Page 1

'.J7i^,

w

MOD^O^

FREEARM, LIGHTWEIGHT,

SUPER-AUTOMATIC WITH BUILT-IN PRACTICAL STITCHES

AND STRETCH STITCHES

INSTRUCTION

MANUAL

XXXXXXXXXXXXXXXXXXXXXD

Page 2

I his booklet has been written for you, to help you use and

enjoy fully your sewing machine. ,

Before you start to use this machine, please take a few

minutes to study this booklet. You will find it will be time

well spent in understanding your machine.

If you have any questions regarding the use of your

overlocking machine please do not hesitate to contact

your dealer or ourselves.

WHITE SEWING MACHINE

Record in space provided below the Serial No. and Model

No. of this appliance.

The Serial No. is located Rear of arm.

The Model No. is located Rear of arm.

Serial No.

Model No.

________;_________________________

...

ET-6 or ET-10 '

Retain these numbers for future reference.

WHITE SEWING MACHINE CO.

Cleveland, Ohio

U.S.A. 44111

Scarborough, Ontario

Canada MIP 2G1

____

Page 3

'A31JE CF CONTENTS

1. KNOWING YOUR MACHINE, Pages..2-17

Acc8Ssori^,1ist of.....................................4-5

Accessory Box

Bobbin,-To insert into Bobbin Case

Bobbin Case, To insert into Shuttle

Bobbin Case, To remove from Shuttle... 9

Bobbin Thread, To pick up........................13

Bobbin Winding

Converting to free-arm sewing

Darning Plate..............................................15

Finger Guard............................................. 11

Free-Arm Sewing and to Convert

Knowing your Machine

Machine Identification

Needle and Thread Table

Needles, to Change...................................11

Power/ Light Switch

Presser Feet, Selection

Presser Feet, to Change............................15

Presser Foot Lever

Reverse Stitch Lever

Seaming Guide Lines

Setting up your Machine

Spool Pins

Stitch Length Control

Stitch Selection Control

Threading Top of Machine

Thread Tensions, Top and Bottom

............................................

........

.........

..........................................

..................

..............

...........................

..............................

.........................

...................................

.............................

.....................................

.................................

................................

............................

...................................................

................................

............................

........................

............

4

10

10

8

7

7

2 - 3

2-3

11

6

15

6

17

17

6

7

16

16

12

14

Lingerie Stitch

Mending.......................................................26

Overcasting, Simple Zig-zag

Overcasting, Three Step Zig-zag

Pin Basting

Piping .........................................................

Ric-Rac Stitch.............................................29

Rolled Hemming....................................... 25

Satin Stitch

Smocking Stitch

Starting to Sew

Straight Stitching

Stretch Overlock Stitch

Stretch Stitches, General Information ...28

Three Step Zig-zag

Top Stitching.

Triple Straight^titch

Turning a Square Comer, Single

Needle

Zig-zag Stitching........................................ 23

Zips, to Insert..............................................22

3. CARING FOR YOUR MACHINE,

Pages

Cleaning the Machine

Cleaning the Shuttle, Feed Dogs ....34-35

Light Bulb, to Change................................34

Sewing Light...............................................34

.........................................................

....................................................

............................................

.....................

..............

.................................................

.................................................

.........................................

...........................................

.......................................

.............................

.....................................

...........................................

...................................

................................

25

24

26

21

22

23

29

18

19

30

26

20

29

20

34 - 35

34

2. STARTING TO SEW, Pages.................18 - 33

Applique......................................................24

Basting

Blind Hems...,

Button Sewing...........................................

Buttonhole Making, Automatic

Buttonholes, Corded

Buttonholes, Tips On

Cording

Darning

Foot Control

Gathering

.......................................................

.............................................

...........

.................................

................................

.......................................................

.......................................................

...............................................

...................................................

31 - 32

21

27

24

33

33

22

20

18

21

4. CHECK CHART FOR PERFORMANCE

PROBLEMS Page

Problem Chart

5. OPTIONAL EXTRA Pages

Even Feed Foot (Optional Extra)

Overcasting Foot (Optional Extra)............38

Rolle Foot (Optional Extra)........................38

Tufting Foot (Optional Extra)

Twin Needle (Optional Extra)

.......................................

............................................

.....................

..............

....................

..............

36

36

37 -40

37

37

39-40

Page 4

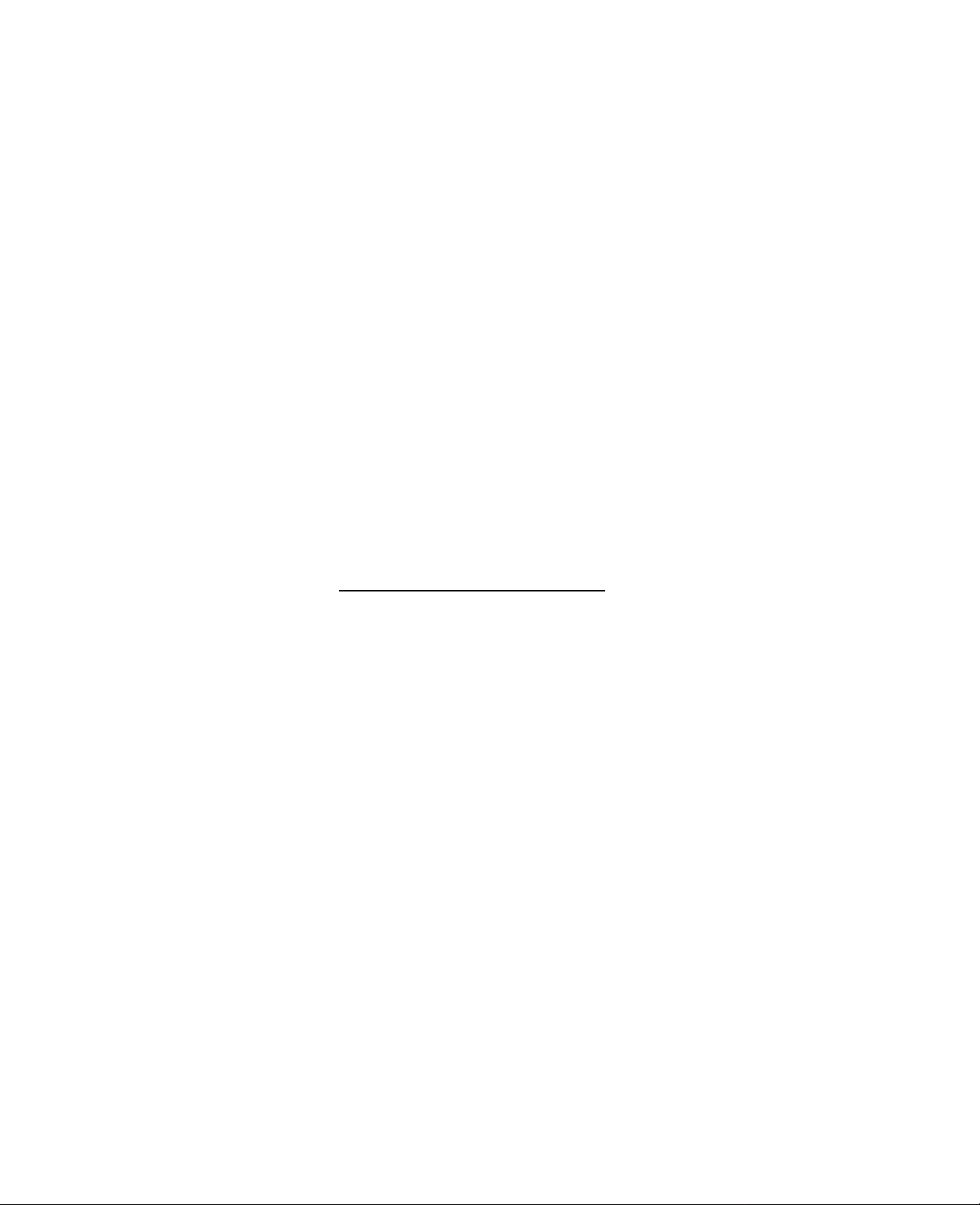

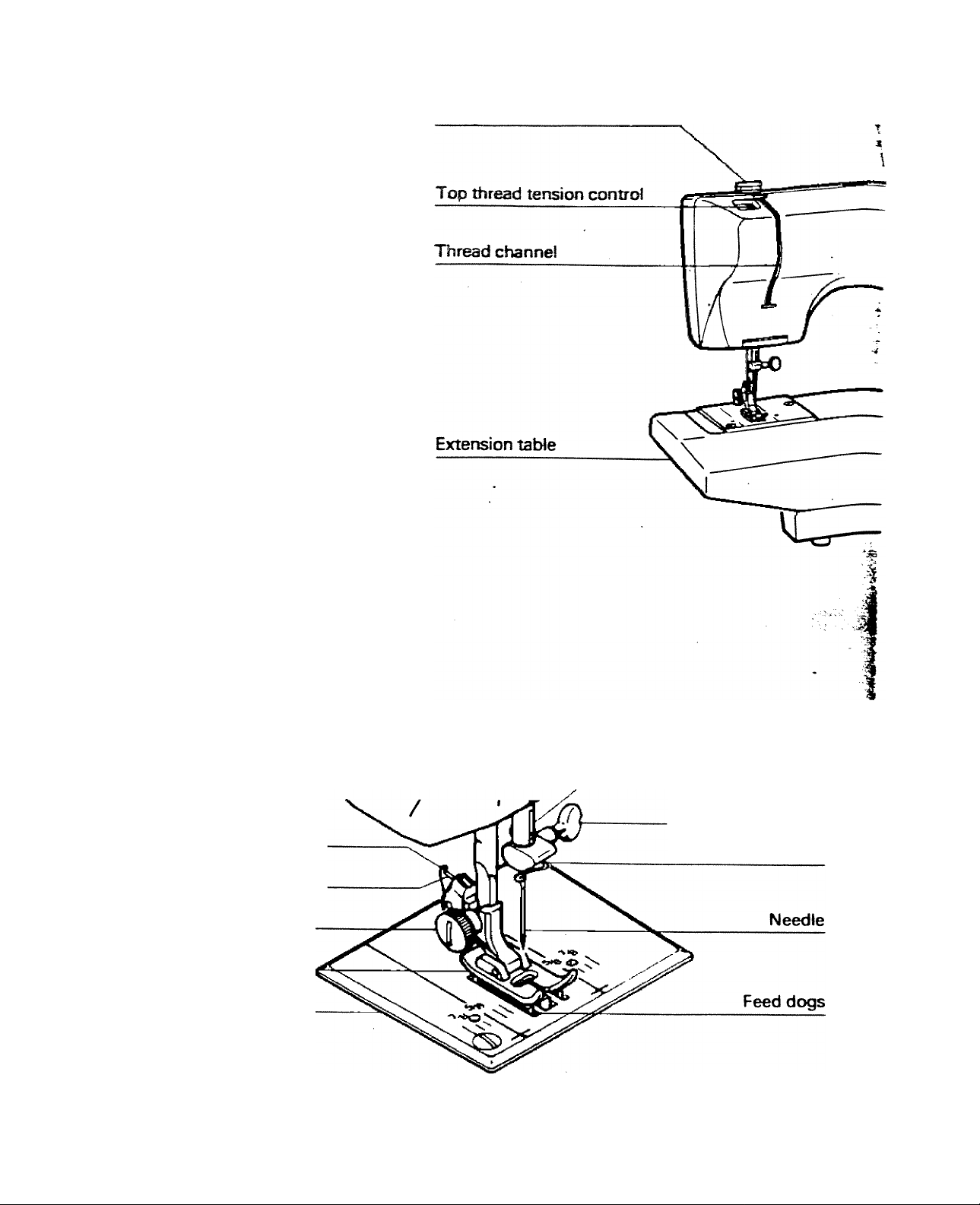

31. KNOWING YOUR SEWING MACHINE

7J1ACHIM1 IDENTIFICATION

Thr^ guide

After unpacking your Sewing

Machine, stand it on a fiat

sturdy surface and study the

diagram to get to know the

various working parts and

their names.

It will be found useful to refer

back to these two pages as

you progress through the

Book to be sure which part b

being referred to.

Needle bar

Needle clamp screw

Presser foot release lever

Thread guide

Thread cutter

Presser foot thumb screw

Presser foot

Needle plate

NOTE: A detailed drawing which shows the parts of the shuttle and bobbin is on page 9.

2

Page 5

Bobbin winder shaft

Extra spool pin

Foot control

Page 6

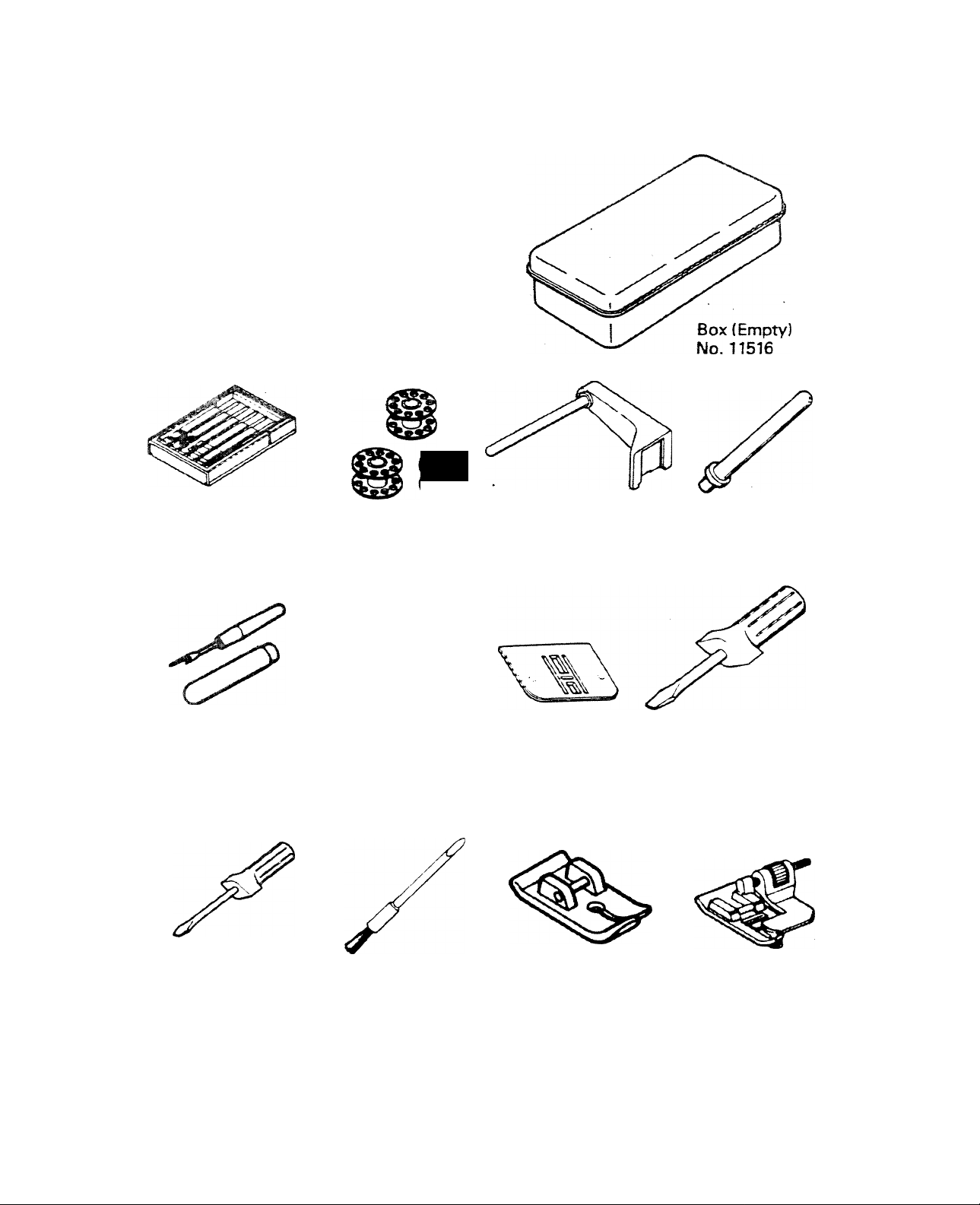

ACCES3fDR!IS

Open the Accessory Box. Inside you will

find a wide* range of acetones and

attachmenis %¥hich will be found useful

for the various sewing -operations that

wil! be described in later pages.

m

Spare needles

N0.7CM3

Seam ripper/

buttonhole opener

No. 7086

Bobbins

No. 100^

Spool pin disc

No. 7056

Spool stand

No. 7053

Darning cover

plate

No. 7057

Extra spool pin

No. 7054

Screwdriver (large)

No. 1627

Screwdriver (small)

No. 1628

Lint brush

No. 7079

Straight stitch

No. 4312

Blind stitch foot

No. 6219

Page 7

Z3S

Zipper foot

No. 3589

Buttonhole guide

No. 7052

Parts and accessories fitted on the machine

Standard zig-zag

foot No. 3550

Presser foot holder

No. 7048

Presser foot thumb

screw No. 76957

No. 7073

Spool pin cap

No. 11423

Needle clamp

screw No. 76061

Bobbin case

No. 77964

Light bulb

No. 3478

Shuttle

No. 7055

Page 8

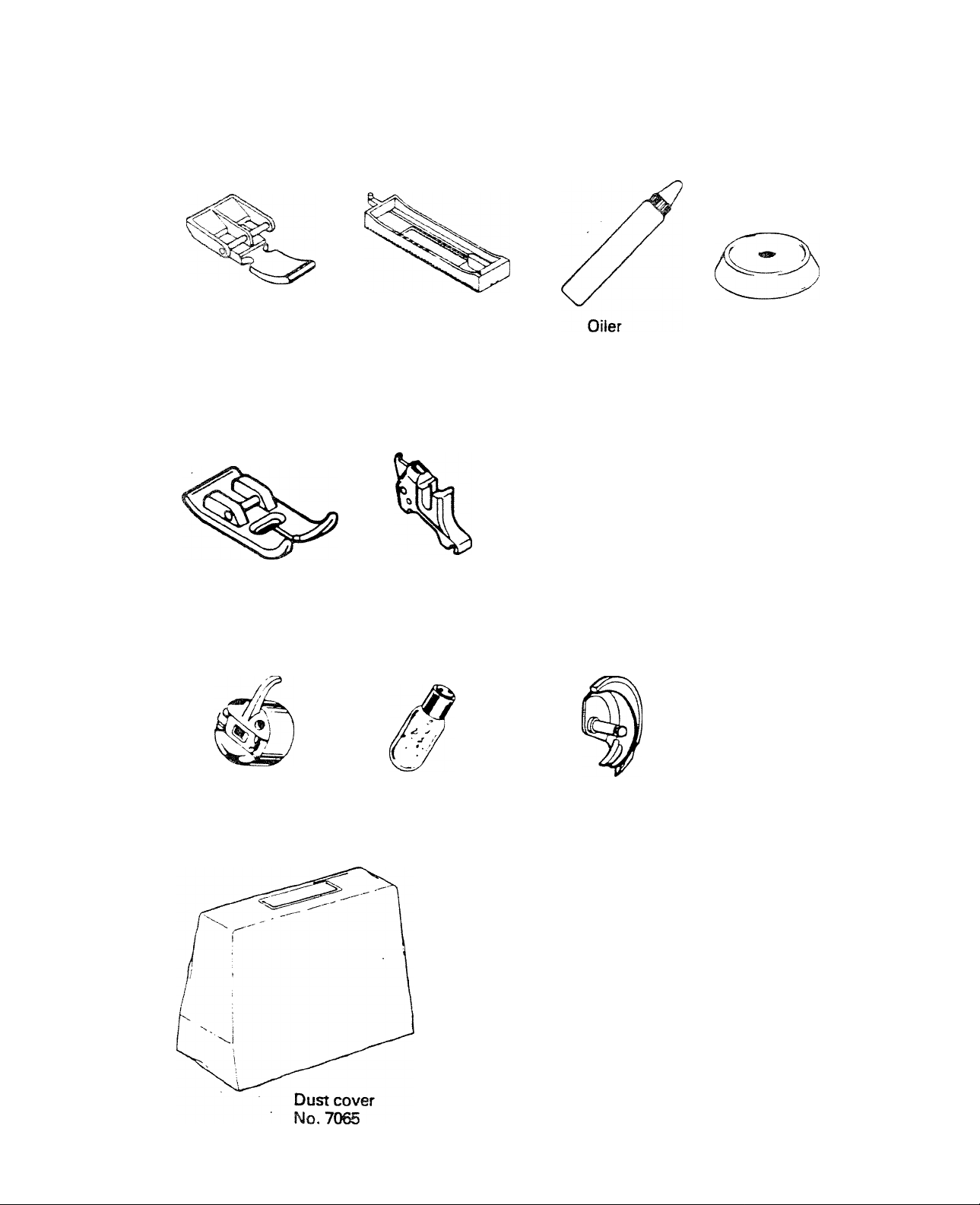

SETTING UP YOUR MACHINE

1. Be sure your machine is resting securely on

a sturdy, flat surface.

2. Before using your machine the first time be

sure to wipe off any surplus oil from around

the needle plate area that may have remained

during transit.

It is also advisable to run the machine

unthreaded with some spare material under

the presser foot, to absorb any excess oil.

FOOT CONTROL

Push foot control plug into the connector

socket at the bottom right-hand side of the

machine. (See also page 18).

POWER/LIGHT SWITCH

Your machine will not operate until the power

switch is turned on. The same switch controls

both the power and the light.

If you are interrupted, or stop sewing, or leave

the machine unattended, the power light switch

must be switched off or the plug must be

removed from the socket-outlet.

When servicing the machine, or when removing

covers or changing needles or lamps, the

machine must be disconnected from the mains

by removing the plug from the socket-outlet.

PRESSER FOOT LEVER

The presser foot lever raises and lowers your

presser foot.

1 • Lower the presser foot lever to sew.

2. Raise the presser foot lever and the pressure

of the presser foot will be released to insert or

remove thin or thick fabrics.

3. Extra height of the presser foot can be

obtained by lifting the presser foot thumb

screw by finger to allow insertion of thicker

material.

NOTE; Presser foot pressure is set at the

factory. No adjustment is required.

Page 9

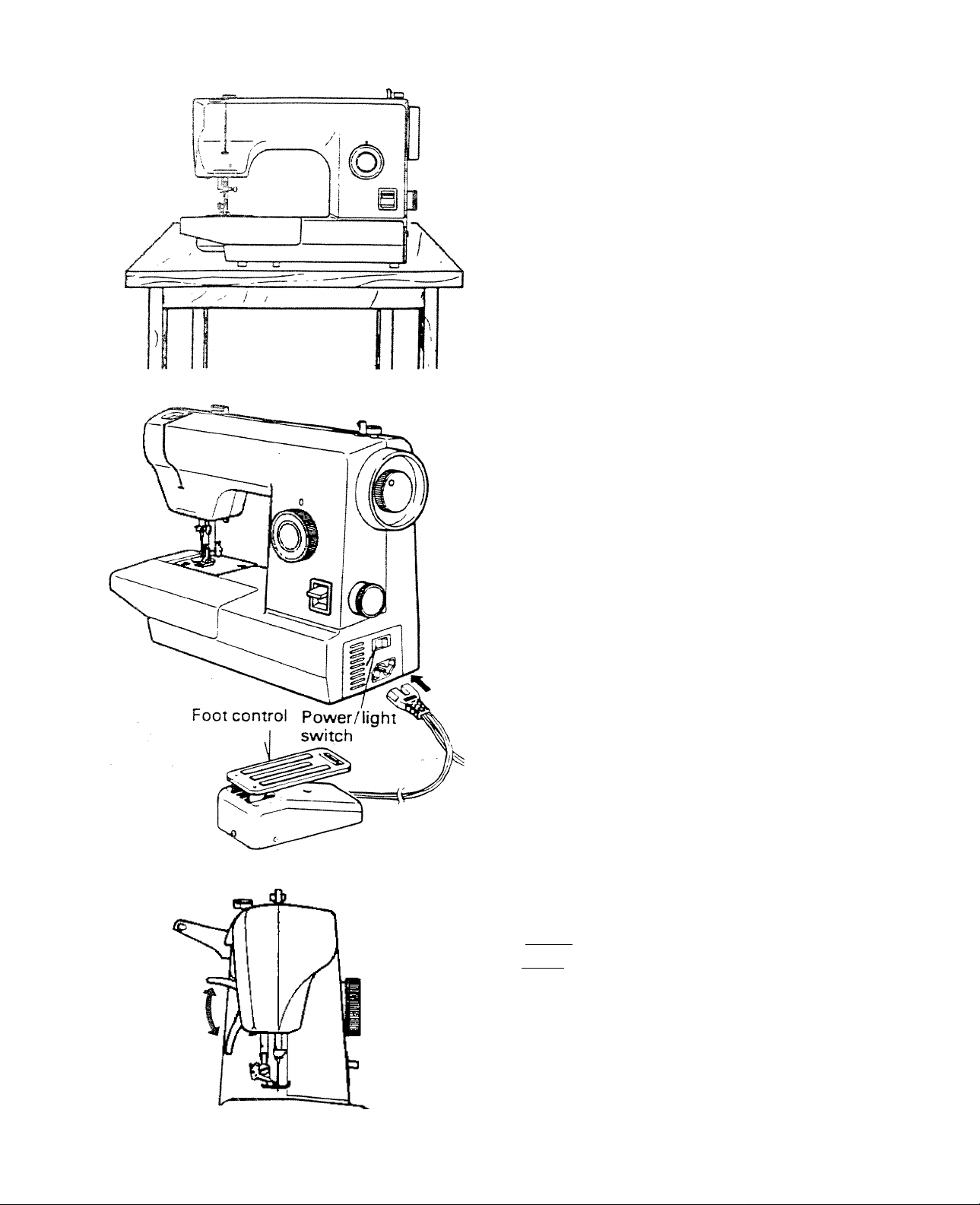

SPOOL PINS

1. Fit the spool stand in the accessory box in

the direction shown by arrow as illustrated.

NOTE: Remember to take off the spool pin

2. Attach the extra spool pin on the right end

of the carrying handle, when sewing with

a twin needle.

#

for storage.

CONVERTING TO FREE-ARM

SEWING

Your machine can be used either as a flat-bed

or as a free-arm model.

With the extension table in position it

becomes a fiat-bed with a large working

surface, which slopes gently towards you to

help the smooth flow of the fabric when

sewing.

By removing the extension table, the

machine converts into a free-arm model

which will be found ideal for sewing ail those

awkward, tight corners especially for small

articles for babies and small children.

The free-arm is easily obtained by simply

pulling the extension table to the left as

shown in the illustration. To replace, reverse

this operation ensuring the lugs A and B are

correctly located into their respective holes.

Extra spool

Other advantages of free-arm sewing are as

follows: —

1. Sewing of any 'tubular' article such as

sleeves, cuffs, trousers, shorts, legs of

almost all garments.

2. Easier mending of worn elbows or knees

of clothes.

3. Sewing-in sleeves, particularly on small

garments.

4. Appliqué, embroidery or hemming around

the edges of cuffs etc.

5. Sewing-in elastic casing at the waistline.

Page 10

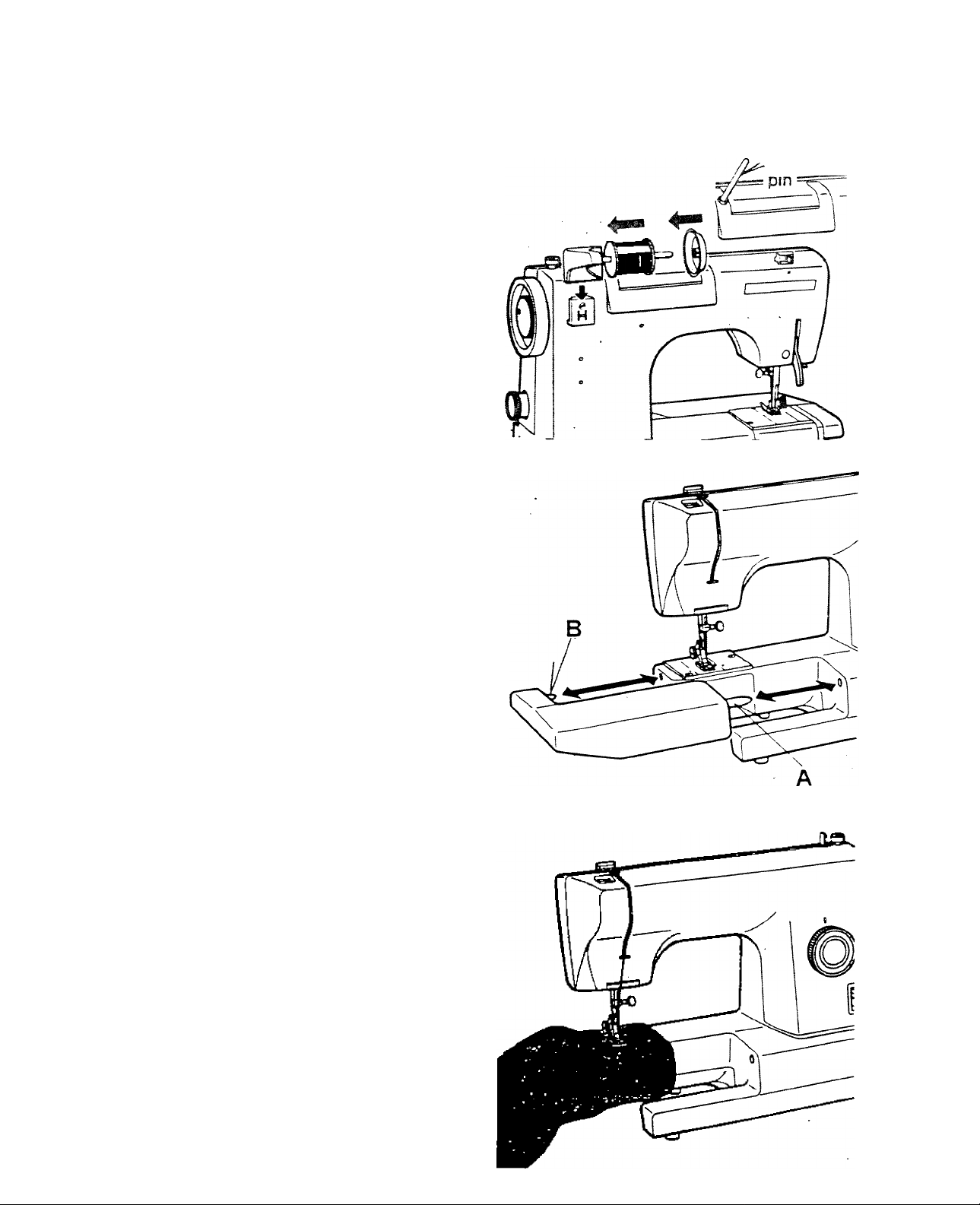

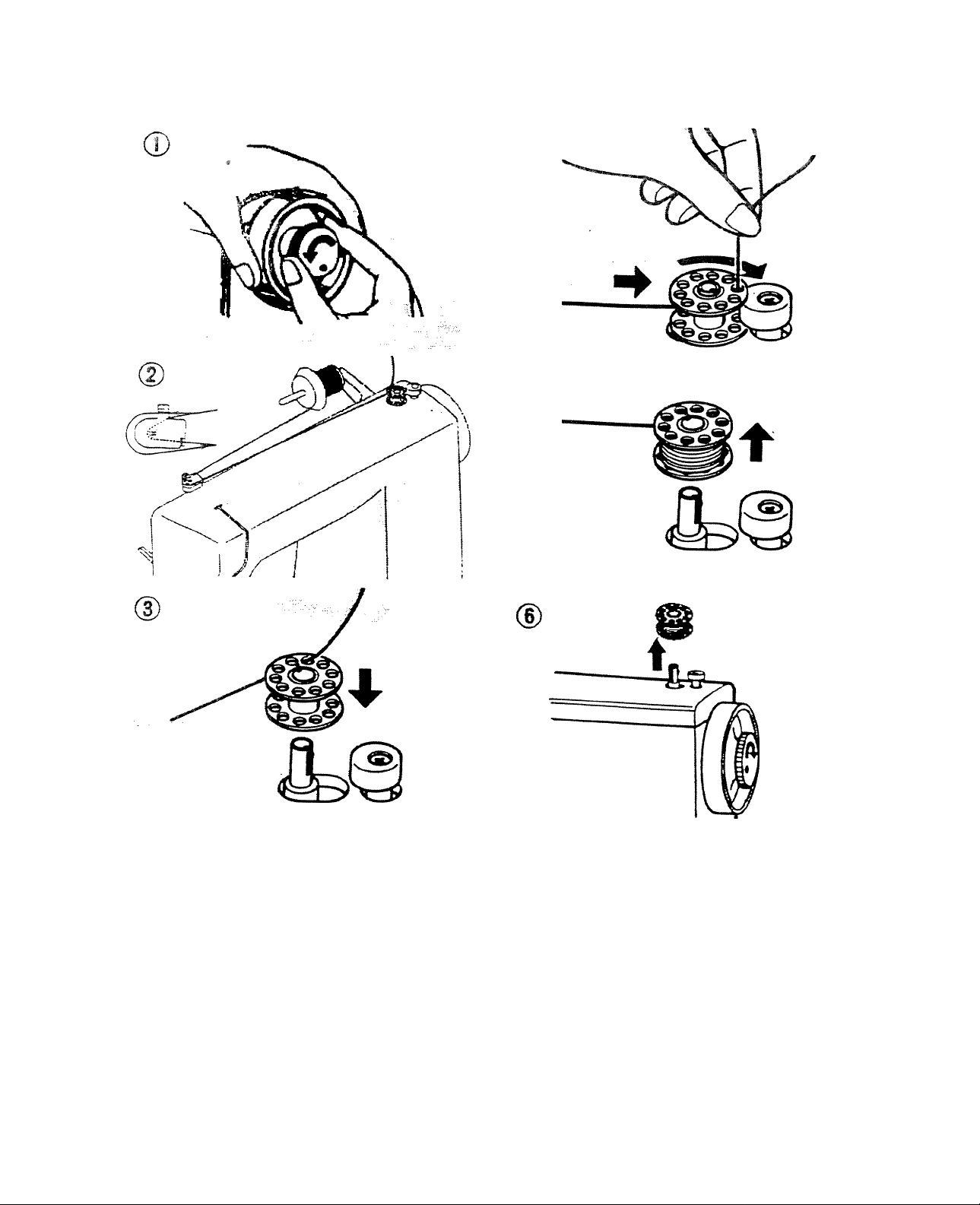

WlilPlMS BCB8IN

1.

Release clutch holding hand wheel and

turning clutch knob towards you.

Draw thread from spool through thread

guide as shown.

3.

Pull end of thread through hole In bobbin

as shown.

4.

Push bobbin winder shaft to far left

position, if it is not already there. Place

bobbin onto shaft with end of thread

8

coming from top of bobbin. Push bobbin

winder shaft to right until it clicks. Hold

onto end of thread.

5. Stert machine. The thread that is held

will snap. Bobbin will cease turning when

completely filled. Push shaft to left to

remove bobbin.

6. Tighten clutch knob and remove bobbin.

Page 11

..

..................................

■ •.«... ..^^1., '^.. A4M.I. .a, %.iu.fi ditinJlk-t.

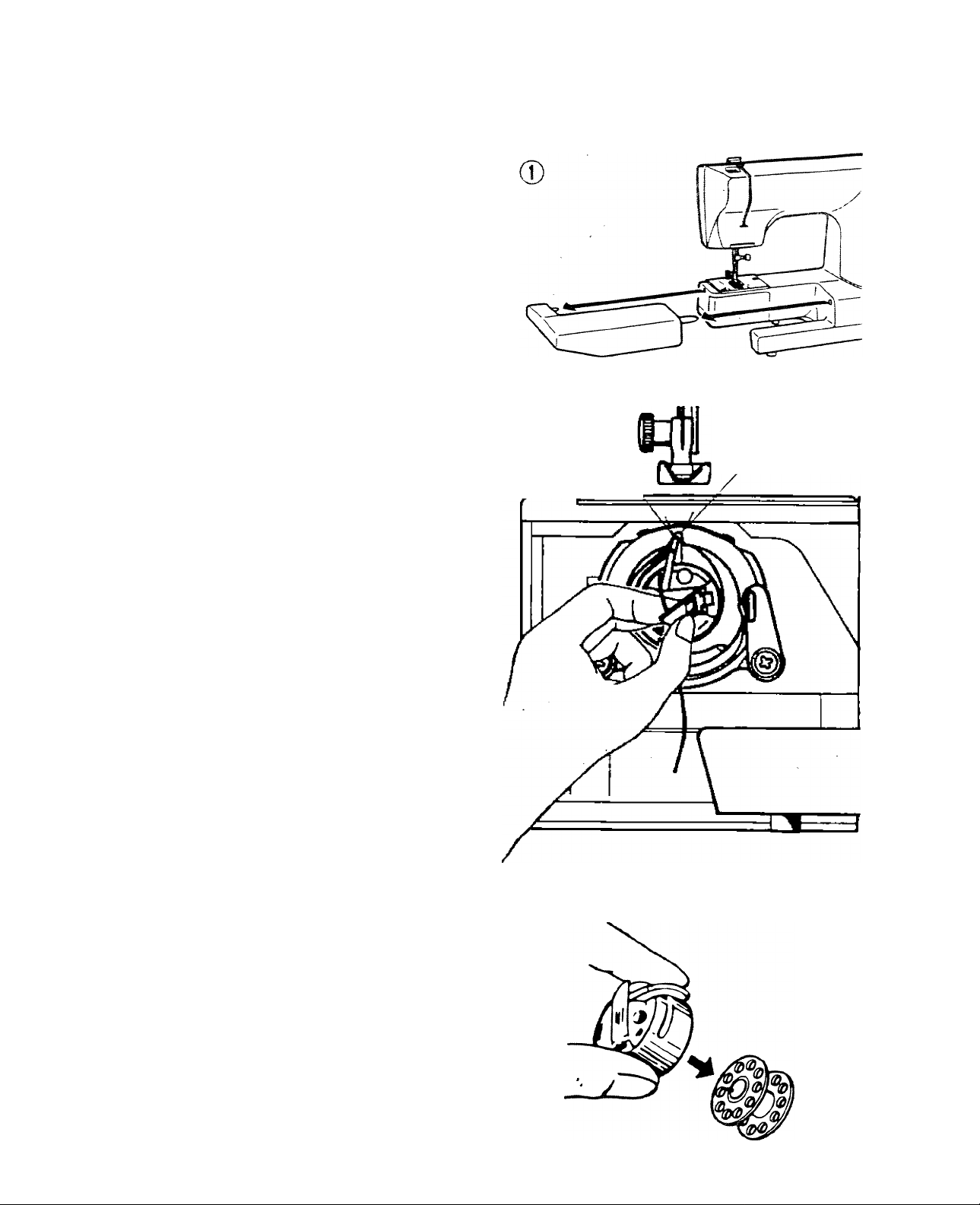

RBimovmQ BOBBIN case

3;-PJTTLl

1. Remove the extension table from the

machine by puiling it to the left.

ha. Open the bobbin access cover by

pulling it down at the notch.

b. With your forefinger and thumb, pull

up the latch on the bobbin case.

c. Using this latch, lift the bobbin case out

of the shuttle.

Locating pin

Locating groove

A

3. Turn the bobbin case upside down and the

bobbin will drop out of the case.

Page 12

la

......

. " ■ '. •

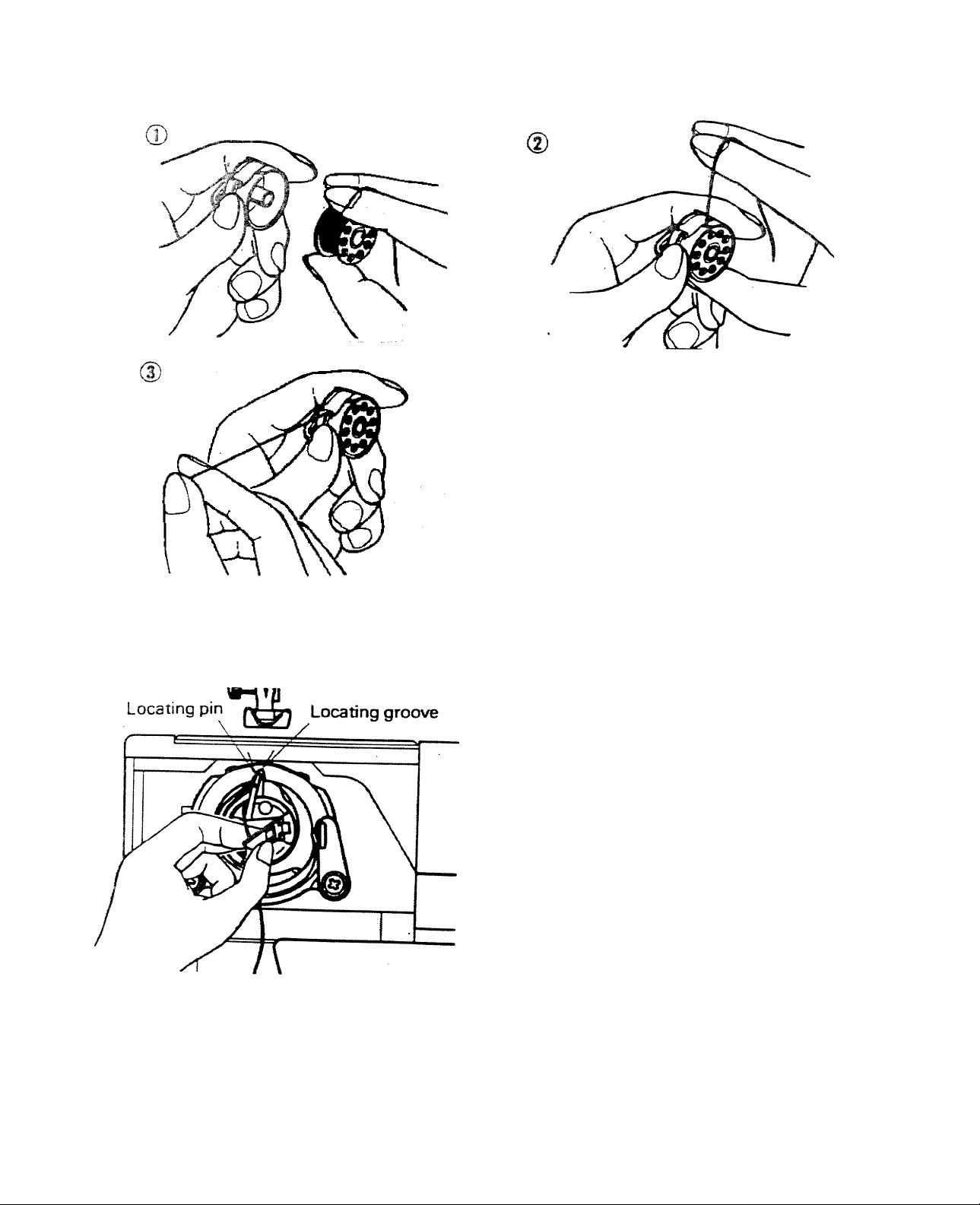

IWSEHTIMG BOBBIN INTO BOBBIN CASE

1. Insert the bobbin into the bobbin case with

the thread running clockwise.

2. Pull the thread through the slit in the

bobbin case.

3 a. Pull the thread underneath the flat

tension spring. It will click when it is in

place.

b- Pull about 6” (15 cm) of the thread from

the bobbin case, to be used later.

INSERT THE BOBBIN CASE INTO THE SHUTTLE

1. -Hold the latch open, with the locating pin

straight up.

2. Slide the bobbin case onto the centre

spindle of the shuttle, keeping the thread

towards you.

NOTE; Be sure the locating pin fits into

3. Release the latch to lock the bobbin case

in place.

the locating groove at the top of

the shuttle.

10

Page 13

■ ■■

NEEDLE AND THREAD TABLE

Use System 705 needles. The size of the

needle should conform to the size of the

thread and both should be suitable to the

material. The same size and type thread

should be used in the bobbin as on the upper

part of the machine for ordinary sewing.

Thread Size

Cotton 60-100

Synthetic

Machine embroidery

Cotton

Synthetic

Silk A

Machine embroidery

Cotton 60 80

Mercerized 50-60

Synthetic

Cotton 30-60

Mercerized heavy

duty

Needle Size Fabric

Continental / American

Blue shank needle

70(7) 11

or

80(8) 12

80(8)

or

90(9)

100 (10) 16 medium to heavy

or

12

or

14

Never use a bent needle nor one with a blunt

point.

For successful sewing of stretch fabrics use

the stretch stitch needles with blue shank.

All stretch fabrics.

Sheer cottons, silk, .

synthetics, fine laces.

batiste, dimity.

Medium weight cottons.

medium weight synthetics.

poplin, seersucker.

gingham, velvet, light

weight woollens, linen.

Heavy weight cottons.

weight woollens, denim.

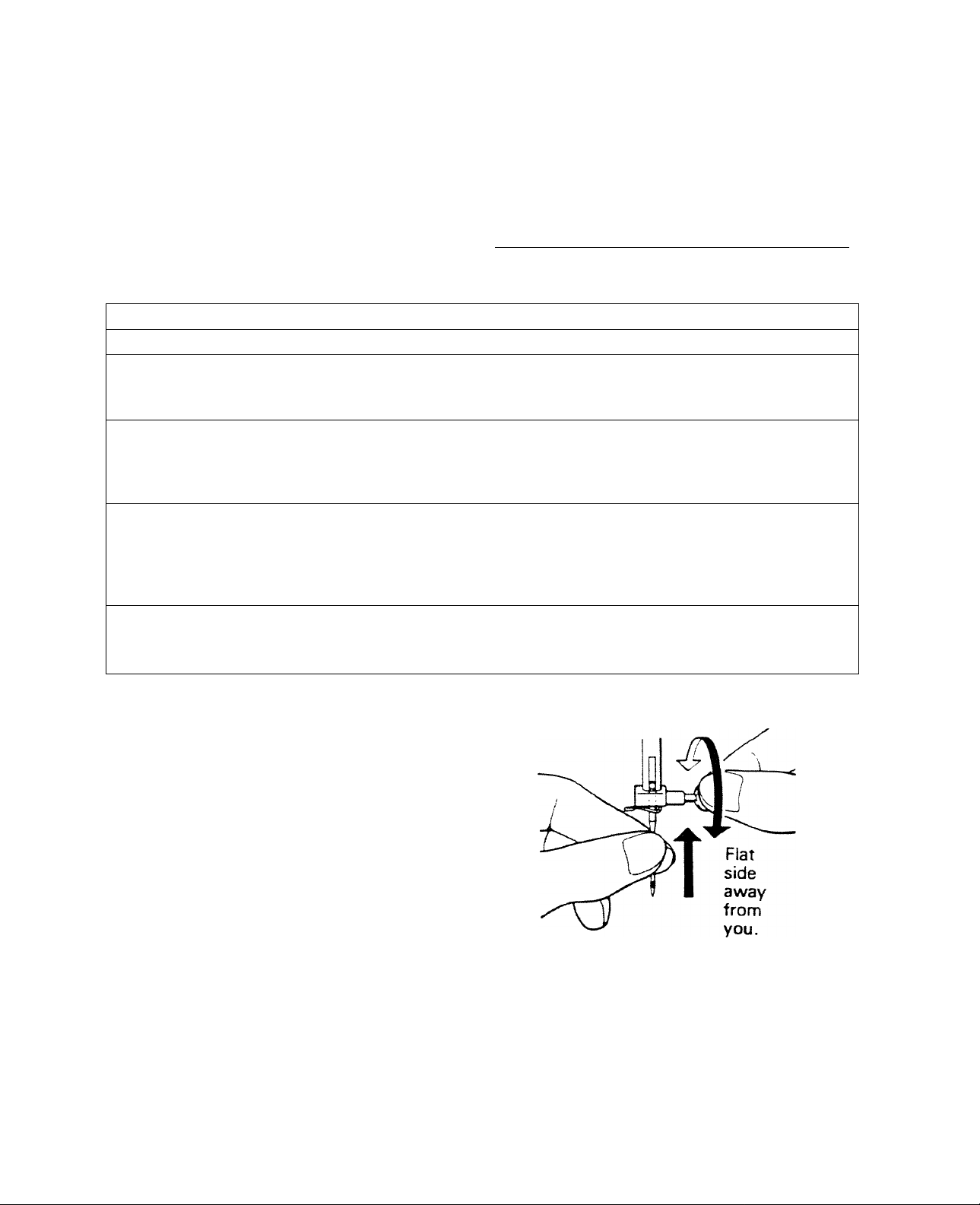

CHANGING NEEDLES

Raise needle bar to its highest position by

turning the hand wheel towards you. Loosen

the needle clamp screw, and remove old or

damaged needle.

Holding the new needle with the flat side

away from you, slip it up into the needle bar

as far as it will go. Tighten the needle clamp

screw.

11

Page 14

THIilADIPJG TOP THREAD

Thread the machine in the follcjwing

order as'illustrated.

Raise the presser foot lever. Raise the

needle to its highest position by rotating

the hand wheel towards you.

1.

Draw the thread from the spool passing

through the top thread guide, and pull it

towards you.

2.

Holding the thread from spool with your

right hand, pull it downward positively

through the tension slot.

12

3.

Slip the thread through the .thread guide

below needle clamp.

Thread the needle from front to back, and

draw about 4" (10 cm) of thread through

the needle eye towards the back of the

machine. .

Page 15

PICKIWG UP BOBBIN THREAD

1. Raise the presser foot lever.

Holding the top thread loosely in the left

hand, turn the hand wheel towards you

with your right hand and bring the needle

to its highest position.

3. Lightly pulling the top thread, pick up the

bobbin thread appearing through the

needle plate slot.

4. Pull both top and bobbin threads

together, passing under the presser foot

towards the rear of the machine, leaving

about 6" (15 cm| clear.

If you cannot pick up the bobbin thread by

following the above steps, check the

following points.

1. Is the needle correctly threaded ?

2. Is the thread tangled around the needle ?

3. Is there about 6” (15 cm)of thread com

ing out from the bobbin case ?

4. Is the thread from bobbin case tangled ?

Page 16

STRAIGHT STITCHING

ADJUSTING TOP THREAD

TENSION

Straight Stitching

The good appearance of your stitching is

largely dependent on the balanced tension of

top and bobbin threads. The tension is well

balanced when these two threads lock in the

middle of layers of fabric. You can adjust the

tension of the top thread with the thread

tension control. If the top thread is too tight,

turn this control away from you to reduce the

tension. If the top thread is too loose, turn it

towards you to increase the tension.

Fabric

puckers

Zig-zag Stitching

The top thread may appear on the underside

of the fabric depending upon the thread,

fabric, type of stitch and sewing speed, but

the bobbin thread must NEVER appear on the

top of the fabric.

ADJUSTING BOBBIN THREAD TENSION

It the straight stitches do not appear satisfac

tory, adjust the tension of top thread, as bobbin

thread tension requires adjustment less fre

quently than the top thread tension.

If the tension looks well balanced, but the

fabric puckers badly, both top and bobbin

thread tensions have to be adjusted.

To check and see if the bobbin thread tension

is correct, suspend the bobbin case by the

thread and jerk it once. The correct bobbin

tension will result in the thread unwinding

only 1 inch.

Use a screwdriver to adjust tension on the

bobbin case.

Page 17

PRESSER FEET

This machine is fitted with a zigzag presser

foot for general sewing purposes. In the

accessor/ box are the following additional

presser feet;

1. Straight stitch foot

2. Zipper foot

3. Blind hem foot

CHANGING PRESSER FEET

Be sure needle is in the up position. Raise

presser foot lever.

Snap-on presser feel

1. Raise foot release lever to remove the

foot. (Fig. 1)

2. Place the desired foot on the needle plate

aligning needle holes. (Fig. 1 )

3. Lower the presser foot lever so that the

foot holder snaps on the foot. (Fig. 2)

DARNING PLATE

There are a few times when you want to

control the feeding of the fabric yourself.

Raise needle to its highest position and raise

presser foot., Attach darning plate over

needle plate aligning two pins of darning

plate with holes of needle plate. You may

then determine the movement of the fabric

yourself.

Fig. 1

Fig. 2

Page 18

STlTC¡’j SSLSCTOR

Your sewing machine can sew a variety of

stitches, and these are shown on the Stitch

Selector Dial’. In addtion, there are three

buTtonhoie Slaps pictured on the dial also.

Straight stitch

NOTE: Beginning on page 19, you will find

detailed instructions on the use of

each stitch.

STITCH LENGTH CONTROL

To lengthen a stitch, turn the dial towards

you. To shorten a stitch, you turn the dial

away from you. THE HIGHER THE NUMBERTHE LONGER THE STITCH.

NOTE; Study the orange, green, yellow and

blue sections on this control. These

are recommended ranges of stitch

Orange zone

j

I Green zone

Yellow zone

Blue zone

•Model ET-10 only.

length and colour-coded to the

stitches pictured on the • Stitch

Selector.

The orange line between 0 and 1 is the sening

used for the shonest stitches such as in satin

stitch.

— Straight stitch

Zig-zag stitch

— Three-step zig-zag

stitch

BBnd tern stitch

* Lingerie stitch

— Ric-tac stitch .

Triple straight stitch

* Stretch overlock stitch li

* Overlook stitch

* Smocking stitch

— Buttonhole stitch

1

1

M'M$

5: . .

J ■

1 .

■

■

s

a fl <D

16

* Model ET-10 only.

Page 19

SEWEiSE STITCH LEVEH

It is best to begin and end seams with a few

stitches made in reverse. This is called

'backtacking', which fastens the ends of the

seams and prevents unravelling.

To achieve reverse sewing, push down the

(Over as shown, and hold there during sewing.

I he fabric will feed backwards until you

release the lever, when it will feed forward

again.

SEAM .3UIDE LIMES

To help you sew straight seams and seams of

uniform width, guide lines have been printed

on the needle plate either side of the needle.

As a standard seam is 5/8” (16 mm) these

lines have been extended in front of, and

beyond the needle. ’

\

Reverse stitch lever

The 'cross lines' are 'cornering guides' which

help when turning a square corner 5/8”

(16 mm) from the fabric edge. Further details

of this can be found on page 20.

17

Page 20

2wmm

,^ow that yoy are familiar with the controls on your sewing machine and with the m:c8s«>rm

provided for the machine, you are ready to start to saw. Mow are some good habits to follow

sach time you sit down at your machine.

TO SEW

Check the needle-it should be straight,

properly set and sharp on the point.

It should be the correct size for the fabric

and thread being used. Do not be afraid

to change your needle frequently. Many

of the new fabrics made of synthetic

blends tend to dull the needles more

easily than fabrics made of natural fibres.

2. Before placing the material on the

machine, see that the ends of the threads

have been drawn about 6" (15 cm) to the

rear of the machine. Hold on the threads

during the sewing of the first 3 or 4

stitches of the seam.

5. Run the machine at a slow, even speed.

The more pressure you put on the foot

control, the faster the machine will sew.

Fasten each seam by back tacking at the

beginning and end of the seam.

fabric you plan to use. The fabric should

be double thickness. Adjust the machine

for the length of stitch and tension

suitable to your fabric.

Fabric should be placed under the presser

foot with the bulk of the material to the

left of the needle and the right edge of the

material placed on the 5/8" (16 mm) seam

marking on the needle plate when making

a simple seam.

needle at its highest point.

8. Guide the fabric gently with your hand in

front of the needle. Never pull or hold the

fabric in such a way that the normal

feeding is altered.

9. When turning the hand wheel manually,

always turn it towards you.

Page 21

37HA3GHT STITCHING

Tc^J thread tersion contrd

Stitch selector

-X----------1

*NOTE; For most straight stitching, the

straight foot will give your best control, but

you may use the zig-zag foot if you prefer.

Straight stitch is probably the most frequently

used of all stitches. Apart from seaming, its

many uses include tacking, basting, top

stitching, gathering, inserting zips etc. It can

be used with single or twin-needles.

FASTENING A SEAM

Be sure both threads are drawn back under

the presser foot. Lower needle into fabric

about 1/2” !1 cm) from beginning of seam.

Depress the reverse stitch lever and stitch in

reverse until needle reaches beginning of

seam. Release control and complete seam.

When you reach the end, depress the reverse

stitch lever and sew back (backtack) over

1/2” (1 cm) of completed seam.

^1

i

mi

£=S }

r>

REMOVING FABRIC

First turn the handwheel toward you until the

needle is at its highest position, then raise the

presser foot, draw materials to the rear and

cut off excess thread with the thread cutter

located on the foot release lever as shown.

Page 22

-^-23

.Ccjmering

Guide

TURNING A SQUARE CORNER

To turn a square comer 5/8" {16 mm) from

the fabric edge, stop stitching with the

needle tip piercing the fabric, when reaching

the cornering guide as shown. Raise the

presser foot, turn fabric. New stitching line

will align with 5/8" (16 mm) seam guide on

side of needle plate. Lower the presser foot

and begin stitching in new direction.

TOP-STITCHING

This is a seam you may want to show off. It's

on the front side of the garment, possibly at

the top of a "kick pleat" or on a lapel, both

functional and decorative. Usually, it's a

simple, forward stitch — with an extra-long

stitch length, or with special thread, match

ing or contrasting.

20

DARNING

SETTINGS

Darning plate

No Presser Foot

Remove presser foot, stretch fabric between

embroidery hoops with hole centred. Draw

the bobbin thread up through the fabric by

holding the top thread and making one stitch

at the spot where you wish to start darning.

Lowering the presser bar, start sewing at a

slow to medium speed. Move the fabric back

and forth with a steady rhythm to cover the

darning area. When it is covered, turn the

fabric and sew another layer of stitching

across the first layer of stitching.

Page 23

TEMPORARY SEWING BY

MACHINEjBASTING)

No longer do you need to baste by hand.

Basting by machine is easy —simply use

straight stitching with longest available

length setting.

PIN BASTING

Sewing over pins is possible as shown

because the presser foot is 'hinged' -and will

'ride' over the pin points. These must be

inserted at right angles to the seam line. They

must always be on the top side of the fabric

NEVER beneath. Sew slowly, and if in doubt,

remove each pin as you approach it.

GATHERING

Set the stitch length at 4 and the top thread

tension at 1 - 2. Sew one or as many as rows

of parallel stitches as required, but do not

backtack at the beginnings and ends of the

rows.

Remove the fabric and draw up the bobbin

thread to gather the fabric to the required

length or fullness. Re-set top thread tension

control to its normal position. .

21

Page 24

INSERTING ZIPPERS AND PIPING

Use zipper foot which allows you to sew to

the right or left of the zipper (or close to a

cord).

Needle to left

of foot

Needle to right

of foot

INSERTING ZIPPERS

To sew down the right side, attach left side

of zipper foot to presser foot holder so that

the needle passes through the opening on the

left side of the foot.

To sew down the left side, attach right side of

foot to foot holder.

PIPING OR CORDING

To pipe soft furnishings, cover cord with a

bias strip of fabric and pin or tack it to the

main piece of fabric. . ‘

Attach right side of zipper foot to foot holder

so that needle passes through the opening on

the right side of the foot.

'22

Page 25

Zm-ZfAQ STJTCHING

Top thread tansion control

Stitch selector

SELECT ZIGZAG WIDTH

By rotating the stitch selector, it is possible to

choose eight different widths of zigzag.

These are illustrated on the dial which will

produce the various zigzag widths as shown in

the diagram.

The stitch selector can be turned in succession

with ease within the zigzag stitch range. Use

this feature to make decorative patterns.

SATIN STITCH

Closely spaced zigzag stitches are called satin

stitches.

Use this stitch for bar tacking, appliqueing,

embroidery and monogramming.

NOTE: You may need to loosen the top thread

tension to prevent puckering. The wider

the stitch, the looser the tension should

be.

Use tissue paper or interfacing beneath a soft

fabric to improve the appearance of this stitch.

:

wiy mtitl

23

Page 26

OVERCASTING STITCH

Use this stitch to keep seams or fabric from

raveling.

NOTE: To reinforce seams with overcasting,

it is recommended to use the three-

step zigzag (see page 26).

1. Stitch so that the point of the zigzag clears

the raw edge of the fabric.

BUTTON SEWING

SETTINGS

Stitch Selector - Zig-zag Stitch

Use Darning Plate.

1. Fix the button on fabric at desired

position with clear tape.

2. Align two holes of button with slot of

presser foot and lower foot to hold the

button securely.

3. Turn hand wheel manually until needle

point is just above button.

4. Set stitch selector at desired zigzag stitch

position so needle will enter one hole of

the button.

5. Turn hand wheel again by hand so needle

enters second hole. Reset stitch selector

if necessary. Make 5 or 6 stitches. ■

6.

Finish sewing with an extra two inches of

thread remaining. Draw these threads to

reverse side of garment and tie.

When sewing a flat button, place needle or

pm between holes of button as shown to

provide flexibility for buttoning.

APPLIQUE

To applique a design on a sewing project or

garment:

1. Baste the applique to the top of your fabric.

2. Then use satin stitch to attach permanently.

You may want to use a contrasting color

thread.

NOTE. For best results, be sure your satin stitch

covers the bottom fabric and the top

fabric.

24

Page 27

jmgee:2 stitch

Top thirad terelon control

(Mode! ET-10 only)

( ^ f Л

Чз

--------о—-------------------------

Stitch sdector

/ ^ ^

В

J

SEAM AND OVERCAST IN ONE

and overcasting

sheer, soft fabrics in one operation It also

prMuces a delicate shell hem on lingerie and

Other fine garments.

P^ce the right sides of the fabric together

and position under the presser foot ^ that

he zig-z^ part of the stitch sews just over

the raw edge.

SHELL HEM

Turn under the raw edge and press. Place the

fabric right side up so that the zig-zag part of

the stitch sews just over the folded edge

pulling the fabric in to form a shell hem ТИгт^

away excess fabric close to the stitching line.

Regular

lingerie stitch

25

Page 28

'THREi-S'TS? ZIG-ZAG STITCH

thi^d COTtrd

Stitch

■«•a:-»:*;!-!:*-*,'*»:.***! :

-iwnwmuwwwii

This IS a strong stitch because as its name

implies, it makes three short stitches where

the normal zig-zag makes only one.

For this reason it is highly recommended for

overcasting all types of fabrics

It IS also ideal for mending tears, patching,

sewing towelling, patch-work and attaching

flat elastic.

MENDING A TEAR

Place beginning of tear under presser foot

and sew, ensuring stitches catch either side

of tear. When repairing three-cornered tears,

stitch down each side to the centre.

OVERCASTING

Place fabric under the presser foot so that the

needle just sews over the raw edge — see

also page 24.

26

Page 29

Bumo HEM

Top thread tension confl-ol

Stitch selector

Blind stitch hems provide a durable hem finish

that is almost invisible and saves hours of

tedious hand sewing.

The important thing to remember is the folding

of the material. Follow the instructions carefully,

studying the diagrams below. It is advisable to

practise first on a waste piece of the same

material you intend using.

CD

First neaten the raw edge. For lightweights turn up and

baste about 3/8 ilOmm). For heavyweights Over

cast, see Page 24 or 26.

Inside

of dress

Final

hem

length

Neatened

raw edge

Screw

Work with the 'wrong side' of the fabric

uppermost and allow about 2li" 165 mm) in

excess of your final desired length. Also use a

closely matching coloured thread.

Set your machine as illustrated above, adjusting

slightly according to the thickness of the

material. Also loosen the top thread tension.

@

Final

hem

length-------

Fold garment away from hem leaving about 1 /8'

14 mm) of hem edge extending.

Neatened

raw edge

0

iuide

Place garment under blind stitch foot with the fold of

the garment against guide and slide it by turning screw

so that the zig-zag just catches the fold.

Press both sides of the finished hem. The right side of

the garment will show only the blind stitches.

27

Page 30

STRETCH STITCHES

Top thread tension cono'ol

Stitch seiector

When sewing stretch stitches on stretch

fabric, use the stretch stitch needle with a

blue shank. When sewing stretch stitches on

non-stretch fabrics, use normal needles.

Stretch stitches, as their names imply, are

mainly for use on stretch and knit fabrics

. ■. . ■! ‘ ' ' • - • : ■ .* * • . ■ ■ ;:: I, »':

such as stretch nylon, stretch towelling,

jersey and cotton jersey; and for sewing

together knitted garments. Stretch stitches

can also be used on non-stretch fabrics.

1. Triple straight stitch

• )\y\

2. Ric-rac stitch

3. Smocking stitch (Model ET-10 only)

4. Overlockstitch (Model ET-10 only!

5. Stretch overlook stitch (Model ET-10 only)

ADJUSTING STITCH LENGTH

Depending upon your preference in stitch

patterns, you may make stretch stitches

closer together without changing the balance

of stitches by turning stitch length dial away

from you within yellow range.

28

Page 31

TRIPLE STRAIGHT STITCH

SETTINGS .

Stitch Selector - il!

Stitch Length - Yellow Range

1 ripie straight stitch is far stronger than

ordinary straight stitch because it locks three

times — forwards, backwards and forwards.

It is particularly suitable for reinforcing the

seams of sportswear in stretch and non

stretch fabrics, and for curved seams which

take a lot of strain.

Use this stitch also to top-stitch round lapels,

collars and cuffs to give a professional finish

TO your garments.

RIC-RAC STITCH

Stitch Selector - %

Stitch Length - Yellow Range

Ric-rac is a quick method of finishing a raw

edge and providing a decorative top-stitch in

one operation. It is ideal for edging neck

bands, armholes, sleeves and hems.

SMOCKING STITCH

Stitch Selector - ^

Stitch Length - Yellow Range

1. Sew rows of straight stitches 1 /2" (1 cm)

apart. Draw up the bobbin thread to

gather the fabric to the required lingth.

If required, back the gathering with a strip

of fabric or bias binding.

2. Sew smocking stitch between the rows of

gathering. When complete, remove the

gathering stitches.

Note; When smocking a garment, the stitch

ing should be done before the piece is

sewn into the garment.

» (Model ET-10 only)

29

Page 32

STRETCH OVERLOOK STITCH

^ (Model ET-10 only)

Stitch Selector - K

Stitch Length - Yellow Range

Designed to produce a narrow, supple seam,

particularly suited to swimwear, sportswear,

T-shirts, babywear in stretch nylon, stretch

towelling, jersey and cotton jersey.

Hand and machine knitted clothes can be

seamed or altered using this stitch, which will

also attach neckbands and sleevebands.

OVERLOOK STITCH

^ (Model ET-10 only)

Stitch Selector - ^

Stitch Length - Yellow Range

This is the same type stitch used by the

garment industry in making sportswear—it

forms and finishes the seam in one operation.

It's very effective for use in repairing raw or

worn edges of older garments.

30

Page 33

3UT1*C?J>10LE ^AlCiWG

Tcp t»«on comrd

Stitch setectcsr

** ADJUSTING STITCH LENGTH

Depending upon your fabric or your own

preference in buttonholes, you may alter the

buttonhole stitch density within the blue

buttonhole range on the stitch length control.

^ turn the control towards

2. For less density, turn the control towards

O .

PREPARATION

Carefully mark the buttonhole length on your

garment. Mount the buttonhole guide onto

the presser foot so that rear edge of presser

foot is at the rear end of the guide as shown

right. Place the fabric with the buttonhole

marked under the buttonhole guide. Slide the

guide forward so that the needle pierces the

fabric at the beginning of the buttonhole.

You have been provided with a standard

buttonhole guide for making buttonholes.

Reproduction of the identical size button

holes is facilitated with the aid of the

graduations on the guide. Graduations act as

reference mark.

(D

31

Page 34

0

1. Set stitch selector at . Stitch forward

until you reach the front markir^ of your

buttonhole. Stop seywng at the left stitch

and then raise needle to Its highest

position.

2. Set stitch selector at Li and bartack

4 or 5 stitches. Stop sewing at the right

stitch. Raise needle to its highest position

as in step 1. ,

0

Set stitch selector at i.lf and continue

sewing until needle reaches beginning of

your buttonhole. Stop sewing at the right

stitch and then raise rieedle as in steps

1 and 2.

Set stitch selector at jj again and bartack

to complete buttonhole.

To make firm well stitched buttonholes in

heavier fabrics, repeat steps 1 and 3.

32

Page 35

CORDED BUI rONHOLES

Hook filler cord (crochet thread or button

hole twist) to the spur, pull both ends of cord

forward under the guide. Sew buttonhole in

such a way that zig-zag stitches cover the

cord. ,

When stitching is completed, release cord'

from foot, pull ends of cord and snip off extra

length.

TIPS ON BUTTONHOLING

scrap of fabric you plan to use Try the

buttonhole with the button you will use.

Always use an interfacing in area of garment

where buttonholes are placed. Tissue paper

or regular interfacing can be used. Tear papj

away after stitching, if it is used.

For heavier weight fabrics, loosen your top

thread tension slightly. ^

‘'“'“"foie on a

33

Page 36

3. CARING FOR THE MACHINE

CHANGE THE LIGHT BULB

1. Unplug the machine.

I

2. a. Using the screw driver, push down the

lever located behind the presser bar and

the bulb will come out.

b. Push the lever to the right to lock.

3. a. Push up the bulb and turn slightly to the

left.

b. Pull down to remove it.

4. a. Insert the new bulb and turn it with

some upward pressure until it stops.

b. Push up the bulb and turn to the right to

lock into place.

5. Push the lever back to the left and then up

into the machine.

CLEANING YOUR MACHINE

Remove mains plug before carrying out any

of the maintenance operations described

below.

Your machine will offer years of household

sewing service, if you clean the machine

regularly, by just removing dusts and lints.

Note: Your machine is produced with the

quality components that are per

manently lubricated, so oiling is not

necessary under the normal use of

household sewing.

CLEANING FEED DOGS

1. Unplug the machine and remove the

presser foot.

2. Remove the needle plate with the large

screwdriver.

3. Use the brush to remove the lint that may

have accumulated around the feed dogs

and in the shuttle area.

34

Page 37

CLEANING SHUTTLE

Shuttle driver

Shuttle

Shuttle cover

Bobbin

case

1. Raise needle to its highest position.

2. a. Take , out the bobbin case from the

shuttle.

b. Turn the two shuttle cover latches

outwards.

c. Take out shuttle cover and thè shuttle.

3. Clean feed dogs and shuttle with brush.

Note: Apply a drop of sewing machine oil

onto the centre stud of shuttle race

as indicated by an arrow

4. a.

Be sure the shuttle driver looks as a half

moon on the left side.

Inserting the shuttle in the centre it

should form the other half moon on the

right side.

35

Page 38

4. CHECK CHART FOR PERFORMANCE PROBLEMS

Your sewing machine is a precision instrument, designed to give you many years of trouble-free

sewing with mmumum maintenance. If you have any performance problem, check the list

anc m many cases you will be able to solve the problem yourself.

GENERAL PROBLEMS

Machine does not sew.

■“Hand wheel is not returned to stitching

position. — Tighten clutch knob (see page 8).

■“Power line cord is not connected. — Check

plug. ■

“Power/light switch turned off. - Turn on the

switch.

Machine jams/knocks.

“Thread is caught in shuttle. - Clean shuttle

(see page 35).

“Needle is damaged. — Replace needle (see

page 11).

Fabric does not move.

Presser foot not lowered. — Lower presser

foot.

“Stitch length control is set at 0. — Set it at 1

to 4.

Darning plate is attached. — Remove darning

plate.

“Thread is knotted under fabric.

STITCHING PROBLEMS

Machine skips stitches.

“Needle size is not correct for thread and fabric

— See page 11.

“Fabric is a ceaain knit or synthetic. — Use

stretch stitch needle.

.Needle is bent or blunt. — Replace needle

(see page 11).

Needle is not all the way up into needle clamp

— — See page 11. “Top thread tension is too tight. - Decrease

top thread tension.

“Machine is not threaded correctly. - See pages

lu and i2.

“Thread is caught in shuttle. - Clean shunie

(see page 35).

Stitches are irregular.

“Needle size is not correct for thread and fabric

— See page 11.

'l^^a^ridT^^ not threaded correctly. - See pages

Top thread tension is too loose. — Increase

top thread tension.

•Fabric is being pulled or pushed against

machine feeding action. - Guide it gently.

Bobbin has not been wound evenly.— Rewind

bobbin.

“There are nicks or burrs at needle plate opening.

— Replace needle plate or smooth out burrs.

Needle breaks.

“Fabric is being pulled or pushed against

^machine feeding action. — Guide it gently.

“Needle size is not correct for thread and fabric

— See page 11.

“Needle is not all the way up into the needle

clamp (see page 11).

“Presser foot holder is not fastened securely.

— Retighten presser foot thumb screw.

THREAD PROBLEMS

Thread bunches.

“Top and bobbin threads are not drawn back

under presser foot before starting seam.

- Draw both threads back under presser foot

. about 6" (15 cm) and hold until a few stitches

are formed.

Needle thread breaks.

“Machine is started too fast. - Start to sew at

a slower speed.

“Machine is not threaded correctly — See

page 12.

“Top thread tension is too tight. - Decrease

top thread tension.

Needle size not correct for thread and fabric

-See page 11. '

Eye of needle has sharp edges. - Replace

needle.

Tfiere are nicks or burrs at needle plate opening.

- Replace needle plate or smooth out burrs.

Bobbin thread breaks.

“Bobbin case is not threaded correctly. — See

page 10.

Lint acumulated in bobbin case or shuttle

- Remove lint (see page35). '

Fabric puckers.

Top and bobbin thread tensions are too tight.

^ — Adjust thread tensions (see page 14)

Two different sizes or types of thread are used

~ thread on top

and in bobbin.

•Needle is bent or blunt. - Replace needle.

Stitch length is too long for sheer or soft

tabric. - Shorten stitch length or use underlay

of tissue paper.

Presser foot holder is not fastened securely

- Retighten presser foot thumb screw.

36

Page 39

3 5. CPTIOWAL EXTRA

On the foliowing pages you will find

illustrated and described a number of

'optional extra' to increase still further its

sewing performance.

' E¥EW FEED FOOT

Even Feed Foot enables you to sew hard-to-sew

fabrics without sliding or slipping and with

perfect matching. Use it for sewing leather,

ultra suede, shiny fabrics (vinyls, patents and

satins), bonded fabrics, pile fabrics and

matching stripes, plaids and patterns. It is not

recommended for use when stretch stitching.

To attach the even feed foot;

I Raise the needle to its highest position. Raise

the presser foot lever.

2. Loosen the presser foot thumb screw and

remove the presser foot holder.

3. Guide the even feed foot into position from

the rear of the machine.

4. Attach the presser bar clamp to the presser

bar and tighten the presser foot screw with

the screwdriver.

5. Attach the screw (A) provided with the foot

to the needle clamp through the fork arm and

tighten securely.

Further details of their availability, together

with the current price can be obtained from

the place from which you purchased your

machine, or in case of difficulty direct from

ourselves.

Presser bar

Needle

clamp

Presser foot

thumb screw

Presser bar

clamp

Fork arm

TUFTING FOOT

This special presser foot is designed to make

Thread loops or tufts which can be utilized for

embroidery sewing or tailor's tacks.

Machine settings:

Stitch selector - 2nd or 3rd of the narrow

zig-zag stitches

Thread tension control - 0

EMBROIDERY

Attractive embroidery designs decorated with

thread tufts are produced by using this foot with

stitch length control between 0 and 1.

TAILOR'S TACKS

Tailor's tacks are used to transfer construction

marking from paper pattern onto double layers

of fabric. Set stitch length control between 0

and 1 or use darning plate. Sew several stitches

and then guide the fabric with your hands

Repeat this process. To remove pattern, cut top

thread loops and thread between tacks.

Separate the layers of fabric clipping thread

between them.

37

Page 40

OVERCASTliye TOOT

This special foot is used to guide the fabric

when overcasting. Use a zig-zag width so

that the needle will span the metal spring on

the foot.

Place the fabric so that the metal spring on

the foot rides on the right edge of the fabric.

Zig-zag stitch around the raw edge of the

fabric so that it is completely covered.

ROLLER FOOT

V- - ■■■I

m i

m

When sewing leather, suede, plastic and

velvet, fit the roller foot to aid the smooth

flow of fabric. However, especially when

sewing softer leather and suede, better

results may be achieved by using the normal

zig-zag foot.

LEATHER/SUEDE

It is easy to sew leather and suede with this

machine to make clothes, bags, belts, purses

etc, but remember that a longer stitch length

IS usually required. You can seam, top-stitch,

satin stitch, embroider, monogram, appliqué,

patchwork, and apply decorative stitches

-just as you can with other fabrics.

PLASTIC

For good results, use a longer stitch length

and use only straight stitch or zig-zag.

VELVET

Use the roller foot to prevent presser foot

marks appearing on velvet. Otherwise sew as

other fabrics.

Page 41

rmm MEEDLE

Twin neaiie is available as an optional extra. Tc^ thread Vision contrd

A twin-needle produces two rows of parallel

stitches for pin tucks, double top stitching

and decorative sewing.

Use only the following stitches when sewing

with twin-needles.

1. Straight stitch

2. First of the 5 narrow zig-zag stitches

3. Blind stitch

4. Triple straight stitch

Never use a twin-needle wider than 1/12''

(1.8 mm).

Never set zig-zag width with twin-needles

beyond the range illustrated alongside.

THREADING TWIN-NEEDLES

1. Fit the extra spool pin as shown in page 7.

Place a spool on each spool pin. Thread

the two threads as one using the double

thread guides provided. Draw one thread

through each of these and then through

each needle from front to back.

2. Pick up bobbin thread as for single needle

sewing. Pull the three threads together

under the presser foot to the back of the

machine, leaving about 6” (15 cm) clear.

39

Page 42

2.; ■ . .. ■:

....................................

V / I

TURNING A CORNER USING A

TWIN NEEDLE

1. Use the hand wheel to stop stitching with

the right-hand needle (the longer of the

two) just piercing the fabric. Turn the

fabric through 45°

Take one stitch, leaving the right-hand

needle piercing the fabric again, and turn

the fabric through another 45°. Continue

sewing.

PIN TUCKS

SETTINGS

Stitch selector Stitch length -

For making pin tucks on shirts and dresses in

fine fabrics, set your machine as above.

Sew one row of double stitches and remove

the fabric. Sewing in ihe same direction,

make parallel rows of double stitches 1 /12” -

3/12" (2-6 mm) apart.

TWIN TOP-STITCHING

For twin lop-stitching of lapels, collars, cuffs

etc., set your machine as follows:

Stitch selector - |

Stitch length - 3-4

2-3

I

40

*>-*• < '.r*- '■‘-r

Loading...

Loading...