Page 1

Instruction

Manual

For generic HA-1

15 class

Sewing Machines

-1-

Page 2

Your HA-1 Sewing Machine

This is a generic instruction manual for straight stitch

sewing machines that are commonly known as HA-1s.

The HA-1 machine is mechanically a clone of the very

old Singer 15 class, such as the 15-30 or 15-87. Many

later 15 class Singers, such as the 15-91, used a different shuttle/bobbin case arrangement which was mostly

reversed from this style. However, this early style became so prevalent that Singer eventually switched back

to the earlier arrangement.

HA-1 machines have been sold with hundreds of different nameplates, but are all essentially the same.

Most of the HA-1 machines have been built in the far

eastern countries since the end of WW2. There have

been numerous modifications, but the basic machine

has remained so similar that this instruction book will

cover the important points for many machines.

The bobbins are the common 15 class, and the needles

are known as 15X1 (US), 705 (H or B, European), or

HAX1 (Japanese or other far eastern), followed by the

# that designates the size. A US size 16 = a European

size 100, size 14 = size 90, size 12 = size 80. The European # tells the actual size of the needle, such as the

100 is 1mm in dia., the 80 is .8mm in dia., etc.

Prepared by:

Bill Holman

Madison, WI

-2-

Page 3

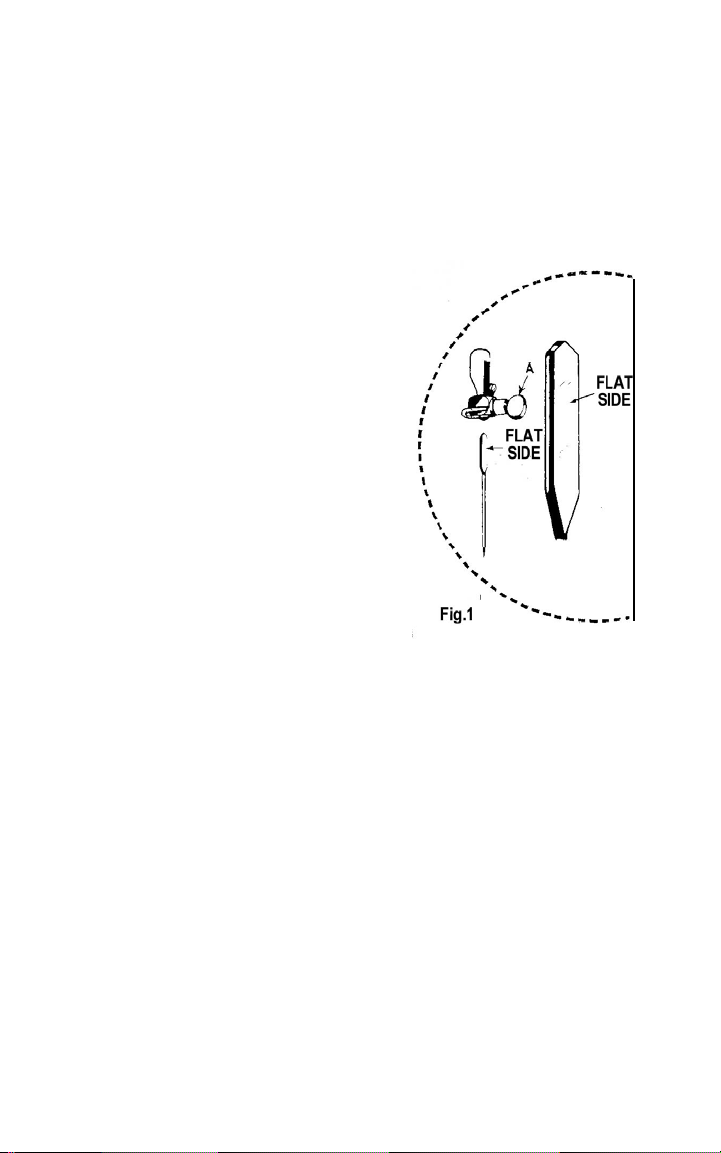

TO REPLACE THE NEEDLE

To replace the needle, raise

the needle bar to its highest

point by turning the hand

wheel (Fig. 3) TOWARD

YOU by hand. Loosen the

needle clamp screw (A) on the

right hand side, and the needle

clamp will open, allowing the

old needle to slip out.

Remove the old needle and

slide the new needle up,

(FLAT SIDE TO THE

RIGHT) as far as it will go.

When the needle hits the stop,

it is positioned correctly.

Tighten the needle clamp

screw securely. For best results change needle frequently.

Note: Use only

15X1, 705, or HAX1

class needles.

NEEDLES AND THREAD

Never use a bent needle, nor one with a blunt point, since this

causes imperfect stitches and may cause the needle to break.

Unless the needle is in all the way, flat side to the right, the machine will not function correctly, and you will not get good results.

The size of the needle should conform to the size of the thread,

and both should be suitable for the material being sewn. In most

applications, use the same thread top and bottom, and always use

good quality thread and needles.

-3-

Page 4

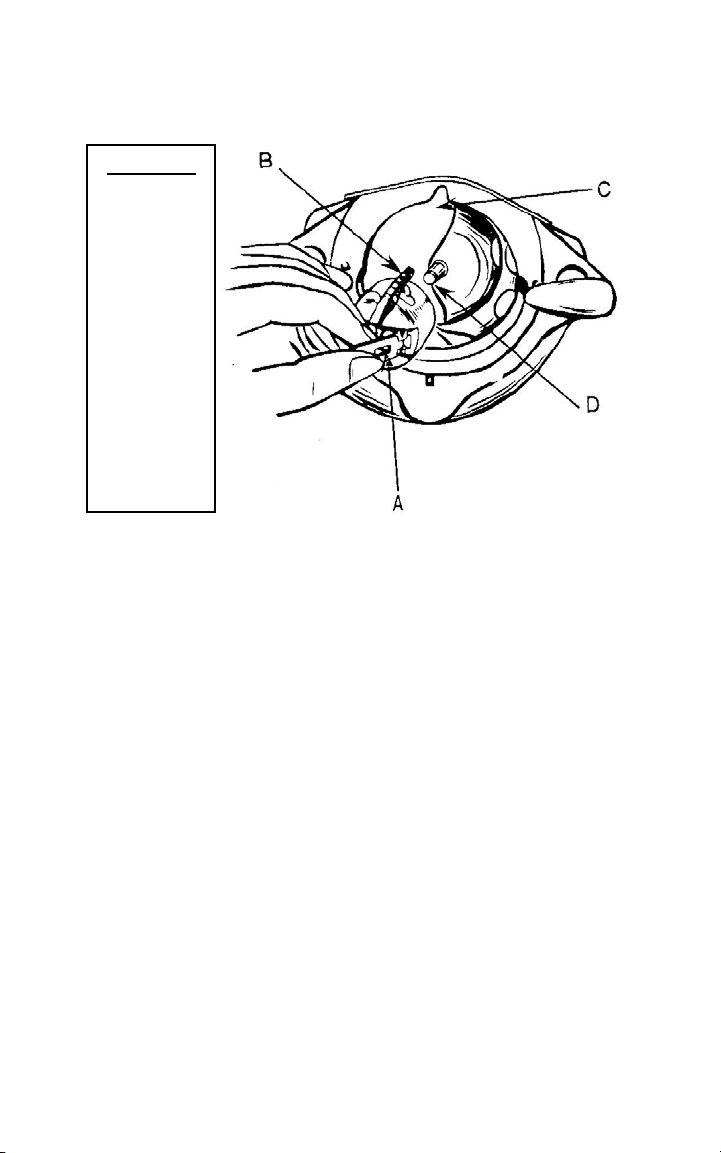

THE BOBBIN CASE

Important

In the following operations, the needle must always be

above the surface of the

machine. In

raising the

needle, always turn the

hand wheel

toward you.

REMOVING THE BOBBIN CASE

Slide or lift the access plate. (Fig. 4) With left thumb and forefinger, open the hinged latch (A-Fig. 2) on the bobbin case, and hold

securely as you withdraw it from the post. (D-Fig. 2) *Note the

position of your fingers on the latch, because it is important to grip

it the same way when reinserting it into the machine.

INSERTING THE BOBBIN CASE

After installing the bobbin in the case, grip the latch with your fingers in the same position* as when you removed it. (Note: If you

grip it with your fingers pointed directly toward the case, it will be

difficult to install it in the machine.) Guide the bobbin case back

onto the post with the finger (B-Fig. 2) into the notch (C-Fig. 2).

This should be an easy operation requiring no force. When you

release the latch, it will snap onto the groove on the post, and the

three or four inches of thread hanging free from the bobbin case

will be brought up through the needle plate as shown on page 8.

-4-

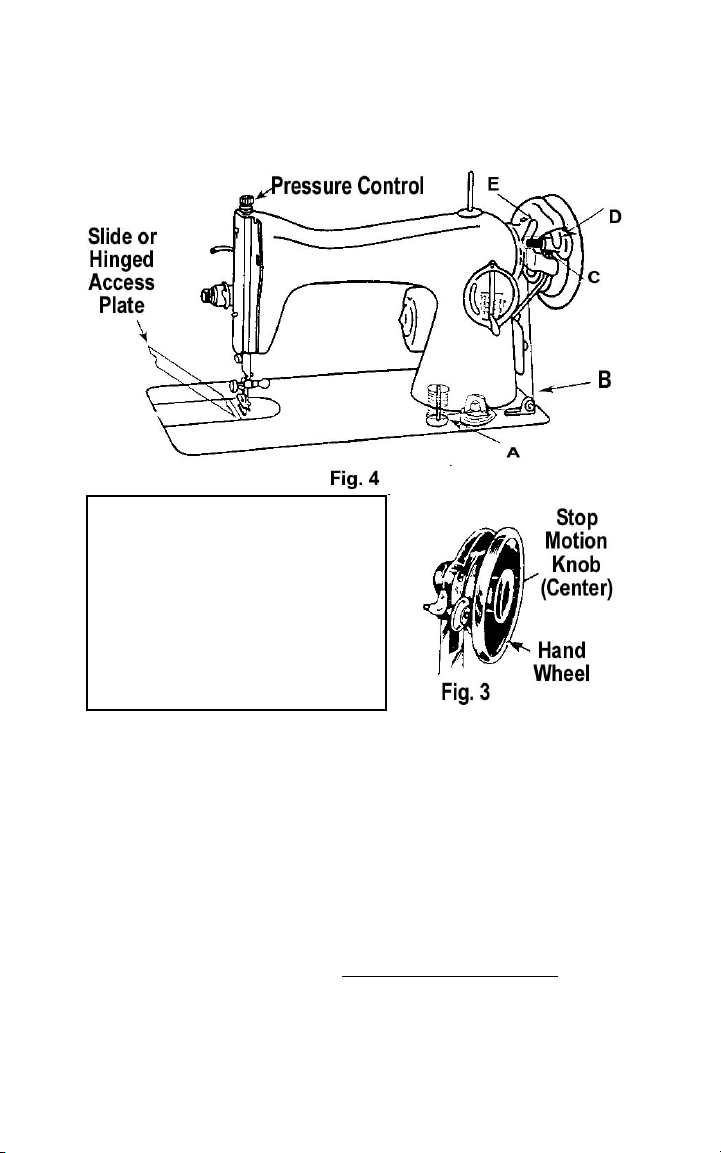

Page 5

WINDING THE BOBBIN

Note: This machine uses standard

15 class bobbins. The bobbin can

also be wound while the machine

is in operation by not releasing the

stop motion knob as described below, in which case, machine and

bobbin winder will operate at the

same time.

While holding the hand wheel with the left hand, turn the stop motion knob toward you. This will permit the hand wheel to turn

freely while the needle bar remains still. Place a spool of thread on

spool pin (A). Pass the thread through the tension disk (B) at right

corner of the base of the machine. Attach the thread to an empty

bobbin by winding it around numerous times or inserting it inside

out through one of the holes. Place the bobbin on spindle (C).

Push the bobbin winder (D) down until the snaps against the hand

wheel, and finger (E) drops between the sides of the bobbin. Operate the motor until the bobbin is full or the finger (E) snaps up and

disengages the bobbin winder. Do not over fill the bobbin

thread, and tighten the stop motion screw while holding the hand

wheel. Your bobbin is now ready to be inserted in the bobbin case

(pg. 6) and installed in the machine (pg. 4).

-5-

. Cut the

Page 6

TO THREAD THE BOBBIN CASE

Hold the bobbin case between

the left thumb and forefinger

with the slot up. With 4 or 5

inches of thread trailing in the

direction shown…

...insert the bobbin into the bobbin case and pull the trailing

thread back into the slot, down

and to the left, until it snaps into

the “delivery eye” under the tension spring. When you pull on

the thread, looking at the bobbin

in the open side of the bobbin

case, the bobbin should rotate

clockwise.

There should be a slight but

consistent tension (drag) on the

thread as it is pulled through the

“delivery eye.” The tension can

be increased by turning the tension screw clockwise decreased

by turning it counter-clockwise.

-6-

Page 7

UPPER THREADING

1– Place a spool of thread on spool pin (A).

2– Bring the thread from the back of the spool, (so that the notch

in the spool is up) and lead it through thread guide (B).

3- Run the thread down, between, and under the tension disks (C)

from back to front.

4– Bring the thread over the guide bar (D) and through the check

spring (E).

5- With the take up lever (F) in its uppermost position, bring the

thread through it from back to front.

6– Run the thread through guides (G) & (H).

7– Thread the needle from left to right, drawing it through about

4-5 inches.

-7-

Page 8

TO PREPARE FOR SEWING

Thread machine as per pages 6 & 7.

Pick up the bobbin thread by holding the loose end of the needle

thread with your left hand while turning the hand wheel toward

you until the needle moves down and up and the thread take up

lever has reached its highest position.

Pull gently on the needle thread where it is looped down through

the needle plate, and the bobbin thread will come up through the

needle hole. (If the bobbin thread does not come up, recheck your

threading, and be sure that there is 4-5 inches of thread trailing

from the bobbin case.)

Finally, place both thread ends toward the rear of the machine,

with the needle thread going between the two presser foot toes

(A).

-8-

Page 9

TO START SEWING

With the needle raised and the threads drawn back at least 4

inches through the toes of the presser foot, place the material

to be sewn beneath the presser foot and lower the presser

foot lift lever. Turn the hand wheel toward you until the needle enters the material. Regulate the desired stitch length

(Fig. 12) and start sewing.

Do not try to help the feeding of the material by pulling by

hand, as this may bend or break the needle. Gently guide the

material as it feeds in the direction you want to sew.

TO REMOVE THE WORK

Stop the machine by releasing the pressure on the foot or

knee control and stopping the hand wheel with your right

hand. If you are stopping to turn a corner, stop with the needle just entering the material. If you are going to remove the

material, stop with the needle and take up lever at their highest positions. Then, raise the presser foot lift lever, draw the

material to the back about 6-8 inches, and cut the thread.

-9-

Page 10

OTHER FEATURES

Fabric Selector: The height of

the feed dog may be regulated

according to the thickness or

other characteristics of the material being sewn, by proper

setting of the drop feed knob.

1– When sewing normal to thick materials, turn the knob to

the “NORM” position.

2– When sewing thin materials, such as silk, which require a

gentler feeding motion, turn the knob to “SILK.”

3– When a situation arises when you want to move the material by hand, such as in darning or embroidery, turn the

knob to the “DARN” or “EMBR” position.

PRESSURE CONTROL

Fig. 11

The pressure control (Fig. 4, pg. 5) controls the amount of

pressure that the presser foot applies to the material. Different HA-1s use two versions of the pressure control, but you

can regulate it by screwing it up and down or using the snap

release, to find the pressure that provides the best feeding

action.

PRESSER FEET & ATTACHMENTS

Your HA-1 is equipped with a standard low shank mounting

system. With this arrangement, it is easy to find almost any

type of presser foot or attachment for your sewing needs.

-10-

Page 11

STITCH LENGTH REGULATION

Regulating the length of the stitch: The machine can

be adjusted to from six to thirty stitches per inch, as indicated by the numbers on the stitch indicator plate.

Changing the length of the stitch is accomplished as

follows:

Loosen the stitch length stop control (B, Fig. 12) and

move it to the bottom of the slot. Move the stitch

length lever (A, Fig. 12) to the desired stitch length.

Now, move the stop control up until the control plate

(visible in the stitch length slot) touches the bottom of

the stitch length lever. Tighten the thumb screw (B)

with finger pressure only. At this point, the stitch

length is “marked,” and you can move the lever up to

sew in reverse at approximately the same stitch length,

and then return it to your desired forward length.

-11-

Page 12

TENSIONS

For ideal stitching, the tension on the upper and lower

threads should be equal, and

just sufficiently strong to

lock both threads in the center of the work. (Fig. 13)

If the upper tension is too

tight or the lower too loose,

the needle thread will lay

straight on the upper surface.

(Fig. 14)

If the lower tension is too

tight or the upper too loose,

the bobbin thread will lay

straight on the underside of

the material. (Fig. 15)

Note: Most minor imperfections in the stitch can be corrected by adjusting the needle tension only.

To increase the upper tension, turn the tension knob

clockwise. To decrease it,

turn counterclockwise. All adjustments should be made gradually,

no more than one number at a time. When the presser foot is in the

raised position, the upper tension is released, so if you pull on the

thread to feel the amount of tension, the foot must be down.

If it becomes necessary to adjust the bobbin tension, this is explained on pg. 6, Fig. 7.

-12-

Page 13

OILING THE MACHINE

Fig. 17

Your HA-1 sewing machine never needs grease. All moving parts

which come in contact with others must be covered with a thin

film of oil, and should not be allowed to become dry. Oil, when

necessary, should be applied at the points indicated by the arrows

in Fig. 17, a single drop of oil is usually sufficient if applied in the

right place. Oil all spots of contact on the underside of the machine. These spots can be identified by rotating the hand wheel

and watching where parts move against one another. The shuttle

race should be kept oiled, and frequently, it is wise to snap open

the clamps that hold the shuttle retainer, and remove the shuttle to

clean the race and apply oil. Once the machine has been oiled, it is

wise to run it to distribute the oil, and sew some stitches on a test

cloth until oil no longer appears on the thread.

Note: Use sewing machine oil only. Multi

purpose oils will often dry leaving a sticky

residue behind.

-13-

Page 14

SEWING HINTS

See that the presser foot screw is securely tightened. It is

dangerous for the foot to vibrate loose while you are operating the machine.

Skipped stitches may be caused by a bent or blunt needle,

by incorrect positioning of the needle, the wrong size of needle, or by thread that is too heavy for the selected needle.

Breaking needles are usually caused by the operator pulling

on the fabric in an effort to help the machine feed. This action will pull the needle out of line and it will strike the

presser foot or needle plate.

Breaking the upper thread may be caused by:

1– Incorrect threading

2– Not bringing up the bobbin thread correctly

3– Upper tension too tight

4– Bad needle, or clamped incorrectly

5– Needle rubbing against attachments or presser foot

6– Needle eye too small for thread

7– Starting the machine at full speed

8– Starting machine without take up lever at highest point

Breaking the lower thread may be caused by:

1– Incorrect threading of bobbin case

2– Too tight a tension

3– Bobbin wound too full to revolve freely

4– Not bringing up bobbin thread correctly

5– Hole in the needle plate damaged by needle strikes

Uneven stitches may be caused by:

1– Presser foot not resting evenly on material

2– Feed dogs not high enough

3– Too short a stitch

4– Pulling the cloth

5– Incorrect needle for the thread, or poor quality thread

-14-

Loading...

Loading...