Page 1

: : : x : ли™

' , л, "л

<Г^ '' уу ™Лл

'' ' л'л --V' ' "^OiOiSi л 'Хо- л Í ' Лл^ л

хЖа f'^

'^MÇ-x.'V ™У^'^ллГл;7 ,,л I

■■ л- ®

"%■ 'л '

''Ví;¡C';Tí:"-:7,”Í

■ ' лч> .V ."Л- ^ ^ г г г

л^ ^Л XX

X л ' "ЛЛЛ^ л-Í^í,™?^ ^ л : л, „л

" 'л' '-' ' '"

/Г ^'1 '/

SSWWWWWSÍÍ

■

'хуххххх' ''х„у 'ху ху X у ху

«ÿ:*K-:w:r»*KK*»B

■^Sйíй:

Х-УХ-У-- ' ^ ^

' 'л'^ '""х'^'х'х' "'xxf' 'х' X Ш.

"ЧЛ

‘^V/xx^xxV^ ху

^ .«w^ ,Л<Чч /л> Й? jA/^ /. '" / ^/««^■■■■х>Н> v^«» /'^jw^/fr^ / ^

y X хХххУххухХхххУ ^ ху y^ y xy 'хуххУУХ, y x-x¡. x^ <>^ %ххУу ''хуууУ' ху x x xx

dV4444sy4^

gjiifeasssssssÿsssss!

Siiÿi««

rSWKWíKÍ^^

г Ф/%й.

Ml

л; л яг;;

^ г

г г Х" ■■

'™ Н:

jÿ «««4W

■■■■ AV Ф

^ ■■ф ■■ ■■

f г ^ ÿ^ Л- ■'

"'Tjr'':'^f;f

, x^'yf^xx

гЯ'^'

Page 2

Zig-Zag & STRETCH Sewing Machine by SINGER

Congratulations...

The new Zig-Zag & STRETCH model 714 sewing machine you are about to

use will take you into a wonderful new world of sewing. In addition to the

familiar Singer exclusives — Slant Needle and Front Drop-in Bobbin — this

sewing machine offers you:

• the simplicity of dial controls. Now you can simply dial a stitch length,

a stitch width, pressure and tension settings

• built-in stitch patterns, which let you produce a straight stitch and a

variety of zig-zag patterns by simpiy turning a dial, plus Flexi-Stitch*

patterns for stitching knit and stretch fabrics and producing intricate

stitch designs

• exclusive built-in threading chart that flips open to keep an easy-to-

follow diagram at your fingertips

• one-way needle clamp that makes it impossible to insert the needle

backwards

• stitch control dial that lets you switch from regular to s-t-r-e-t-c-h

stitching

• guidelines on both sides of the throat plate, which help you keep seams

straight

• convenient power and light switch that gives you a choice of two

speeds

• easy throat plate changing — throat plate secured by magnets is easy

to lift out for cleaning.

• three-position presser foot lifter that lets you place bulky fabric or

many fabric layers under the presser foot

• built-in sewing light that illuminates the sewing area

Your SINGER sewing machine is the key to your sewing success when used

properly. To achieve professional results, SINGER suggests you sit down

at your machine and go through this book step by step before you begin to

sew. You’ll discover all the many advantages of sewing with your ZigZag & STRETCH sewing machine.

Enjoy sewing!

SINGER* Service is always close at hand. If your machine should need

servicing, call your local SINGER Sewing Center to be sure of warranted

SINGER Parts and Service. You wiil find the address in the telephone direc

tory under SINGER COMPANY.

Copyright © 1973 THE SINGER COMPANY

All Rights Reserved Throughout the World

Page 3

CONTENTS

1. Getting to Know Your Machine.................................................................................................................... 2

Principal Parts and What They Do.......................................................................................................... 3

Accessories ............................................................................................................................................. 4

2. Getting Ready to Sew................................................................................................................................... 7

Preliminary Steps ................................................................................................................................... 7

Choosing Needle and Thread................................................................................................................. 8

Threading the Machine........................................................................................................................ 10

Winding the Bobbin • Threading the Bobbin Case • Threading the Needle • Raising the

Bobbin Thread

3. Straight Stitching ...................................................................................................................................... 14

Preparation .............................................................................................................................................. 14

Starting to Sew ....................................................................................................................................... 14

Adjusting for Your Fabric...................................................................................................................... 15

Sewing a Seam ....................................................................................................................................... 17

Pin Basting • Placing Fabric • Starting a Seam • Guiding and Supporting Fabric •

Keeping Seams Straight • Turning Square Corners • Curved Seams • Reinforcing End

of Seam

4. Ali about Zig-Zag Stitching...................................................................................................................... 21

Two Kinds of Zig-Zag Stitches.............................................................................................................. 21

Adjusting Dials ................................................................................................................................... 22

Setting Pattern Dial • Adjusting Stitch Placement • Adjusting Width of Design»Adjusting

Needle-Thread Tension • Adjusting Stitch Length

Satin Stitching

............

............................................................................................................................ 24

5. Buttons and Buttonholes.......................................................................................................................... 25

Buttons .................................................................................................................................................... 25

Buttonholes ............................................................................................................................................. 26

6. Sewing the Professional Way.................................................................................................................... 28

Construction Details .............................................................................................................................. 28

Zippers • Blindstitch Hems • Corded Seams • Seams in Fabrics That Ravel

Sewing Knit and Stretch Fabric............................................................................................................ 32

Stretch Stitch Chart • Guiding and Supporting Fabric • Finishes for Hems and Facings

• Plain Stretch Seams • Lingerie Seams • Overedged Seams • Mock Overedging

Hints on Sewing Special Fabric........................................................................................................... 36

Leather-Look Vinyl • Ciré • Deep-Pile Fabrics • Velvet and Velveteen

Decorative Touches

Border Designs • Applique

Keeping Up Appearances..................................................................................................................... 39

Mending a Tear • Blanket Binding • Repairing Seams • Repairing Stretch Garments •

Darning

7. Caring for Your Machine............................................................................................................................. 42

Cleaning the Machine............................................................................................................................. 42

Removing Covers, Bobbin Case, and Bulb

Performance Checklist.......................................................................................................................... 46

8. Fashion* Aids .......................................................................................................................................... 47

Index

.................................................

...

....................................................................................................................... 38

.....................................................................................

................................................................................................... 48

43

Page 4

■.■АУЛХ.?.ЧУЛ?ЛХЛУЛ?.?.?Лу.»

Page 5

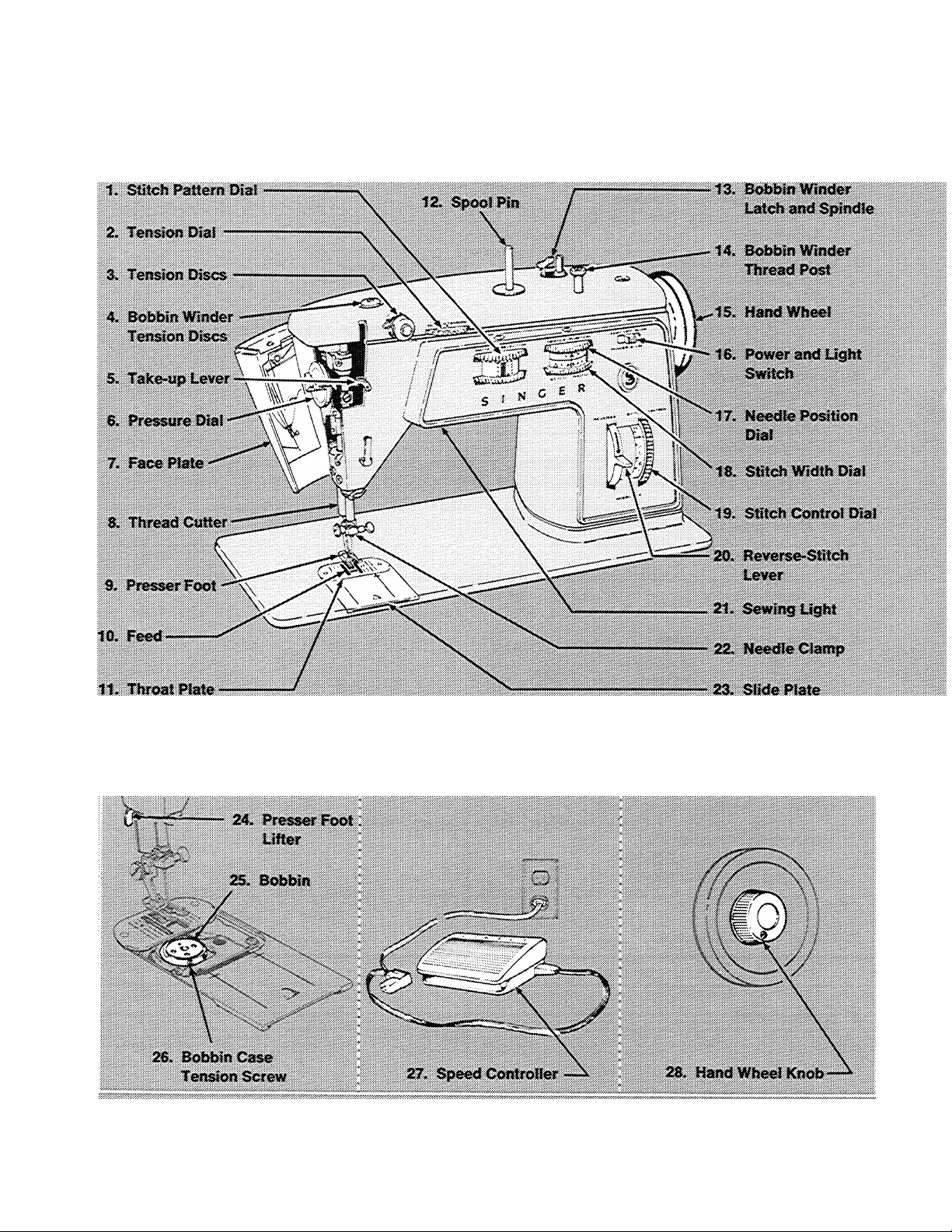

principal parts and what they do

1. Stitch Pattern Dial can be set to produce

a smooth straight stitch or a practical (and

decorative) zig-zag stitch.

2. Tension Dial lets you select Just the right

tension for your stitch, thread, and fabric.

The numbers eliminate guesswork

plicating settings.

3» Tension Discs, controlled by the tension

dial, regulate the amount of tension on

your needle thread,

4. Bobbin Winder Tension Discs regulate

thread tension for bobbin winding.

5. Take-up Lever controls flow of needle

thread.

Pressure Dial regulates presser-foot pres

sure on fabric. It has an all-purpose sew

ing setting plus settings for extra-light and

extra-heavy pressure and for darning.

7. Face Plate swings open for access to

threading chart and pressure dial.

8. Thread Cutter is built into presser bar for

safety and convenience.

9. Presser Foot holds fabric against feed.

10. Feed moves fabric under the presser foot.

In du

17. Needle Position Dial places needle in

either L (left), A (center) or R (right)

stitching position.

18. Stitch Width Dial controls the width of

zig-zag stitching and positions the needle

for straight stitching.

19- Stitch Control Dial allows for a variety of

stitch lengths; also has a special STRETCH

setting for straight or zig-zag stretch

stitching,

20. Reverse-Stitch Lever instantly reverses

stitching direction at the touch of your

finger,

21. Built-in Sewing Light illuminates sewing

area. Pull-down bracket makes It easy to

replace bulb.

22. Needle Clamp is designed to make needles

self-setting and eliminate the possibility

of inserting needle backwards.

23. Slide Plate, opens easily, lets you see

bobbin. Seam guidelines (extended from

throat plate) have cross lines to help you

turn square corners.

11. Throat Plate, secured by magnets, lifts out

for removal. Guidelines on right and left

sides of plate help you keep seams straight.

12. Spool Pin holds spools of various sizes.

13. Bobbin Winder Latch and Spindle let you

fill bobbin quickly and easily. Latch dis

engages when bobbin is full.

14. Bobbin Winder Thread Post guides the

thread when winding the bobbin.

15. Hand Wheel controls movement of take-up

lever and needle. Alv/ays turn it toward

you.

18. Power and Light Switch turns on machine

and sewing light simultaneously. FAST and

SLOW speed range settings let you choose

the best sewing speed for your work.

24. Presser-Foot Lifter, at back of machine,

allows you to raise and lower presser foot.

Extra-high lift position permits easy place

ment of bulky fabrics.

25. Bobbin shows thread supply, is easily re

moved for winding.

26. Bobbin Case Tension Screw regulates

bobbin-thread tension. Seldom needs ad

justment,

27. Electrical Connections and Speed Con

troller are designed for your convenience

and safety.

28. Hand Wheel Knob engages hand wheel to

sewing mechanism. Loosen knob for bob

bin winding.

Page 6

accessories

The accessories that come with your sewing

machine are designed to help you do many

kinds of sewing easily and perfectly.

To increase the versatility of your machine still

iurther, additional accessories can be pur

chased at your Singer Sewing Center. For de

scriptions, see page 47.

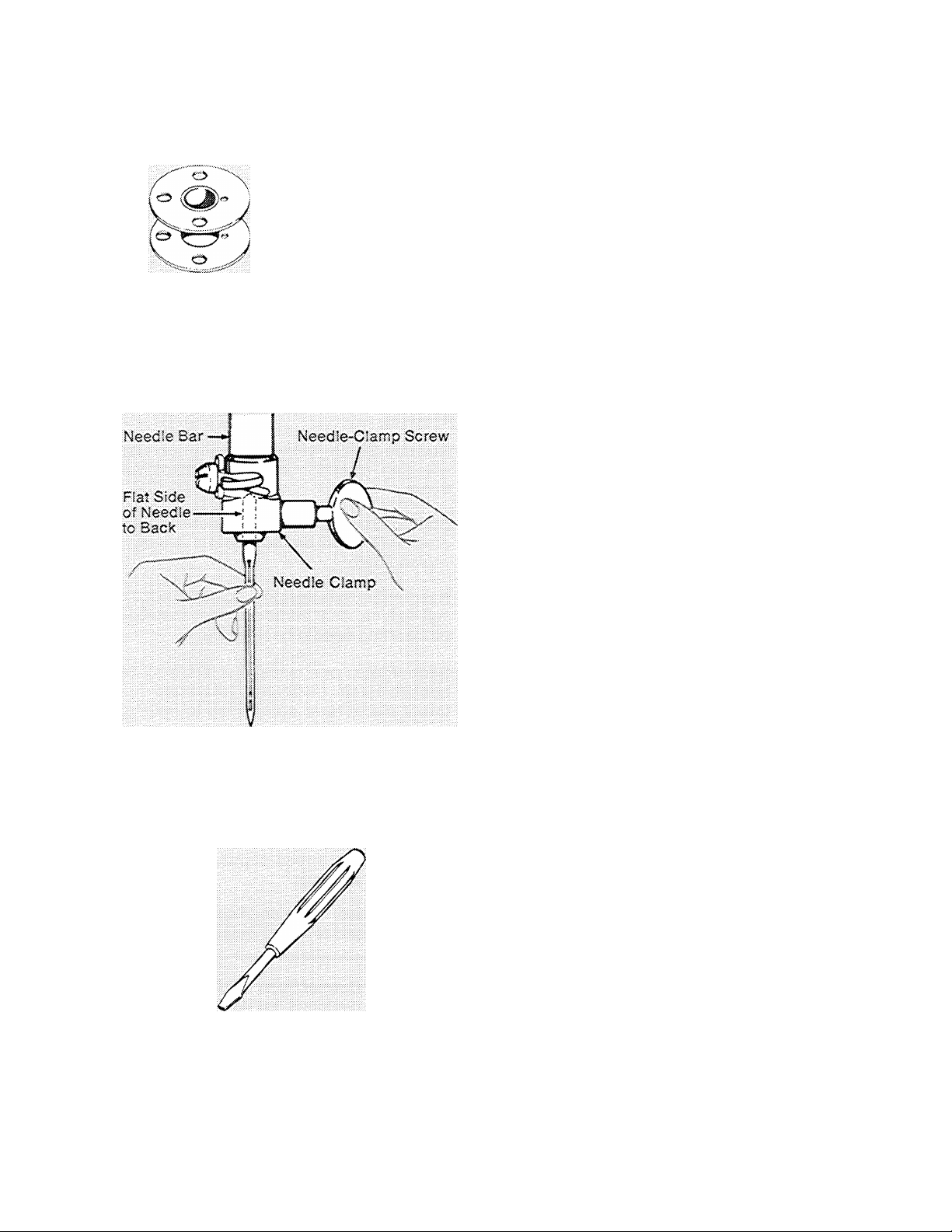

1, BOBBINS

Bobbirt

(Ho. iraaaa)

Changiiig the Needle

Regular Balî«Poinî

Needle Needle

CCataoao) (Catao4S)

• One 6rop-m steel bobbin in your machine.

• Extra drop-in steel bobbins with your acces

sories.

2. NEEDLES

In place in your machine ~~

• Catalog 2020 (15x1)

With your accessories —

• Catalog 2020 (15x1) needles, for all-purpose

sewing.

• Catalog 2045 ball-point (yellow band)

needles, for sewing synthetic knits and

stretch fabrics.

Changing the Needle

The needle clamp has been designed so that

the needle can only be inserted with the flat

side of the shank toward the back.

1. Raise needle bar to its highest position,

loosen needle-clamp screw, and remove

needle,

Tension Screwdriver

2. Insert new needle in clamp, with the flat

side of the needle to the back, and push

it up as far as it will go,

3. Tighten needle-clamp screw.

3. TENSION SCREWDRIVER

Designed to fit the bobbin case tension screw,

this screwdriver makes adjustment of bobbinthread tension quick and easy. (For instruc

tions on bobbin-thread tension adjustment, see

page 16.)

Page 7

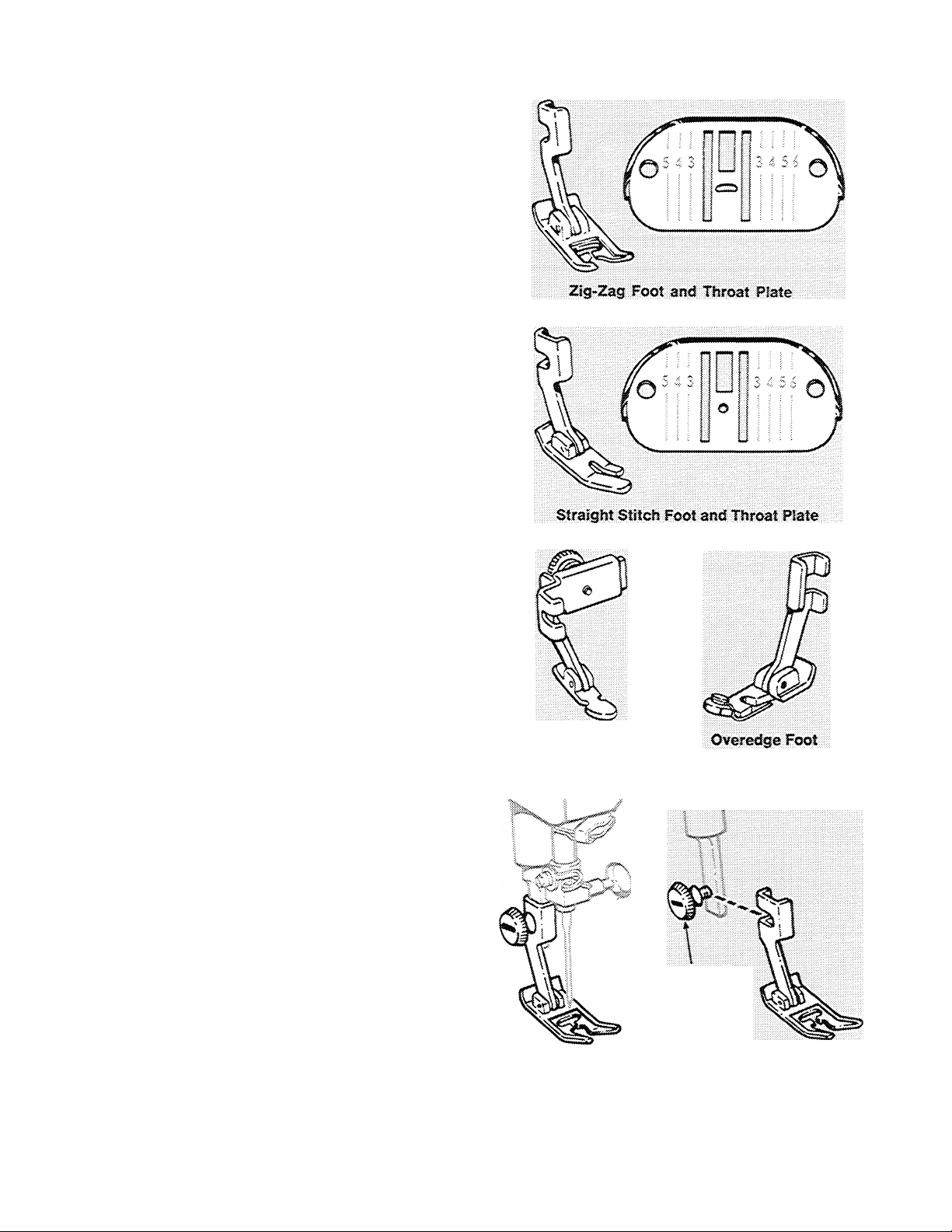

4. ZIG-ZAG FOOT AND THROAT PLATE

The zig-zag foot and the zig-zag throat plate

are in place on your machine, ideal for all util

ity sewing, these fittings can be used for either

straight or zig-zag stitching. Always use them

together when alternating between straight

and zig-zag stitching.

5. STRAIGHT STITCH FOOT AND

THROAT PLATE

The straight stitch foot and the straight stitch

throat plate are used when your fabric or sew

ing procedure requires close control Espe

cially useful for:

• Precision stitching of curved and scalloped

edges, topstitching, edge stitching, etc.

♦ Stitching on delicate or spongy fabrics, syn

thetics, and knits.

6. ZIPPERFOOT

The zipper foot is used to place stitching close

to a raised edge. Thus, it is as useful for corded

seams and tubular cording as it is for zipper

Insertion (page 28), It can be adjusteb to either

the right or left side of the needle and may be

used with the straight stitch or zig-zag throat

plate.

7. OVEREDGE FOOT

Zipper Foot

Overedge foot, used with overedge stretch

stitch, enables you to produce flexible over

edged seams and edge finishes. It is particu

larly useful in construction of garments made

of knit, stretch, and elastic fabric.

Changing Presser Foot

1. Raise needle to its highest position and

raise the presser foot,

2. Loosen presser foot screw and remove the

foot.

3. Hook new foot around the presser bar and

tighten presser foot screw.

Presser Foot

Screw

Changing Presser Foot

Page 8

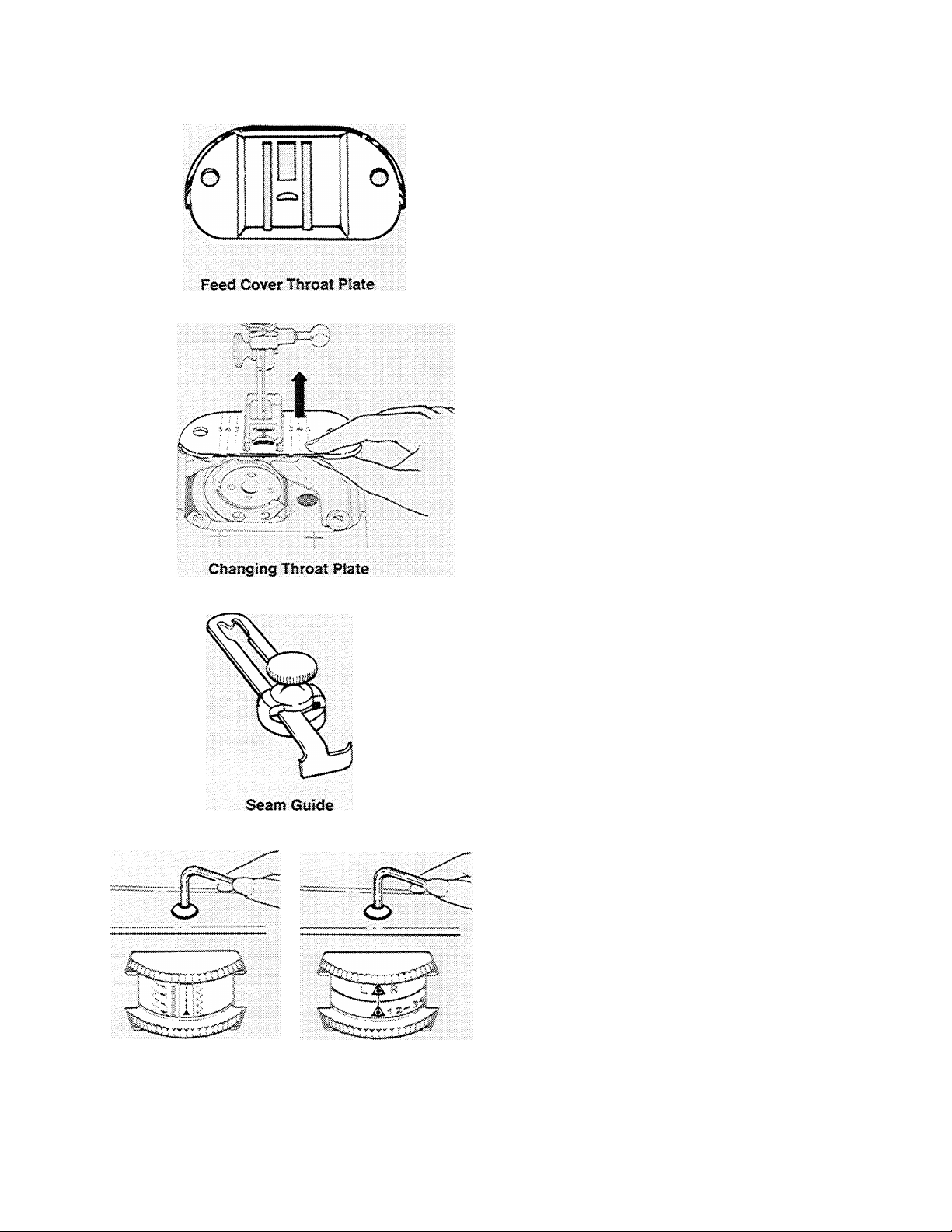

8. FEED-COVER THROAT PLATE

The feed cover throat plate replaces the throat

plate when fabric feeding is not desired. Use it

for button sewing (page 25) and free-motion

darning (page 41).

Changing Throat Plate

(NOTE: Remove bobbin if it contains thread in

order to prevent thread being caught when

throat plate is replaced.)

1. Raise needle to its highest position and

raise presser foot.

2. Open slide plate. Remove throat plate by

placing thumb under plate and lifting it up

and out.

3. Position new plate over the two pins and

release. (Throat plate is drawn into position

by magnets.)

4. Close slide plate,

a SEAM GUIDE

straight Stitch Locking Key

The seam guide will help you to stitch seams of

perfectly uniform width. It 1$ especially useful

for curved seams or topstitching, when ab

solute accuracy is required. Also, because it

allows you to guide stitches at any distance

between 1/8 inch (3mm) and 1-1/4 inches

(32mm) from fabric edge, it is useful for very

narrow or unusually wide seams.

Attaching the Seam Guide

Place screw in hole to the right of the slide

plate; line up straight edge of guide with the

throat plate guideline for desired seam width,

and tighten screw.

10, STRAIGHT STITCH LOCKING KEY

The locking key furnished with your acces

sories is used to remove the pins that lock the

dial controls for straight stitching in center

needle position. Insert key into locking pin and

turn key counterclockwise to remove pin. To

‘lock” the m.achine in straight stitch position,

set dials at A , A and i . insert pins from

top through dials and turn key clockwise.

Page 9

Z. GETTING READY TO SEW

preliminary steps

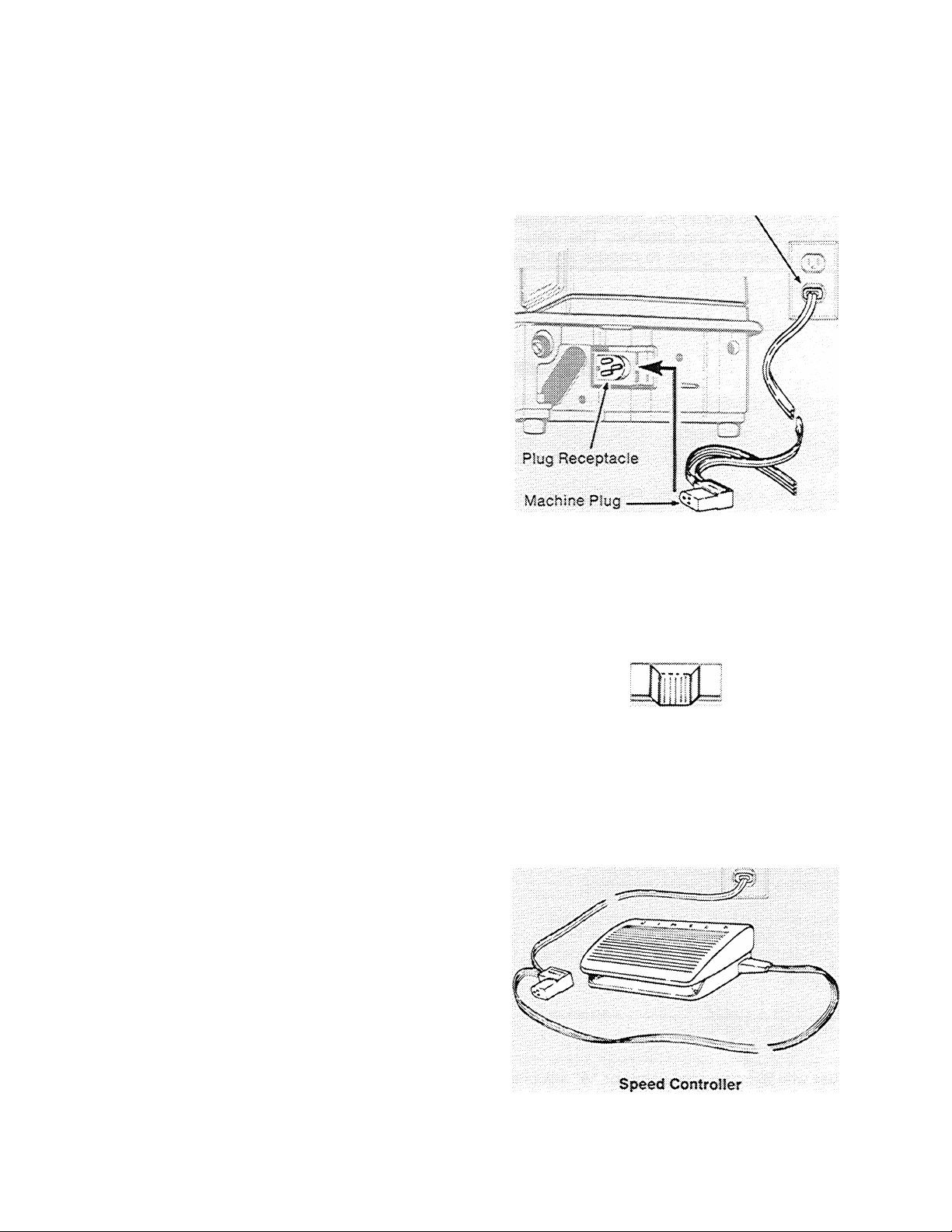

1. CONNECTING MACHINE

Before plugging in your machine, be sure that

the voltage and number of cycles indicated at

the right end of the machine, or on the inside

of the face plate, conform, to your electrical

power supply.

To connect machlm, push the machine plug

into the plug receptacle.Then Insertthe power«

line plug into your electrical cutlet

2. OPERATING MACHINE AND

CONTROLLER

To turn on both the machine and sewing light

and set speed range, slide the power and light

switch to the selected range.

♦ The FAST setting allows for full speed ca

pacity of the machine. It Is best for long,

straight seams, easy-to-handle fabrics, and

general sewing where a variety of speeds

is needed.

Power-Line Plug

Electrical Connections

for Household Machine

FA.3T OFF 3L.OW

• The SLOW setting allows for maximum con

trol at lower sewing speeds. Use this setting

for special jobs such as button sewing,

buttonhole making, and where construction

details require close controL

CAUTION: We recommend that you turn oft

the power and light switch before changing

needles, presser feet or throat plates and v/hen

leaving the machine unattended. This elimi

nates the possibiiity of starting the machine by

accidentally pressing .the speed controller.

To run the machine, press the speed controller

(or knee lever). The harder you press, the

faster the machine will sew within the selected

speed range.

F>OW3FR ^ L.ÍOFÍX

Power and tight Switch

Page 10

choosing needle and thread

The needle and thread you choose whf depend

upon the fabric being stitched. The table be

low is a practical guide to needle and thread

FABRIC, THREAD AND NEEDLE TABLE

FABRIC THREAD

DELICATE — tulle, chiffon, fine lace, or

ganza

LIGHTWEIGHT — batiste, organdy, jersey,

voile, taffeta, crepe, chiffon velvet, plas

tic film

MEDIUM WEIGHT — gingham, percale,

pique, linen, chintz, faille, satin, fine cor

duroy, velvet, suitings, knits, deep pile

fabrics, vinyl

Fine mercerized cotton

selection. Refer to it before starting a sewing

project Be sure to use the same size and type

of thread in both needle and bobbin.

NEEDLES

TYPE

CATALOG

Fine synthetic thread

50 mercerized cotton

silk

Synthetic thread

Polyester core/cotton

50 mercerized cotton

60 cotton

^‘A'^ silk

Synthetic thread

Polyester core/cotton

2020

(15x1)

CATALOG

2020

(15x1)

CATALOG

2020

(15x1)

SIZE

0

11

14

MEDIUM HEAVY — gabardine, tweed, sail

cloth, denim, coatings, drapery fabrics,

vinyl, deep pile fabrics

HEAVY — overcoatings, dungaree, uphol

stery fabrics, canvas

WOVEN FABRICS (ALL WEIGHTS) -decorative straight-stitch topstltching

SYNTHETIC KNITS AND STRETCH FAB

RICS — polyester doubleknit, nylon tri

cot, Jersey, spandex, ciré tncoi. panne

velvet

LEATHER *-suede, kldskin. capeskin,

lambskin, lined leathers

tUse with 50 mercerized cotton or ''A” silk

Heavy-duty

mercerized cotton

40 to 60 cotton

Synthetic thread

Heavy-outy

mercerized cotton

24 to 40 cotton

Synthetic thread

^^D^^silkf

(Buttonhole twist)

50 mercerized cotton

Polyester core/cotton

50 mercerized cotton

Synthetic thread

‘^A’’ silk

Polyester core/cotton

in bobbin

nylon

silk

CATALOG

2020

(15x1)

CATALOG

2020

(15x1)

CATALOG

2020

(15x1)

CATALOG

2045

Ball Point

(Yellow Band)

CATALOG

2032

(15x2)

16

18

18

14

11

14

16

Page 11

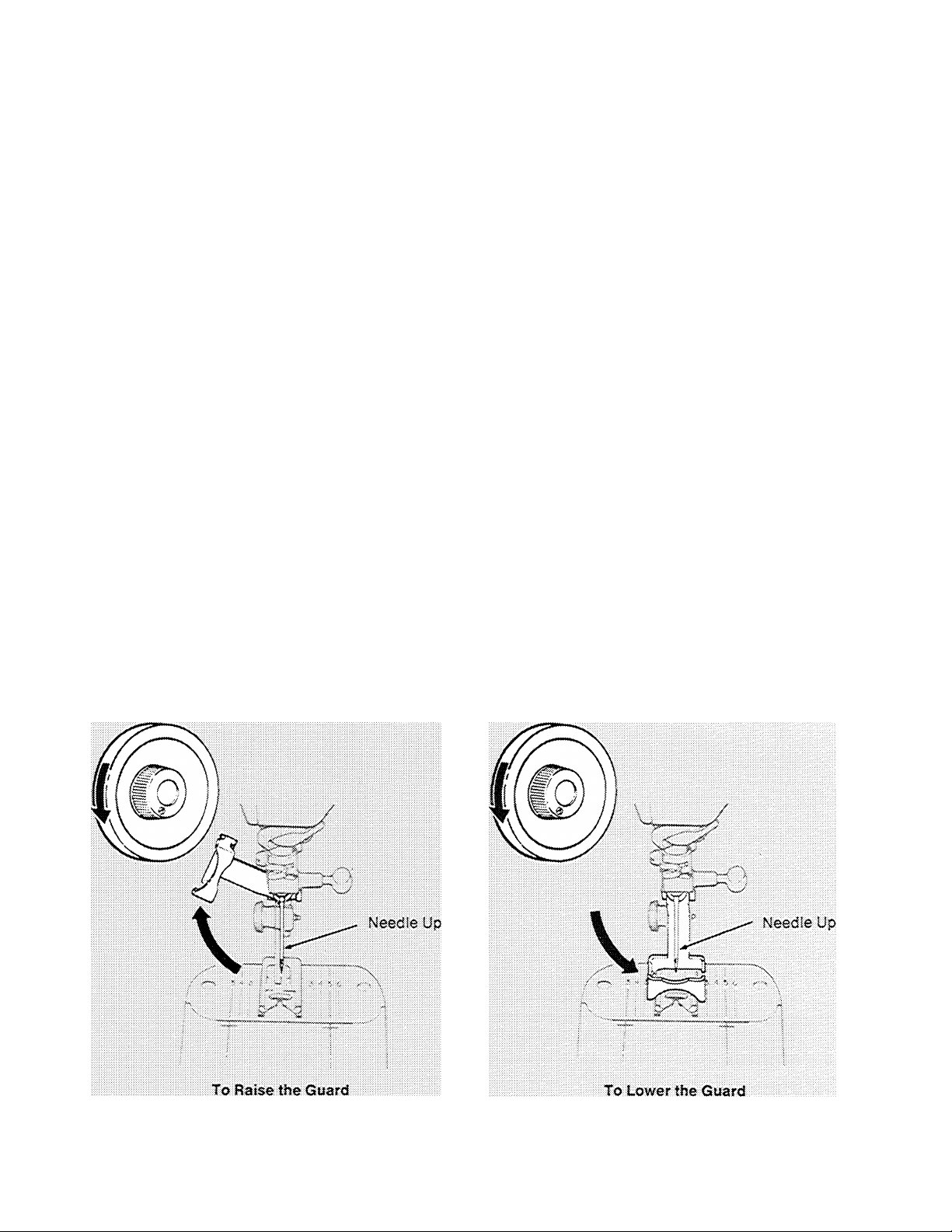

INSTRUCTIONS FOR USING THE FINGER

GUARD

{Furnished with classroom machines,)

Positioning the Guard

Before raising or lowering the guard, turn off

the power and light switch. This will avoid the

possibility of accidentally starting the machine

while the needle is unguarded.

Raising the Guard

To thread and replace the needle and change

the presser foot:

# Position the needle above the throat plate

by turning the hand wheel toward you,

• Swing the guard out to the left and raise it

to the position shov/n.

Lowering the Guard

For sewing and bobbin winding:

♦ Position the needle above the throat plate

by turning the hand wheel toward you.

•

• Swing the guard down and position it as

far to the right as it vnil go.

Using the Guard

The finger guard can be used with all of the

accessories supplied with your machine and

many of the Special Accessories available at

your local Singer Sewing Center. The standard

sewing procedures outlined in this instruction

manual should be used, except as noted below,

SPECIAL REQUIREMENTS

Darning with an Embroidery Hoop

When using the feed cover throat plate for

darning with an embroidery hoop, as explained

on page 41, swing the finger guard out of the

way. For hoop darning v/ith the finger guard,

use the general purpose or straight stitch

throat plate. Follow the same sewing pro

cedure with all plates.

Using the Seam Guide

To avoid the possibility of interference be

tween the finger guard and the seam guide,

lower the finger guard and the presser foot

before positioning and securing the seam

guide to the machine.

Page 12

threading the machine

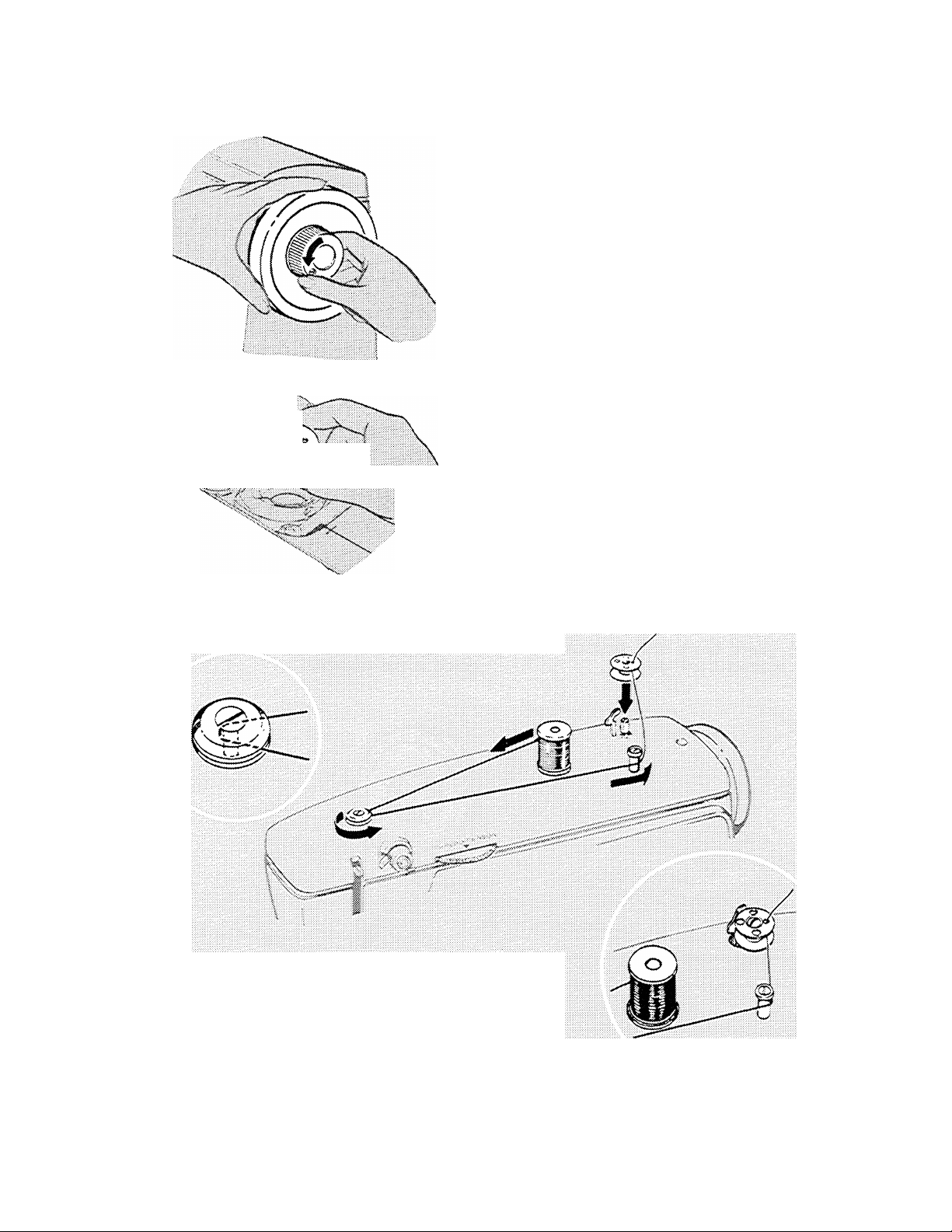

WINDING THE BOBBIN

Preparation

it is best to wind the bobbin before you thread

the machine*

1* Turn hand wheel toward you until needle is

at its highest position.

2, Disengage hand wheel from sewing mech

anism by loosening the hand wheel knob

with your right hand while holding the hand

wheel with the left.

3. Open the slide plate. Lift out the bobbin.

Winding Steps

1. Place thread spool on spool pin over the

spool pin felt. Lead thread between tension

discs (as shown), around thread post and

through small hole In bobbin (from the in

side out).

10

2, Place bobbin on spindle.

Page 13

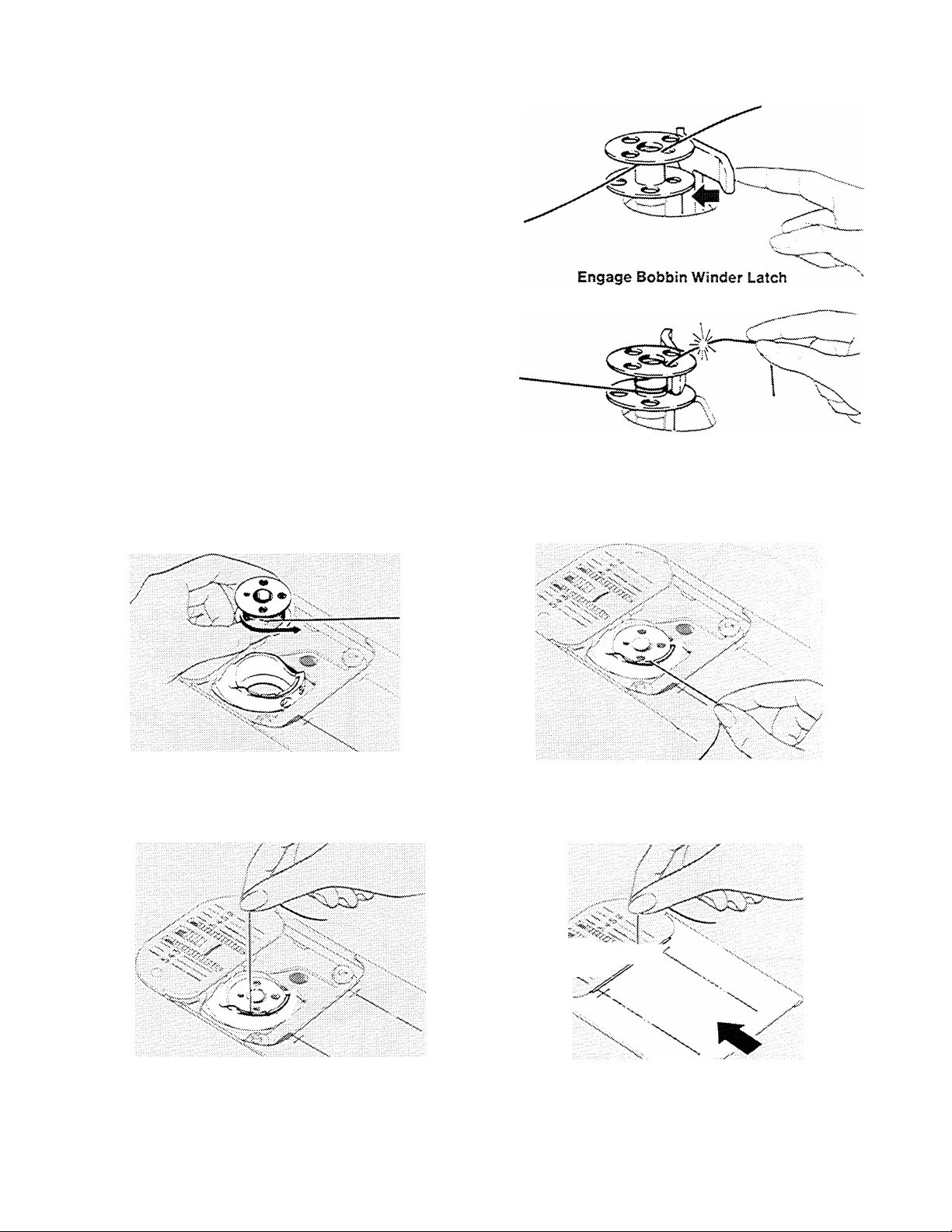

Winding Steps (continyed)

3. Engage latch by pressing it toward the

bobbin.

4. Hold thread end as shown and start the ma

chine. Thread end will snap off after a few

coils have been wound on the bobbin.

5. When required amount of thread has been

wound (full bobbin will automatically re

lease), cut thread and remove bobbin from

spindle.

6. Tighten hand wheel knob by turning it away

from you with your right hand while holding

the hand wheel with your left hand.

THREADING THE BOBBIN CASE

Hold Thread End to Start Winding

1. Hold bobbin so that the thread unwinds

in direction shown, and put bobbin in

bobbin case.

3. Draw approximately three inches of

thread diagonally across the bobbin.

2. Pull thread into notch in bobbin case,

draw it under the tension spring, and

into the slot

4. Close slide plate, allowing the thread

to enter the slot in the slide plate.

11

Page 14

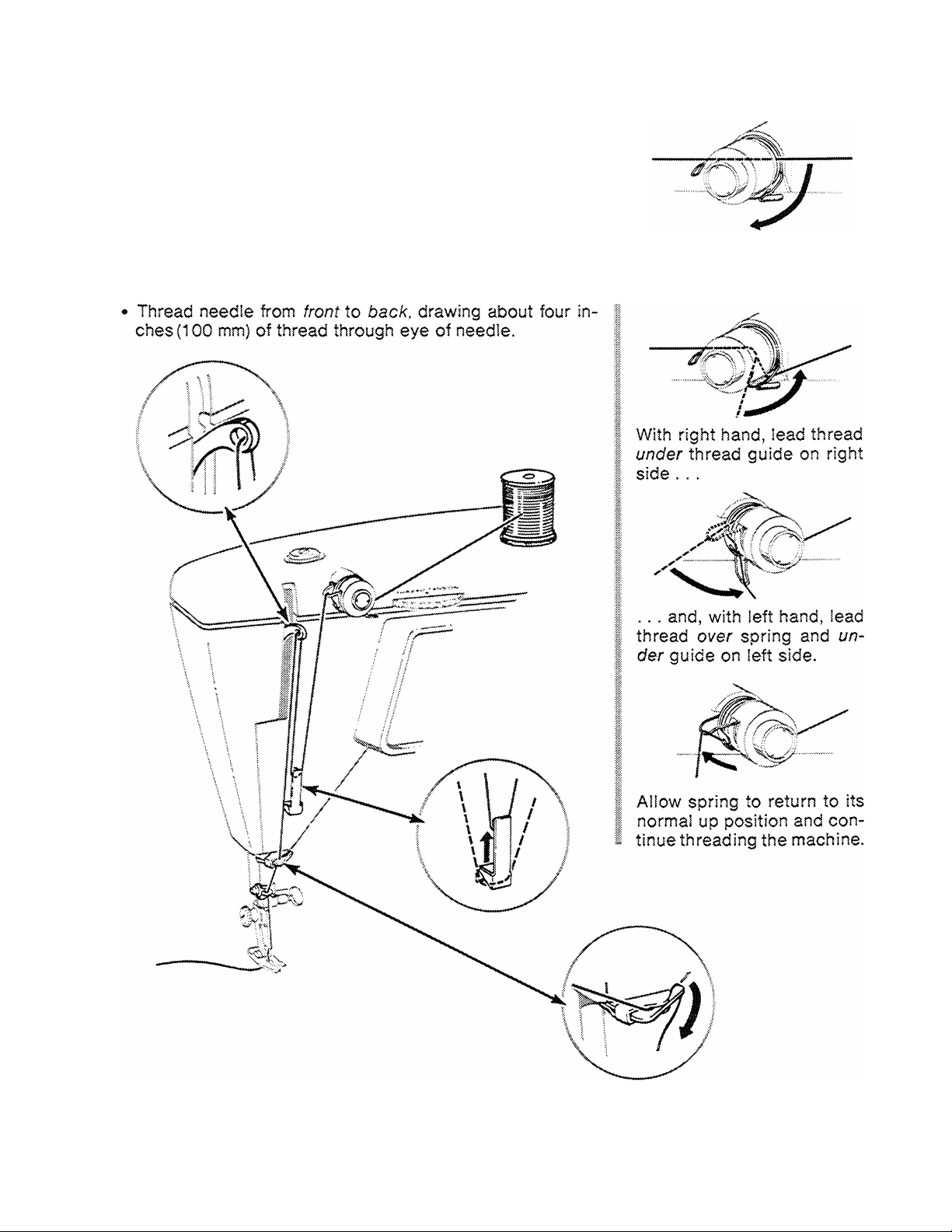

THREADING THE NEEDLE

1. Turn hand wheel toward you to raise needle to highest

position with take-up lever midway in slot Raise presser

foot to release tension discs,

2, Place spool of thread on spool pin over the spool pin felt.

Lead thread through all points as shown, making sure to:

• Thread tension discs as illustrated, W3^

* Thread take-up lever from right to left

With two hands, slip thread

horizontally between ten

sion discs from the top.

12

Page 15

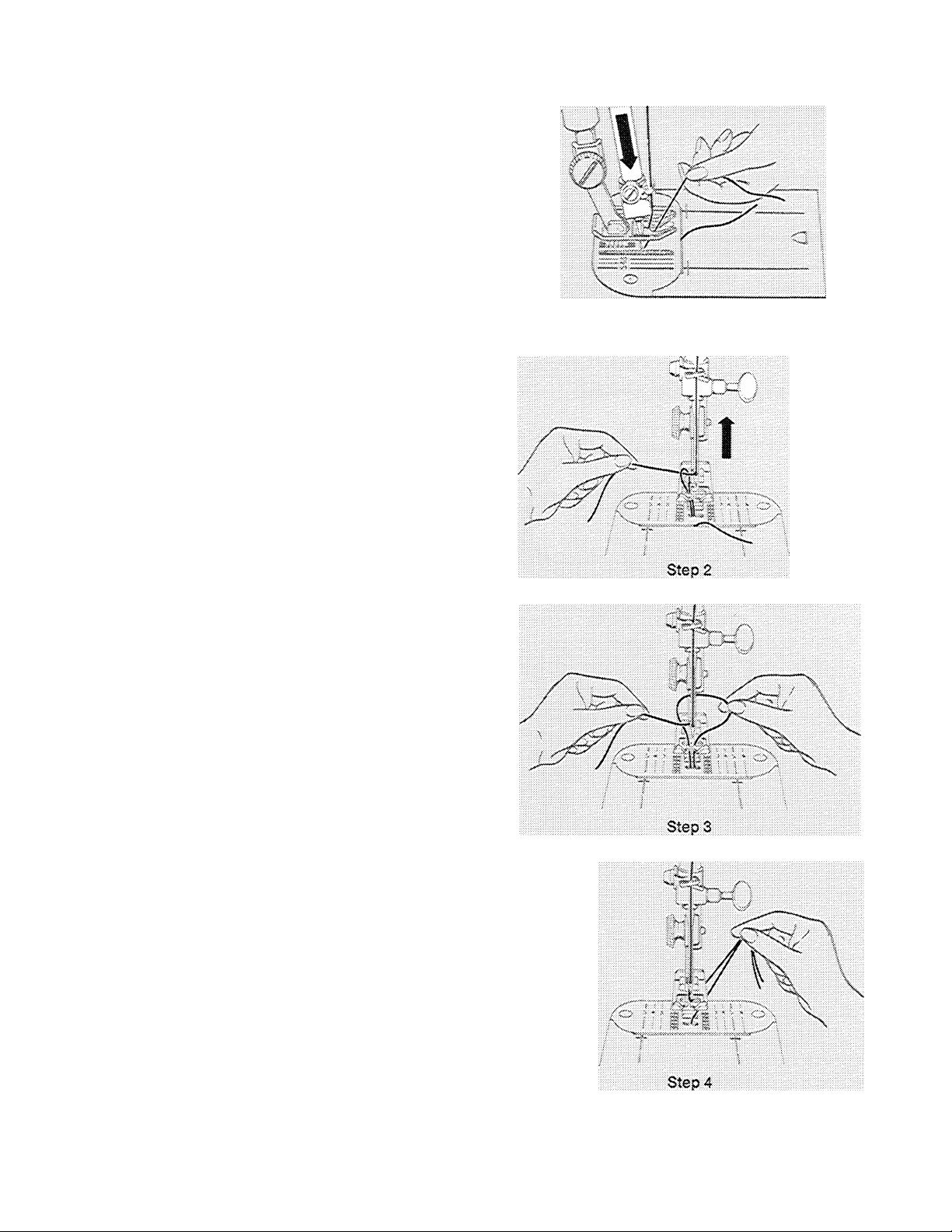

RAISING THE BOBBIN THREAD

Now that you have wound the bobbin and

threaded the needle, you will need to raise the

bobbin thread through the needle hole In the

throat plate.

1, Hold needle thread lightly with the left hand

and turn the hand wheel slov/ly toward you

so that the needle enters throat plate.

2, Continue turning hand wheel and holding

needle thread until needle rises and brings

up bobbin thread in a loop.

Step 1

3. Undo the loop with your fingers.

4. Place both needle and bobbin threads un

der presser foot and draw to back of ma

chine.

... you are now ready to sew

13

Page 16

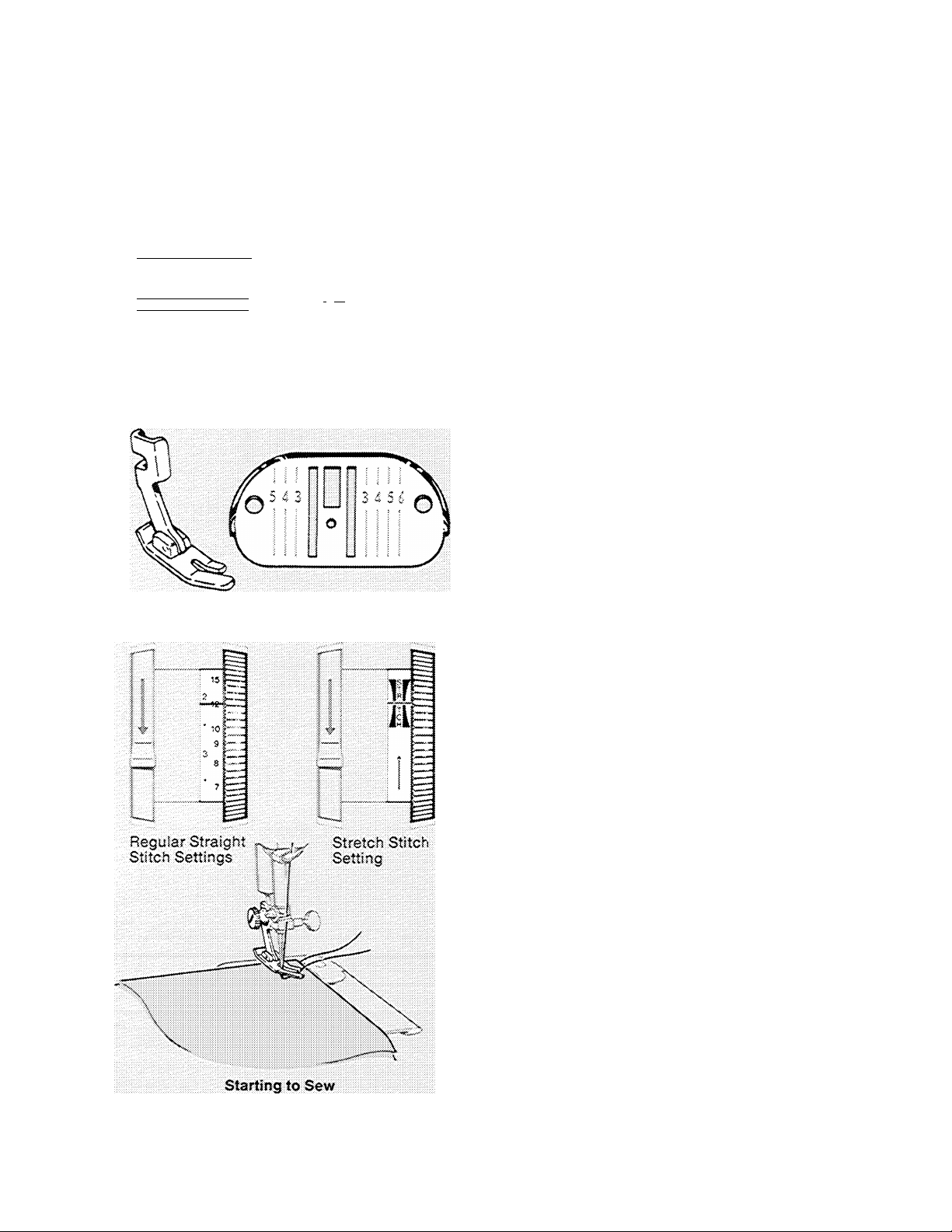

3. STRAIGHT STITCHING

Pattern: Straight Stitch

Needle Position: A

Stitch Width: A

Stitch Control: To suit fabric

Straight Stitch Throat Plate o;

Zig-Zag Throat Plate

Straight Stitch Foot or

Zig-Zag Foot

preparation

Before you set the dials for straight stitching,

turn the hand wheel toward you until the needle

is above the throat plate.

s;

: i > ;'

■ ■' - :i; ! ;

I

Dials Set for Straight Stitching

I Ij IJ I I ,i II II II l

X

•vrm-

Straight Stitch Foot an<i Needle Plate

SETTING THE MACHINE

5

1. Set pattern dial selector at .

2. Move needle position dial to A .

3. Set stitch width dial on A *

4. Set stitch control for desired stitch length.

For regular straight stitching, turn dial to

a numbered setting; for straight stretch

stitching, turn dial to STRETCH setting.

CHOOSING ACCESSORIES

Best results will be obtained if you use the

straight stitch foot and throat plate. However,

the zig-zag foot and throat plate may also be

used.

starting to sew

♦ Place needle and bobbin threads under pres-

ser foot and draw to back of machine.

♦ Position the needle in the fabric where de

sired for stitching start.

14

♦ Lowerihe presser foot and start the machine.

To sew perfectly on a wide variety of fabrics

adjust stitch length, pressure and thread ten

sion as instructed on the following pages.

For information on straight stretch stitching,

turn to page 34.

Page 17

adjusting for your fabric

Red Line

SETTING STITCH LENGTH

The stitch control dial regulates the length of

both straight and zig-zag stitches. The numbers

6 to 20 represent the number of straight

stitches per inch and the numbers 1 to 4 repre

sent stitch length in millimeters. Generally,

shorter stitches are best for lightweight fabric,

longer ones for heavy fabric. Curved seams,

bias-cut seams, and scallops require short

straight stitches for elasticity and smooth contours.

The FINE area is used for adjustment of zig-zag

satin stitching (page 24).

The STRETCH setting is used for straight-

stretch stitching and FlexhStitch patterns only.

For information on Flexi-Stitch patterns and

straight-stretch stitching, see pages 21 and 32.

• To set stitch control, turn dial until setting

desired is under the red line.

For reverse stitching, simply press reversestitch lever all the way down and hold in place.

Release lever for forward stitching.

Setting for

Stretch Stitching

Reverse Stitch Lever

Stitch Control Dial

REGULATING PRESSURE

The pressure dial regulates the pressure that

the presser foot exerts on the fabric. Correct

pressure is important because it means fabric

feeds smoothly and evenly. The HOHM (nor

mal) setting is an all-purpose setting that can

be used for sewing a wide variety of fabrics

of different weights and textures. Intermediate

notched settings, above and below NORIVI,

are also provided. When you need extra con

trol to sew very heavy fabric, use the MAX

(maximum) setting.

Lov/er the presser foot before setting pressure,

♦ To increase pressure, turn dial from NORM

toward MAX.

♦ To decrease pressure, turn dial from NORM

toward DARN.

♦ For darning, set dial on DARN,

\V„//7

Decrease

Pressure Dial

Darning

15

Page 18

Meedle-Thread Tension

REGULATING THREAD TENSION

Correct tension Is important because too much

or too little will weaken your seams or cause

your fabric to pucker. Make a test sample with

the fabric and thread you plan to use, and ex

amine it A perfect stitch will have the needle

and bobbin threads looked between the two

layers of fabric with no loops on top or bottom

and no puckers.

Needfe-Ttiread Tension

The tension dial regulates the degree of ten

sion on your needle thread. Set it according to

the type of thread and fabric you use. The

numbers on the dial eliminate guesswork in

duplicating settings.

If the stitches in your test sample look loose,

increase needle-thread tension. If the fabric

puckers, decrease tension.

♦ To increase tension, turn dial to higher num

ber.

• To decrease tension, turn dial to lower num

ber.

Bobbin-Thread Tension

Bobbm-thread tension is controlled by a screw

located on the bobbin case. You will seldom

need to adjust bobbin-thread tension since It

is usually possible to obtain the correct bal

ance by adjusting needle-thread tension

alone.

On those rare occasions when it becomes

necessary to adjust the bobbin-thread ten

sion, use the small tension screwdriver fur

nished with your accessories, A very slight

turn on the screw nearest the thread slot on

the bobbin case will produce a noticeable

change in bobbin-thread tension.

^ To increase tension, turn screw clockwise,

* To decrease tension, turn screw counter

clockwise.

16

Page 19

sewing a seam

PIN BASTING

Pin basting is a time saver and can be used in

place of hand basting when you are straight

stitching seams in easy4o-handie fabric.

Use fine pins and place them so that:

• They are at right angles to the presser foot

and just nip into the fabric at the stitching

line.

♦ They do not extend under both sides of the

presser foot. Never place pins on the under

side of the fabric in contact with the feed.

Pin Placement When

Seam <5uide Is Used

PLACING FABRIC

Most fabric can be placed under the presser

foot by raising the presser-foot lifter to its

normal up position. When placing bulky fab

rics, such as coating, knit or terry cloth, or

multiple fabric layers, you will find it conven

ient to raise the presser-foot lifter to the highrise position. Hold lifter in position (since it

does not lock) while placing fabric under the

presser foot. Make sure the lifter is all the way

down before starting to sew.

Presser Foot Lifter Settings

17

Page 20

I

Starting a Seam

Guiding and Supporting Fabric

Applying Gentle Tension

Stitching a Seam

STARTING A SEAM

1« With presser foot raised, turn hand wheel

toward you to position needle in fabric

about 1/2 inch (13mm) from starting edge.

Lower the presser foot.

2, Press reverse-stitch lever all the way down

and hold in place. Backstitch to edge of

fabric for reinforcement.

3. Release reverse-stitch lever and stitch in

forward direction.

GUIDING AND SUPPORTING FABRIC

Most fabrics need only to be guided in front of

the presser foot. Some fabrics, however, re

quire support while being stitched, as shown.

These fabrics require using the straight stitch

presser foot.

18

Applying Firm Tension

* For filmy sheers, knits, tricot, etc., apply

gentle tension by holding seam in front and

back of the presser foot.

* For stretch fabrics, apply firm tension front

and back when stitching in the same direc

tion as the stretch. For seams not on the

stretch direction, stitch in the conventional

manner, guiding fabric in front of the presser

foot.

Page 21

KEEPING SEAMS STRAIGHT

To keep the seam straight, use one of the num

bered guidelines on the throat plate. The num

bers indicate distance, in eighths of an inch,

from the needle. If you want a 5/8 inch (16mm)

seam, for example, line up your fabric with the

number 5 guideline. Note that both number 5

guidelines (the most commonly used) are ex

tended on the slide plate for your convenience:

the crosslines serve as cornering guides when

stitching a square corner.

For extra help in keeping the seam straight, you

may wish to use the seam guide. Because it

allows you to guide stitches between 1/8 inch

(3mm) and 1*-1 /4 inches (32mm) from the fabric

edge, it is useful for very narrow or unusually

wide seams.

TURNING SQUARE CORNERS

To turn a square corner 5/8 inch (16mm)

from the fabric edge, you need not measure

or mark the seam. Simply use the

crosslines on the slide plate.

Line up your fabric with right or left

guideline 5 on the throat plate. Stitch

seam, slowing speed as you approach

corner.

Pivoting at Corner

Stop stitching, with the needle down,

when the bottom edge of the fabric

reaches the cornering crosslines on the

slide plate.

Raise presser foot and turn fabric on

needle, bringing bottom edge of fabric

in line with guideline 5.

Lower the presser foot and stitch in new

direction.

Fabric at Crosslines

Fabric after Turning

19

Page 22

CURVED SEAMS

1. Use a short stitch for elasticity and

strength. For example, if you use 12

stitches to the inch (stitches approximately

2mm long) for straight seams, select 15 to

20 per inch (stitches approximately 1.5mm

long) to stitch curved seams in the same

fabric.

2. If you use the seam guide to guide stitch

ing, attach it at an angle so that the edge

that is closer to the needle acts as a guide.

REINFORCING END OF SEAM

1. Stitch to the edge of the fabric.

2. Press reverse-stitch lever all the way down

and hold in place. Backstitch approx

imately 1 /2 inch (13mm) to reinforce end of

seam. Release lever.

3. Raise needle to its highest position, raise

the presser foot, and remove the fabric by

drawing it to the back and left.

4. Cut threads on thread cutter at rear of

presser bar.

20

Ending a Seam

Page 23

4. ALL ABOUT ZIG-ZAG STiTCHliyG

two kinds of zig-zag stitches

The zig-zag stitches buiit into your machine

include basic zig-zag stitches and Flexi-Stitch

patterns, in addition to the obviousiy decora

tive uses of these stitches, some aiso serve

praoticai purposes. Under the section called

“Sewing the Professional Way” beginning on

BASIC ZIG-ZAG STITCHES AND THEIR DIAL SETTINGS

Stitch Pattern

mmHmmmmmmmmmmm

Flam Ztg-Zag Stitch

Multi-Stttch Zig-Zag

rVT'VTT'TTTTT

Bhndstitch

page 28, you will find instructions for both

decorative and practical uses of these stitches.

Ail of the basic zig-zag stitches and some of

the Flexi-Stitch patterns are charted below.

(When sewing Fiexi-Stitch patterns, set speed

range at SLOW.)

Pattern

Dial

I

/

%

-<

Stitch

Width

Diai

1-5

1-5

1-5

Position

Needle

Diai

L A R

L A R

L A R

Stitch

Control

Numbered

Area thro

FINE

Humbered

Area

Numbered

Area

FLEXI-SmCH PATTERNS AND THEIR DIAL SETTINGS

Stitch Fatter«

wvswwwwwww

Ric-Rac Stitchf

Semaphore Stitch

Fatter«

Dial

1

i

rffrrjrrmiTTTrmTm

Slant Overedge Stretch Stitchf

VAAAAAAAAAAAA

Overedge Stretch Stitch

tThis stitch is designed for strength and permanence and cannot be readily ripped out without risk of fabric damage.

<<

1

g

Stitch

Width

Dial

2-5

2-5

2-5

2-5

Needle

Position

Dial

L A R

L A R

L A R

L A R

Stitch

Control

6.

c

H

S

T

R

T

c

K

r

«

t.

T

c

H

T

«

e

T

c

«

21

Page 24

adjusting dials

SETTING PATTERN DIAL

Before moving the dial, make sure needle is

above the fabric.

Push the pattern dial in and turn it until de

sired zig-zag stitch pattern is between the red

lines.

To produce a Flexi-Stitch pattern, the stitch

control dial must be turned until the symbol

STRETCH appears under the red line.

Miiiliiiili.

i <-i|

1 >:lil

1 ■ > i 1

“|K

-ai—1,

iminiM.

Push In

Rotate

Release

Adjusting Stitch Placement

ADJUSTING STITCH PLACEMENT

Before moving needfe position dial, move

stitch width to 5, and make sure needle is

above the fabric.

Needle position setting A places the needle

in center stitching position. Settings L and R

place the needle in left and right stitching

positions at stitch widths less than 5,

Setting A is used most often. Settings L and

R are for special placement of stitching. For

example, an L setting is required for buttonholing and button sewing. An L or R setting

can be used to place narrow zig-zag stitching

to the left or right of center in decorative work.

To adust stitch placement, turn needle posi

tion dial until desired setting is aligned with

the red line.

nunninF^

Left Needle Position

Center Needle Position

...........^.....

Right Needle Position

22

Page 25

ADJUSTING WIDTH OF DESIGN

Before moving dial, make sure needle is above

the fabric.

To produce a zig-zag stitch, turn the stitch

width dial to any setting between 1 and 5. The

higher the number, the wider your stitch wiil

be. A stitch width setting of 2 or more is rec

ommended for Flexi-Stitch patterns.

ADJUSTING NEEDLE-THREAD TENSION

Zig-zag stitching usually requires less needlethread tension than straight stitching. Make a

test sample with the fabric and thread you plan

to use so that you can adjust tension to suit the

stitch pattern you have chosen. The stitches

should lie flat against the fabric without causing

the fabric to pucker.

if the stitches are not flat and the fabric is

puckered, lower the needle-thread tension by

turning the dial to a lower number.

Adjusting Width of Design

ADJUSTING STITCH LENGTH

Any stitch control setting in the numbered area

will give you an open zig-zag stitch of the pat

tern you select except Flexi-Stitch patterns.

The triangular symbol on the dial designates

the FINE stitch area and is used for the adjust

ment of zig-zag satin stitching (see page 24 for

specific instructions).

To produce the overedge stretch stitch or any

other Flexi-Stitch pattern (refer to stitch pat

tern chart), the stitch control dial must be set

on the STRETCH symbol. Simply turn the dial

downward until the symbol is centered under

the red line. No further adjustment is neces

sary.

V/hen using the STRETCH setting of the stitch

control, you cannot backstitch the stitch pat

tern.

'

.....

Ц-

:! ;! ; \fi\t

i 20

----

1^ *

i i i ’*

Stitch Control Dial

Correct

If

Emiim

>«~v~

23

Page 26

mm.

wm:>

''

li; li;

Stitch Control in FINE Area

I

As the Dial Is Rotated, Stitches Close Up

satin stitching

Satin stitching, a series of closely spaced zig

zag stitches that form a smooth, satin-like sur

face, is useful for both practical and decorative

work. The plain zig-zag stitch, for example, is

suitable for bar tacks and applique when

closed up to form a satin stitch. The f/ex/-

Stftch patterns, however, have a single stitch

length setting (STRETCH) and cannot be satinstitched.

When you wish to produce a satin stitch, make

a test sample first so that you can adjust the

stitch length and threa6 tension properly. Soft

fabrics may require a backing to ensure firm

satin stitching. Crisp lawn or organdy is suit

able for this purpose. For best results use the

special purpose foot.

DIAL SETTINGS

Pattern: Plain Zig-Zag I

Needle Position: A *

Stitch Width: a to $

Stitch Control: In FINE area

Zig-Zag Throat Plate

Zig-Zag Foot or

Special Purpose Foot (see note)

Adjusting Thread Tension

Adjusting Stitch Length

1. Set stitch control dial at bottom of FINE

area.

2. Run machine at SLOW speed.

3. Gradually turn dial downward until stitches

are closely spaced and form a smooth sur

face.

Correct

Adjusting Thread Tension

Satin stitching requires less tension than

straight stitching or open zig-zag stitching.

Furthermore, the wider the satin stitch, the

lighter the tension on the thread must be. No

tice the stitching on your sample. If the fabric

is puckered, lower the needle-thread tension

by turning the tension dial to a lower number.

NOTE: For best results in satin stitching, the spe

cial purpose foot is recommended {available for

purchase, see page 47).

24

Page 27

5. BUTTONS AND BUTTONHOLES

buttons

Pattern: Plain Zig-Zag I

Stitch Width: À and 4

Needle Position: L

Feed Cover Throat Plate

Zig-Zag Foot

The space between the holes in the button de

termines the stitch width settings. The A set

ting must always be used to position the needle

over the left hole and fasten stitching. For but

tons with standard hole spacing, use settings

A and 4. For buttons with unusual hole spac

ing, use setting A and increase or decrease

the width setting 4 as necessary.

To sew on two- or four-hole buttons, approxi

mately one inch ( 25 mm) in diameter or larger:

1. Set stitch width dial at A . Position button

under foot so that the needle will enter the

left hole. Lower foot. Turn hand wheel to

ward you until needle rises out of button

and is just above the foot.

2. Set stitch width at 4. Then, when you begin

to stitch, the needle should enter the right

hole of button. Take six or more zig-zag

stitches at this setting, ending on left side.

3. To fasten stitching, return to stitch width

A and take about three stitches.

For best results with buttons smaller than one

inch (25mm) in diameter, it is recommended that

the Button Sewing Foot be used. See page 47.

mwmbuhrnlllll

25

Page 28

buttonholes

• Pattern: Plain Zig-Zag |

• Stitch Widtix: i^V2 and 5 or to suit fabric

• Needle Position: L

• Stitch Control: FINE

• Zig-Zag Throat Plate

• Zig-Zag Foot or Special Purpose Foott

Always make a test buttonhole on a sample of

your fabric. Be sure to duplicate the thickness

of the garment and include interfacing if ap

propriate,

BUTTONHOLE LENGTH

First decide how long the opening needs to be.

This will depend on the diameter and the thick

ness of the button. To find the right length, cut a

small slit in a scrap of your fabric and gradually

enlarge it until the button slips through easily.

Then add at least 1 /8 inch or 3mm (1 /16 inch or

1.5mm for each bar tack), and mark the fabric as

illustrated. This bar-tack measurement Is ap

proximate: on some buttonholes, you may need

to increase it to arrive at pleasing proportions.

IVIarking Lines

STITCH WIDTH SETTINGS

Next, determine the two stitch width settings

that you will need: one for side stitching and

one for bar tacks (closings at ends of button

hole). Settings 2Vz and 5 are illustrated below,

although other combinations may be used, as

long as the combined width of side stitching

does not exceed the width of the bar tacks.

m

rrrTTmnV

.iiiiiiiiiiiiiiitiiitiiiiiUiiii

Selector

m

atZVa

Side Sistching

Length of

Cutting Space

Bar Tacks

Bar Tacks and

Side Stitching

ErmfTfj

Selector

atS

i I

TппппппiilJl

tlhe Special Purpose Foot described on page 47 is designed to aid in making buttonholes,

26

Page 29

PROCEDURE FOR MAKING BAR-^TACK BUTTONHOLES

With needle position dial at L, set stitch width

dial on 2Y2 for side stitching of buttonhole.

Place work under needle, aligning center mark

ing of buttonhole with slot in the presser foot.

Side Stitching: Position needle in fabric at

point A. Lower the foot and stitch to end of

marking. Leave needle in fabric at point B,

Raise the foot and pivot work on needle. Lower

the foot. Take one stitch without changing

width setting, bring needle to point

Bar Tack: Adjust stitch width for bar tacks and

take at least six stitches. Stop at point D,

C.

■"■¿iUUij.,

±i

it

EmShiiiiä

Side Stitching

A*::

4 i 1

C B

Side Stitching: Readjust stitch width for side

stitching. Complete work to point £. Leave

needle in fabric.

Final Bar Tack: Adjust stitch width for bar

tacks, and take at least six stitches in reverse,

ending at point F.

Fastening Stitch: To secure stitching, move

stitch width dial to A and take three stitches.

Remove work, draw threads to underside,

fasten and trim. Cut opening for button with

sharp scissors.

rrrm

Uilniiiiilii

1

man. mam

1

----

;r-....T

4

Bar Tack

4 5

Side Stitching

Ar*.

nrrrrrn

1-

Final Bar Tack

27

Page 30

6. SEWING THE PROFESSIONAL WAY

construction details

ZIPPERS

At the notions counter in your Singer store,

you will find many different kinds of zippers,

one of which will be just right for whatever you

wish to sew. How the zipper is inserted will

depend on the type of garment and the loca

tion of the zipper. The zipper package will con

tain easy-to-follow instructions. And, if you use

the zipper foot, you will find it easy to form an

even line of stitching close to the zipper.

Pattern: Straight Stitch

Stitch Width:

Needle Position: A

Stitch Control: 10 to 15 (approximately 1,5 to 2,5)

Zig-Zag or Straight Stitch Throat Plate

Zipper Foot

Adjusting the Zipper Foot

When the zipper is to the right of the needle:

1. Loosen the thumb screw at the back of the

foot, and slide the foot to the left of the

needle,

2. Check the position of the foot by turning the

hand wheel to lower the needle into the side

notch of the foot, making sure it clears the

foot,

3. Lock the foot into position by tightening the

thumb screw.

4. Lower presser bar. Make sure the needle

clears the foot on all sides of the notch.

When the zipper is to the left of the needle,

adjust the foot to the right of the needle in the

same way.

28

Adjusting the Zipper Foot

Zipper Foot to

Right of Needle

Zipper Foot to

Left of Needle

Zipper Insertion

Page 31

BLIMDSTITCH HEMS

Pattern: Blindatiteli -è

Stitch Width: 2 to 5

Needle Position: A

Stitch Control: 10 to 20 (approximately 1 to 2.5)

Zig-Zag Throat Plate

Zig-Zag Foot

Seam and Blindstitch Hem Guide

Blindstitching provides a durable hem finish

that is almost invisible. It is best suited to

straight or slightly curved hems. Taped, bound,

turned, or unfinished hem edges can be blind-

stitched with equal ease. Blindstitching takes

a little practice, however, so make a test sam

ple first.

1. Mark, turn, and press hem in the usual way.

2. Baste a guideline 1/4 inch (6mm) from top

of hem edge.

3. With the work wrong side up, turn the hem

under, creating a soft fold about 1/4 inch

(6mm) from top of hem.

Blindstitch Hem

4. Place hem edge over feed of machine with

bulk of fabric to the left.

5. Screw seam and hem guide into hole at

right of slide plate and adjust it over the

right toe of the presser foot so that it rests

next to the soft fold.

6. Stitch so that straight stitches fall on hem

edge and sideward stitches pierce the soft

fold. While stitching, guide the fold evenly

against edge of hem guide.

7. When stitching is completed, swing guide

out of position before raising presser foot

Remove basting stitch.

Basted Guideline

Blindstitching a Hem

29

Page 32

I

Making the Welting

Making a Corded Seam

CORDED SEAMS

The corded seam is a professional treatment

for slipcovers, children’s clothes, blouses, and

lingerie. To make a corded seam, make the

welting first (or buy it ready-made at a notions

counter), then stitch it into the seam.

Pattern: Straight Stitch

Stitch Width:

Needle Position: A

Stitch Control: Slightly longer than for regular

seaming

Zig-Zag or Straight Stitch Throat Plate

Zipper Foot

Making the Welting

1. Buy cabie cord of desired size.

2. Cut bias strips of fabric to cover cord

(width: three times the diameter of the cord

plus 1-1/4 inches or 32mm).

3. If it is necessary to sew strips together to

obtain desired length, Join on the length

wise fabric grain.

4. Fold bias fabric strip over cord, raw edges

even.

5. Adjust zipper foot to ieft side of needie.

6. Lower the presser foot.

7. Stitch dose to cord {do not crowd stitching

against cord), pulling gently on the strip,

both in front and in back of the zipper foot.

Stitching Welting into Seam

1. Adjust zipper foot to the right of the needle

so that the bulk of the fabric will fail to left.

2. Stitch welting to the right side of a single

seam edge; guide the edge of the foot next

to the cord but do not crowd.

30

3. Place the attached welting over the second

seam edge, and pin or baste together.

4. Place the work under the needle, with the

first stitching on top so that you can use it

as a guide.

5. Stitch, crowding the foot against cord.

Page 33

SEAMS IN FABRICS THAT RAVEL

Seam edges support the garment and should

be given a durable finish if the fabric is likely

to ravel There are two ways of finishing

seams in such fabrics: trimming seam edge or

overedging. Make a test sample first to deter

mine whether method #1 or method #2 best

suits your fabric.

Method ¿¿t — Trimmed Seam Finish

Pattern: Plain Zig-Zag | or

Multi-Stitch Zig-Zag <

Stitch Width: 4 or 5

Needle Position: A

Stitch Control: 8 to 20 (approximately 1 to 3).

to suit stitch and fabric

Zig-Zag Throat Plate

Zig-Zag Foot

1. Select the stitch pattern that best suits your

fabric.

2. Adjust stitch width and stitch length to give

the most ‘'open'' stitch that will secure the

fabricedge; avoid harsh over-stitching.

3. Place stitching near the edge of the seam

allowance.

4. Trim seam edges evenly, as shown, after

stitching is completed.

Method #2 — Overedged Seam Finish

♦ Pattern: Piain Zig-Zag | , Blindstitch ^ ,or

Multi-Stitch Zig Zag <

♦ Stitch Width: 4 or 5

♦ Needle Position: A

♦ Stitch Control: 8 to 20 (approximately 1 to 3),

to suit stitch and fabric.

^ Zig-Zag Throat Plate

♦ Zig-Zag Foot

1. Adjust stitch length and stitch width to suit

your fabric.

2. Trim seam edges evenly.

3. Place trimmed seam under the presser foot

and stitch so that the zig-zag stitches fall

over the edge of the seam allowance.

Overedged Finish

31

Page 34

I

sewing knit and stretch fabric

When you are sewing stretch fabrics, double-

knit, tricot or jersey, choose one of the stretch

patterns that build s-t-r-e4-c-h into the seam.

The table below will help you make the right

selection.

STRETCH STITCH CHART

Stitch

Straight Stretchf

Straight Stitch — Stitch Width A

Stitch Control on STHETCH

Multl-SlUch Zig-Zag

Built-in Pattern

Remember to use a ball-point (yellow band)

needle, Catalog 2045, in the machine, and In

crease presser foot pressure when you are at

taching elastic or sewing a synthetic knit or

stretch fabric.

Where to Use

Plain seams that s-t-r-e-t-c-h (press-open or

closed construction) -* Crotch seaming —

Sleeve and gusset Insertion — Flexible top

stitching — Swim and ski suit construction

Attaching patch pockets — Repairing and

reinforcing seams.

Attaching elastic and stretch lace — Linge

rie and swimsuit construction — Girdle seams

— Seam finishes — Casings and waistband

finishes.

Plain Zig-Zag

Buiit-ln Pattern

Ric-Rao Stltchf

(See Stitch Pattern Chart on Page 21)

Blindstitch

Built-in Pattern

Overedge Stretch

Built-in Pattern

Slant Overedge Stretch Stitchf

(See Stitch Pattern Chart on Page 21}

All-purpose stretch sewing — Lingerie seams

— Attaching stay tapes *- Seam finishing —

Edge finishing — Attaching stretch lace.

Heavy-duty, all-purpose stretch sewing

Reversible topstitch applications.

Flexible blindstitch hemming *- Overcast

seam finishing — Shell hems in lingerie.

Overedge seams that stretch—Crotch seams

—Waistband and seam finishes in shorts and

slacks — Ski-suit, snow-suit, and swimsuit

construction.

Sweater and swimsuit construction — Over

cast seams in bulky knits and stretch terry

cloth — Attaching elastic and stretch lace —

Edge finishes for seams, hems, and facings.

tThis stitch is designed for strength and permanence and cannot be readily ripped out without risk of fabric damage.

32

Page 35

GUIDING AND SUPPORTING FABRIC

Most fabrics of stretch or knit construction

need only to be guided in front of the presser

foot when you use one of the stretch stitches.

Simply let the machine move the fabric to

make the stitches that give to the

seam.

Some fabrics — nylon

fabrics, for example-

tricot and elasticized

-do require support

while being stitched.

For nylon tricot and similar synthetic knits,

apply gentle tension by holding the seam in

front and back of the presser foot as you

sew.

For elasticized fabric, stretch lace, and knits

with an unusual amount of elasticity, apply

firm tension in front and back of the presser

foot to stretch the seam as the stitches are

being placed.

FINISHES FOR HEMS AND FACINGS

• Pattern: Multi-Stitch Zig-Zag ;> or

Slant Overedge Stretch ^ (see page 21)

• Stitch Width: 5 ^

• Needle Position: A

• Stitch Control: 8 to 20 (approximately 1 to 3)

for Multi-Stitch Zig-zag or STRETCH for Slant

Overedge Stitch

• Zig-Zag Throat Plate

• Zig-Zag Foot

Applying Gentle Tension

Applying Firm Tension

Hem and facing edges in knit and stretch fab

rics will be less apt to press through and mark

when given a flat edge-finish. Edge finishing

with the slant overedge stitch or multi-stitch

zig-zag eliminates the bulk of turneúAn edges

and retains fabric flexibility.

1. Make a test sample to check thread tension

and stitch length if you are using the multistitch zig-zag.

2. Place stitching about 1 /2 inch (13mm) from

hem or facing edge.

3. Press after stitching and trim away excess

fabric close to the stitching line.

33

Page 36

PLAIN STRETCH SEAMS

Pattern: Straight Stitch

Stitch Width: A

Needle Position: A

Stitch Control: STRETCH

Zig-Zag Throat Piate

Zig-Zag Foot

of elasticity, it should be stitched under

tension as instructed on page 33 (Guiding

and Supporting Fabric).

3. Press seam as when using the regular

straight stitch.

LINGERIE SEAMS

When you use the straight stretch stitch to

seam knit, stretch, and elasticized fabric,

s-t-r-e-t-c-h and strength are built in as the

seam is being sewn. Because it is equally use

ful for closed or press-open seam construction

and will not break thread under stress, the

straight stretch stitch is also good for seams

that receive an unusual amount of strain when

the garment is worn. For example: crotch

seaming, sleeve insertion, and construction

seams in sportswear and swimsuits.

Procedure

1. Make a test sample to determine the cor

rect thread tension. Be sure to insert a yel

low-band needle in the machine if you are

stitching a synthetic knit fabric.

2. Stitch and guide fabric as you do for plain

seams stitched with the regular straight

stitch, letting the machine make the backand-forth stitches that give

the seam, if fabric has an unusual amount

s-t-r-e-t-c-h to

Pattern: Plain Zig-Zag I

Stitch Width: 1 to 2V2 *

Needle Position: A

Stitch Control: 12 to 20 (approximately 1 to 2)

Zig-Zag Throat Plate

Zig-Zag Foot

To make a lingerie seam durable and flexible,

use the plain zig-zag stitch at a narrow width

setting. This seam treatment is particularly

suitable for bias seams. When seaming nylon

tricot, insert a yellow-band needle in the ma

chine before you begin to sew,

♦ Straight-stitch the seam (dials set on black

A sym.bols) on wrong side of fabric.

♦ Press both seam allowances in the same di

rection.

♦ From the right side, topstitch with narrow

zig-zag stitching, letting the needle alter

nately enter the seam line and the seam

thickness.

34

straight Stretch Stitching Lingerie Seam

Page 37

OVEREDGED SEAMS MOCK OVEREDGING

Pattern: Overedge Stretch

Stitch Width: 5

Needle Position:

Stitch Control: STPETCH

Speed: In SLOW range

Zig-Zag Throat Plate

Overedge Foot

A

Seams m knit and stretch fabrics can be

joined and finished in one operation when you

use the overedge stretch stitch.

Procedure

1. Make a test sample before beginning gar

ment construction to test machine settings.

Be sure to duplicate the cut of the garment

seam in your test, and use a bail-point

(yellow band) needle if you are sewing a

synthetic knit fabric.

2. Cut and fit the garment in the regular way,

using a 6/8 inch (16mm) seam allowance.

Baste seam line.

3. Trim seam edge evenly to a scant 1 /4 inch

(6mm) from seam-line basting.

Pattern: Slant Overedge ^ (see page 21)

Stitch Width: 5

Needle Position: A

Stitch Controi: STRETCH

Speed: In SLOW range

Zig-Zag Throat Plate

Zig-Zag Foot

When it is not practical to overedge a seam

because of the construction of the fabric, a

mock overedge finish can be applied. This

finish IS appropriate for bulky knits, fine tri

cots, and fabrics that curl or ravel.

Procedure:

1. Make a test sample to check machine ad

justments before beginning garment con

struction.

2. Cut and fit the garment, allowing for 5/8-

inch (16mm) seam allowance. Baste seam

line.

3. Place seam under the presser foot so that

the straight stitches fall on the seam-line

basting.

4. Place trimmed seam under the overedge

foot so that the straight stitches fali on the

basted seam line and zig-zag stitches fall

over the seam edge.

Overedged Seam

4. Press after stitching and trim away fabric

to produce a narrow seam. When the seam

supports the garment, omit the trimming

step.

35

Page 38

hints on sewing special fabric

LEATHER-LOOK VINYLf

• Use masking tape or zipper adhesive tape

instead of pins or basting to hold seams, zip

pers and hems in place for stitching.

• Stitch with a long stitch {setting of 8 to 10 or

2.5 to 3). A short stitch may cut the fabric.

• Sew with a steady, even pace and stitch ac

curately. Seams cannot be ripped out with

out leaving needle marks in the fabric.

• The shiny side of some vinyls tends to stick

to metal surfaces. Use a strip of tissue paper

between the fabric and metal machine sur

faces to prevent this.

• Reinforce button and buttonhole areas with

interfacing. Bound buttonholes are the best

choice for vinyls with knit backing.

• Topstitching holds seams and garment edges

smooth and flat, and adds a decorative note.

• For sharp points on collars and lapels, take

one or two stitches diagonally across the

point to allow enough space to enclose the

seam edge smoothly.

CIRÉ {Wet-Look Taffeta and Tricot)f

• Do not use pins in any area of the garment

that will be visible when completed.

• Use masking tape or zipper adhesive tape

instead of pins or basting to hold seams, zip

pers and hems in place for stitching.

• Stitch accurately; seams cannot be ripped

out because needle marks remain in the

fabric.

Sew seams under gentle tension by holding

fabric slightly taut at front and back of

needle.

Stitch ciré taffeta with a fairly long stitch and

use an enclosed edge finish for seams and

hems.

Stitch ciré knits with a medium-length stitch

(setting of 12 or approximately 2) and use a

fine bail-point needle.

Machine-worked buttonholes, as well as

bound buttonholes can be made in ciré fab

ric. Always use an interfacing and make sure

the close zig-zag stitches do not cut the

fabric.

Turning a Sharp Comer on Leather-Look Vinyi

+The Even-Feed Foot described on page 47 is designed to aid in sewing this fabric.

36

Page 39

DEEP-PILE FABRICS (Fake Fur) f

• Pin, rather than baste, seams. Place pins at

short intervals at right angles to the seam

line. Pins with colored heads are easy to see

and remove.

• Sew in direction of nap.

• Stitch with a fairly long machine stitch (set

tings of 8 to 10 or approximately 2.5 to 3)

and use polyester/cotton thread in a size 14

or 16 Catalog 2020 needle.

• As seam is stitched, smooth pile away from

seam allowance with a darning needle or up

holstery pin.

• After stitching seams with a 5/8 inch (16mm)

seam allowance, use small hand scissors to

shear pile from entire seam allowance to

reduce buik.

• Stitch 1/4 inch (6mm) preshrunk tape into

neckline and shoulder seams for stability and

reinforcement, or stitch with the straight

stretch stitch (stitch control set on

STRETCH).

• Leather and leather-look fabrics comple

ment fur fabrics; use them for bound button

holes and easy button loops.

Smoothing Pile Away

from Seam Allowance

• Coat hems are less bulky if narrow and

finished with a 3 inch (76mm) fabric facing or

gros-grain ribbon.

• Slash through the center fold of darts and

Stitching Deep-Piie

Fabrics {Fake Fur)

finger-press open or stitch with a narrow zig

zag stitch and trim away excess fabric after

stitching.

VELVET AND VELVETEEN f

• Use a light pressure dial setting to prevent

crushing pile.

• Mark and baste with siik thread.

• Use a Catalog 2020, size 11 needle and a

fine thread for seaming. “A” silk or nylon

thread is recommended for sewing velvet

and velveteen.

• Always stitch in the direction of the nap.

tThe Even-Feed Foot described on page 47 is designed to aid in sewing this fabric.

Pin or hand-baste seams and sew under

gentle tension by holding fabric slightly taut

at front and back of needle {see page 18).

Extra-long straight seams may be machine

basted with a long, wide zig-zag stitch.

To sew panne velvet, use a bail-point needle

(yellow band) and a shorter-than-normai

stitch length (settings of 12 to 15 or approx

imately 1.5 to 2).

37

Page 40

decorative touches

BORDER DESIGNS

Border designs that add a decorative touch to

wearing apparel and househoid items can be

created by combining different types of

straight stitching and zig-zag stitching. Simple

or elaborate, delicate or bold, they can be var

ied to suit the application. Use them as you

would a braid or to simulate horizontal, vertical

or bias stripes on plain fabric.

Procedure

Mark or crease fabric for the center line of first

row of stitching. If spacing between rows is not

greater than 1 /2 inch {13mm), gauge additional

rows with the pressar foot. If spacing is wider,

iM

mark for each line of stitching. Use a backing of

crisp lawn, organdy or organza and be sure to

make a test sample on a swatch of your fabric

to check stitch settings and thread tension.

APPLIQUE

Applique adds beauty and interest to clothing

and household linens. You can create your

own design, trace a simple outline from a col

oring book, or use a motif cut from a printed

fabric. Fabrics of like or different texture com

bine equally well.

Use a closely spaced, fairly narrow zig-zag

stitch. Although you may vary stitch width to

accommodate fabric weave or texture, never

allow the stitch to be too wide.

When appliqueing, make a test sample to help

you decide which of the foilowing methods is

more appropriate for your fabric and design.

Preparation

• Baste applique design to fabric.

• Outline design with straight stitching (use a

short stitch).

• Remove basting and press.

Border Design

• Attach zig-zag throat plate and foot.

Method #t

1. Set stitch width dial. Adjust stitch length in

the FINE area of the stitch control.

2. Outline the entire design with applique

stitching.

3. Cut away the fabric on the outer edges of

the stitching with embroidery scissors.

Method

1. Trim outside edges close to straight stitch

2. Set stitch width dial. Adjust stitch length in

3. Overedge the design with satin stitching.

MeUiod #1—^Trimming after Stitching

NOTE: For best results In satin stitching, the special purpose foot is recommendeci (available for purchase, see page 47).

it

2

outline of design.

the FINE area of the stitch control.

This step will produce a smooth, lustrous

finish that requires no additional trimming.

38

Page 41

keeping up appearances

Many zig-zag siiich patterns are Just as useful

for mending as they are for creative sewing.

The muiti-stitch zig-zag (a built-in pattern)

forms a firm, flexible bond that is ideal for re

pairing tears.

MENDING A TEAR

• Pattern: Muiti-Stitch Zig-Zag

• Needle Position: A

• Stitch Width: 2 to S

• Stitch Control: Approximately 20 (1 to 1.5)

• Zig-Zag Throat Plate

• Zig-Zag Foot

1. Trim ragged edges.

2. Place underlay on the wrong side of tear for

reinforcement. (It is best not to baste or pin

the underlay, since you will be bringing the

edges together in the next step.)

3. Stitch on the right side, bringing the edges

of the tear together. Shorten stitch length at

ends and corners to give extra strength.

4. Trim underlay.

Tear amended with Multi-Stiteh Zig-Zag

BLANKET BINDING

Often you can make an old blanket look almost

new by replacing the binding.A zig-zag stitch

pattern such as the plain zig-zag or muitistitch zig-zag or the semaphore Flexl-Stltch

pattern may be used.

• Pattern: Desired zig-zag stitch (see above)

♦ Stitch Width: 5

• Needle Position: A

• Stitch Control: STRETCH for Flexi-Stitch pattern,

or approximately 15 to 20 (1.5), to suit stitch and

fabric

♦ Pressure: NORM or less

* Zig-Zag Throat Plate

♦ Zig-Zag Foot

1, Make a sample to determine correct dial

settings. Reduce pressure on fabric and

increase stitch length, if necessary, so that

blanket feeds freely.

2, Remove worn binding and baste new bind

ing securely in place.

Blanket Binding

3, Stitch, and remove basting.

39

Page 42

REPAIRING SEAWfS

Breaks in press-open garment seams can be

repaired quickly and easily when you use the

straight stretch stitch (stitch pattern ^ , stitch

width A and stitch control on STRETCH set

ting). This reinforced stitch is both strong and

flexible. It is ideal for knit and stretch fab

rics and particularly useful for repairing or

strengthening curved seams or seams that will

receive strain when worn.

1. Make a test sample to check dial settings.

2. Remove loose thread along the break and

press the seam edges together.

3. Re-stitch along original seam line, guiding

seam under presser foot without stretch

ing fabric, letting the machine move the

fabric to make the back-and-forth stitches

that give s-t-r-e-t-c-h to the seam. Overlap

stitching one inch at each end. Press seam

open.

Seam Repair

Stretch Garment Repair

REPAIRING STRETCH GARMENTS

Pattern: Plain Zig-zag I

Needle Position; A *

Stitch Width: 3 to 5

Stitch Control: 20 {approximately 1 to 1.5) or

to suit fabric

Zig-Zag Throat Plate

Zig-Zag Foot

Seams and hems in stretch and elasticlzed

garments retain their elasticity when stitched

with the plain zig-zag stitch. This stitch is par

ticularly effective when used In topstitch ap

plications (as shown) or to overedge. Make a

test sample to check dial settings.

Bar Tacks

Bar tacks, to reinforce points of strain, are

made with the plain zig-zag stitch at satin

stitch length. Use them at pocket corners, to

attach garters, secure shoulder straps, belt

loops and zipper openings.

40

Page 43

DARNING

With Embroidery Hoop

Worn or torn spots on children’s clothes, knits,

and household linens can be darned effort-

lessly and quickly with little practice. You may

choose to darn either with or without an em

broidery hoop. When greater control is needed,

an embroidery hoop is usually best.

Without Embroidery Hoop

Pattern: Straight Stitch

Needle Position: A ^

Stitch Width: A

Stitch Control: 10 to 15 (approximately 1.5 to 2.5)

Pressure: DARN

Zig-Zag Throat Plate

Zig-Zag Foot

1. If area to be darned is open, baste an under

lay in place.

2. Place area to be darned under presser foot;

lower presser foot and start stitching, al

ternately drawing fabric toward you and

pulling it gently away from you.

3. Continue this forward and backward motion

as you fill the area with parallel lines of

stitching. For additional strength, cover

area with crosswise lines of stitching.

Pattern: Straight Stitch

Needle Position: A

Stitch Width: A

Stitch Control: In FINE area

Feed Cover Throat Plate

No presser foot

1. Trim ragged edges from area to be darned.

2. Center worn section in embroidery hoop.

3. Position work under needle over feed cover

plate and lower presser bar to engage ten

sion.

4. Hold needle thread loosely with left hand,

turn hand wheel over and draw bobbin

thread up through fabric. Hold both thread

ends and lower needle into fabric.

5. Outline area to be darned with running

stitches for reinforcement

6. Stitch across opening, moving hoop under

needle at a slight angle from lower left to

upper right Keep lines of stitching closely

spaced and even In length.

7. When opening is filled, cover area with

crosswise lines of stitching.

Darning without Embroidery Hoop

Darning With Embroidery Hoop

41

Page 44

7. CARING FOR YOUR SEWING MACHINE

cleaning the machine

Your machine will serve you perfectly for many

years if you take a few moments of your time

to keep it dean. How often you will need to

clean the machine will depend on how often

you use it

CAUTION: Before cleaning your machine, dis

connect power-line plug from electrical supply.

Remove lint or fluff from exposed parts. With a

soft cloth, clean:

• Tension discs, presser bar, and needle bar

• Take-up lever and thread guides

• Bobbin case (If there is a lot of lint in the

area, rernove bobbin case for cleaning. See

page 44 for Instructions.)

• Machine surface {If necessary, damperi the

cloth and use a mild soap.)

Open the face plate and clean area behind it

with a brush.

Remove throat plate as instructed on page 6

and, using a brush, clean the rotating hook

area under the throat plate and slide plate.

After cleaning, apply only SINGER* oil at

points indicated below. SINGER oil is speci

ally prepared and does not contain harmful

deposits that can interfere with the smooth

action of precision parts.

Approximately once every year, remove top

and bottom covers as instructed on page 43,

and clean and lubricate all moving or rotating

machine connections to ensure freedom of

movement and to protect metal parts from

excessive wear. To determine which connec

tions are moving or rotating, turn hand wheel

slowly (by hand) while covers are removed.

42

Page 45

removing covers, bobbin case, and bulb

CAUTION: Before removing covers, bobbin

case, and light bulb, disconnect power-line

plug from your electrical supply.

RES/fOVlNG AND REPLACING

TOP COVER

Move take-up lever to a low point and lower

the presser foot

1 Open face plate and remove screw A, llfi

up right end of top cover, and slide cover

toward left and off machine,

2. Replace cover by positioning it on top of

arm with a slight overhang on left side.

3. Engage bobbin winder latch and slide cover

to the right as far as it will go. Replace and