HOW TO USE AND CARE FOR YOUR

UJHITgDe LWM© ZIG-ZAG

MODEL 3051

seming machine

mm

GanteMti.

‘’mi

CONTENTS

NAME OF EACH PART

SPECIAL FEATURES ................................................................... 3

1. TO WIND THE BOBBIN ........................................... 4~5

2. TO THE SET NEEDLE ................................................... 5

3. TO THREAD THE BOBBIN CASE ... 6

4. TO REPLACE AND REMOVE

5. TO CLEAN THE SHUTTLE RACE ... 8

6. TO THREAD THE

7. TO PREPARE FOR SEWING................................ 10

8. TO COMMENCE SEWING .......................................... 10

9. TO REMOVE THE WORK

10. TO REGULATE

n. TO REGULATE THE

...............................................................................

..............................................................

THE BOBBIN CASE

MACHINE &■ NEEDLE

STITCH LENGTH

....................................

...........................

...................................

THE THREAD TENSION ... 11~12

........................................

9

11

Page

1

2

7

12

12. TO REGULATE THE PRESSURE

ON THE PRESSER FOOT

13. TO USE THE DROP FEED

14. TO OIL SEWING MACHINE

15. SOME USEFUL SEWING HINTS

16. CAUSES OF TROUBLES

17. ZIGZAG SEWING ..................................................

18. HOW TO OPERATE AUTMATIC 19

19. SEWING ON BUTTONS ..............................................

20. MAKING BUTTONHOLES

21. DARNING AND EMBROIDERY

22. QUILTING ....................................................................

23. SEWING BRAIDS

24. NARROW HEMMER

25. HOW TO DO FELLING

26. CLOTH GUIDE <&- THUMB SCREW...

26. NEEDLE THREAD SIZES

......................................

...................................

........................................

....................................

...................................

.........................................................

....................................................

.................................................

..................................................

22

^age

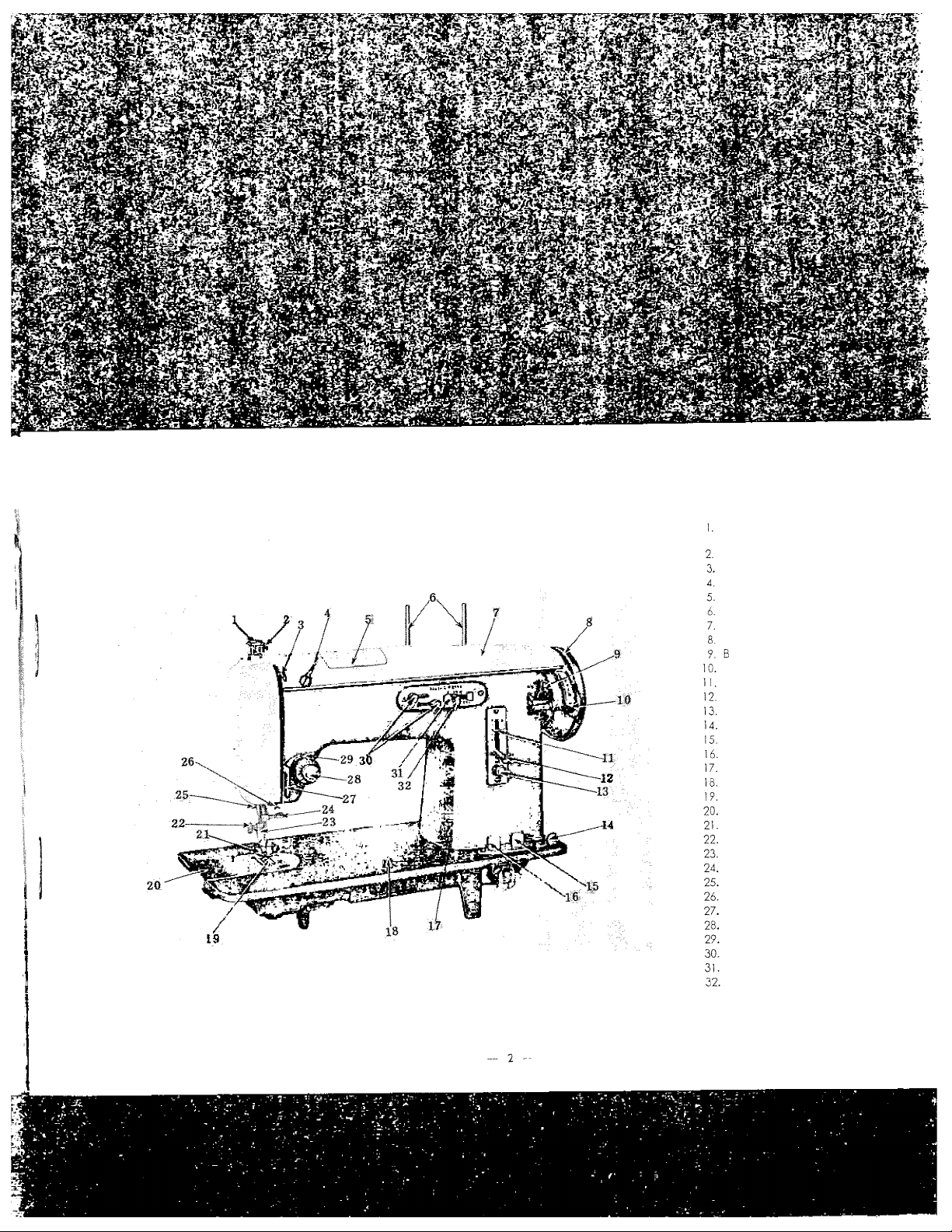

f^ame. S’OcU poAt

Automatic darner

(Pressure regulator)

Pressure release lever

Take-up lever

Upper arm thread guide

Zigzag disc chamber

Spool pins

Top plate

Balance wheel

bbin winder release

Bobbin winder

Stitch length indicating window

Stitch length regulating lever

Stitch length regulating dial

Bobbin winder thread guide

Drop Feed push button

Drop Feed release button

Arm

Bed

Feed dog

Slide plate

Hinged presser Foot

Pressure Foot thumb screw

Needle

Needle clamp

Thread cutter

Arm thread guide

Thread guide tension arm

Thread tension indicator

Check spring

Lock screw For indicator ¿31

Zigzag indicator

Zigzag width adjusting lever

fW-;',-! ■‘--=.»tir f.^i TS4ii 'it Ci'.l

iira

l'^

, \r^*-

mm

S’liifAii

W*i

0M:.

*-i3iii

j'-Sy’

mm

. a' *''.

Sfwdal ^e<iti4/i^

AUTOMATIC DARNER (PRESSURE REGULATOR) - enables you to select the exact pressure

according to the kind of material you are sewing,

STITCH REGULATOR - regulates the stitch length and helps you to select the stitch size

with ease and accuracy.

AUTOMATIC BOBBIN WINDER-winds your bobbin and stops automatically when your bobbin is

filled.

CALIBRATED UPPER THREAD TENSION REGULATOR - allows the tension of the upper

thread to be easily and accurately adjusted according to thread and material weight differences.

DROP FEED PUSH BUTTON - regulates the height of your feed for embroidering or darn

ing and for different weights of fabrics,

SNAP-OUT RACE - is so constructed that cleaning and eliminating tangled threads are very

simple and quick.

FLOATING PRESSER FOOT- glides over pins.

automatic sew discs - enable you to embroider automatically

/. *7a

1. To wind the bobbin the balance wheel must be disconnected from the stitching mechanism. Hold the balance

wheel with your left hand and turn the clotch (Fig. 1 ( toward you with your right hand. This will permit

the hand wheel to turn freely while the needle bar remains motionless. The balance wheel is now

disconnected for the bobbin winding operation.

2. Place a spool of thread on the spool pin ».Fig. 1).

Draw thread from spool over guides, then down

ward across machine from left to right.

3. Pass the thread through the tension discs at the

right corner of the base of the machine.

4. Now wind the end of the thread around an empty

bobbin seven or eight times and place the threaded

bobbin on the spindle of the bobbin winder.

5. By pressing on the bobbin winder lever, the small

rubber wheel is brought in contact with the balance

wheel. To lock into position, press bobbin winder

lever until a click is heard. The bobbin winder

release latch is now touching the shaft of the bobbin.

It holds the bobbin in place.

Wind tUe BoMm

Pig. 1

6. operate the foot control or knee

control in the same manner as far

sewing and when the bobbin is

completely full it will stop turning

automatically.

Remove bobbin from spindle. Hold

balance wheel firmly v/ith the left

hand and with the right hand turn

clutch away from you until it can

not be moved any farther. The

needle bar now moves with the

tuning of the balance wheel.

»

^¿1^1

£

NfEDLE BAg_

THBEAD GUW?D

NEEOLE

HOLE

•needle

BAR

--CUMP

SCREW

'''NEEDLE

CLAMP

-NEEDLE

^,'THREAD

Fig. 3

.NEEDLE

---FLAT

Fig. 2

<2. *7o ¿/ie Set f^eed-le

SURFACE

1. Turn the balance w-heel toward you, raising needle be

its highest position, and loosen the needle clamp scre^

2. Hold the needle in the left hand with the point down,

insert the needle up into the needle clamp as far as it

go, with its flat surface to the right ; then retighten

clamp screw (Fig. 3.(

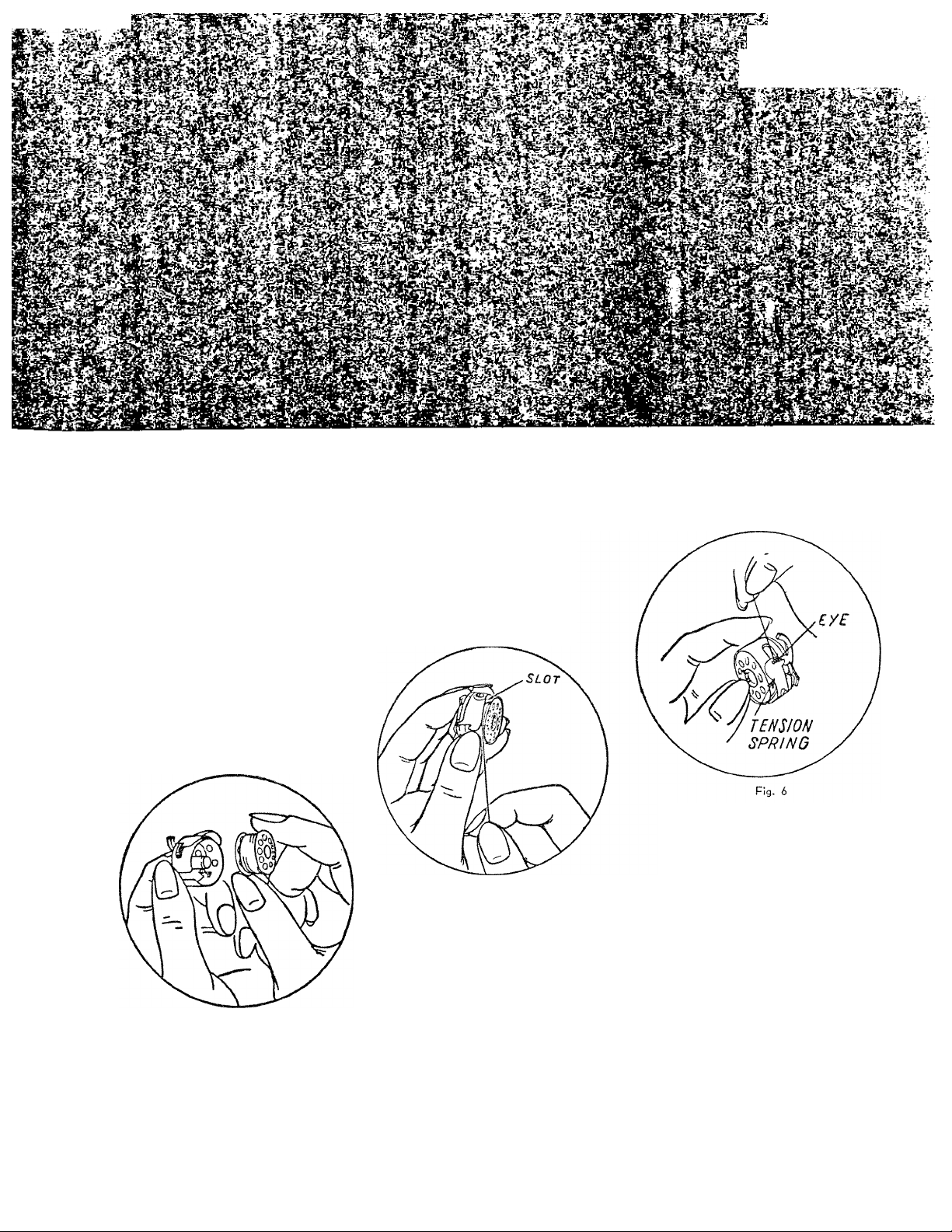

3. *^0- *HiAe<jA tlte. BoMJUn GcUe.

Before threading the bobbin case, study Fig. 4, 5, and 6 to

aet a general idea as to how it is done.

1. Hold the bobbin case with your left hand and put the bobbin into

the bobbin case with your right hand, leaving about two inches

of the thread end unwound

(Fig. 4). As the bobbin is being

inserted in the bobbin case

the thread flow is clockwise.

F!g. 5

2. While holding the bobbin case

as before, grasp the thread end

with your right hand, and guide

it into the cross slot (Fig. 5).

Fig. 4

3. Then pull it through under the tension spring of the

bobbin case (Fig. S) until it enters the delivery

eye (Fig. 6).

J№ifi

Efts.

Sf^-V

£V,'

Mi

4. Replace and Hemmjte the. BaUUn. Cade.

-rS\

m

1. Raise the presser foot by lifting the presser bar lifter.

2. Raise the needle bar to its highest point, by turning the

balance wheel toward you.

3. Open hinged slide plate to its highest point (Fig. 7f.

4. After threading the bobbin case, hold it by the latch with

its position finger opposite the notch at the top of the

shuttle race. Replace it on the center stud of the shuttle

, ,

.....

..... (Fig- 8).

5. Then release ¡-34IC

the latch and ■ .-2-,

press the bob- (avT;bin case in , '

until the latch

catches the

groove near

the end of the

stud and click into potion.

6. Allow the end of the thread to hang free abo

7. Pull back slide plate.

Fig. 8

To remove the bobbin case do all the above in

Fig. 7

ut 2 to 3

reverse o

5. ^o. Qleatt Shutti^ Race

When the thread is tangled in the race or dust gets into

the space between the shuttle and shuttle race, follow this

procedure

1. Raise the needle bar to its highest position and take out

the bobbin case.

m

!

?S.

Fig. 10

Fig. 9

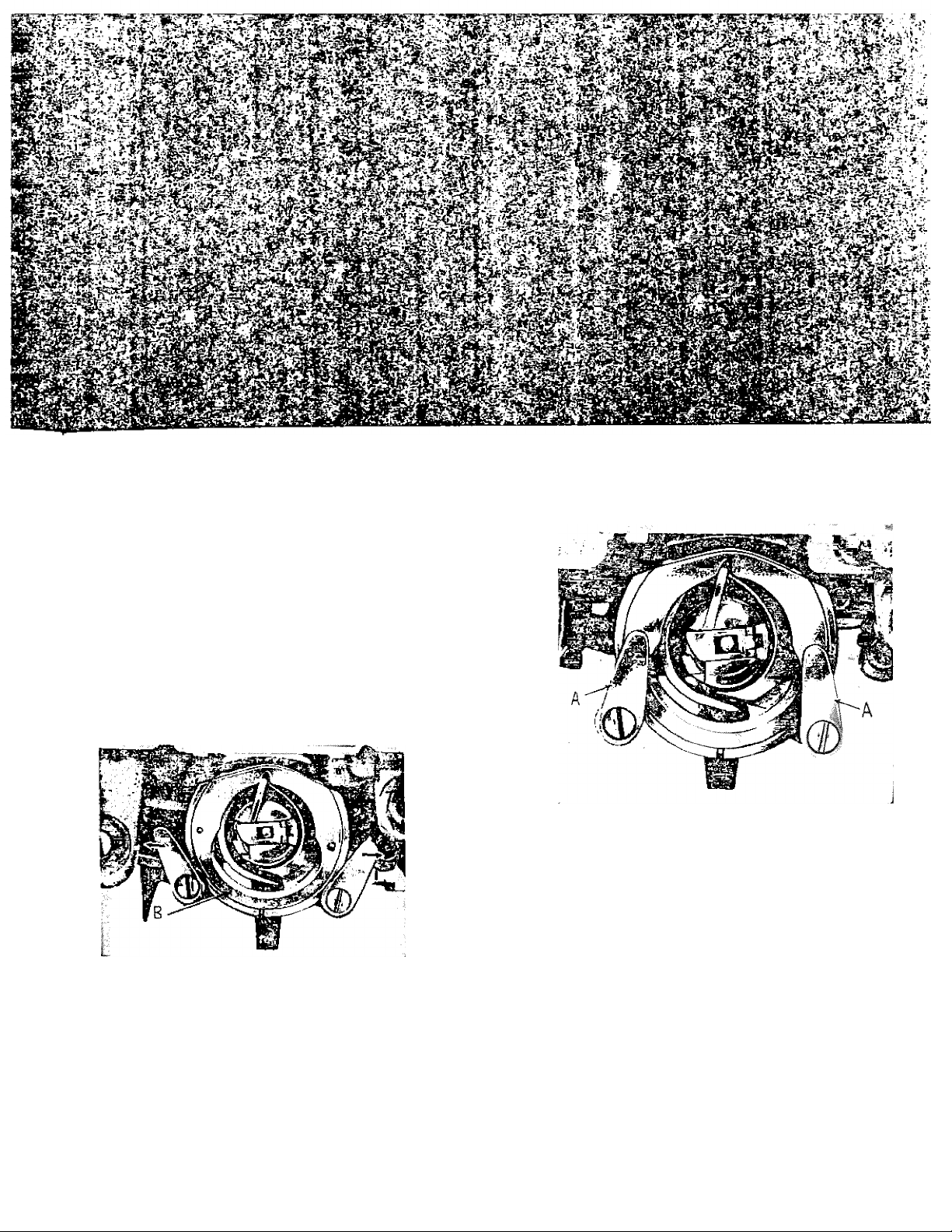

2. Release the KNOBS (A) on both sides of shuttle race by

pulling them sidewise, then take out the race cover B

and the shuttle. (Fig. 9, 10

3. After shuttle race and bobbin case have been cleaned, put

all of them back in reverse order.

4. Snap knobs into place as seen in Fig. 9.

6. *7b *7U^ead Um MacUine & Needle

1. Turn the balance wheel toward you to raise the needle bar

to its highest position,

2. Place a spool of thread on the spool pin.

3. Lead the thread through the arm thread-guides (Fig. 11).

4. Run the thread down through the thread-guide to the

tension discs From right to left and up.

Then draw the thread up through the deck spring.

5. Take the thread up, through the thread guide and run the

end through the eye of the thread take-up lever from right

to left,

6. Now run the thread down through the face plate guides

and then through the loop of the needle bar guide from

the back.

7. Finally, run the end of the thread through the eye of the

needle FROM LEFT TO RIGHT, drawing it through about

3 or 4 inches.

Fig. n

7.

1. Hold the end of the upper thread with the left hand, leaving

it slack from the hand to the needle.

2. Turn the balance wheel toward you as the needle goes

down and rises to its highest position.

3. Hold the upper thread and the lower thread will be brought

up with it through the hole in the needle plate, as shown

(Fig. 12). ^ ^

4. Place both ends of the upper and lower thread behind the

presser foot (Fig. 13)

*7a Pn£f4S/m jpn,

Fig. 12

S. *7c Seminif

1. Place the Fabric to be sewn beneath the presser foot.

2. Lower the presser foot, by lowering the presser bar lifter

(Fig. n).

3. Commence sewing by slowly turning the balance wheel

towards you while gradually pressing the lever of the foot

or knee control.

Always turn balance wheel toward you and not away from you.

10

9. flemme, ike Q4Joàk

1. Raise the needle bar to its highest position by turning the balance

wheel toward you,

2. Raise the presserò foot by lifting the presser bar lifter.

3. Move the fabric back to the left and cut off the thread by passing

it over the thread-cutter above the presser foot.

4. Leave both ends of the thread a few inches long, under and to the

back of the presser foot.

Fig. 14 Correct Stitch

Needle Threed Tension too strcn

fO, a (lecfddJxUe ike *7knead *7etfdia*i.

For ordinary stitching the tension of the upper and

lower threads should be equal so as to lock both

threads in the center of the material (Fig. 14). If one

tension is stronger than the other, imperfect stitching

will result. Fine materials require a light tension,

while heavy materials require more tension to obtain

a perfect stitch.

To INCREASE the tension, turn the thread tension

indecator (Fig. 15) clockwise.

TO LESSEN the tension, turn the thread tension

indicator to the opposite direction. (When regulating

tension always have the presser foot down).

Needle Thread Tension too weal

Fig. 15

H

J

As all machines are correctly adjusted before leaving the factory and readjusted

dealer delivers them to you, the lower tension seldom requires to be altered,

becomes necessary, tighten the screw in the tension spring on the outside of

case for more tension, or loosen the screw slightly for lesser tension (Fig. 161.

//. *7o. the. ^¿titch Jle4ix^.th

The length of stitch can be changed by adjusting the stitch

length regulating lever "L" (Fig. 17),

When the lever is at 0 the material is not being fed through

the machine.

To change stitch length, loosen lock screw "S” by turning it

to the left.

Now move the lever gradually downward to feed material for

ward and to lengthen stitch.

The indicattes the length of stitch. Set lever to desired

length of stitch and lock the screw by turning to the right.

To sew backward move stitch regulating lever upward past

0 until it stops.

Machine will automatical! maintain same length of stitch for

ward and backward.

before the

but, if this

the bobbin

\

f

I

^ ,

I

i

Fig. 17

12

/=2. */a

Light material will not sew well under too much pressure, nor will heavy Fabrics under too little.

To adjust for correct pressure, use your automatic darner. When used right in co-ordination with t

thread tension regulator and the drop feed dial, this automatic darner becomes an effective tool for

good sewing results.

To regulate the pressure for darning and enbroidering press release lever dcwn there by releasing pressure

Make sure presser foot is down when pressing lever. For ordinary sewing, push automatic darner dcwn

Re<^44iate the P^eddu^ a^ the. P^mM-e/i. ^aat

/3. Vo the-

'per

ling

8).

9).

By using the drop feed device you may adjust the feed dog for sewing different types of materials

and for embroidering or darning (Fig. 20).

1. For sewing very light fabrics, push the drop feed button "DOWN" half-way; for heavier cloth push

the button marked "UP" to return feed to highest level.

2. When the d,op feed bu.lon "DOWN" Is pushed down conspletely, .he feed will lowered below

the surface of the needle plate.

This is for embroidering and darn

ing, and you will be able to move

your work freely about in any

direction you choose.

3. For embroidering and darning,

first release pressure of presser

foot (Page 19'i.

Fig. 20

14

ps%

i^. ^o. 0il MedAM-Hc^ Mcu^ltidte.

To have your machine always in smooth running condition

you must keep it oiled at all times.

No grease is necessary. Just a drop of oil is sufficient

at each time. Oiling points are illustrated in Fig. 21,22. Tilt

the machine over to get oiling points underneath the bed.

After oiling, run the machine at high speed for a few

minutes to get oil to penetrate to all parts.

S ■ * TV'.^iif •^-, .'.

■rir'f;,

s

d=

■ -v',

f

U'AvSS

Fig. 21

SriFV

Fig- 22

NT I

15

So4^m ^4^«/ Se44M4tq, cMi4ii6.

TO TURN CORNERS :

1. Stop the machine while the needle is still in the material.

2. Raise the presser foot and turn the fabric using the needle as a pivot.

3. Lower the presser foot and resume sewing.

TO SEW ELASTIC FABRICS:

In sewing such elastic materials as jerseys, bias cut cloth, etc., it is advisable to sew them with reduced

upper thread tension, otherwise the thread will break when the sewn materials are stretched.

TO SEW VERY THIN CLOTH :

When sewing very thin cloth which tends to gather as you sew, place a sheet of newspaper or any other

thin paper underneath the material and sew with the shortest stitch possible. This will keep your work

from gathering.

BASTIN6 :

1. Reduce the tension of the upper thread and employ the longest stitch possible.

2. The stitches may then be easily removed by pulling the lower thread.

TO KEEP YOUR MACHINE IN PERFECT CONDITION :

1. Keep all moving parts of the machine constantly oiled and clean.

2. Always turn balance wheel toward you, even when by hand.

3. Do not run machine without doth.

4. When sewing, do not pull the material because you will bend the needle. The machine is designed

to feed the material automatically.

5. Do not operate machine when the presser bar lifter is raised.

16

mm

/6, QoHie. ajf "^fiauâle.

BREAKING OF THE UPPER THREAD:

1. Incorrect threading, 2. Upper thread tension too tight.

3. Defective needle, or needle set incorrectly.

4. Needle rubbing against presser foot or other attachments.

5. Needle eye too small for thread used. 6. Imperfections in sewing thread.

7. Stitch hole in needle plate damaged and rough.

BREAKING OF THE LOWER THREAD:

1. Incorrect threading of the bobbin case. 2. Lower thread tension too tight.

3. Bobbin being wound too fully.

BREAKING OF THE NEEDLE:

1. Pulling the fabric while machine is sewing thus causing the needle to strike the needle plate

2. Using bent needle.

SKIPPING STITCHES:

1. Using bent or blunt needles. 2. Needle inserted incorrectly.

3. Needle threaded improperly. 4. Using wrong size needle.

5. Pressure on presser foot insufficient, especially when sewing heavy material.

UNEVEN STITCHES:

1. Presser foot not resting evenly on material. 2. Feed dog not adjusted high enough.

3. Too short stitches used. 4. Pulling the cloth while the machine is sewing.

5. Needle too fine for material or thread too coarse.

17

17. SedAAiHtf

Your Zig-Zag Sewing Machine, by virtue of its design, permits

you to do zig-zag sewing and numerous other kinds of worK

requiring a similar stitch. The controls for the zig-zag stitch

are located on the arm of the machine, as may be seen on

Fig. 23, Notice lever "B” which adjusts the width of the zig

zag seam. For ordinary straight sewing this lever must be set

to the left of marking 0 in the indicator. By moving this

lever gradually to the right toward 5 the machine will sew a

zig-zag seam of increasing width, depending on the position of

the lever. For the purpose of reverting to a previously used

width of zig-zag stitch after having done some straight sewing, ^

or for special types of work such as sewing buttons or making tacks, indicator A will be found useful. Thi^s

indicator serves as a stop for dial "B”, To set indicator "A”, loosen lockscrew "D”, turning it to the left.

You then will be able to turn same sideways which, at the same time, moves indicator TA” to the desired marking.

Tighten lockscrew "D” by turn-ing it to the right. The lockscrew also tightens slide "C”. The purpose of this

slide is to make possible a second setting of zig-zag width. Thus, when you want to alternate between a narrow

and a wide zig-zag stitch, you use both indicator "A” and slide “Ch For example, set indicator “A” at marking

4 and slide "C at marking 1, tightening the lock screw. This will assure you of being able to always revert

to the same narrow and wide zig-zag seams. You will find this feature especially convenient when making

ZI52AG SU№

Fig. 23

buttonholes. Refer to chapter on Buttonhole Sewing .

18

m

fS. afiom ¿a Ofxe^Kite /luiomaicc

1. Open the small lid of top plate.

2. Move limiter knob (A) to the right end.

3. Set lever to the extreme right with right hand and keep it holding

at its position, while with left hand match automatic cam shaft pin

(B) and automatic cam pin hole (C), and slide the cam in.

— 19 —

/9- SeufiH^ an ß44Üom

Turn balance wheel toward you to raise needle to its highest position. Raise

presser bar and remove regular presser foot. Attach button sewing Foot

shown in Fig. 25. Drop the feed as required for darning and embroidery.

Upper and lower thread tensions remain the same as for ordinary sewing.

Place material or garment with button under the presser foot, so that

holes in button line up with oblong opening in presser foot.

With zigzag stitch (ever “B” (Fig. 23) adjust width of zig zag stitch to

permit needle to pass through center of holes in button. Before sewing

with power, turn balance wheel by hand (toward you) making one stitch

into each hole in the button, to be sure that needle clears. Then sew

five to six stitches to attach button. Move zigzag stitch lever "B” (Fig.

23) to 0 and take two or three stitches through the same hole to lock thread,

machine and snip threads.

When attaching four-hole buttons, follow above procedure twice.

Fig. 25

Remove garment fror

21

3.0. But¿ai^alг¿.

I

I

From

1. Set the zigzag stitch locking dial “S" (Fig. 23) at 2.

2. Raise presser foot and turn balance wheel toward you to bring needle to its highest position. Remove regular

presser foot from presser bar by loosening thumb screw, and attatch special buttonhole foot shown in

fig. 26. Tighten thumb screw.

3. Set stitch length regulator knob "L” to obtain closely spaced forward stitches. Best length of stitch for

buttonholes is when the knob "L” (Fig. 17) is placed between 0 and 1. Adjust length of stitch, if

necessary, to get best possible appearance of buttonhole.

4. Slightly tighten needle thread tension, turning tension

regulator to the right. If appearance of buttonhole

should not prove satisfactory, slightly vary tension

until the desired results are obtained.

NOTE : It is suggested that you make one or two sample

buttonholes on a scrap of your garment fabric, to test

adjustments of machine and to make corrections, if

needed. Also mark with pencil or chalk the position

and exact length of buttonhole on garment.

To sew buttonhole, place garment under the button

hole presser foot with the start of pencil or chalk

marking showing in center of presser foot opening.

— 22 —

Stitch left side of buttonhole to end of marking. Stop machine with needle to the right of stitching.

Leave needle in fabric, raise presser foot and turn garment half-way around in clockwise direction. Let

presser foot down, raise needle and turn zigzag lever "B” (Fig. 23} to 4 width. Sew four or five stitches

to make the bar at one end of the buttonhole. Return zigzag stitch lever to the left position at 2 and

sew the other side of buttonhole. When arriving at end of buttonhole, again move zigzag stitch lever

to the right for making second bar with four to five stitches. Remove garment from machine and open

buttonhole with cutter or buttonhole scissors. Be careful to avoid cutting the buttonhole- stitching. To

make reinforced buttonholes introduce gimp of proper size into the small hole at the front of the button

hole foot. Sew over gimp as machine makes buttonhole seams. For flat buttonholes leave thread tension

pretty much the same as for ordinary sewing. Pearl stitch buttonholes require a tight tension of the

needle thread. For better appearance, use needle thread of the next heavier size.

<2/. and

Push the drop feed button "DOWN” all the way down to permit the fabric to be moved in any direction.

Remove presser foot and release button as shown in Fig. 20.

Embroidery is most successful when fabric is stretched in a hoop. Flold hoop on machine bed with both

hands, operating machine at a fairly high speed while moving the work slowly. Slightly increase the

bobbin thread tension to prevent the lower thread being pulled up.

— 23

o2<2.

The quilting attachment (Fig. 27) will enable you to sew evenly spaced

lines on padded fabrics without marking them in advance.

To attach the quilter to the presser bar of the machine, first pull long

curved bar out of horse-shoe shaped clamp. Place the clamp on the

presser bar above presser foot, and push the bar through holes in

clamp.

Adjust curved end of bar to desired distance from needle so that it

presses into fabric. Then tighten thumb screw to lock quilter attach

Fig. 27

ment into place. When sewing, quilter bar should follow preceding

line of stitching.

Zigzag stitch quilting is done the same as straight stitch quilting with

the zigzag stitch dial set for any desired width.

3.3. SenuHif B^uuJU.

Remove regular presser foot from the machine and attach braiding foot,

as shown in Fig. 28. Thread braid through small hole at front of foot.

Adjust width of zigzag seam and length of stitch to obtain a covering of

the braid which appears most desirable for the material you are sewing.

Using needle thread of a contrasting color will enhance the beauty of

your braiding.

_ 24 —

Fig. 28

3.4. Man/ma* eMe4ftmen.

Turn balance wheel toward you until needle reaches its highest

point. Raise presser bar and remove regular presser foot.

Attach hemmer foot (Fig. 29). Now handle material as

follows :

1. Fold over edge of material approximately then fold

it over again for about 2". Insert this folded end into

spiral formed opening (scroll) of hemmer foot.

Move material back and forth until the hem forms itself

in the scroll.

Fig. 29

2. Pull material toward you until the beginning of the hem is

just below the needle.

3. Lower presser foot and begin to sew.

Guide material into hemmer foot while proceeding with work

Fiq. 29'.

NOTE : Do not crowd material into scroll and do not leave scroll only partly filled by material. Feed just

enough material into the hemmer foot to fill out the scroll.

Instead of a straight stitch^ you can also use a zigzag stitch for this hemming operation. Be sure,

however, to adjust the width of the zigzag stitch to the width of the hem. Using a very long stitch

and tight tensions will produce a shell stitch.

25

2.5. eMcMAA ¿a do.

The hemmer foot can also be used for doing felling. Proceed in the

following manner :

1. Lay two pieces of cloth one on top of the other with their RIGHT

sides facing each other. The right edge of the bottom piece must ex

tend about Vs inch beyond the right edge of the top piece. See fig. 30.

2. Sew both pieces of cloth together, using the hemmer foot like a regular

presser foot. Use the right edge of long toe of hemmer foot to guide

the bottom piece of material, while the left edge of the same toe

serves as a guide for the top piece of material

3. Open and spread out material and put back on machine right side down

ward. Make sewn edges of material stand up.

4. Fold over the edges to the left

and insert them into the scroll

of the hemmer foot. Sew as

you would do ordinary hemming.

Use left edge of long toe of

hemmer foot as guide, having

original seam run alongside of it

(Fig. 31).

Fig. 30 shows this detail.

<2<5. QUUt Quide & *^Uumk Sc^eiu

This is an attachment designed as a guide for straight stitching

when making wide hems, deep tucks, or seam width which are

greater than presser foot allows. (Fig. 28)

It is attached to machine as illustrated...a very simple operation.

26

Fig. 32

27. NEEDLE - THREAD - FABRIC - STITCHIN© GUIDE

Fabric

Extremely heavy tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery fabric, ticking,

denim, leatherette, etc.

Medium heavy drapery fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth, percale, gingham,

linen, chintz, taffeta, sheer wool,

shantung, etc.

Sheer voile, lawn, dimity, crepe,

handkerchief linen, plastic film, etc.

Very sheer chiffon, batiste, lace,

organdy, ninon, net, marquisette, etc.

Needle No.

4

......^ ..............

3

2

1

0

00

i Machine

I Stitches

j per Inch

6

to

; 8

i 8

; to

1 10

i 10

; to

; 12

; 12

i to

: ''4

i 12 to 14

i (Plastic Film

5 8 to !0)

i 16

: to

^ 20

• Cotton

i Thread

. 10

‘ to

! 30

^ 30

' to

1 40

: 40

; to

i 60

^ 60

^ to

; 80

i 80

: to

i 100

! 100

i to

i 150

Mercerized :

Thread

Heavy Duty ;

1 Heavy Duty '

: Heavy Duty ■

i

............

............. ■

I 50 1

! 50

; 50

Silk or

Nylon

—

/

.......-...

A

A

—

-

A

27

Loading...

Loading...