Page 1

You are about

you

going

are

to begin

to

an adventure

sew with one

of the

in creativi$:

easiestto

use

going

You are

machines ever

to sew!

made'

And,

The following

rewarding

.

Clearly

.

Electronic

o

Autotension,

features

hours

defined

speed

requiring

projects.

r

One-step

In addition,

both

removed

impossible

pattern

this

flat and

and easily

to

free-arm

put

Take some time

machine.

cover

Whether

how easy

DearCustomer:

recommend that

we

your

Sewing

Machine

have

of uncomplicated

path,

thread

sewing

reducing the

included

been

control, assuring

noadjustmentsfor

selection,

machine

replaced;

needle in backwards.

the

to acquaint

you

is

it

to

eliminating

features

sewing;

a

snap-on

a one-way

and

yourself

novice or

are a

create something

for future

in the space

reference

provided.

your

on

pleasure:

possibility

smooth,

even sewing.

majority

a

complicated

removable

bed extension,

presser

needle

with this

owner's

an experienced

uniquely

your

you

record the serial

machine,

of threading

of

selection

promising

errors.

your

operation.

permitting

that are

feet

clamp

that

manual

you

sewer,

own!

Number

sewing

quickly

makes it

your

and

will dis-

of

to illustation

Refer

righttorl@ation

at

of

Numberon

Serial

yourmachine.

Serial

To

ensure

bilities,

design or

No.

Part

No.

that

manufacturer

the

accessories

1 1

9625-001

you

are always

'A

Serial

provided

reserves

of this sewing

Trademark ol

The Singer

No.

the

with

right

the

machine

when considered

Company

most modern

to change

the

capa-

sewing

appearance'

necessary.

Taiwan

in

Printed

Page 2

Table of Contents

1. Getting lo

Principal Parts

Accessories

2. Getting

Fabric, Thread

lmportantsafeguards

ConnectingtheMachine/RunningtheMachine

ChoosingandChangingNeedles

Free Arm Sewing

Changing the

Attaching Feed

Winding a Bobbin

Inserting

Threading

Raising the Bobbin

SelectingaPattern

3. Straight Stitching

Preparation

Sewing a Seam

lnserting

Know Your Machine

. .

Ready lo

and

Presser Foot . .

Bobbin

a

Machine

the

aZipper

. . 5

Sew

Needle Table

Cover

Thread . .

. .

.

..:....

Preparation

Zig-Zagstitch .

Zig-Zag Blindstitch

Multi-Stitch Zig-Zag.

"M"

Stitch

CrescentStitch . .....

StretchOveredgeStitch . . . .

Fagoting

Ric-Rac/Straight

Stitch.

Stretch Stitch

.

........ 6

........ 7

...,.

.. .. .. . .

.

2

2

4

5

.. I

8

9

I

12

13

14

14

14

16

18

19

19

21

21

22

23

23

24

24

25

Four-Step Buttonholing

5.

6. Caring for Your Machine

Removing

Removing

Cleaning

Performance

and Replacing Bobbin Case.

and Replacing Light Bulb

the Machine

Checklist

Additional Accessories

.

lndex

26

28

.

28

29

30

31

32

33

Page 3

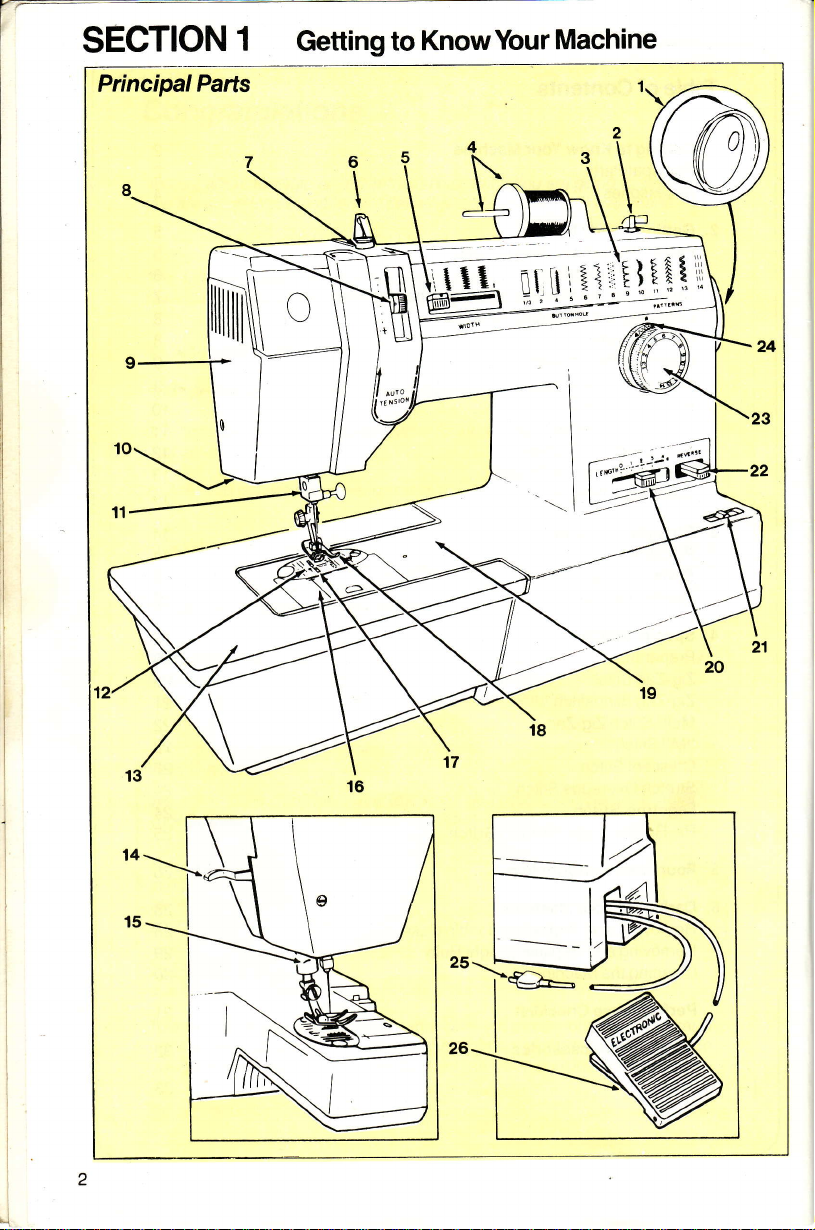

SECTION

Principal Parts

1

Getting

to KnowYour

Machine

13

14

15

__1,

25

26

Page 4

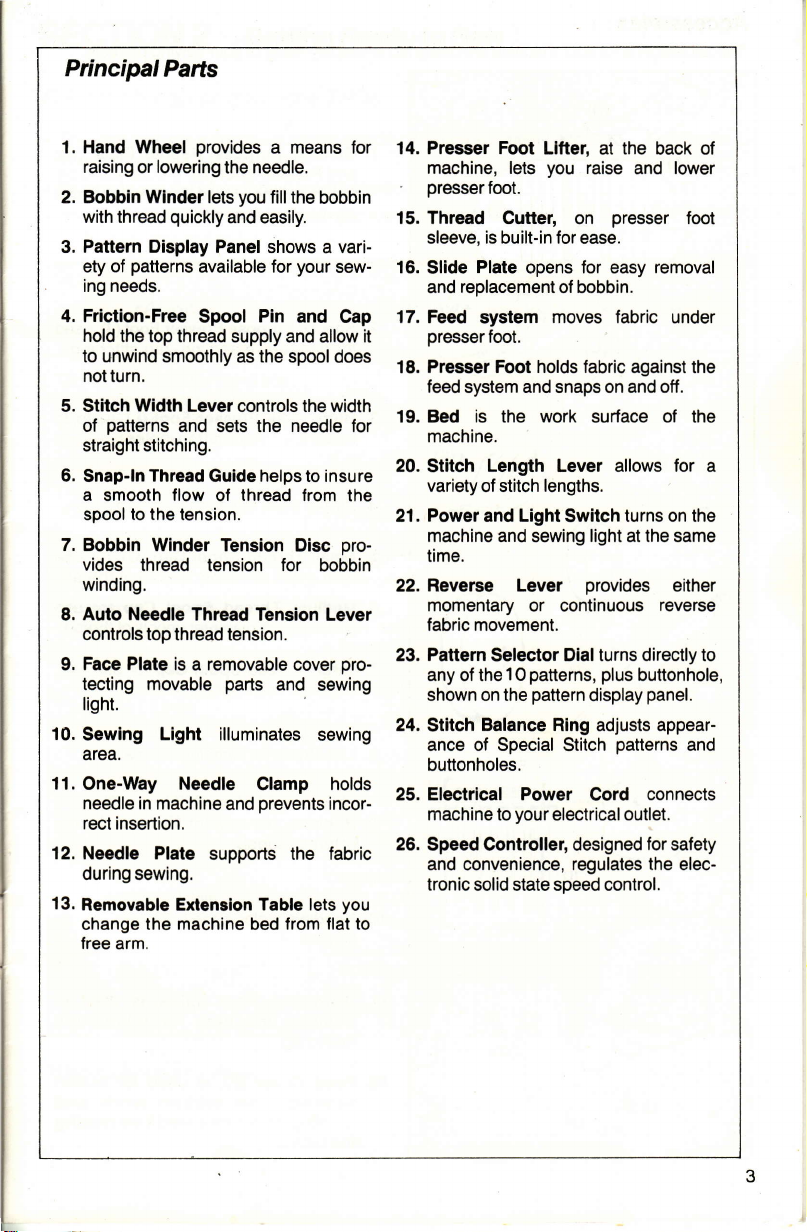

Principal

Parts

1. Hand Wheel

raising

2. Bobbin Wlnder lets

with thread

3. Pattern Display Panel

4. Friction-Free

5. Stitch

6. Snap-ln Thread Guide helps to insure

7.

8. Auto Needle Thread Tension

9. Face

10.

11.

12. Needle Plate

13.

patterns

ety of

ing needs.

hold

the top thread supply and allow it

to unwind

notturn.

Width

patterns

of

straight stitching.

a smooth flow

to the

spool

Bobbin Winder Tension Disc

vides thread

winding.

controls

Plate

tecting movable

light.

Sewing Light illuminates

area.

One-Way Needle

needle in machine

rect

insertion.

during sewing.

Removable

change the machine bed

free

arm.

provides

lowering

or

quickly

available

Spool

smoothly as the spool does

Lever controls the width

and

tension.

tension

top thread tension.

is a removable

supports the fabric

Exlenglon

a means

the needle.

you

fillthe

and easily.

shows a vari-

for

Pin and

the needle

sets

thread from

of

for

parts

and

Glamp

prevents

and

Table lets

from flat to

your

cover

bobbin

sew-

Cap

the

pro.

bobbin

Lever

pro-

sewing

sewing

holds

incor-

you

for

14. Presser Foot Lifter.

machine, lets

"

presserfoot.

15. Thread Cutter,

16.

17. Feed system moves fabric under

18.

19. Bed is the work surface of the

for

20.

21. Power and Light

22. Reverse Lever

23.

24. Stitch

25. Electrlcal Power

26.

is

sleeve,

Slide

and

presserfoot.

Presser Foot holds fabric against

feed system and snaps on and off.

machine.

Stitch

variety of stitch lengths.

machine

time.

momentary or continuous

fabric movement.

Pattern

any

shown on the

ance of Special

buttonholes.

machine

Speed Controller, designed

and convenience, regulates

tronic solid state speed control.

built-in for ease.

Plate

replacement

of the

opens for easy removal

Length Lever allows for a

and sewing

Selector Dialturns directly to

patterns, plus

10

pattern

Balance

your

to

al

you

raise

presser

on

of bobbin.

Switch

light

provides

display

Ring adjusts appear-

electrical outlel.

Stitch

Cord

patterns

the

back of

and lower

foot

the

turns on the

the

at

same

either

reverse

buttonhole,

panel.

and

connects

forsafety

the

elec-

Page 5

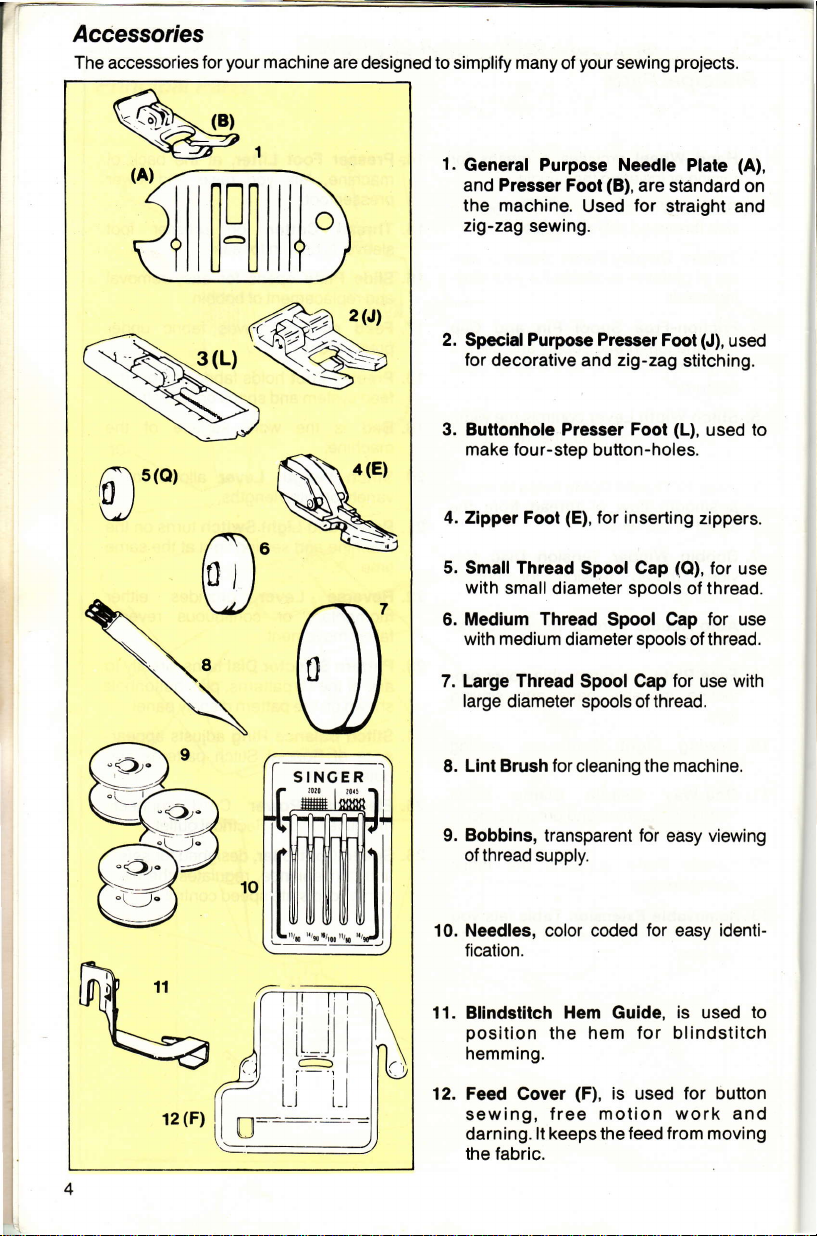

Accessories

The accessories

for

your

machine

are designed to simplify many

of

your

projects.

sewing

il!tl

tl

?l

[]-IJ

cs(o)

tl

t+

1.

General Purpose Needle

and Presser

the machine.

zig-zag

Speclal Purpose Presser

tor

3.

Butlonhole Presser

make four-step

4.

Zipper Foot

5.

SmallThread

with

Medium Thread

6.

with

7. Large Thread Spool Cap

large diameter spools of thread.

sewing.

decorative and

small diameter spools

medium

(B),

Fool

(E),

diameter spools of thread.

are standard

for

Used

Foot

zig-zag

Fool

button-holes.

for inserting

Cap

Spool

Spool

(A),

Plate

on

straight and

(J),

used

stitching.

(L),

(Q),

of thread.

Cap for use

for

to

used

zippers.

for use

use with

Lint Brush for

8.

9. Bobbins,

of thread supply.

Needles, color

fication.

11.

Blindetitch

position

hemming.

Feed Cover

12.

sewing,

darning.

the fabric.

4

cleaning the

transparent for easy viewing

coded for easy identi-

Hem

Guide,

hem for blindstitch

the

(F),

is

motion work

free

lt keeps the feed from moving

used

machine.

is used

for button

and

to

Page 6

SECTION

2

Getting

Readyto Sew

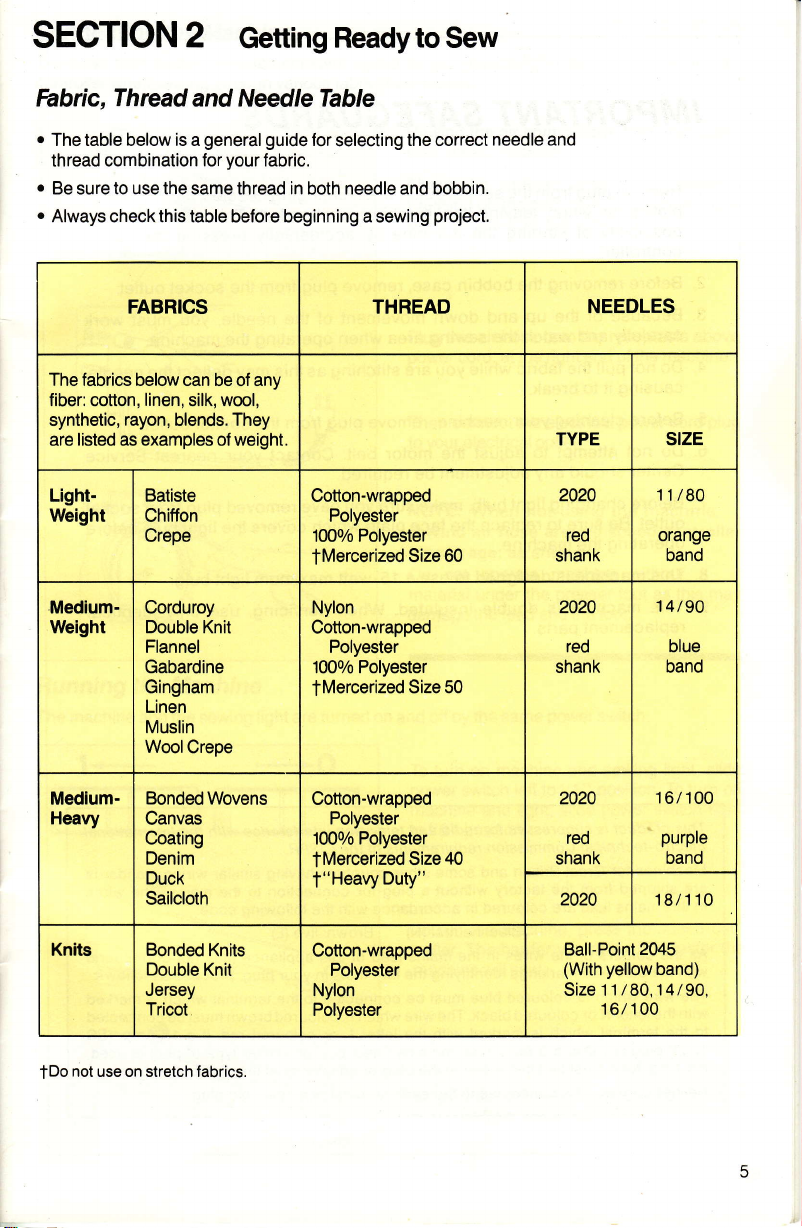

Fabric,

r

The table below is a

thread combination for

o

Be sure to use the same thread in both needle and bobbin.

.

Always check this table before beginning a sewing

The fabrics below can be of any

fiber:

synthetic,

are

LightWeight

Medium-

Weight

Thread

FABRICS

cotton,

rayon,

listed as examples of weight.

and NeedleTable

general guide

your

fabric.

linen,

Batiste

Chiffon

Crepe

Corduroy

Double Knit

Flannel

Gabardine

Gingham

Linen

Muslin

WodCrepe

wool,

silk,

blends. They

for

selecting

the correct

project.

THREAD

Cotton-wrapped

Polyester

1000/o Polyester

Mercerized Size 60

f

Nylon

Cotton-wrapped

Polyester

1000/o Polyester

tMercerized Size 50

needle and

TYPE stzE

2020

shank

2020

shank

NEEDLES

red

reo

11/80

orange

band

14 /90

blue

band

MediumHeayy

Knits Bonded

not use on stretch fabrics.

tDo

Bonded Wovens

Canvas

Coating

Denim

Duck

Sailcloth

Double

Jersey

Tricot

Knits

Knit

Cotton-wrapped

Polyester

1000/o Polyester

Mercerized Size 40

f

t"Heavy

Cotton-wrapped

Nylon

Polyester

Duty"

Polyester

2020

red

shank

2020 18/1 10

Ball-Point

(With

Size 11

16/100

purpE

2045

yellow

band)

/80,14/90.

16/100

band

Page 7

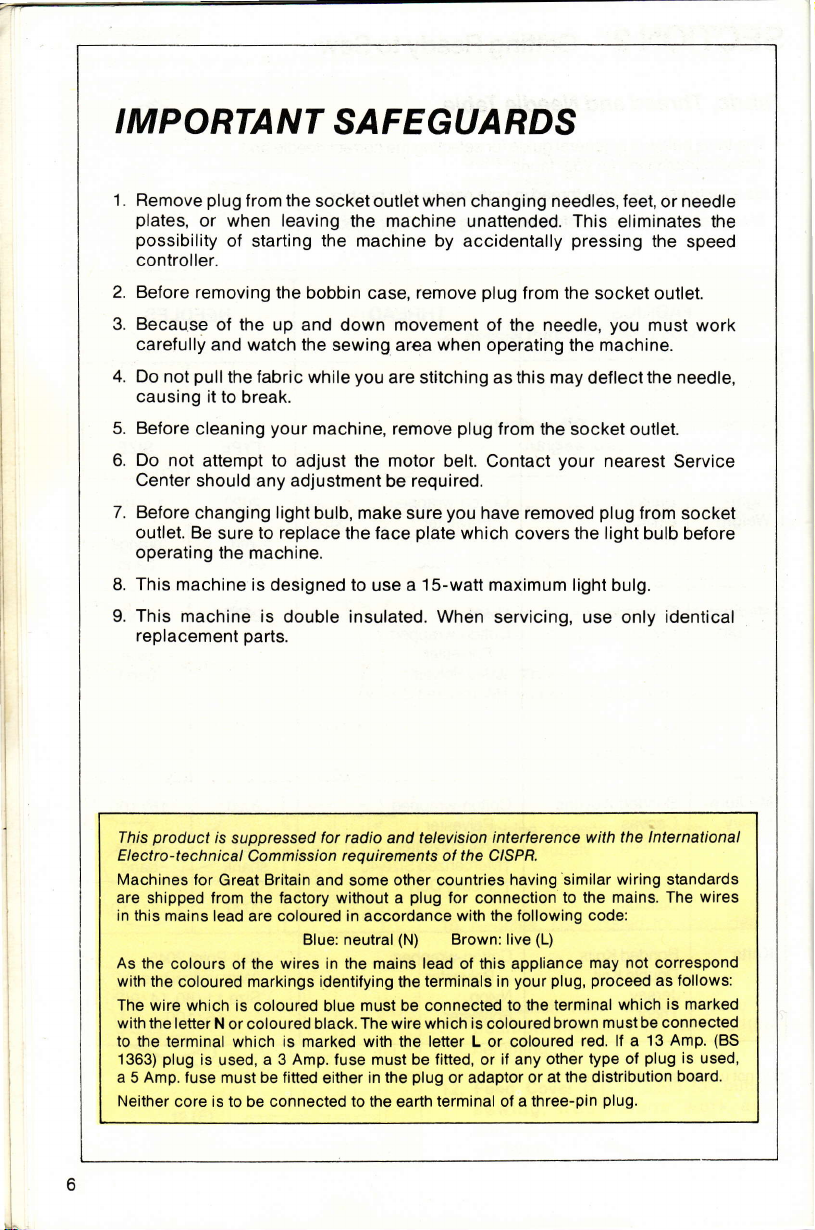

IMPORTANT

SAFEG

UARDS

1. Remove

plates,

possibility

plug

f rom the

or when

of starting

controller.

2. Before

3. Because

removing the

the up

of

carefully and watch the

4. Do not

5. Before

6.

7. Before

8. This machine

9. This

pull

causing it

the fabric while

to break.

cleaning

Do

not

attempt

Center should

changing light

outlet. Be

operating

sure to replace

the machine.

machine is

replacement

parts.

your

to

any

is designed

socket outlet

leaving

the machine

the machine

bobbin case, remove

when

changing needles, feet,

unattended. This eliminates the

by accidentally

plug

from the

and down movement of the needle,

sewing area

you

machine, remove

adjust the motor belt.

adjustment

bulb, make sure

the face

to use a

when

operating the machine.

are stitching as this may

plug

from

the socket outlet.

Contact

your

be required.

you

plate

have removed

which

1S-watt

covers the light bulb

maximum light bulg.

double insulated. When servicing,

pressing

the

socket outlet.

you

must

the needle,

deflect

nearest

plug

from

use only

or needle

speed

work

Service

socket

before

identical

product

This

Electrolechnical

Machines for

are shipped trom the tactory without a

in this

As the

with the

The wire which

with the

to the terminal

1363)

a 5 Amp. tuse must be fitted

Neither

ls

suppressed

Commission

Great Britain and

mains lead are coloured in accordance

colours of

coloured

letter N

plug

core

the wires in the mains lead of this appliance

markings identifying

is coloured blue must be

or coloured

which

is

used,

is to be connected to the

tor

radio and television

requirements

gome

other countries having

Blue: neutral

black. The wire which is coloured

is

marked

a 3 Amp. fuse must be fitted, or

either

with

in the

of

plug

for connection

(N)

Brown: live

terminals in

the

connected to

letter L

the

plug

or

terminal

earth

interfercnce with the

the CISPR.

similar wiring standards

with the following code:

or coloured

if

adaptor

of a three-pin

to the mains. The

(L)

may not

plug, proceed

your

the terminal

any

or

must be connected

brown

red. lf a

type of

other

at the distribution

plug.

lnternational

correspond

as follows:

which

13 Amp.

plug

wires

is

marked

is used,

board.

(BS

Page 8

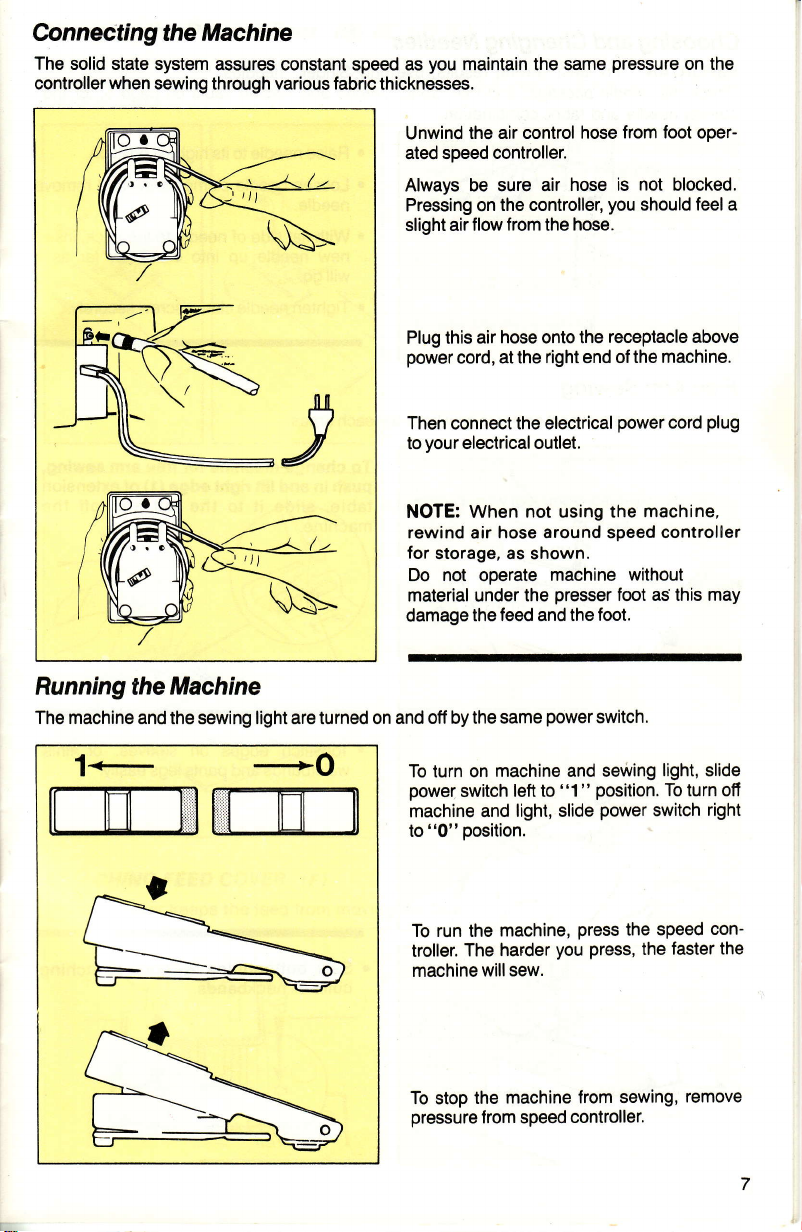

Connecting the Machine

The solid state system

controller

when

sewing

assures constant speed as

through

various fabric

you

thicknesses.

maintain the same

pressure

on the

RunningtheMachine

The machine

and the sewing light are turned on and

Unwind

ated

Always be sure air

Pressing on

slight air flow

Plug this air

power

Then connect the electrical

to

NOTE: When not using

rewind air hose around speed

for

material

damage

the air control hose

speed controller.

the controller,

from

hose onto the

at the

cord,

your

electrical outlet.

storage. as shown.

not

Do

oDerate

the

under

feed

the

otf by the same

the

right

machine

presser

and

power

from foot oper-

hose is

hose.

the foot.

not

you

should

receptacle above

of the machine.

end

power

the machine,

without

foot as this may

switch.

blocked.

feel a

plug

cord

controller

1-

+-o

To turn on

power

machine and

to

"0"

To run the

troller.

machine

To stop

pressure

machine and sewing

switch

position.

machine,

harder

The

will sew.

machine from sewing,

the

from speed

left

to

"1"

light, slide

press

press,

you

controller.

position,

power

light, slide

To turn ofi

switch

speed

the

the faster

right

con'

the

remove

Page 9

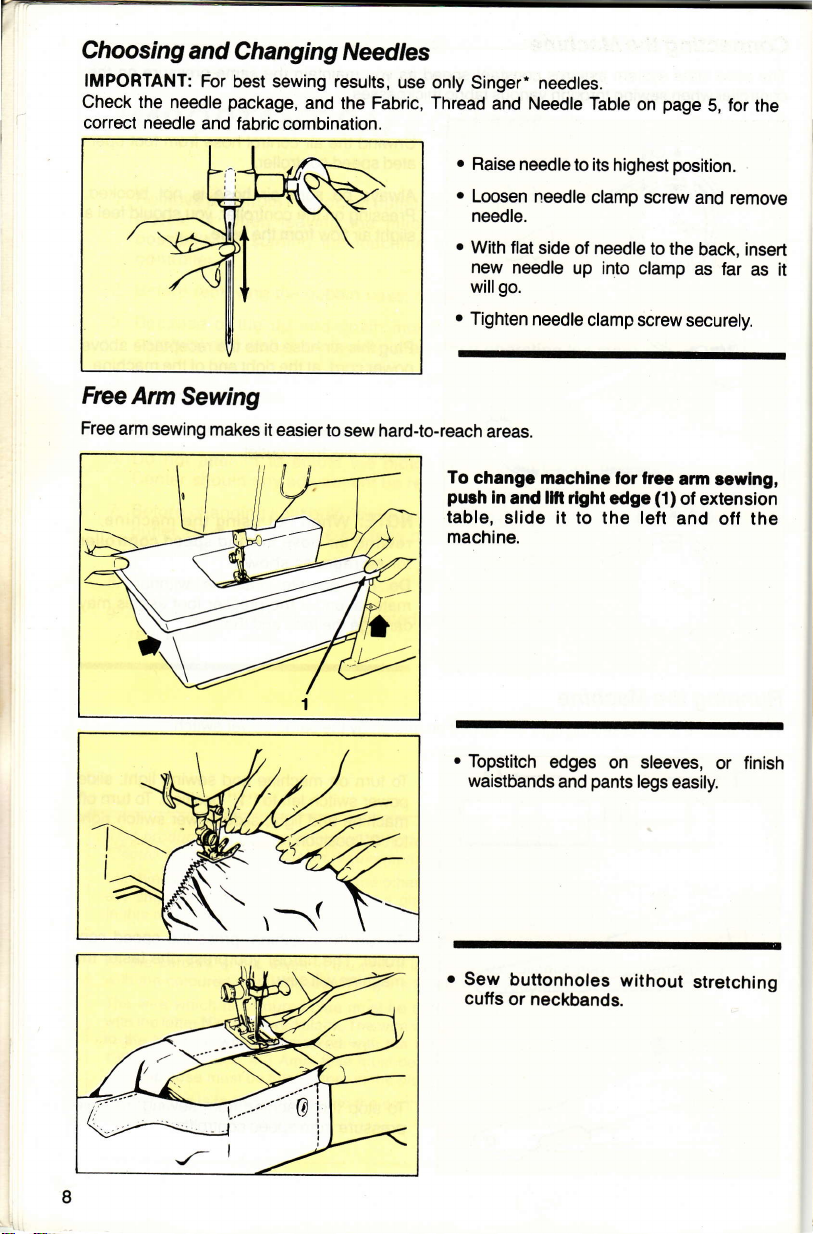

Choosing

IMPORTANT:

Check the needle

correct needle

Free

Arm

Free

arm

and

For

and

Seuhg

sewing

makes

Changing Needles

sewing results,

best

package,

fabric combinalion.

and the Fabric, Thread

it easierto

use only

sew

hard-to-reach

Singer- needles.

Needle

and

o

Raise

needle

to its highest

r

Loosen needle

needle.

.

With flat

new needle

willgo.

.

Tighten

side

of needle

up into clamp

needle

areas.

To

changc machlnc for

push

in

table,

and llfl rlghl

slide it to the left

machine.

on

lree

edge

page

position.

to the

arm

(1)

Table

clamp screw

clamp screw

and

for

S,

and remove

back, insert

as far

securely.

cewlng,

of

extension

off the

the

as it

.

Topstitch

waistbands

o

Sew buttonholes

cuffs

edges

and

or neckbands.

on sleeves,

pants

legs

easily.

without

finish

or

stretching

Page 10

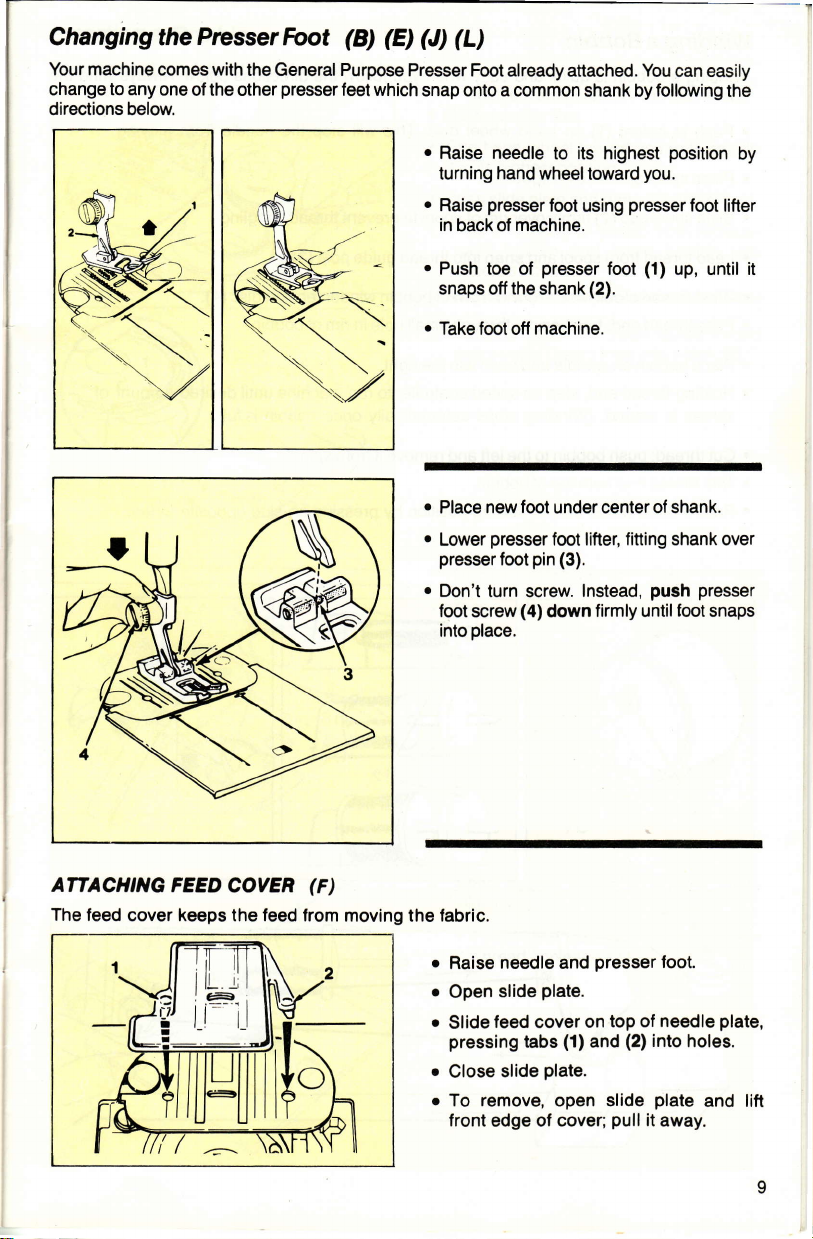

Changing thePrcsserFoot

Your machine comes

change to any one

directions below.

with the General Purpose

of the other

presser

(E) (J)

(B)

Presser Foot

feet which

(L)

snap onto a common

already attached.

shank by

You

can easily

following

the

.

Raise needle

turning hand

.

r

Raise

in

back ol

Push

presser

toe of

snaps otf

.

Take foot otf machine.

.

Place new

r

Lower

presser

presser

r

Don't turn

foot screw

place.

into

to its highest

wheel toward

foot using

machine.

presser

the

shank

foot

under center of shank.

foot

pin (3).

fool

screw.

(4)

down

position

by

you.

presser

foot

(1)

up, until it

foot

lifter

(2).

lifter, fitting shank over

Instead,

push presser

firmly until foot snaps

ATTACH,NC

The feed

cover keeps the feed lrom

FEED COVEN

G)

moving the

fabric.

o

o

o

o

o

needle and

Raise

slide

Open

feed

Slide

pressing

Close

To remove, open slide

front

tabs

slide

edge of

plate.

cover

(1)

plate.

cover;

presser

on

and

top of

(2)

pull

it away.

foot.

needle

into

holes.

plate

plate,

and litt

Page 11

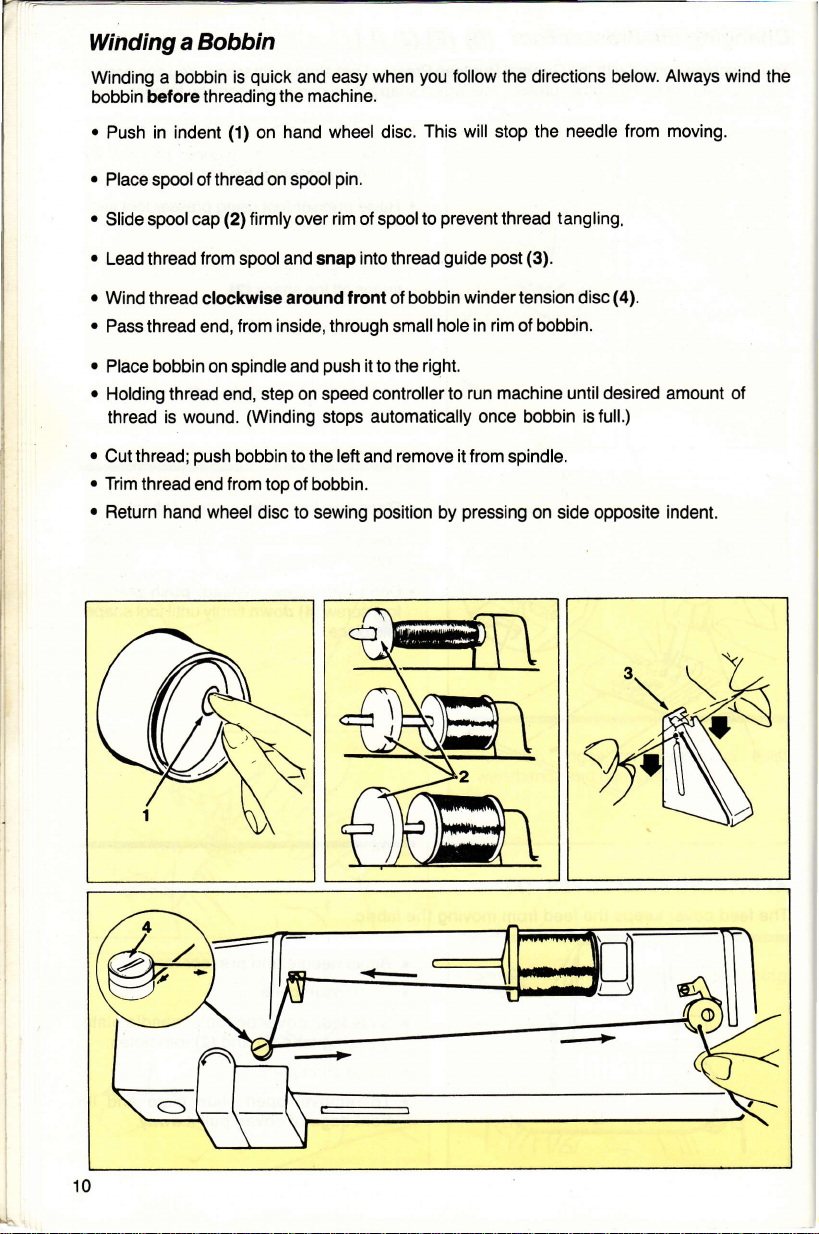

Winding a

Push

a bobbin is

before

in indent

Winding

bobbin

r

Bobbin

quick

threading

('l)

on hand

easy

and

the machine.

wheel disc,

you

when

follow

the directions below.

This will stop the needle from

Always

moving.

wind the

o

Place spool of

r

Slide spool cap

o

Lead thread from spool and snap

o

Wind

thread clockwise

.

Passthread end, from

r

r

o

o

.

bobbin

Place

Holding thread

thread is wound.

Cut thread;

Trim thread

Return hand wheel

thread on spool

(2)

firmly over rim of spoolto

around front of bobbin

inside, through

on spindle

end,

push

end from top of bobbin.

and

step on speed controller

(Winding

bobbin to the left and remove it from spindle.

disc to sewing

pin.

prevent

post (3).

into

push

it

to the

stops automatically once bobbin

position

guide

thread

winder

in rim

hole

small

right.

to run machine until desired amount of

pressing

by

tangling,

thread

tension

of bobbin.

on side opposite

(4).

disc

isfull.)

indent.

10

Page 12

lnserting

To insert

a bobbin,

a

Bobbin

followthe instructions

below

.

.

.

1. Pull 4"

2.

presser

Raise

Turn

hand wheel

foot.

is in its highest

Open slide

plate

(10cm)

ment

bobbin

case, as

Holding

into notch

shown.

bobbin

(1),

toward

position.

remove

and

of thread from replace-

and insert

place, guids

in

then into notch

and

3. Draw several inches

bobbin.

you

until needle

bobbin.

bobbin into

thread

of

thread

(2).

across

4. While holding

plate.

slide

o

Follow

directions

Thread"

on

page

thread on outside,

"Raising

for

close

Bobbin

13.

Page 13

Threading

Your

sewing machine is

have been designed as internal

threading

clear

To thread

r

Raise

a

Raise needle to its highest

a

Place

a

Slide spool cap

a

Snap thread into thread

a

Following

firmly

Thread

the Machine

path

your

machine

presser

spool of

pull

foot lifter.

arrows,

thread.

needle

easily

helps

correctly, simply follow the steps below:

thread

on spool

(2)

firmly over the

guide

from

front to back.

you

position

guide post

thread

threaded. Tension discs,

parts,

eliminating many extra threading steps.

threading

avoid

by turning hand wheel toward

pin

(1).

rim

(3).

into auto

errors.

of the spool

tension

guides

prevent

to

channel

3

(4)

and take-up

you.

tangling.

thread

needle

to

down

lever

The

and

12

I

--<

Page 14

Raising

the needle

Once

thread must be brought up through the hole in the needle

the

Bobbin

has

Thread

been threaded and the

bobbin

placed

plate.

in the

bobbin case, the

bobbin

tFHl[i

f

iltffiilllt

1. Hold needlethread

.

Turn hand wheel

lowering

2.

Continue to do

above

o

Pull

up

3. Open

bobbin thread.

needle into hole in

needle

gently

bobbin thread in a loop.

loop with fingers to tind

with

slowly toward

this until needle rises

plate.

on needle thread and bring

left

hand.

you,

plate.

end of

Draw needle thread

4.

opening

r

Pull both threads

presser

in

through

foot.

to back

left

side

of machine.

13

Page 15

Selecting

pattern

The

trated

selector

patterns.

a Pattern

dial is numbered

1

through 14,

and matches the numbers of the illus-

!:l:iFlEaliii

5678910r.t1213ta

ffi

With

each application, recommended

easy identification.

force

to

select

SECTION

Before

beginning

the best needle

You

patterns

a sewing

and thread combination for

can adjust each setting, however, as desired. To reduce

the

stitch length

3

Straight

project,

settings are

control can be

Stitching

check the

your

r

Select

on the

the

o

For

you

lines

o

To

tern

number.

given.

Fabric, Thread

fabric.

RECOIT'MENDED

pattern

a

dial with

dial.

instance,

would

turn the

up under indicating

change

the stitch

selector

dial

These have

moved to

and

by aligning

the indicating

to

sew a Zig-Zag

selector dial

pattern,

left

right

or

highlighted for

been

position.

"O"

Needle Table

SETTINGS

the

dot above

dot.

turn

to

the

page

on

number

Stitch,

until 116

pat-

the

desired

dial

for

5

Stltch Selectlon:

i:l::iFlFAliil

5C7a0r0ilt21314

PATTEFNS

Adjusting Stitch

REVERSE

I nn-im

14

[i"

I

The stitch length indicator

The lower numbers are

Shorter stitches

fabrics; longer ones for

adjust the

stitch

wtdrh:

silrbh

Length:

Stllch

Foot:

Needle Plate:

length

length levertothe

Straight StitchffiJ

lln

Lill

1-112lo 4

General Purpose

General

Length

are best

your

of

Purpose (A)

is numbered 0-4.

shorter stitches.

for lightweight

heavy fabrics.

stitches, slide

left

right.

or

(B)

To

the

Page 16

Adjusting

The

sewing applications. This

tension lever for

T h read

thread tension

the majority of

Tension

your

on

sewing machine has

auto tension feature

your

sewing

projects.

pre-set

been

eliminates the need for

in the

auto

position

you

to adjust

to suit most

the

Proper tension will

stitches on both the front and back of

(1).

fabric

Too much tension will

stitch, causing

tension by moving lever up toward a looser

setting.

"

"

-

a

produce

produce

puckered

seam

identical

vour

a tight

(2).

Adjust

F]

Too little tension

stitch, causing

Adjust tension by

atighter"+"setting.

will

loops in

moving

produce

your

seams

lever

down

loose

a

(3).

toward

lA

Page 17

Sewing a Seam

You

can sew seams

easily and accurately when

you

follow

suggestions

the

Basting

Pin

basting and hand basting are

to make

temporary seams before machine

sewing.

.

pin

To

NEVER

fabric

in contact with the feed. Do not

plns;

over

r

To

hand baste, make long, loose

insert

baste,

place pins

pull

them out as

that can be easily removed.

below.

easy ways

pins

at stitching line.

on the underside

sew

you

stitch.

stitches

of

1+

REVERS€

YZ

Placing Fabric

o

place

To

presser

(2),

where it locks

o

The lifter

"extra

high"

Under Presserfuot

fabric under

foot lifter

(1)

place.

in

can be raised

position (3)

to its

Stitchrngin Reyerse

.

To reinforce

push

straight stitch in

hold

o

For

lever in and slide

lock

right

beginnings or ends of seams,

in reverse lever, Machine will

reverse for

lever in.

the

continuous reverse stitching,

the left

it to

reverse lever by sliding it

letting

and

it return to its normal

position.

presser

foot, raise

"up"

position

and held in the

for

bulky

fabrics.

as long as

to lock. Un-

back to the

you

push

16

Page 18

Keeping

SeamsStraight

To keep seams straight, use one

guidelines

commonly used

slide

guides

Turnlng

To

turn a square corner, use crosslines on

slide

o

Line up fabric with

needle

speed as

o

When

on

the

line

plate.

The crosslines

when stitching square corners.

Sguare Corners

plate.

plate

and stitch seam, slowing

you

approach corner,

edge of fabric reaches

bottom

nering crosslines

plate.

needle

(1)

is extended onto the

(2)

extended

(2)

guidelines

on slide

plate,

The

serve as

stitching.

o

Be sure needle

o

Raise

presser

bringing

(1).

line

o

Continue stitching seam.

is

in fabric,

down

foot slightly.

Turn fabric,

bottom edge in line with

the

of

most

on

cor-

stop

guide-

Sewing Curved Seams

r

Baste

o

Use a

line.

seam

short stitch

strength.

r

Guide fabric to

follow

curve,

for

elasticity

and

17

Page 19

lnserting

The

zipper

package

aZipper

will

provide

complete instructions

for inserting

zippers.

ciY

W

RECOMMENDED

StitchSelectlon:

s*rch

wrdrh:

Stitch

Length:

Foot

Needle

.

.

Plate:

When zipper

left

side of zipper

dle will

close along zipper

Attach right

when

needle.

of foot,

enter left notch

a zipper is to the right

The needle

sewing close along

SETTINGS

Hl

Zipper (E)

General

is to the left

foot to

teeth.

side

of

StraightStitchi#fl

I

1-1t2lo

zipper

will enter right

= o

4

puroose

of needle,

shank. The nee-

of foot,

zipperteeth.

foot to

side of

attach

sewing

shank

the

notch

Page 20

SECTION4

The 9

Special Stitches on

section are

for many other

recommended

sewing

projects.

Speciatstltches

your

machine

applications for each

have a variety of

stitch.

practical

However,

and decorative uses. In

these stitches

can be used

this

:lrffFn:i!

PATTEFIS

I

A

Before beginning a sewing

Fabric, Thread

the

page

for

the best

5

bination for

With

tings

highlighted for easy identificalion.

adjust

your

each application,

have

been

setting, however, as desired.

each

Adjusting

To widen or narrow a Special Stitch

move the stitch width

Stitch,

at the

toward any other width sefting

,

i

right.

and

needle

fabric.

given.

Stitch

project,

Needle Table

and thread com-

recommended set-

These have

You

Width

lever

off Straight

check

on

been

can

pattern,

!!lr-

=:

ReveRse

justing

Ad

The

stitch length indicator is numbered

The

area between 0 and 1 will

dense stitching. For more open stitching,

slide the stitch length lever

to 4. When sewlng

and13/14 numbered In

panel,

3r/z-4 area.

Stitch Length

length

the

produce

anywhere

Speclal Stltches

rcd on

MUST be set

from 2

thedisplay

In

0-4.

very

11,12

the

19

Page 21

ju

Ad

sti

Special Stitch

Some

proper

tension

be using.

ng T h read Te n

patterns

your

for

application,

n

sio

may

require looser thread tension than

make a test sample with the thread

others. To find

and fabric

you

the

will

C_-l

::"lH

I

:llli

ll!

J

:"F I

.ill

Proper tension

(1).

stitch

much

Too

(2),

causing

by moving

setting.

little tension

Too

(3),

causing

tension by

tighter"+"setting.

produces

tension

fabric

lever up

will

loops in

moving

will

to

toward a

a

smooth, even

produce

pucker.

lever down toward

Adjust tension

produce

pattern.

your

stitch

a tight

looser

"

loose stitch

a

Adjust

-

"

a

Adjusting Stitch

You

on

20

change the appearance of Special Stitch

can

the display

panel,

Balance

byturning

the stitch

patterns

balance

By turning

the

anced

illustrated

When stitches

separate them

ring to the

When stitches

them

balance

11,12 and

ring.

the stitch balance

pattern

selector

fagotingstitch #12 should

(3).

right.

closer

ring to the left.

13/14, numbered in

dial(2),

are too close

by turning

too far apan

are

together

(1)

ring

behind

a correctly bal.

appear as

together

the stitch balance

(5),

by turning

the stitch

red

(4),

bring

Page 22

Zig-Zag Stitch #6

The Zig-Zag

decorating.

:

6

can be used when sewing

Stitch

7A/r

seams, appliqu6ing,

SeamFinishi,ng

a zig-zag stitch to finish

Use

fabrics

o

Sew seams as desired; trim and

open.

are likely to

that

RECOMMENDED

Stitchselccilcn:

wrdth:

strtch

Length:

Slftch

Foot

Needle

Plate:

monogramming

seam edges of

unravel.

SETTINGS

Zig-ZagStitchlffi-l

r[i-F?l

ilt

I

to 4

I

General

General

Purpose

PurPose

-lfl

or

press

(B)

(A)

Zig-Zag

Blindstitching

weight fabrics. Blindstitching trakes a little

first.

;

7

Blindstitch

provides

#7

a durable hem

finish that

o

Place

as shown,

o

Stitch close

fallover

can be

practice,

however,

Stitch Sefecti on:

Lengthz 2lo

Stitch

Foot: General

Attach

Prepare

pressing

want

to baste the

as

shown.

basting

the

top

Wth the wrong

most,

turn the hem under,

creating

hem.

Pin or

together in

of seam

edge

edge.

used on

blindstitch

the hem by folding it

it in

lf

least

at

edge of the

a softfold

place.

allowance under

to edge,

so

Purpose

so,

letting outer zig-zag

variety ol different

a

a test sample

make

Zig-Zag

4

(B)

guide

hem

the usual way. You may

hem

to hold it in

be sure to

th

inch

hem

side of fabric

from

all three layers

baste

Blindstitch@

and

place,

place

(12mm)

allowance.

as shown,

thetop

the

below

upper-

edge of

foot,

21

Page 23

Position the hem under the

foot with the

wall

the

of

guide

the

the top of the

is belween

soft

guide.

hem, as

fold resting

Be

sure the

the

shown.

soft

presser

against

flange

fold

and

of

Multi

-Stitch

Zig

Mending, overcasting,

i:i

I

22

-Zag

joining

#8

or reinforcing

.

and

the

the wall

.

can all be done

the

Lower

sewing

stitches

width il necessary.

guide

and

lf layers of fabric

remove

not sew over

making certain the straight

fall on

the zig-zag stitches

fold of the

soft

the hem edge

feed the

of

pins

using the

MendingaTear

r

Trim ragged edges

o

lining

a

Cut

.

Bring the edges

lining to

wrong side

RECOMMENOED

Slltch

Selectlon:

Stltch Wldth:

Stltch Lenglh:

Fool:

Needle Plate:

r

Place tear, right side up, under

foot.

.

o

r

.

over the

Stitch

length at each end for

stitch

ment.

Trim

thread ends close

lf needed,

Trim away lining close to stitching.

presser

soft

the

as

loot

the edge

work. Adjust

While

in a

fold

guide.

pinned

are

you

cometo

pins.

evenly against

Multi-Stitch Zig-Zag.

tear.

of

for reinforcement.

fabric

of

otteartogether

of fabric.

SETTINGS

Multi-Stitch

Zig-Zag@

itFElo

1 or l5li67

Special Purpose

General Purpose

line

the

of

to fabric.

over tear again.

sew

and begin

the hem

of

just

pierce

stitch

stitching,

straight

together,

them. Do

and baste

presser

shortening

tear,

reinforce-

line

(J)

Page 24

t.

"M"

Stitchl#)

This

stitch can be used for

E

9

stretch seams

and decorative stitching.

LaceTrim

Lace

and children's wear.

r

.

may

trim

lace to

Cut

Pin lace

desired.

desired size.

to

RECOMMENDED

Slitch

Selectlon:

be added to

right

side of

SETTINGS

"M"

blouses, lingerie

fabric

where

StitchlF-l

l'

Crcscent Stitch

This stitch is ideal for

borders, edges, smocking and embroidering.

#10

Stllch Wldth:

Stltch Length:

Foot:

Needle

o

r

Border designs decorate clothing and many

household items.

.

RECOMMENDED

SlllchSelectlon:

Stltch Wldth:

Stltch Lsnglh: 1 or

Fook

Needlc Platc:

Plale:

Carefully stitch along both

as shown.

Trim away the fabric

stitching lines.

BorderD*ign

r

Sew seams

Mark stitching lines on fabric where

desired.

in

iFE-90

2

or lower

Special

General

usual

SETTINGS

CrescentStitchlF[6'l

Special

General

Purpose

Purpose

edges

the lace near

under

manner

rlF-3|

I

,,i I

ll

and

< <'

lower

Purpose

Purpose

=10

(J)

lace,

of

press.

(J)

.

Center

and stitch.

o

Pull threads to wrong side of fabric; tie

and trim.

marked line under

presser

foot

23

Page 25

St etch Overedge

This stitch is

primarily

Stitch #11

used

F

'tt

to finish

seams, hems and lacings requiring

OveredgeSeam

.

Baste

seams.

r

Trim

line.

seam

edge

1/a"

stretch.

(6mm)

from

basting

Fagoting

this

Use

stitch for fagoting,

Stitch #12

embroidery,

patchwork

Stltch

Selectlon:

ffit"n

$irchwrdrh:

Stilch Lang[hz

Foo[

Needle

Adjust

.

o

r

o

Fagoting

two

o

o

.

Plale:

balance, if necessary

Position

foot. as

Stitch along

Straight stitches should fall

line; zig-zag

seam eoge.

Remove

or

strengthening

Fagoting

Fold

Baste

sheet of tissue

Position

presser

trimmed seam under

shown.

basting stitches

is an open, lacy

oieces of fabric.

under

edges

the edges

center of work under

foot.

I

llF=I,

3-11ffi

Special Purpose

General

line.

basting

stitches should fall

seams.

stitch used to

joined

to be

t1t"

(3mml

paper

for support.

Overedge

Purpose

on basting

press.

and

and

apart onto

center of

(J)

presser

over

join

press.

a

24

RECOMMENDED

Stitch

Selection:

Slilch Widlh:

Stitch Length:

Fool:

Needle

Adjust

o

.

Plate:

balance, if necessary

you

As

stitch

the other.

After

sue and basting.

sew, the

first in one fabric strip, and

stitching

needle should

is completed, remove

SETTINGS

Fagoting

llm,

3-l12lo 4

Special Purpose

General Purpose

make

then in

(J)

a

tis-

Page 26

Patchwork

Patchwork

it

both durable and flexible.

can be used for

both household

items

and clothing;

.

Cut square

r

Turn

patch,

o

Cut a backing to fullsize of finished work.

r

Baste

being

another.

and the Fagoting

patches

under 7e"

and

patches

sure all edges

(6mm)

press.

to backing where desired,

to desired size.

line

Stitch

makes

around edges of

next

up

to one

Ric-Rac

This

is a heavy-duty,

g

13

/Straight

#13

stretch

stretch slitch that

RECOMMENOED

StilchSelectlon: Fagotingstitchl#l21

Slitch Width:

Slilch Lenglh:

Foot:

Needle Plate:

Adjust

r

Stitch

ping patches,

o

lf

desired, sew a binding along

edges of

o

Pull threads

trim.

stitch

can also be used

#14

Topstitching

Topstitching is

rate

and

.

Sewseams

r

For topstitching

vert

RECOMMENDED SETTINGS

Slllch Selectlon:

Stitch widih: m IE-l^

Slltch Lengthz

Foot Special

Needle Plate:

Adjust balance, if necessary

balance,

lengthwise

as shown.

work.

to underside

for

topstitching.

a

reinforce

in

machine to

SETTINGS

ilm,

3-112to

Special

General

il necessary

and crosswise, overlap-

practical

your garment.

mannerand

usual

hard-to-reach

free

arm sewing.

Ric-Rac

Stretch Stitch

l,lt

General

4

Purpose (J)

Purpose

of work:

way to

l#131 /Straight

ll

3-112to

Purpose

both deco-

press.

areas, con-

liiTill

=lo

4

Purpose

outer

tie and

r

.

garment

Place

Slowlytopstitch desired

r

Pull threads to

and trim.

.

To

create

stitch

set

length to

stitch

right

wrong

a straight stretch stitch,#

width

#4.

side up, under

areas.

of fabric;

side

to the

left

and

foot.

tie

14

25

Page 27

SECTION 5

Your machine

You never need to move the fabric or

'

reposition the needle.

.

Always make a

sample

.

Be sure bobbin contains enough thread.

[il

1/3 2 4

makes buttonholes

practice

your

of

fabric.

G

Four-Step

in four easy steps.

buttonhole on a

Buttonholing

.

When making buttonholes on hard-to-

reach

areas convert

arm sewing.

.

Mark

buttonhole

pattern.

in

cated

.

When

sewing

piece

positioning

presser

from

the teeth on the underside

from

paper

of

the

foot

the foot. This will

under

picking

machine

position

delicate fabrics,

over the fabric when

garment.

and slip

and

on fabric

the

pulling

Lower

paper

the fabric.

Settlngs

bed to free

as

place

the

out

prevent

foot

of the

indi-

a

___r

Selecllon

: Buttonhole

widrh:ill-il

Lensth:

Buttonhole

Plate:

7

Step

.

.

.

o

r

o

o

Step2

.

.

o

presser

Raise

Place fabric underfoot.

Center a red

around beginning line

Select Buttonhole Stitch

Position

Lower

portion

ing

ward. Make 4

point

(3).

needle.

Raise

Sefect

Stitch

down

Raise needle.

g--t-+l....''Fll

(L)

General

foot,

guideline (1)

needle

the foot and make

Buttonhole

in

of the

or

point

to

fabric

foot

5 stitches

Stilch #2.

Stitch

Purpose

(4).

(A)

of foot

of buttonhole.

#1/3.

point

(2).

at

the

sure

is all the way for-

ending at

slid-

26

rS

Step3

r

.

.

Buttonhole Stitch #1

Select

Make four or five stitches,

point

(5).

Raise needle.

/3.

ending at

Page 28

Step 4

o

Select

Buttonhole

.

Stitch

up to

o

Raise needle.

point

Stitch #4.

(6).

.

.

=ffi

r

Adjusting Balance

lf the two stitching sides

are unequal,

located

On some heavy

ment might be necessary.

.

)

presser

Raise

from machine.

Clip thread ends.

Carefully

ripper

seam

behind

lf

right

the

turn stitch balance ring

until

both sides are equal.

foot and

cut buttonhole

small,

or

turn the stitch balance ring

the

weight fabrics

side of

remove

sharp

ol Buttonhote

of

selector dial.

stitching

slightly to the right

garment

opening with a

scissors

your

buttonhole

adjust-

an

is too

open

(7),

(8),

$,

il

)

*,

il

.

lf the left side of stitching

turn stitch balance

left

until both sides are equal.

ring slightly to the

is

too open

(9),

27

Page 29

SECTION 6

Caring forYour Machine

Removing

and Replacing

Bobbrn

Case

CAUTION: Before

the

machine,

socket

.

.

o

.

To

o

r

outlet.

presser

Raise

Open slide

To

remove the bobbin case, the

must be removed first.

olate

Lift needle

slide out from under foot.

Remove Bobbin Case

With a small screwdriver, turn

back as

Lift out bobbin case.

far as it will

remove

foot and

plate

and remove

plate

(1)

cleaning

plug

needle.

from right

go.

or adjusting

from

the

bobbin.

needle

corner and

lever

(2)

28

To

Replace Bobbrn

.

Guide forked end

under feed

.

Draw

plate

.

Turn lever

case in

NOTE: After locking

is not tight, but

r

To

pin

o

Press needle

o

Insert

(4).

rim

of

bobbin

(5).

(2)

toward

place,

can

replace

(6)

needle

push

and

bobbin and close slide

it to the left.

plate

Case

(3)

of bobbin case

case under

you,

in

case

move

slightly.

plate,

in

down

position

locking bobbin

place,

be sure

it under

slide

place.

plate,

it

Page 30

Removing

Replacing LightBulb

and

rrrrrul

/

\

\*-

\k

CAUT:I,pN:

r

Before

you

outlet. Be

which

operating the machine.

o

This machine is designed

To change the

first

changing

have

covers

maximum

be removed.

sure

light bulb.

light

removed

to replace the

the light bulb before

light bulb, the

bulb,

plug

to use

from

face

make

socket

plate

face

a 1s-Watt

plate

must

sure

G

ddd

.

.

To Removethe Light Bulb

.

o

To Replace

.

o

.

r

and remove

Loosen

plate

face

Slide

rnachine,

Push bulb up into

to the

Pull bulb down

Push new

to the right

Reposition

plate

of

Line

hole in machine.

Insert

to unlock bulb

left

the

bulb

until

face

under edge of top cover.

up screw hole in

screw

down

and out of

Light

up into

pins

plate

tighten.

and

screw

and away

socket

pins.

Bulb

socket

lock into

by sliding top edge

plate

(1).

(2)

socket.

position.

with

from

and turn

and

turn

screw

29

Page 31

Cleaningthe

Your machine

reliability, take a few minutes

how often

you

Machine

is

designed to

use it.

give you

keep

to

years

many

machine clean. How often

the

of dependable service.

you

To

clean it

ensure this

depends on

ilt[ilil

the lint brush,

Using

from:

-presser

-needle

-bobbin

area,

cleaning)

-machine

a soft cloth and use

the surface)

Remove needle

clean exposed area

oar

bar

(if

case

remove

there

surface

plate

the bobbin case

remove

(if

necessary,

a mild

with a

lint

is a lot of lint in this

dampen

soap

as instructed and

lint

brush.

or dust

for

to clean

Page 32

Pertormance

When

sewing

correctly following the instructions. lf

you

help

to correct it.

Checklist

difficulties

occur,

look back through

you

still

have a

manual to make

this

problem,

the reminders below

sure

you

are

may

NeedleDoesNotMoye

ls machine connected

supply?

power

ls

the

ls

controller connected?

ls

air supply

Needle Moves

lsNotFormed

ls needle

ls needle fully inserted

clamp?

Are

bobbin and needle

threaded?

ls bobbin correctly

bobbin case?

NeedleBreafts

ls needle

ls

needle correct

ls needle

clamp?

Are controls

Are

accessories

Bobbi

ls thread

ls

bobbin winder

ls

thread end securely held

of

and light

from

defective?

straight and sharp?

fully inserted into needle

properly

n W i ndi ng Dilticulties

unwinding freely from

wind?

to electrical

switch on?

controller

But

Stitch

into needle

correctly

inserted into

size?

set?

for

correct

engaged?

clear?

application?

at start

spool?

UpperThread

ls

machine

ls

thread freely

proper

ls

ls needle

ls upper

ls

ls

LowerThread

ls

ls

ls

SkrppedStitches

ls

ls fabric firmly

ls

ls needle

Fabric Does

Under Presser Foot

ls

ls

ls

thread tension too tight?

bobbin case

bobbin

bobbin correctly

bobbin correctly inserted into

bobbin

bobbin

machine

needle correct

presser

to machine?

presser

stitch length

Breaks

properly

spool

correct

rim free

case?

case correctlythreaded?

properly

straight

foot

foot

threaded?

unwinding from

cap being used?

for thread?

size

properly

held

NotMove Proper$

correctly attached

lowered?

correctly set?

inserted?

of nicks?

Breaks

wound?

threaded?

down?

style and size?

and sharp?

spool?

QI

Page 33

Ad d i

Additional

sewing center.

o n a I A

ti

Accessories for

ccessories

your

sewing

machine

are available at

your

St'trvt

K ffi,.*,

.",u

Fl

9

@

u,g"k

sM,ru

@

1.

Seam Gulde

allowance

2. Blindstitch Presser Foot

guide

fabric for nearly invisible

hems.

stitch

3. Button

4. Darning

5. Even Feed Fool

6. Oveledge

7. Seam

.

Sewlng

securely

recommended

such as embroidery,

and decorative designs.

hard

to

fabrics. Also

and topstitching.

Stretch Stitch for seams in stretch

fabrics.

Ripper,

threads

(N),

even.

Foot

for fastening.

Embroidery Foot

and

for

(M),

pile,

feed

quickly

stretch and bonded

excellentfor

Foot, use wilh

used to

and

helps

keep

(K),

(H),

holds buttons

free

motion work,

monogramming

is

used for

neatly.

plaids,

Overedge

pick

and

sewing

seam

helps

blind-

(G),

is

stripes

cut

\

*|]\

ilil+w,

v,'[R

tN

ffiK

32

Twln

8.

9.

10.

11.

Needle and Spool Pln

used for decorative twin

threads)

labrics.

Needle Threader

threading machine

Narrow Hemmer Foot

a narrow

Stralght Stitch

Needle Plale

stitching light-weight

stitching

hem in

a single

Preeser Fool

(C),

are used

on woven

needle.

needle

(P),

assists

is

used

operation.

when

fabrics,

(R),

are

(2

and knit

in

to

stitch

(D),

and

straight

Page 34

lndex

Accessories

Balance

Basting

Blindstitch Hems. .......21

Blindstitch

Bobbin .

Bobbin

Bobbin Thread,

Border

Buttonhofe Presser

Buttonholing,

Caring

Cleaning The Machine

Connecting The

Corners, Turning

Fabrics

FacePlate

Feed

Fagoting .

Free-Arm

Lace

LightBulb

LintBrush

Needles

NeedlePlate

OperatingTheMachine

Hem

Guide 4,22

Winding

Inserting

Case ...... .. 28

Removing

Cleaning

Designs

For Your

Placing

Cover

Trim ..........

Replacing .......29

Selecting .........5

Changing ........8

Changing ........28

Raising ..... 13

..... ....... 23

Foot

Four

Step . 26,27

Machine

Machine .......,...

Square

Fabric

Under

Sewing

......4,32

.. 20.27

.....16

...... 4

.........10

........11

.......28

........30

.. ....... 4.26

.... 28,29,3O

. .. . .

.......... 17

.......5

Foot .......

.........29

.......

.... . 8,25,26

..........29

........4,30

..

.........4

...... 7

.22

30

16

... 9

... 24

23

.... 4

Patchwork

PerlormanceChecklist

Presser Feet

Changing

General Purpose

Special

PresserFootLifter

Principal

ReverseStitching

Seams:

Curved ..........17

Finishes

KeepingStraight

Overedge Seam .

SewingASeam

Spool Caps

Stitch

7

Blindstitch

CrescentStitch . .,......23

Fagoring

"M"

Multi-StitchZig-zal

Ric-Rac/Straight

StraighrStirch.

Stretch Overedge

Zig-Zagstitch . ..........

Stitch

stitchwidth

Tears, MeldinS . .... ..... . . 22

Tension ........15.20

Thread ....... 5

Threading The

Topstitching ........25

ZipperFoot

Zipper,lnsertingA ..

..

Purpose .......... 4

Parts . ....2,3

Patterns

Zig-Za7

Stitch..

Sritch

Srrelch

Stitch

Lenglh ...

Machine

..........25

....31

.

...... 4

........9

.........4

.........

.......... 16

......21

........17

........24

.....16, 17

....... 4,10

........24

. ..... . 23

Stitch. . .

.........14

. ....... 24

........19

.......4,18

16

,24

. ..... 22

..... 22

25

21

14,19

.. . . 12

....... 18

33

Page 35

Part No.

119625-O01

(B:Oo

Page 36

.€

'r,

;l

."

1&.

4

.&4r-

Llt

t

t

(\a^

/

n {11

\)a)\)

SINGER

Loading...

Loading...