6217

SINGER

r

V.

Dear Customer;

We recommend that for future reference

you record the Serial Number of your

Sewing Machine in the space provided.

Refer to illus

tration at

rightfor loca

tion of Serial

Number on

your

machine.

Serial No.

Serial No.

Congratulations

r---------------------------------------

Table of Contents

As the owner of a new Singer sewing

machine, you are about to begin an

exciting adventure in creativity. From the

moment you first use your machine, you

will know you are sewing on one of the

easiest to use sewing machines ever

made.

In addition to the many familiar SINGER

exclusives, like a removable extension

table and a 1 horizontal spool pin, this

machine offers you these features:

• Zig-zag stitching for buttonholes,

mending and decorative stitches.

• Flexi stitch patterns for sewing knitted

and other stretch fabrics.

• Built-in 4-step buttonholer that takes

the difficulty out of making a buttonhole.

• Blindstitching for invisible hems.

• Easy to find “Letter-Coded” Acces

sories.

• Drop in front bobbin for easy, quick

bobbin replacement.

• Simple stitch length dial and push

button reverse stitching.

• Snap-on presser feet that are quickly

removed and easily replaced.

• One-way needle insertion that makes

it impossible to Insert the needle

incorrectly.

May we recommend that, before you start

to use your sewing machine, you discover

the many advantages and the ease of

operation by going through this instruc

tion book, step by step, seated at your

machine.

To ensure that you are always provided

with the most modern sewing capabilities,

the manufacturer reserves the right to

change the appearance, design or acces

sories of this sewing machine when

considered necessary.

*A Trademark of The Singer Company

Copyright 1984 The Singer Company

All rights reserved throughout the world

1. Getting To Know Your Machine .. 02

Principal Parts ................................ 03

Accessories

2. Getting Ready To Sew.....................05

Important Sefeguards

Operating the Machine

Choosing and Changing Needles . 06

Changing Presser Feet

Changing the Needle Plate

Attaching the Feed Cover

Removing and Replacing the

Extension Table

Fabric, Thread and Needle Table . 09

Winding a Bobbin ............................10

Inserting a Bobbin

Threading the Machine

Raising the Bobbin Thread

3. Straight Stitching

Stitch Width Selector

Stitch Length Selector

Needle Position Selector ....... 14

Reverse Stitch Button

Adjusting Thread Tension

Sewing a Seam

Darning ............................................18

Quilting

Inserting a Zip .

4. Zig-Zag Stitching

Stitch Pattern Selector

Needle Position Selector .................20

Stitch Width Selector

Adjusting Stitch Length

Needle Thread Tension

Zig-Zag Stitch No. 4

Multi Stitch Zig-Zag No. 8

Blindstitch No. 6

Ladder Seams .................................25

“M” Stitch No. 10

Attaching a Button .

5. Rexi Stitch Patterns

Stitch Pattern Selector

Stitch Width Selector

Needle Position Selector

Balancing Flexi Stitches ..................29

Straight Stretch Stitch No. 3

RIc Rac Stitch No. 5.........................30

Slant Overedge Stitch No. 7 ............31

Honeycomb Stitch No. 9

Overedged Seams

6. Four Step Buttonhole........................34

7. Free-Arm Sewing

8. Twin Needle Sewing

9. Caring For Your Machine

Removing and Replacing the

BobbinCase......................................38

Changing the Light Bulb

Cleaning the Machine

Lubricating the Machine

ADDITIONAL ACCESSORIES

PERFOrtMANCE CHECKLIST

INDEX

V

______________________

..................................

...............................

.....................

...................

..................

..............................

...........................

...................

..............................

........................

......................

................ 14

................

................................

............................................

..............................

.............................

....................

........................

...................

..................

........................

................

..............................

.............................

...

.....................

...........

..................

.................

................

.................

..........................

............................

.......................

..................

.............. 40

--------

. 04

.............

...............

.............

.............

29

............

................

.... 41

.............

.............

...............

05

06

07

08

08

08

11

12

13

14

14

14

15

16

18

19

20

20

20

21

21

22

23

24

26

27

28

28

29

30

32

33

36

37

38

39

42

43

44

y

01

1. GETTING TO KNOW YOUR MACHINE

02

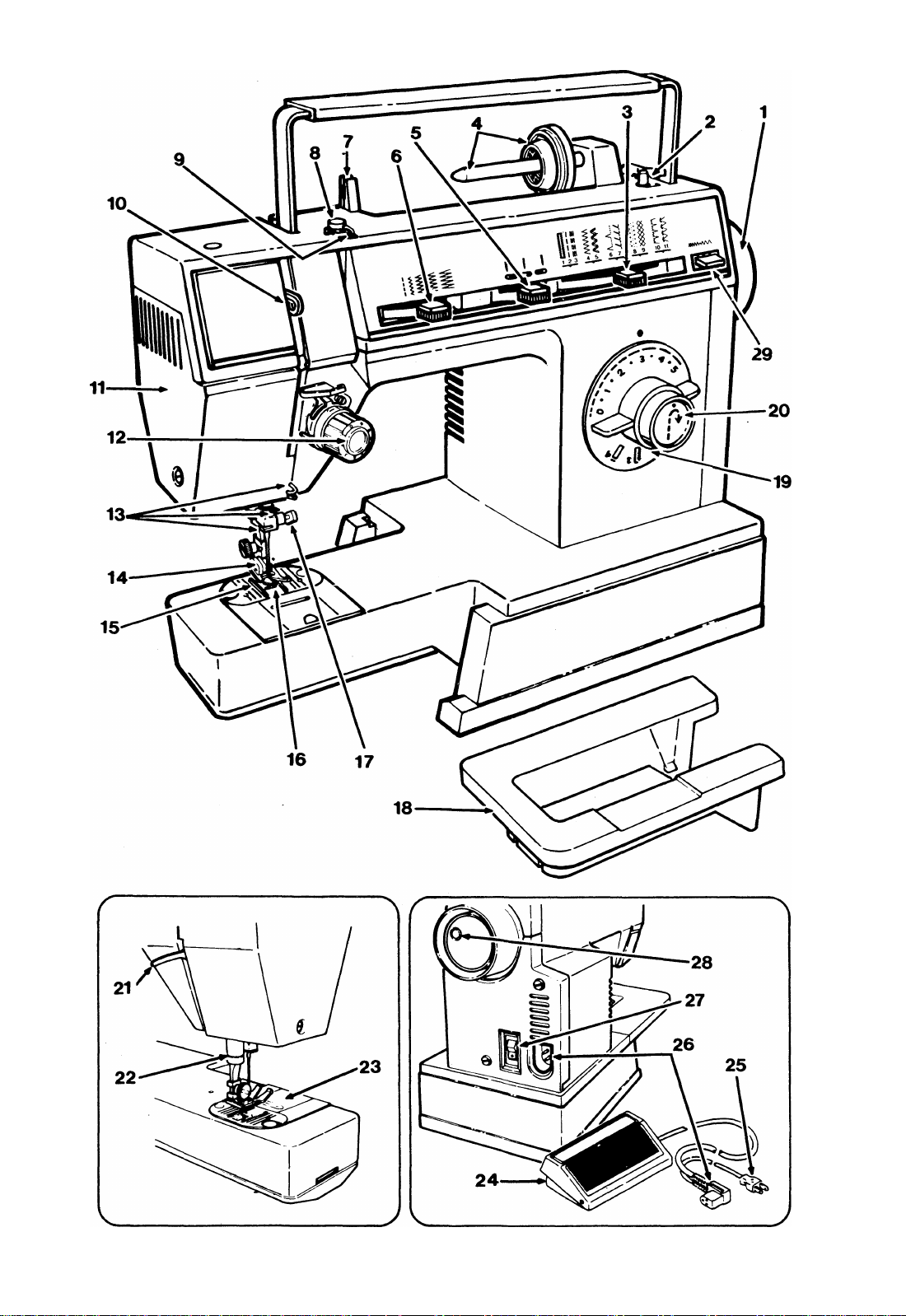

Principal parts

1. Hand wheel

2. Bobbin winder

3. Pattern selector lever

4. Horizontal spool pin

5. Needle position selector

6. Stitch width lever

7. Snap-in thread guide

8. Bobbin winder tension

disc

9. Thread guide

10. Take up lever

11. Faceplate

12. Needle thread tension

dial

13. Thread guides

14. Snap on presser foot

15. Feed system

16. Needle plate

17. One-way needle clamp

18. Removable extension

table

19. Stitch length dial

20. Push button reverse

21. Presser foot lifter

22. Threat cutter

23. Slide plate

24. Foot control

25. Electrical lead

26. Machine plug

27. Power and light switch

28. Bobbin winding indent

29. Stitch balance control

Notes

J V.

03

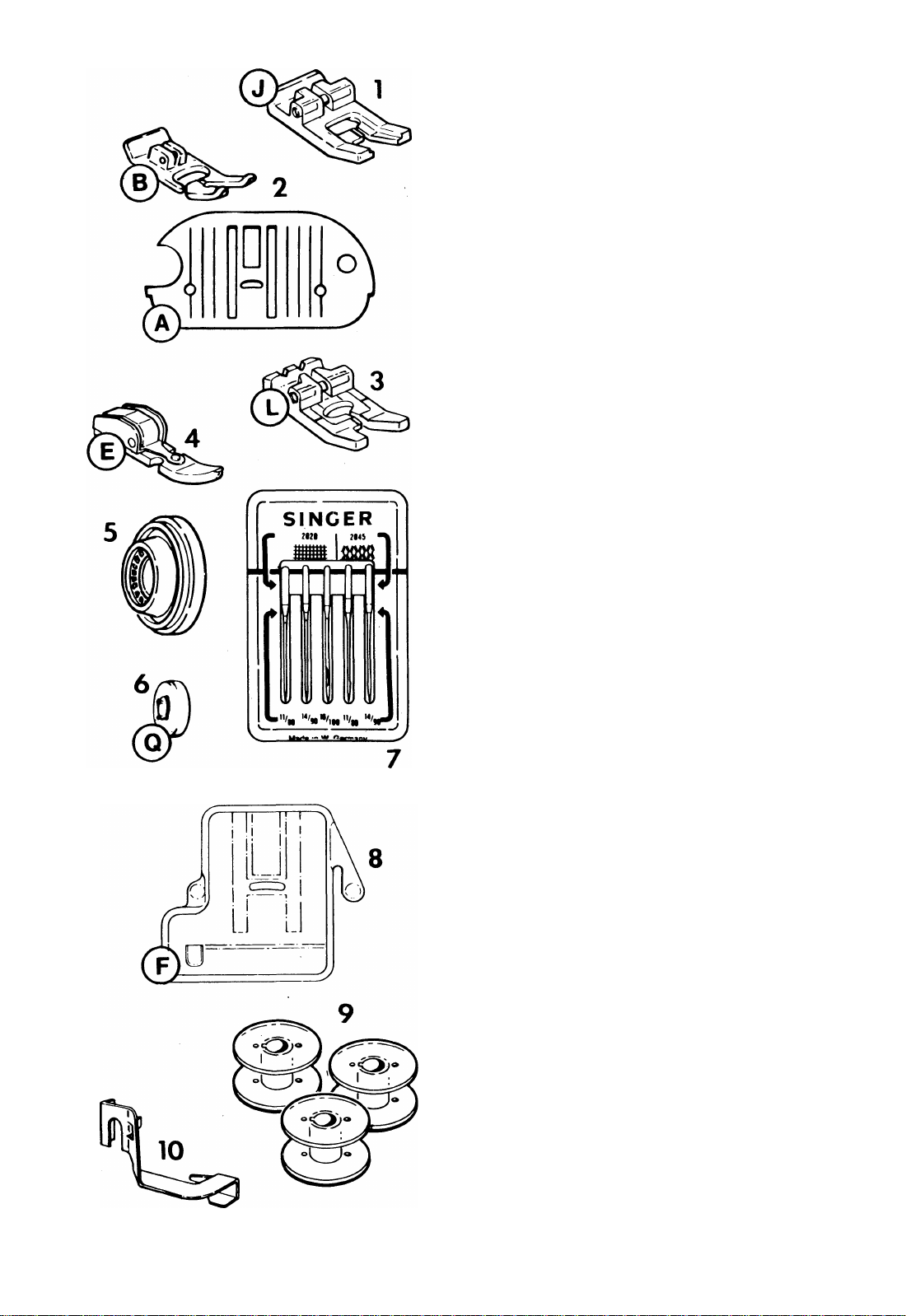

Accessories

The following accessories furnished with

your sewing machine are designed to simplify

your sewing projects and increase the

versatility of your machine.

The letter in a circle adjacent to the illustrated

part is reproduced on the part itself to help

you select the correct attachment for the type

of work you are doing.

1. Special purpose presser foot (J) is used

for decorative and zig-zag sewing.

2. General purpose needle plate (A) and

presser foot (B) are on your machine

when delivered. Use together for alter

nating between straight and zig-zag

stitching.

3. Buttonhole presser foot (L) is used with

the General Purpose Needle Plate to

make four-step buttonholes.

4. Zip foot (E) is used for inserting zips and

stitching corded seams.

5. Friction free spool holder is used to hold

various size spools and allows thread

to unwind smoothly. The spool does not

turn.

6. Small thread spool holder (Q) for use

with small diameter spools of thread.

7. Needlepack includes an assortment for

sewing various types of fabrics.

8. Feed cover (F) is used to prevent the

feed from moving the fabric when

darning or free motion embroidery.

9 Transparent bobbins for easy viewing of

thread supply.

10. Blindstitch hem guide is used to position

the hem for blindstitch hemming.

2. GETTING READY TO SEW

IMPORTANT SAFEGUARDS

1. Unplug the machine at the socket when changing needles, feet, or needle plates, or when

leaving the machine unattended. This eliminates the possibility of starting the machine

by accidentally pressing the speed controller.

2. Before removing the bobbin case, unplug the machine at the socket.

3. Because of the up and down movement of the needle, you must work carefully and watch

the sewing area when operating the machine.

4. Do not pull the fabric while you are stiching as this may deflect the needle, causing It

to break.

5. Before cleaning your machine, it must be unplugged at the socket.

6. Do not attempt to adjust the motor belt. Contact your nearest Service Centre or an authorized

SINGER dealer should any adjustment be required.

7. Before changing light bulb, make sure you have removed plug from socket outlet. Be sure

to replace the face plate which covers the light bulb before operating the machine.

8. This machine is designed to use a 15-watt maximum light bulb.

This product is suppressed for radio and television interference with the International Electro

technical Commission requirements of the CISPR.

Machines for Great Britain and some other countries having similar wiring standards are

shipped from the factory without a plug for connection to the mains. The wires in this mains

lead are coloured in accordance with the following code:

Blue: neutral (N) Brown: live (L)

As the colours of the wires in the mains lead of this appliance may not correspond with

the coloured markings Identifying the terminals in your plug, proceed as follows:

The wire which is coloured blue must be connected to the terminal which Is marked with

the letter N or coloured black. The wire which is coloured brown must be connected to

the terminal which is marked with letter L or coloured red. If a 13 Amp. (BS 1363) plug is

used, a 3 Amp. fuse must be fitted, or if any other type of plug is used, a 5 Amp. fuse must

be fitted either in the plug or adaptor or at the distribution board.

Neither core is to be connected to the earth terminal of a three-pin plug.

05

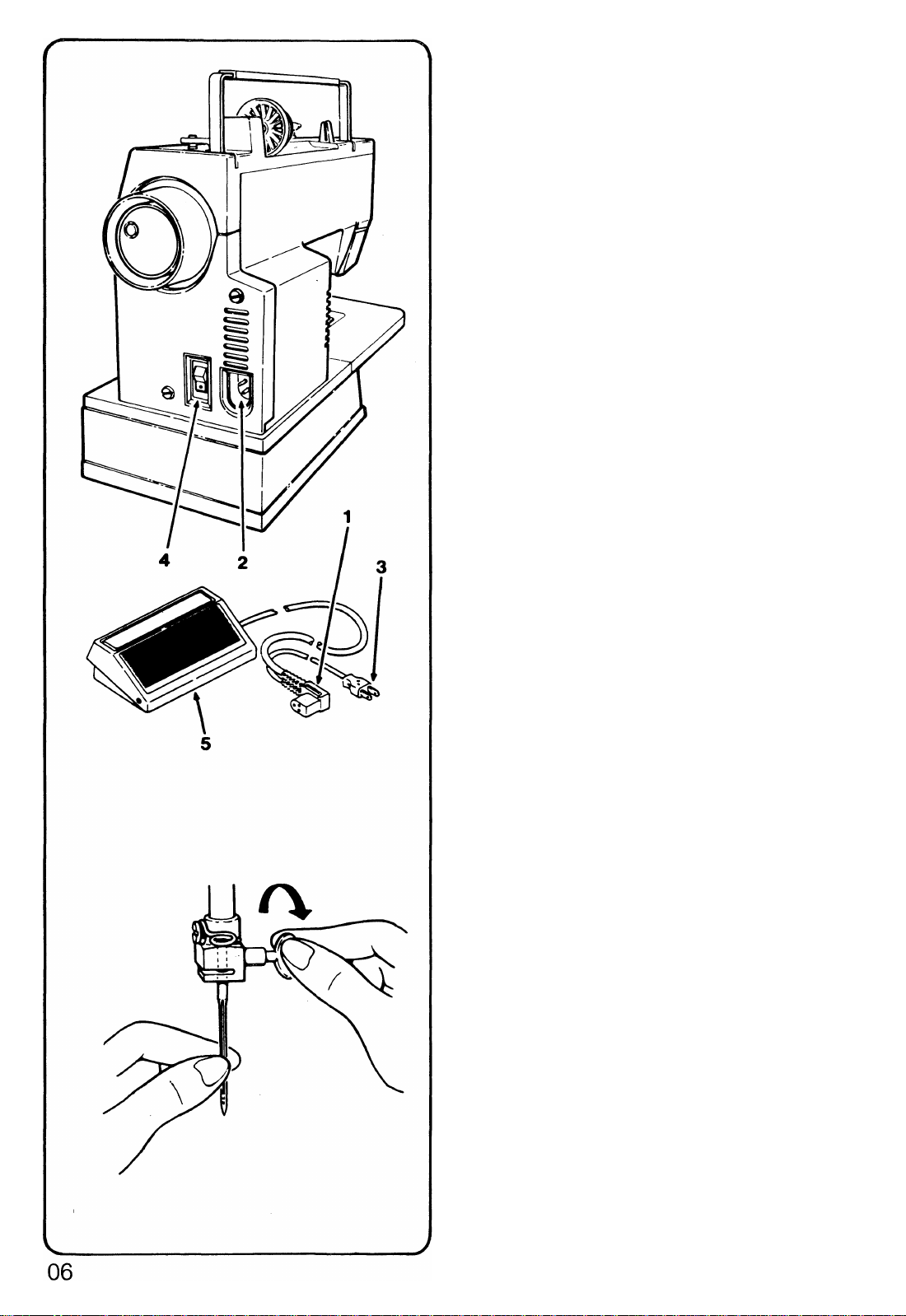

Operating the machine

Connecting the machine

Push plug (1) into the receptacle (2) at the

right end of the inachine. Then connect plug

(3) to your socket outlet.

Running the machine

To turn on machine and sewing light, press

upper portion of power switch (4). To turn

off machine and light, press lower portion “O”

of power switch.

To run the machine and contol speed, press

the foot control (5) with your foot. The harder

you press, the faster the machine will sew.

To stop machine, remove foot from control.

Note: Do not operate machine without fabric

under the presser foot as this may damage

the feed and the presser foot.

Choosing and changing

needles

Important: For best results from your sewing

machine, use only SINGER* needles. Check

the needle package, and the Fabric, Thread

and Needle Table on page 09 for the correct

needle and fabric combination.

• Raise needle to its highest position.

• Loosen needle clamp screw and remove

needle.

• With flat side of needle to the back, insert

new needle up into clamp as far as it will

go.

• Tighten needle clamp screw securely.

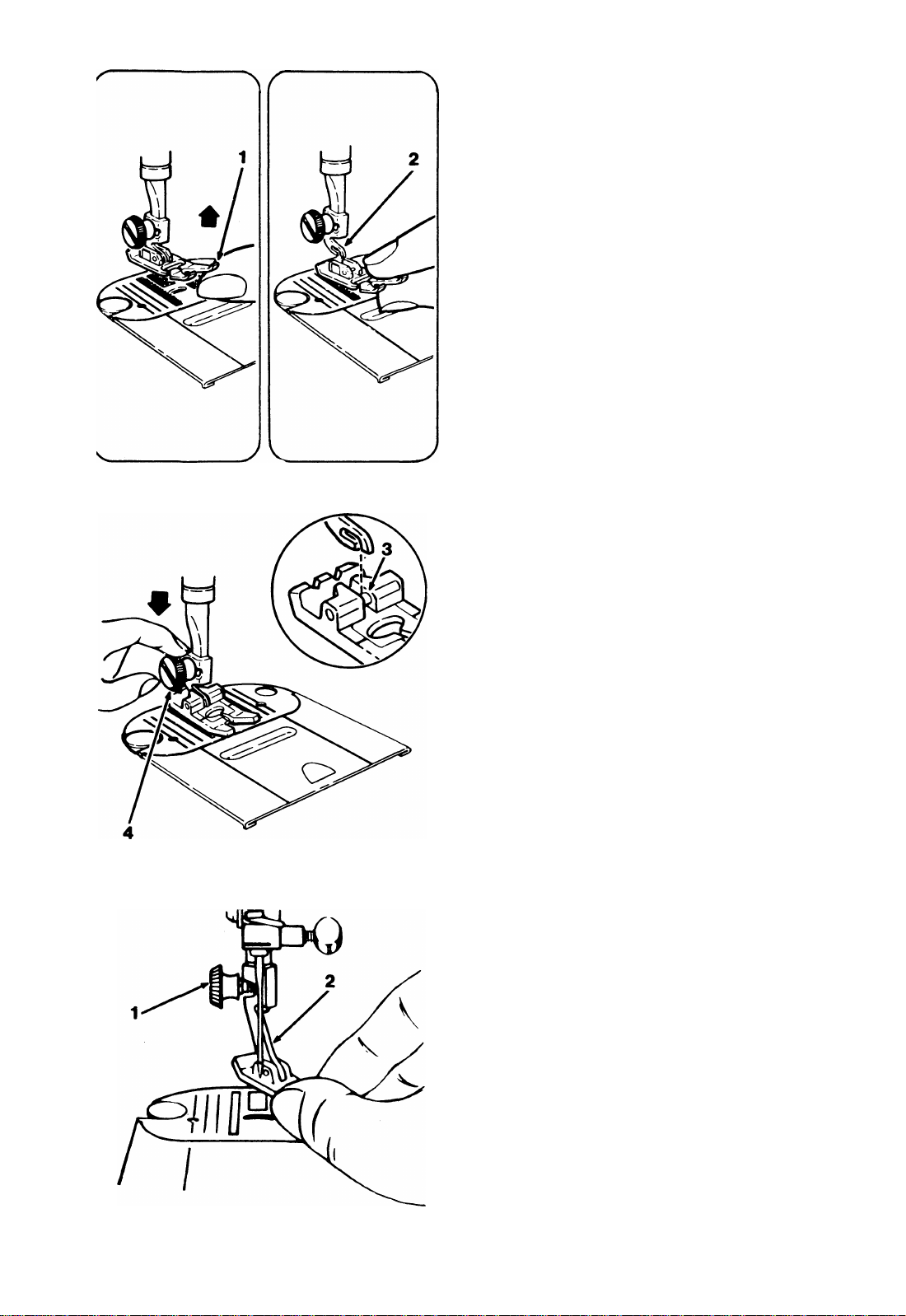

Changing snap-on presser feet (B), (D),

(J), (L)

Your machine comes with the General

Purpose Presser Foot (B) already attached.

You can easily change to any one of the other

presser feet which snap onto a common

shank by following the directions below.

• Raise needle to its highest position by

turning hand wheel toward you.

• Raise presser foot using presser foot lifter

at back of machine.

• Push toe of presser foot (1) up, until it snaps

off the shank (2).

• Remove foot from machine.

Place new foot under centre of shank.

Lower presser foot lifter, fitting shank over

presser foot pin (3).

Don’t turn screw. Instead, push presser

foot screw (4) down, firmly until foot snaps

into place.

Changing screw-on presser feet (H), (G)

Some special presser feet can be purchased

at your SINGER stockist which have builtin shanks that can be replaced as follows:

• Raise needle and presser foot.

• Loosen presser foot screw (1) and remove

presser foot with shank (2), guiding it

toward you and to the right.

• To replace presser foot with shank, hook

shank around the presser bar and tighten

presser foot screw with the use of a coin.

07

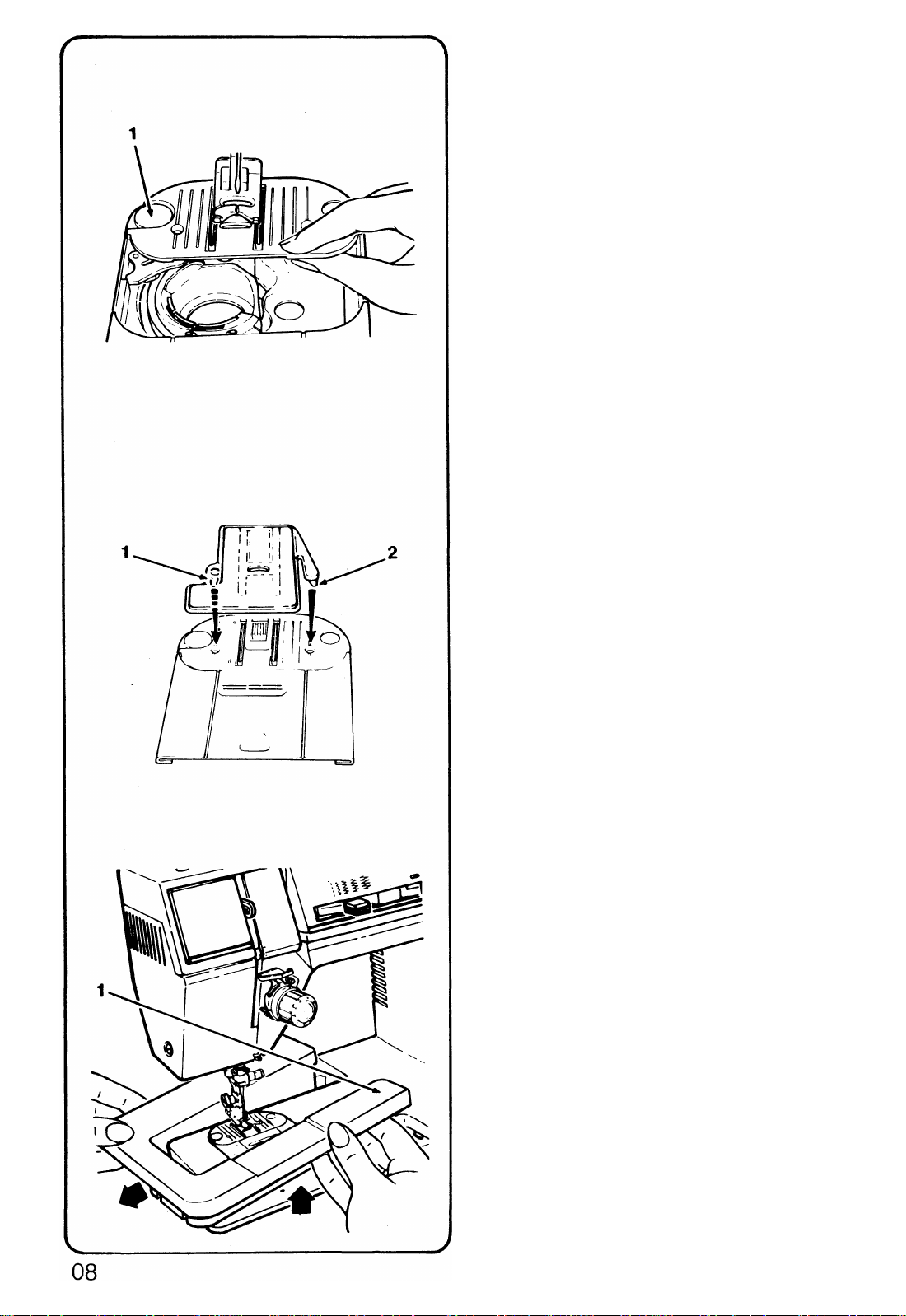

Changing the needle plate (A), (C)

Your machine comes with the General

Purpose Needle Plate (A) attached. The

Straight Stitch Needle Plate (C) may be

purchased at your sewing centre and can

be attached as follows:

• Raise needle and presser foot.

• Open slide plate.

• Lift up needle plate from right corner and

slide out from under foot.

• To replace needle plate, slide it under pin

(1) and push it firmly to the left.

• Press down until it snaps into place.

Attaching the feed

cover (F)

The feed cover is used to keep the feed from

moving the fabric when attaching a button,

darning or sewing free-motion embroidery.

To attach it, follow the directions below:

• Raise needle and presser foot.

• Open slide plate.

• Slide feed cover on top of needle plate,

pressing tabs (1) and (2) into holes.

• Close slide plate.

• To remove, open slide plate and lift front

edge of cover; pull it away.

Removing the extension

tabie

Free arm sewing makes it easier to sew hardto-reach areas.

To change machine for free arm sewing, lift

right edge (1) of extension table, slide it to

the left and off the machine.

To replace the extension table, slide it to the

right keeping it even with the free arm, until

the tabs on the right lock into place.

Fabric, thread and needle table

The needle and thread you choose will depend upon the fabric being sewn. The tabje below

is a practical guide to needle and thread selection. Always refer to It before beginning a

sewing project. Be sure to use the same size and type of thread in both needle and bobbin.

The fabrics below can be of any fiber; cotton, linen, silk, wool,

synthetic, rayon, blends. They are listed as examples of weight.

NEEDLES

Fabrics Thread

Light-

Weight

MediumWeight

MediumHeavy

Knits Bonded Knits

Batiste

Chiffon

Crepe

Corduroy

Flannel

Gabardine

Gingham

Linen

Muslin

Wool Crepe

Bonded Wovens

Canvas

Coating

Denim

Duck

Sailcloth

Double Knit

Jersey

Tricot

Type Size

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 40

t“Heavy Duty” 2020 18/110

Cotton-wrapped

Polyester

Polyester

Nylon

2020 11/80

2020 14/90

2020 16/100

Ball-Point 2045

Size 11/80,14/100,

16/110

fNot recommended on stretch fabrics

09

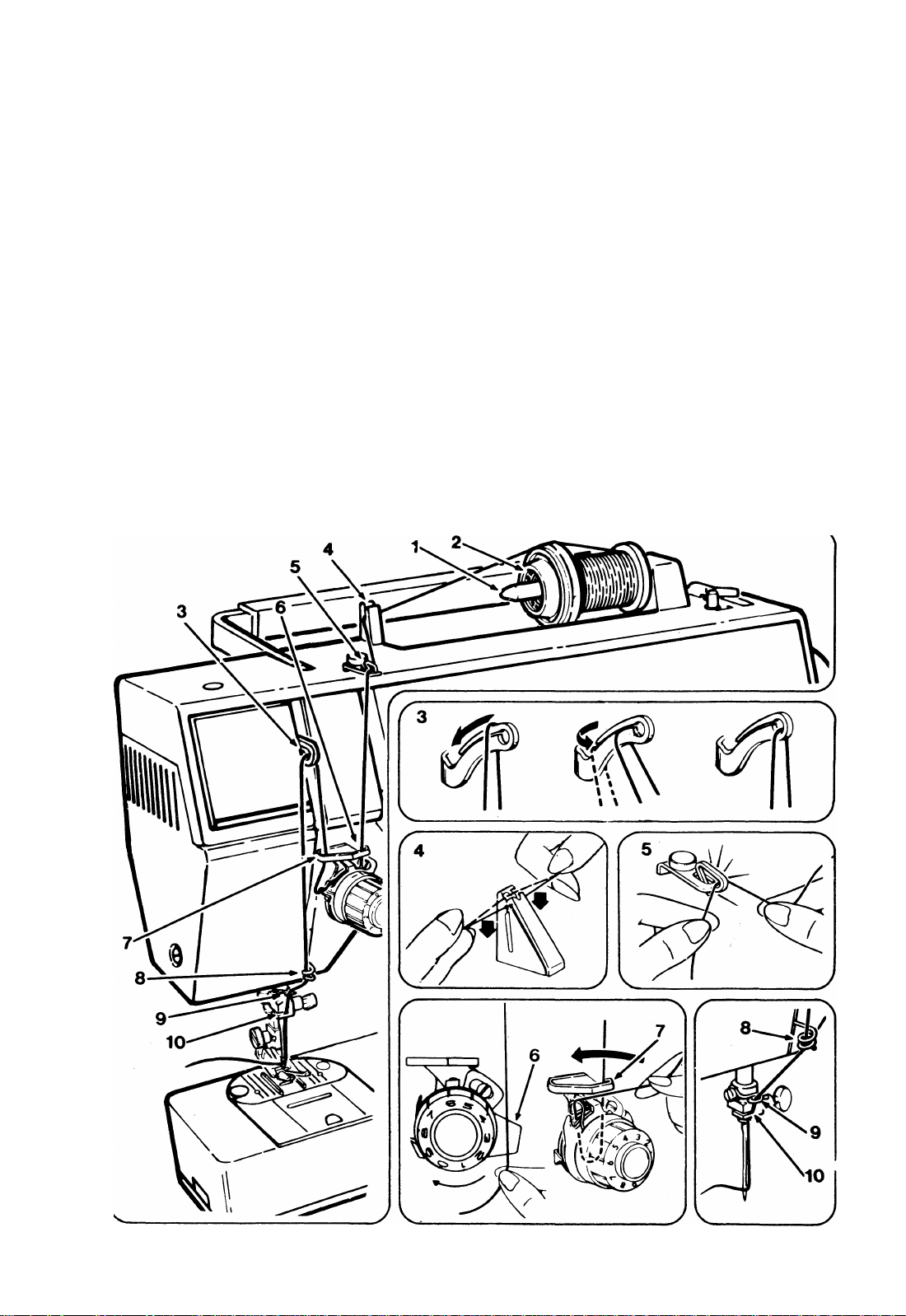

Winding a bobbin

Winding a bobbin is quick and easy when you follow the directions below. Always wind

the bobbin before threading the machine and needle.

• Push In indent (1) on hand wheel disc. This will stop the needle from moving.

• Place spool of thread on spool pin.

• Slide spool'cap (2) firmly over rim of spool to prevent thread tangling.

• Lead thread from spool and snap into thread guide post (3).

• Wind thread clockwise around front of bobbin winder tension disc (4).

• Pass thread end, from inside, through small hole In rim Of bobbin.

• Place bobbin on spindle and push it to the right.

• Holding thread end, step on speed controller to run machine until desired amount of thread

is wound. (Winding stops automatically once bobbin Is full.)

• Cut thread; push bobbin to the left and remove it from spindle.

• Trim thread end from top of bobbin.

• Return hand wheel disc to sewing position by pressing on side opposite indent.

10

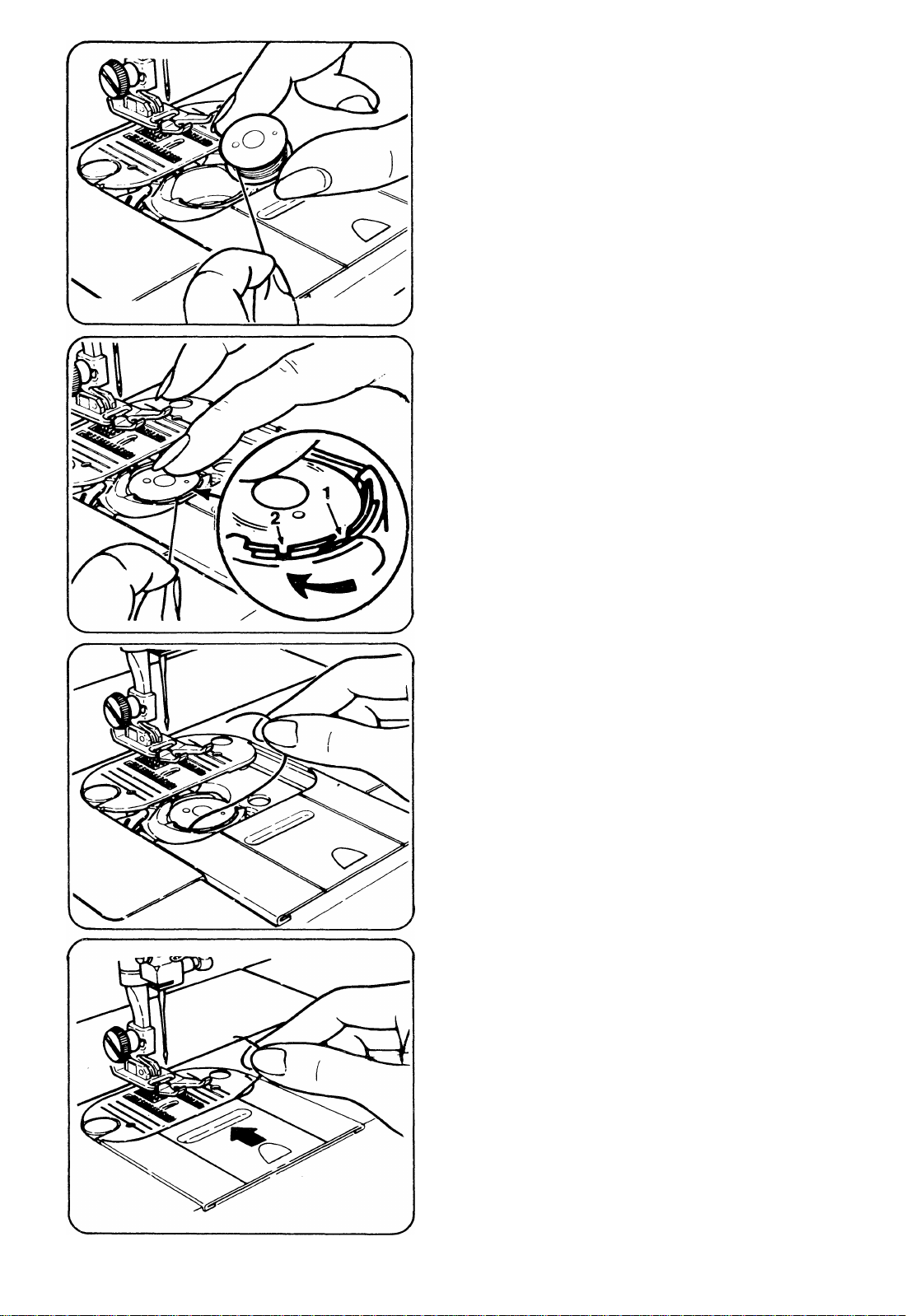

Inserting a bobbin

To insert a bobbin, follow the instructions

below:

• Raise presser foot.

• Turn hand wheel toward you until needle

is in its highest position.

• Open slide plate and remove empty bobbin.

1. Pull 4” (10cm) of thread from replacement

bobbin and insert bobbin into case, as

shown.

2. Holding bobbin in place, guide thread into

notch (1) and then down the slot to the

left and guide around into notch (2).

3. Draw several Inches of thread diagonally

across the bobbin toward the back of the

machine.

4. While holding thread on outside, close the

slide plate, allowing thread to extend

through the slot between the slide plate

and needle plate.

• Follow directions for “Raising Bobbin

Thread” on page13.

n

Threading the machine

To thread your machine correctly, follow the steps below:

• Raise take-up lever (3) to highest position by turning hand wheel toward you.

• Raise presser foot to release thread tension.

• Place spool of thread on spool pin (1).

• Slide spool cap (2) firmly over rim of spool to prevent thread tangling.

• Lead thread from spool and snap into thread guides (4) and (5).

• Thread the tension discs by leading thread down against the tab (6), as shown, between

the tension discs and up under the spring on the left side. Hold the spool lightly with

finger, pull thread gently up and to the right, lifting the spring and allowing thread to slip

into thread guard. Then, lead thread up behind thread guide (7).

• Slip thread into take-up lever as illustrated (3).

• Pass thread through guides (8) and (9).

• When sewing with medium to heavy weight threads, do not thread the lower thread guide

(10).

• Thread needle from front to back, pulling 4" (10cm) of thread through eye.

12

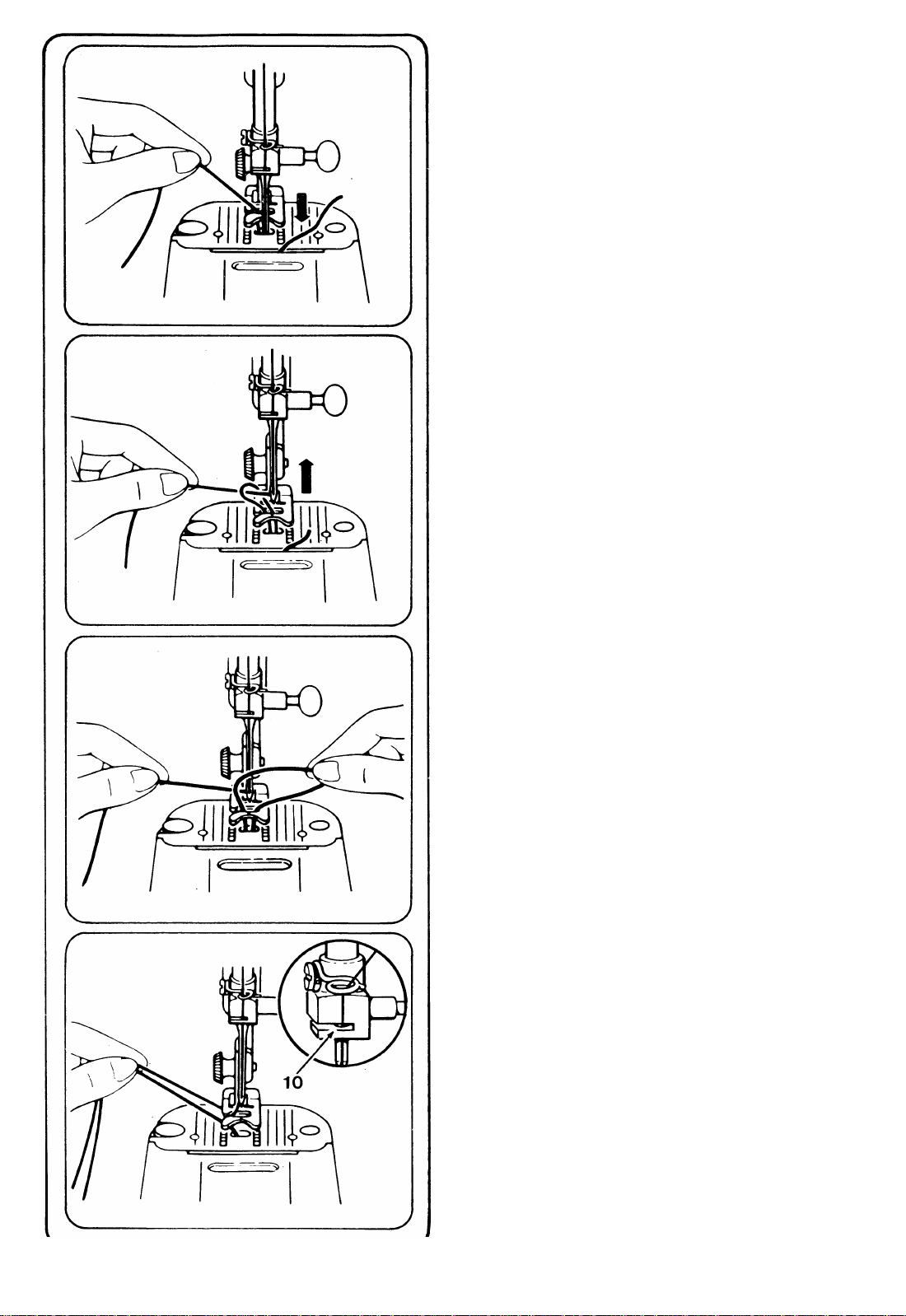

Raising the bobbin

thread

Once the needle has been threaded and the

bobbin placed in the bobbin case, the bobbin

thread must be brought up through the hole

in the needle plate.

1. Hold needle thread loosely with left hand.

• Turn hand wheel slowly toward you,

lowering needle into hole in plate.

2. Continue to do this until needle rises

above needle plate.

• Pull gently on needle thread and bring

up bobbin thread in a loop.

3. Open loop with fingers to find end of bob

bin thread.

4. Draw needle thread through left side

opening in presser foot.

Pull both threads to back of machine.

13

r

V,

r

Timiniir

3. STRAIGHT

STITCHING

Stitch width selector

Before you move the selectors to set your

machine for straight stitching, turn the hand

wheel toward you until needle is at its highest

point.

Straight stitching can be performed with

pattern selector in any position; stitch width

J

lever must be set at ( i ) only.

Needle position selector

Needle Position Selector positions the needle

in left ( ), centre ( •’ ) or right ( ^ )

needle positions. **

V

J

r

Stitch length selector

The stitch length indicator is numbered 0 to

5. The lower the number, the shorter the stitch.

Shorter stitches are best for lightweight

fabrics: longer ones for heavy fabrics. To

adjust the length of your stitches, turn the

dial so that desired stitch length is positioned

under ( • ) symbol.

• To shorten stitch length, turn dial toward

a lower number.

• To lengthen stitch length, turn dial toward

a higher number.

0 — 5

J

Reverse stitch button

14

The reverse stitch button, with the ( P )

symbol,, is located in the centre of the stitch

length selector.

• For reverse stitching, push in the button

and hold in place. The machine will stitch

in reverse only as long as you keep the

button pushed in.

Adjusting thread tension

When an even amount of tension is exerted

on both threads, a smooth even stitch, known

as a balanced stitch, is produced.

Correct tension is important because too

much or too little will weaken your seams

or cause your fabric to pucker. Make a test

sample with the fabric and thread you plan

to use and examine it.

A perfect, well balanced stitch (1), will have

the needle and bobbin threads locked

between the two layers of fabric with no loops

on top or bottom and no puckering.

V.

r

r

J

Too much tension will produce a tight stitch

(2) which will cause the fabric to pucker.

• To decrease tension, turn the dial to a lower

number.

J

Too little tension will produce a loose stitch

(3) which will cause loops in your seam.

To increase tension, turn the dial to a higher

number.

15

Sewing a seam

You can sew seams easily and accurately

when you follow the suggestions below.

Placing fabric under foot

Most fabrics can be placed under the foot

by raising the presser foot lifter (1) to its

normal “Up” position (2), where it locks in

place.

When using bulky fabric, multiple fabric

layers or an embroidery hoop, raise the lifter

to the high rise position (3), thus increasing

the space between the foot and the needle

plate.

• Lower presser foot lifter all the way down

and you are ready to sew.

Basting

Pin basting and hand basting are easy ways

to make temporary seams before machine

sewing.

• To pin baste, insert pins at stitching line.

NEVER place pins on the underside of

fabric in contact with the feed. Do not sew

over pins; pull them out as you stitch.

To hand baste, make long stitches that can

be easily removed.

Keeping seams straight

To keep seams straight, use one of the

guidelines on the needle plate.

The most commonly used line (1), the 5/8

inch (1.6 cm) seam allowance, is extended

onto the slide plate.

16

starting a seam

Place fabric under presser foot 1 /2 inch (12

mm) from rear of fabric. Align the right edge

with one of the seam guidelines on the throat

plate. Lower the presser foot.

Backstitch to the edge of the fabric for

reinforcement by pushing in the reverse

button located in centre of the stitch length

dial. Hold button in until stitching reaches

edge of fabric.

Release push button for forward stitching.

Guiding and supporting

fabric

Most fabrics need only to be guided in front

of the presser foot. Some fabrics, however,

require support while being stitched.

• For tricot, and other similar synthetic knits,

apply gentle tension by holding the fabric

at the front and back of presser foot as

you sew. Do not pull fabric.

For elasticated fabric, stretch lace, and

knits with an unusual amount of elasticity,

hold the fabric firmly in front and back of

the presser foot to stretch the seam as the

stitches are being placed.

Sewing in reverse

To neaten the end of a seam, push in the

reverse button and backstitch 3-4 stitches.

Raise needle and presser foot and remove

fabric by drawing it to the back and left, Cut

thread on thread cutter on presser bar.

17

Darning

I

I

I

1

2

J

Worn or torn spots on children’s clothes and

household linens can be darned effortlessly

and quickly with little practice. When greater

control is needed, an embroidery hoop and

a special darning and embroidery foot, which

may be purchased at your SINGER stockist

should be used.

Recommended settings

Stitch Selection:

Needle Position:

Stitch Width:

Stitch Length:

Foot:

Needle Plate:

Attach feed cover plate (F).

If the area to be darned is open, baste a

backing on the underside.

Place area to be darned, right side up,

under presser foot; lower the foot and begin

stitching, alternately drawing the fabric

toward you and pulling it gently away from

you.

Continue this forward and backward

motion as you fill the area in with parallel

lines of stitching.

Straight Stitch

III IS

2-4

General Purpose (B)

General Purpose (A)

Quilting

Quilting is the art of stitching two or more

thicknesses of fabric together in a planned

design. A padding is used to produce a soft,

puffed effect.

Recommended settings

Stitch Selection: Straight Stitch

Needle Position:

Stitch Width:

Stitch Length:

Foot:

Needle Plate: General Purpose (A)

Mark the design or quilting lines with a

tailors chalk or a washable marker on the

right side of garment.

Place a wadding, or padding, over the

underside of garment and cover it with a

backing or lining fabric.

Baste together to prevent the layers from

moving.

Place fabrics under needle and carefully

begin to stitch along your marked pattern

on the fabric.

If you are quilting a very large piece, work

from the centre of the fabric to the outside

edge and guide fabric with both hands.

[ijiiii

2-5

General Purpose (B)

18

r

Inserting a zipper

We recommend using the Zip Foot to form

an even line of stitching close to the zipper.

Recommended settings

Stitch Selection:

Straight Stitch no. 2

Needle Position:

Stitch Width:

Stitch Length:

Foot:

Needle Plate:

When the zipper teeth are to the left of the

needle.

• Slide the adjusting block, (1) which slides

on the pin, across to the right.

• Snap on the foot to the left side of the pin.

(See changing snap-on presser feet.)

• Check the position of the foot by lowering

the needle into the notch on the side of

the foot, to ensure that it clears the foot.

UIU

01 Hi

2-5

Zipper (E)

General Purpose (A)

When the zipper teeth are to the right of the

needle.

• Slide the adjusting block, (1) across to the

left.

• Snap-on the foot to the right side of the

pin. (See changing snap-on presser feet.)

Check the position of the foot by lowering

the needle into the notch on the side of

the foot, to ensure that it clears the foot.

19

4. ZIG-ZAG

STITCHING

1 2 3 4 5

6 7

10 11

/WWV-AAA

Stitch pattern selector

Raise the needle to its highest position.

• Set the stitch width selector to the straight

position ( j ). (This allows the pattern

selector to be moved easily).

• Slide the pattern selector to the centre of

the desired pattern group.

Needle position selector

Before moving selector, make sure needle

is fully raised.

Most of your zig-zag stitching will be done

with the needle in the centre ( ' ) position.

• Left( ^ ) and right ( ^ ) settings are used

for special stitch placement.

stitch width selector

Before moving selector, make sure needle

is fully raised.

To produce any of the zig-zag stitches, the

stitch width selector is moved from its

straight position ( i ) to any of its other

four positions. The further you move the

selector level toward the right, the wider

your stitch will be.

20

Adjusting stitch iength

Any stitch length setting from 1 to 5 will give

you an open zig-zag stitch.

The higher the number, the more open, or

further apart your stitches will be.

The area between 0 and 1 on the dial is used

for satin stitching, a series of closely spaced

plain zig-zag stitches that form a smooth

satin-like surface.

Needle thread tension

The needle-thread tension dial regulates the

amount of tension on the needle thread and

lets you select just the right setting for your

fabric and thread.

The correct tension setting will produce a

smooth even stitch (1).

Too much tension will produce a tight stitch

(2), causing fabric to pucker. Loosen tension

by turning dial to a lower number.

Too little tension will produce a loose stitch

(3), causing loops in your pattern. Tighten

tension by turning dial to a higher number.

21

Zig-zag stitch no. 4

The Zig-Zag Stitch can be used when sewing

seams, appliqueing, monogramming or for

decorative sewing.

Recommended settings

Stitch Selection; Zig-Zag Stitch no. 4

Needle Position:

Stitch Width;

Stitch Length;

Foot;

Needle Plate:

2-5

General Purpose (B)

General Purpose (A)

Seam finishing

Use a zig-zag stitch to finish seam edges

of fabrics that are likely to fray.

• Sew seams as desired: trim and press

open.

• Place edge of seam allowance under foot,

as shown,

• Stitch close to edge, letting outer zig-zag

fall over edge of fabric.

J

Satin stitching

Recommended settings

Stitch Selection:

Needle Position;

Stitch Width;

Stitch Length;

Foot;

Needle Plate;

Zig-zag Stitch no. 4

;

!

lili

0-2

Special Purpose (J)

General Purpose (A)

22

Satin stitching is a series of closely spaced

zig-zag stitches. Satin stitch can be used for

monograms, embroidery and applique work

to produce a smooth satin-like finish.

• Practice to get desired stitch appearance.

Block monogramming

• Lightly trace letters on right side of fabric.

• Centre tracing under needle.

• Stitch entire outline, leaving needle in

fabric when turning.

• Pull threads to wrong side of fabric, tie and

trim.

Multi-Stitch zig-zag no. 8

Mending, overcasting, joining or reinforcing

can ali be done using the Multi-Stitch Zig-

Zag.

Recommended settings

Stitch Selection;

Multi-Stitch

Zig-Zag no. 8

Needle Position:

Stitch Width;

Stitch Length:

Foot:

Needle Plate:

mu

Hill

1-2

Special Purpose (J)

General Purpose (A)

Mending a tear

• Trim ragged edges of tear.

• Cut a lining for reinforcement.

• Bring the edges of tear together and baste

lining to wrong side of fabric.

• Place tear, right side up, under foot.

• If necessary, sew over tear again.

• Trim away lining close to stitching.

Bar tacks

Strong multi-Stitch bar tacks are effective

for tacking belt loops on heavy fabrics such

as denim.

Recommended settings

Stitch Selection:

Needle Position:

Stitch Width:

Stitch Length:

Foot;

Needle Plate;

Mark start and finish lines of belt loop on

fabric.

Place one end of belt loop, wrong side

up, on beginning mark on fabric and

straight stitch in place.

Trim raw end close to stitching and fold

belt loop over, right side up.

Stitch a bar tack about Vs" (3 mm) from the

fold, as shown.

Fold loose end of belt loop under and

press it in place on finishing line.

Stitch second bar tack about Vs" (3 mm)

from the fold.

Multi-Stitch

Zig-Zag no. 8

mu

iiilEZl

1-2

special Purpose (J)

General Purpose (A)

23

Blindstitch no. 6

Blindstitching provides a durable hem finish

that can be used on a variety of different

weight fabrics. Blindstitching takes a little

practice, however, so make a test sample

first

Recommended settings

Stitch Selection:

Needle Position;

Stitch Width:

Stitch Length: 1

Foot:

Needle Plate: General Purpose (A)

Attach Blindstitch Hem Guide

Prepare the hem by folding it and pressing

it in the usual way. You may want to baste

the hem to hold it in place, as shown. If so,

be sure to place the basting at least Va inch

(12mm) below the top edge of the hem

allowance.

Blindstitch no. 6

$ i •

1 1 1

1

Ills

-1/2 to 2-1/2

General Purpose (B)

With the wrong side of fabric uppermost, turn

the hem under, as shown, creating a soft fold

from the top edge of hem. Pin or baste all

three layers together in place.

Position the hem under the presser foot with

the soft fold resting against wall of the guide.

Be sure the flange of the guide is between

the soft fold and the top of the hem, as shown.

Lower the presser foot and begin sewing

making certain the straight stitches fall on

the edge of the hem and the zig-zag

stitches just pierce the soft fold of the work.

Adjust stitch width if necessary. While

stitching, guide the hem edge in a straight

line and feed the soft fold evenly against

the wall of the guide.

24

If layers of fabric are pinned together,

remove pins as you come to them. Do not

sew over pins.

Ladder seams

A ladder seam made with blindstitching is

functional and decorative at the same time.

Appropriate for stretch and knitted fabrics,

it provides stretchable, decoratively con

structed seams and edge finishes for collars,

pockets and necklines in sportwear and

swimwear.

Recommended settings

Stitch Selection;

Needle Position:

Blindstitch no. 6

• 1 1

Stitch Width:

Stitch Length:

Foot: General Purpose (B)

Needle Plate:

Make a test sample to adjust thread tension

and stitch length to suit your fabric. Needle

thread tension should be lighter than

normal.

Cut and fit garment, allfow % inch (16mm)

seam allowance. Baste seam line.

11111

1-1/2 to 2-1/2

General Purpose (A)

Position fabric so that the large zig-zag

stitches fall on the stitching line, towards

the centre of the garment

When stitching is completed, open the

seam by pulling the fabric back on opposite

sides of seam to produce a ladder effect

and press seam allowances.

25

“M’’ STITCH

This stitch can be used for stretch seams

and decorative stitching.

Elastic insertion

RECOMMENDED SETTINGS

stitch Selection: “M” Stitch No. 10

Needle Position:

Stitch Width: 11 ifil

Stitch Length: 1-2

Foot Special Purpose (J)

Needle Plate: General Purpose (A)

• Fit eiactic for snugness and allow 1

inch (25m'm) for joining. Lap the two

ends and stitch.

• Divide eiactic and garment into equal

quarters. Place elastic over the fabric

and pin the two together at these polnls

keeping top edges even.

• Anchor the elastic to the fabric with

a few stitches. Now stretch elastic

between the pins as you sew, using

both hands to hold elastic tight in

front and back of presser foot.

26

J

Lace insertion

Lace is inserted after fabric is cut, but

before it Is sewn together.

RECOMMENDED SETTINGS

Stitch Selection: “M” Stitch No. 10

Needle Position: * • *

Stitch Width: • I

Stitch Length: V2-2

Foot: Special Purpose (J)

Needle Plate: Generai Purpose (A)

Cut iace to desired size.

Position lace on right side of fabric

and pin in place.

Place the work under the presser foot

so that the stitches fall over the lace

edges, as shown.

After both sides of lace are sewn, turn

fabric over to the back side and cut

the fabric on both sides close to the

stitching lines and remove.

I <

r.

Attaching a button

Flat buttons can be sewn on quickly and

easily using the plain zig-zag stitch. A special

button sewing foot (H), may be purchased at

your SINGER stockist.

Recommended settings

Stitch Selection:

Needle Position:

Zig-Zag Stitch no. 4

Stitch Width:

Foot:

Needle Plate:

Attach Feed Cover (F)

Before you can attach a button, the bobbin

thread must be brought up through the hole

In the feed cover.

1. Set stitch width at ( j ), and needle

position selector at ( ^ ). Position button

under foot and lower the needle into the

centre of the left hole. Lower the foot. Turn

hand wheel toward you until needle rises

out of button and is above the foot.

To suit Button

Button Sewing (H)

General Purpose (A)

2. Move stitch width selector until needle is

over the other hole In the button. Then,

when you begin to stitch, the needle

should enter into the right hole of the

button. Take six or more zig-zag stitches

to attach button and finish with the needle

on the left side.

3. To fasten stitching, adjust width to ( j ),

and take three or four stitches. Remove

work, draw threads to underside, fasten,

and trim.

27

5. FLEXI STITCH

PATTERNS

In addition to straight and zig-zag stitches,

your machine can produce a variety of other

patterns.

Flexi stitches

These stitch patterns are used for sewing

knits and other stretch fabrics. Flexi Stitch

patterns are made by the side to side

movement of the needle along with the

backward and forward movement of the feed.

Stitch pattern selector

Raise the needle to its highest position.

Set the stitch width selector to the straight

position ( j ). (This allows the pattern

selector to be moved easily).

Slide the pattern selector under the center

of the desired pattern grouping.

Turn the stitch length dial to the left until

the dot ( • ) on the dial lines up with the

dot ( • ) on the machine, as shown.

Note: If for any reason the machine does not

start sewing your desired pattern after

aligning the two dot symbols, push-ln on the

reverse stitch button.

28

stitch width selector

To produce a Flexi-stitch pattern, the stitch

width selector must be moved from straight

stitch setting to any of its other four positions.

The far right pattern will produce the widest

stitch.

J

r

Needle position selector

Flexi-stitch patterns, may be sewn .in either

«iiiiiiiir

left ( ^ ), centre ( ^ ) or right ( ^ ) posi

tions.* Centre needle position Is

recommended.

V.

r

mN\*NV\

J

Balancing flex! stitches

You may need to adjust the Flexi-stitch

Balance selector when using a flexi-stitch

pattern in order to achieve the correct pattern

appearance.

Before you move the stitch balance dial from

its neutral position, make a test sample using

two layers of scrap fabric. If adjustment is

required stitch slowly and move the selector

as you sew.

Move selector to the left to bring stitches

of the pattern together.

Move selector to the right to separate

stitches of pattern.

29

r

straight stretch stitch no. 3

When you use the straight stretch stitch for

stress seam or to seam knitted, stretch and

elasticated fabric, both stretch and strength

are built into the seam as it is being sewn.

• Place garment right side up, under presser

foot.

Required settings

Stitch Selection:

Needle Position:

Stitch Width:

Stitch Length: At dot (•)

Foot:

Needle Plate:

• Lower the foot and start machine, holding

the thread ends as the first few stitches

are made.

• Guide the fabric lightly as you sew, letting

the machine make the backward and

forward stitches that give stretch to the

seam.

• Press seam after stitching.

Straight Stretch no. 3

Special Purpose (J)

General Purpose (A)

Ric-rac stitch no. 5

This is a heavy-duty, stretch stitch that can

also be used for topstitching.

• Sew seams in usual manner and press.

• For topstitching hard-to-reach areas,

convert machine to free arm sewing.

Required settings

Stitch Selection:

Needle Position:

Stitch Width:

Stitch Length:

Foot:

Needle Plate:

Place garment right side up, under foot.

Slowly topstitch desired areas.

Pull threads to wrong side of fabric; tie and

trim.

Ric-Rac Stitch no. 5

illii

At dot (•)

Special Purpose (J)

General Purpose (A)

30

Slant overedge stitch

no. 7

Seams in knitted and stretch fabrics can be

joined and finished in one operation when

you use the slant overedge stitch.

• Baste the garment together on the seam

line allowing for a 5/8” seam allowance

and fit in the usual way.

Required settings

Stitch Selection;

Slant Overedge no. 7

Needle Position:

Stitch Width:

Stitch Length:

Foot:

Needle Plate: General Purpose (A)

After making any adjustments, trim the

seam edge evenly to a 1 /4” from the seam

line basting.

Place trimmed seam under the foot so that

the straight stitches fall on the basted seam

line and the zig-zag stitches fall over the

seam edge.

iEU

iiillMl

At dot (•)

General Purpose (B)

31

Honeycomb stitch no. 9

Use the Honeycomb Stitch for smocking,

mending and sewing stretch fabrics. Smock

ing is decorative stitching across evenly

spaced gathers of fabric.

To gather fabric

• Sew rows of straight stitches, 1 /4" apart,

across area to be smocked.

• Pull thread evenly, gathering fabric.

• Tie ends of every two rows of stitching

together to hold gathers in place.

• Baste a backing to wrong side of fabric.

To smock fabric

Required settings

Stitch Selection:

Honeycomb Stitch

no. 9

Needle Position:

Stitch Width:

Stitch Length:

Foot: Special Purpose (J)

Needle Plate:

• Sew between rows of straight stitches.

• Pull out straight stitches when completed.

idi

¡111$

At dot (•)

General Purpose (A)

Patchwork quilting

Patchwork quilting can be used effectively

on a wide range of household items.

• Cut fabric squares to the desired size.

• Join the alternating squares with the

straight stitch.

• Finger-press open.

• After stitching, cut a backing to the full

size of the finished work.

Ì2

• Create a quilted effect by basting a pad

ding layer to the backing.

• Stitch lengthwise and crosswise, overlap

ping the patches so the seams are

straddled.

• Pull the threads to the underside of the

work, and trim.

• Finish by sewing a binding to the edges.

OVEREDGED SEAMS

Seams in knit and stretch fabric can be

joined and finished in one operation. Two

different methods may be used. Method

No. 1 is recommended for firm fabrics

where a 6mm (1/4”) seam allowance Is

adequate. Method No. 2 Is recommended

for bulky knits and fabrics that have a

tendency to curl or fray and where a wider

seam allowance is needed for support.

Make a test sample to help you decide

which method is best for your fabric and

garment. Remember to use a Catalog 2045

ball-point (yellow band) needle if you are

sewing a synthetic knit.

Required settings

Stitch Selection: Overedged Seams

No. 11

Needle Position: <

Stitch Width: i 111¥

Stitch Lenght: At dot (•)

Foot: Special Purpose (J)

Needle Plate: General Purpose (A)

Method No. 1 — OveredgJng

1. Cut and fit the garment, allowing for a

1.6cm (5/8”) seam allowance. Baste

seam line.

2. Trim seam edge evenly to a scant 6mm

(1/4”) from seam line basting.

3. Place seam under the presser foot so

that the straight stitches fall on the

basted seam line and zig-zag stitches

toward the seam edge, as illustrated.

Method No. 2 — Mock Overedging

1. Cut and fit garment, allowing for a

1.6cm (5/8”) seam allowance. Baste

seam line.

2. Place seam under presser foot so that

the straight stitches fall on the basted

seam line and zig-zag stitches toward

the seam edge.

3. Press after stitching and trim away

excess fabric to produce a narrow

seam edge. When seam supports the

garment, omit the trimming step.

33

6. FOUR-STEP

BUTTONHOLE

Your machine makes buttonholes to any

size you choose in only four, easy steps.

• You never need to move the fabric or repo

sition the needle.

• Always make a practice buttonhole on a

sample of your fabric.

• Be sure bobbin contains enough thread.

• When making buttonholes on hard-toreach areas convert machine bed to free

arm sewing.

• Mark buttonhole position on fabric as indi

cated in pattern.

\

/

V».

Recommended settings

Stitch Selection: Buttonhole Stitch

no. 1

Stitch Width: Pre-set

Foot:

Needle Plate: General Purpose (A)

Buttonhole (L)

step 1

Raise presser foot.

Place fabric under foot.

Centre 3 red guidelines (1) of foot around

beginning line of buttonhole.

Turn buttonhole dial to the first buttonhole

symbol for the first step.

Position needle in fabric at point (2) by

turning the hand wheel towards you.

Stitch down to point 3.

step 2

34

• Raise needle out of fabric.

• Turn buttonhole dial to the second button

hole symbol for the second step.

• Make at least four stitches, ending at

point (4).

r

V.

r

r

steps

• Raise needle out of fabric.

• Turn buttonhole dial to the third buttonhole

symbol for the third step.

• Stitch up to point (5).

step 4

• Raise needle out of fabric.

• Turn buttonhole dial to the fourth button

hole symbol for the fourth step.

• Make at least four stitches, ending at point

(6).

• Raise presser foot and remove garment

from machine. Clip thread ends.

• Carefully cut buttonhole opening with a

J

seam ripper or small, sharp scissors.

Balancing the buttonhole

On some kinds of fabrics, there may be a

difference in the density of the stitches on

the right or the left side of the buttonhole.

This is easily adjusted by turning the balance

knob (1), in the center of the stitch length dial

to balance the density of the stitching. A very

slightturn of the dial will produce a noticeable

change.

• If the stitches on the right side of the

buttonhole (A) are too open, turn the

balance dial slightly to the right, until the

density of the stitches increases.

If the stitches on the left side of the

buttonhole (B), are too open, turn the

balance slightly to the left, until the density

of the stitches increases.

After the buttonhole has been made and the

balance has been altered, return the balance

dial back to its neutral position after all the

buttonholes on the garment have been sewn.

35

7. FREE-ARM

SEWING

Fabric handling, when sewing tubular and

hard to reach garment areas, is simplified and

made easier when you use the free-arm

sewing capability of your sewing machine.

Sleeves

• Free-arm sewing takes the difficulty out of

topstitching, sleeves, finishing waistbands

and trouser legs rotate smoothly under the

needle, around the arm, allowing you to

place your stitching accurately.

Buttons

• Sewing buttons on a cuff or neckband is

easy with free-arm sewing. The sewing

arm allows room for cuffs to slip onto

without being stretched out of shape, and

you can also see and handle the stitching

area more easily.

Bar tacks

• Bar tacks reinforce areas of strain and can

be applied to ready-made garments, as

well as to those sewn at home. Use the

free-arm surface to avoid fabric bulk

around the needle when you apply bar

tacks to pockets, pleats and waistlines.

J

r

8. TWIN NEEDLE

SEWING

Twin needle sewing produces two parallel

lines of closely-spaced decorative stitching.

You can sew with either one or two thread

colours.

Your machine is not supplied with the twin

needle or spool pin. These may be obtained

from your local SINGER stockist as optional

accessories.

Recommended settings

Stitch Selection:

Needle Position:

Desired stitch

Stitch Width:

Stitch Length:

Foot:

Needle Plate:

• Turn the machine off.

• Insert the twin needle with the flat side of

the shank toward the rear of the machine.

• Thread the machine as you normally would

for single needle stitching, except pass the

thread between the centre and the back

tension discs A, and through the left eye

of the twin needle.

• Insert a second spool pin into the hole on

the top cover of the machine, as illustrated.

• Thread the machine in the usual way,

except pass the thread from the second

spool between the centre and the front

tension discs B, as shown.

• Pass the thread through the remaining

points, making certain to omit the thread

guide just above the needle and pass

thread through right eye of needle.

II

2-5

General Purpose (B)

General Purpose (A)

• Draw both threads under the foot and back

along with the bobbin thread.

• Slowly lower the needle into the hole in

the needle plate by turning the hand wheel

toward you to make sure the needle clears

the plate.

• Make sure not to use a stitch width greater

than that what is recommended when twin

needle stitching.

37

9. CARING FOR YOUR MACHINE

Removing and replacing

bobbin case

Caution; Before cleaning or adjusting the

machine, remove plug from the socket outlet.

• Raise presser foot and needle.

• Open slide plate, remove bobbin and

remove needle plate.

To remove bobbin case

• With a small screwdriver, turn bobbin case

holder (1) to the rear as far as it will go.

• Lifting the left side of the bobbin case, slide

it out from machine.

To replace bobbin case

• Guide forked end (2) of bobbin case under

feed (3).

Draw rim of bobbin case under position

plate (4). Be sure bobbin case is freely

seated on hook race.

• Turn bobbin case holder (1) forward as far

as it will go, locking bobbin case in place.

Note: Turn handwheel towards you to check

to make sure it is properly replaced.

• Replace needle plate (see instruction on

page 08).

• Insert bobbin and close slide plate.

J V.

r

Changing the light bulb

Caution: Before changing light bulb, make

sure you have removed plug from socket

outlet and remove face plate which covers

the light bulb. Be sure to replace the face

plate which covers the light bulb before

operating the machine.

This machine is designed to use a 15-watt

maximum light bulb with a bayonet fitting.

• Loosen and remove screw (1) located on

face plate.

• Remove face plate by grasping it around

the bottom edge and pulling toward the left,

then down and away from machine.

• Do not attempt to unscrew light bulb.

• Push bulb up into socket and turn in the

direction of arrows to unlock bulb pin.

• Pull buib down and out of socket.

• Push new bulb up into socket and turn in

the direction of arrows until pins lock into

position.

Making sure the presser foot lifter is up,

replace the face plate by guiding front top

corner under and behind lowest front

corner of top cover. Push bottom of face

plate up and back until it is aligned with

top cover.

Insert screw and tighten.

39

Cleaning the machine

Your machine is designed to give you many

years of dependable service. To ensure this

reliability, take a few minutes to keep the

machine clean.

The machine surfaces and covers can be

cleaned when necessary, with a damp, soft

cloth and a mild soap.

Remove lint and fluff from exposed parts and,

with a lint brush clean these parts:

• Tension discs.

• Take-up lever and thread guides.

• Presser and needle bars.

• Bobbin case and needle plate areas.

Your machine should be periodically

checked by your local SINGER stockist for

wear.

Lubricating the machine

How often you need to lubricate the machine

depends on how often you use it and where

you keep it. The following general guidelines

assume that you will be sewing several times

a week. But if you use your machine more

frequently, lubricate it more often than the

guidelines suggest.

Approximatley once a year, lubricate all

moving connections, as shown, to ensure

freedom of movement and to protect metal

parts from excessive wear.

To determine which connections move and

need lubrication, turn the handwheel slowly,

by hand, while face plate is removed.

When lubricating, apply only SINGER* oil at

the points shown. SINGER oil is specially

prepared and does not contain harmful

deposits that can interfere with the smooth

action of precision parts.

41

Additional accessories

Additional Accessories for your sewing

machine are available for purchase at your

SINGER stockist.

1. Straight stitch presser foot (D) and needle

plate (C) are used together when straight

stitching lightweight fabrics or when your

fabric or sewing procedure requires close

control.

2. Button sewing foot (H) is used to hold any

two-hole or four-hole button securely for

stitching.

3. Darning and embroidery foot (G) is

recommended for free motion work, such

as embroidery, monogramming and decor

ative designs.

4. Lint brush is used for cleaning hard to

reach areas on your sewing machine.

5. Twin needle and spool pin are used to

stitch two parallel rows of decorative

stitching simultaneously. When using

twin-needle for decorative stitching, set

stitch width selector no greater than mid

range of zig-zag graphics.

6. Oil container for machine lubrication.

7. Felt for twin needle spool pin.

Performance checklist

When sewing difficulties occur, look back

through this manual to make sure you are

correctly following the instructions. If you

still have a problem, the reminders below

may help you to correct it.

Needle Does Not Move

Is machine connected to electrical

supply?

Is the power and light switch on?

Is controller connected?

Is the handwheel engaged for bobbin

winding?

Needle Moves But Stitch Is Not

Formed

Is needle defective?

Is needle fully inserted into needle clamp?

Are bobbin and needle correctly

threaded?

Is bobbin correctly inserted into bobbin

case?

Needle Breaks

Is needle straight and sharp?

Is needle correct size?

Is needle fully inserted into needle clamp?

Are controls properly set?

Are accessories correct for application?

Bobbin Winding Difficuities

Is thread unwinding freely from spool?

Is bobbin winder engaged?

Is thread end securely held at start of

wind?

Is thread hanging up on the slit on the

thread spool?

Upper Thread Breaks

Is machine properly threaded?

Is thread freely unwinding from spool?

Is proper spool cap being used?

Is needle correct size for thread?

Is upper thread tension too tight?

Is bobbin case properly inserted?

Is bobbin rim free of nicks?

Lower Thread Breaks

Is bobbin correctly wound?

Is bobbin correctly inserted Into bobbin

case?

Is bobbin case correctly threaded?

Is thread hanging up on the slit on the

thread spool?

Skipped Stitches

Is machine properly threaded?

Is fabric firmly held down?

Is needle correct style and size?

Is needle straight and sharp?

Fabric Does Not Move Properiy

Under Presser Foot

Is presser foot correctly attached to

machine?

Is presser foot lowered?

Is stitch length correctly set?

43

Index

Accessories...........................................04

Additional Accessories .........................42

Balance Control

Basting..................................................16

Blindstitch Hem Guide

Bobbin ..................................................04

Winding ............................................10

Inserting

Bobbin Case

Cleaning .......................................... 40

Bobbin Thread, Raising

Buttonhole Balancing ...........................35

Buttonholes, Making

Buttonhole Presser Foot

Button Sewing Foot

Caring For Your Machine......................38

Cleaning the Machine

Connecting the Machine

Control, foot

Electrical lead

Extension Table ...................................08

Fabric, Thread and Needle

Table ....................................................09

Face Plate, Removing

Feed Cover ..........................................04

Attaching

Feed System ...................................... 02

Fieri Stitches Patterns

Ric-Rac Stitch No. 5

Slant Overedge Stitch No. 7

Straight Stretch Stitch No. 3

Honeycomb Stitch No. 9

Overedged Seams ...........................33

Free-Arm Sewing .................................33

General Purpose Needle Plate

General Purpose Presser Foot

Handwheel............................................02

Length, Adjusting Stitch

Light Bulb, Replacing

Lint Brush

Monogramming.................................... 22

Needles

Choosing and Changing

Twin Needle .....................................37

Needle Clamp ......................................02

............................................

...................................

.........................

.............................................

........................................

...

...................

.............................

......................

.............................

..........................

......................

.......................................

.......................................

..........................

..........................................

.........................

........................

.............

............

...................

............

............

.......................

..........................

............................................

...................

02

04

11

38

13

34

04

42

40

06

02

02

39

08

28

30

31

30

32

04

04

21

39

42

04

06

Needle Plate . ;

Changing

Straight Stitch

Needle Position Selector ...

Operating thé Machine

Patterns, Selecting ...............

Performance Checklist

Power and Light Switch ....

Presser Feet

Changing

General Purpose

Special Purpose

Straight Stitch

Presser Foot Lifter

Principal Parts ......................

Reverse Stitch Button

Reverse Stitching

Safeguards, Important

Seams, Sewing

Keeping Straight

Starting ............................

Guiding and Supporting Fabric ... 17

Slide Plate

Spool Cap

Stitch Pattern Selector

Stitch Width Selector

Stitch Length Selector ..........................14

Straight Stitching ..................................14

Darning

Quilting .............................................18

Seam Finishing

Satin Stitching...................................22

Monogramming ...............................

Tension, Thread ...................................02

Thread Cutter .......................................02

Threading the Machine

Twin Needle Sewing

Zig-Zag Stitching ..................................20

Zig-Zag Stitch No. 4

Multi Stitch Zig-Zag No. 8

Blindstitch No. 6 ...............................24

“M” Stitch No. 10

Zip, Inserting A

Zip Foot ................................................19

.....................

..........................

...................

...........

...........

...........

...........

..........

...........

...........

..........

...........

...........

........................

..........................

..............

...............

...................

...............

...........

...........

...........

...........

...........

...........

.... 02, 03

...........

.............

.........

....................

...............

...........

...........

...........

...........

...........

...........

...........................................

............................................

...................

......................

...........................................

....................................

........................

...........................87

.........................

.................

...............................

...

.................................

20, 28

20, 29

04

08

42

14

06

20

43

02

04

07

04

04

42

02

14

17

05

16

16

17

02

04

18

22

22

12

22

23

26

19

44

oc

UJ

s

Part N.° 119709-002-ENG.

Printed in Brazil

Loading...

Loading...