Singer Valve 106-SC, 206-SC Installation, Operating And Maintenance Instructions

SINGER MODEL 106/206-SC

Solenoid Control Valve

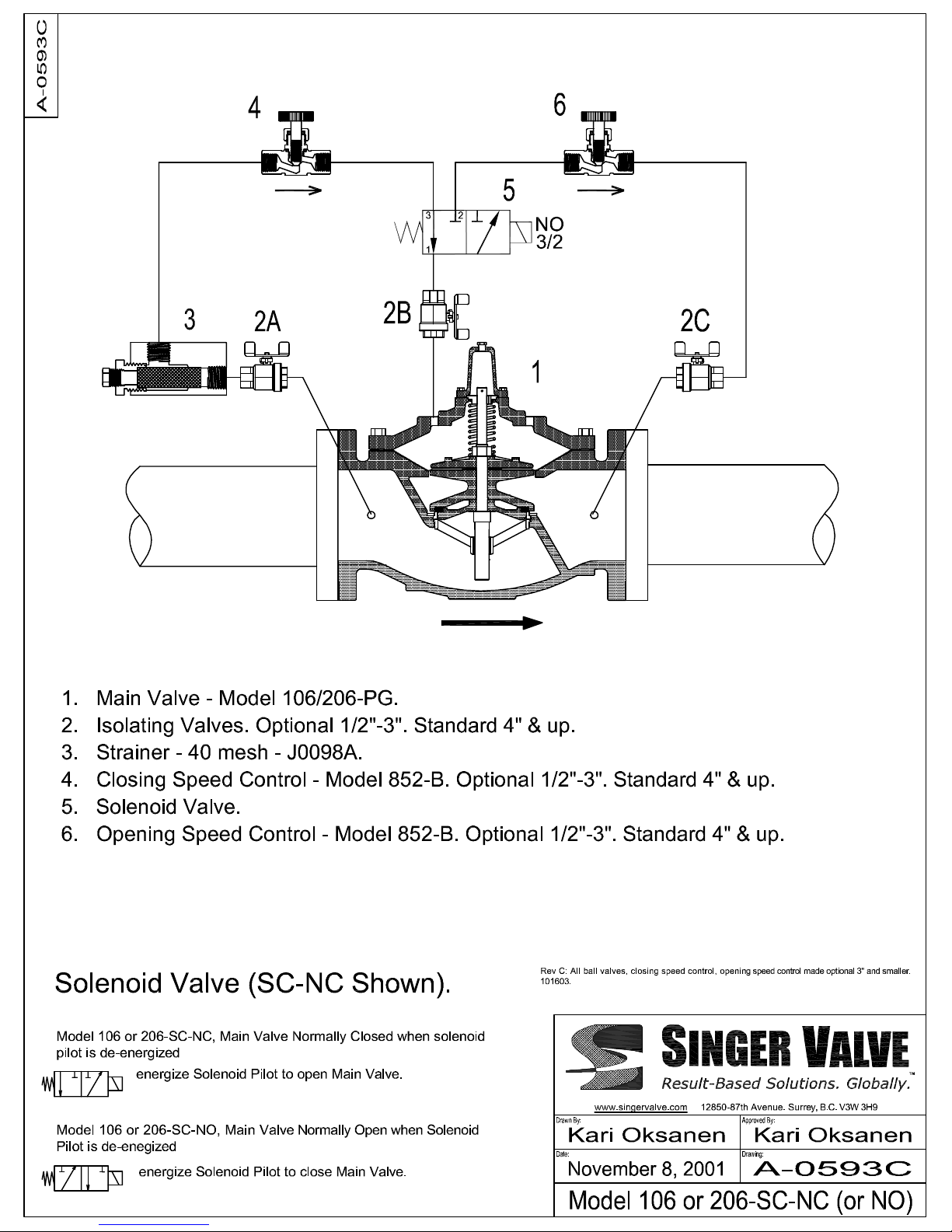

Schematic A-0593C

Installation, Operating and Maintenance Instructions

DESCRIPTION:

Model 106/206-SC is a globe or angle pattern valve

designed for two position (open or closed) operation.

The position of Main Valve (1) is selected electrically

by energizing or de-energizing Solenoid Valve (5).

These valves are available as Normally Closed (NC)

models, which close when the solenoid is deenergized or as Normally Open (NO) models, which

open when the solenoid is de-energized.

DESCRIPTION OF OPERATION:

Main Valve (1) closes when the inlet pressure is

directed to the bonnet and opens when the bonnet is

vented to downstream. Refer to 106/206-PG

"Description of Operation". Solenoid Valve (5)

connects the bonnet to upstream or downstream, as

required.

Opening Speed Control (6) limits the rate of flow from

the bonnet to downstream. Closing Speed Control (4)

limits the rate of flow from the upstream to the

bonnet. Note that Speed Controls (5) and (6) are

optional on 3” and smaller valves and standard on 4”

and larger. If the valve is not equipped with Speed

Controls, the rate of opening and closing is fixed and

can not be adjusted.

All valves include Strainer (3). Isolating Valves (2A),

(2B) and (2C) are optional on 3” and smaller valves.

They are standard on 4” and larger.

IOM A-0593C Page 1 of 1 January 2001

Surrey, BC. Canada. V3W 3H9

INSTALLATION:

1. Refer to 106/206-PG "Installation".

2. Check Solenoid Valve (5) name plate for correct

pressure. Check voltage at the side of the coil

(not the name plate).

3. Connect a suitable power source to the solenoid.

Refer to solenoid valve instructions. Never

energize an A.C. coil when the coil is removed

from the solenoid valve; the coil will be

destroyed in a matter of seconds.

ADJUSTING PROCEDURE:

If your valve is equipped with Speed Controls you can

adjust the opening and closing speed. Turn

appropriate Speed Control clockwise for reduced

speed; counterclockwise for increased speed. DO

NOT fully close either of the speed controls, or the

valve will not operate.

SERVICE SUGGESTIONS:

1. See service suggestions for 106/206-PG and

Solenoid Valve.

2. To reduce pressure drop on low flows, the

exhaust of Solenoid Valve (6) can be piped to

drain rather than downstream (provided that there

is 5 psi or higher pressure in the downstream).

3. NEVER ENERGIZE AN AC SOLENOID COIL

WHEN THE COIL IS REMOVED FROM THE

SOLENOID VALVE.

12850-87th Avenue

www.singervalve.com

Ph: 604-594-5404

Fx: 604-594-8845

Loading...

Loading...