Singer Valve 106-EF-8837BX, 206-EF-8837BX Installation, Operating And Maintenance Instructions

Model 106/206-EF-8837BX

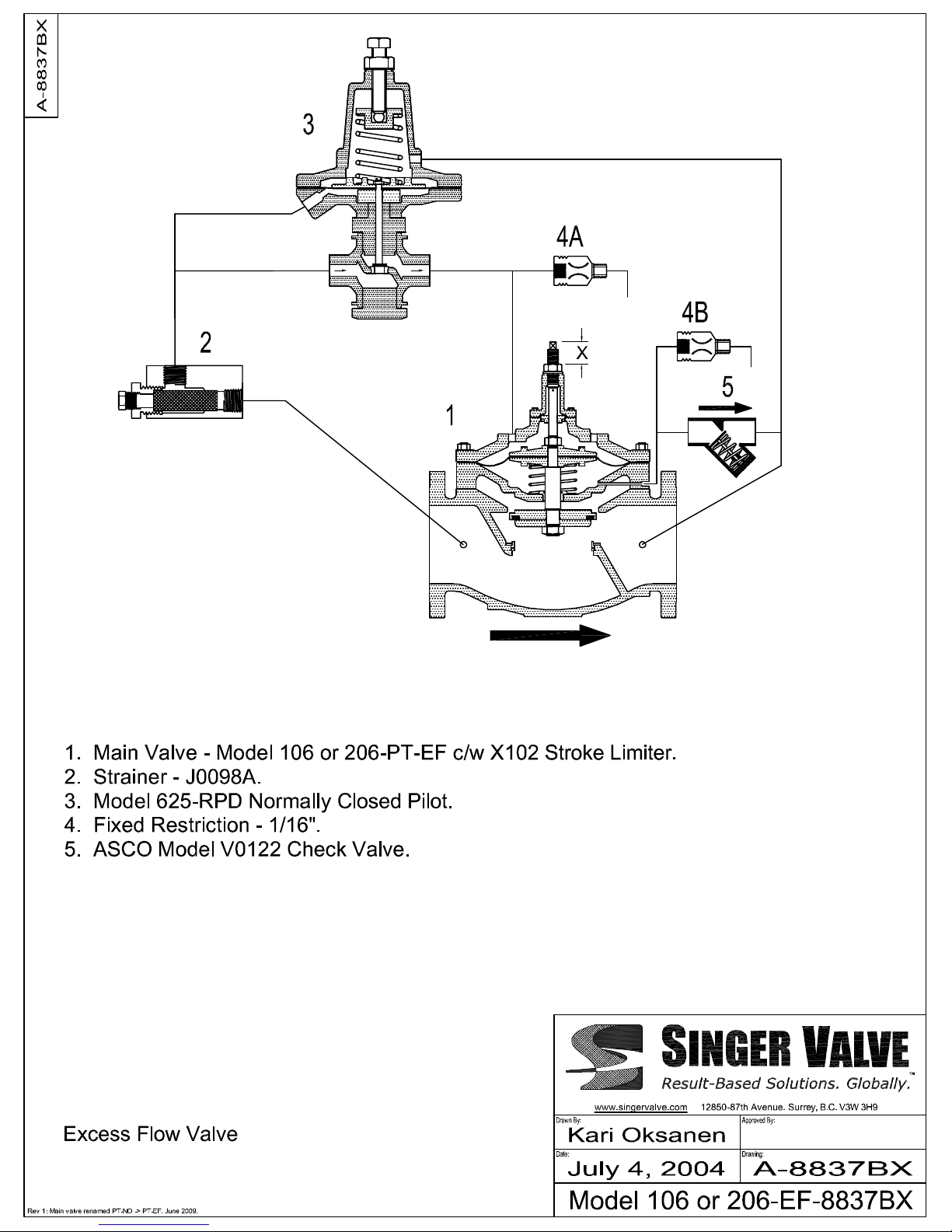

EXCESS FLOW VALVE

Schematic A-8837BX

DESCRIPTION:

Model 106/206-EF-8837BX is normally open

an adjustable amount. The valve senses the

pressure drop across itself and closes when

the pressure drop reaches a pre-set value

(typically 5 psi). Once closed, the valve

requires a minimum inlet pressure of 10 psi to

remain closed until re-set by equalizing the

pressure on both sides of the valve. Since the

pressure drop on a partially open valve is

related to the flow through the valve, the

valve trips (closes) at a pre-determined flow.

DESCRIPTION OF OPERATION:

Main Valve (1) is held partially open by a

spring under the diaphragm, a Stroke Limiting

Screw and by the inlet pressure acting on the

unbalanced area of the stem.

Normally Closed Pilot (3) senses the

pressure differential between the inlet and

the outlet of Main Valve (1). When this

pressure differential reaches the set-point of

Pilot (3), Pilot (3) opens. The inlet pressure of

Main Valve (1) is connected to the bonnet of

the Main Valve to close the valve. Closing is

positive even with low inlet pressure because

the underside of the diaphragm is at

atmospheric pressure.

Check Valve (5) assures that the valve closes

and remains closed in installations where the

outlet pipe runs downhill. There will be

continuous flow through Fixed Restriction

(4A) to drain as long as Pilot (3) is open. This

acts as an indication of tripping conditions

and also makes the valve operation more

predictable because the Main Valve closes at

a positive flow through Pilot (3), not at a nonpredictable leakage.

IOM A-8837BX Page 1 of 1 February 2007

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

INSTALLATION:

See 106/206-PT-EF ‘Installation’.

START-UP AND ADJUSTMENT:

To check operation of the valve and the flow

at which the valve trips, a high flow must be

generated and some means of measuring the

flow must be available.

This valve closes fast. Observe inlet surge

caused by valve closing. Closing surge is

proportional to flow change. Start by closing

from low flow. If closing surge is too high,

install a Closing Speed Restrictor.

When the flow increases, the pressure drop

on the Main Valve increases exponentially.

When the pressure drop reaches the set

point of Pilot (3), the Pilot opens. There will

be flow to drain from Fixed Restriction (4) and

the Main Valve will close.

Pilot (3) can be adjusted to trip at a pressure

drop from 3 psi to 8 psi. Any attempt to set

the pilot outside of this range will result in

unreliable operation.

Important Safety Notice:

X102 Stroke Limiter is limited in the safe

pressure drop that it can handle. Make sure

that under no circumstance will the

pressure drop exceed the rating of the

X102 Stroke Limiter. This means that the

X102 Stroke Limiter will not be used to close

the valve past the point where the maximum

pressure drop caused by the valve at

maximum flow is higher than the rating of the

X102 of that particular size.

Loading...

Loading...