Singer Valve 106-PG, A206-PG, 206-PG, S106-PG, S206-PG Installation, Operating And Maintenance Instruction

...Page 1

MODEL 106/206-PG POWER OPERATED GLOBE VALVE

Sizes 1/2" to 8" (106-PG) 3" to 10" (206-PG)

DESCRIPTION:

This valve is the basic component used for most Singer

Model 106/206 Automatic Valves. It is a hydraulically

operated valve.

DESCRIPTION OF OPERATION:

The valve opens when the bonnet (area above the

diaphragm) is connected to the downstream side of the

valve AND a pressure drop of 5 psi (35 kPa) is available

across the valve. The valve also opens when the

bonnet is vented to atmosphere, regardless of pressure

drop, provided that the line pressure is 5 psi (35 kPa) or

more.

The valve closes when the inlet pressure is directed to

the bonnet.

The valve can be made to modulate by varying the

bonnet pressure between inlet pressure and outlet

pressure. This is done by the pilot circuit.

In some cases the line media is unsuitable for use in

the pilot system. In these circumstances external water

pressure can be used in the pilot system. The external

pressure must be equal to or higher than the line

pressure.

If available pressure drop is less than 5 psi (35 kPa),

spring lift and external water pressure must be used

(consult factory).

Unless otherwise specified, the valve is assembled with

components suitable for water service up to 180

C). For other service conditions, contact your Singer

Valve representative.

STORAGE:

This valve must be stored indoors, away from direct

sunlight.

INSTALLATION:

Use washers under nuts when bolting valve flanges

to pipe flanges to protect the Epoxy Coating.

Control valves must be installed in a horizontal pipe

with the bonnet up. Smaller valves (6” and smaller) can

be installed in a vertical pipe if the order states the

orientation. Disassembly is difficult but not impossible in

valves installed in vertical pipe.

A stable, non-failing source of pressure is necessary to

operate a pilot operated control valve.

Installation, Operating and Maintenance Instructions

Operating fluid must be clean and free of air.

Under high velocity conditions the pressure signal,

when the pick-up point is located on the main valve

inlet, may be adversely affected. As an example, a relief

valve will operate more effectively and control more

accurately if the operating pressure and sensing

pressure is connected to the header.

Ideally, six pipe diameters of straight pipe is required on

the inlet of any control valve but

• Fully open Gate Valve can be installed on the inlet

of a valve, provided it is used as an isolating valve

and never used in partially open condition.

• A Butterfly Valve with stem horizontal can not

installed in the inlet of a control valve unless

operating pressure and sensing lines are connected

upstream of the butterfly valve, in a location that

gives true system pressure.

• A Butterfly Valve with stem vertical can be

installed in the inlet of a control valve as long as

velocity does not exceed 15 ft/sec. The butterfly

valve can not be used for throttling. If problems

develop at high flows, operating pressure and

possible sensing can be connected upstream of the

butterfly valve, in a location that gives true system

pressure.

o

F (80o

IOM 224A Page 1 of 2 June 2007

• A control valve can be installed with no straight pipe

on the inlet if the operating and sensing lines are

connected to a location that gives true system

pressure.

The connection point should be made at the pipe

centerline to avoid air pick-up at the top of the pipe.

1. It is possible that diaphragms may take a set

after shipping and storage. It is highly

recommended that Bonnet and Body Bolts or

Nuts be tightened after installation but before

pressurizing the valve. If a leak develops after

pressurizing, de-pressurize the valve and

tighten the bolts or nuts.

2. For most convenient operation and maintenance,

line isolation valves should be installed.

3. A suitable bypass should be provided to allow for

servicing of the valve without interrupting the flow.

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

be

Page 2

Installation (Cont.):

4. Install pressure gauges upstream and/or

downstream of valve as appropriate. This will

facilitate ease of setting the pilot system.

5. A strainer with a suitable basket should be installed

ahead of the valve to protect it from foreign

material.

6. Sufficient space should be provided around the

valve for disassembly.

7. Flush system of all foreign matter before installing

the valve.

8. Check direction of flow (inlet of valve is marked OR

an arrow on the side of body indicates flow

direction) and install the valve accordingly.

VENT AIR FROM THE BONNET. After installation,

9.

when the valve is pressurized, vent air from the

bonnet:

a) Valves installed in horizontal piping with bonnet up

(NO LIMIT SWITCH):

Sizes up to 2" where pilot connection is to the guide

bushing at the center of the valve do not require

venting (they vent automatically).

Sizes up to 2" with position indicator: use bleed-cock

on indicator.

Sizes 2-1/2" and larger, loosen pipe plug at the

center of the bonnet to bleed air. If equipped with

position indicator, use bleed-cock on indicator.

b) Valves installed in horizontal piping with bonnet up

(WITH LIMIT SWITCH): Refer to Drawing A0707A.

Use bleed screw (63) to vent air.

c) Valves installed in vertical pipe: The pilot connection

will be to the highest point on the bonnet if the

orientation and flow direction were specified on the

order. Some sizes vent automatically. Some sizes

are provided with a small screw to facilitate bleeding

(do not remove completely).

d) Valves that do not have the bleed screw and do not

bleed completely from existing connections must be

bled by loosening the bonnet bolts.

SERVICE SUGGESTIONS:

POSSIBLE CAUSE / REMEDY

FAILS TO OPEN

1. Insufficient inlet pressure. / Increase pressure

IOM 224A Page 2 of 2 June 2007

Surrey, BC. Canada. V3W 3H9

2. Pressure in the bonnet is not released:

• Isolating valves on pilot lines closed. - Open valves

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

• Pilot components not functioning. - Refer to specific

instructions on pilot components

• Foreign material in pilot system. - Clear obstruction

FAILS TO CLOSE

Lack of pressure in the bonnet due to:

• Pilot components not functioning. - Refer to specific

instructions on pilot components.

• Foreign material in pilot system.

• Ruptured diaphragm.

• Obstruction in the valve.

• Worn main valve disc.

PULSATIONS

• Air in the bonnet. - Vent air. Refer to "Installation

(9)" above.

• Improper adjustment to pilot components. - Refer to

specific instructions on pilot components.

• Valve oversized. A smaller valve in parallel may be

required.

MAINTENANCE:

The SINGER Model 106/206-PG requires a minimum of

maintenance. All parts are accessible for inspection

and repair without removing the valve from the line.

1. Close upstream and downstream isolating gate

valves.

2. Disconnect body and bonnet pilot lines.

3. Remove bonnet. If bonnet does not come free

readily, it can be pried loose with a small pry-bar.

4. Remove main valve assembly for inspection. Do

not remove seat ring unless inspection shows that it

is damaged.

5. Replace worn or defective parts and reassemble.

NOTE REGARDING FREEZING:

This valve does not drain completely when inlet and

outlet pipes are drained. Where freezing conditions are

expected, one of the following must be performed:

• Drain valve and pilot system completely.

• Add suitable anti-freeze to valve and pilot system

(Non-potable water service only).

• Provide insulation and/or heating to keep the valve

from freezing.

Page 3

Page 4

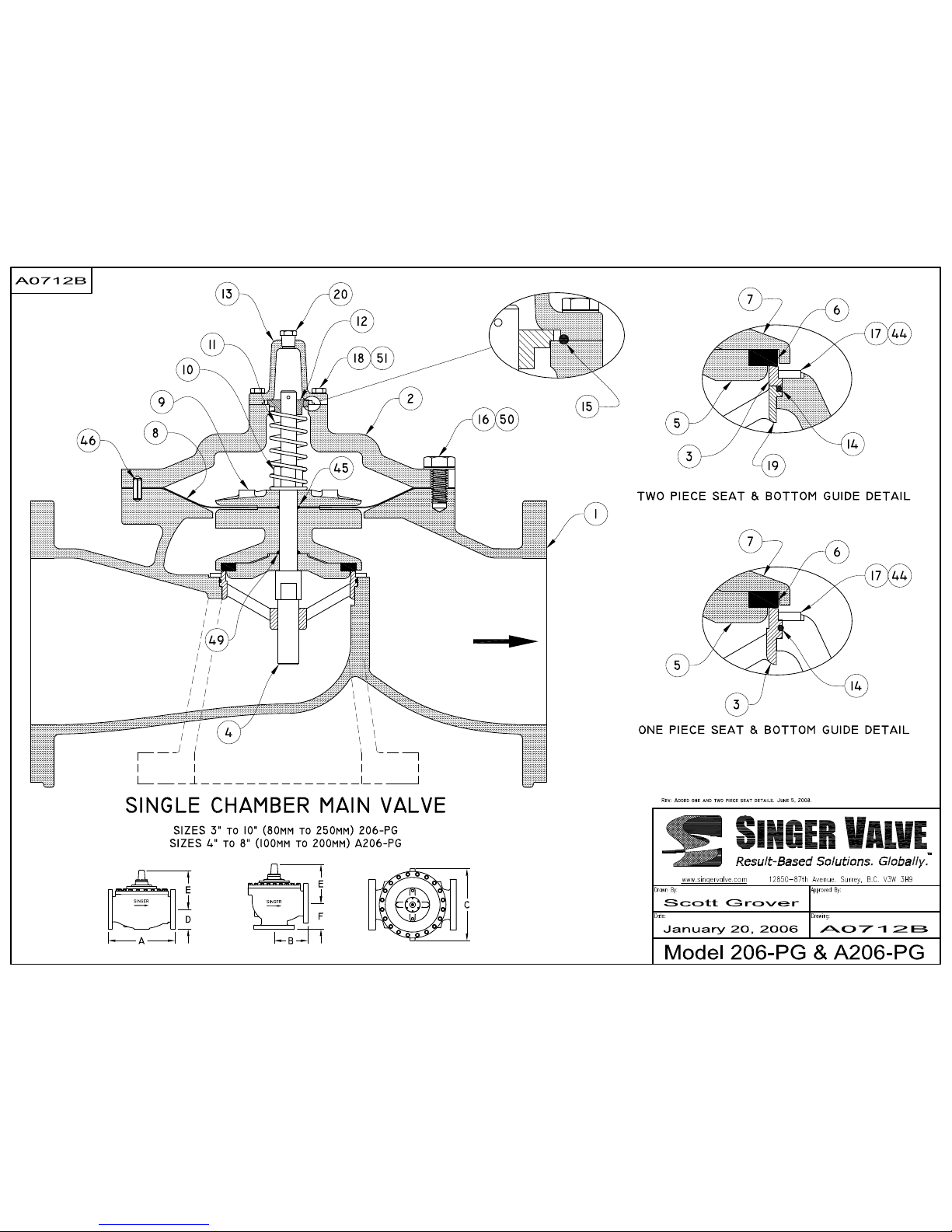

Material Specifications & Dimensions

Item

Part Name Material Item Part Name Material

1 Body Ductile Iron

2 Bonnet Ductile Iron

3 Seat Ring Stainless Steel

4 Stem Stainless Steel

5 Disc Retainer Brass on 3” & 4”

6 ** Resilient Disc EPDM or Buna-N

7 Inner Valve Cast Iron

8 ** Diaphragm EPDM or Buna-N

9 Clamp Plate Cast Iron

10 Stem Nut Brass

11 Spring Stainless Steel

12 Guide Bushing Brass

13 Stem Cap Ductile Iron

14 ** Seat Ring Seal Buna-N

15 ** Stem Cap Seal Buna-N

Bronze on 6”

Cast Iron on 8” and 10”

206-PG & A206-PG

3”

4”

6”

8”

10”

150F / PN16

150F / PN10, PN16,

PN25, PN40

300F

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

80mm

100mm

150mm

200mm

250mm

A D E C B E F

12”

305mm

15”

381mm

15.63”

397mm

20.12”

511”

21”

533mm

25”

635mm

26”

660mm

24.50”

622mm

25.88”

657mm

3” to 10” (80mm to 250mm) 206-PG

4” to 8” (100mm to 200mm) A206-PG

For Drawing A0712B

Globe Globe & Ang Angle

4”

102mm

4.60”

117mm

5”

127mm

5.50”

140mm

6.25”

159mm

6.75”

171mm

7.50”

191mm

8”

203mm

8.63”

219mm

16 Body Capscrew Stainless Steel

17 % Seat Ring Screw Stainless Steel

18 Stem Cap Capscrew Stainless Steel

19 Φ Bottom Guide Ductile Iron & Bronze

44 % Retaining Washer Stainless Steel

45 ** Diaphragm Seal Buna-N

46 Locating Pin Steel

49 ** Disc Retainer Seal Buna-N

50 Body Washer Stainless Steel

51 Stem Cap washer Stainless Steel

** Recommended spare parts (included in the Rebuild Kit)

Φ Bottom guide includes bronze bearing bushing

% Not required on size 3”, (One piece seat ring and guide, shown as item 3)

7.50”

191mm

9.62”

244mm

9.62”

244mm

10.50”

267mm

10.50”

267mm

14.12”

359mm

14.12”

359mm

18.63”

473mm

18.63”

473mm

8.19”

208mm

10”

254mm

10”

254mm

12.50”

318mm

12.50”

318mm

16”

406mm

16”

406mm

20”

508mm

20”

508mm

- - -

7.56”

192mm

7.88”

200mm

10.19”

259mm

10.63”

270mm

12.50”

318mm

13”

330mm

- - -

- - -

Surrey, BC. Canada. V3W 3H9

7.75”

197mm

7.75”

197mm

8.82”

224mm

8.82”

224mm

11.30”

287mm

11.30”

287mm

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

5.94”

151mm

6.25”

159mm

6.19”

157mm

6.81”

173mm

9”

229mm

9.50”

241mm

Anti-Cavitation (-AC) trim equipped valves are NOT available in Reduced Port 206-PG Valves.

April 2006

Page 5

MODEL S106/S206-PG POWER OPERATED GLOBE VALVE

Sizes 6” to 16" (S106-PG) 12” to 24" (S206-PG)

Installation, Operating and Maintenance Instructions

DESCRIPTION:

This valve is the basic component used for most

Singer Automatic Valves. It is a hydraulically

operated valve.

DESCRIPTION OF OPERATION:

The valve opens when the bonnet (area above the

diaphragm) is connected to the downstream side of

the valve AND a pressure drop of 5 psi (35 kPa) is

available across the valve. The valve also opens

when the bonnet is vented to atmosphere, regardless

of pressure drop, provided that the line pressure is 5

psi (35 kPa) or more.

The valve closes when the inlet pressure is directed to

the bonnet.

The valve can be made to modulate by varying the

bonnet pressure between inlet pressure and outlet

pressure. This is done by the pilot circuit.

In some cases the line media is unsuitable for use in

the pilot system. In these circumstances external

water pressure can be used in the pilot system. The

external pressure must be equal to or higher than the

line pressure.

Unless otherwise specified, the valve is assembled

with components suitable for water service up to

o

180

F (80o C). For other service conditions, contact

your Singer Valve representative.

STORAGE:

This valve must be stored indoors, away from

direct sunlight.

INSTALLATION:

Use washers under nuts when bolting valve

flanges to pipe flanges to protect the Epoxy

Coating.

Control valves must be installed in a horizontal pipe

with the bonnet up. Smaller valves (6” and smaller)

can be installed in a vertical pipe if the order states

the orientation. Disassembly is difficult but not

impossible in valves installed in vertical pipe.

A stable, non-failing source of pressure is necessary

to operate a pilot operated control valve.

IOM 224C Page 1 of 2 August 2007

Surrey, BC. Canada. V3W 3H9

Operating fluid must be clean and free of air.

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

Under high velocity conditions the pressure signal,

when the pick-up point is located on the main valve

inlet, may be adversely affected. As an example, a

relief valve will operate more effectively and control

more accurately if the operating pressure and sensing

pressure is connected to the header.

Ideally, six pipe diameters of straight pipe is required

on the inlet of any control valve but

• Fully open Gate Valve can be installed on the

inlet of a valve, provided it is used as an isolating

valve and never used in partially open condition.

• A Butterfly Valve with stem horizontal can not

be

installed in the inlet of a control valve unless

operating pressure and sensing lines are

connected upstream of the butterfly valve, in a

location that gives true system pressure.

• A Butterfly Valve with stem vertical can be

installed in the inlet of a control valve as long as

velocity does not exceed 15 ft/sec. The butterfly

valve can not be used for throttling. If problems

develop at high flows, operating pressure and

possible sensing can be connected upstream of

the butterfly valve, in a location that gives true

system pressure.

• A control valve can be installed with no straight

pipe on the inlet if the operating and sensing lines

are connected to a location that gives true system

pressure.

The connection point should be made at the pipe

centerline to avoid air pick-up at the top of the pipe.

1. It is possible that diaphragms may take a set

after shipping and storage. It is highly

recommended that Bonnet and Body Bolts or

Nuts be tightened after installation but before

pressurizing the valve. If a leak develops after

pressurizing, de-pressurize the valve and

tighten the bolts or nuts.

Revised April 28, 2010

Page 6

Installation (Cont.):

2. For most convenient operation and maintenance,

line isolation valves should be installed.

3. A suitable bypass should be provided to allow for

servicing of the valve without interrupting the flow.

4. Install pressure gauges upstream and/or

downstream of valve as appropriate. This will

facilitate ease of setting the pilot system.

5. A strainer with a suitable basket should be

installed ahead of the valve to protect it from

foreign material.

6. Sufficient space should be provided around the

valve for disassembly.

7. Flush system of all foreign matter before installing

the valve.

8. Check direction of flow (inlet of valve is marked

OR an arrow on the side of body indicates flow

direction) and install the valve accordingly.

9. VENT AIR FROM THE BONNET After ins tallation,

when the valve is pressurized, vent air from the

bonnet:

• Valves with no Limit Switch: Loosen pipe plug at

the centre of the bonnet to bleed air. If

equipped with position indicator, use bleed-cock

on indicator.

• Valves with Limit Switch: Refer to Drawing

A0707A. Use bleed screw (63) to vent air.

POSSIBLE CAUSE / REMEDY

FAILS TO OPEN

1. Insufficient inlet pressure. / Increase pressure

2. Pressure in the bonnet is not released:

• Isolating valves on pilot lines closed. - Open

valves

• Pilot components not functioning. - Refer to

specific instructions on pilot components

• Foreign material in pilot system. - Clear

obstruction

SERVICE SUGGESTIONS:

IOM 224C Page 2 of 2 August 2007

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

www.singervalve.com

FAILS TO CLOSE

Lack of pressure in the bonnet due to:

• Pilot components not functioning. - Refer to

specific instructions on pilot components.

• Foreign material in pilot system. - Clear

obstructions.

• Ruptured diaphragm. - Replace worn parts.

• Obstruction in the valve. - Remove obstructions.

• Worn main valve disc. - Replace disc.

PULSATIONS

• Air in the bonnet. - Vent air. Refer to "Installation

(9)" above.

• Improper adjustment to pilot components. - Refer

to specific instructions on pilot components.

• Valve oversized. A smaller valve in parallel may

be required.

MAINTENANCE:

The SINGER Model S106/S206-PG requires a

minimum of maintenance. All parts are accessible for

inspection and repair without removing the valve from

the line.

1. Close upstream and downstream isolating gate

valves.

2. Disconnect body and bonnet pilot lines.

3. Remove bonnet. If bonnet does not come free

readily, it can be pried loose with a small pry-bar.

4. Remove inner valve assembly for inspection. Do

not remove seat ring unless inspection shows that

it is damaged. Be very careful not to damage

the epoxy coating when removing and

installing the inner valve assembly.

5. Replace worn or defective parts and reassemble.

NOTE REGARDING FREEZING:

This valve does not drain completely when inlet and

outlet pipes are drained. Where freezing conditions

are expected, one of the following must be performed:

• Drain valve and pilot system completely.

• Add suitable anti-freeze to valve and pilot system

(Non-potable water service only).

• Provide insulation and/or heating to keep the

valve from freezing.

Ph: 604-594-5404

Fx: 604-594-8845

Revised April 28, 2010

Page 7

Page 8

Material Specifications & Dimensions

10” to 16” (250mm to 400mm) S106-PG & SA106-PG

12” to 24” (300mm to 600mm) S206-PG

For Drawing A0867C

Item

Part Name Material Item Part Name Material

1. Body Ductile Iron

2. Bonnet Ductile Iron

3. Spring Casing Ductile Iron

6. Bottom Guide Ductile Iron & Stainless Steel

7. Seat Ring Stainless Steel

8. Seat Ring Washers Stainless Steel

9. Stem Stainless Steel

10. Disc Retainer Ductile Iron

11.** Resilient Disc EPDM or Buna-N

12. Inner Valve Ductile Iron

13. Piston Ductile Iron

14. Clamp Plate Ductile Iron

15.** Diaphragm EPDM or Buna-N

16. Stem Nut Stainless Steel

17. Spring Stainless Steel

18. Bonnet Locating Pins Steel

19. Bleed Valve Stainless Steel

20.** Seat Ring Seal Buna-N

21.** Spring Casing Seal Buna-N

22.** Stem Seals Buna-N

23. Bonnet Bolts Stainless Steel

24. Bonnet Washers Stainless Steel

25. Spring Casing Locating Pins Steel

26. Spring Casing Screw Stainless Steel

27. Spring Casing Washers Stainless Steel

28. Seat Ring Screw Stainless Steel

29. Eye Bolt Steel

31. Clamp Plate Screw Stainless Steel

32. Inner Valve Screw Stainless Steel

** Recommended spare parts (included in the Rebuild Kit)

S106-PG & SA106-PG

10”

12”

14”

16”

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

250mm

300mm

350mm

400mm

A D E C B E F

29.75”

756mm

31.12”

790mm

34”

864mm

35.50”

902mm

31”

787mm

32.50”

826mm

41.38”

1051mm

43.50”

1105mm

Globe Globe & Ang Angle

8.56”

217mm

9.56”

243mm

9.50”

241mm

10.25”

260mm

10.50”

267mm

11.50”

292mm

11.75”

298mm

12.75”

324mm

23.31”

592mm

23.31”

592mm

26.75”

679mm

26.75”

679mm

26.80”

681mm

26.80”

681mm

31.40”

798mm

31.40”

798mm

22.13”

562mm

22.13”

562mm

26”

660mm

26”

660mm

26”

660mm

26”

660mm

32”

813mm

32”

813mm

11.50”

292mm

12.19”

310mm

13.75”

349mm

14.50”

368mm

- - -

- - -

18”

457mm

18.81”

478mm

S206-PG

12”

300mm

16”

400mm

18”

450mm

20”

500mm

24”

600mm

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

150F / PN10, PN16

300F / PN25, PN40

A D E C B E F

27.50”

699mm

29”

737mm

36”

914mm

37.63”

956mm

42”

1067mm

43.63”

1108mm

45”

1143mm

46.38”

1178mm

50.50”

1283mm

52.25”

1327mm

Globe Globe & Ang Angle

9.50”

241mm

10.50”

267mm

11.75”

298mm

12.75”

324mm

12.50”

318mm

14”

356mm

13.75”

349mm

15.25”

387mm

16”

406mm

18”

457mm

23.35”

593mm

23.35”

593mm

26.75”

679mm

26.75”

679mm

31.38”

797mm

31.38”

797mm

31.38”

797mm

31.38”

797mm

31.38”

797mm

31.38”

797mm

22.12”

562mm

22.12”

562mm

26”

660mm

26”

660mm

30.31”

770mm

30.31”

770mm

30.50”

775mm

30.50”

775mm

36”

914mm

36”

914mm

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

Surrey, BC. Canada. V3W 3H9

20”

508mm

20”

508mm

23.75”

603mm

23.75”

603mm

28.50”

724mm

28.50”

724mm

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

12.50”

318mm

13.19”

335mm

12.50”

318mm

13.25”

337mm

15.69”

399mm

16.50”

419mm

For Anti-Cavitation (-AC) trim equipped valves please see PG-AC spec sheet January 2006

Loading...

Loading...