Page 1

INSTRUCTION MANUAL

HD 6600C • HD 6605C

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

Read all instructions before using this household sewing machine. Keep the instructions at a suitable place

close to the machine. Make sure to hand them over if the machine is given to a third party.

DANGER –TO REDUCE THE RISK OF ELECTRIC SHOCK:

• A sewing machine should never be left unattended when plugged in. The electrical socket, to which the

machine is plugged in should be easily accessible. Always unplug this sewing machine from the electric

outlet immediately after using and before cleaning, removing covers, lubricating or when making any other

user servicing adjustments mentioned in the instruction manual.

WARNING –TO REDUCE THE RISK OF BURNS, FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSON:

• Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized

dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot control free from the accumulation of lint, dust, and loose cloth.

• Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• The foot control is used to operate the machine. Never place other objects on the foot control.

• Do not use the machine if it is wet.

• If the LED lamp is damaged or broken, it must be replaced by the manufacturer or its service agent or a

similarly qualified person, in order to avoid a hazard.

Page 3

• If the cord connected with the foot control is damaged, it must be replaced by the manufacturer or its

service agent or a similarly qualified person, in order to avoid a hazard.

• This sewing machine is provided with double insulation. Use only identical replacement parts. See

instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

FOR CENELEC COUNTRIES ONLY:

This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

The noise level under normal operating conditions is less than 80 dB.

The machine must only be used with foot control of type C-8000 manufactured by Zeng Hsing, Taiwan.

FOR NON CENELEC COUNTRIES:

This sewing machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the sewing machine by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the sewing machine.

The noise level under normal operating conditions is less than 80 dB.

The machine must only be used with foot control of type C-8000 manufactured by Zeng Hsing, Taiwan.

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No ground means

is provided on a double-insulated product, nor should a means for grounding be added to the product.

Servicing of a double-insulated product requires extreme care and knowledge of the system and should be

done only by qualified service personnel. Replacement parts for a double-insulated product must be identical

to those parts in the product. A double-insulated product is marked with the words ‘DOUBLE INSULATION’

or ‘DOUBLE INSULATED’.

Page 4

TABLE OF CONTENTS

INTRODUCTION .................................................. 1

Intended Use...............................................................1

Machine Overview .......................................................1

Needle Area Overview .................................................2

Top of Machine............................................................2

Overview Accessories..................................................3

Included Accessories (Not Pictured)... .................. .......... 3

Presser Feet ...............................................................4

Optional Accessories.............................. ..................... 4

Stitch Overview ...........................................................5

Utility Stitches .......................................................... .5

Decorative Stitches .....................................................6

PREPARATIONS.................................................. 8

Unpacking the Machine................................................8

Connect to the Power Supply .......................................8

Packing Machine after Sewing......................................8

Free Arm/Removable Accessory Tray ...........................9

Presser Foot Lifter .......................................................9

Thread Knife ...............................................................9

Spool Pin ..................................................................10

Wind the Bobbin ........................................................ 11

Insert the Bobbin ....................................................... 11

Thread the Machine...................................................12

Needle Threader .......................................................13

Needles ....................................................................13

Important Needle Information .... ................................. 14

Selection Guide — Needle Size, Fabric, Thread ............. 14

Change the Needle.................................................... 14

Thread Tension ......................................................... 15

Sew without Feed Teeth.............................................15

Presser Foot Pressure ...............................................15

Change the Presser Foot ...........................................16

Operations and Stitch Control Buttons......................... 16

Reverse Button ........ ................................................ 16

Needle Up/Down.......................................... ............ 16

Menu/Sound On/Off ..... .................................... ........ 16

Navigation Arrows ............................... .................... 17

Utility and Decorative Stitches .................................... 17

Stitch Width / Needle Position ............................... ..... 17

Stitch Length ........................................................... 17

Select Stitch ..............................................................17

SEWING............................................................... 18

Sewing .....................................................................18

Start to Sew – Straight Stitch ......................................18

Change Needle Position ............. ................................ 18

Change Sewing Direction........................................... 18

Finish Sewing............................................................19

Straight Stretch Stitch ................................................19

Multi-Step Zigzag Stitch .............................................19

Slant Overedge Stitch ................................................20

Closed Overlock Stitch............................................... 20

Blind Hems ............................................................... 20

Darning and Mending.................................................21

Repair Large Holes ..................... .............................. 21

Repair Tears ........................... ................................. 22

Repair Small Holes . ................................................. . 22

Jeans Hem................................................................ 23

Button Sewing ........................................................... 23

One-Step Buttonhole .................................................24

Sew Zippers .............................................................. 25

Centered Zipper ....................................................... 25

Hand-Look Quilt Stitch ............................................... 26

MAINTENANCE.................................................. 27

Cleaning the Machine ................................................27

Cleaning the Bobbin Area...........................................27

Cleaning under the Bobbin Area ................................. 27

Troubleshooting......................................................... 28

Technical Specification...............................................31

Page 5

INTRODUCTION

Intended Use

Optimal use and maintenance are described in these instructions. This product is not intended for industrial use.

Additional assistance, by region, may be found on the web at www.singer.com.

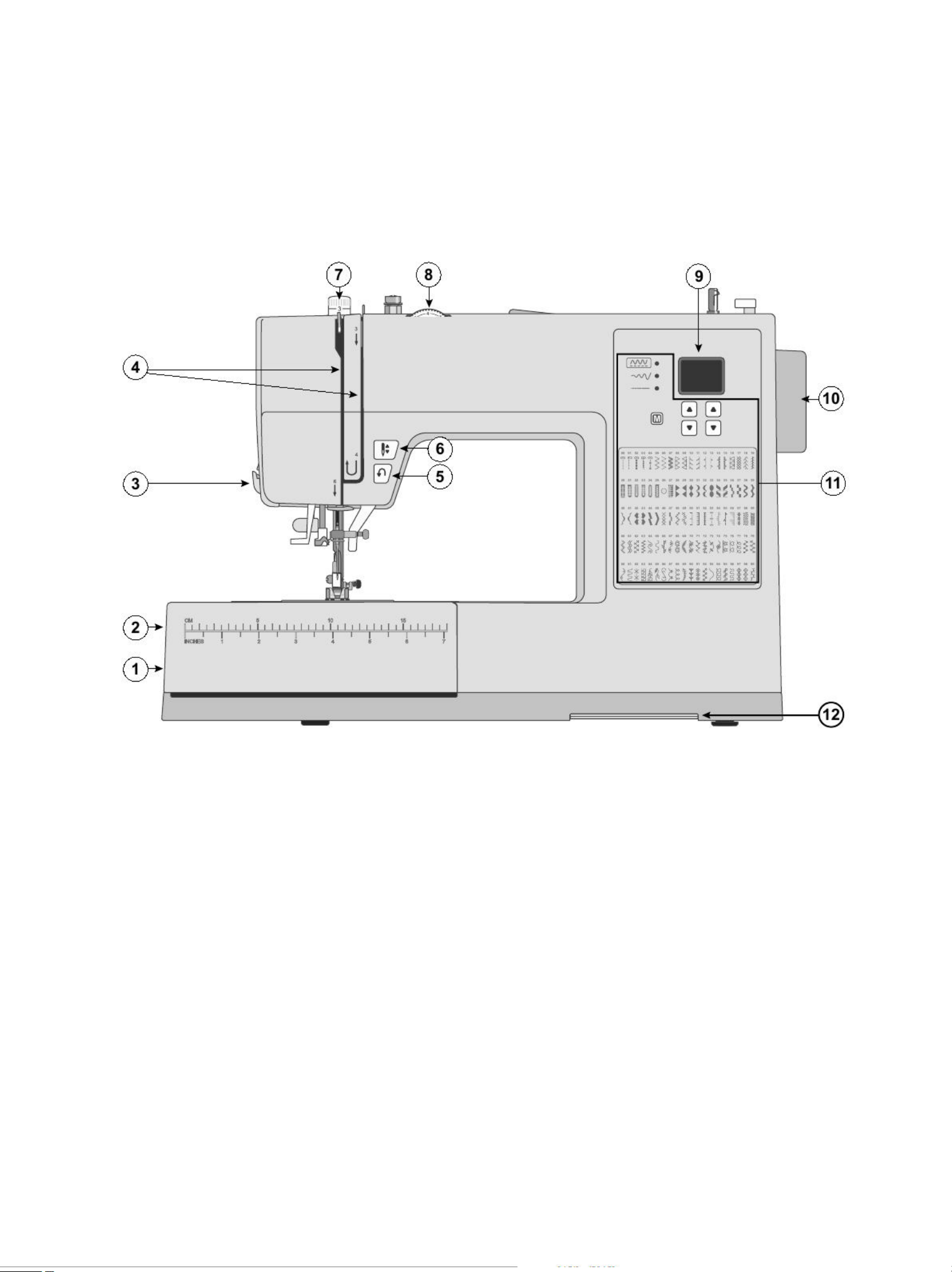

Machine Overview

1. Feed Teeth Lever — move from side to side to engage or

disengage the feed teeth. Positioned at the back of the free

arm.

2. Accessory Tray / Free Arm — provides a flat surface

when sewing and allows storage for your accessories.

Remove the accessory tray to use the free arm which

makes it easier to sew, e.g., trouser hems and sleeves.

3. — for trimming thread ends at the end ofThread Knife

sewing.

4. — thread paths with tension discs andThreading Slots

take up lever.

5. — Press and hold to sew in reverse, e.g.,Reverse Button

when securing the beginning or ending of a seam.

6. — Press to raise and/or lowerNeedle Up/Down Button

the needle.

7. — controls the pressure the presserPresser Foot Pressure

foot exerts onto the fabric.

8. Thread Tension Dial — set the right tension for your

stitch, thread and fabric.

9. — Current stitch and settings are displayed.Display

10. — used to manually control the movement ofHand Wheel

the needle and the thread take-up lever.

11. — Choose menu, select stitch andStitch Control Panel

adjust your stitch settings with these buttons (see page 16

—page 17).

12. —Slide forward to seePresser Foot Recommendation

what presser foot that is recommended for your selected

stitch.

Introduction – 1

English

Page 6

Needle Area Overview

11

9

2

7

3

1

4

5

6

8

12

10

13 14

1. — provides a flat area around presser footNeedle Plate

for sewing. Guide lines make it easy to guide the fabric

straight when sewing.

2. Feed Teeth — feed the fabric under the presser foot when

sewing.

3. — holds fabric against feed teeth whichPresser Foot

draws fabric under the presser foot as you sew.

4. — loosen the screw toPresser Foot Holder Screw

remove the presser foot holder.

5. — holds the presser foot.Presser Foot Holder

6. — press this lever to releasePresser Foot Release Lever

the presser foot from the holder.

7. — used for buttonhole sewing.Buttonhole Lever

8. — thread the needle quicklyBuilt-in Needle Threader

and easily.

9. — accommodates the presser footPresser Foot Bar

holder.

10. — secures the needle.Needle Clamp Screw

11. — helps maintain thread flow when sewing.Thread Guide

12. — helps maintain thread flowNeedle Thread Guide

when sewing.

13. — protects the bobbin while sewing.Bobbin Cover

14. — push to open the bobbinBobbin Cover Release Button

cover.

Top of Machine

6542 7

9 8

1

3

1. Bobbin winding tension disc

2. Thread guides

3. Handle

4. Spool pin

5. Hole for auxiliary spool pin

6. Bobbin winding spindle

7. Bobbin winding stopper

8. Thread tension discs

9. Thread take-up lever

2 – Introduction

English

Page 7

Overview Accessories

Bobbin x4 — Only use the type of transparent bobbins delivered with your machine (SINGER®

Class 15 transparent bobbins). One of the bobbins is inserted in the machine upon delivery.

Felt Pad — Used to cushion the spool of thread when using the Auxiliary Spool Pin.

Spool Cap — Two sizes (large and small) for various thread spool styles.

Auxiliary Spool Pin — For sewing with large thread spools or when using specialty threads.

Brush and Seam Ripper — Used to remove stitches/brush off lint.

L-Screwdriver — Used to remove the needle plate, presser foot holder or needle screw.

Included Accessories

(Not Pictured)

• Needles

• Foot control

• Power cord

• Soft cover

Introduction – 3

English

Page 8

Presser Feet

All Purpose Foot (T)

(attached on the machine upon delivery)

This foot is used for general sewing on most types of fabric. The bottom of the foot is flat, so that the

fabric is held down firmly against the feed teeth while sewing. It also has a wide slot so that the needle

can move from left to right, depending on which stitch you sew.

The foot has a “lock in place” button, the button is pushed to lock the foot in horizontal position when

sewing over thick seams (see page 23).

F

Blind Hem Foot (F)

The Blind Hem Foot is used for sewing blind hems in fashions and home decor. There is an adjustable

guide with an extension at the front, used to guide the fold of the hem while stitching.

Zipper Foot (I)

This foot is used for inserting zippers. Attach the foot to the presser foot holder on either side of the

foot, depending on which side of the zipper is being sewn. The Zipper Foot can also be used to create

and insert piping.

One–Step Buttonhole Foot (D)

This foot allows you to make perfectly sized buttonholes for your button. It has a space at the back for

a button, used to set the size of the buttonhole. The machine will automatically sew a buttonhole to fit

that button size.

Satin Stitch Foot (A)

This foot is used for satin stitches and other decorative stitches.

Optional Accessories

Additional optional accessories are available for your machine. Visit the SINGER® website for more information.

4 – Introduction

English

Page 9

Stitch Overview

Utility Stitches

The stitches described in the below chart are utility stitches, used mainly for utility sewing.

The stitches available on your machine are printed on the front of the sewing machine.

When sewing, use a thread tension between 3–5. Always test sew on a piece of scrap fabric, and adjust the tension if necessary.

Application

Straight Stitch

Center Position

The basic stitch used for sewing. The most common use for a straight stitch is to sew

two pieces of fabric together.

Straight Stitch

Left Position

For all types of sewing.

Straight Stretch

Stitch

Stronger than a regular straight stitch, on stretch knit fabrics, because it locks three

times — forward, backward and forward again. Use it to reinforce seams of

sportswear and for curved seams which take a lot of strain.

Stretch Stitch For seams in tricot and stretch fabrics.

Zigzag Stitch A very versatile stitch for decorative sewing, applique and attaching ribbons and

trims.

Multi-Step

Zigzag Stitch

Finish seam allowances to prevent the fabric from unravelling. When seam finishing,

the smaller step of the stitches will help keep fabric more flat than a regular zigzag.

It can also be used for mending tears and sewing elastic.

Reinforced

Zigzag Stitch

For joining fabric edge to edge or overlapping in leather. For decorative sewing.

Overlock Stitch Sew seam and overcast in one step along the edge or trim later. For medium and

medium/heavy stretch fabrics.

Blind Hem

Stitch

F

Sew hems that are practically invisible from the right side of the fabric. It is used for

skirts, dresses, trousers, curtains etc, made with non-stretch fabrics.

Stretch Blind

Hem Stitch

F

Sew hems that are practically invisible from the right side of the fabric. It is used for

garments and other projects made with stretch knit fabrics.

Slant Overedge

Stitch

Seam and overcast in one step along the edge or trim later. For medium and heavy

stretch fabrics.

Introduction – 5

English

Page 10

Closed

Overlock Stitch

Sew decorative hems and overlapped seams, belts and bands. For medium/heavy

stretch fabrics.

Honeycomb

Stitch

For elastic insertion, decorative stitching, smocking, couching and hemming.

Buttonhole Sew buttonholes on home decór, garments, crafts and more.

Rounded

Bartack

Buttonhole,

Reinforced

For light weight fabrics.

Keyhole

Buttonhole

Square end for tailored jackets, coats, etc.

Keyhole

Buttonhole,

Reinforced

Square end for tailored jackets, coats, etc.

Keyhole

Buttonhole,

Tapered

Tapered end for tailored garments.

Stretch

Buttonhole

For stretch fabrics.

Darning Stitch Darn and mend small holes in work clothes, jeans, tablecloths and linen towels.

Button Sewing

Stitch

-

For sewing on buttons.

Decorative Stitches

Your machine also features decorative stitches. The stitches not described in the previous chart are decorative stitches. When

sewing the decorative stitches, make sure to use a stabilizer underneath the fabric for better appearance. Use a thread tension

between 3–5. Always test sew on a piece of scrap fabric, and adjust the tension if necessary.

6 – Introduction

English

Page 11

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

Stitch Overview

Introduction – 7

English

Page 12

PREPARATIONS

Unpacking the Machine

1. Place the box on a steady, flat surface. Lift the machine out of the box, and remove the packaging.

2. Remove all outer packing material and the plastic bag.

3. Wipe off the machine with a dry cloth to remove any lint and/or excess oil around the needle area.

Note: Your sewing machine is adjusted to provide the best stitch result at normal room temperature. Extreme hot and cold

temperatures can affect the sewn result.

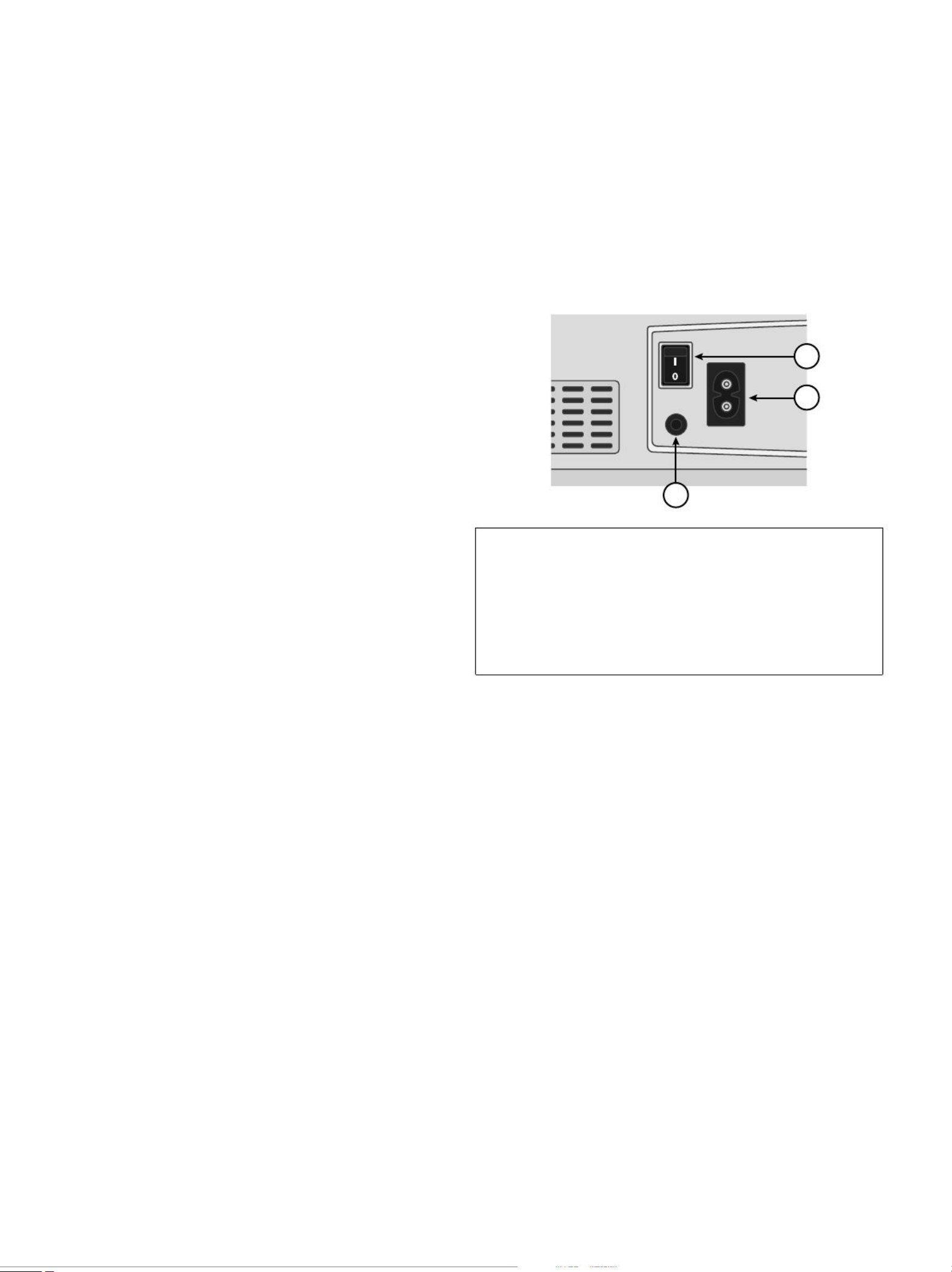

Connect to the Power Supply

A

B

C

For the USA and Canada

This sewing machine has a polarized plug (one blade wider

than the other). To reduce the risk of electric shock, this plug

is intended to fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install the

proper outlet. Do not modify the plug in any way.

Among the accessories you will find the power cord and the

foot control.

Note: Consult a qualified electrician if in doubt as how to

connect the machine to the power source. Unplug the power

cord when the machine is not in use.

For this sewing machine, foot control model C-8000

manufactured by Zeng Hsing, Taiwan must be used.

On the bottom right side of the sewing machine, you find the

connecting sockets and the ON/OFF button.

1. Connect the foot control cord to the front socket on the

bottom right side of the machine (A).

2. Connect the power cord to the rear socket on the bottom

right side of the machine (B). Plug the cord into the wall

socket.

3. Press the ON/OFF switch (C) to "I" to turn on power and

light.

The sewing speed is regulated by pressing the foot control.

Note: After turning off the machine, residual power may

remain in the machine. This could cause the light to stay on for

a few seconds while the power is consumed. This is normal for

an energy efficient appliance.

Packing Machine after Sewing

1. Switch the main switch off. After switching off, residual power may still remain in the machine. This may cause the light to

stay on for a few seconds while the power is consumed. This is normal behavior for an energy efficient appliance.

2. Unplug the cord from the wall socket and then from the machine.

3. Wind the cord around the foot control for easy storage.

4. Place all accessories in the accessory tray. Slide the tray on to the machine around the free arm.

5. Place the foot control and cord in the space above the free arm.

6. Place the soft cover on the machine to help protect it from dust and lint.

8 – Preparations

English

Page 13

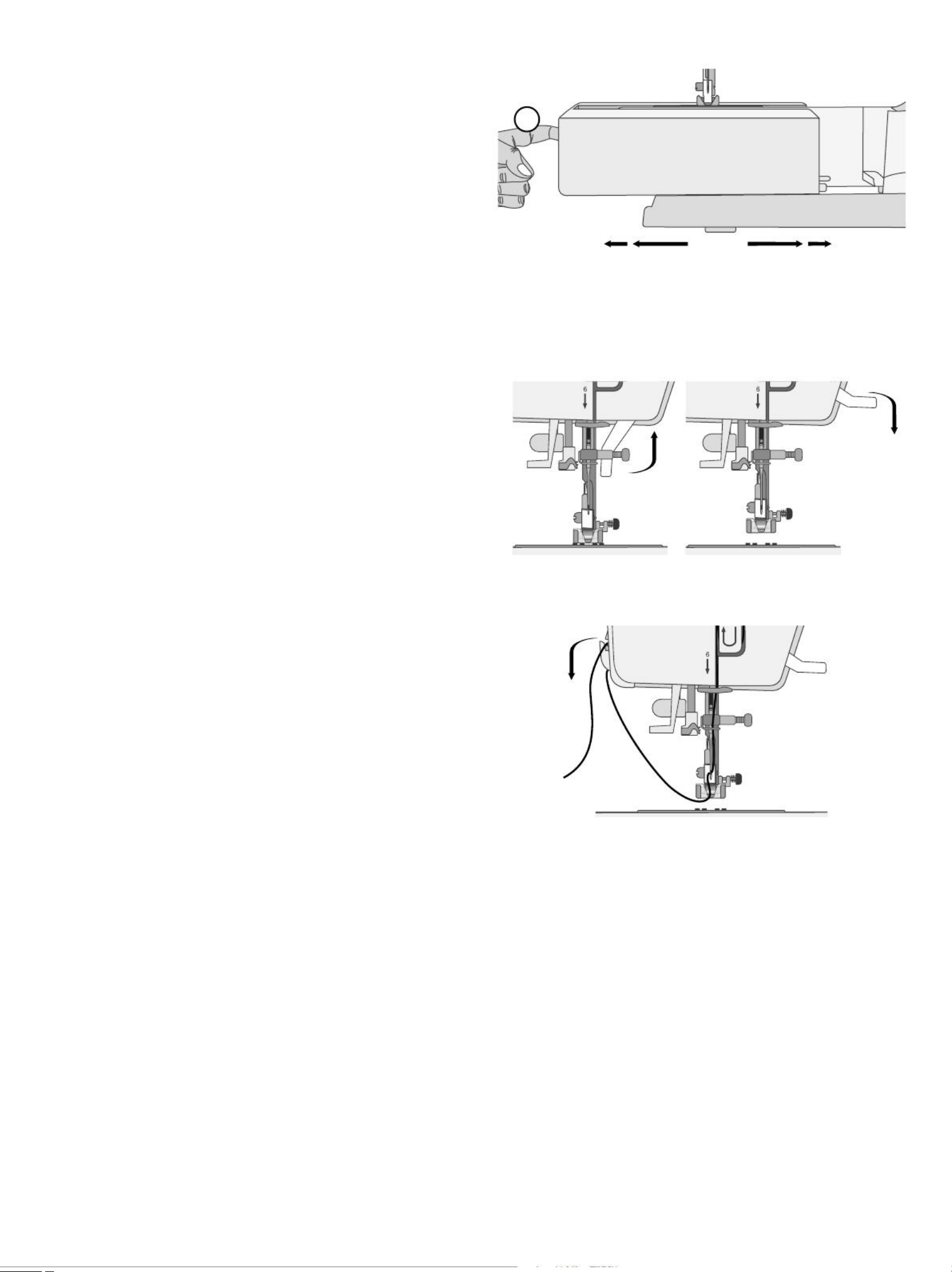

Free Arm/Removable Accessory Tray

A

Store presser feet, bobbins, needles and other accessories in

the accessory tray so that they are easily accessible.

Keep the accessory tray on the machine to provide a larger, flat

work surface.

Use the free arm to facilitate sewing trouser legs and sleeve

hems. To use the free arm, slide off the accessory tray. When

attached, a hook keeps the accessory tray securely attached to

the machine. Remove the tray by sliding it to the left.

When the accessory tray is removed from the machine, open

the door by putting a finger in the groove at the left side of the

accessory box (A) and carefully pull it open. Push the door

closed before putting the tray back onto the machine.

Presser Foot Lifter

The presser foot lever is located at the right side of the sewing

machine head. The lever is used to raise and lower the presser

foot. Raise the lever up for machine threading, lower it for

sewing.

By raising the presser foot lever and then pressing it farther

upwards, the lift height of the presser foot is increased to an

extra height allowing you to slide very thick projects under the

foot.

Thread Knife

To use the thread knife, pull the thread from back to front as

illustrated. Doing this will leave the thread ends long enough

so that the needle doesn't become unthreaded when you start to

sew again.

Preparations – 9

English

Page 14

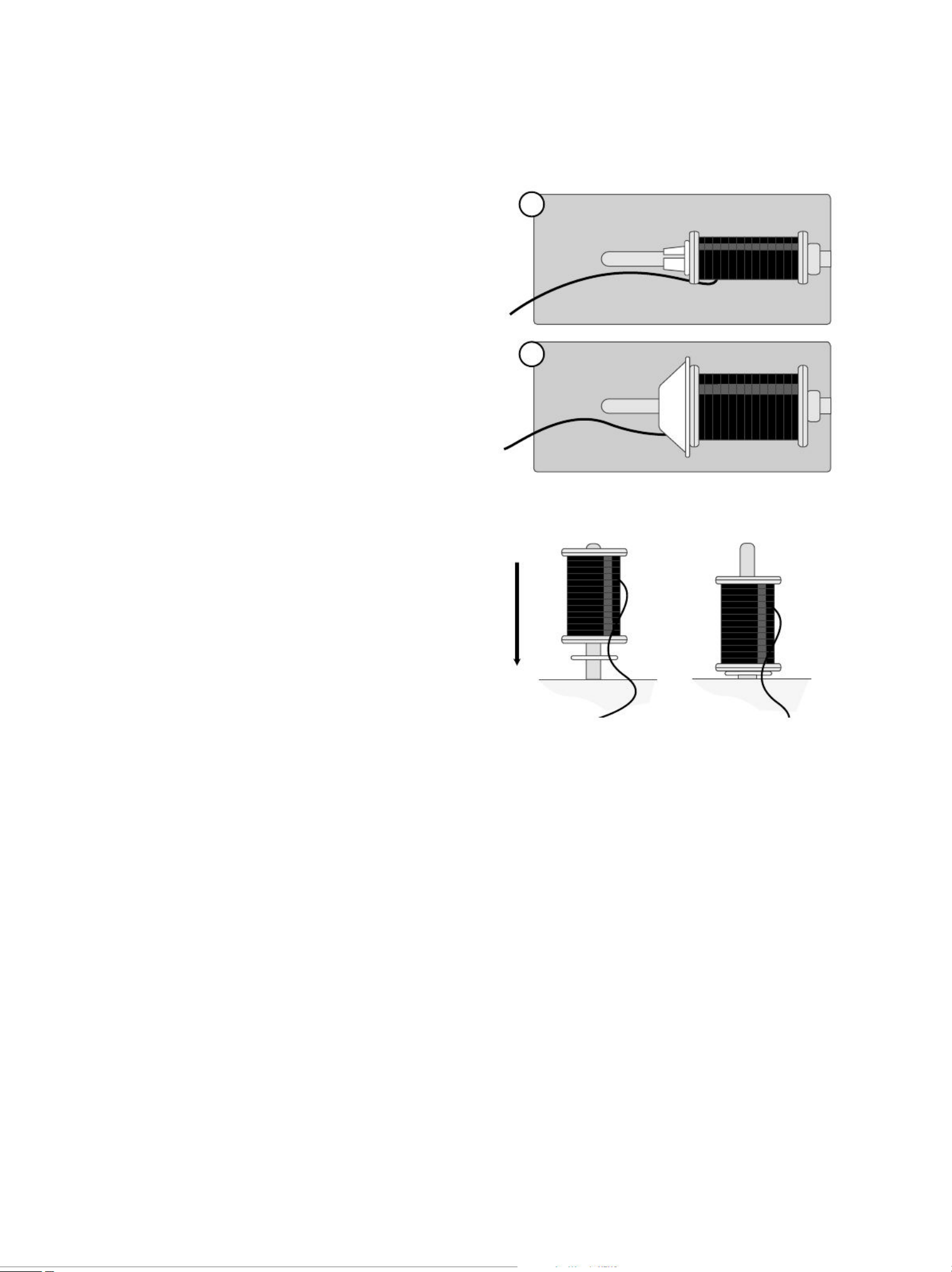

Spool Pin

Your machine has two spool pins, a main spool pin and an Auxiliary Spool Pin. The spool pins are designed for all types of thread.

The main spool pin is used in a horizontal position (the thread reels off the spool) and the Auxiliary Spool Pin in a vertical position

(the thread spool rotates). Use the horizontal position for normal threads and the vertical position for large spools or specialty

threads.

Main Spool Pin

A

B

Place the thread spool on the spool pin. Make sure that the

thread reels off the spool counter clockwise and slide on a

spool cap. Use a spool cap slightly larger than the thread spool.

For narrow thread spools (A), use a smaller spool cap in front

of the spool. For large thread spools (B), use a larger spool cap

in front of the spool. The flat side of the spool cap should be

pressed firmly against the spool. There should be no space

between the spool cap and the thread spool.

Note: Not all thread spools are manufactured in the same way.

If you experience problems with the thread, turn it in the

opposite way or use the vertical position.

Auxiliary Spool Pin

The Auxiliary Spool Pin is used when winding a bobbin thread

from a second spool of thread or when sewing with large

spools or with specialty threads. Insert the Auxiliary Spool Pin

into the designated hole at the top of the machine. Place a felt

pad under the thread spool. This is to prevent the thread from

reeling off too fast. Do not place a spool cap on top of the

spool pin as that would prevent the spool from rotating.

10 – Preparations

English

Page 15

Wind the Bobbin

1. Place the thread spool on the spool pin. Slide a spool cap

firmly against the spool.

2. Place the thread into the thread guide (A) from front to the

back. Bring the thread clockwise around the bobbin

winding tension disc (B), making sure that the thread is

pulled snuggly between the discs.

3. Thread through the hole in the bobbin (C) from the inside

to the outside.

4. Place the bobbin on the bobbin winding spindle. Make sure

the bobbin is pushed down firmly.

5. Push the bobbin winding spindle to the right. Hold the

thread end, and press the foot control to start winding.

After a few turns, take your foot off the foot control to stop

winding. Cut the excess thread tail above the bobbin,

making sure to trim it close to the bobbin. Step on the foot

control to resume winding. When the bobbin is full, the

bobbin winding will slow down and stop automatically.

When the winding spindle is pushed to the right, a bobbin

winding icon is shown on the display.

6. Push the bobbin winding spindle to the left. Remove the

bobbin and cut the thread.

Note: When the bobbin winding spindle is pushed to the right, the machine will not sew. Make sure to push the bobbin spindle back

to the sewing position (left) before sewing.

Insert the Bobbin

Note: Make sure that the needle is fully raised and the

machine is turned off before inserting or removing the bobbin.

1. Remove the bobbin cover (A) by pushing the small button

to the right of the cover (B) towards the right.

2. Insert the bobbin in the bobbin case with the thread

running in a counterclockwise direction.

3. With the tip of your finger on the bobbin, pull the thread

slightly to the right and under the guide (C) then towards

the left.

4. Continue guiding the thread up toward the left and around

the curve (D).

5. Bring it down the channel toward the front and into the

bobbin thread knife (E).

Replace the bobbin cover and pull the thread to the right to

cut off the excess thread.

Preparations – 11

English

Page 16

Thread the Machine

C

A

D

B

Machine from above

Machine from front

Important! Make sure that the presser foot is raised and the

needle is in its highest position by turning the handwheel

toward you. This is very important to help ensure that the

machine is correctly threaded. Not doing so can result in poor

stitch quality when you start to sew.

1. Place the thread on the spool pin and fit the appropriately

sized spool cap.

2. Pull the thread into the thread guide (A) from front to the

back and thread guide (B) from back to front. Pull the

thread between the tension discs (C).

3. Continue bringing the thread down through the right

threading slot, around the U-turn, then back upwards

through the left threading slot.

4. Bring the thread from the right into the take-up lever (D)

and down in the left-hand threading slot, into the lower

thread guide (E) and to the needle thread guide (F).

5. Thread the needle from front to back.

12 – Preparations

English

Page 17

Needle Threader

C

A

B

D

The built-in needle threader allows you to thread the needle

quickly and easily.

The needle must be in its highest position to use the built-in

needle threader. Turn the hand wheel towards you until the

needle is in its highest position, or press the needle up/down

button. It is also recommended that you lower the presser foot.

• Use the handle (A) to pull the needle threader all the way

down. The metal flanges cover the needle. A small hook

will pass through the needle eye (B).

• Place the thread from the back over the thread guide (C)

and under the small hook (D).

• Let the needle threader gently swing back. The hook pulls

the thread through the needle eye and forms a loop behind

the needle. Pull the thread loop out behind the needle.

• Raise the presser foot and place the thread under it.

• Pull out about 6–8” (15–20cm) of thread beyond the needle

eye. This will prevent the machine from coming unthreaded

when you start to sew.

Note: The needle threader is designed to be used for size 70110 needles. You cannot use the needle threader for size 60

needles or smaller, wing needles or twin needles. There are

also some optional accessories that require manual threading

of the needle. When threading the needle manually, make sure

that the needle is threaded from front to back.

Needles

The sewing machine needle plays an important role in successful sewing. Use only quality needles. We recommend needles of

system 130/705H. The needle package included with your machine contains needles of the most frequently used sizes.

Be sure to match the needle to the thread you are using. Heavier threads require a needle with a larger needle eye. If the

needle eye is too small for the thread the needle threader may not work properly.

Universal Needle

Universal needles have a slightly rounded point and come in a variety of sizes. For general sewing in a

variety of fabric types and weights.

Stretch Needle

Stretch needles have a ball point and a special scarf to eliminate skipped stitches when there is a flex

in the fabric. For knits, swimwear, fleece, synthetic suedes and leathers.

Denim Needle

Denim needles have a sharp point to penetrate tightly woven fabrics without deflecting the needle. For

canvas, denim, microfibers.

Embroidery Needle

Embroidery needles have a special scarf, a slightly rounded point and a slightly larger eye to avoid

damage to thread and materials. Use with metallic and other specialty threads for embroidery and

decorative sewing.

Wing Needle

Wing needles have wide extensions on each side of the needle to poke holes in the fabric when sewing

entredeux and other hemstitches on natural fiber fabrics.

Preparations – 13

English

Page 18

Important Needle Information

A

B

C

Change the needle often. As a general rule,

needles should be changed every 6-8 hours of

actual stitching time.

Always use a straight needle with a sharp point and make sure

the point is not bent or damaged (A).

A damaged needle (B) can cause skipped stitches, breakage or

snapping of the thread. It can also damage the needle plate.

Do not use asymmetrical twin needles (C), they can damage

your sewing machine.

Selection Guide — Needle Size, Fabric, Thread

Needle Size Fabric Thread

70–80 (9–11) Lightweight fabrics: Fine cotton, voile, silk, muslin,

interlock, tricot, jersey, crepe, polyester, chiffon, organza,

organdy

Light duty all purpose thread

80-90 (11-14 ) Medium weight fabrics: Quilting cotton, satin, double knit,

lightweight wool, rayon, polyester, lightweight linen

Use polyester threads on synthetic fabrics and

all-purpose or cotton thread on natural fabrics

for best results.

90 (14) Medium weight fabrics: Firm woven, medium weight

linen, cotton/polyester blend, terrycloth, chambray,

double knit

100 (16) Heavy weight fabrics: Canvas, wool, denim, home decor,

fleece, heavy knit

110 (18) Heavy weight fabrics: Coat weight wool, upholstery

fabrics

Heavy duty thread for needle, with all-purpose

thread for the bobbin.

Change the Needle

1 2

3 4

Note: Before you begin changing the needle, it can be helpful

to place a small piece of paper or fabric underneath the needle

area, over the hole in the needle plate, so that the needle

doesn't accidentally fall down into the machine.

1. Loosen the needle clamp screw. If it feels tight, use the

screwdriver from your accessories to aid with loosening

the screw.

2. Remove the needle.

3. Push the new needle upwards into the needle clamp with

the flat side away from you.

4. When the needle will go up no further, tighten the screw

securely.

14 – Preparations

English

Page 19

Thread Tension

A

B

C

To set the thread tension, turn the dial on top of the machine.

Depending on the fabric, thread, etc, the tension may need to

be adjusted. For the best stitch appearance and durability,

make sure the needle thread tension is correctly adjusted. For

general sewing, the threads evenly meet between the two

layers of fabric (A).

If the bobbin thread is visible on the top side of the fabric, the

needle thread tension is too tight (B). Reduce the needle thread

tension.

If top thread is visible on the underside of the fabric, the

needle thread tension is too loose (C). Increase the needle

thread tension.

For decorative stitches and buttonholes, the top thread should

be visible on the underside of the fabric.

Make a few tests on a scrap piece of the fabric you are going to

sew and check the tension.

Sew without Feed Teeth

21

When sewing on buttons or doing other sewing techniques

where you don't want the fabric to feed, you need to lower the

feed teeth.

The feed teeth lever is found at the back of the free arm.

1. Lower the feed teeth by moving the lever to the “Feed

Teeth Down” position.

2. Raise the feed teeth by moving the lever to the “Feed Teeth

Up” position.

Note: The feed teeth will not raise immediately when the lever

is switched. Turn the hand wheel toward you one full turn or

start sewing to re-engage the feed teeth.

Presser Foot Pressure

The presser foot pressure is used to control the amount of

pressure that the presser foot exerts onto the fabric, to ensure

smooth feeding of the fabric while sewing. The presser foot

pressure has been pre-set to the standard value "2". Though it

needs no adjustment for most fabrics, it can be adjusted for

very thick or very thin fabric - increase for heavy weight

fabrics, decrease for lightweight fabrics.

Note: If the dial is turned counterclockwise too much, it could

come off. If this happens, simply replace the dial and turn it

clockwise until it stays in place.

Note: If the dial is turned clockwise until it comes to a stop, it

has reached the maximum pressure available. Do not try to

turn the dial any further!

Preparations – 15

English

Page 20

Change the Presser Foot

1. Make sure that the needle is in the highest position and the

presser foot is lifted. The presser foot release lever extends

out the back of the presser foot holder. Press this lever to

release the presser foot.

2. To attach a presser foot to the holder, place the desired

presser foot with its pin directly under the slot in the

presser foot holder. Lower the presser foot lifter and the

presser foot will snap into place.

Note: If you find it difficult to place the presser foot in the

correct position, keep the release lever pressed while

lowering the presser foot. Use your thumb to carefully

guide the presser foot into the correct position and it will

snap into place.

Operations and Stitch Control Buttons

The Machine Operation Controls are used to operate the machine, and are found on the sewing head of the machine. On the Stitch

Control Panel (next to the display) you find buttons used to adjust and select stitches.

Each functionality is listed and described further below.

Reverse Button

The Reverse Button has different functionality depending on what stitch that is selected.

Stitch 00–05

Press and hold the Reverse button to sew in reverse. Release it to resume sewing forward. The machine sews in

reverse only as long as the reverse button is pressed.

Stitch 06–19, 28–99

Press the Reverse button and the machine sews 3 tie-off stitches then stops automatically.

Reverse has no functionality for buttonholes, darning and button sewing stitches.

Needle Up/Down

Press Needle Up/Down to move the needle down or up. You can also tap the foot control to raise or lower needle.

Menu/Sound On/Off

Press to toggle between the Menus. There are three menus, Utility/Decorative Stitches, Stitch Width and Stitch

Length. When a menu is selected, a light next to the icon becomes lit.

This button is also used to turn off the machine sound. Press and keep depressed for 2 seconds with the machine

turned on, when an audio beep is heard, the sound is turned off. Press for 2 seconds until two audio beeps are

heard and the sound is turned back on. The setting remains even if the machine is turned off.

16 – Preparations

English

Page 21

Navigation Arrows

Press the up and down arrows to select stitch and/or to adjust the stitch settings.

The left set of arrows change the left number on the display and the right arrows changes the right number.

Note: Make sure that the correct menu is selected before using the selection arrows. A light next to the menu is lit

when a menu is active.

Utility and Decorative Stitches

Select this menu for sewing. The stitches included in your machine are pictured on the machine. Next to each

stitch is a number, this is the number used to select the stitch.

Stitch Width / Needle Position

Select this menu to adjust the stitch width of the selected stitch.

When you select a stitch, your machine automatically sets the best stitch width. The default setting is indicated on

the display. The stitch width can be adjusted between 0–7mm. Some stitches have a limited stitch width. Increase

the stitch width by pressing “up”, decrease it by pressing “down”.

When a straight stitch or a reinforced straight stitch is selected, the Stitch Width button is used to adjust the

needle position. When pressing “up”, the needle position is moved to the right. When pressing “down”, the

needle moves to the left. Center needle position is set when the stitch width is 3.5.

Stitch Length

Select this menu to adjust the stitch length of the selected stitch.

When you select a stitch, your machine automatically sets the best stitch length. The default setting is indicated

on the display. The stitch length can be adjusted between 0–4.5mm. Some stitches have a limited stitch length.

Increase the stitch length by pressing “up”, decrease it by pressing “down”.

Select Stitch

When you turn on your machine, the Utility and Decorative

Stitch Menu is active. This is indicated by the light, next to the

menu icon (A). Straight stitch (stitch no.00) (B) is selected by

default.

The stitches are printed on the machine. The Stitch Number is

printed above the picture of respective stitch (C).

Press the up and down arrows to select stitch. The left set of

arrows change the left number on the display and the right

arrows changes the right number (D).

Each stitch has a pre-set stitch length and width. At the bottom

right of the machine, you can slide forward a chart showing

what presser foot that is recommended for each stitch.

Preparations – 17

English

Page 22

SEWING

Sewing

A. Stitch

B. Presser foot

C. Stitch width in mm

D. Stitch length in mm

E. Thread tension

Next to each stitch or sewing technique described in this

section of the manual is a chart showing the recommended

settings and presser foot. See sample of the chart to the right.

Note: Some fabrics have a lot of excess dye which can cause

discoloration on other fabric but also on your sewing machine.

This discoloring may be very difcult or impossible to remove.

Fleece and denim fabric in especially red and blue often

contain a lot of excess dye. If you suspect that your fabric/

ready-to-wear garment contains a lot of excess dye, always

pre-wash it before sewing to avoid the discoloring on your

machine.

Note: For best sewing result, use the same thread on top and

bobbin. If sewing with specialty/decorative threads, use

regular sewing thread in the bobbin.

Start to Sew – Straight Stitch

3.5 2.0–4.0 3–5

Set up for straight stitch

Set your machine for straight stitch (see chart to the right).

Raise the presser foot and position the fabric under it, next to a

seam allowance guide line on the needle plate. On the bobbin

cover there is a 1/4" (6mm) guide line.

Place the top thread underneath the presser foot.

Lower the needle to the point where you want to start. Bring

the threads toward the back and lower the presser foot. Press

the foot control. Gently guide the fabric along the seam guide

letting the machine feed the fabric (A). If the bobbin thread

isn’t pulled up, it will be automatically as you start to sew.

To secure the beginning of a seam, press and hold the reverse

button. Sew a few reverse stitches. Release the reverse button

and the machine will sew forward again (B).

Change Needle Position

Some sewing is done more easily by changing the needle

position, e.g., topstitching a collar or sewing in a zipper. The

needle position is adjusted with the Stitch Width button (see

page 17).

Change Sewing Direction

To change sewing direction, stop the machine. Press the

Needle Stop button to activate the Needle Down position. The

needle is brought down into the fabric.

Raise the presser foot.

Pivot the fabric around the needle to change sewing direction

as desired. Lower the presser foot and continue sewing in the

new direction.

18 – Sewing

English

Page 23

Finish Sewing

Press and hold the Reverse button and sew a few stitches in reverse when you reach the end of the seam. Release the button and

sew forward again to the end of the seam. This will secure the seam so the stitches don't unravel.

Turn the handwheel toward you to raise the needle to its highest position. Raise the presser foot and remove the fabric, pulling the

threads to the back.

Pull the threads up and into the thread knife so that the threads are cut the proper length and your needle won't come unthreaded

when you start the next seam.

Straight Stretch Stitch

3.5 2.5 3–5

Set up for Straight Stretch Stitch

This stitch is stronger than regular straight stitch, due to the

fact that it is a triple and elastic stitch. The Straight Stretch

Stitch can be used for heavy stretch fabrics, for crotch seams

which are subject to considerable strain and for topstitching

heavy fabrics.

Carefully guide the fabric while sewing as the fabric moves

back and forth.

Multi-Step Zigzag Stitch

3.0–5.0 1.0 3–5

Set up for multi-step zigzag stitch

Multi-step zigzag stitch is used to overcast raw edges. Make

sure the needle pierces the fabric on the left side and overcasts

the edge on the right side.

The stitch can also be used as an elastic stitch to allow seams

to stretch when sewing knit fabrics.

Sewing – 19

English

Page 24

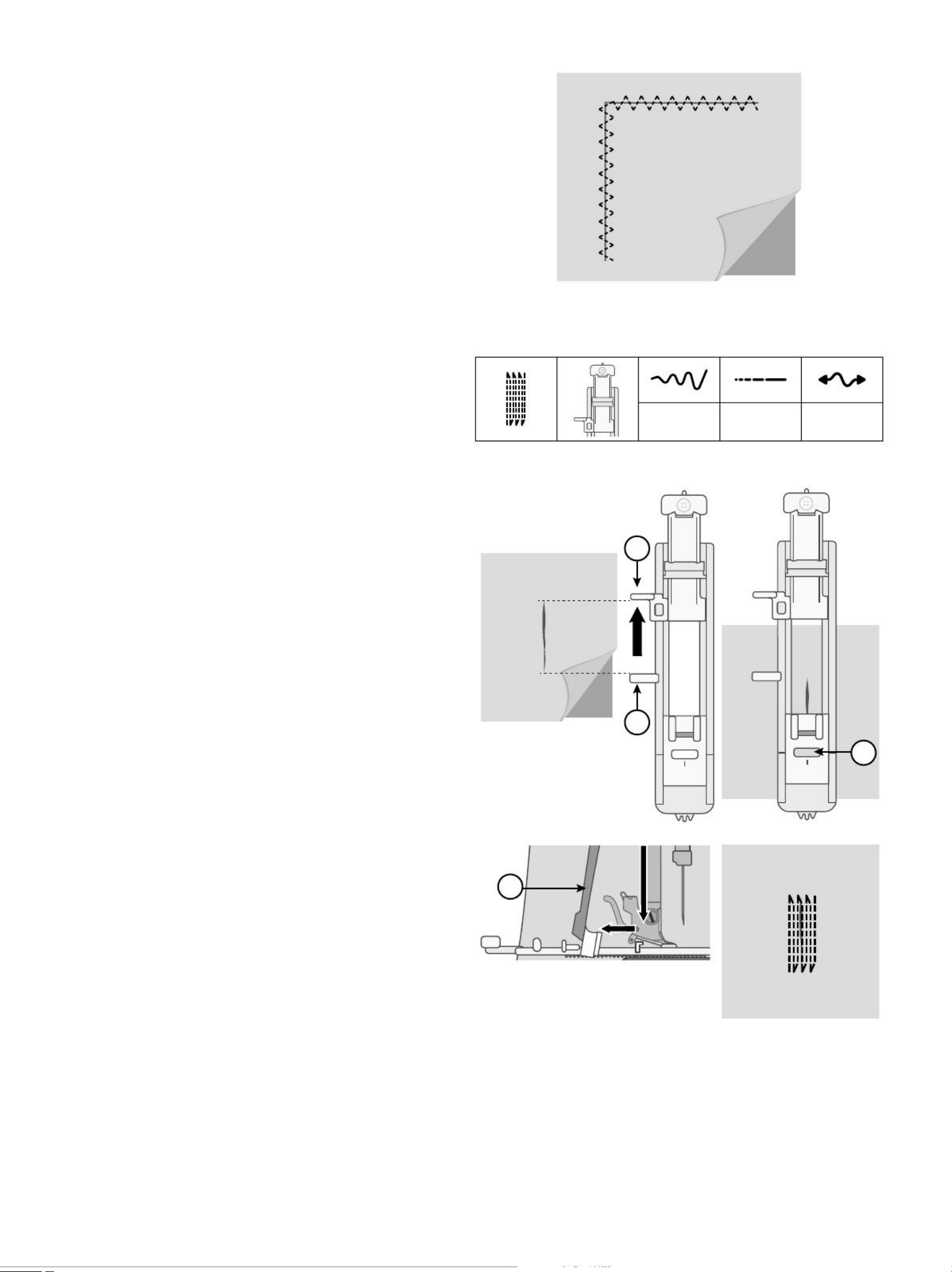

Slant Overedge Stitch

5.0 2.5 3–5

Set up for slant overedge stitch

The slant overedge stitch sews the seam and overcasts the edge

all at one time, perfect for stretch fabrics. This stitch is more

elastic than normal seams, very durable and quickly sewn.

Place the fabric under the presser foot aligning the edge of the

presser foot with the edge of the fabric. Once the seam is

finished, trim excess fabric outside the seam.

Tip: Use the Blind Hem foot to sew at the very edge of the

fabric. Adjust the extension on the foot, and let it guide along

the fabric edge. Always test sew on a piece of scrap fabric first,

the result might vary due to the fabric weight and quality.

Closed Overlock Stitch

5.0 2.5 3–5

Set up for closed overlock stitch

The closed overlock stitch can be used for sewing medium to

heavier weight stretch fabrics.

Use this stitch to hem stretch fabrics (A) and for belt loops (B).

Fold a hem to the wrong side and stitch with closed overlock

stitch from the right side. Trim away excess fabric.

Blind Hems

F

(1) (2)

3.50 1.5–2.0 3–5

Set up for blind hem

The blind hem stitch is used to make invisible hems on skirts,

trousers and home décor projects. There are two types of blind

hem; one is recommended for medium to heavy woven fabric

(1), the other for medium to heavy stretch fabric (2).

20 – Sewing

English

Page 25

B

A

Woven fabric Stretch fabric

Right side of fabric

• Finish the raw edge of the hem if sewing on a woven fabric.

There is no need to finish the raw edge first on most knits.

• Fold and press the hem allowance to the wrong side.

• Fold the hem back on itself so approximately 3/8" (1 cm) of

the finished edge extends beyond the fold. The wrong side

of your project should now be facing up.

• Place the fabric under the presser foot so that the fold runs

along edge guide (A).

• When the needle swings into the fold it should catch a

small amount of fabric. If the stitches are visible on the

right side, adjust edge guide (A) by turning the adjusting

screw (B) until the stitch that catches the hem just barely

shows.

Darning and Mending

Repair Large Holes

4.0–6.0 2.0 3–5

Set up for zigzag

5.0 1.0–2.0 3–5

Set up for multi-step zigzag

To cover large holes it is necessary to sew a new piece of

fabric onto the damaged area.

Baste the new piece of fabric onto the damaged area on the

right side of the fabric.

Sew over the fabric edges with the zigzag or the multi-step

zigzag stitch.

Trim the damaged area close to the seam from the wrong side

of the fabric.

Sewing – 21

English

Page 26

Repair Tears

On tears, frayed edges or small holes it is useful to lay a piece

of fabric on the wrong side of the fabric. The underlayed fabric

reinforces the damaged area.

Lay a piece of fabric underneath the damaged fabric. It must

be a little larger than the damaged area.

Sew over the damaged area using the zigzag or multi-step

zigzag stitch.

Trim the piece of fabric used as reinforcement.

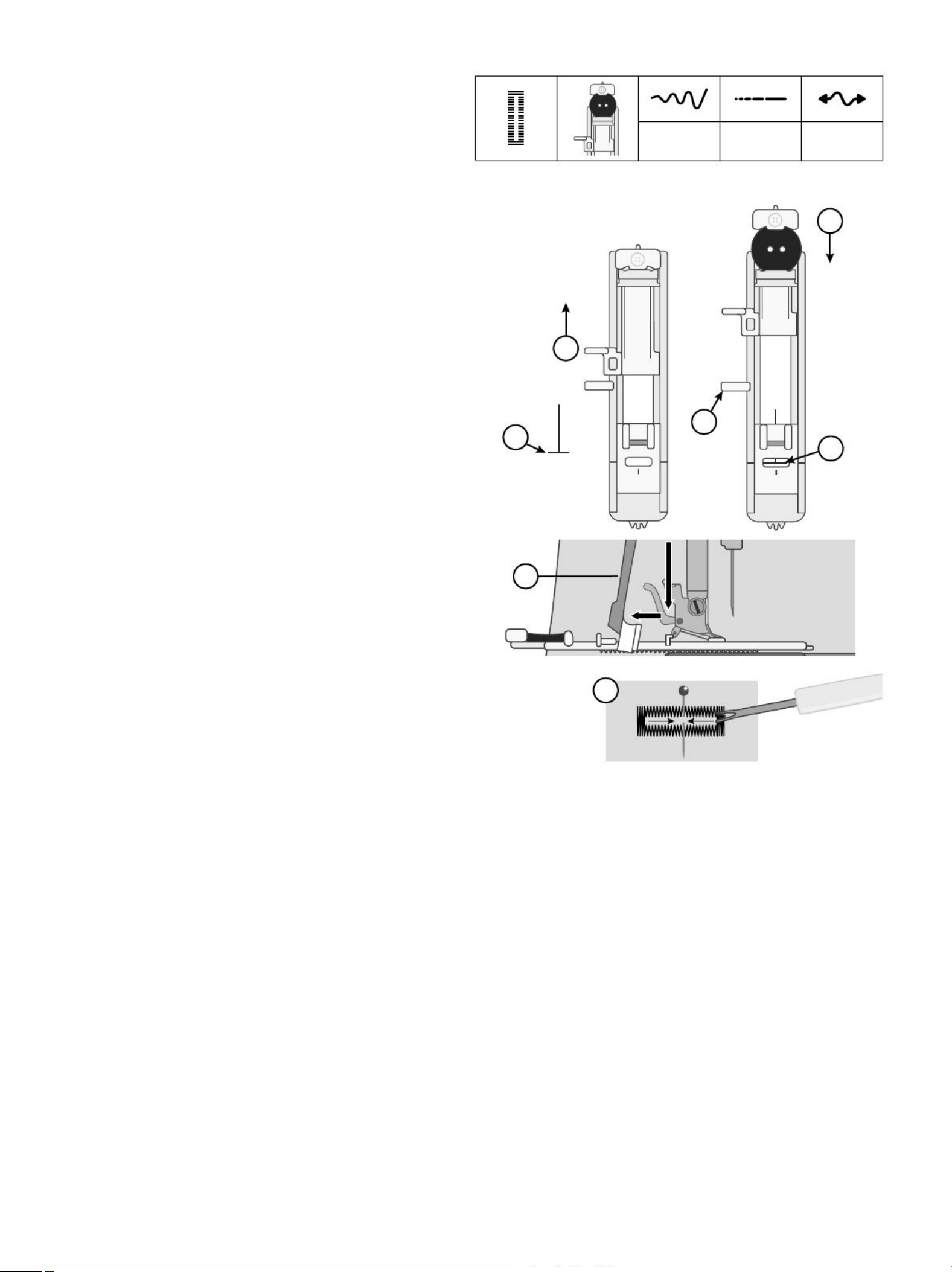

Repair Small Holes

7.0 2.0 2–4

Set up for darning stitch

A

B

C

D

A small hole or tear is easily darned with the darning stitch.

This stitch automatically sews small stitches back and forth to

cover small holes or tears.

Thread your machine with a thread in a color as close to your

fabric as possible.

1. Select the Darning Stitch.

2. The darning stitch is used together with the Buttonhole

Foot. Measure the length of the tear/hole. Push the button

holder lever (A) out to the corresponding length. The

distance between the button holder lever and the stopper

(B) is the approximate length of the darning stitch. The

maximum length is approximately 1 1/4” (3cm) (If the tear

is longer, repeat the stitch).

3. Attach the Buttonhole Foot to your machine. Place your

fabric under the presser foot. Align the fabric so that the

bottom of the tear is slightly above the center of the presser

foot (C).

4. Lower the Buttonhole Lever (D) all the way down, and

push it away from you. The Buttonhole Lever should fit

between the button holder lever (A) and the stopper (B).

5. Start sewing, the machine will stop automatically once the

darning stitch is completed. Move your fabric and repeat

until the whole damaged area is covered.

Note: To make the darning even sturdier, place a fabric

underneath the hole/tear before sewing.

22 – Sewing

English

Page 27

Jeans Hem

3.5 4.0 3–5

Set up for jeans hem

When sewing over seams in extra heavy fabric or a jeans hem,

the presser foot may tip as it rides over the seam. To be able to

obtain even feed also over thicker seams, the All-Purpose Foot

(T) is equipped with a “lock in place” button, that locks the

foot in a horizontal position.

As you approach the thicker seam and the presser foot begins

to raise over the thickness, stop sewing. Lower the needle into

the fabric and raise the presser foot. As you lower the presser

foot again, push the button on the presser foot towards the

groove (A) in the presser foot ankle. This will lock the foot in

a horizontal position, allowing the foot to pass the thick parts

without needle breakage. The lock position will release

automatically after a few stitches.

Button Sewing

—

3.5

—

2–4

Set up for button sewing

Fasten buttons easily and quickly with the special button stitch.

1. Select the Button Sewing Stitch.

2. Lower the feed teeth.

3. Remove the presser foot.

4. Mark the placement of the button with a marking pen (A).

5. Place the button on top of the marking and tape in place.

Position your project under the presser foot holder aligning

the holes of the button with the needle. Lower the presser

foot holder (B).

6. Turn the handwheel toward you very slowly to be sure the

needle clears the holes. Adjust the stitch width if needed

(C).

7. Start sewing at a low speed. The machine stops

automatically after a few stitches.

8. Leave a long thread tail and pull it under the button. Wind

the thread tail around the shank.

9. Use a hand sewing needle to pull the thread to the wrong

side of the fabric and secure.

10. To re-engage the feed teeth, move the Feed Teeth Lever

back to regular sewing position, and then turn the hand

wheel toward you one full revolution.

Sewing – 23

English

Page 28

One-Step Buttonhole

5.0 0.4 3–5

Set up for buttonhole

F

B

A

C

E

G

D

Sew buttonholes perfectly sized for your button. The fabric

should be interfaced and/or stabilized where buttonholes are to

be sewn.

1. Mark the start position of the buttonhole on the fabric (A).

2. On the One-Step Buttonhole Foot, push the button holder

open by pushing the lever backwards (B). Insert the button.

Push the button holder forward until the button is locked in

place (C). The button will determine the length of the

buttonhole. The distance between the button holder lever

(B) and the stopper (D) is the length of the buttonhole.

3. Attach the One-Step Buttonhole Foot.

4. Make sure that the thread is pulled though the hole in the

presser foot and placed under the foot.

5. Position your fabric under the presser foot so that the

marking on the fabric is aligned with the center of the

Buttonhole Foot (E).

6. Lower the Buttonhole Lever (F) all the way down, and

push it away from you. The buttonhole lever should fit

between the button holder lever (B) and the stopper (D).

7. Hold the end of the upper thread and start sewing. The

buttonhole is sewn from the front of the presser foot to the

back. Stop sewing when the buttonhole is finished.

8. Once the buttonhole is finished, raise the presser foot. Push

the buttonhole lever all the way up.

9. To secure the bartack, thread the end of the top thread into

a hand sewing needle, pull to the wrong side and tie the

end before cutting excess thread.

10. Use a seam ripper and cut the buttonhole open from both

ends towards the middle (G).

If you want to sew another buttonhole, do not push the

buttonhole lever up when the buttonhole is finished. Instead,

push it away from you again. Sew another buttonhole.

Note: Always sew a test buttonhole on a piece of scrap fabric.

24 – Sewing

English

Page 29

Sew Zippers

3.5 2.0–3.0 3–5

Set up for sewing zippers

A B

The Zipper Foot can be attached on either the right or the left

of the needle, making it easy to sew both sides of the zipper.

To sew the right side of the zipper, attach the foot in the left

presser foot position (A).

To sew the left side of zipper, attach the foot in the right

presser foot position (B).

Centered Zipper

• Place the fabric pieces right sides together and pin. Mark

the zipper length on your fabric.

• Baste the zipper seam using the specified seam allowance

(use straight stitch with stitch length 4mm, thread tension 2).

Baste to the end of zipper marking (C).

• Set up the machine for straight stitch (see table above),

backstitch a few stitches and sew the rest of the seam using

the specified seam allowance (C).

• Press the seam allowances open. Place the right side of the

zipper to the wrong side of the seam, tape in place (D).

• Flip your project, making sure that the right side is facing

up. Snap on the Zipper Foot, to the left side of the needle

(A).

• Sew along the right side of the zipper to the end of your

zipper, remember to backstitch in the beginning. Stop with

the needle down in the fabric, lift the presser foot and turn

your project to sew across the bottom of the zipper (E).

• Attach the Zipper Foot to the right side of the needle (B).

Sew the remaining zipper side as you did with the first side

(F).

• Flip your project to remove the tape on the back side.

• Flip your project to the right side again and remove the

basting stitches.

Sewing – 25

English

Page 30

Hand-Look Quilt Stitch

3.5 2.0–3.0 6–9

Set up for hand-look quilt stitch

Simulate the look of handmade quilting with the Hand-look

Quilting stitch. Thread the needle with either transparent

thread or with a thread that blends with the color of the top of

the fabric. Thread the bobbin with a thread color that

coordinates or contrasts with the top of the fabric, depending

on the look you want for your project (the bobbin thread will

actually appear on the top of the fabric).

Tip: Use a size 100 Topstitch Needle for an even greater effect.

A. Bobbin thread

B. Top thread

• To get the accurate hand stitched look it is important that

the stitch is sewn using a high thread tension. Make sure to

set the tension according to the recommendations in the

stitch chart.

• Stitch along one of the seams of your project, or around an

appliqué. The handlook effect is created as the bobbin

thread is pulled up to the top of the quilt.

26 – Sewing

English

Page 31

MAINTENANCE

Cleaning the Machine

To keep your sewing machine operating well, clean it often. No lubrication (oiling) is needed. Wipe the exterior surface of your

machine with a soft cloth to remove any dust or lint built up.

Cleaning the Bobbin Area

Raise the needle and turn off the machine.

Remove the presser foot. Slide off the bobbin cover and

remove the bobbin.

Remove the screws in the needle plate by using the Lscrewdriver. Lift up and remove the needle plate.

Clean the feed teeth and the bobbin area with the brush found

among the accessories.

Place the needle plate over the feed teeth, replace and tighten

the screws.

Attach the presser foot, insert the bobbin and replace the

bobbin cover.

Cleaning under the Bobbin Area

Raise the needle and turn off the machine.

Clean the area under the bobbin case after sewing several

projects or any time you notice an accumulation of lint in the

bobbin case area.

Remove the presser foot. Slide off the bobbin cover and

remove the bobbin.

Remove the screws in the needle plate by using the Lscrewdriver. Lift up and remove the needle plate.

Remove the bobbin case by lifting it up. This is easier if you

push it slightly to the left or right as you lift.

Clean the area with the brush or with a dry cloth.

Note: Do not blow air into the bobbin case area. The dust and

lint will be blown into your machine.

Guide the “forked” end of the bobbin case (A) under the

bobbin case holder (B) and under the feed teeth. Move the

bobbin case slightly from right to left until it slips correctly

into the hook race (C). To make sure the bobbin case is

properly replaced, turn the handwheel towards you. The hook

race (C) should rotate freely in a counter-clockwise direction.

Place the needle plate over the feed teeth, replace and tighten

the screws.

Attach the presser foot, insert the bobbin and replace the

bobbin cover.

Maintenance – 27

English

Page 32

Troubleshooting

Thread Loops on Underside of Fabric

Possible cause:

Thread looping on the underside of the fabric is always an indication that the upper thread is not correctly

threaded. This happens when the upper thread is not correctly placed in the thread tension mechanism and

has not been threaded through the take up lever.

Solution:

Rethread the machine, making sure to first raise the presser foot lifter before starting to thread, so thread

can be properly seated in the tension mechanism and take up lever. To know if you have rethreaded the

machine correctly, try this test:

• Raise the presser foot lifter (page 9) and thread the top of the machine (page 12).

• Thread the needle, but don't put the thread under the presser foot yet. As you pull the upper thread to

the left, it should pull freely.

• Put the presser foot lifter down. As you pull the upper thread to the left, you should feel resistance. This

means you are threaded correctly.

• Put the thread under the presser foot, and then draw up the bobbin thread. Slip both thread tails under

the presser foot towards the back. Lower the presser foot and begin sewing.

If you put the presser foot lifter down, but the thread still pulls freely (you feel no difference whether the

presser foot is up or down), this means that you have threaded incorrectly. Remove the upper thread and

rethread the machine.

Bobbin Thread Breaking

Possible cause:

Bobbin threaded incorrectly.

Solution:

Check that bobbin is placed correctly in the bobbin holder (page 11).

Possible cause:

Bobbin wound too full or unevenly.

Solution:

Bobbin thread may not have been correctly placed into bobbin winding tension disc during the bobbin

winding process (page 11).

Possible cause:

Dirt or lint in bobbin holder.

Solution:

Clean bobbin holder (page 27).

Possible cause:

Wrong bobbins being used.

Solution:

Use bobbins that are the same style as those that come with the machine (SINGER® Class 15 transparent

bobbins) – don’t substitute.

Bobbin Thread Showing on Top of Fabric

Possible cause:

Top thread too tight.

Solution:

Reduce upper thread tension (page 15).

Possible cause:

Thread path is obstructed, putting extra tension on top thread.

Solution:

Check that the top thread path is not obstructed and thread is moving freely through the thread path.

Possible cause:

Bobbin thread not in bobbin case tension.

Solution:

Rethread bobbin (page 11).

Bobbin Winding Difficulties

Possible cause:

Bobbin thread loosely wound on bobbin.

Solution:

Rewind bobbin, making sure that the thread is placed snuggly in the bobbin winding tension disc (page

11).

Possible cause:

Bobbin winding spindle not fully engaged, therefore bobbin not winding.

Solution:

Check that the bobbin winding spindle has been fully engaged before starting to wind.

28 – Maintenance

English

Page 33

Possible cause:

Bobbin is winding sloppily because thread end not held at beginning of winding process.

Solution:

Before starting to wind, hold the thread tail (coming out of the bobbin) securely, allow the bobbin to

partially fill, then stop to trim the thread tail close to the bobbin.

Fabric Puckers

Possible cause:

Top thread is too tight.

Solution:

Reduce top thread tension (page 15).

Possible cause:

Stitch length is set too short.

Solution:

Increase stitch length setting (page 17).

Possible cause:

Wrong style needle for fabric type.

Solution:

Use correct needle style and size for your fabric (page 13 and page 14).

Fabric Is Tunneling Under Stitches

Possible cause:

Fabric is not properly stabilized for the density of the stitches (for example, satin stitch applique).

Solution:

Add a fabric stabilizer underneath the fabric to help keep the stitches from tunneling in together, forming

a puckered ridge in fabric.

Loud Noise When Sewing

Possible cause:

Thread not in take-up lever.

Solution:

Rethread the machine, making sure the take up lever is in its highest position so thread goes in the eye of

the take up lever — turn machine hand wheel toward you to raise the take up lever to its highest position

for threading.

Possible cause:

Thread path is obstructed.

Solution:

Check that thread is not caught on the thread spool or behind the spool cap.

Machine is Not Feeding Fabric

Possible cause:

Presser foot lifter has not been lowered onto fabric after threading.

Solution:

Lower the presser foot lifter before starting to sew. Don´t “push” or “pull” the fabric as you sew.

Possible cause:

Solution:

The feed teeth need to be raised and re-engaged by turning the handwheel one full revolution (page 15).

Possible cause:

Stitch length is set at zero.

Solution:

Increase stitch length setting (page 17).

Machine Will Not Run

Possible cause:

Bobbin winding spindle is engaged when you try to sew.

Solution:

Disengage bobbin winding spindle by pushing it to the left.

Possible cause:

Power cord and/or foot control not plugged in correctly.

Solution:

Make sure power cord/foot control are correctly seated in machine and power supply (page 8).

Possible cause:

Wrong bobbins being used.

Solution:

Use bobbins that are the same style as those that come with the machine (SINGER® Class 15 transparent

bobbins)– don’t substitute.

Maintenance – 29

English

Page 34

Needles Breaking

Possible cause:

Bent, dull or damaged needle.

Solution:

Discard needle, insert new needle (page 14).

Possible cause:

Wrong size needle for fabric.

Solution:

Insert appropriate needle for fabric type (page 13).

Possible cause:

Machine not threaded correctly.

Solution:

Rethread the machine completely (page 12).

Possible cause:

“Pushing” or “pulling” fabric.

Solution:

Don’t manually push/pull fabric in order to sew, but allow the machine’s feed teeth to draw fabric under

the presser foot as you guide it.

Needle Threader Not Working

Possible cause:

Needle not in correct position.

Solution:

Raise needle to its highest position by turning hand wheel toward you.

Possible cause:

Needle inserted incorrectly.

Solution:

Needle all the way up in the needle clamp.

Possible cause:

Needle is bent.

Solution:

Remove the bent needle, insert new needle (page 14).

Possible cause:

Hook pin damaged.

Solution:

Needle Threader needs replacement. Contact authorized service center.

Skipping Stitches

Possible cause:

Needle inserted incorrectly.

Solution:

Check that flat side of needle top is toward back of machine and needle is up as far as it can go, then

tighten needle clamp screw.

Possible cause:

Wrong needle for fabric sewn.

Solution:

Use correct needle style and size for your fabric (page 13 and page 14).

Possible cause:

Bent, dull or damaged needle.

Solution:

Discard needle and insert new needle (page 14).

Stitches Distorted

Possible cause:

“Pushing” or “pulling” the fabric.

Solution:

Don’t manually push/pull fabric in order to sew, but allow the machine’s feed teeth to draw fabric under

presser foot as you guide it.

Possible cause:

Incorrect stitch length setting.

Solution:

Adjust stitch length setting (page 17).

Possible cause:

Stabilizer may be needed for technique.

Solution:

Place stabilizer underneath fabric.

Thread Bunching at Beginning

Possible cause:

Top and bobbin threads have not been properly placed underneath presser foot before starting to sew.

Solution:

Ensure that both the top thread and the bobbin thread are under the presser foot and toward the back

before starting to sew.

30 – Maintenance

English

Page 35

Possible cause:

Sewing was started with no fabric under the presser foot.

Solution:

Place fabric under foot, making sure that needle comes down into fabric; lightly hold both thread tails for

first few stitches.

Possible cause:

Stabilizer may be needed for technique.

Solution:

Place stabilizer underneath fabric.

Upper Thread Breaking

Possible cause:

Thread path obstructed

Solution:

Check if thread is caught on thread spool (rough spots on the spool itself) or behind spool pin or spool

cap (if the thread has fallen behind the spool cap and therefore cannot feed freely through the machine

path).

Possible cause:

Machine is not threaded correctly.

Solution:

Remove upper thread completely, raise presser foot lifter, rethread machine making sure thread is in takeup lever (raise take up lever to its highest position by turning hand wheel toward you.

Possible cause:

Upper tension too tight.

Solution:

Reduce upper thread tension (page 15).

Technical Specification

Sewing Speed

Maximum 1000 ± 50 rpm

(using straight stitch with default stitch length)

Rated Voltage

240 V/50Hz, 230 V/50Hz, 220 V/5060Hz, 127 V/60 Hz, 120 V/60 Hz,

100V/50-60Hz

Presser Foot Rise Height

6mm

Protection Class

II (Europe)

Stitch Width

0–7.0mm

Stitch Length

0–4.5mm

Type of Lamp

LED light

Machine Dimensions

Length: ≈440mm

Width: ≈190mm

Height: ≈280mm

Weight

7kg

Maintenance – 31

English

Page 36

Page 37

Page 38

Page 39

INTELLECTUAL PROPERTY

Singer, and the Cameo “S” Design are exclusive trademarks of The Singer Company Limited

S.à.r.l. or its Affiliates.

We reserve the right to change the machine equipment and the assortment of accessories

without prior notice, or make modifications to the performance or design. Such modifications,

however, will always be to the benefit of the user and the product.

Please note that on disposal, this product must be safely recycled in accordance

with relevant National legislation relating to electrical/electronic products. Do

not dispose of electrical appliances as unsorted municipal waste, use separate

collection facilities. Contact your local government for information regarding

the collection systems available. When replacing old appliances with new ones,

the retailer may be legally obligated to take back your old appliance for

disposal free of charge.

If electrical appliances are disposed of in landfills or dumps, hazardous

substances can leak into the groundwater and get into the food chain, damaging

your health and well-being.

Manufacturer

VSM GROUP AB, SVP Worldwide

Soldattorpsgatan 3, SE-55474, Jonkoping, SWEDEN

Page 40

4710717-26G · English · © 2020 The Singer Company Limited S.à.r.l. or its Affiliates. · All rights reserved

Loading...

Loading...