SINGER W312 User Manual

t. V 1?”

i'.'ÿ

CONTENTS

■SEC1S0N r PfíELtMINARY INFORMATION

Parts identification

Principle Parts..........................................................................................................4

Accessories ...........................................................................................................6

Installing Machine Head into Portable Case

or cabinet and Connecting Machine

Selection of Needles and Threads ............................................................................... 8

Needle-Thread-Fabric-Stitching Guide

Changing Needle..................................................................................................... ,10

Changing Needle Plate

Selection of Presser Foot.............................................................................................; ,11

Winding Bobbin .......................................................................................................... 12

Upper Threading

Threading Bobbin Case...................................................................................................14

Placing Bobbin Case in Shuttle .......................................................................................14

Selection of Stitch

Stitch Length Control....................................................................................., 15

Reverse Button ................................................................................................... 15

Stitch Width Control...............................................................................................16

Relating Stitch Length to Stitch Width ................................................................. 16

Stitch Selector

Controls

Adjusting Thread Tensions....................................................................................18

Adjusting Pressure on Fabric and Feed Dog Height

Sewing Light..........................................................................................................20

Creative Embroidery Control.

....................................................................................................10

...

....................................................................................................... 13

.......................................................................................................17

.......................................................................

....

............................................................

.............................................

.....

..........................................................................20

PAGE

7

9

19

SECrrtON^V^CW/ígrOíSEW - ‘

Preparing to Sew ............................................................................................................21

Guiding Fabric................................................................................................................ 21

Turning Corners...............................................................................................................21

Curved Seams................................................................................................................ 22

Sewing Across Heavy Seams ..

Removing the Work.........................................................................................................22

Straight Stitch

Seams................................................................................................................ 23

Basting/Topstitching..............................................................................................23

Darning ................................................................................................................ 23

Cording/Sewing in Zipper......................................................................................24

Quilting...................................................................................................................24

Zigzag Stitch

Overcasting ...........................................................................................................25

...

..................................................................................22

Sewing Krifts .............................................................................................................. 25

Sewing on Buttons................................................................................................ 25

With a Thread Shank

...........................................................................

Satin Stitching........................................................................................................26

Tapering/Creative Embroidery

Manual Embroidery Designs

.................................

;.............................................27

............................................................................

Freehand Monogramming

Applique

.........

Gathering Over a Cord - .

Lace Application

Fiutter Hem

Sewing Tips

Shaping Darts m Interfacings

Buttonholes

................

........................

.......................

Preparation................................

Turn-Around Buttonhole.........................................................................................32

Cordeci Sutronhoie

Siraighi Stretcn Stitch . . .

Topstitchtng

Rick-Rack Stretch

..............

iflMftiNtENANGeOF you R MACH INE

Oiling Machine

Cleaning and Oiling Shuttle Area

Adjusting Bobbin Winder

Adjusting and Changing Motor Belt

Problem and Remedies

......................

PAGE

26

27

28

2C

29

29

29

30

30

■ 31

32

33

33

33

Binder

.........................................................

Folded Binding

Two-Tone Binding

Hand-Cut Bias Binding

The Set of Hemmers

................................

..........................

...................

..................................

Rufiier ......................................................

Narrow Hemmer

Lace Trimmed Hems

.........................................

.......................

Lace Edge with invisible Stitching

French Seam ...................................

40

40

40

•

40

41

42

43

44

44

44

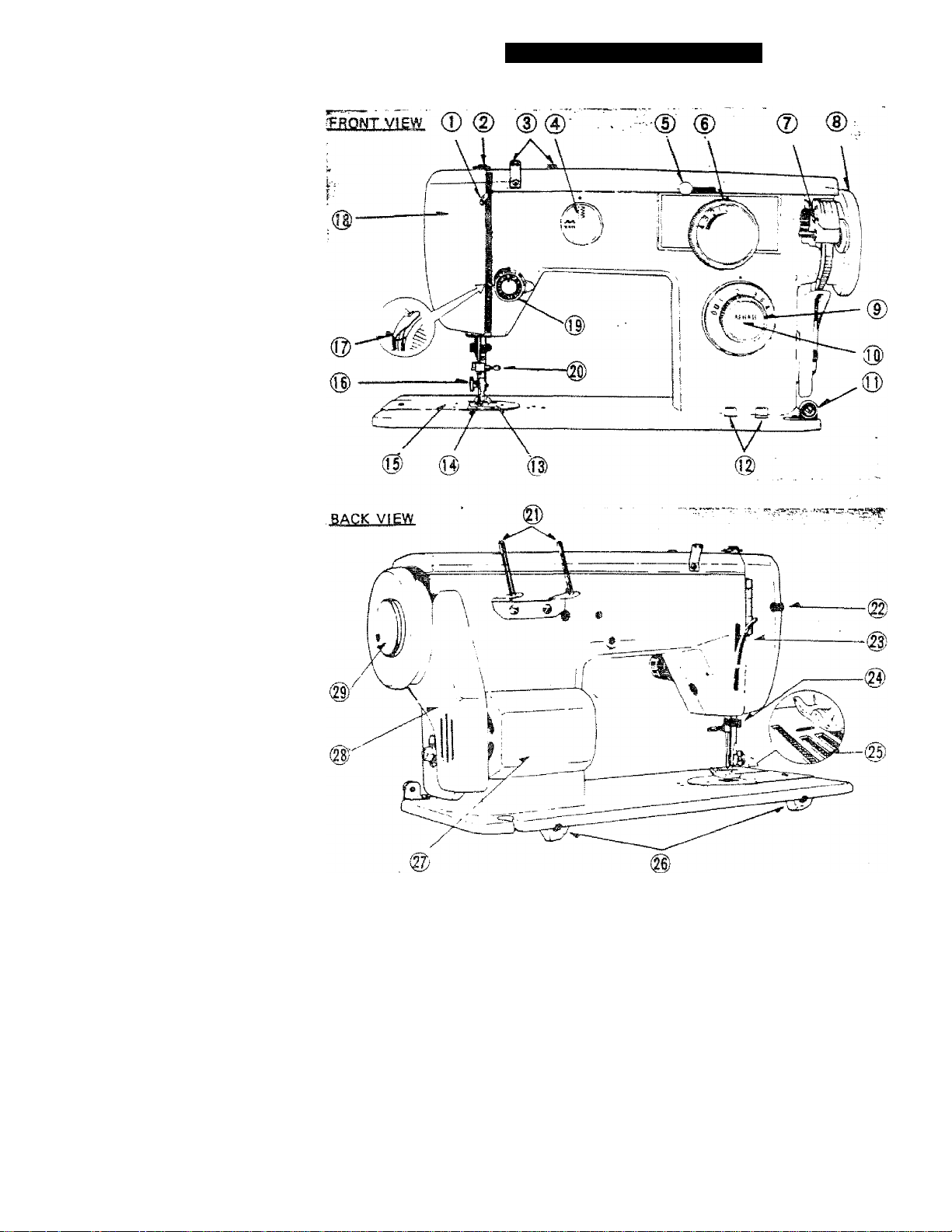

SECTION I

PARTS IDENTIFICATION

PRINCIPLE PARTS

PRELIMINARY INFORMATION

1. fake-up

2. Pressure Control

3. Top Thread Guides

4. Stitch Selector

5. Creative Embroidery

Control

S. Stitch Width Control

7. Bobbin Winder

8. Hand Wheel

9. Stitch Length Control

10,

Reverse Button

11

Sobfain Winder Ten:

Discs

reed Dog Height

Control

i

Needle Plate

Presser Foot

14.

15.

Slide Plate

16.

Thumb Screw

17,

Check Spring

18.

Face Cover

19

■Tension Control

Needle Clamp

Spool Pins

Light Switch

23

Presser Foot Lever

24

Thread Cutter

25. Feed Dog

26. Head Hinge Holes

27. Motor

28. Belt Cover

2S. Clutch Nut

.Always at its highest position when beginning or ending

sewing.

For regulating the pressure on fabric.

For leading thread to tension control for sewing

For changing between ordinary and stretch stitches.

For precise adjustment of zigzag stitch width as well as

tapering.

For setting stitch width

For winding thread on bobbin.

For the control of the up and down movement of the

needle.

For selecting stitch length between no feeding and

about 6 stitches per inch.

For easy backtacking to lock thread ends.

For providing proper tension on thread when bobbin

winding.

For regulating feed dog height for various materials and

types of sewing.

With guide lines for sewing accuracy.

For holding fabric when sewing.

For opening an access for bobbin and bobbin ca^.

For tightening presser foot in place on presser bar.

For automatic precise adjustment of flow of upper thread.

Hinge-open type for replacement of light bulb and oiling.

For regulating the amount of tension on upper thread.

For holding needle in place in the slot of needle bar.

For holding spools, preventing over-spin of spools.

For turning on or off the light inside face cover.

For lifting or lowering presser bar and presser foot.

For convenience to cut both upper and lower threads

after sewing.

Diamond point to move fabric accurately.

For installation of machine head into portable case or

cabinet.

110 — 115 Volts, for running machine.

For covering motor belt.

For releasing movement of the needle bar in order to wind

bobbin.

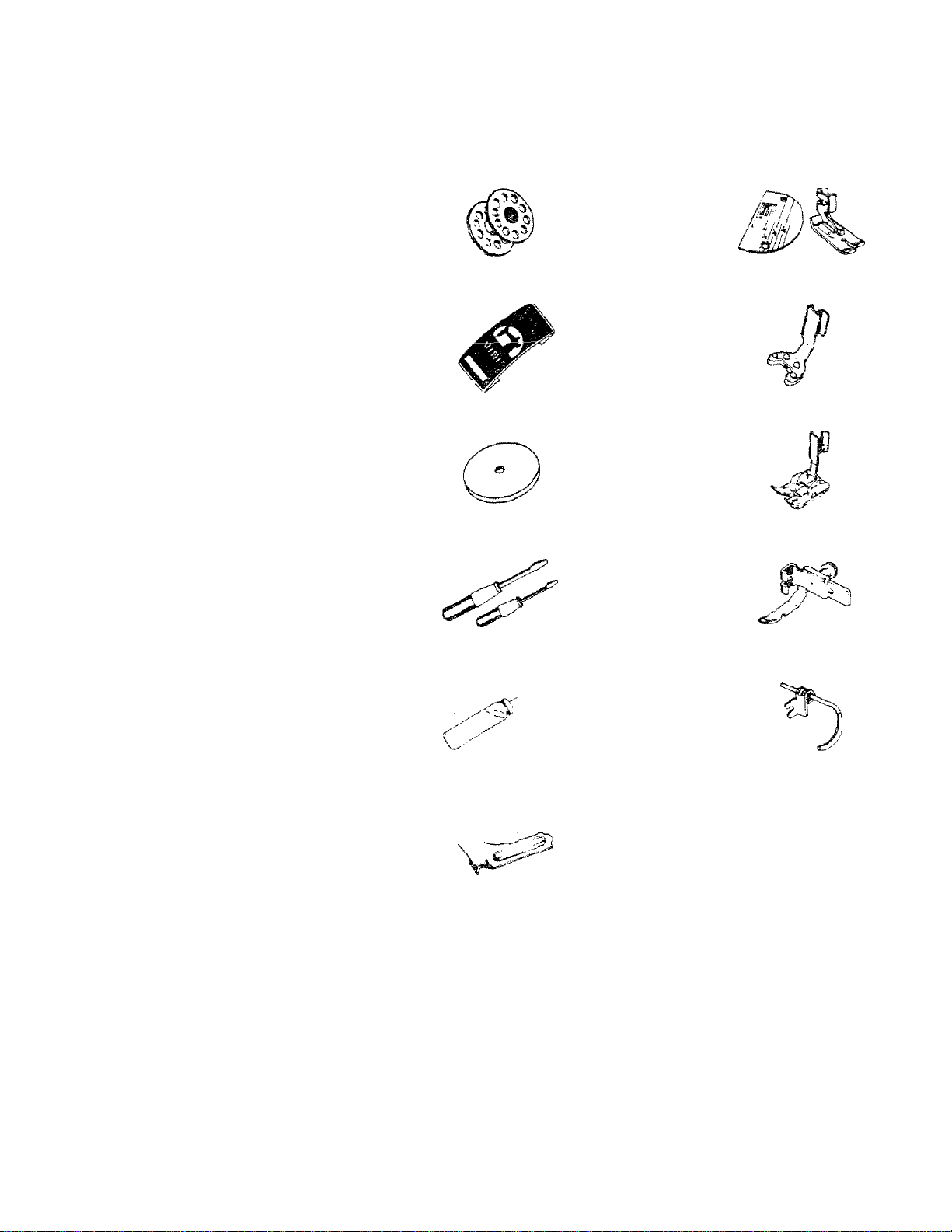

ACCESSORIES

Your new sewing machine comes equipped with the foliowing set of accessories

to make your sewing easier.

METAL BOBBINS

; Three metal bobbin*

r are included.

A PACK OF NEEDLES

One each of sites

#11. #14 and #16

light ball point

needles.

SPOOL CUSHIONS

Place felt spool

cushions on spool

pins to reduce sound

of spool spinning

SCREW DRIVERS

Srrtall one for bobbin

thread tension ad

justment. Large one

for thumb screw,

needle clamp, etc.

STRAIGHT STITCH FOOTS NEEDLE PLATE

For straight stitch

ing on wry sheer

soft or very light

weight stretchy ma

terials where extra

control is needed.

SUTTON FOOT

For holding buttons

in place when stitch

ing.

BUTTONHOLE FOOT

Use for bultonhoiing. Do not use

when normal sew

ings

CORDING AND ZIPPER FOOT

For stitching very

close to the edge

of a cord or tipper.

OILER

Containing machine

oil, use as oiler.

CLOTH GUIDE WITH SCREW

Aid in creating

straight seams,

QUILTING GUIDE

Helps make parallel

rows of stitching.

SEAM RIPPER

For cutting open

the buttonholes and

for removing stnches.

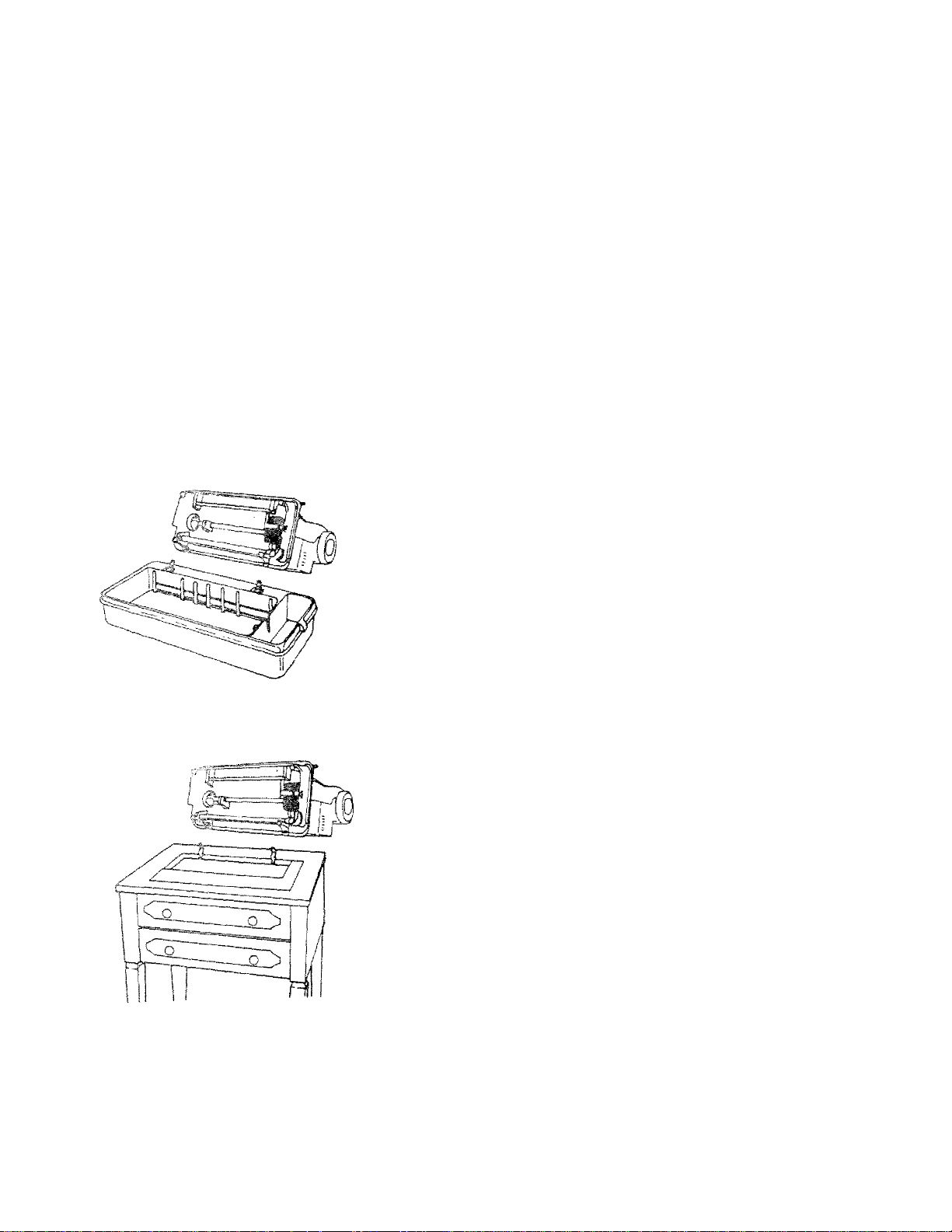

INSTALLING MACHINE HEAD INTO PORTABLE CASE

OR CABINET-AND CONNECTING MACHINE

Loosen both head hinge set screws

on the back of machine bed plate

until head hinge holes are clear.

Tilt head hinge pins up and back

as far as they will go.

Carefully slip machine head onto

hinges - making sure the head

hinge pins are inserted as far as

they can go into head hinge holes.

Allow machine head to rest in its

tilted back position.

Tighten both set screws securely

with screwdriver.

Plug electrical leads from machine

head into sockets located inside

cabinet or portable case. Cord

identified with "motor” tag must

be piugged mto socket marked

"motor". Untagged cord goes to

"light" socket.

Insert plug into a wall outlet of

110-115 Volts.

I SECTION H

PRIWE PREPARATION OF MACHINES

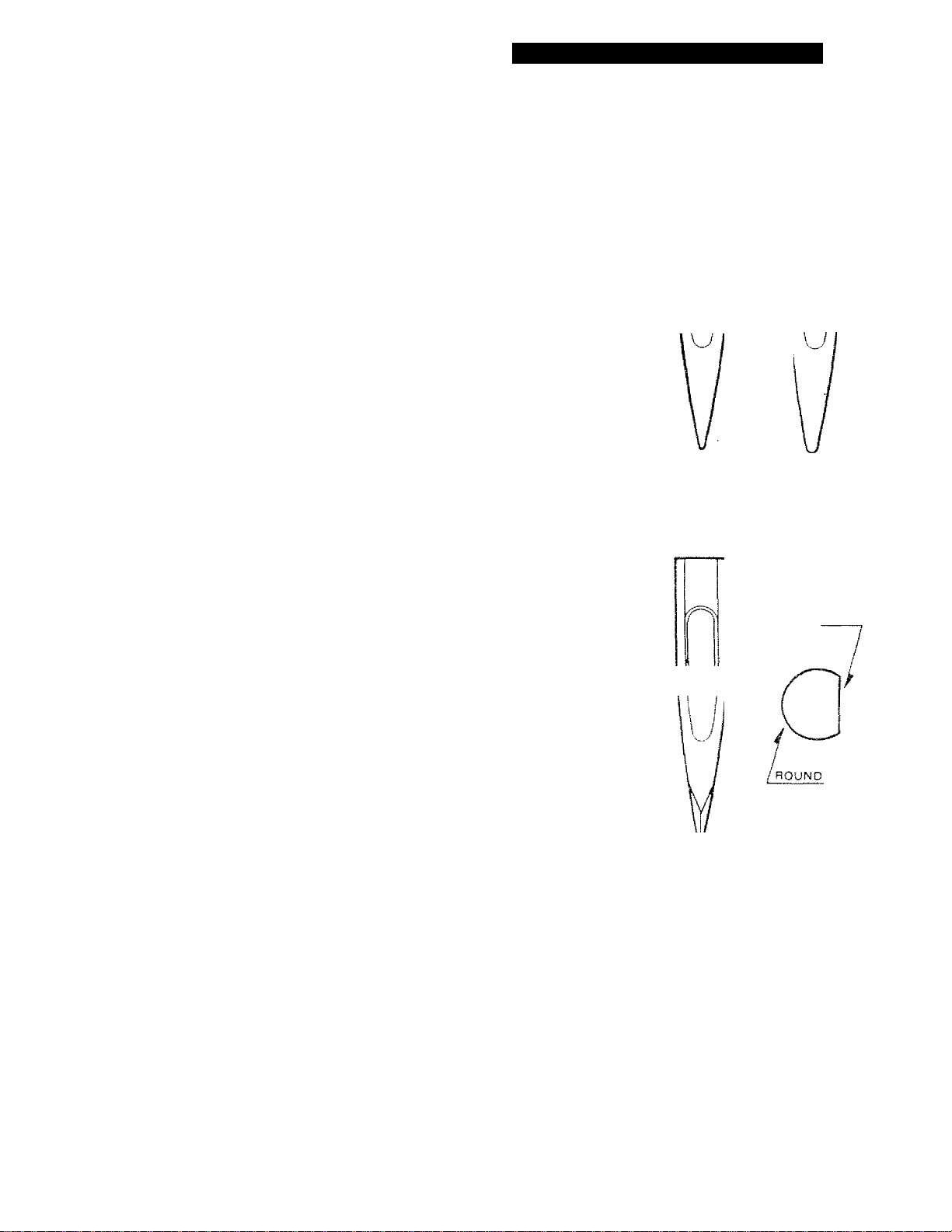

SELECTION OF NEEDLES AND THREADS

The needle and tiiread you choose depends

upon the" fabric you are stitching. The correct

selection of needle and thread is very important

to avoid damaging light weight or tightly woven

fabrics, to prevent skipped stitches when sewing

on very sheer, stretchy fabrics or needle breakage

when stitching heavy or stiff fabrics. For best

results, sewing machine needles should be replarad

when they become even slightly dull or bent

or at the completion of every other garment.

A regular needle is suggested for use with

woven fabrics. Needles, style 15 x 1, of the

range in size from 8 to 20 are used on this

machine. The lower number indicates the finer

needle. The most commonly used sizes are 11

and 14.

A bail point needle is recommended for use

with tricots, jerseys, lingeries and power nets.

Unlike diarp pointed needles, which pierce

fibers of knit fabrics destroying elasticity,the

ball point needle slips between fibers without

damage to fabric and skipped stitches.

A wedge point needle is recommended for use

with leather and leather-look vinyls. A wedge

cutting point pierces leather more easily than

ordinary sewing machine needles, resulting in

more satisiactory stitching.

REGULAR

SHAH? NEEDLE

BALL POINT

NEEDLE

FLAT

Although a ball point needle is recommended

for knit fabrics and sewing on very stretchy

fabrics of knits, the placement of a thin paper

under the fabric and the use of a finer needle

are suggested to prevent skip stitches.

Always use the same type and size of thread

in both needle and bobbin. Use a good quality

thread without knots for best stitches.

WEDGE POINT

NEEDLE

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

r'*r-4. ■ . -

ExtremeÌY heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, ieafhereiis.

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

. wool, ^antung, ete.

Sheer voile, lawn,

dimity, crepe,

handkerchief iinan.

Plastic film, ate.

Vary sheer chiffon,

batiste, lace, organdy,

nylon net, marquiseite, etc.

Needle

No.

18

18

16

14

11

Machine ¿ Stitdiing Per Inch i

6

to

8

8

to

10

10

to

12

to

14

14

to

16

(plastic film)

8 to 10

16

to

20

Heavy Duty

Heavy Duty

Heavy Duty

50

50

O

o

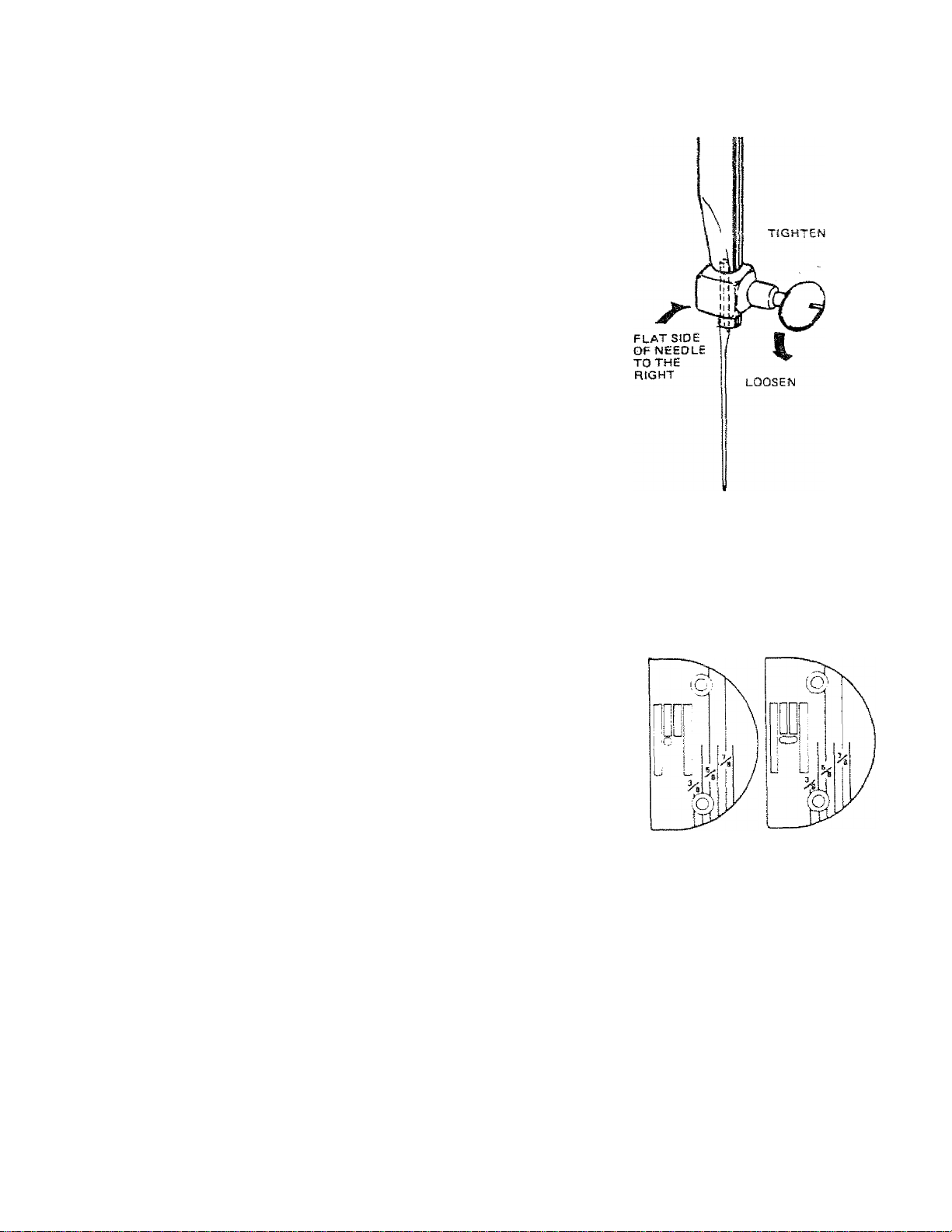

CHANGING NEEDLE

Always change the needle after every

other garment especially when sewing on

polyester and nylon fabrics which dull

needles much faster. When needles are

dull or bent, they damage both your

fabric and the machine. A general rule

when placing sewing machine needles is

that the flat side of the needle is placed

to the right of the machine, when the

bobbin is put in from the left,- If the

needle is inserted incorrectly, the stitches

will not form.

To change the needle

1. Raise the needle bar to its highest

position by turning the hand wheel

toward you.

2. Loosen needle clamp to remove the

needle.

3. Place needle (flat side to the right and

long groove to the left) in the needle

clamp and push it upward as far as it

will go, tighten needle clamp.

4. After changing the needle, make one

complete turn of the hand wheel by

hand to be sure the needle is clearing

the needle plate.

CHANGING NEEDLE PLATE

Although an all-purpose, utility needle

plate is fixed on your machine, for

straight sewing on fme fabric or soft very

stretchy fabric, you may want to use the

straight stitch needle plate with the

straight stitch foot, which are included in

your accessory box.

To change the needle plate, simply slide

the slide plate as far left as possible.

Remove the two screws holding the

plate in place. Lift the needle plate and

replace.

The needle plate is removed for cleaning

the lint which may pile up between

needle plate and feed dogs.

10

STRAIGHT STITCH

NEEDLE PLATE

UTILITY

NEEDLE PLATE

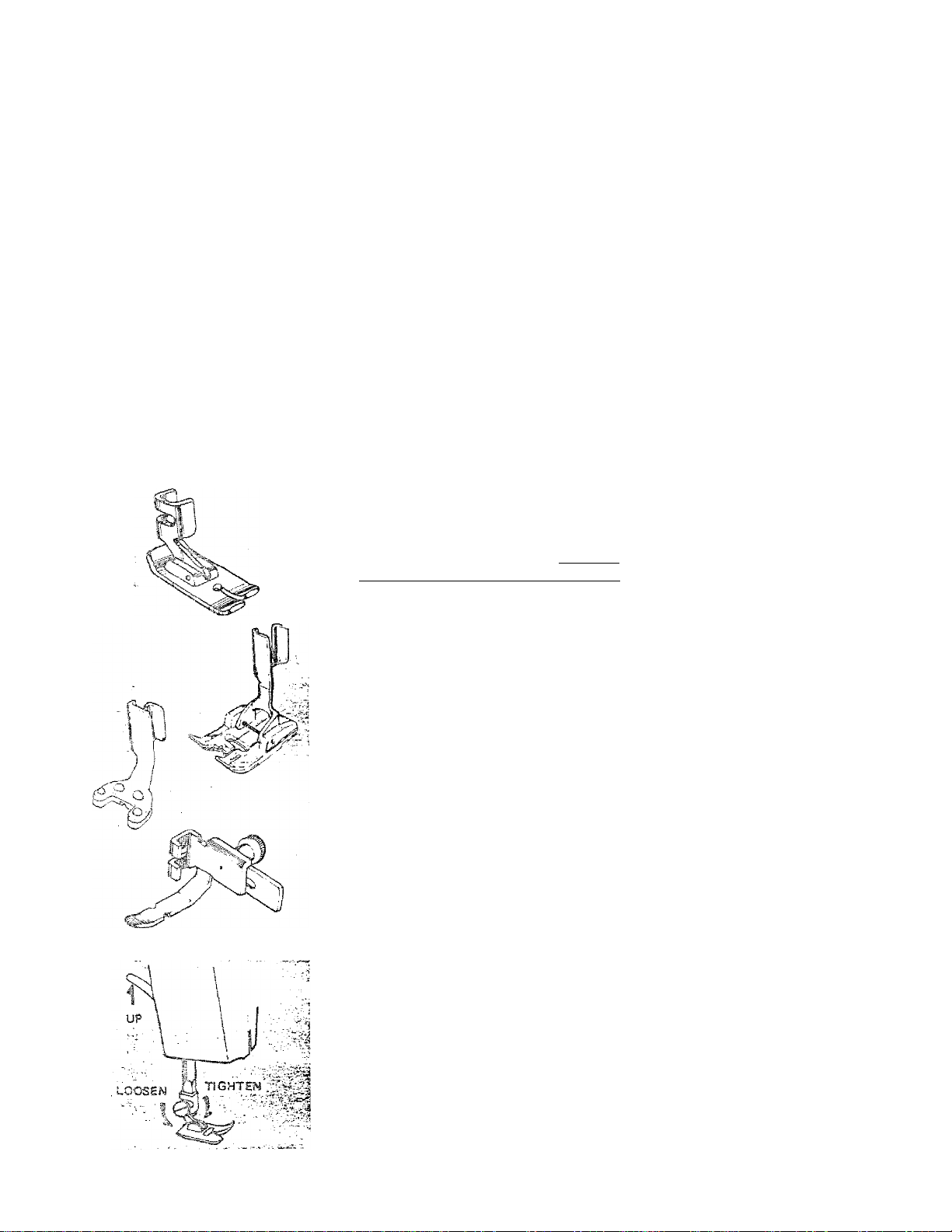

SELECTION OF PRESSER FOOT

For most ordinary sewing the original ail-purpose foot can be used. However, the

following feet in your accessory box are recommended for special purposes.

Straight Stitch Foot

This has only a narrow hole to accommo

date only straight stitching. It may be

used on sheer or soft fabrics for more

control. When using this foot, the Stitch

Width Control should be at 0 to avoid

hitting the foot and breaking the needle.

Buttonhole Fool

This foot has a groove underneath, to

allow the narrow satin stitch or button

hole to form evenly. However, if skip-

stitch occurs on sheer fabrics with this

foot, it may be necessary to use thin

paper underneath.

Cording Of Zipper Foot, and Button Foot

Use for sewing very close to the edge of a

cord or zipper, and sewing on buttons

respectively.

CHANGING FOOT

Use the large screwdriver to loosen thumb

screw. Turn the screw backward until the

foot becomes loose. Then, lift up on

presser foot lever until it is in its highest

position in order to remove the foot.

Replace with desired foot and tighten

thumb screw securely.

I !

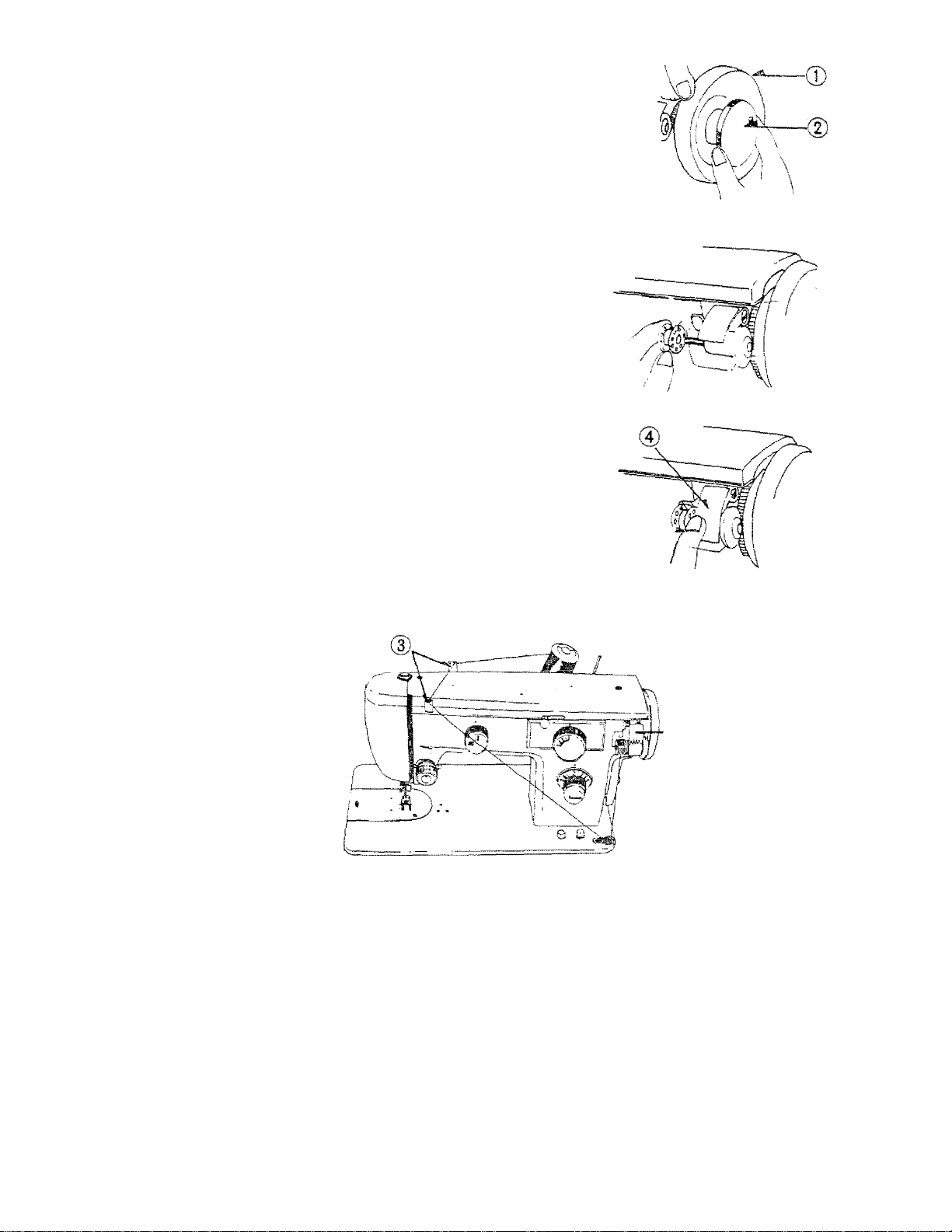

WINDING BOBBIN

Disengage the hand wheel {1) from

the stitching mechanism bv turning

the dutch nut (2) toward you or

counter-clockwise.

Place a spool of thread on one of

the spool pins and lead thread

through the Top Thread Guide

(3) and Bobbin Winder Tension

Disc at the right front of bedplate.

Run the end of thread through a

hole in the bobbin edge and place

bobbin on spindle of bobbin winder

fitting the notch on bobbin over

small pin on Spindfs.

Press bobbin winder latch ¡4)

down, and hold the thread erxl

loosely then start machine slowly,

and bobbin winder latch wiil be

released to stop winding when

bobbin is full.

Turn clutch nut away from you

until sewing mechanism is again

engaged so that needle moves when

you turn the hand wheel.

Break off loose thread end used to

start the winding and cut other

thread end. Then remove bobbin

from bobbin winder.

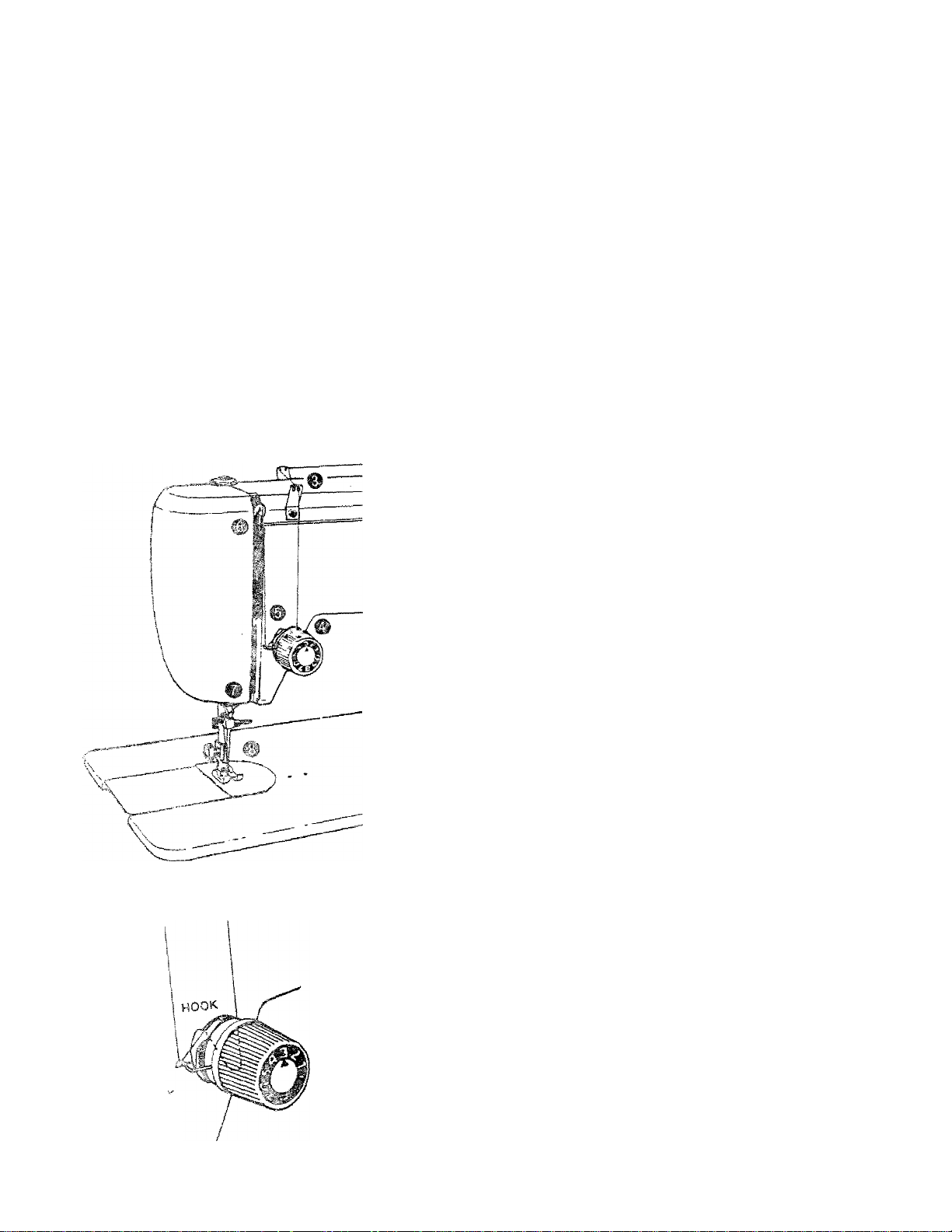

UPPER THREADING

T Torn the hand wheeS toward you

to raise the take-up lever to its

highest position.

2. ‘Place a spool of thread on the

spool pin.

3. Lead the thread through the top

thread guides.

4. Down and between the tension

discs, from right to left.

5. Draw the thread up through the

check spring and with a slight

tug into the hook.

6. Up and through the eye of take-

up lever from right to left.

7. Lead thread down through the

thread guide at the bottom of

the threading slot, then, through

the needle bar thread guide from

The back.

снес

SPSING

8. Thread the needle FROM LEFT

TO RIGHT, drawing it through

about 3 or 4 inches. Hold the

end of the upper thread loosely

and turn the hand wheel toward

you until the n^dle goes all the

way down and comes back up.

A thread loop will form over

the upper thread which then can

be pulled out straight. Place

both thread ends under presser

foot and draw toward the side

of the machine, leaving both

threads three or four inches

long.

13

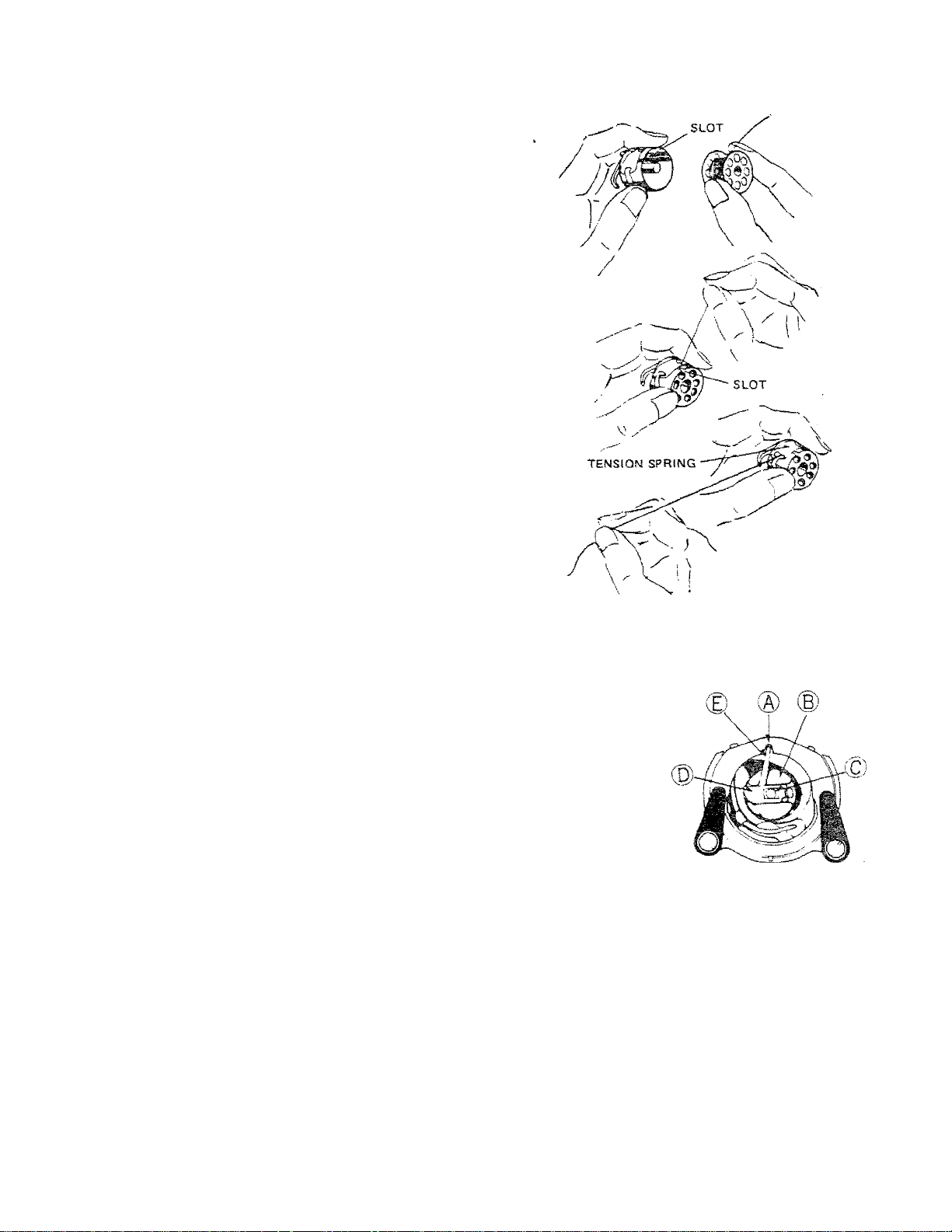

THREADING BOBBIN CASE

■1. Hold bobbin case be

tween thumb and fore

finger of left hand, so

that the slot in the edge

of the bobbin case is on

top. Take the bobbin

between thumb and fore

finger of right hand so

that the thread on top

leads from left to ri^t.

2, Insert bobbin into bob

bin case, pull the thread

into the siot of the

bobbin case and draw it

under tension spring and

into the fork-shaped

opening of the spring.

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to its highest position, and slide plate to

the left. Hold the bobbin case latch (D) between the

thumb and forefinger of the left hand, with at least three

inches of thread running from The top of the bobbin case

to the right- Insert and center the bobbin case on the

stud of the shuttle body iCt. Be sure the bobbin case

finger (E) IS opposite the shuttle race notch (A}. Press

the bobbin case (B) into the shuttle as far as possible

until the latch catches on the center post of the shuttle.

Then release the bobbin case latch (D). Press the bobbin

case again after the latch has been released to make sure

the bobbin case is locked securely m place. Close the

slide piate.

U

Loading...

Loading...