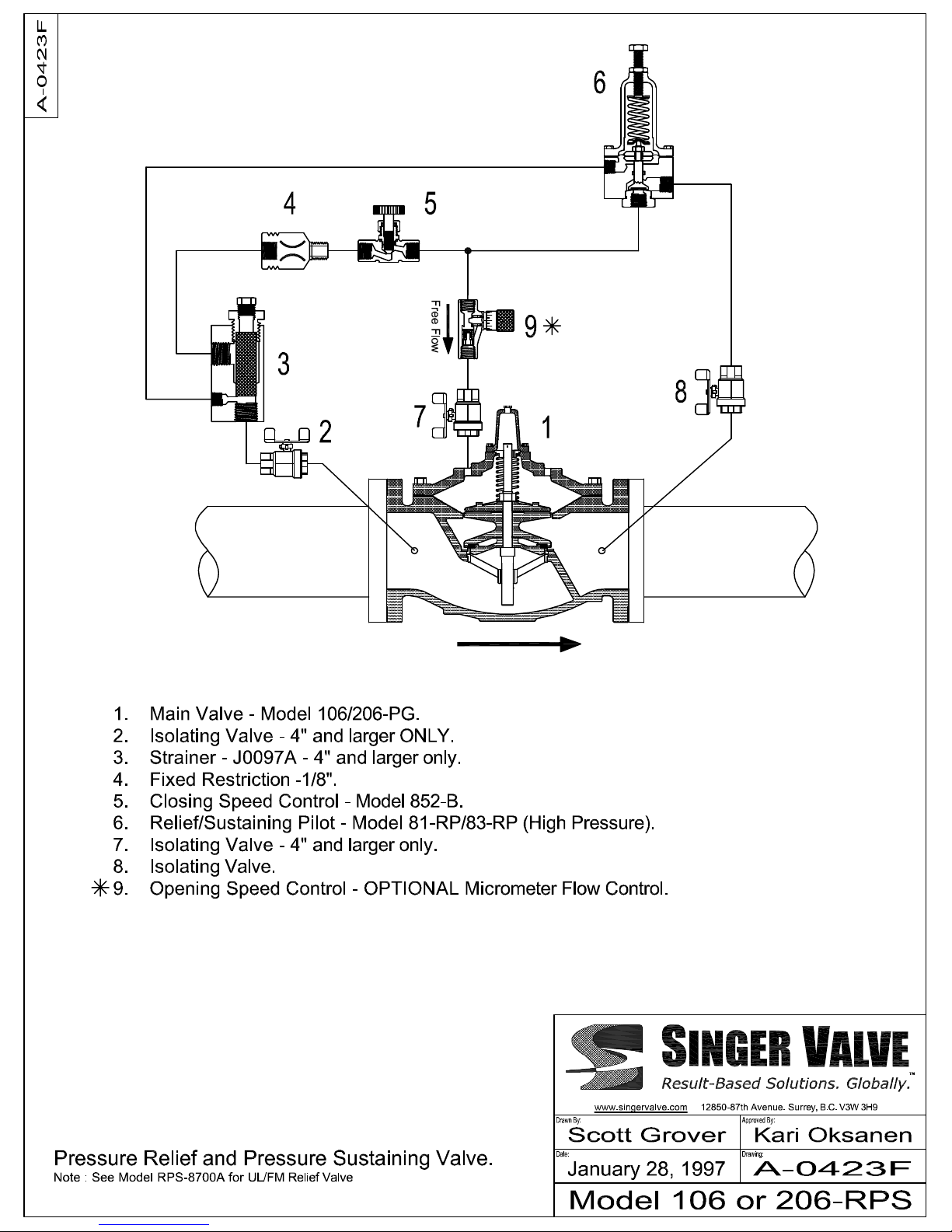

Singer Valve 206-RPS, 106-RPS Installation, Operating And Maintenance Instructions

SINGER MODEL 106/206-RPS

Pressure Relief or Sustaining Valve

Schematic A0423F

DESCRIPTION:

Singer model 106/206-RPS is a pilot operated pressure relief

or pressure sustaining valve designed to open when the inlet

pressure exceeds a predetermined setting.

DESCRIPTION OF OPERATION:

Main Valve (1) is normally open when pressure is applied to

the valve inlet. When the same pressure is applied to the

bonnet, the valve closes tight because the area of the

diaphragm is greater than the area of the seat. By controlling

the bonnet pressure, the Main Valve can be made to open,

close or throttle.

Unless otherwise stated, this valve is built for maximum

temperature of 60o C (140o F).

Bonnet pressure of the Main Valve is controlled with a pilot

circuit consisting primarily of Closing Speed Control (5) and

Relief Pilot (6). Pilot (6) senses the upstream pressure of the

Main Valve. When this pressure is less than the setting of

Pilot (6), Pilot (6) is closed. Pressure from the upstream side

of Main Valve (1) is directed to the bonnet through Closing

Speed Control (5), keeping the Main Valve closed. When the

upstream pressure is greater than the setting of Pilot (6), Pilot

(6) opens to allow flow. If this flow is greater than the flow

coming through Closing Speed Control (5), Main Valve bonnet

pressure is reduced and the Main Valve opens.

When the high pressure has been released and the inlet

pressure drops to less than the setting of Pilot (6), Pilot (6)

closes. This increases the bonnet pressure; the Main Valve

closes. The closing speed is controlled by the setting of

Closing Speed Control (5).

On back pressure service, where the valve is to maintain a

predetermined upstream pressure, Pilot (6) will modulate its

flow so that the bonnet pressure is varied. This, in turn, will

modulate the Main Valve. If the inlet pressure rises slightly,

Pilot (6) opens a little wider and causes the Main Valve to

open further. When the inlet pressure decreases, Pilot (6)

closes slightly and the Main Valve will also close slightly. The

valve reacts to maintain the upstream pressure with varying

flows.

OPTIONAL Opening Speed Control (9) controls flow out of

the bonnet of the Main Valve, thereby controlling the opening

speed. Controlling opening speed can help stabilize the valve

at low flows.

Installation, Operating and Maintenance Instructions

IOM A0423F Page 1 of 1 March 2006

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

INSTALLATION:

1. See 106/206-PG “Installation”.

2. Improved accuracy of control can be achieved by

connecting the sensing of pilot (6) to header or upstream

of the valve.

3. After pressurizing the valve, bleed air from the bonnet.

ADJUSTING PROCEDURE:

1. Turn adjusting screw of Relief Pilot (6) counterclockwise

until spring is free.

2. Apply pressure to valve inlet. Main Valve (1) should be

wide open.

3. Turn adjusting screw slowly clockwise until pressure at the

Main Valve inlet reaches desired point.

4. Lock adjusting screw in place. Valve is now set to relieve

at the desired pressure.

TROUBLESHOOTING AND MAINTENANCE:

Unstable operation: Bleed air from the Bonnet. Connect

sensing line to header. Install Opening Speed Control.

Valve does not open: Pilot set too high. Isolating Valve(s)

closed. Opening Speed Control closed. Pilot Diaphragm

ruptured. Not enough pressure drop on the Main Valve.

Valve does not close: Closing Speed Control (5) closed.

Strainer (3) plugged. Obstruction in the line from inlet to

bonnet. Main Valve Diaphragm ruptured. Obstruction in the

Main Valve. Ball Valve (9) connects the bonnet to

atmosphere.

Maintenance: Clean Strainer. Frequency depends on local

conditions. Clean Main Valve and Pilot as required. Lubricate

the Body Seal in the Pilot. No other lubrication is required.

Check condition of Main Valve and Pilot Diaphragms and

other resilient parts. Replace when required.

To increase pressure setting of pilot valve, turn adjusting

screw clockwise. As an approximate guide:

Range 1 turn equals

5 - 50 psi 8 psi change

10 - 80 psi 10 psi change

20 - 200 psi 25 psi change

100 - 300 psi 40 psi change

200 - 500 psi 42 psi change

To close Main Valve faster, turn Closing Speed Control (5)

counterclockwise, to close Main Valve slower, turn Closing

Speed Control (5) clockwise - do not close tight.

Loading...

Loading...