MODEL SERIES 917

CONTENTS

SINN SPEZIALUHREN ZU FRANKFURT AM MAIN

PREFACE BY PETER GÖBEL

THE "CLASSIC CAR RALLY" ADVENTURE

MODEL SERIES 917

INSTRUCTIONS FOR USE

Ar-DEHUMIDIFYING TECHNOLOGY

TECHNICAL DETAILS

SERVICE

6 – 9

10 – 11

12 – 19

20 – 21

22 – 27

28 – 29

30 – 31

32 – 33

4

DEAR CUSTOMER,

We know from numerous

conversations that the people

who buy our watches do so out of

conviction. This includes people with

a pronounced affinity to technology

who are fascinated, for example,

by the solutions we have devised

for magnetic field protection and

scratch-resistance. Some of our

customers, such as divers, pilots or

the German GSG 9 special police

unit, need to rely on their watch in

their respective careers because

their life depends on it.

They all swear by the high

performance, resilience and

durability, as well as the quality

and precision of these timepieces.

The water and pressure-resistance

5

data are reviewed and authenticated at regular intervals, as is the case

with our diving watches, for instance. We, for our part, give absolute priority

to functionality, which ultimately determines the design. Our watches only

feature technological attributes that really make sense. All the while, we

remain committed to our guiding principle that products have to speak for

themselves.

The basic question that we ask ourselves is: which innovative technologies

and materials can be employed for our craft and provide solutions for

rendering our watches even more practical for everyday use? It is often worth

indulging in a little lateral thinking to see what is going on in other industrial

sectors or fields of science. We repeatedly go to the limits of physical

resources to upgrade our watches — with the aim of making what's good

even better. Most of our best developments are yet to come!

I am delighted that you have decided to buy a SINN timepiece and hope

that it will continue to give you pleasure for many years to come.

Yours sincerely, Lothar Schmidt

6

It was back in 1961 that the pilot and blind-flying instructor Helmut Sinn

founded the company. Since then, we have been committed to producing

high-specification mechanical watches. In 1994, the graduate engineer

Lothar Schmidt took control. This marked the beginning of a new era for the

SINN brand, because the new owner took a decisive step towards more

innovation. Under his leadership, new technologies and materials were

introduced, thus providing the crucial incentives for our company's evolution

and gradual emergence as an insiders' tip for lovers of fine watches. Today,

our name stands for technical innovations, much to the delight of both the

trade and our customers alike.

SINN SPEZIALUHREN ZU FRANKFURT AM MAIN

7

All developments thoroughly tested

Take, for instance, the absolutely condensationfree and anti-reflective diving watch made of

stainless steel — designed with HYDRO Technology.

Other examples include a chronometer

chronograph fashioned from a 22-carat gold

alloy, which is as hard as stainless steel, and a

chronometer whose resistance to magnetic

interference is 20 times greater than normal. Or

those models filled with protective gas and

featuring an integrated dehumidifying capsule to

counteract moisture infiltration and the ageing of

the watch movement. This list would not be

complete without mentioning the development of

so-called Einsatzzeitmesser (EZM) watches for

special police units and border guards, and the

lubrication and tolerance technology that allows

mechanical watches to perform at temperatures

ranging from –45 °C to +80 °C. The 303 KRISTALL

model passed the fire and ice test during the 1998

Yukon Quest sledge dog race that crosses the icy

wilderness of Canada and Alaska, where

temperatures are known to plunge to –40 °C. The

watch was strapped to the arm of some of the

participants on top of their protective clothing.

This was followed in 1999 by the 203 ARKTIS model.

This diving chronograph passed its field test in the

North Polar Sea with flying colours.

8

Innovations and authentications

One of our most important inventions is the oil-free DIAPAL Technology, based

on low-friction materials for the key functional parts of the watch, enabling

them to run without lubrication. This technology was first employed in our

jubilee model, the palladium alloy/white gold Frankfurt Financial District

Watch. TEGIMENT Technology, with which SINN achieves a virtually scratch

resistance surface hardness up to 1500 HV (Vickers hardness) for its stainless

steel watches, represents another milestone. Other innovations include diving

watches made from original submarine steel, as used in the construction

of the outer shell of German class 212 submarines. Germanischer Lloyd,

the world's biggest classification society providing marine safety services,

has been testing the aspects of water and pressure resistance since 2005.

Moreover, an official authentication process conducted by Germanischer

Lloyd in 2006, SINN diving watches as diving gear for the very first time in

the watch making sector and tested them in keeping with European diving

equipment standards. The result: these timepieces passed the temperature

resistance and functionality tests with a sensational success. All test results

are authenticated with signature and seal.

9

Ongoing advancement in technology and quality

Our top priority is always to develop watches which offer superior

performance — both in daily and in professional use. Which is why our

engineers are working continually to identify which innovative methods,

materials and technologies are best suited for optimising our watches.

Each new development first has to undergo rigorous practical tests before

being incorporated. And no watch leaves our workshops before it has

been subjected to thorough checking and fine adjustment by our master

watchmakers.

Workshop modifications and hand-engraving

From the robust case and the polished crystal

through to elaborate refinements: we make sure

that each and every detail in our watches is fit

for purpose. The same applies to our workshop

modifications. Only the perfect interaction of all

components and technologies ensures that our

watches can meets all its design specifications

in full. For example: the SZ02 calibre of our U1000

diving chronograph. The 60 minute scale of

the stop-minute counter is much simpler and

more intuitive to read than the 30 minute scale

commonly found in other watches. The hand

engraving represents a highly personal form

of refinement. If required, our specially trained

master engraver can etch a name, initials,

monograms or symbols onto the rotor, movement

bridge and case back.

10

PREFACE BY PETER GÖBEL

German Rally Champion 2002, 2004, 2005 and 2006

Sometimes, meeting someone for coffee can be a life-changing event.

In 1987, during the Hunsrück Rally, I invited world champion Walter Röhrl to

join me for a cup of coffee and a piece of cake – and he accepted. Five

years later, the two of us paired up for my very first rally. Since then, I’ve been

having the time of my life – since taking up a sport in which time plays such

an important role. Whether you’re dealing with a countdown or a time trial,

one thing is always the same: hours, minutes and seconds mean the difference between victory and being an also-ran.

Now, after 18 years in rally racing and more than 250 events all over the world

– from small-scale regularity tests to the legendary Dakar Rally – I have seen

again and again that a stopwatch is the most important tool a co-driver and

navigator can have. And if you are fortunate enough to own a chronograph

that was designed and engineered with rally racing in mind, “taking time” is

even more fun, and makes the navigator’s task much easier.

11

The Rallychronograph 917 from SINN

is a special treat for me, particularly

because my own experience and ideas

played a part in its development.

As a rally navigator I am especially

pleased that the SINN company from

Frankfurt am Main has incorporated

some of the specific, everyday requirements of one of the most fascinating

sports disciplines in the world.

12

13

From brand-new rallies like the Hamburg-Berlin Klassik, via popular courses

like the Saxony Classic and the Silvretta Classic, to the legendary Mille

Miglia route – classic car rallies are gaining more and more fans. No matter

which rally you participate in, they all have one thing in common: the thrill

of a sporting challenge on fascinating routes. And everyone involved enjoys

taking advantage of personal experience and superior technology to

achieve the best possible results for the team and vehicle. That goes for

both road rallies and complex time trials.

THE "CLASSIC CAR RALLY" ADVENTURE

In road rallies, the team faces two primary tasks: orientation (for example with

the help of pacenotes and the information in the road book) and time trials.

In vintage car rallies these are often regularity trials which require a given

stage of the route to be driven in a specified length of time. In this case,

a precise stopwatch is indispensable. In the so-called “hourglass category”

only mechanical watches and chronographs are allowed – in homage to the

era in which the vehicles themselves were built. The 917 Rally Chronograph

was specially developed to meet the exacting requirements of classic rallies.

14

Always in demand: A good sense of direction

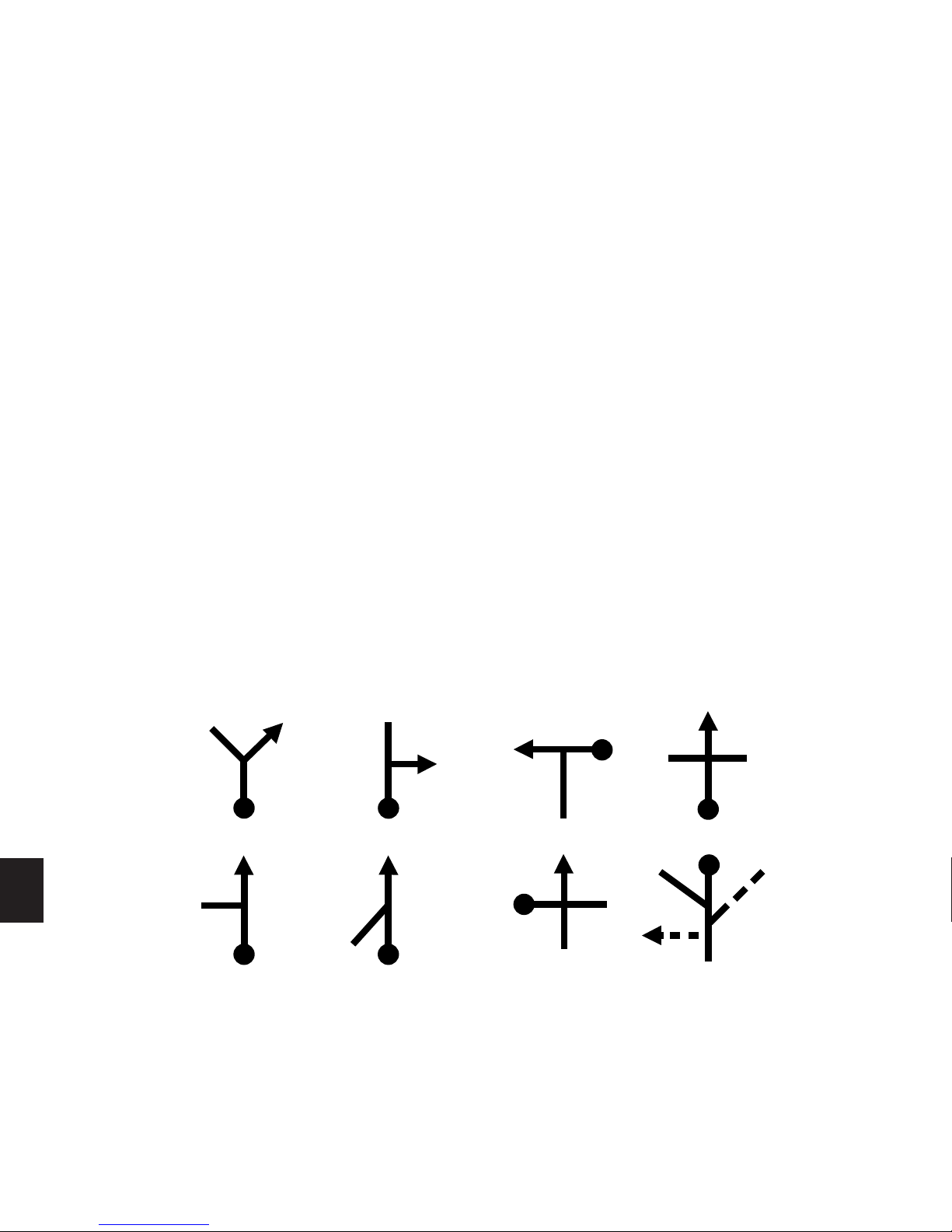

Pacenotes are symbols which are used to describe the rally course. There

are different versions, with some remotely resembling Chinese pictograms.

Pacenotes can be used with maps or “au natural” – which means the route

includes roads that are not indicated on conventional maps.

The pictograms show the course of the route in the direction of travel.

A dot indicates the direction the driver is coming from. One version is called

the “mileage road book”, which numbers the kilometers consecutively.

In this case, it is recommended to set the counter to zero at the starting

line of the race.

Example of pacenotes

15

Mileage road book

16

17

Precision work: The time trial

Regularity rallies, also called time-speed-distance rallies (TSD), are a type of

time trial. They are indicated by a yellow road sign (TSD 1/100). At the signpost, an official gives the drivers a hand signal telling them when to start.

Time is recorded beginning after a few meters, coinciding with a red flag

signal when the vehicles pass a photoelectric sensor or pressure hose sensor.

The co-driver presses the stopwatch at this starting line and begins measuring

the target time. The team should continue driving once the TSD has been

completed so as not to hinder the vehicles behind it.

Lichtschranke = Photoelectric sensor

Schlauch = Pressure hose sensor

18

Example 1

Example 2

Time Trial

Lichtschranke = Photoelectric sensor

Schlauch = Pressure hose sensor

19

Example 1: Each team, naturally, has its own preferences and methods for

stopping the times during time trials. Proposal for the time trial shown left: use

the chronograph (stop) function in combination with the backwards counting

bezel. Before starting, set 17 on the bezel to 12 o’clock. Start the stopwatch

at the precise point of passing photoelectric sensor A. You can then count

down the time to sensor AB for the driver. On driving through sensor AB, trip

the stopwatch to zero and then restart it immediately. Now set 45 on the bezel

to 12 o’clock; you can then let the driver know precisely how much time he

has left until the end of the special stage.

Example 2: To make reading off the time intervals as clear as possible, the Rally

Chronograph 917 is equipped with a backwards counting bezel in which the

all-important last few seconds are highlighted in red. Suggestion for the time

trial shown left: Before starting, set 9 on the bezel to 12 o’clock. Start the stopwatch at the precise point of driving over the pressure hose sensor. You can

now read off the precise time remaining to photoelectric sensor A on the bezel

and count this down for the driver. Without stopping the stopwatch, set 27 on

the bezel to 12 o’clock after passing photoelectric sensor A; after passing

sensor B set 12 to 12 o’clock (the second hand reaches the zero mark on the

bezel after 1:12 minutes) and set 46 to 12 o’clock after passing C (the second

hand reaches the zero mark after 106 seconds = 1:46 minutes). You can then

count down the precise amount of time remaining for the driver.

20

21

On the road for 5 hours. Having successfully negotiated the winding

pass roads, it’s now time for the next time trial. In a rally, it’s all down to

maximum precision and practicality. And this is where the 917 series scores

highly. Because, besides technical refinement, the 917 Rally Chronograph

has the resilience of a high-grade mechanical watch: it is shock resistant

and anti-magnetic, has a solid stainless steel case and offers a degree of

condensation resistance which can only be provided by our Ar-Dehumidi-

fying Technology. Giving it the best possible qualification for rallies and

for everyday use.

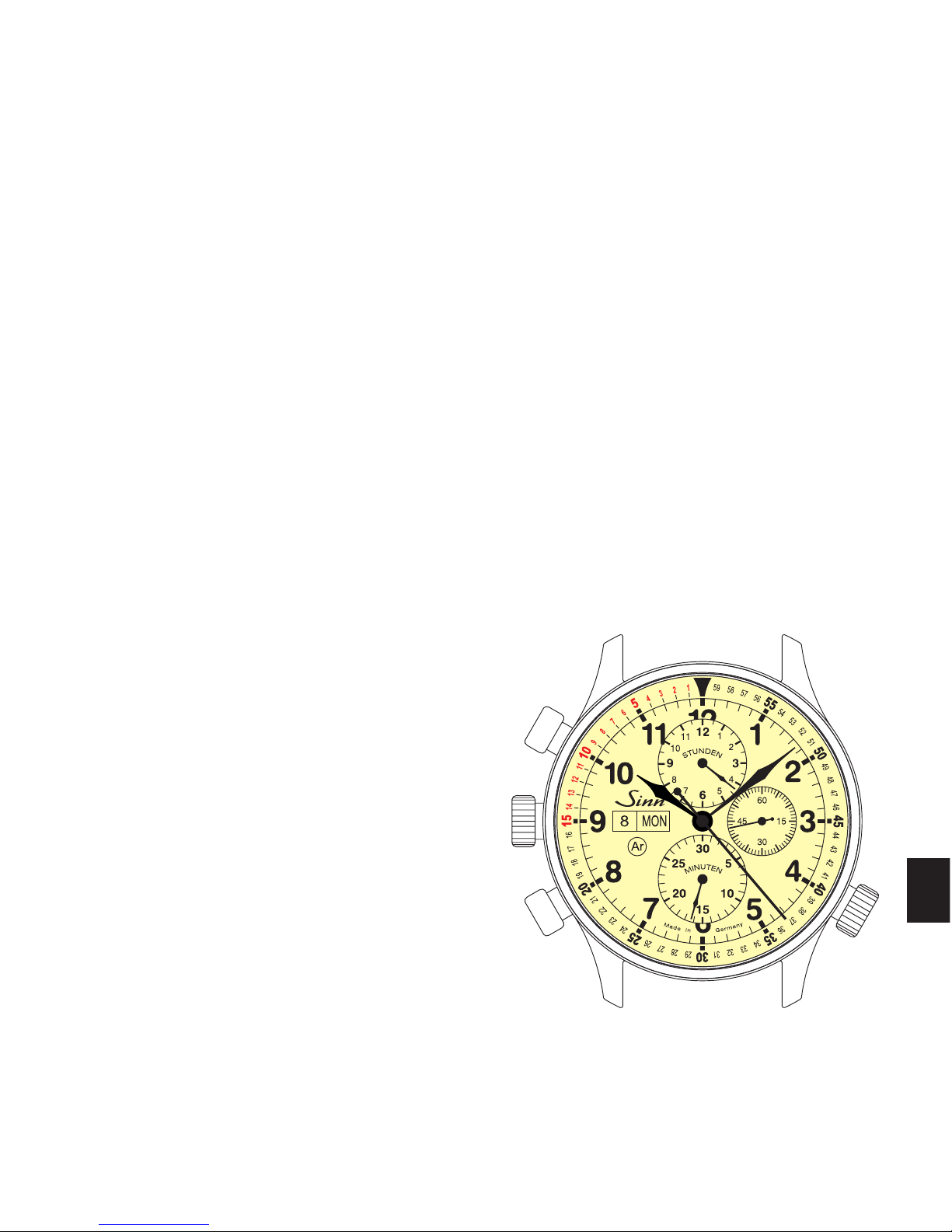

MODEL SERIES 917

Special feature: the interior backwards counting bezel. This permits precision

setting and easy reading of exact target times. Red numerals for the last

15 seconds raise attention levels in the critical time zone. All information can

be read off at a glance from the classic dial with anti-reflective sapphire

crystal glass. And the winding reserve display in the form of a petrol tank

indicator means that you can be sure that your chronograph will be fully

operational up to the finishing line and beyond.

22

INSTRUCTIONS FOR USE

Model 917 GR

Second hand

Hour hand

Power reserve

indicator

Date display

Stopwatch hour hand Minute hand

Stopwatch second hand

1 0

23

Crown position

Stopwatch minute hand

Crown for

Countdown bezel

Countdown bezel, easy to read with

to-the-second precision in time trials

23

To wind the watch (crown position 1)

The crown is screwable (crown position 0). To loosen the crown, turn it

counter-clockwise. The movement is wound by turning the crown clockwise.

About 40 winds of the crown are generally enough to ensure its reliable

functioning. Under normal circumstances, simply wearing the watch every

day should suffice to keep the self-winding mechanism wound. The power

reserve allows you to take off your watch overnight without having to rewind

it.

Time adjustment (crown position 3)

In crown position 3, the motion is paused. This helps you to set the watch

precisely. For accurate time setting, we recommend moving the hand past

the desired minute marker and then adjusting it counter-clockwise. Please

make sure that the date changes at midnight and not at midday when

adjusting the time. Move the hand forward until the date changes before you

attempt to set the time. The movement restarts as soon as you leave crown

position 3.

Quickset date adjustment (crown position 2)

Do not use this function between 9 p.m. and 3 a.m. Set the crown in the

position 2 and turn it clockwise until the correct date appears in the date

display window. Please do not use the date setting function between 9 p.m.

and 3 a.m. Between these times, the gear wheels used for changing the date

are engaged, and the movement could become damaged.

Please take care to fasten the crown after making adjustments.

24

INSTRUCTIONS FOR USE

To wind the watch (crown position 1)

The crown is screwable (crown position 0). To loosen the crown, turn it counterclockwise. The movement is wound by turning the crown clockwise. About

40 winds of the crown are generally enough to ensure its reliable functioning.

Under normal circumstances, simply wearing the watch every day should

suffice to keep the self-winding mechanism wound. The power reserve allows

you to take off your watch overnight without having to rewind it.

Model 917

Date and

weekday

display

Second hand

1 0

23

Crown position

Stopwatch second hand

Stopwatch minute hand

Hour hand

Stopwatch hour hand

Minute hand

Crown for

Countdown bezel

Countdown bezel,

easy to read with

to-the-second precision

in time trials

25

Time adjustment (crown position 3)

In crown position 3, the motion is paused. This helps you to set the watch

precisely. For accurate time setting, we recommend moving the hand past

the desired minute marker and then adjusting it counter-clockwise. Please

make sure that the date changes at midnight and not at midday when

adjusting the time. Move the hand forward until the date changes before you

attempt to set the time. The movement restarts as soon as you leave crown

position 3.

Quickset date and day of the week adjustment of the week (crown position 2)

Do not use this function between 9 p.m. and 3 a.m. Crown position 2 can

be used to change the date and day of the week quickly and simply. To set

the date, pull the crown to the second position and turn it clockwise until the

current date appears in the display window. To set the day of the week, turn

the crown counter-clockwise until the desired day of the week is indicated.

Please do not use the date setting function between 9 p.m. and 3 a.m.

Between these times, the gear wheels used for changing the date are

engaged, and the movement could become damaged.

Please take care to fasten the crown after making adjustments.

26

ADJUSTING THE LENGTH OF THE WATCH STRAPS

If you don't know how to shorten or lengthen the solid bracelet, please

contact your SINN dealer or the watchmakers in our customer service

department in Frankfurt am Main. Our customer service employees are also

happy to help you on the telephone.

Adjusting the length of the solid bracelet

To adjust the length of the bracelet, you will need a watchmaker's screwdriver

or the SINN watchband replacement tool kit and AN 302-42 medium-strength

threadlock adhesive.

For optimal comfort, each side of the watchband should contain the same

number of links. If you choose to remove an uneven number of links, the

upper portion of the watchband (on the 12 o'clock side) should be longer.

For example: If you want to shorten the bracelet by removing a total of three

links, you should remove two from the 6 o'clock side and just one from the

12 o'clock side. When they leave the factory, the solid bracelets have the

same number of links on the 12 o'clock side and the 6 o'clock side. If you

have requested a shorter length, please be sure to check the number of

links on each side before making any additional changes.

27

1. Remove the screws on the side of the link you wish to remove,

or at the point where you wish to add a link.

2. Remove the excess link or insert the new one.

3. Before replacing the screw, add a small drop (not too much!) of the

threadlock adhesive to the screw thread.

28

The colour scale for the Ar-Dehumidifying Technology: the capsule continues

to absorb moisture until the darkest colouration is reached.

Indication colours of the drying capsule

Pale blue

up to 25 %

saturation

Light blue

up to 50 %

saturation

Medium blue

up to 75 %

saturation

Dark blue

up to 100 %

saturation

Initial condition Drying capsule

saturated

u

Ar

-DEHUMIDIFYING TECHNOLOGY

29

Perfect freedom from fogging

All watches in this series are water-resistant as per DIN 8310. But even with

watertight instruments, the air enclosed in the case contains water in a

gaseous state. And air can also penetrate the seals and acrylic glasses.

When the water vapour in the case condenses into liquid, the instruments

are impossible to read. To prevent this from happening, we have developed

the Ar-Dehumidifying Technology. The combination of a special drying

capsule, EDR seals (extreme diffusion reduction) and a filling of protective

gas guarantee that the crystal remains free from fogging, even in difficult

conditions.

Longer service intervals

The sophisticated Ar-Dehumidifying Technology considerably retards the

aging process of the watch's inner workings and keeps the movement

functioning properly for longer. That is why we issue a three year warranty

on all our watches featuring Ar-Dehumidifying Technology. When the drying

capsule is saturated indicated by a deep blue colour, refer to picture on the

left side), we recommend you have it exchanged so you can continue to

enjoy all the advantages of the Ar-Dehumidifying Technology (enhanced

reliability, longer maintenance intervals).

30

Mechanical Movement

• Calibre Valjoux 7750

• Self-winding mechanism

• 25 bearing jewels

• 28,800 semi-oscillations per hour

• Shock resistant as per DIN 8308

• Anti-magnetic as per DIN 8309

Watch Case

• Stainless steel, polished

• Sapphire crystal glass in front,

anti-reflective on both sides

• Transparent case back made of

sapphire crystal glass,

anti-reflective on the interior

• Case back screw-fastened

• Ar-Dehumidifying Technology

• Water-resistant as per DIN 8310

• Water-resistant and pressure resistant

up to 10 bar (= 100 m underwater depth)

• Low pressure resistant

• Band lug width 22 mm

• Case diameter 44 mm

TECHNICAL DETAILS 917 GR

Functions

• Hours, minutes,

subsidiary seconds

• Chronograph

• Date display

• Power reserve indicator

• Countdown bezel, easy to read

with to-the-second precision in

time trials

31

TECHNICAL DETAILS 917

Functions

• Hours, minutes,

subsidiary seconds

• Chronograph

• Date display

• Day of the week display

• Countdown bezel, easy to read

with to-the-second precision in

time trials

Mechanical Movement

• Calibre Valjoux 7750

• Self-winding mechanism

• 25 bearing jewels

• 28,800 semi-oscillations per hour

• Shock resistant as per DIN 8308

• Anti-magnetic as per DIN 8309

Watch Case

• Stainless steel, polished

• Sapphire crystal glass in front,

anti-reflective on both sides

• Transparent case back made of

sapphire crystal glass,

anti-reflective on the interior

• Case back screw-fastened

• Ar-Dehumidifying Technology

• Water-resistant as per DIN 8310

• Water-resistant and pressure resistant

up to 10 bar (= 100 m underwater depth)

• Low pressure resistant

• Band lug width 22 mm

• Case diameter 44 mm

32

General advice

To preserve the water resistance for as long as possible, the

watch should be rinsed whenever it has been in contact

with seawater, chemicals, etc. If your watch is frequently

worn in/under water, we recommend having its water

resistance checked at yearly intervals.

The watch is designed to withstand high levels of

mechanical wear and tear and is shock resistant as per

DIN 8308. Nevertheless, it goes without saying that continual

mechanical stress in the form of impacts or vibration will

affect its durability. Care should therefore be taken to

protect your watch from unnecessary wear and tear. It is

only possible to judge how well the watch keeps time after it

has been in operation for approximately eight weeks, since

it takes that long for the working mechanism to become

adjusted, especially in view of the fact that everybody

has different lifestyles and habits. In the event of any

excessive deviation, please keep a day-to-day record of its

timekeeping over a period of about one week, for example.

SERVICE

Do you have any questions?

Our employees will be pleased to advise you. Simply get

in contact with us. We look forward to talking to you.

Telephone: + 49 (0) 69 / 97 84 14 - 400

Telefax: + 49 (0) 69 / 97 84 14 - 401

E-mail: kundendienst@sinn.de

33

You can also find comprehensive information about SINN, our watches and technologies at www.sinn.de/en.

Sinn Spezialuhren GmbH

Kundendienst

Im Füldchen 5 –7

60489 Frankfurt am Main

Germany

Please send your watch to the following address:

• Name, address, e-mail address and fax number (where applicable) and a

daytime telephone number.

• A detailed description of the problem: Exact nature of the defect? At what

time does the problem arise? How often does the problem occur?

• Wherever possible, please state the date of purchase and your customer no.

(indicated on the invoice) or enclose a copy of the invoice.

For information about the process, please refer to the section entitled "Repairs"

in our "General Terms and Conditions of Business". You'll find our "General

Terms and Conditions of Business" on our website www.sinn.de/en. We will be

pleased to send you a copy of the "General Terms and Conditions," or you can

contact our customer service department directly. For insurance reasons, we

strongly recommend sending us any return goods by registered parcel post. As

an alternative for customers in Germany, there is also the option of a collection

service covered by transport insurance, on request. To ensure your request is

dealt with smoothly, please call our customer service department! We regret

that we are unable to accept deliveries with unpaid postage!

Should you send your watch in to customer service, we need to ensure

the process goes smoothly, the following information:

34

Im Füldchen 5 –7 · 60489 Frankfurt/Main

Telefon + 49 (0) 69 - 97 84 14 - 200 · Fax -201

http://www.sinn.de · vertrieb@sinn.de

© Sinn Spezialuhren GmbH

2. Auflage / 2nd Edition

08 2011

Technische Änderungen vorbehalten.

Subject to changes technical specifications.

35

Loading...

Loading...