Page 1

SINGER MODEL 160

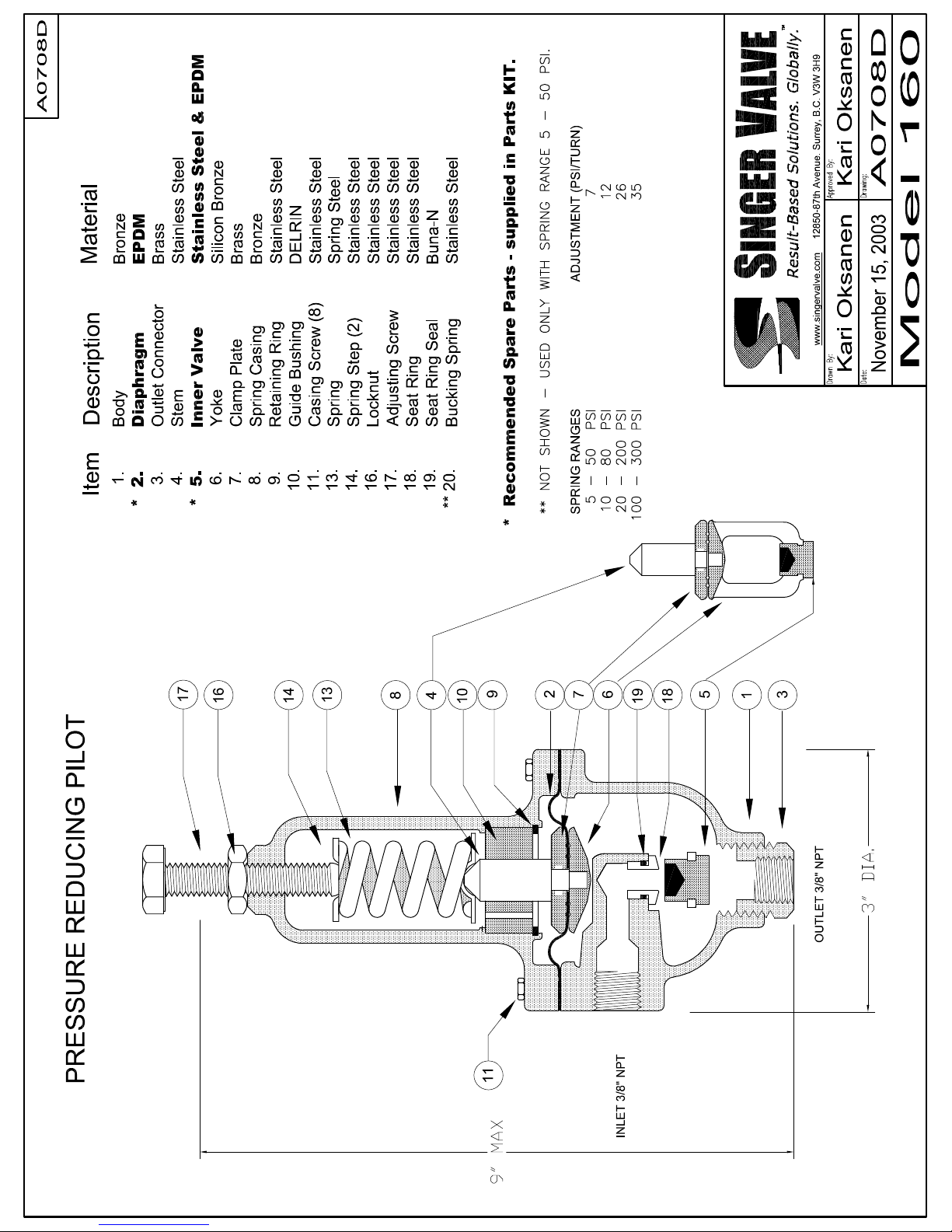

Pressure Reducing Pilot Drawing A0708D

Installation, Operating and Maintenance Instructions

DESCRIPTION AND OPERATION:

Model 160 is a direct acting, spring and diaphragm type

pressure reducing valve. The valve is held open by the

spring. The outlet pressure acting on the diaphragm

opposes the spring to close the valve.

INSTALLATION:

1. Install the valve as shown in the enclosed schematic

or drawing.

2. Note the direction of flow and install the valve

accordingly.

3. The valve should be installed with the adjusting screw

pointing up.

ADJUSTMENT:

Turn the adjusting screw clockwise for increased

pressure, counterclockwise for reduced pressure setting.

Range of adjustment is shown on the name plate.

DISMANTLING:

1. Close upstream and downstream isolating valves.

2. Remove the valve from the pilot system.

3. Remove the adjusting screw.

4. Remove the body screws (11) and remove the spring

casing assembly.

5. Loosen the diaphragm if it adheres to the body and

remove the Stem/Yoke assembly. Be careful to avoid

damage to the stem as any interference or friction

between the stem (4) and guide bushing (10) can

cause problems.

If further disassembly is required:

INNER VALVE REPLACEMENT:

Hold the inner valve (5) HEX in a vise and use a

screwdriver or similar tool to turn the Yoke (6).

IOM A0708D Page 1 of 1 November 2003

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

DIAPHRAGM REPLACEMENT:

• Note the orientation of the diaphragm to help install

the replacement diaphragm properly.

• Hold the inner valve (5) HEX in a vise and use a

3/16” Allen Key (Hex Drive) on top of the stem (4) to

turn the stem counterclockwise. If required, use a

screwdriver or similar tool at the Yoke (6) to prevent

the yoke from turning. BE CAREFUL NOT TO

DAMAGE THE STEM GUIDING SURFACE.

• Replace the diaphragm and orient it to straddle the

legs of the yoke.

REASSEMBLY:

Reassembly is the reverse of disassembly. Ensure that

parts are replaced in the sequence shown on the

drawing.

TEST PROCEDURE:

Connect a source of air or water to the inlet. Attach a

3/8" line with a pressure gauge and shut-off valve to the

outlet. Back off the adjusting screw, then proceed to turn

it in. The gauge should show an increase within the

range marked on the valve. Open the shut-off valve

slightly and bleed flow to atmosphere. Pressure should

drop slightly and return to setting when the shut-off valve

is closed. This check should be performed at various

settings.

SERVICE SUGGESTION:

POSSIBLE CAUSE / REMEDY

FAILS TO OPEN:

Valve underset./ Increase setting.

FAILS TO CLOSE:

Valve overset. / Reduce setting.

Obstruction on seat. / Clear obstruction.

Ruptured diaphragm. / Replace diaphragm.

Worn inner valve. / Replace inner valve.

Page 2

Loading...

Loading...