Reduce the electromagnetic interference

on the input side.

Input side EMC

filter

Break unit

Braking resistor

Ground

Output reactors

Ground

Motor

AC Driver

Page 28

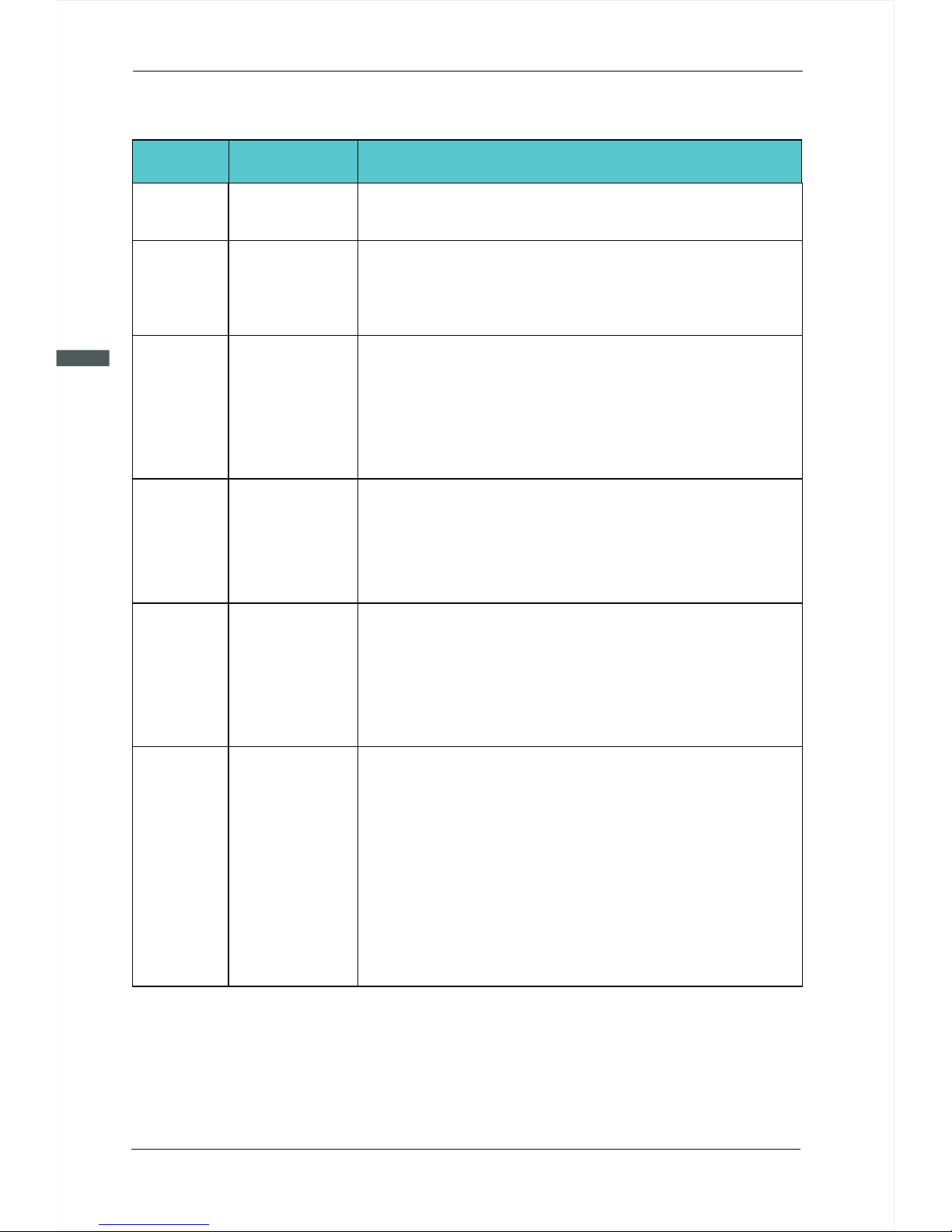

2.8.1 Peripheral Electrical Components Description

2

SD200 User Manual

Chapter 2 Product Information

-2 8-

Installation

position

Function Description

Accessory

Name

MCCB

Interrupt th e po wer supply when overcurrent occurs

ª

on downstrea m de vices.

Power

receiving side

Contactor

ª

drive frequently by switching the contactor on and off

(less than twice per minute) nor use it to directly start

the AC drive.

Start and stop the AC drive.Do not start and stop the AC

Between MCCB

and the AC drive

input side

AC input

reactor

ª

Eliminate the higher harmonics of the input side effecti-

ª

vely and prevent other devices from being damaged due

to distortion of the voltage waveform;

Eliminate the input current unbalance due to unbalance

ª

between the power phases;

Improve the power factor of the input side;

AC drive

input side

EMC input

filter

ª

nce of the AC drive;

Decrease the conduction interference flowing from the

ª

power end to the AC drive and improve the anti-interfe rence capacity of the AC drive.

Reduce the external conduction and radiation interfere-

AC drive

input side

DC reactor

ª

Improve the efficiency and thermal stability of the AC

ª

drive;

Eliminate the impact of higher harmonics of the AC drive

ª

input side and reduce the external conduction and

radiation interference.

Improve the input power factor;

SD200 series

AC drive of

30G and above

configured

with DC reactor

as standard

AC output

reactor

ª

higher harmonics. When the motor is far from the AC

drive, there is much distributed capacitance in the circuit

and certain harmonics may cause resonance in the

circuit, bringing about the following two impacts:

a.Degrade the motor insulation performance and damage

the motor in the long run.

b.Generate large leakage current and cause frequent AC

drive protection trips.

If the distance between the AC drive and the motor is

ª

greater than 100 m, install an AC output reactor.

The output side of the AC drive generally has much

Between the AC

drive output side

and the motor,

close to the AC

drive

Page 29

2

SD200 User Manual

Chapter 2 Product Information

-2 9-

Note:

1.

Otherwise, it may cause faults to the AC drive or damage to the capacitor and surge

suppressor;

2. Input/output (main circuit) of the AC drive include harmonic components, which may

interfere with the AC drive attachment communications equipment. Therefore, install

an anti-aliasing filter to minimize the interference;

3. Details of peripherals and options refer to Chapter 2 selection of peripheral devices.

Do not install capacitor or surge suppressor on the output side of the AC drive.

2.9 SD200 Optional Parts

Peripheral optional braking unit, each function expansion card and the outer lead operator,

etc..As shown below. Seeing detailed usage instructions for use of the accessory. For the

following options, please note when ordering.

Type

RemarkName

Internal

braking unit

Models

followed

by letter "C”

Function

Models power under 22KW are

installed with the internal braking

unit as standard configuration

External

braking unit

SDBUN

37KW and above need to be

configured with an external

braking unit

For 30KW model power,

the braking unit is optional

Multiple braking ones are

connected in parallel for

the models above 90KW

Multi-function

I/O expansion

card

SDIO1

Increase 3 digital inputs, 2 digital

outputs, two relay outputs, two

analog voltage input T_Motor

It applies to all models

Modbus

communication

card

SDCM01

One RS - 485 communication

card, one CAN communication

card.

Coming soon

Profibus-DP

card

SDDP01

Profibus-DP card,DB9interface

Coming soon

External LCD

panel

SDPG01

External LCD display and keypad,

you supply copy parameters

Coming soon

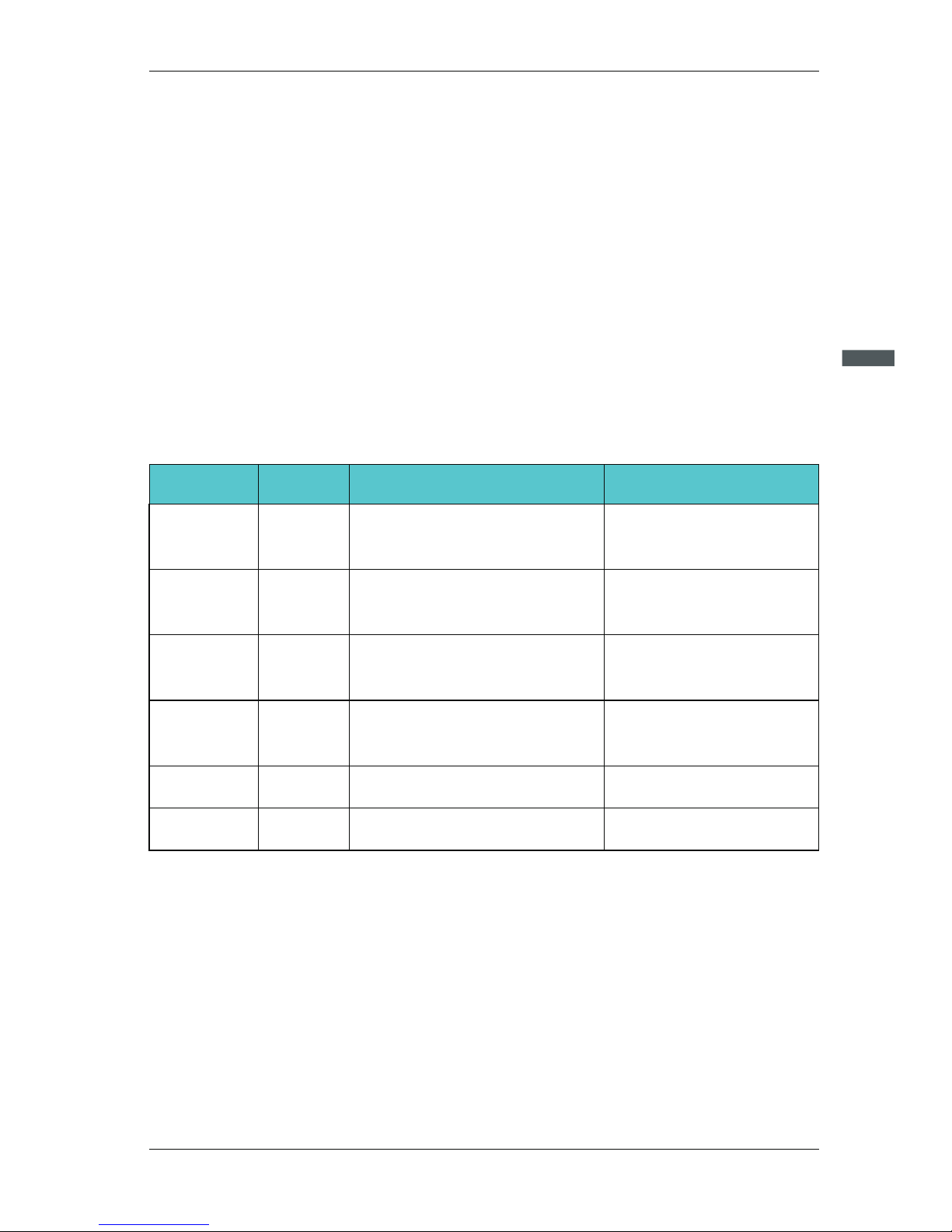

2.9.1 Selection Braking Unit

The section recommend braking assembly is instructional data, user can select different

resistance value and power according to actual situation. (Resistance values can not be

lower than the recommended ones , the power can be higher than recommended ones).

Braking rem inertia, deceleration time, energy of potential energy load. Customs select

the AC drive should comply esistance can be selected according to the power of motor in

actual applied system. They are also related to systwith the actual situation. The bigger of

the system inertia, the shorter of the deceleration time, the more frequent of the braking,

and the braking resistence should select larger power and smaller resistance .

Page 30

2

SD200 User Manual

Chapter 2 Product Information

-3 0-

2.9.1.1 The Selection of Resistance Value

When braking, almost all renewable energy consumption of the motor is on the braking

resistor,According to the formula:

U*U/R=Pb

ª U------ Braking voltage at stable braking system.

(System selections differs in braking voltages, The AC380Vsystem usually selects

DC700V braking voltage.)

ª Pb-----Braking power

2.9.1.2 The Selection of braking Resistor Power

Elevator---20%~30% Open and draw volume---20%~30%

Centrifuge---50%~60% Accidental braking load---5%

Commonly take 10%

2.9.1.3 Selection of Reference

When the AC drive is driven by the control device requiring rapid braking, the braking unit

needs to release the power of the motor braking feedback to the DC bus. 400V voltage

level 0.4 ~30kw is equipped with built-in braking unit, if you need to rapid stop, please

refer to the appropriate braking to select the unit and braking resistance, AC drive

capacity, if need to stop, it can be directly connected to the braking resistance. Please

choose the appropriate braking unit according to the braking resistance of the AC drive

capacity.

Page 31

2

SD200 User Manual

Chapter 2 Product Information

-3 1-

AC drive

Capacity

(kw)

Braking Unit

Specification

Quantity

Braking Resistor

Resistance

Power

Quantity

≥30 0Ω0. 4

0. 75

1. 5

2. 2

4. 0

5. 5

7. 5

11

15

18 .5

22

30

Built-in as

standard

1

1

1

1

1

1

1

1

1

1

1

1

≥30 0Ω

≥22 0Ω

≥20 0Ω

≥13 0Ω

≥90 Ω

≥65 Ω

≥40 Ω

≥32 Ω

≥25 Ω

≥22 Ω

≥16 Ω

15 0W

15 0W

15 0W

25 0W

30 0W

40 0W

50 0W

80 0W

10 00W

13 00W

15 00W

25 00W

1

1

1

1

1

1

1

1

1

1

1

1

37

45

55

75

90

1

1

1

2

2

≥16 Ω

≥16 Ω

≥8Ω

37 00W

45 00W

55 00W

37 00W

45 00W

1

1

1

EHBU70

11 0

16 0

20 0

13 2

18 5

22 0

2

3

4

3

4

4

55 00W

55 00W

55 00W

37 00W

45 00W

55 00W

≥8Ω

≥8Ω

≥8Ω

≥8Ω

≥8Ω

≥8Ω

≥8Ω

≥8Ω

2

2

2

3

4

3

4

4

SD200 series under 30KW(30KW included) AC drive braking resistor connection as shown

in figure 2-16.

2.10 Connection Methods

2.10.1 Braking Resistor Connection

Figure 2-16 braking r esistor connectio n

Braking

resistor

P+

PB

AC Driver

Page 32

SD200 User Manual

Chapter 2 Product Information

-3 2-

2

SD200 series AC drive and the braking unit connection as shown in figure 2 -17.

2.10.2 Braking Unit Connection

Wh en a s ingle braking unit failin g t o m eet the needs of the braking energ y, two or more

br aking on es ar e requir ed in paralle l connection, as shown in figure 2-18.

2.10.3 Braking ones in Parallel Connection

Figure 2-17 braking u nit connection

+

-

B2

B1

braking

unit

P+

P-

AC Driver

Braking

resistor

Figure 2-18 braking o nes in parallel conne ct ion

+

-

B2

B1

P+

P-

+

-

B2

B1

AC Driver

Braking

resistor

braking

unit

Braking

resistor

braking

unit

Page 33

Chapter 3

Mechanical and Electrical Installation

3.1 Chapter of This Content

This chapter i nt roduce the mechanical and electrical installation of the AC drive.

Danger

Only those who are traine d a nd qualified professi onals can operate the wor k de scribed

ª

in thi s c hapter. Please operate according to the se ction of "pay attentio n to security

matters", failure t o these may cause perso nal injury or damage to e qu ipment.

Power supply of AC dr ive must be disconn ec ted before the inst allation. If the AC d rive

ª

has connected to power, please power off fir st an d the n wai t not le ss th an th e time

marked on the AC drive an d confirm the Charge La mp was already of f, users in such

condition are advised to use the multim eter to measure if the DC bus voltage of the AC

drive is under 36v.

The installation and design of the AC drive must comply with relevant laws and

ª

regulations of th e installation regi on. If the installa tion of the AC drive vi olates the

requirements of local l aw s an d re gulations, We Our company d oes not as su me any legal

responsibility. In addition, if user are not comply with the recommendati on s, the AC

drive may appear some f aults not covered by th e warranty.

-3 3-

Page 34

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 4-

3

3.2 Mechanical Installation

3.2.1 Installation Environment

In order to ma ke full use of th e perfor mance of the AC drive an d mainta in its functi on for a

lo ng time, it is ver y im portant to instal l the envi ronment . Please install the AC drive in the

fo llowing table of the desc ribed environment .

Conditions

Environment

Installation site Indoor

Ambient

temperature

ª

If the ambien t temperature of the AC drive is above 40℃, dera te

ª

3% for every add it ional 1℃.

It is not recommended to use the AC drive if the ambient

ª

temperatur e is a bove 50℃.

In order to impr ov e the reliability of the device, do not use the

ª

inverter if th e am bient temperature changes frequently.

Please provide co ol ing fan or ai r conditioner to control the

ª

internal ambient temperature below the required one if the AC

drive is used in a c lo se space such as in the control cabinet.

When the temperature is too low, if the AC drive needs to restart

ª

to run after a long stop, it is necessary to provide an extern al

heating device to increase the internal temperature, other wi se

damage to the de vi ces may occur.

-10~+50℃

Humidity

ª

No condensation is allowed, The maximum relative humidity should

ª

be equal to or less than 60% in corrosive air.

Rh≤90%

Storage

temperature

-30~+60℃

Running

Environment

Condition

The installation site of the AC drive should:

keep away from the electromagnetic radia tion source

ª

keep away from contaminative air, such as corrosive gas, oil mi st

ª

and flammable gas;

ensure foreign objects,such as metal pow er,dust,oil,water can not

ª

enter into the AC drive(do not install the AC drive on the flammable

materials such as wood)

keep away from direct sunlight,oil mist,steam and vibration

ª

environment;

;

Altitude

<1000m,If th e se a level is above 100m,please derate 1% for every

addition al 1 00 m.

Vibration

≤5.8m//s²(0 .6 g)

Installation

direction

AC drive shoul d be i nstalled on an upright position to ensure sufficient

cooling effe ct .

Page 35

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 5-

Note:

1.

ing to enclosure classification.

2. Cooling air must be clean,free from corrosive materials and electrically conductive dust.

SD200 series AC drive should be installed in a clean and ventilated environment accord-

3.2.2 Installation Direction

Th e AC driv e may be installe d on the wall or in a cabinet.

Th e AC driv e must be install ed in an upright position. Check th e instal lation site accord ing

to the requ irements below.Re fer to chapter 3. 1 outlin e diagra m for fra me de tails.

Figure 3-1 Installa tion direction of AC dr ive

OK

A. Vert ical installation

B. Alinic installation

NG

C. Tran sverse installation

NG

Figure3-2 Install ation manner

3.2.3 Installation Manner

Wa ll mo unting(for the AC drive of 380V≤315KW)

1.

charpter;

2. Fix the screws or bolts to the marked locations;

3. Put the AC drive against the wall;

4. Tighten the screws in the wall securely.

Mark the hole location. The location of the holes is shown in the outline diagram in 3.2

3

Page 36

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 6-

3

3.2.4 Single Installation

3.2.5 Multiple Installation

Figure 3-3 Single ins tallation

Note:

The minimum space of B and C is 100mm.

Figure 3-4 Parallel i nstallation

Warm Air

Cool Air

C

C

A

A

B

B

D

Note:

1.

ience of later maintenance;

2. The minimum space of B, D and C is 100mm.

Before installing the different sizes AC drive, please align their top position for the conven-

B B

A

A

C

C

Warm Air

Cool Air

Page 37

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 7-

3.2.6 Vertical Installation

Figure 3-5 Vertical i nstallation

C

ool

A

ir

Wind Board

Warm

Ai

r

Wind Board

W

a

rm

A

ir

Cool Ai

r

Note:

Windscreen should be installed in vertical installation for avoiding mutual impact and insuffici-

ent cooling.

Page 38

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 8-

3

3.2.7 Canted Installation

Figure 3-6 Tilt insta llation

W

arm A

i

r

C

o

ol

Ai

r

W

ar

m

A

i

r

Cool A

i

r

W

a

rm

Air

Cool A

i

r

Note:

Ensure the seperation of the wind input and output channels in tilt installation for avoiding

mutual impact..

Page 39

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-3 9-

3.3 Standard Wiring

3.3.1 Main Circuit Wiring Diagram

Figure 3-7 Main circu it wiring diagram

M

P+ P-

18.5KW

(including)Below

MCCB

R

S

T

3-phase 380V

input power 50/60HZ

PB

W

V

U

PE

R

S

T

braking resistor

R

S

T

22~30KW

P

P+

P-

M

PB

DC reac tor

R

S

T

W

V

U

PE

3-phase 380V

input power 50/60HZ

MCCB

37KW

(including)Above

P

P+

P-

braking unit

DC reac tor

braking r esistor

M

W

V

U

PE

R

S

T

R

S

T

3-phase 380V

input power 50/60HZ

MCCB

Note:

1. DC reactor, braking unit and braking resistor are optional accessories”.

2. P1 and(+) are short circuited in factory, if need to connect with the DC reactor, please

remove the contact tag between P1 and (+).

3.3.2 Main Circuit Terminals Diagram

Figure 3-8 7.5KW belo w main circuit termin al diagram

P+ P- PB R S T U V WP+ P- PB R S T U V W

PEPE

Page 40

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 0-

3

Figure 3-9 11~18.5k w main circuit termin al diagram

P+ P- PB R S T U V W

PE

P+ P- PB R S T U V W

PE

P+ P- P B R S T U V W PEP+ P- P B R S T U V W PE

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

Figure 3-10 22kw main c ircuit terminal dia gram

PE

P P+ P- P B R S T U V W

PE

P P+ P- P B R S T U V W

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

PE

P P+ P- PB R S T U V W

PE

P P+ P- PB R S T U V W

Figure 3-11 30kw main c ircuit terminal dia gram

R S T PB P P+ P- U V W R S T PB P P+ P- U V W

R S T PB P P+ P - U V W

PE

R S T PB P P+ P - U V W

PE

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

PEPE

Figure 3-12 37~45kw m ain circuit termina l diagram

R S T P P+ P- U V W

R S T U V W P P+ P-

POWE R(电源)

POWE R(电源)

MOTO R(电机)

MOTO R(电机)

PE

PE

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

R S T P P+ P- U V W

R S T U V W P P+ P-

PO W ER (电源)

PO W ER (电源)

MO T OR (电机)MO T OR (电机)

PEPE

Page 41

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 1-

Figure 3-14 380V 132~ 185kw main circuit te rminal diagram

R

R

S

S

T

T

P

P

P-

P-

U

U

V

V

W

W

PE

PE

P+

P+

R

R

S

S

T

T

P

P

P-

P-

U

U

V

V

W

W

PE

PE

P+

P+

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

Figure 3-15 380V 200~ 500kw main circuit te rminal diagram

P+

P+

R

R

S

S

T

T

P

P

U

U

V

V

W

W

PEPE

P-

P-

P+

P+

R

R

S

S

T

T

P

P

UUV

V

W

W

PE

PE

P-

P-

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

Figure 3-13 55~110k w main circuit termin al diagram

P P+ P- R S T U V W

P P+ P- R S T U V W

POW ER(电 源)

POW ER(电 源)

MOT OR(电 机)MOT OR(电 机)

PEPE

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOTTRIP

Hz A V

RPM

%

P P+ P- R S T U V W

P P+ P- R S T U V W

POWE R(电源)

POWE R(电源)

MOTO R(电机)

MOTO R(电机)

PE

PE

Page 42

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 2-

3

Terminal

Terminal Name

18.5KW

(including)

below

Function Description

22~33KW

R、S T、

Power input of the main circuit

3-phase AC input terminals

which are generally connected with the power supply.

Braking resistor

terminal

P

Without the

terminal

P+

P、P1 and (+) are connected

with the terminals of DC

reactor.

(+) and (-) are connected

with the terminals of braking

unit.

PB and (+) are connected

with the terminals of braking

resistor.

P P

P

DC reactor

terminal

P-

/

/

PB

400V:Grounding resistance is less than 10Ω

PE

Protective grounding terminals, every machine is provided 2 PE terminals as the

standard configuration.These

terminals should be grounded

with proper techniques.

37KW

(including)

above

DC reactor

terminal

DC reactor

terminal

braking unit

terminal

Braking unit

terminal

Without the

terminal

AC drive output

U、V W、

Three-phase AC output terminals, general connected to

the motor.

DC reactor

terminal braking resistor

terminal

Braking resistor

terminal

Braking resistor

terminal

Note:

1. Do not use an asymmetrically constructed motor cable. If there is a sysmmetically cons-

tructed grounding conductor in the motor cable in addition to the conductive shield,con-

nect the grounding conductor to the grounding terminal at the AC drive and motor ends;

2. Braking resistor, braking unit and DC reactor are optional parts;

3. Route the motor cable,input power cable and control cables seperately;

4. If the terminal description is"/",the machine does not provide the terminal as the external

terminal.

Page 43

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 3-

3.3.3 Main Circuit Terminal Wiring Process

1. Fasten the grounding conductor of the input power cable with the grounding terminal of

the AC drive(PE)by 360 degree grounding technique. Connect the phase conductors to

R, S, and T terminals and fasten;

2. Strip the motor cable and connect the shield to the grounding terminal of the AC drive by

360 degree grounding technique. Connect the phase conductors to U, V and W

terminals and fasten;

3. Connect the optional brake resistor with a shielded cable to the designated position by

the same procedures in the previous step;

4. Secure the cables outside the AC drive mechanically.

Figure 3-15 Screw ins tallation diagram

NG Y

Screws are not fastened Screws are fastened

Figure 3-16 360-deg ree grounding techn iq ue diagram

PE

OK

Enclosure

Enclosure

Correct grounding method

PE

PE

NG

Enclosure

Enclosure

Wrong grounding method

Page 44

3.3.4 Control Circuit Wiring Diagram

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 4-

3

Figure 3-17 Wiring di agram of Control Circ uit

3-phase380V/480V

Input power 50/60Hz

braking resistor

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

High-speed pulse input

Keypad interface

Open collector output 1

(High-speed pulse output)

Open collector output2

Relay output1

Relay output2

Expansion card interface

MCCB

AI 2

AI 1

+1 0V

DC:0~10V/0~20mA

DC:-10V~10V

1kΩ 5kΩ~

R

S

T

SD200

1

2

3

GND

CO M

DI 5

HD I1

DI 4

DI 3

DI 2

DI 1

OP EN

DI SP1

J7

AO 2

GN D

HD O1

CM E

CM E

T1 C

T1 B

T1 A

DO 1

J4

I

V

Analog output AO 1,AO2

0V-10V/0mA-20mA

J9

I

V

T2 C

T2 A

AO 1

J3

I

V

A

B

485 communication interface

+2 4V

485

OFF

ON

DC:-10V~10V

AI 3

A

B

T

S

R

S

T

U

V

W

PB

P-

P+

M

Main circuit

Control circuit

PE (connec t ca binet )

An alog inpu t

re ference v oltage

An alog inpu t 1

An alog inpu t 2

An alog inpu t 3

Note:

This diagram is only suitable for the AC drive’s power rate below SD200-4T-18.5,for other

power rate refer to this chapter 3.3"Main Circuit Terminal Wiring".

Page 45

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 5-

DIGITAL PANEL

FWD/REVRUN/TUNE LOCAL/REMOT TRIP

Hz A V

RPM

%

A

+10V

AI2

AO1 AO2 HDI 1 DI2 DI4 OPEN +24V COM

T1A

B

AI1

GND

AI3

GND D I1

DI3 DI5

COM CME HOD1 DO1

T1B T1C

T2A

T2C

3.3.5 Control Panel Terminals

Figure 3-18 Control t erminal diagram

Control Panel Terminal Function Instructions

Specification

Type

Analog

input

Terminal

+10V

Terminal name

Analog input

reference

voltage

10.5V(+3%)

Maximum output current 25mA/ the potentiometer

resistance range is more than 4KΩ.

Internal isolated with COMGND

Analog ground

0~20mA:Input resistance 500Ω, max input current is 25mA

Input range: 0–10VDC/0–20 mA, switched by jumper J9 on

the control board and factory defaulted as voltage input.

0~10V:Input resistance 100KΩ, max input voltage 12.5V

AI1

Analog Input 1

-10V~10V:Input resistance 25KΩ

Max. input voltage range:-12.5V~+12.5V

AI2

Analog Input 2

-10V~10V: Input resistance 25KΩ

Max input voltage range: -12.5V~+12.5V

AI3

Analog Input 3

0~20mA:Input resistance 200Ω~500Ω

Input range: 0–10 VDC/4–20 mA, switched by jumper J3 on

the control board and factory defaulted as voltage input.

0~10V:Input resistance >10KΩ

AO1

Analog output 1

Digital

output

0~20mA:Input resistance 200Ω~500Ω

Input range: 0–10 VDC/4–20 mA, switched by jumper J4 on

the control board and factory defaulted as voltage input.

0~10V:Input resistance >10KΩ

AO2

Analog output 2

Internal isolated with COMGND

Analog ground

Switch the high and low electric level during digital input, it

was connected with + 24 V short circuit in factory which

means it’s effective when the digital input is with low level.

24V±10%,Internal isolated with GND

+24V +24V

OPEN

Digital input

terminal common

Page 46

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 6-

3

Cont rol Panel Terminal Function Instructions(continued)

Specification

Type

Digital

input

Terminal

DI1~DI5

Terminal name

Digital input 1-5

Input specification:24VDC,5mA

Internal isolated with GNDCOM

+24V

Frequency range:0~200Hz

Voltage range:10V~30V

HDI1

High-speed

pulse input /

digital input 6

Voltage range:10~30V

Digital input: equal with DI1~DI5

Voltage Pulse input Maximum frequency 50KHz:

DO1

Open collector

output

Current range:0~50mA

Voltage range:0~24V

Digital

output

HDO1

High-speed

pulse output

Pulse output::0~50KHz

CME

DO1/HDO1

Digital output

public ground

CME and COM is internal isolated, but the factory has an

external short circuit (DOI default is + 24V drive). when DO1

driven with an external power supply, it must be disconne cted the external shorting of CME and COM.

0~20mA: Input impedance: 500Ω Max input current: 25mA ,

T1A、

T1B、

T1C

Relay 1 output

Contact capacity:250VAC/5A,30VDC/5A

T1A-T1B:NC T1A-T1C:NO

Relay

output

T2A、

T2C

Relay 2 output

Contact capacity:250VAC/3A,30VDC/3A

T2A-T2C:NO

A

485 differential

signal +

Speed rate:1200/2400/4800/9600/19200/38400

Rs485

commun

-ication

485 differential

signal -

Use twisted pair or shielded cable, the longest distance:300m

B

Internal isolated with COMGND

Analog ground

Switching Dial Code Switch Function Description

Factory setting

Name

Jumpers

Figure

Function

485

ON

OFF

AI1

I

V

0~10V

OFF

Rs485 communication terminating resistor selection

ON: 120Ω termination resistor connection is valid

OFF: Without termination resistor connection

I is the current input(0~20mA)

V is voltage input(0~10V)

AO1

I

V

0~10V

I is current output(0~20mA)

V is voltage output(0~10V)

Page 47

Switching Dial Code Switch Function Description(continued)

Factory setting

Name

Jumpers

Figure

Function

J14,J15

Choose whether connect PE with GND/COM.

Occcasions with interference, Connect PE

with GND/COM can improve the ablility to

resist the interference.

AO2

I

V

0~10V

I is current output(0~20mA)

V is voltage output(0~10V)

3

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 7-

T/A,S/B

TAS

B

T S

A

B

Speed tracking / closed-loop encoder input

function selection

T and S group: speed tacking option

A and B group: closed-loop encoder impulse

selection

Note:

only allow appear the following

combination:T and S, or A and B

COM

GND

J15

J14

When no connection(Jumper is

on the right side of the control

board when you face to the

control board)

Note:

For the selection of the jumper of T/A,S/B, when you choose the speed tracking start func-

tion, please set the combination of T and S.

3.3.6 Input/output signal connection diagram

3.3.6.1 AI Analog input terminal

We ak analog volta ge signals are easy to suf fer e xternal inte rferenc e, and t herefore the

sh ielded c able mus t be us ed and the cabl e length must b e less than 20 m, as shown in

fo llowing figure3-19.In applic ations where the analog signal suffers severe inter ference,

in stall fi lter cap acitor or ferrit e magnet ic core at the analog signal so urce, as shown in th e

fo llowing figure 3-20.

Fig3-19 Analog inpu t and output terminal w iring diagram

+10V

AI1

GND

PE

<20米

AC Driver

Figure 3-20 Analog in put terminal proces s wiring diagram

AI1

GND

In the same direction or in the same

direction through about 2 to 3 turns

Ferrite bead

0.022UF

50V

C

AC Driver

Page 48

3.3.6.2 DI Digital Input Terminals

Ge nerally, select shielded cable no longer th an 20 m. When active driving is adopted,nece ssary fi ltering measures shall be taken to prevent the interfere nce to th e power supply.

It is recommend ed to use the contact control mode.

SD200 User Manual

Chapter 3 Mechanical and Electrical Installation

-4 8-

3

+24V

+24V

OPEN

+VCC

Singnal

DI1

DI5

COM

2.4K

0V

2.4K

NPN

3.3Ω

External

controller

AC drive control board

Figure 3-21 Sink wiri ng

Th is is t he most commonly used wiring mode. To apply external power supply, remove

ju mpers between +24 V and O PEN and connect the 24V pos itive pole of e xternal power

su pply to OPEN and connec t the ext ernal p ower 0V to the c orresponding DI terminal via

co ntrol th e contact control.

Note

In this In such wiring mo de, the DI terminals of d ifferent AC drives ca nn ot be connected in

ª

parallel. Otherwi se, DI mal-function m ay result. If paralle l co nnection (differe nt AC drives)

is required, connec t a diode in series at the DI a nd the diode needs to sat is fy the

requirement: IF>1 0mA, UF <1 V.As shown in Fi gure 3-22.

Figure 3-22 DI termin als connected in

parallel in SINK mo de

+24V

OPEN

+VCC

信号

DI1

DI1

COM

2.4K

0V

2.4K

NPN

3.3Ω

+24V

+24V

OPEN

COM

AC drive 1

control board

AC drive 2

control board

External

controller

+VCC

+24V

+24V

OPEN

2.4K

2.4K

0V

DI5

3.3Ω

PNP

信号

DI1

COM

AC drive

control board

External

controller

Figure 3-23 Source Wi ring