Sinometer BM3548, BM3549 User Manual

User Manual of BM3548 and BM3549

Insulation Tester and Multimeter

Distinguished users:

Thank you for purchasing the meter of our company. To use the meter

correctly, please read the operating instructions thoroughly and carefully before

use it, especially the section of “Safety information”.

Please keep the operating instructions in a safe place after reading it, putting it

where the meter is or keeping it in handy for future reference.

Attention: A test cable is provided for the meter. It is not allowed to

perform insulation test by holding the test cable with your hands. Ensure

that the to-be-tested object is securely clamped and keep your body away

from the circuit before press the TEST key to output high voltage.

I. Overview

Welcome to use the product!

BM3548/49 digital multimeter with auto range selection is a real digital

insulating resistance tester + digital millimeter. It has features of complete

functions, high accuracy, reliability in operation, and convenience in use. Output

test voltage can be switched among 250V/500V/1000V/2500V, depending on

different models. An ordinary insulating resistance meter can not measure the

output high voltage of its own. When the output high voltage of the insulating

resistance meter doesn’t conform to the rated value, it is not easy for the user to

find the unconformity so that deviation of the measured result is over large

sometimes and causing hidden troubles in safety. BM3548/49 can monitor the

output high voltage in a real-time way. At any time, the user can observe actual

measurement voltage that is output by the meter, effectively avoiding

misjudgment caused due to output voltage not conforming to the rated value.

The measurement range of the meter can reach up to 40GΩ. The measurement

time can be set up according to requirements. After a measurement is completed,

the measured result can be kept automatically. Functions of the digital

multimeter include AC/DC voltage, current, resistance, capacitance, frequency,

diode, and ON/OFF measurement. The functions of the digital multimeter are

completely separated from those of the insulating resistance tester. When use

functions of the multimeter, you need not be worried that you would suffer

electric shock due to high voltage generated by the insulating resistance tester.

The product is applicable to measurement of the insulating resistance of various

insulating materials and electric equipments such as transformers, motors,

cables, switches, and electric apparatuses. It is also applicable to maintenance,

test, and inspection of various electric equipments. It is compact in structure,

convenient to carry, and an ideal electrical and electronic testing meter of yours.

II. Safety information

(1) Description of safety marks:

Warning: important safety information the user must read!

Danger: high-voltage electric shock is present!

Double-insulated protection

(2) Read the operating instructions carefully before use the meter.

(3) It is strictly prohibited to use the meter before its rear cover is put in place.

Otherwise, it might cause an electric shock.

(4) Check and make sure the insulating layer of the test cable is in good

condition without any breakage.

(5) To avoid electric shock, do not touch the test cable and the circuit under test

when performing a test.

1

(6) Make sure one end of the test cable is securely inserted into the terminal.

(7) During test, any range must not exceed its specified maximum input value.

(8) During test, do not operate the switch knob for changing a range to avoid

damaging the meter.

(9) DC voltage over 50V or AC voltage over 36V can cause danger of electric

shock. Be careful when taking measurement.

(10) Before performing insulation test, make sure the range selection switch has

been set within an appropriate voltage range.

(11) Do not perform insulating resistance test in a combustible environment.

Spark may cause explosion.

(12) Stop using the meter, if its case or test cable is broken during use and the

metal is exposed

(13) When open the rear cover for changing battery, make sure the test cable has

been removed out of the test terminal and the range switch switched to

OFF position.

(14) Take the battery out when the meter will not be used for a long time.

(15) When “

- +

” is displayed in the meter, it is necessary to change the battery

in time to ensure measurement accuracy.

III. Name and function of parts (see the figure)

1. Function switch knob

Switch among power ON/OFF, measurement voltage of the insulating

resistance, and various functions of the multimeter.

2.TEST/STOP key: it is used to measure the insulating resistance

RANGE key: it is used to switch between hand-operated and auto range mode

as the meter is used as the multimeter. The function is not available when the

meter is used as the insulating resistance tester. On startup, the meter is preset

to auto range mode. Press the key to switch to hand-operated range mode. In

hand-operated range mode, every time press the key, the range goes up one

level until to the maximum level. After the maximum level is reached, every

time press the key, the range goes to the minimum level. The process is

repeated. If press and hold the key over 2 seconds, the meter is switched to

auto range mode.

3.SELECT key: it is used to set the measurement time of the insulating

resistance as well as various function switch of the same position

4.DH/BL key

Data hold/backlight function: press the key to lock the displayed result.

Press it again to restore normal measurement (when OL is displayed in the

meter, Hold function is not available). Press and hold the key for 2 seconds to

switch between backlight on/off (in adjustment mode, backlight is not

available).

5.L (LIN E) input terminal (connected to line terminal of the to-be-tested

object).

6.V/Ω/mA/Hz/CAP input terminal: common positive input terminal of the

digital multimeter;

7.COM/G input terminal (COM is common EARTH of the multimeter /G is

shielded terminal of the insulating resistance).

8.E (EARTH) input terminal (connected to EARTH terminal of the

to-be-tested object)

9.Liquid crystal display

Small 8888: measured value of high voltage

of the insulating resistance

-8888: measured value of various functions

Min: measurement time of the insulating

resistance (minute)

OL: overflow display, indicating the measured

value exceeds the maximum display value.

ERR: indicating that serious current leakage

or short circuit occurs to the equipment

- +

: Battery capacity is insufficient

10 Indicator light of high voltage

11 Holding box of the test cables

12 Ring used to fasten the hanging strip

IV. General characteristics

(1) Auto range: “OL” will be displayed for overload.

(2) Display mode: Liquid crystal display; maximum display: 4000;

(3) Sampling rate: 2 times per second;

(4) The meter can display actual insulation test voltage. LED light is used to

indicate high voltage output status;

(5) Operating environment: 0°C-40°C, less than 75%RH;

(6) Storage environment:-10°C-60°C, less then 80%RH;

(7) Maximum power consumption: 4.5W; minimum power consumption 18mW.

(8) Indication for insufficient battery capacity: “

- +

” is displayed;

(9) Power supply: 6 pieces of AA 1.5V battery (LR6×6)

(10) Auto power off: The multimeter is turned off automatically in approx. 15

minutes after it is turned on if no key is pressed or the knob is not turned.

(11) External dimension: 170(length)×156(width)×64(height)mm

(12) Weight: Approx. 650 grams (including the battery)

V. Technical characteristics and operating description of the insulation

tester

Accuracy:±% reading ± number, one-year warranty

Environment to guarantee the accuracy: 23°C±5°C, less than 75%RH

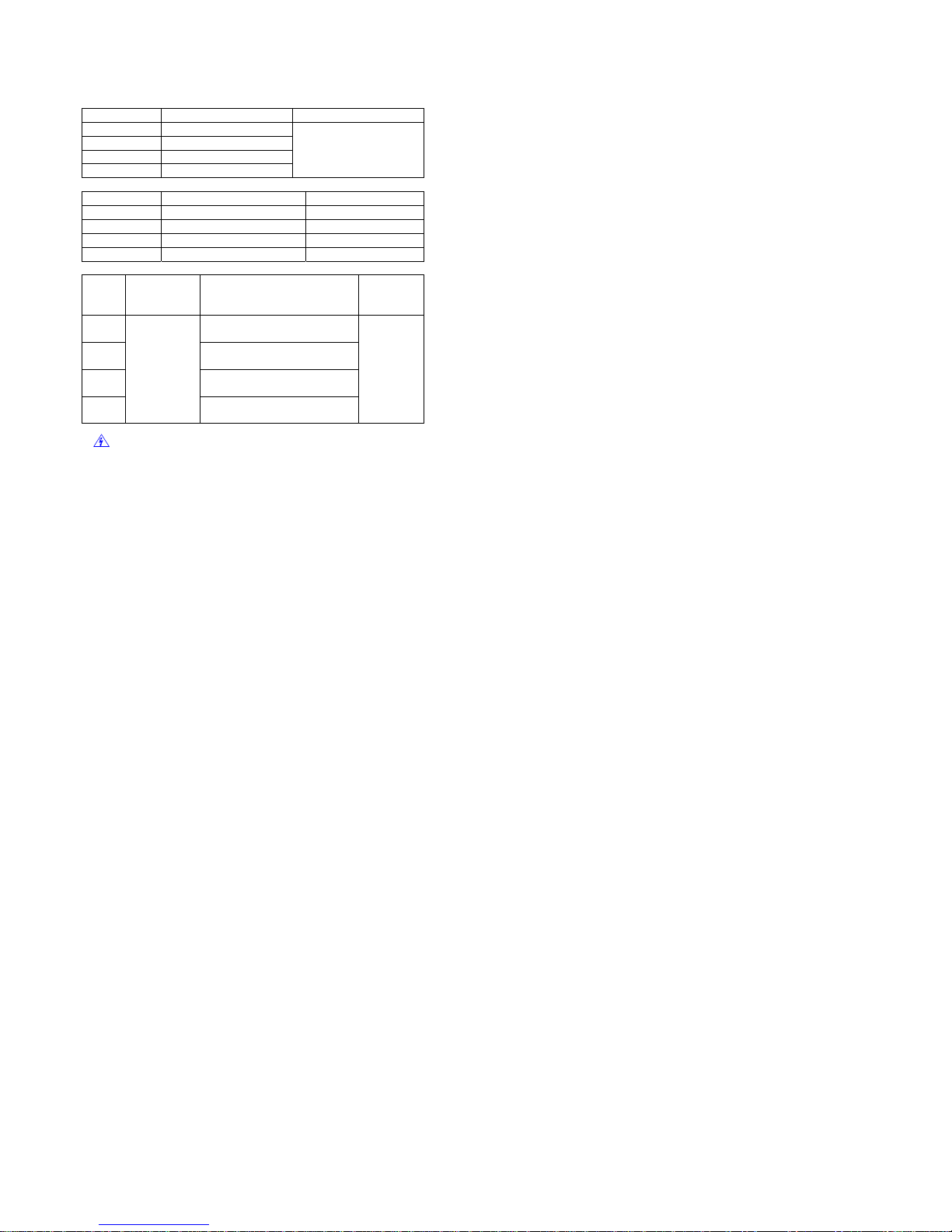

Rated measurement voltage, valid measurement range, and precision

Rated voltage Measurement range Accur acy

250V 0.25M-400MΩ

500V 0.5MΩ-4GΩ

1000V 1.5M-40G

2500V 5M-40GΩ

0.2M-200MΩ:±3%rdg±5,

200M-4GΩ:±5%rdg±5,

4G-40GΩ:±10%rdg±5

2

Display range

Rated voltage Display range (auto range ) Resolution

250V 4M/40M/400MΩ 1k/10K/100KΩ

500V 4M/40M/400M/4GΩ 1k/10K/100K /1MΩ

1000V 40M/400M/4G/40G 10k/100K/1M /10MΩ

2500V 40M/400M/4G/40GΩ 10k/100K/1M /10MΩ

Characteristics of the measurement terminal

Rated

voltage

Allowed range

of open circuit

voltage

The measurement resistance value that

can maintain lower limit of the rated

voltage

short circuit

current

250V 250KΩ (ERR is displayed when it is

less than 200KΩ)

500V 500KΩ (ERR is displayed when it is

less than 400KΩ)

1000V 1.5MΩ (ERR is displayed when it is

less than 1MΩ)

2500V

90%-110% of the

rated voltage

5MΩ (ERR is displayed when it is less

than 2MΩ)

Not less than

1.5mA

Usage for insulating resistance measurement

Danger: If there is any measurement error, it may cause personal injury

and meter failure. Operate it only after read the operating instructions carefully

and thoroughly. Our company will take no responsibility for the accident not

caused due to any reason of our company.

Operating description

1. Safety information

1) Watch out for high-voltage electric shock. When completing the

insulating resistance test, remove the test cable only after making sure high

voltage across the tested object is less than 50V.

2) During measurement, do not touch the object under test and watch out for

high-voltage electric shock.

3) When test the insulating resistance, the object should not be electrified.

Make sure the to-be-tested object is securely earthed. Before test, it is necessary

to short-circuit and discharge two test terminals of the to-be-tested object.

4) When test the insulating resistance, make sure no external voltage is

applied to the test circuit.

5) Before starting test, make sure position of the range switch knob is correct

and the test cable is securely connected.

6) After press the high voltage key, high voltage from 250V to 2500V will

be output between L terminal and E terminal (depending on different models

and positions). Here, be sure not to touch the meter and exposed part of the

object under test. Otherwise, danger of electric shock would occur.

2. Insulating resistance test

1) Connection of the test terminals

Insert one end of the test pen with a high voltage test bar into L terminal

socket of the meter. Insert one end of the test cable with a test clamp into E

terminal socket of the meter. Insert one end of the test cable with a black test

pen (the pen with a clamp) G terminal socket of the meter. Make a good

connection respectively.

2) Test connecting cable

Connecting cable of E terminal socket of the meter is earthing cable;

Connecting cable of L terminal socket of the meter (with a high voltage test bar)

is circuit cable;

Connecting cable of G terminal socket of the meter (the pen with a clamp) is

shielding cable and connected to surface of the to-be-tested object to prevent

surface leakage and affect impedance test.

3) Rated voltage selection

Select a rated voltage you need in the insulating resistance test. Turn the range

switch knob to a corresponding voltage position, and press “SELECT” to

make selection among 1min/2min/10min according to test time requirement

4) Connect pen of the test bar to another terminal of the to-be-tested object.

Press high voltage switch (TEST/STOP). Here, the red indicator light turns

on, indicating high voltage output for test is connected. Actual high voltage

value can be displayed in the meter.

After the test is started, numerical value is displayed in the meter. The

displayed value is the insulating resistance value of the object under test. For

convenience of use, when the set test time comes, the meter cuts high voltage

off automatically, and locks and saves the measured result. When the

measured result is less than the set minimum resistance value under the

measurement voltage, “ERR” is displayed in the meter. If there is a need to

remeasure, press any key to release the lock status and start the measurement

over again.

Attention: do not short-circuit the two test pens with high voltage output or take

measurement of insulating resistance after high voltage is output. The

improper operation is very easy to generate spark, cause fire disaster, and

damage the meter.

Special attention in operation:

Before test, make sure the to-be-tested circuit is not electrified. Do not take

measurement of any electrified equipment or electrified circuit. During test,

dangerous voltage output exists in the meter. Be sure to operate it carefully.

Ensure the to-be-tested object is securely clamped and keep your hands away

from the test clamp before press TEST key to output high voltage.

Attention in operation:

When use 500V measurement voltage to measure resistance less than 2MΩ,

1000V to measure resistance less than 5MΩ, and 2500V to measure resistance

less than 10MΩ, measurement time must not exceed 10 seconds.

5) Power off

After the test is completed, release lock status of the meter and observe

voltage display value of the insulating resistance tester. When it is less than 50V,

turn the range switch knob to OFF position, and then remove the test cable. The

test is over.

Attention: the meter can not be turned off automatically when it is used as

an insulating resistance tester. Please turn the range switch knob to OFF

position after the test is over.

Notices in use of the insulating resistance tester

1. Brief introduction

The insulating resistance tester can be used to verify completeness of motor,

transformer, switching equipment, and coil and cable of electric equipment. For

example, when electric cable or switching equipment (low capacitance

equipment) is tested, time-related capacitive leakage current is not noticeable

and would quickly drop to zero. Within a short time (one minute or less), it will

reach a stable conductive leakage current quantity of, providing a good

condition for spot-check of reading/short-time impedance test.

In the other hand, time-related current will last for several hours when the

equipment under test is long cable, large-sized motor or generator (high

capacitance equipment). The current would cause ceaseless change of the

reading of the insulating resistance tester. It is impossible to obtain an accurate

reading. If trend analysis among readings can be made, for example, step

voltage or medium absorption test, the situation can be overcome. The analysis

doesn’t rely on a single reading, but on a large quantity of related readings. As

time-related current drops quickly when low capacitance equipment is tested,

results from multiply tests are the same. Therefore, use of the multiply test

method will waste time.

2, Test in assembly

The most important reason of the insulation test is to ensure the public and

individual safety. Through high voltage DC test among live wire, earthing and

earthing wire, you can eliminate short circuit or earthing phenomenon that is

dangerous to the human life. Usually, the test is performed after preliminary

equipment installation is completed. Performing the test can find connection

error and defective equipment, guarantee high quality installation, and prevent

fire disaster or explosion.

3. Test in maintenance

Another important reason of the insulation test is to protect and lengthen

service life of electric system and motor. Electric system is affected by such

factors as dust, grease, temperature, stress, and vibration for a long time. These

conditions may cause insulating deterioration, loss in production, and even fire

disaster. Regular maintenance and test can provide very valuable information

of system wear and tear status and help forecast system failure possibility.

Solving problems in time can guarantee that a system operates without any

fault and effectively lengthen service life of various equipments.

To obtain meaningful insulating resistance result, an electrician should check

the to-be-tested system carefully before take measurement. When the following

conditions are satisfied, the best results will be obtained:

1) Shut down the system or equipment and disconnect it from other circuits,

electric switches, capacitors, electric brushes, lightning rods, and circuit

breakers. Ensure the test is not affected by leakage current that flows through

switches and over-current protection components.

2) The temperature should be higher than dew point of the environmental air. If

the condition is not satisfied, a layer of water smoke will be formed in the

insulating surface. In some cases, it would be absorbed by insulating material.

3) In surface of the conductor there should be no carbon and other impurity that

are easy to form a conductor.

4) The applied voltage should not be too high. When low voltage system is

tested, too high voltage would cause overload or damage a insulator.

5) The to-be-tested system should be fully discharged to the earth. The earthing

discharge time should be approx. fivefold of the charge time.

6) Temperature influence is worth attention. As insulating resistance is in

inverse ratio with insulating material temperature (the higher the temperature is,

the lower the impedance is). The recorded impedance reading would be changed

by insulating material temperature. It is suggested to perform measurement in a

standard temperature of 20℃ (68

o

F). Compare a reading with a result at a

temperature of 20℃ according to conventional practice. with a temperature over

20℃, the impedance value at 20℃ will be twofold of its reading every time the

temperature goes up for 10℃ (18

o

F); with a temperature under 20℃, the

impedance value at 20℃ will be one half of its reading every time the

Loading...

Loading...