Singer Valve 106-RPS-RR, 206-RPS-RR Installation, Operating And Maintenance Instruction

SINGER MODEL 106/206-RPS-RR

Anticipating Relief Valve (on Rate of Rise)

Installation, Operating and Maintenance Instructions

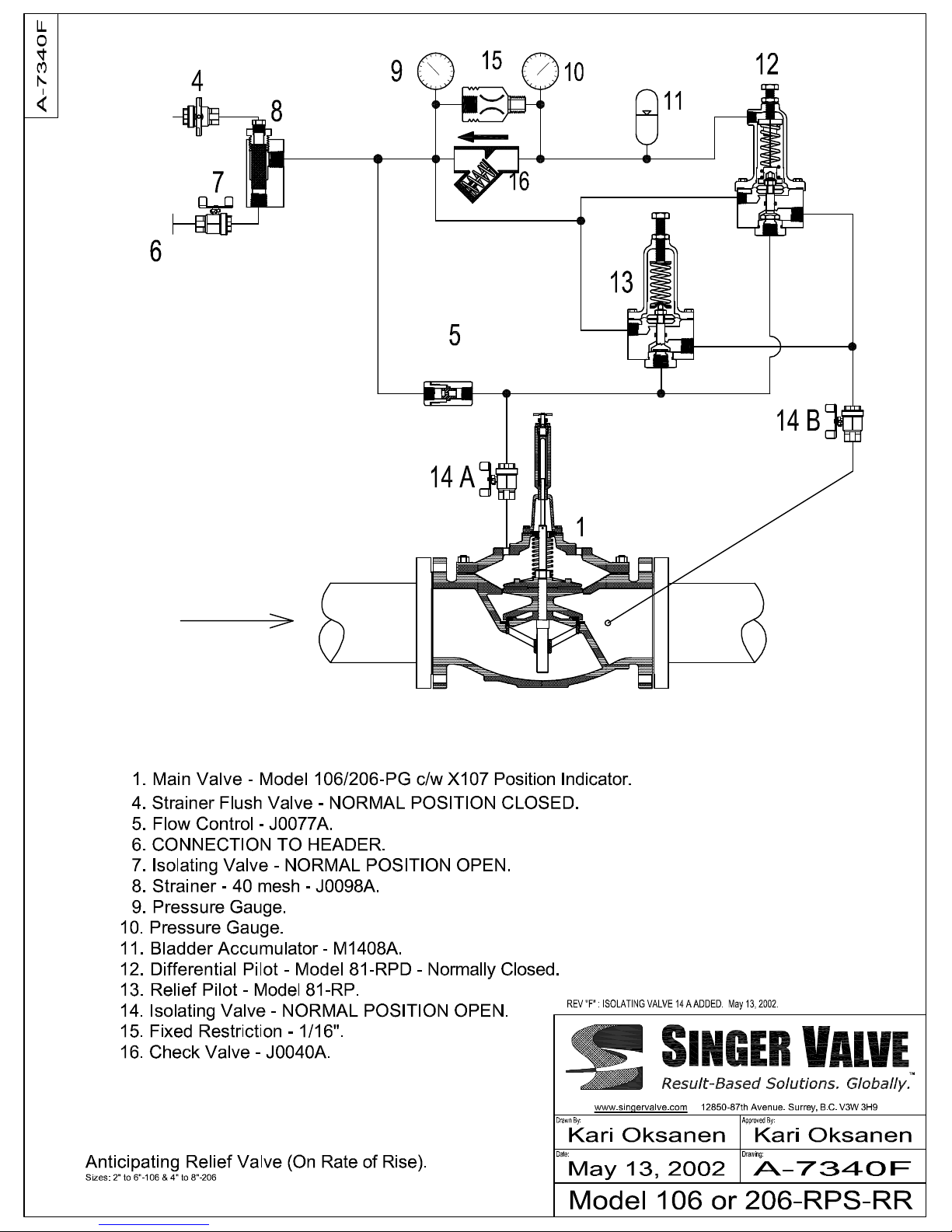

Up to 6” 106/8” 206 Schematic A-7340F 8” 106/10” 206 & larger Schematic A-7340F1

DESCRIPTION:

Model 106/206-RPS-RR is an anticipating relief valve

designed to dissipate surges caused by power failure or other

sudden stoppage of a pump.

The valve opens when the header pressure rises faster than

a rate determined by the pilot system. The valve also opens

if the header pressure reaches the setpoint of Relief Pilot

(13).

MODEL 106/206-RPS-RR:

• Anticipates the surge by opening as soon as the

pressure starts to rise.

• Closes after the surge has been dissipated and the

header pressure is stable.

• Handles initial filling of the system automatically.

• Is not affected by over sizing the way standard

anticipating surge valves are.

DESCRIPTION OF OPERATION:

Main Valve (1) closes when BOTH Pilot (12) and Pilot (13)

are closed. The Main Valve opens when EITHER Pilot (12)

or Pilot (13) opens. On larger valves (Schematic A7340F1), Pilot (12) acts through a Booster Valve (18) to

increase opening speed.

When the header pressure increases slowly, the two

pressures sensed by Pilot (12) remain equal and Pilot (12)

remains closed. When the header pressure increases

rapidly, the pressure in the spring casing (above the

diaphragm) of Pilot (12) lags behind the pressure below the

diaphragm. Pilot (12) opens. The rate of pressure rise

required to open Pilot (12) depends on Accumulator (11) and

the size of Fixed Restriction (15).

For Schematic A-7340F, Pilot (12) opens the Main Valve

(1) as soon as the header pressure starts increasing after a

power failure (pump stoppage). This gives the Main Valve

sufficient time to be fully open before the pressure rises to

destructive levels.

For schematic A-7340F1, Pilot (12) operates the Main

Valve by opening Booster Valve (18). When Booster Valve

(18) opens, the Main Valve opens. When Booster Valve (18)

closes, the Main Valve closes.

Pilot (13) opens the Main Valve if the header pressure

reaches the set point of Pilot (13).

INSTALLATION:

Model 106/206-RPS-RR is installed on a "Tee" from the main

line (header) into atmosphere.

1. Refer to 106/206-PG "installation". Bypass and strainer

are normally not used.

2. Model 106/206-RPS-RR operates under conditions which

cause very high velocities and severe cavitation. These

conditions may cause considerable vibration. The

supports for the valve must be designed accordingly.

IOM A-7340F Page 1 of 1 July 2005

Surrey, BC. Canada. V3W 3H9

3. CONNECT PILOT SENSING (6) TO THE HEADER.

4. Open isolating valves (7), (14 A) and (14 B).

ADJUSTMENT AND TEST PROCEDURE:

1. Setting of Pilot (12) and pre-charge of Accumulator (11)

should not be changed without a clear understanding of

the consequences. These are factory set and should not

require adjustment.

2. Relief Pilot (13) can be set approximately by removing

the tubing from the outlet of Pilot (13) and observing Pilot

(13) under maximum pumping pressure. Pilot (13) should

be set about one turn of the adjusting screw higher than

the point where it starts leaking.

3. If a more exact pressure setting is required, a hydrostat

pump or other source of pressure should be connected to

the sensing line of Pilot (13).

4. To test Accumulator (11), Check Valve (16) and Fixed

Restriction (15):

a) Close Isolating Valve (14 B).

b) Close Isolating Valve (7).

c) Open Strainer Flush Valve (4). Water should flow for

one or two seconds and should then stop suddenly.

There should not be any appearance of air in the flow.

d) Close Strainer Flush Valve (4).

e) Observe Pressure Gauges (9) and (10) and open

Isolating Valve (7). Gauge (9) should jump to line

pressure immediately but Gauge (10) should rise slowly

and steadily over several seconds. The rate at which

Gauge (10) rises is the rate of pressure rise that triggers

Pilot (12).

If it is desired to test Differential Pilot (12) and Main Valve

(1), repeat above procedure with Isolating Valve (14 B) open.

Main Valve (1) should open fast and close slowly after the

pressure readings in Gauges (9) and (10) have equalized.

NOTE: DO NOT ADJUST PILOT (12) TO ADJUST THE

RATE OF RISE SETTING. If a different rate is required,

Fixed Restriction (15) must be changed.

If the closing speed of Main Valve (1) needs adjustment,

insert of Flow Control (5) must be changed.

Accumulator loading should be approximately 20% of the

maximum pumping pressure. This loading can be tested IF

REQUIRED at the fitting on top of Accumulator (11). The

loading should not be checked too frequently, as some

nitrogen will be lost on each test. Only nitrogen should be

used for charging the accumulator.

After testing, check to make sure that Isolating Valves are in

the proper position:

• Valves 7, 14 A and 14 B - OPEN

• Valve 4 - CLOSED

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

Loading...

Loading...