Singer Valve 106-RF, 206-RF Installation, Operating And Maintenance Instructions

SINGER MODEL 106/206-RF

Rate of Flow Control (Flow Limiting) Valve

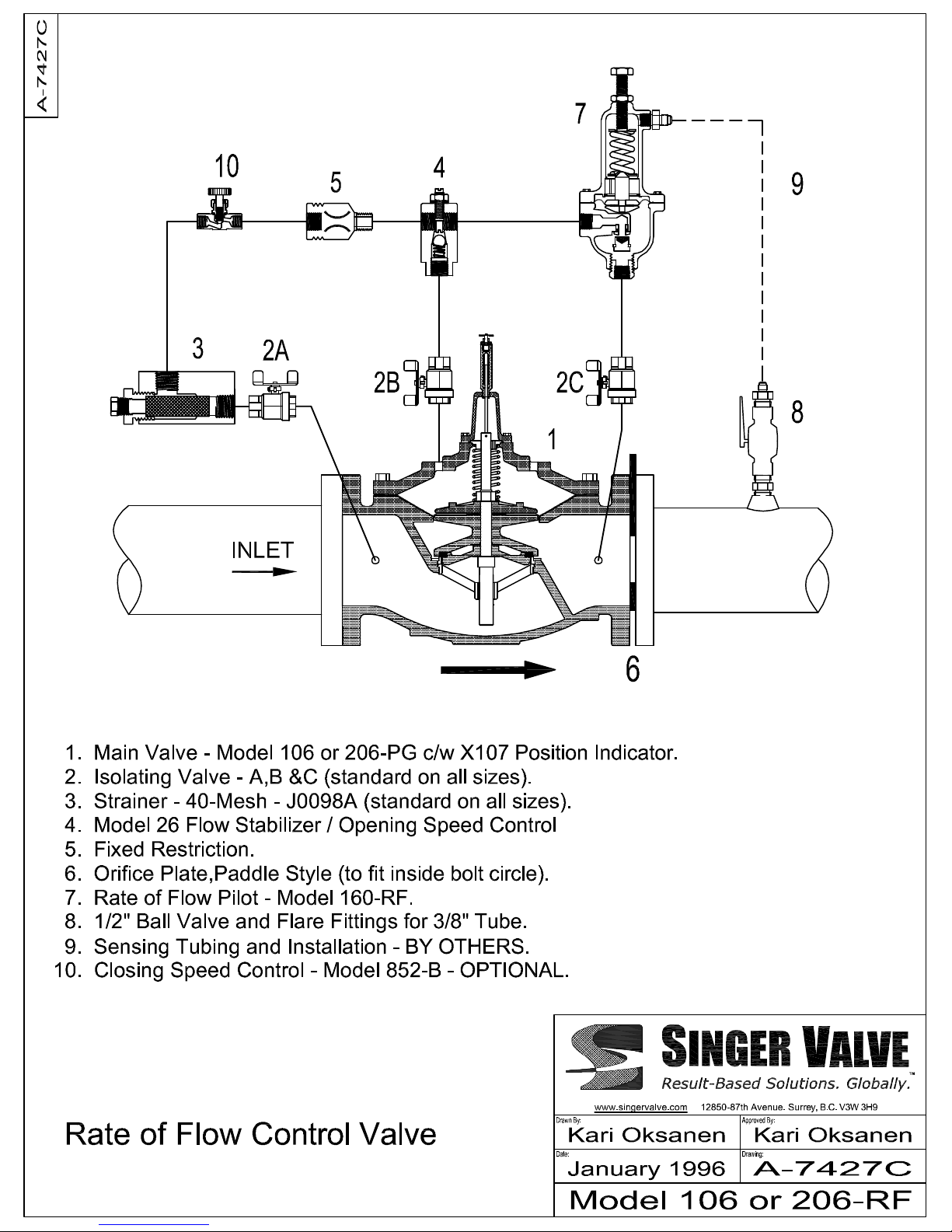

Schematic A-7427C

Installation, Operating and Maintenance Instructions

DESCRIPTION:

The Singer Model 106/206-RF is a pilot operated

valve that limits the flow to a predetermined

maximum regardless of upstream and downstream

pressure fluctuations. Flow Limiting Pilot (7) senses

differential pressure across Orifice Plate (6) and

positions Main Valve (1) as required to limit the flow

to the predetermined maximum.

The flow setting can be adjusted over a limited range

by adjusting Pilot (7); a typical ratio is 2:1 between

maximum and minimum flow setting. Orifice Plate

(6) must be changed for flow setting outside of this

range.

Differential pressure setting of Pilot (7) is designed to

minimize the pressure drop across Orifice Plate for

the set point flow. Normally, Orifice Plate differential

pressure is 3 at the low end of the range and 12 psi at

the high end of the range. Pressure drop across

Orifice Plate (6) increases exponentially as the flow

setting is increased.

DESCRIPTION OF OPERATION:

Main Valve (1) is normally open when pressure is

applied to the valve inlet. When the same pressure is

applied to the bonnet, the Main Valve closes tight

because the area of the diaphragm is greater than the

area of the seat. Pressure above the diaphragm

determines the position of the Main Valve.

Pressure above the diaphragm is controlled by a pilot

circuit consisting primarily of Fixed Restriction (5) and

Rate of Flow Pilot (7). Pilot (7) senses the pressure

differential produced by Orifice Plate (6).

At flows below set point, Pilot (7) is open because the

differential pressure produced by Orifice Plate (6) is

not sufficient to overcome the spring force of the

Pilot. The bonnet of the Main Valve is vented to

downstream and the Main Valve remains open.

When flow reaches the desired maximum, pressure

drop across Orifice Plate (6) closes Pilot (7). Bonnet

pressure increases and Main Valve (1) starts closing.

The valve then modulates to keep the flow from

exceeding the set point.

IOM A-7427C Page 1 of 1 January 2008

Surrey, BC. Canada. V3W 3H9

www.singervalve.com

INSTALLATION:

1. See 106/206-PG "Installation".

2. Install Orifice Plate (6) between two flanges

downstream of the Main Valve outlet. The Orifice

Plate is designed to fit inside the bolt circle of the

Main Valve.

3.

INSTALL BALL VALVE (8) WITH PILOT TUBE

FITTINGS IN THE CUSTOMER SUPPLIED HEADER

CONNECTION

, as shown on Schematic A-7427C.

4. NOTE: Singer supplied orifice housing, with all

necessary pilot connections, are available as an

OPTION.

5. Pressurize the valve slowly and vent air from the

Main Valve bonnet. Use Wing Nut on top of the

Position Indicator to bleed air.

ADJUSTMENT:

1. To adjust the flow setting, turn Pilot (7) adjusting

screw counterclockwise for reduced flow,

clockwise for increased flow.

2. If the valve starts to oscillate or hunt, adjust Flow

Stabilizer (4). Refer to Model 26 instructions.

SERVICE SUGGESTIONS:

In addition to service suggestions listed in the 106PG/206-PG instruction, we suggest the following:

IF THE VALVE FAILS TO CLOSE:

Check that Isolating Valves (2A), (2B) and (8) are

open. Close Isolating Valve (2C). If the Main Valve

closes, Pilot (7) is defective.

If the valve does not close, close Isolating Valve (2A).

Remove the copper tube between Strainer (3) and

Flow Stabilizer (4). If there is continuous flow from

Flow Stabilizer (4), Main Valve diaphragm is ruptured.

If there is no flow from Flow Stabilizer (4), open

Isolating Valve (2A) slowly. If there is no flow, Strainer

(3) is plugged.

IF THE VALVE FAILS TO OPEN:

• Isolating Valve (2B) or (2C) is closed.

• Flow Stabilizer (4), if so equipped, is incorrectly

set.

• Insufficient pressure drop available.

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

Loading...

Loading...