Page 1

Instruction Manual

Singer

UT-1 Device

ST-1 Device

for

755U Machine

756U Machine

Page 2

INSTRUCTION MANUAL

(DRAFT)

SINGER@

UT-l/ST-l DEVICE

FOR

755U/756U MACHINE

®A registered trademark of The Singer Company Limited

Copyright©! 997 The Singer Company Limited

AÌÌ Rights Reserved Throughout The World

Page 3

OONTENTTS

PAGE

1. Application

.......-... .

-...................... .........-....-................

1-1 Threading and testing —...........................-

1-2 Installment and adjustment of the synchronizer

...... . ...... ..-......-.........

1- 3 Electricity and connection of its power control cycle

2. Maintenance and adjustment

2- 1 Lower moval knife and fixed knife

........................-......-----

-------------

----2-2 Setting the height of the lower fixed knife carrier guide

2-3 Setting the position of thread trimmer -------2-4 Double-checking

3. Tension release equipment

4. Adjustment for spreader trimmer

4-1 The explanation for trimming operation

4- 2 Maintenance and adjustment

5. Illustrated parts list

5- 1 UT-1 Underbed trimmer components

-------------

.... ..

------------------------------------------

--- --

-----------------

-----.. .

-------

------------------------------

........------------------------- ------

--------

--------------------------------------

-------

----

------------------

------

-----------------------

-------------------

------------------------------------ 12

-----------

---------------- 2

....................... 4

-----------------

---------------

------

----------------------

---------

--------

---10

----

-......... 12

----

----

----

----

2

3

5

5

6

7

8

9

10

10

5-2 ST-1 Spreader thread trimmer components 5-3 Compressed air components

---------------------------------------------

------------------------------

14

16

5-4 Thread tension and motor components ..................................... 18

5-5 Air piping diagram

-------------------------------------------------------

20

Page 4

1. APPUCATION :

1-1 THREADING AND TESTING

THE THREADING OF THIS SEWING MACHINE IS THE SAME AS CT

SERIES, PLEASE REFER TO THE USER GUIDE OF CT SERIES

INTERLOCK MACHINE.

PLEASE BE AWARE THAT THE WRONG THREADING IS THE MAIN

REASON TO CAUSE THE SKIP STITCH PROBLEM. IF THE UTA-1

DEVICE IS NOT ASSEMBLY ON THE MACHINE BY OUR FACTORY BLTT

PURCHASE SEPARATELY PLEASE ADJUST AND TEST THE MACHINE

TO REACH THE BEST SEWING EFFECTS ACCORDING TO THE

FABRICS AND .THREAD YOU ARE USING FIRST AND THEN,

ASSEMBLE THE UTA-1 DEVICE AFTERWARDS.

[ DO NOT OPERATE THE UTA-1 DEVICE IF THERE IS NO FABRICS

UNDER THE PRESSER FOOT.

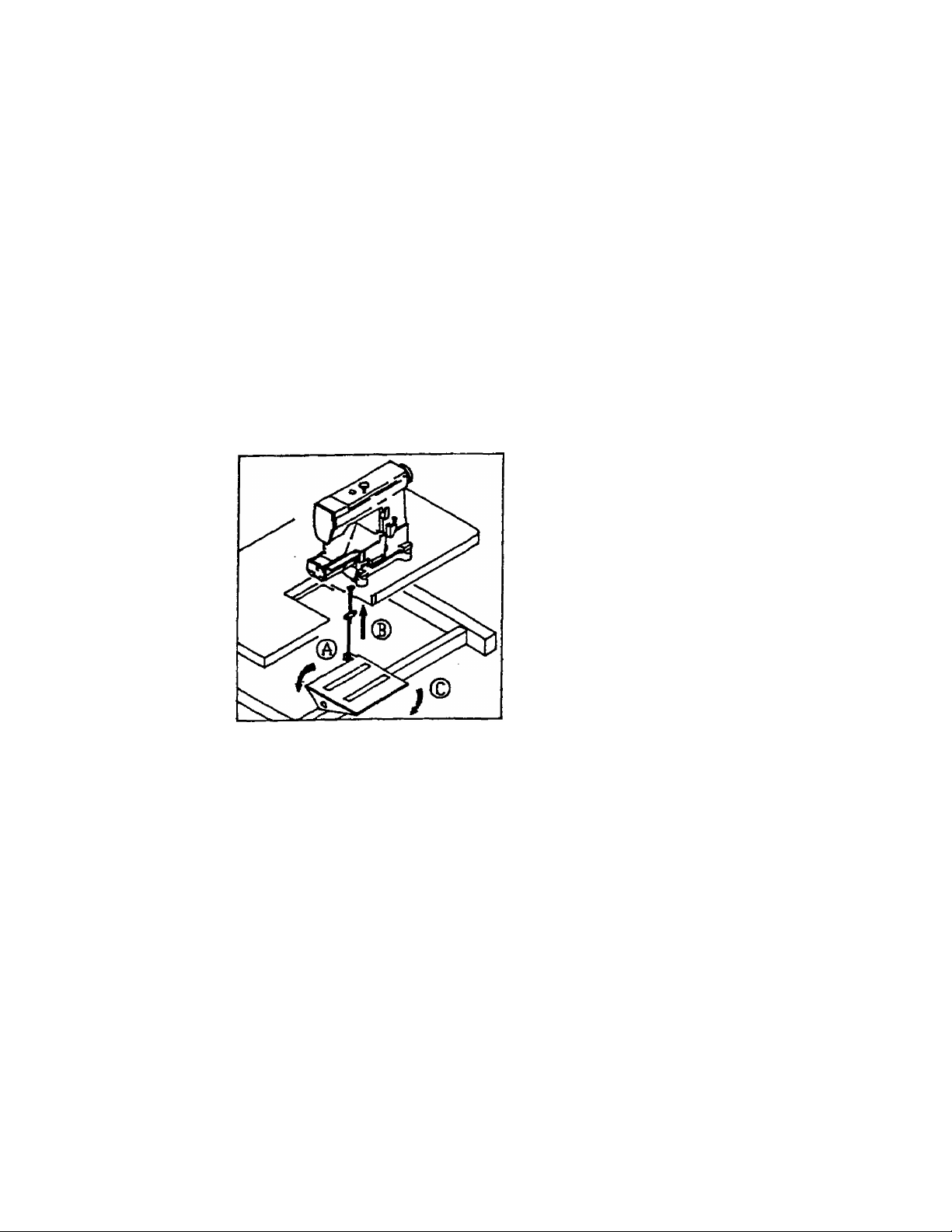

1. START THE SEWING MACHINE BY PUSHING THE PADEL

FORWARD®

2. WHEN PEDAL BACK TO NEUTRAL POSITION © THE SEWING

MACHINE STOP AND AT THIS MOMENT. YOU CAN SET THE

NEEDLE TO ITS UPPER SET STOP POSITION OR LOWER SET STOP

POSITION.

3. WHEN PUSHING THE PEDAL BACKWARD ©THE NEEDLE REACH

ITS UPPER SET STOP POSITION AND STOP THEN TRIMMING KNIFE

START ITS OPERATION TO CUT THE LOOPER THREAD AND

NEEDLE THREADS FIRST THEN CUT THE SPREADER THREAD NEXT

AND PRESSER FOOT UFT UP AUTOMATICALLY.

4. TAKE OFF THE SEWING FABRICS AND PREPARE FOR THE NEXT

SEWING OPERATION.

BEFORE YOU PUSH THE PEDAL FORWARD. YOU CAN PUSH THE

PEDAL BACKWARD AND LIFT UP THE PRESSER FOOT IN ORDER

TO ADJUST THE FABRICS POSITION AT ANY TIME.

Page 5

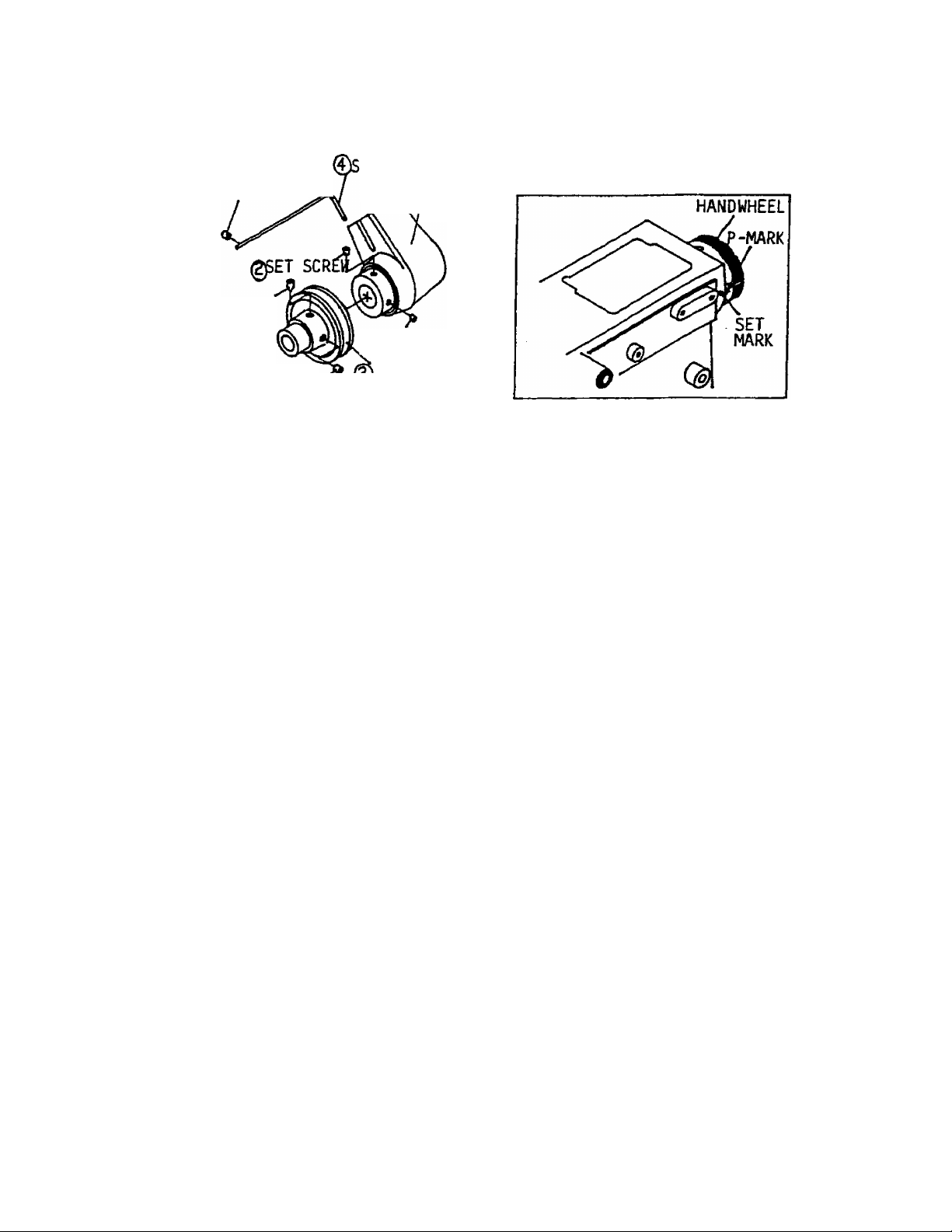

1-2 INSTALLMENT AND ADJUSTMENT OF THE SYNCHRONIZER :

TOPPER

©SET SCREW

(pSYNCH^2^-

(§)SEP..

^ SCREW

©5ET SCREW

gSET scre'S^ pulley

1. INSTALL SYNCHRONIZER©INTO BELT PULLEYQ)AND TIGHTEN THE

SET SCREW© LIGHTLY.

2. INSERT ONE END OF STOPPER®INTO THE HOLE ON THE MACHINE

AND INSERT THE OTHER END OF STOPPER INTO THE GROOVE OF

SYNCHRONIZER AND THEN TIGHTEN THE SET SCREW®

3. CONNECT THE POWER OF MOTOR ( PLEASE DO NOT CONNECT THE

ELECTRIC POWER OF TRIMMING KNIFE YET)

4. PUSH THE PEDAL AND START THE SEWING MACHINE AND THEN

PUSH THE PEDAL BACKWARD TO STOP THE MACHINE. BY THIS

TIME, THE SEWING MACHINE WILL STOP AT CERTAIN POSITION

AUTOMATICALLY.

5. OBSERVE THE "P" SET MARK FROM HANDWHEEL AND WHEN THE

MACHINE STOPPED. THE "P" SET MARK FROM HANDWHEEL SHOULD

MATCH THE SET MARK ON THE SEWING MACHINE AND AT THIS

MOMENT, THE NEEDLE SHOULD REACH ITS UPPERMOST DEAD POINT.

WHILE ADJUSTING, LOOSEN THE SET SCREW® TURNING THE BELT

PULLEY® THEN TIGHTEN THE SET SCREW LIGHTLY, REPEAT SUCH

PRECEDURE SEVERAL TIMES TO MAKE SURE THE "P’ SET MARK

FROM HANDWHEEL CAN MATCH EVEN WITH THE SET MARK OF THE

MACHINE BODY.

6. AFTER TIGHTEN THE SET SCREW, PLEASE DOUBLE CHECK THE

RELATED POSITION ONCE MORE TO MAKE SURE THESE TWO SET

MARKS ARE MATCHING EVENLY.

Page 6

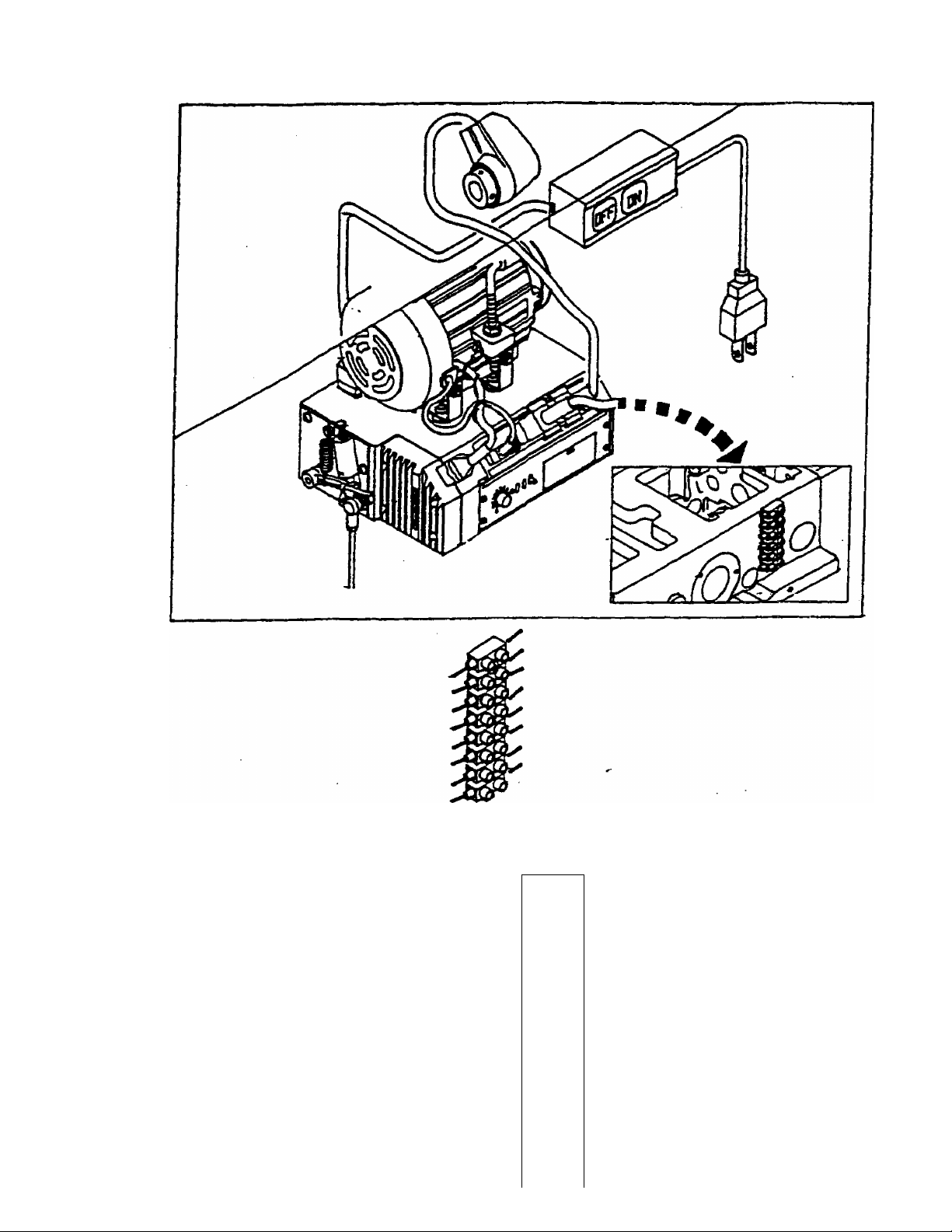

1-3 ELECTRICITY AND CONNECTIUN ui- iia rwwcn uwmnwk

CYCLE.

GENERAL CONNECTIDN DIAGRAM OF AC SERVE MDTCR

<

SPREADER TRIMMER

UNDER BED TRIMMER

PRESSER FDDT <

SAFTY SWITCH <

l.RED

2. BLACK

3.RED ^

4. BUCK

5. BLACK

6. BLACK

7. BLACK

8. YELLOW

/

-----

^

© ©

e ©

6 © 3. WHITE

© ©

© 9

© é

© ©

© ©

^

J

l.RED

2. DEEP BLUE

4. GRAY

5. ORANGE

6. GREEN

7. YELLOW

8. BLACK

*>

*>

s

>

Page 7

2. MAINTENANCE AND ADJUSTMENT

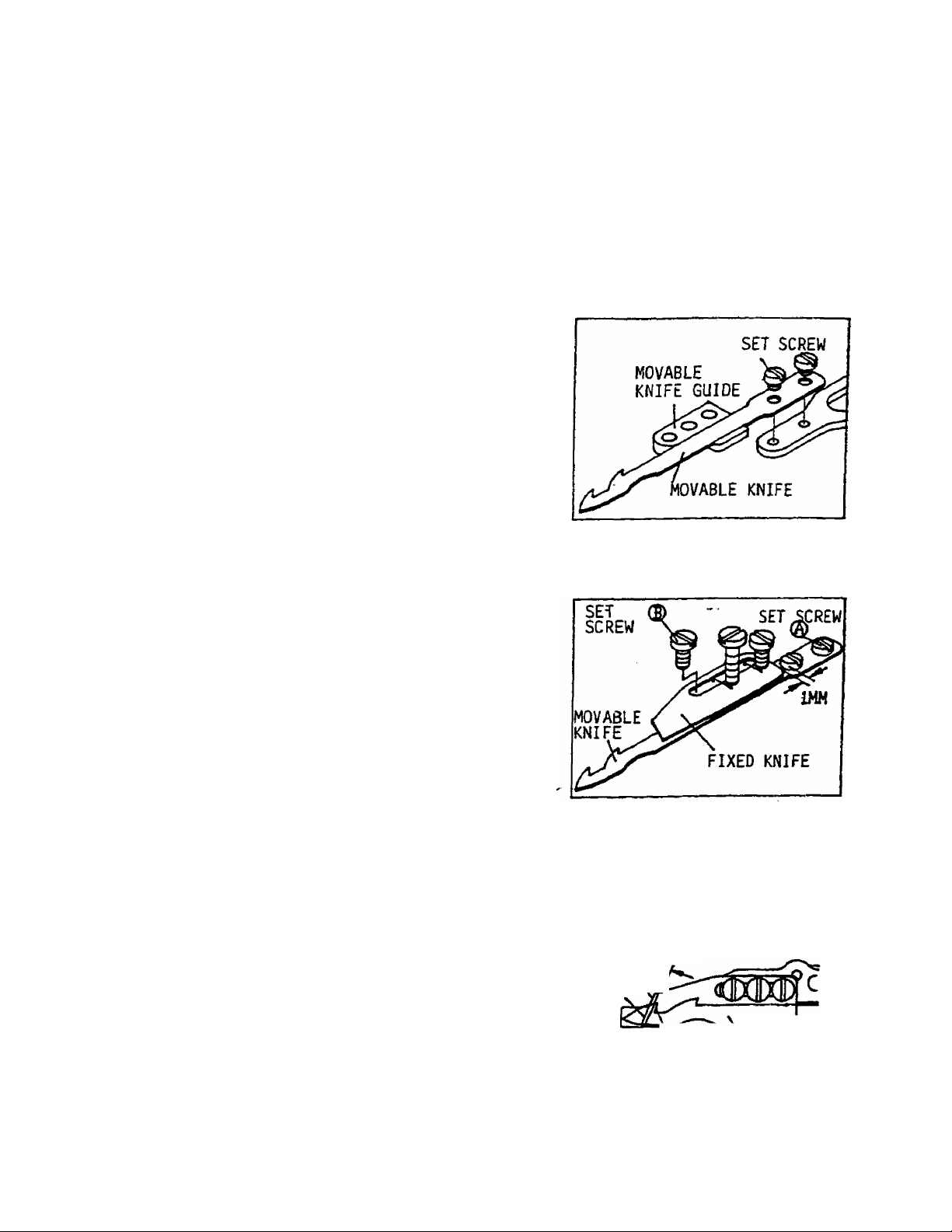

2-1 LOWER MOVABLE KNIFE AND FIXED KNIFE

IF YOU ARE RESHARPING THE KNIVES, OR CHANGING THE KNIVES, OR

INCASE, TAKING OFF THE TRIMMING KNIFE SET IF NECESSARY AND

YOU WANT TO RE-INSTALL THE TRIMMING KNIFE SET BACK, PLEASE

REFER TO FOLLOWING ITEMS AND ADJUSTING THE RELATED PARTS

INVOLVED.

@ PLEASE MAKE SURE THE POWER IS -OFF*

LOOSENINq-THE COMPRESSED AIR JOINT

AND ADJUSTING THE POSITION OF

LOWER MOVABLE KNIFE IN ORDER

TO MAKE THE MOVABLE KNIFE CAN

BE SLICED EASILY IN THE LOWER

MOVABLE KNIFE GUIDE AND CAN NOT

INTERFERENCE WITH THE KNIFE GUIDE.

WHEN MOVABLE KNIFE MOVED TO ITS

LEFTEST DEAD POINT THERE SHOULD

HAVE A INTERVAL OF 1m.m. BETWEEN

SET SCREW A AND FIXED KNIFE AND

CAN NOT COLLIDE WITH EACH OTHER.

YOU CAN ADJUST THE INTERNAL BY

LOOSEN THE SET SCREW B AND MAKE

SURE THE EDGE OF MOVABLE KNIFE

MATCH EVENLY WITH THE EDGE OF

FIXED KNIFE.

WHEN MOVABLE KNFE MOVED TO ITS

RIGHTEST DEAD POINT, THE HOOK

BALDE OF MOVABLE KNIFE SHOULD

BE RETREAT Im.m. INSIDE FROM

THE BLADE OF FIXED .KNIFE.

MATCH \a

EVEN

HOOK SLADE''MOVABLE

KNIFE

Page 8

THE RELATIONSHIP AMONG CLAMP SPRING.

KNIFE PRESSURE SPRING AND CLAMP

SPRING PRESSURE ADJUSTING PIECE.

WHEN THE HOOK BUDE OF MOVABLE

KNIFE A RETREATED 1mm INSIDE FROM

THE BALDE OF FIXED KNIFE B, THE

FRONT EDGE OF CLAMP SPRING C

SHOULD MATCH EVEN WITH THE TOP

OF MOVABLE KNIFE. SIDE EDGE

OF MOVABLE KNIFE AND CLAMP SPRING

ALSO SHOULD MATCH EVENLY.

WHEN LOOPER THREAD BEEN CUT.

THE CLAMP SPRING SHOULD HOLD

THE LOOPER THREAD AND MOVING

AWAY TOGETHER WITH KNIFE BASE

FROM THE LOOPER AND THE PRESSURE

OF CLAMP SPRING CAN BE ADJUSTED

BY ADJUSTING THE CLAMP SPRING

PRESSURE ADJUSTING PIECE AND PLEASE

REFER TO NEXT ITEM.

2-2 SETTING THE HEIGHT OF THE LOWER FIXED KNIFE

CARRIER GUIDE

FIXED KNIFE®

jm

PRESSURE SPRING f 3

PRESSURE SPRING pippp

WHEN LOWER MOVABLE KNIFE MOVE

FORWARD FROM LOWER KNIFE HOLDER,

THE INTERNAL BETWEEN MOVABLE KNIFE

AND THE RIDGE OF LOOPER SHOULD

BE 0.1

LOOSENING THE SET SCREW A AND ADJUSTING

THE HEIGHT OF LOWER FIXED KNIFE CARRIER

GUIDE TO ITS PROPER POSITION THEN TIGHTEN

THE SET SCREW A.

PLEASE MAKE SURE THE LOWER MOVABLE

KNIFE CAN BE MOVH) FORWARD AND

BACKWARD SMOOTHLY.

Page 9

2-3 SETTING THE POSITION OF THREAD TRIMMER

WHEN THE PISTON OF. KNIFE DRIVING

CYUNDER REACH ITS LEFTEST DEAD

POINT AND TRIMMING KNIFE SET WILL

MOVE TO THE SIDE OF THE LOOPER.

THERE WILL BE A 2m.m. INTERVAL

BETWEEN THE TRIMMING KNIFE SET

AND THE LOOPER.

LOOSEN THE SET SCREW NLIT (A),

TURNING THE PISTON CLOCKWISE

TO REDUCE THE INTERVAL OR

COUNTER CLOCKWISE TO INCREASE

THE INTERVAL, TO ADJUST THE

TRIMMING KNIFE SET TO ITS PROPER

POSITION AND THEN TIGHTEN THE

SET SCREW NUT

TURNING THE HANDWHEEL AND MAKE

SURE THE "P" SET MARK MATCH THE

SET MARK FROM THE MACHINE HEAD.

USING HAND TO MOVE THE PISTON

OF THE KNIFE DRIVING CYLINDER IN

ORDER TO MOVE THE TRIMMING KNIFE

SET TO THE LOOPER

SET MARK o

KEEP PUSHING THE PISTON OF KNIFE

DRMNG CYLINDER, THEN THE MOVABLE

KNIFE START TO MOVE FORWARD.

WHEN THE MOVABLE KNIFE MOVE TO

FROM THE LEFT EDGE OF FEED

DOG’S RIGHT COLUMN.

THE TIP OF THE MOVABLE KNIFE SHOULD

LOCATED ON THE TOP OF THE CENTER

LINE OF LOOPER'S RIDGE

7 FEED DOG

tjmi

LOOPER

HANDWHEEL

15MM

- RR-\10VABL

TIP

Page 10

WHEN MOVABLE KNIFE KEEP MOVING TO

THE LEFT TILL 1.5mm AWAY FROM THE

RIGHT SIDE OF FEED DOG*S LEFT COLUMN.

THE TIP OF THE MOVABLE KNIFE SHOULD

STILL STAY WITHIN THE RIDGE OF THE LOOPER.

WHEN ADJUSTING. LOOSENING THE SET SCREW (A)

AND TURNING THE ECCENTRIC STUD AND SETTING

THE POSITION OF THE TIP OF MOVABLE KNIFE

(THE SET MARK OF THE ECCENTRIC STUD MUST

FACING TOWARD THE RIGHT SIDE).

2-4 DOUBLE-CHECKING

AFTER ASSEMBLED THE THREAD TRIMMING SET, PRIOR TO THE

SEWING OPERATION. YOU MUST DOUBLE CHECK THE CORRELATION OF

NEEDLE THREAD, LOOPER THREAD, LOWER MOVABLE KNIFE AND

LOOPER. AND ALSO DOUBLE CHECK IF THE THREAD TRIMMER CAN

TRIM THE THREADS PROPERLY AND IF CLAMP SPRING CAN HOLD THE

LOOPER THREAD PROPERLY.

WHEN MOVABLE KNIFE (A) MOVE FROM

RIGHT TO THE LEFT. IT MUST PASSING

THROUGH THE LOOP OF THE NEEDLE

THREADS (U) (LT). IN THE SAME TIME,

THE POSITION OF HOOK BLAD (a^ MUST

BE IN THE FRONT OF LOOPER THREAD.

WHEN MOVABLE KNIFE (A) RETREAT FROM

ITS LEFTEST DEAD POINT TO THE RIGHT.

HOOK BLADE(a;AND(a’)WILL PULL THE

NEEDLE THREAD AND LOOPER THREAD TO

THE FIXED KNIFE AND. CUT THE THREADS

IN ORDER AND THE CLAMP SPRING WALL

HOLD THE THREAD END AND MOVE TO THE

BACK OF LOOPER TOGETHER WITH TRIMMING

KNIFE SET (A). YOU CAN ADJUST THE HOLDING

PRESSURE OF CLAMP SPRING TO AVOID THE

THREAD END CAME OFF DURING THE

MOVEMENT BY ADJUST CLAMP SPRING

PRESSURE ADJUSTING PIECE.

Page 11

THE TRIMMING ABIUTY OF KNIFE MUST

BE MODERATE OR THE.KNIFE WILL BE

WORE OLTT VERY SOON. IF THE TENSION

OF KNIFE PRESSURE SPRING IS TOO BIG,

YOU CAN ADJUST IT BY MOVING KNIFE

PRESSURE SPRING TO THE RIGHT OR

LEFT IN ORDER TO GET PROPER TENSION.

DOUBLE CHECK THE POSITION OF SAFETY

SWITCH WHEN THE POWER IS ON. THE

TRIMMING KNIFE SET MUST BE IN ITS SET

POSITION.

THE TRIMMING KNIFE SET CAN ONLY

FUNCTION WHEN THE KNIFE DRIVING

CYLINDER (B) PUSH AWAY SAFETY STITCH (A).

WHEN ADJUSTING. LOOSENING SET SCREW (C)

AND SETTING THE DESIRED POSITION FOR

SAFETY SWITCH THEN TIGHTEN SET SCREW(C).

AFTER TIGHTEN THE SET SCREW (C) YOU

DOUBLE CHECK IF SAFETY SWITCH IS

MUST

SET PROPERLY.

3. TENSION RELEASE EQUIPMENT

EACH OF SET SCREWS FOR THE TOP

THREE THREAD GUIDE HOOK UNITS IS

SETTING IN THE MIDDLE OF TWO THREAD

GUIDE EYELETS AND EACH OF SET

SCREWS FOR THE BOTTOM TWO THREAD

GUIDE HOOK UNITS IS SETTING IN THE

DISTANCE OF lOm.m. APART FROM THE

THREAD GUIDE EYELET.

THE RELEASE WEDGE MUST REACT

EARLIER THAN THE THREAD TRIMMER'S

OPERATION. WHEN ADJUSTING, LOOSENING

THE SET SCREW. SETTING THE PROPER

POSITION OF RELEASE WEDGE. IN THE

MEANTIME. PLEASE MAKE SURE THE

RELEASE WEDGE CAN PUSH TENSION

DISC COMPLETE APART AND ALSO CAN

RETREAT COMPELELY ( CAN NOT

INTERFERENCE WITH TENSION DISC.)

Page 12

4. ADJUSTMENT FOR SPREADER TRIMMER

4-1 THE EXPLANATION FOR TRIMMING OPERATION.

WHEN NEEDLE MOVED TO ITS UPPERMOST

DEAD POINT, MOVABLE KNIFE (A) PASSING

THROUGH THE NEEDLES AND THE LOOP

OF SPREADER THREAD (CAN NOT

INTERFERENCE WITH EACH OTHER.),

WHEN THE TIP OF MOVABLE KNIFE

MOVED TO THE HALF DISTANCE

BETWEEN SPREADER AND PRESSER

fOOT AND START RETREATING BY THIS

MOMENT THE HOOK BLADE OF MOVABLE

KNIFE IS PULLING THE ORNAMENTAL

THREAD BACK TILL THE FIXED KNIFE CUT

THE ORNAMENTAL THREAD AND THE

THREAD CLMAP SPRING IS HOLDING THE

ORNAMENTAL THREAD END.

4-2 MAINTENANCE AND ADJUSTMENT

WHEN MOVABLE KNIFE PASSING THOUGH

THE NEEDLES AND SPREADER, THE

INTERVAL BETWEEN MOVABLE KNIFE

AND SPREADER SHOULD BE 0.1-0.3 m.m.

LOOSEN THE SET SCREW AND ADJUST

THE SPREADER TRIMMER SET TO ITS

PROPER POSITION AND THEN TIGHTEN

THE SET SCREW.

WHEN MOVEABLE KNIFE MOVE FORWARD

AND MEET WITH SPREADER, THE TIP OP

HOOK BLADE SHOULD SQUARE MATCH TO

THE THREAD HOOK OF SPREADER

LOOSEN THE SET SCREW, ADJUST THE

HOOK BLADE OF MOVABLE KNIFE TO ITS

PROPER POSITION AND LINE UP WITH

THREAD HOOK OF SPREADER THEN

TIGHTEN. THE. SET SCREW.

WHEN MOVABLE KNIFE MOVE FORWARD

TO ITS LOWEST DEAD POINT. THE TIP OF

THE MOVABLE KNIFE SHOULD LOCATE

AT THE HALF DISTANCE BETWEEN

SPREADER AND PRESSER -FOOT. LOOSEN

THE NUT OF CYLINDER ADJUST THE

PISTON TO ITS PROPER POSITION THEN

TIGHTEN THE NUT.

Page 13

WHEN RE-SHARPENING THE KNIVES, OR

CHANGING THE KNIVES OR TAKING OFF

THE SPREADER TRIMMER SET IF

NECESSARY, PLEASE ASSEMBLE BACK

THE SPREADER TRIMMER ACCORDING

TO FOaOWJNG ITEMS.

MOVABLE KNIFE SHOULD SLIDE SMOOTHLY

IN THE SLIDE BLOCK AND CAN NOT HAVE

ANY INTERVAL BETWEEN MOVABLE KNIFE

AND SLIDE BLOCK.

THE SIDE EDGE OF FIXED KNIFE SHOULD

MATCH EVENLY WITH FIXED KNIFE HOLDER.

FIXED KNIFE HOLDER

MATCH

EVENLY

FIXED KNIFE

WHEN MOVABLE KNIFE MOVE BACKWARD.

THE HOOK BLADE OF MOVABLE KNIFE

SHOULD RETREAT O.Sm.m. INSIDE FROM

THE BLADE OF FIXED KNIFE.

WHEN MOVABLE KNIFE MOVE TO ITS UPPERMOST

DEAD POINT. THE FRONT EDGE OF THREAD

CLAMP SPRING AND MOVABLE KNIFE SHOULD

BE EVEN. AND THE FRONT EDGE OF KNIFE

PRESSURE SPRING AND FIXED KNIFE SHOULD

BE EVEN.

FIXED

KNIFE

INTERVAL

MOVABLE

-KNIFE

THREAD 'MATCH

CLAMP EVENLY

SPRING

MOVABLE KNIFE

HOOK

BLADE

(L5MH^

FIXED

KNIFE

ADJUSTING SCREW IS USED FOR SETTING

THE TENSION OF CUMP SPRING IN ORDER

TO HOLD THE ORNAMENTAL THREAD

PROPERLY. IF THE TENSION BETWEEN

THREAD CLAMP SPRING AND MOVABLE

KNIFE IS TOO BIG, THEN MOVE THE KNIFE

PRESSURE SPRING FORWARD IN ORDER

TO GET PROPER TENSION,

FIXED KNIFE

•KNIFE

MOVABLE KNIFE

SET SCREW

CLAMP

SPRING

Page 14

5-1 UT-1 UNDERBED TRIMMER COMPONENTS

Page 15

UT-1 Pneumatic Underbed Trimmer Components

Ref. No. Part No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

VUTA0201

VUTA0202

VHE04280608C

VUTA0204

VUTA0205

VME03241006C

VME03240506A

VUTA0208

VSB24560204A

VUTA0210

VSB24560505A

VSB24560905A

VUTA0213

VUTA0214

VUTA0215

VUTA0216

VUTA0217

VSB24560405A

VUTA0219

VUTA0220

VUTA0221

VMB04280608A

VUTA0223

VUTA0224

VUTA0225

VUTA0226

VUTA0227

VMB04280608C

VUTA0229

VMB05320710E

Description Q* ty

Lower Knife Holder ------------ Oscillating Center Ring

Screw ............................................

Lower Knife Carrier

Knife Guide Ring

Screw

...........................................

Screw

..............................................

Lower Movable Knife Screw Lower Fixed Knife

Screw Screw

Lower Movable Knife Guide

Clamp Spring

Knife Pressure Spring

Clamp Spring Pressure Holder

Clamp Spring Pressure Adjusting Piece

Screw

Crank Chancier Cover

Lower Fixed Knife Carrier Guide Supplementary Spring

Screw

Spring

Pin

Driving Lever

Driving Roller ------------------------------------ 1

Adjusting Ring ------------------------------------ 1

Screw

Joint Block

Stud --------------------------------------------- 1

.....................----------

--------------------------------------------

..........................................

............................................

---------------------------------------------

-------------------------------------------

-------------------------------------------

.........................................

-- -- -

................................

..................................

---------------------------------------

------

--------------------------------- 1

....

......

...............-................

.....-.......

...........------------------

--------------------------------

------------------------

..............................

............................

-------------------------------

.................

-.................. 1

2

.....

...........

--------------

1

..................

....................

1

1

1

1

1

1

1

1

...

1

2

1

1

1

1

2

1

1

2

1

1

1

2

1

Page 16

3-¿ ûl“i ûrnCAUCn inncnu 1П11ШПЕ1\ UUmrUi'iO'liû vrun /3QU Wfttfnjincùj

Page 17

Spreader Thread Trimmer Components (FOR 756U MACHINES)

Ref. No. Part No.

1

2

3

4

5

6

7 VUTA0307

VUTA0301

VMB04280508A

VUTA0303

VUTA0304

VUTA0305

VUTA0306

8 VUTA0308

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

VSB24560204A

VUTA0310

VUTA0311

VUTA0312

VUTA0313

VMD04280808D

VUTA0315

VUTA0316

VUTA0317

VMA08400311A

VMA04280307A

VUTA0320

VUTA0321

VSB24560405A

VUTA0323

VUTA0324

VUTA0325

VMN02160300A

Description Q* ty

Knife Holder Plate

Screw

.......

Connecting Bracket

Knife Holder Bracket

Stud

.....-........... .. .

Upper Movable Knife Base

Screw Movable Knife

Screw

Left Slide Block

Fixed Knife Holder

Knife Guide Bracket

Cylinder Holder

Screw

Spring Washer----------------------------------------- 4

Cylinder ......................................... 1

Speed Controller ------------------------------------ 2

Nut

Nut ----------------------------------------------- 2

Joint

Fixed Knife

Screw

Thread Clamp Spring---------------------------------- 1

Knife Pressure Spring--------------------------------- 1

Knife Pressure Adjusting Piece ------------------------ 1

Screw -------------------

.............................................

----------------------------------------------

------------------------------------------------

-----

-----

......................—..........-......

.... ....

--------------------------------------

------------------------------------------ I

-- -- -

------------------------------------------ 4

..................................

---------------------------------

-------------------------------.. .

........-----

... .. ..........

...................

.....

...

....-.............

....

......------------

....

....

......

-------------------------------------

-----------------------------------

-------------

.... ....

.........-.....

---------.....

----- ----

-........-

- -

.......

....

------------

....

.....

....

1

6

1

1

2

1

1

1

2

1

1

1

1

4

1

1

1

Page 18

Page 19

Compressed Air Components

Rel No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Part No.

VUTA0401

VMD06401010A

VUTA0403

VMA08500613A

VUTA0405

VMC06402314E

VMA06400510B

VUTA0408

VUTA0409

VMM04283007B

VMD03203006D

VUTA0412

VUTA0413

VUTA0414

VUTA0415

VUTA0416

VUTA0417

VUTA0418

VMD03201306D

VUTA0420

VMC04280608A

VUTA0422

VUTA0423

VMD06401410A

VMD05321409A

VUTA0426

VMC06401210E

VUTA0428

VLTA0429

VMA06400510A

VUTA0431

VUTA0432

VUTA0433

VUTA0434

VMC04281107A

VUTA0436

VUTA0437

VUTA0438

VUTA0439

VUTA0440

VMA04280307A

VMM04281407A

VUTA0443

VMC04280810A

VMA04280307A

VUTA0446

Description Q* ty

Base

--------------

Screw

---- -Cylinder

Nut

...........-.....-.......

-------

..........................................

Speed Controller

Stud ..........-.....-----

Nut

....

....

.....

Electromasietic Valve Base Electromagnetic Valve

Screw

.......................------------------------

Screw ....................

-----

......

-------------------

......

..............

- -

......----- -----

--------

.... ...

...............-.....-...........

---------

.............

-........-

----- ----------

.............

..........................

................................

-

-----------------------

1

----...

1

2

1

2

1

1

1

2

2

4

Connector............................................ 2

Connector

Elbow Connector

Elbow Connector

---------

....................................

..........

---------- ---------

.... ........ ....-........

--------------

2

2

1

Washer ---------------------------------------------- 4

Washer

.. . ..

........-........

....

.....—...........

2

Safety Switch ...................................... 1

Screw

.....

...........................-------

Safety Switch Bracket

Screw

.............................................

........-......................

--------

2

1

2

Cylinder Holder Bracket------------------------------- 1

Connecting Lever

Screw

-----------

---------- ----

-------

----------............

---

---------

.....

..... ..

" I

2

Screw --------------------------------------------- 4

Cylinder Holder --------Screw

...... .

........-....-............

Speed Controller ----------------Cylinder

-----------------

-----.............

.. .

-------------

------

---- ----......

.. .

... .. .

.........

--- -- -

......1

1

1

2

Nut ............................................... 1

Bearing

Joint

Pin

Connecting Arm

Screw-----E-ring

--- ---

--------------------------------------

---------------------------------------------

----------------------------------------------

.....................................

----------------------------------------

............................................

1

1

1

1

2

1

Pin ----------------------------------------------- 1

Washer -----------Speed Controller ---------Cylinder -

....................

--- --- -

------

--------- ------....

------....

-........-

................

........... 1

2

2

Nut ................................................ 1

Screw

............

Joint

........

..... ..

.....-.....................

...............-.....

..............

...

1

1

Screw---------------------------------------------- 1

Nut Tension Release Lever---------

............................................

--- --- -

-------

------

1

— 1

Page 20

Page 21

Thread Tension and Motor Components

Ref. No.

1

Part No.

VUTA0501

2

3 VUTA0503

4

5

VMM04281407A

VUTA0505

6 VUTA0506

7 VUTA0507

8

9

10

11

VUTA0508

VUTA0509

VUTA0510

VUTA0511

12 VUTA0512

13 VUTA0513

14

15

16

17

18

19

20

21

VUTA0514

VUTA0515

VUTA0516

VUTA0517

VUTA0518

VUTA0519

VMC04281007A

VUTA0521

Description Q* ty

Thread Guide Eyelet Thread Tension Spring Assanbly Set (See List Below)

Spacer

.....

... .. .

Screw ............

Thread Guide Hook Unit

E-ring

Spring -

................................-......

................-.....-..........

Tension Release Shaft

Pin

---------------- ------

Spring ..........

Guide Bar

Dust Cover

-- -- -

...................................

....-......

........-

....

......

......-....... 1

.. .

..........-.. .. .

.... ... .... ... .-.....-...........

.....

............

.......

..... .

......

------------------------

...

....-------

-------

---------- --------

--------

---1

----

---- --

----------------------------------

---1

.....

-.....1

.....

1

1

2

2

5

1

1

1

Guide ------------------------------------------- 1

Cloth Plate

AC Servo Motor Power Cord

---------------------------------------

.....------

......-------

---------- ---------

------------------------

-- - - -

1

----

1

1

Electromagnetic Valve Cord ------------------------- 1

Synchronizer ----------------------------------- 1

Stopper -------------------------------------------- 1

Screw

-- - - -

Regulator

----

----

--------------

----------

----

— 1

-------------------------------------------

1

2.Thread Tension Spring Assembly Set

Variety

755U200

755U300

756U200

756U300

Part No.

VCTA030610

VCTA030620

VCTA030630

VCTA030640

Page 22

Loading...

Loading...