Singer Valve 106-2SC-PCO,206-2SC-PCO Installation, Operating And Maintenance Instructions

SINGER MODEL 106/206-2SC-PCO

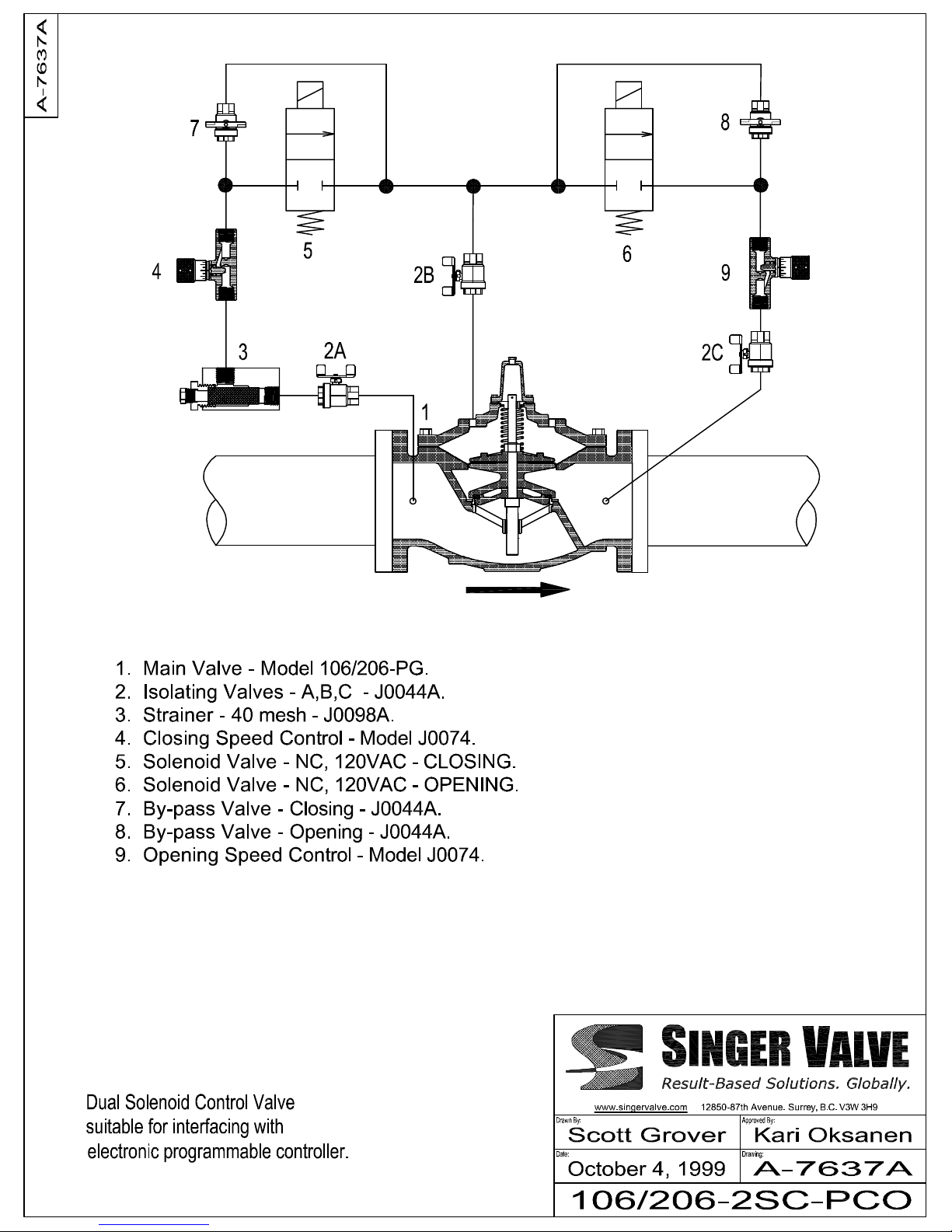

Dual Solenoid Control Valve

Schematic A-7637A

DESCRIPTION:

Model 106/206-2SC-PCO is a valve positioned by

intermittent operation of Solenoid Valves (5) and (6).

It is normally operated by a programmable process

controller. The process controller is not included with

the standard valve.

DESCRIPTION OF OPERATION

Main Valve (1) closes when the inlet pressure is

directed to the bonnet (above the diaphragm) and

opens when the bonnet is vented to the downstream.

Refer to 106/206 PG “Description of Operation”.

Solenoid Valves (5) and (6) are normally closed.

When both solenoids are de-energized, Main Valve

(1) remains in position. Energizing Solenoid Valve (5)

closes the valve. Energizing Solenoid Valve (6) opens

the valve.

Solenoids Valves (5) and (6) are normally equipped

with 120 VAC coils. 12 or 24 Volt DC coils that can be

driven by DC logic (SSR DRIVE) outputs from a

process controller are available.

MANUAL-BY-PASS

The pilot system is equipped with By-pass Valves (7)

and (8) so that the Main Valve can be opened or

closed without electricity. To close the Main Valve

manually, By-pass Valve (7) should be opened while

By-pass Valve (8) is closed. Reversing this operation

will open the Main Valve.

INSTALLATION:

1. Refer to 106/206-PG “Installation”.

2. Check Solenoid Valves (5) and (6) for correct

voltage and operation.

3. Wire Solenoid Valves (5) and (6) to the controller

as required.

4. Pressurize the valve slowly and bleed air from the

bonnet of the Main Valve. See 106/206-PG

Instructions.

IOM A-7637A Page 1 of 1 July 2005

Surrey, BC. Canada. V3W 3H9

12850-87th Avenue

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

ADJUSTING PROCEDURE:

This valve is normally operated by pulsing Solenoid

Valve (5) or (6) to position the Main Valve as

required. This means that the Main Valve moves in a

step fashion. Size of these steps is determined by the

length of the pulse (time of of energization) and the

setting of Speed Controls (4) and (9).

Adjust pulse width and Speed Control settings to get

required control.

SERVICE SUGGESTIONS:

1. See service suggestions for 106/206-PG Main

Valve and Solenoid Valve.

2. Never energize the solenoid coil when the coil

is removed from the Solenoid Valve.

3. If the Main Valve fails to close, the inlet pressure

is not connected to the bonnet because:

- Isolating Valve (2A) or (2B) is closed.

- Strainer (3) is plugged.

- Closing Speed Control (4) is closed.

- Solenoid Valve (5) is de-energized or faulty.

- By-pass Valve (8) is open.

- Main Valve diaphragm is ruptured.

- An obstruction in the Main Valve seat is

preventing closure.

If the Main Valve does not open, pressure is not

being relieved from the bonnet because:

- Solenoid Valve (6) is not energized or is

faulty.

- Opening Speed Control (9) is closed.

- Isolating Valve (2B) or (2C) is closed.

- There is not sufficient pressure drop available

to open the Main Valve.

Loading...

Loading...