Singer 591D303A, 591D305A Service Manual

SERVICE

INSTRUCTIONS

(PULLER

FEED

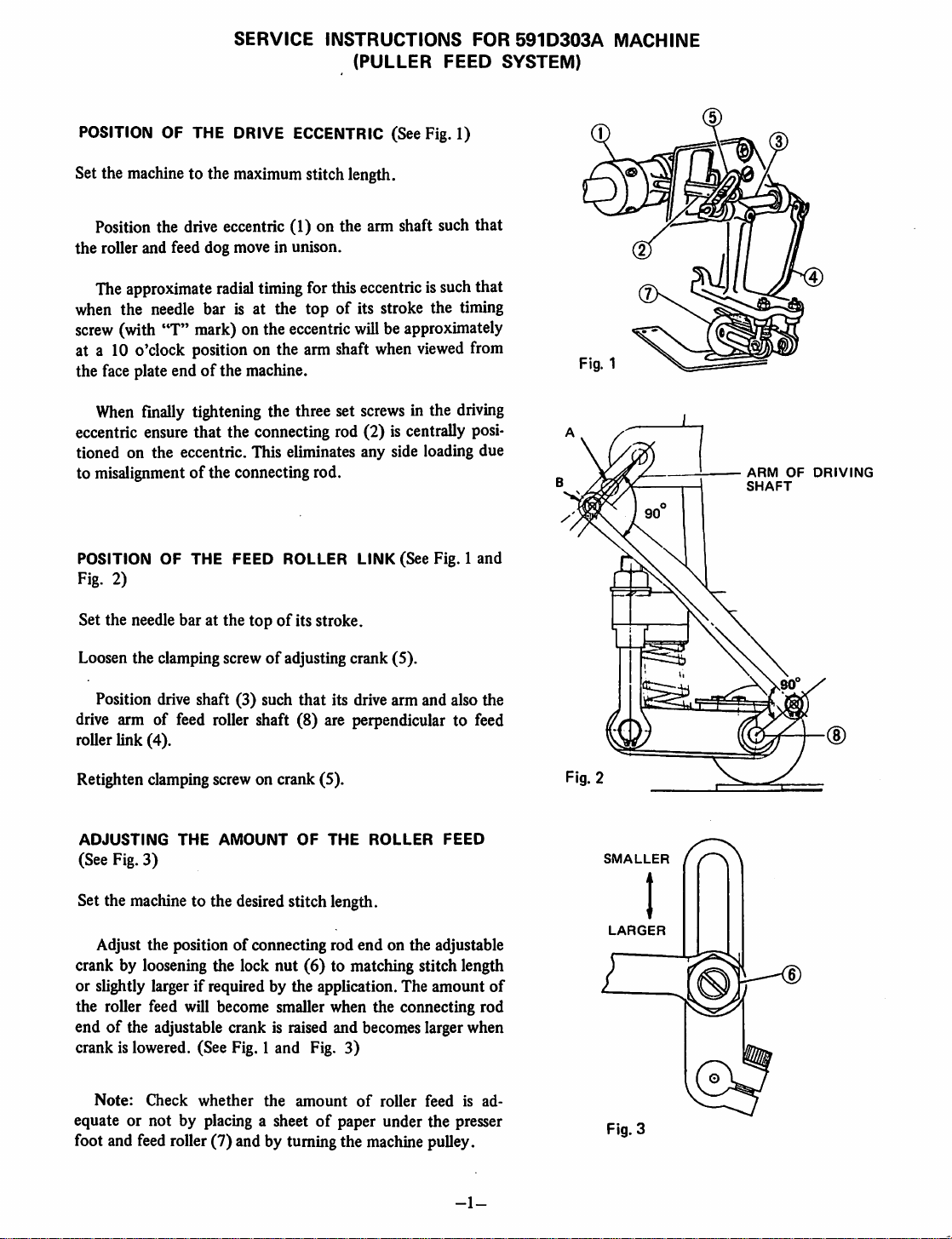

POSITION OF THE DRIVE ECCENTRIC (See Fig. 1)

Set the machine to the maximumstitch length.

Position the drive eccentric (1) on the arm shaft such that

the

roller and feed dog move in unison.

FOR

SYSTEM)

591D303A

MACHINE

Cm

Theapproximate

radial

timingfor this eccentric is suchthat

when the needle bar is at the topofits stroke the timing

screw

(with "T" mark)on the

at a 10 o'clock positionon the arm shaft when

eccentric

willbeapproximately

viewed

from

the face plate endofthe machine.

When

finally tightening the three set

screws

in the driving

eccentric ensure that the connecting rod (2) is centrally posi

tioned on the eccentric. This eliminates any side loading due

to misalignmentofthe connecting rod.

POSITION OF THE FEED ROLLER LINK (See Fig. 1 and

Fig. 2)

Set the needle bar at the

Loosen the clamping screw

topofits stroke.

of

adjusting crank (5).

Position drive shaft (3) such that its drive arm and also the

drive arm of feed roller shaft (8) are perpendicular to feed

roller link (4).

Retighten clamping screw on crank (5).

ARM

SHAFT

OF

DRIVING

ADJUSTING

(See Fig. 3)

THE

AMOUNT

OF

THE

ROLLER

FEED

SMALLER

Set the machine to the desired stitch length.

Adjust the positionofconnecting rod

crank by loosening the lock

nut

(6)

end

on the adjustable

to matching stitch length

or slightly larger if required by the application. The amount

of

LARGER

the roller feed will become smaller when the connecting rod

endofthe adjustable crank is raised and becomes larger when

crank is lowered. (See Fig. 1 and Fig. 3)

Note:

CHieck

equate or not by placing a sheetofpaper under the presser

foot and feed roller (7) and by turning the machine puUey.

whether

the

amount

of

roller

feedisad

Fig. 3

-1-

HOW

TO USE THE

TWO

HOLES ON THE LEVER OF THE DRIVING SHAFT (See Fig. 2)

The 2 holes

provided

on the

driving

shaft(3) leverisusedas

sewing machine which is set with the feed regulating dial.

When the sewing machine stitch length is set within the boundaries

use the short pitch hole A.

When the sewing machine stitch length is set between 10 SJ*.I and 4

use the long pitch hole B.

OILING (See Fig. 4)

In addition to the automatic oil wicking system, it is re

commended

a few dropsofSINGER TYPE

"C"

oil be

that

added every two weeks to the location shown in Fig. 4.

If the needle bearings of drive shaft (3) are replaced, they

should be packed with a bearing grease similar to Exxon

Unirex

N3.

follows

depending

of20SJ

SJ.I.,

OIL

THESE

POINTS

TWO

WEEKS

SINGER

"C"

OIL

uponthe stitch lengthof the

.1.—8

SP.I.,

NEEDLE

BEARINGS

EVERY

TYPE

TO

REPLACE

THE

REAR

COVER

Whenrear cover plate is replaced after

pound (Three

oil leakage.

TO

REPLACE

Bond

#1104 or equivalent) to the

THE

FEED

ROLLER

(See Fig. 5)

Hook the ballofthe lifting cable

(10) adjusting the ball

place. Fix with the lock

upward

nut

(11).

sothat it willnot vibrate out of

PLATE

removing

LIFTING

(9)

into the lifting arm

it from the rearofarm, it is necessary to apply seal com

CABLE

gasket

Fig. 4

glued

onto the cover plate in order to prevent

(0)

Fig. 5

-2-

Loading...

Loading...