Page 1

TT700

Mending Machine

TT700 Instruction Manual

Table of Contents | Next Page

Page 2

TT700

TABLE OF CONTENTS

Handy Reference Guide 03

Getting Ready to Mend 07

Winding the Bobbin 08

Inserting the Wound Bobbin 11

Threading the Machine 12

Working Light 13

Raising the Bobbin Thread 14

Mending a Broken Seam 15

Securing a Seam 16

Free Arm Mending 16

Adjusting Tension 17

Changing Needles 18

Bobbin Case Replacement 19

Performance Checklist 25

TT700 Instruction Manual

Even if you have sewn before,

these instructions will make your

first use much easier!

Previous Page | Next Page

Page 3

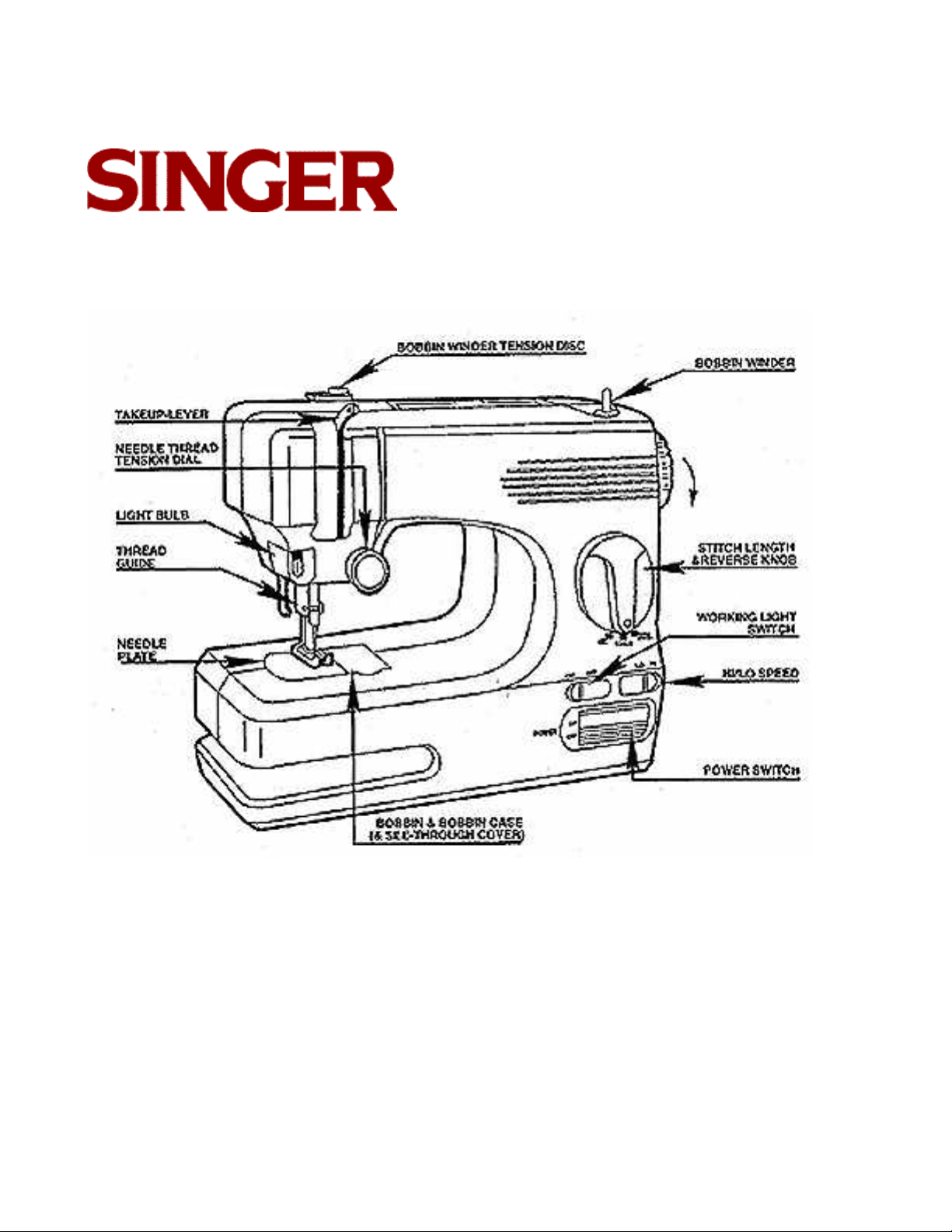

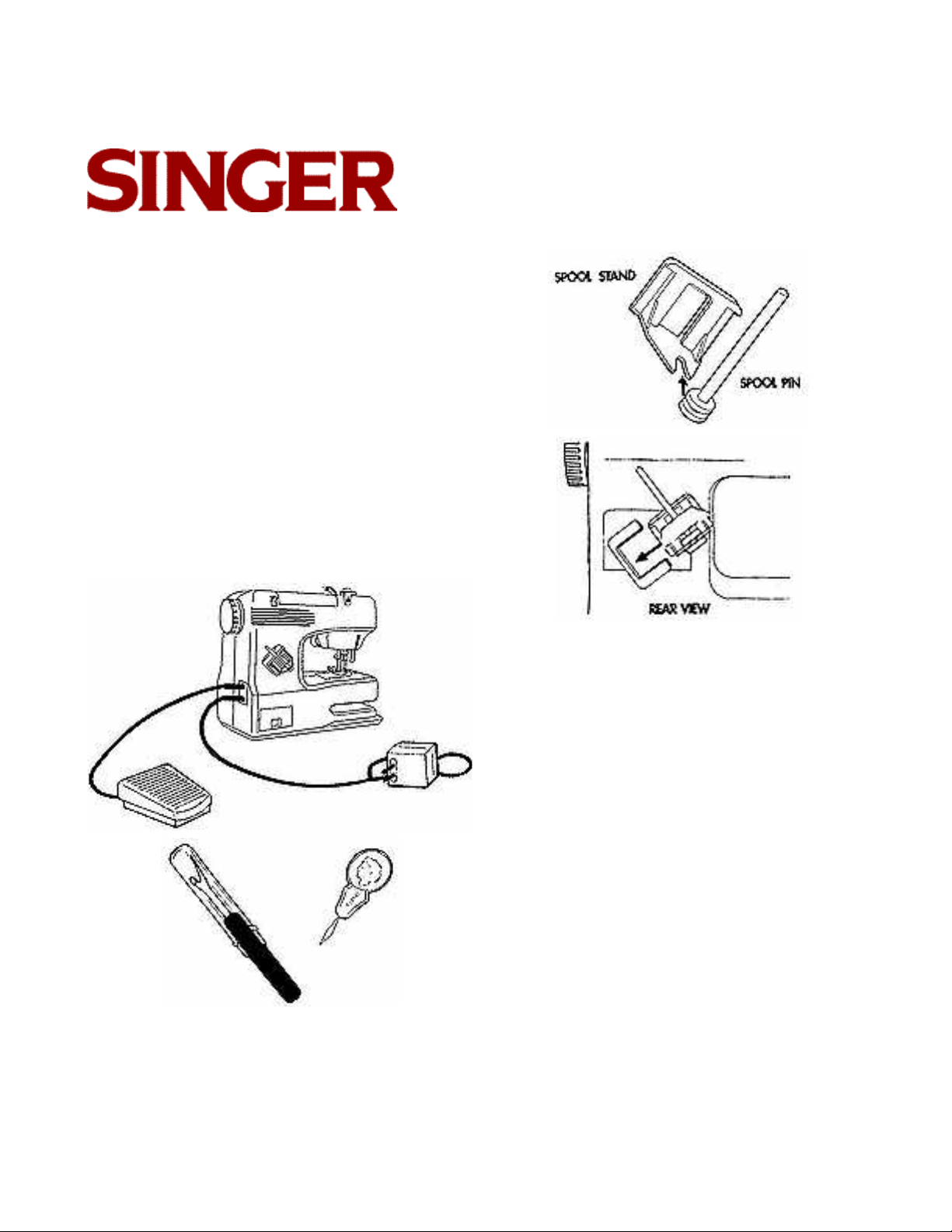

PARTS AND ACCESSORIES

TT700

Table of Contents Previous Page | Next Page

3

Page 4

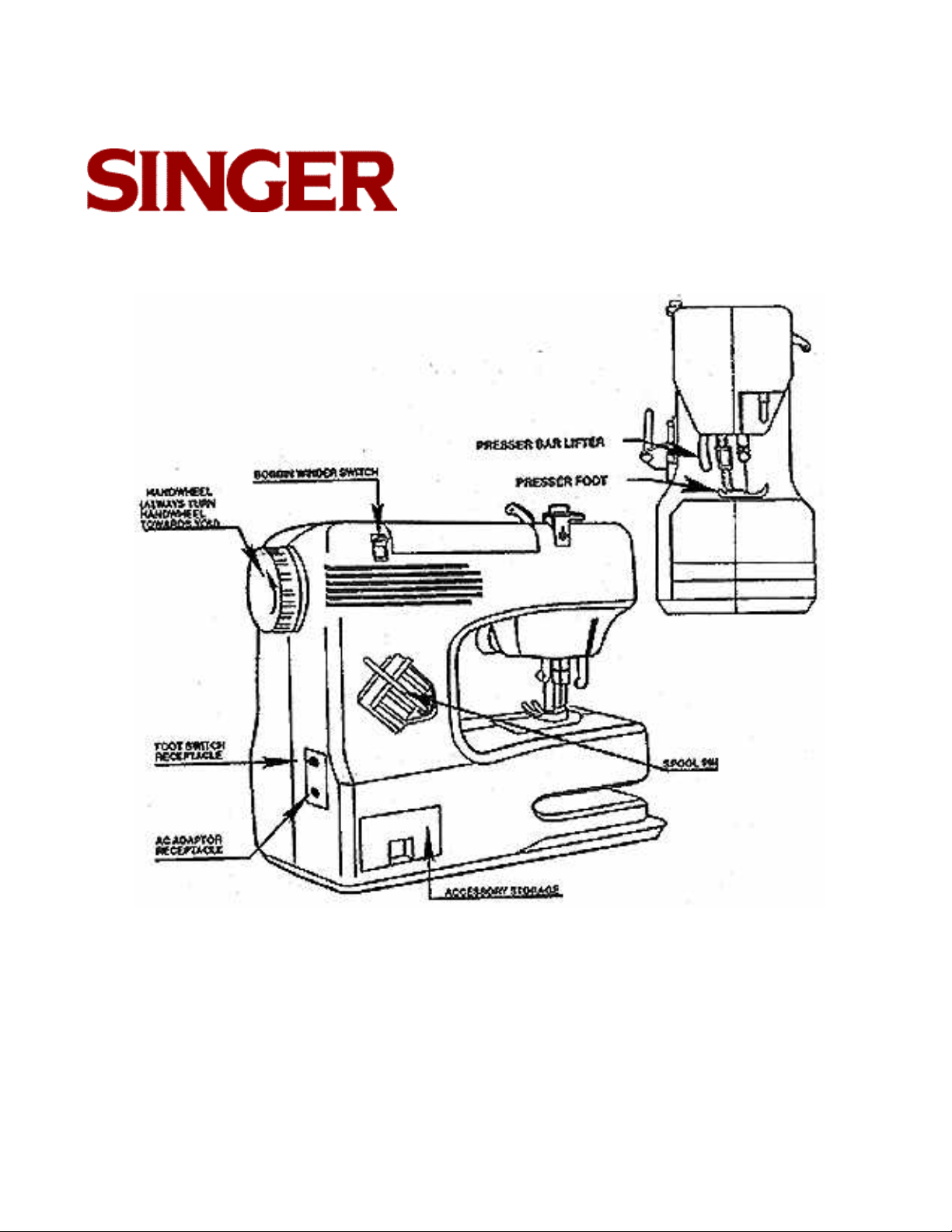

PARTS AND ACCESSORIES

TT700

Table of Contents Previous Page | Next Page

4

Page 5

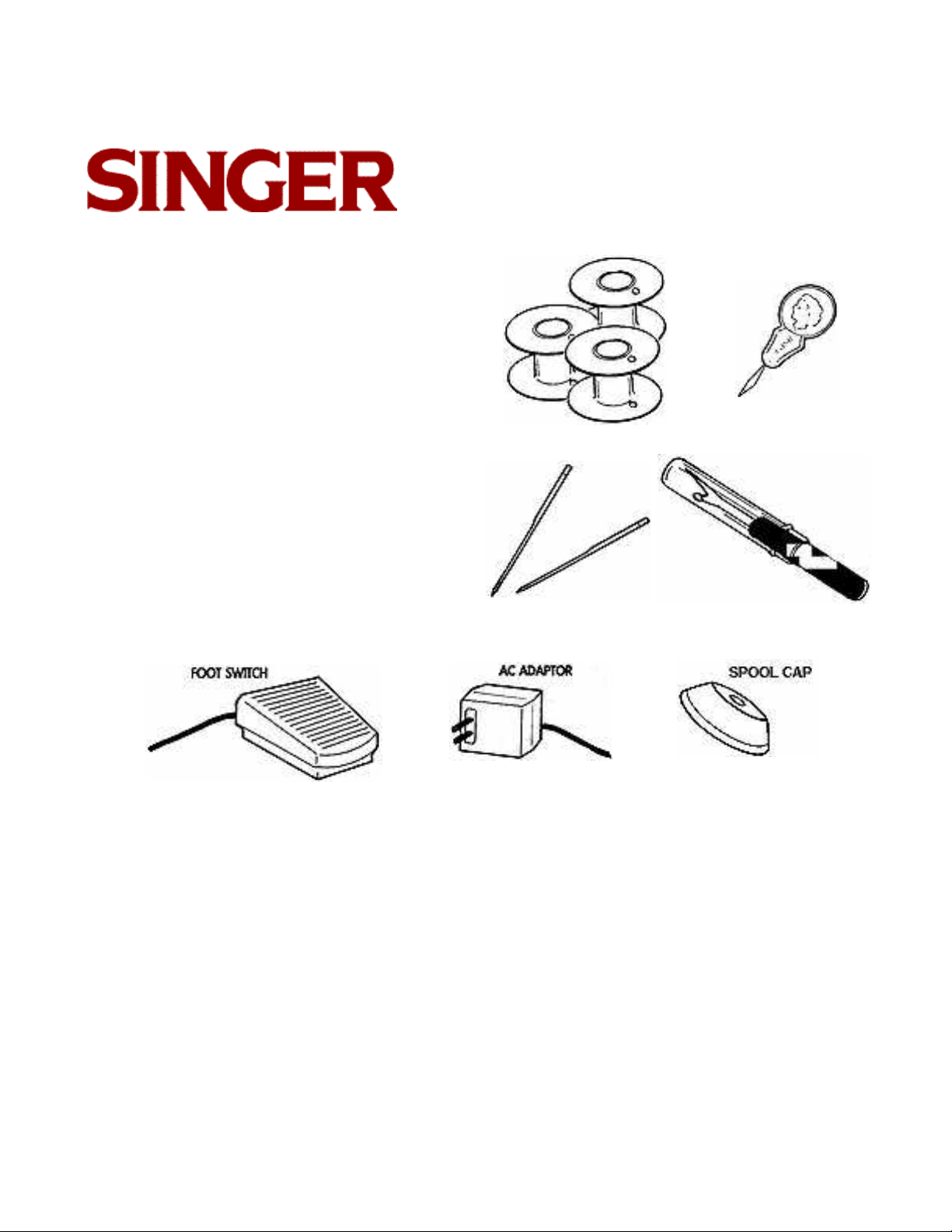

ACCESSORIES INCLUDED

in Accessory Drawer

• 3 Bobbins (1 in machine)

For replacement bobbins,

use Class 66 bobbins

• 1 needle threader

• 2 needles (1 in machine)

For replacement needles,

Use Size 90/14 needles.

• Combination seam ripper/thread

trimmer tool

TT700

Table of Contents Previous Page | Next Page

5

Page 6

TT700

IMPORTANT SAFEGUARDS

• Before connecting machine, be sure that the voltage on the AC adapter

matches your electrical supply.

• Always disconnect the foot switch or AC adapter when changing needles,

removing the bobbin, or cleaning the machine.

• Always disconnect the AC adapter whenever machine is unattended.

• Work carefully and watch the sewing area to avoid the needle during operation.

• Do not pull the fabric while mending as the needle may bend and break or

cause other damage

• Check that the machine is threaded carefully before mending.

• The bobbin case tension is Pre-set at the factory and cannot be adjusted.

• If the thread gathers underneath the material, this indicates that the tension

needs to be increased e.g., for cotton material the tension should be

tightened as far as it will go then turned anti-clockwise 2 and a half turns.

• Please avoid sideways pressure on the needle when sewing around corners

as this could cause the machine to jam and render it inoperative.

Table of Contents Previous Page | Next Page

6

Page 7

TT700

GETTING READY TO MEND

1. Assemble spool holder by snapping spool

pin into spool stand.

2. Slide spool stand into its holder on rear left

of machine, until it snaps firmly into place.

Then install spool cap on spool pin

3. Make sure that power switch is in the ON

position. Plug in foot switch and AC

adapter plugs.

4. Remove red-handled seam ripper/thread

trimmer and needle threader from

accessory drawer.

Table of Contents Previous Page | Next Page

7

Page 8

TT700

WINDING THE BOBBIN

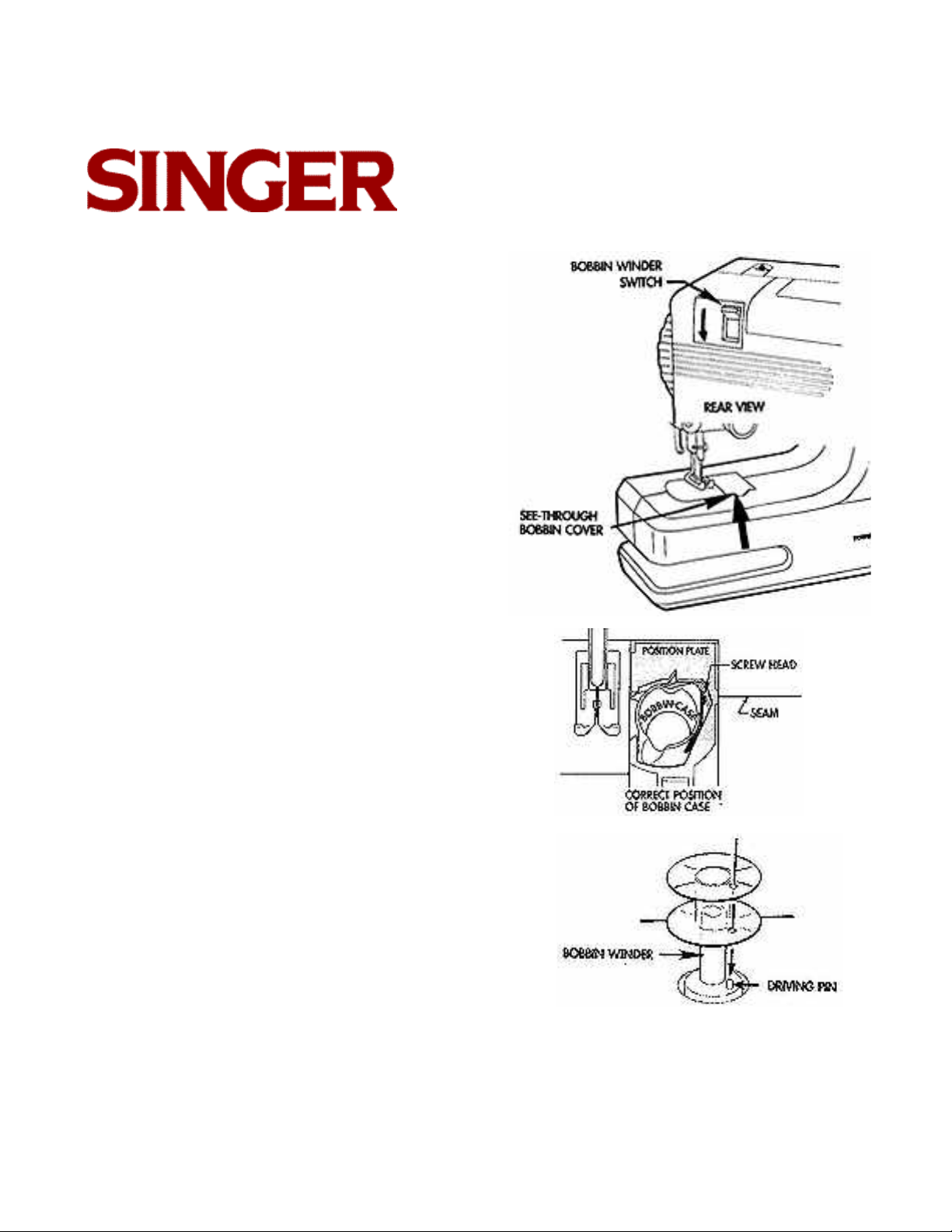

1. Push bobbin winder switch down to raise

bobbin winder.

2. Remove see-through bobbin cover by

pulling it upwards.

Check that bobbin case is in proper position. The bobbin case is held in place by a

position plate which is designed to flex

slightly to allow the bobbin case to move

back and forth freely, about 1/16"

Screw head should line up with seam in

plastic casing of machine and bobbin case

should move back and forth slightly (about

1/16'') when handwheel is turned. If not,

refer to page 17 for repositioning instructions.

3. Remove empty bobbin from bobbin case.

The seam ripper may make removal easier.

Place bobbin on bobbin winder, aligning

hole in bobbin with driving pin on bobbin

winder. You may have to turn the handwheel

to help locate the driving pin.

Table of Contents Previous Page | Next Page

8

Page 9

TT700

WINDING THE BOBBIN continued...

4. Install spool cap on spool pin.

Slide spool of thread onto spool pin.

5. Pull thread from spool and, using two

hands, pull it through diagonal slit in first

thread guide.

First thread guide should look like this

when properly threaded.

6. Wrap thread one time counterclockwise

around tension disc.

Table of Contents Previous Page | Next Page

9

Page 10

TT700

WINDING THE BOBBIN continued...

7. Feed end of thread through small hole in

top of bobbin from the inside, leaving a 3"

tail.

8. Slide power switch into ON Position Hold

end of thread (the "tail") firmly and step

on foot switch until a few coils are wound

onto bobbin and stop.

9. Use thread trimmer to cut off tail, flush

with top of bobbin. Continue winding until

desired amount of thread is wound on

bobbin. A full bobbin holds 35 yards.

10. Cut thread about 4" from bobbin and

remove from machine. Leave spool of

thread on spool pin on back of machine.

Push bobbin winder switch up into off

position.

Table of Contents Previous Page | Next Page

10

Page 11

TT700

INSERTING THE WOUND BOBBIN

1. Insert wound bobbin into bobbin case with

thread spooling off to left side, as shown.

2. Guide end of thread to the back of the

bobbin.

3. Pull the thread toward you so that it hooks

on notch A (at 3 o'clock position) and then

pull to the left so that it passes through

notch B (at 4 o'clock position).

4. Leave several inches of thread laying

across top of bobbin toward the left of

machine. Slide cover back into position

ready for sewing.

Caution: If lower thread is not fixed

properly, the thread will be

very loose after sewing.

Bobbin threading is now complete.

(See Page 9 to raise lower thread for sewing)

Table of Contents Previous Page | Next Page

11

Page 12

TT700

THREADING THE MACHINE

There are five thread guides that the top

(needle) thread passes through. The diagram

at right shows an overview of the threading

procedure; refer to the specific instructions

below for important details.

Your spool of thread should be in the same

position as it was for winding the bobbin, on

the spool pin on the back of the machine. Cut

the thread near the spool and pull the tail out

of the thread guide and tension disc.

1. Pull thread from spool and, using two

hands, pull it through diagonal slit in

thread guide A. Do not wrap thread

around tension disc for sewing.

Thread guide A should look like this

when properly threaded.

2. Guide thread around tension dial B and

Pull thread between the tension discs.

Table of Contents Previous Page | Next Page

12

Page 13

TT700

THREADING THE MACHINE continued...

3. Turn handwheel toward you until take-up

lever is in highest position. Pass thread

through hole in take-up lever C from right

to left.

4. Turn handwheel toward you so that needle

lowers and thread guide D is accessible.

Place thread behind thread guide D to the

right side, and pull forward. The thread

guide will thread itself.

5. Turn handwheel toward you again to raise

needle to its highest position.

Feed wire needle threader through needle

eye from right to left.

Insert thread through wire loop and pull

needle threader back to the right.

The needle is now threaded.

WORKING LIGHT

Slide to "ON" Position for brighter area to

sew.

Table of Contents Previous Page | Next Page

13

Page 14

TT700

RAISING THE BOBBIN THREAD

1. Hold top (needle) thread and turn hand-

wheel toward you until needle goes to its

lowest and then its highest point.

Raise the presser foot using the presser

bar lifter.

2. Gently pull top (needle) thread until lower

(bobbin) thread comes up in form of a

loop.

3. Use the flat side of seam ripper/thread

trimmer to open up bobbin thread loop

until end is visible.

4. Pull both thread tails straight back under

presser foot.

5. Replace see-though bobbin cover by

sliding it back into place.

Table of Contents Previous Page | Next Page

14

Page 15

TT700

MENDING A BROKEN SEAM

1. Set stitch control knob to desired stitch

length. For most mending, the "long stitch"

setting is acceptable.

Turn hand wheel toward you to raise nee-

dle to highest position.

2. Lift presser foot using presser bar lifter.

Make sure that both needle (top) thread

and bobbin (lower) thread are pulled

straight back behind needle about 4".

3. Position area to be mended under presser

foot. Turn handwheel toward you to lower

needle into existing stitches in fabric.

Lower presser foot.

4. Step on foot switch and machine will start

to mend the broken seam. Continue until

new stitches overlap existing stitches by

about an inch and then step off foot switch.

5. Raise presser foot using presser bar lifter

and pull fabric straight back. Cut both

threads about 4" from edge of fabric.

NOTE: If it is difficult to pull thread toward

back without noticeably bending the

needle, a slight backward and forward

movement of the handwheel will

make it easier to remove the fabric.

Table of Contents Previous Page | Next Page

15

Page 16

TT700

SECURING A SEAM

There are two methods of securing the

threads at the start and end of the seam

repair.

METHOD #1: Backstitching

Turn stitch control knob to REVERSE (left)

position and backstitch 4-5 stitches at start

and end of seam repair

METHOD #2: Tying off

When seam is completed, use needle

threader to pull top thread to underside of

fabric. Tie a square knot with the bobbin

thread and trim.

FREE ARM MENDING

A free arm for mending sleeves, Pant legs.

etc. To utilize this handy feature just slip the

item onto the free arm.

Table of Contents Previous Page | Next Page

16

Page 17

TT700

ADJUSTING TENSION

All tension adjustment is accomplished

using the needle thread tension dial.

The bobbin case tension is pre-set at

the factory and cannot be adjusted.

The tension level may be determined by

using two different color threads for the needle and bobbin threads, and then analyzing

the resulting stitches.

When an even amount of thread is exerted

on both threads, a smooth, even stitch known

as a balanced stitch is produced.

A perfect, well balanced stitch will have the

needle and bobbin threads locked between

the two layers of fabric with no loops on top

or bottom and no puckering.

ALWAYS DOUBLE CHECK THREADING

BEFORE ATTEMPTING TO ADJUST

TENSION!

Too much tension will produce a tight stitch,

which will cause the fabric to pucker. To

decrease tension, turn the tension dial

Counter-clock-wise

Too little tension will produce a loose stitch,

which will cause loops in your seam. To

increase tension, turn the dial clockwise

Table of Contents Previous Page | Next Page

17

Page 18

TT700

CHANGING NEEDLES

IMPORTANT: For best results,

Use Size 90/14

needles.

1. Turn handwheel to raise needle to its highest position. Loosen needle clamp screw

just enough to remove needle. A small

screwdriver may be helpful.

2. With flat side of needle to the right (same

side as needle clamp screw), insert new

needle up into clamp as far as it will go.

3. Re-tighten needle clamp.

Table of Contents Previous Page | Next Page

18

Page 19

TT700

BOBBIN CASE REPLACEMENT

A special feature of the machine is the anti-thread jamming bobbin case. The bobbin case is

held in place by a positioning plate which is designed to flex slightly to allow the bobbin case

to move back and forth freely, about 1/16".

In the event that the bobbin case becomes displaced and does not move freely or pops out

completely, follow the three easy steps below. To assist you, the instructions are color coordinated to the illustrations.

STEP 1:

Remove bobbin from bobbin case.

If bobbin case has popped out, put back in

position as follows: Place bobbin case under

position plate so that screw head is under

notch in position plate. Then, slide bobbin

case around until metal bracket sits between

2 o'clock and 4 o'clock positions. Proceed to

step 2.

Table of Contents Previous Page | Next Page

19

Page 20

TT700

STEP 2:

Use left index finger to pull bobbin case

toward the right and up, until lower half of

metal bracket touches angled edge of posi-

tion plate. Rotate handwheel until bobbin

case rests in correct position. Proceed to

step 3.

STEP 3:

Check bobbin case for' proper positioning.

Screw head should line up with seam in plas-

tic casing of machine. From side view, top of

bobbin case will be level with (or slightly

above) position plate.

Table of Contents Previous Page | Next Page

20

Page 21

TT700

SPECIAL EDITION:

BOBBIN CASE REPLACEMENT

The bobbin case actually "floats" on top of the bobbin case housing. The bobbin case

is held in place by a position plate, and can only be removed with extreme pressure.

If for some reason the bobbin case is removed or displaced, follow the three steps below to reinsert.

STEP 1:

• Remove bobbin from bobbin case.

• Put bobbin case intobobbin case housing

• Have point A & B of bobbin case sit on top

of point C & D of position plate (See FIG 1).

• Make sure the screw head aligns

with opposite side of plastic joint

• Do not touch the tension spring.

STEP 3:

• Hold left finger inside bobbin case to hold

steady then with right finger press down

point E (See FIG 3)

• Turn the handwheel to make sure bobbin

case is free and bobbin case housing can

be rotated freely.

Table of Contents Previous Page | Next Page

STEP 2:

• Slightly turn the bobbin case counterclockwise (then clockwise) and position point A

of bobbin case underneath point C of posi-

tion plate Point B remains on top of point D

(See FIG 2).

21

Page 22

TT700

Drawing A

Breakdown view of bobbin case,

position plate and bobbin case housing

Drawing B

• Correct position of bobbin case after

installation.

• The screw head aligns with opposite side

of plastic joint.

• The scoop section located to right side of

point C

Table of Contents Previous Page | Next Page

22

Page 23

TT700

Drawing C

• Wrong position of bobbin case. As indicated, the scoop section will be stuck underneath point C. This is wrong.

Drawing D

• Correct relationship of bobbin case, position

plate and bobbin case housing.

• Most important is that the rim of bobbin

case supported by the rim of bobbin case

housing. The bobbin case is floating on top

of the bobbin case housing and the bobbin

case housing turns easily under the bobbin

case.

Table of Contents Previous Page | Next Page

23

Page 24

TT700

SPECIAL EDITION FOR ADJUSTING TENSION

• Please note the needle thread tension dial can be rotated 9 full circle turns (From MIN to

MAX).

An easy way to have a balanced stitch is to turn the tension dial to the half-way position

(4 or 5 full circle turns from the MIN position).

If you have difficulties in adjusting tension, follow instructions below:

• Turn the tension dial counterclockwise to

MIN position until it stops.

• Turn clockwise & count the number of circles you turn until it reaches 4 or 5 full circle

turns (a half-way position)

• Make a test sample to find proper tension

before sewing on your fabric.

• Some threads and fabrics require readjusting tension slightly to improve stitch appearance.

• Always double check threading before

attempting to adjust thread tension.

• Refer to Page 12, for detail adjusting ten-

sion instructions.

• The bobbin case tension is pre-set at the

factory and cannot be adjusted. DO NOT

TOUCH THE TENSION SPRING.

Table of Contents Previous Page | Next Page

24

Page 25

TT700

PERFORMANCE CHECKLIST

When sewing difficulties occur, refer back to this manual to make sure that you are correctly

following the instructions. If you are still having a problem, the reminders below may help you

correct it. Use only correct needles and bobbins (See Page 2).

Needle does not move

• Is machine connected to electrical supply?

• Is foot switch connected?

• Is bobbin case displaced? (pg. 14)

Needle moves, but stitch is not formed

• Is needle in backwards?

• Is needle defective?

• Is bobbin correctly inserted into bobbin

case?

• Is upper thread tension too tight?

• Is bobbin case properly inserted? (pg. 14)

• Is needle fully inserted into needle clamp?

• Are bobbin and needle correctly threaded?

Needle breaks

• Is needle straight and sharp?

• Is needle correct size?

• Is needle fully inserted into needle clamp?

Bobbin winding difficulties

• Is thread unwinding freely from spool?

• Is bobbin winder engaged?

• Is thread end securely held at start of wind?

• Is thread correctly lead around bobbin

winder tension disc?

Upper thread breaks

• Is machine properly threaded?

• Is thread freely unwinding from spool?

• Is needle size correct for thread?

• Is bobbin rim free of nicks?

Lower thread breaks

• Is bobbin correctly wound?

• Is bobbin correctly inserted into bobbin

case?

• Is bobbin case correctly threaded?

• Is bobbin case properly inserted? (pg. 14)

Skipped stitches

• Is machine properly threaded?

• Is fabric firmly held down?

• Is needle correct style and size?

• Is needle straight and sharp?

Fabric does not move properly

under presser foot

• Is presser foot lowered?

• Is stitch length correctly set?

Table of Contents Previous Page

25

Loading...

Loading...