SINGER 514 User Manual

SINGER Service

Wherever you go you wil! find expert, dependable SiMGER Service close at

hmd, SINGER will always assist you to keep your SINGER Sewing Machine

properly functioning. For this reason you should always call your SINGER

Sewing Centre or an Authorised SINGER Dealer's Shop if your sewing

machine requires maintenance or repair. There you oan obtain the services of

a trained SINGER repair man. and warranted SINGER parts.

To ensum that you am aiways provkiad wkh the most modem sewing

capabHities^ The Singer Company reserves the right to change the appear

ance, design or accessories of this sewing machine when considered

necessary.

tlMPQRTANT ElECTRlCAl INFORMATION

The wires in the mains lead are coloured in accordance with the following

Blue — Neutral (N) Brown — live (t)

As the coiours of the wires in the mains lead of this appliance m<ty not

correspond with the coloured markings identifying the terminais in your

plug, proceed as follows:

The wire which is coloured blue, must he connected to the terminal

which is marked with the letter N or coloured black

The wire which is coloured brown, must be cormected to the terminal

which is marked with the letter L or coloured red.

tWIre colours in the meins iead for Australia may be red Active {A) or

Live {L) arKi black Neutral (N) and should be correspondingly connected.

Form KB772 (376) Copyright ;c: tB73 by The Siegor Company (U*KT Umited

Pfinted in Groat Brilain All nght$ reservùd thfoughùut thè worki

CONTENTS

Page

Principal Parts

Accessories

Changing Neecilo Plate .....................

Changing Noodle

Changing Foot

Operating your Sewing Machine.

Fabric, Thread and Noodle Chart

Threading your Machine

Straight Stitching

Zig-Zag Stitching .................................

Ffoxi-Smeh* Sowing

Twin-Needle Stitching

Sewing the Professional Way

Seams

......................................

................................

....................................

.......

......................

...............................

.........................

..........................

............................

3-4

6-7

a

8

9

10-11

12

13-17

18-21

22-24

.

25-27

28-29

30-68

30-36

Seam Finishes.................

Darts

..............................

Zipper Insertion

Corded Seams

Buttonholes—

Buttons. < >... <

Hems...............................

Finishing Touches .....

Hints on Sewing Special Fabrics ..

Keeping up Appearances

Mending

Tears

Darning..........................................

Caring for your Machine ... <

Hints for Home Service ................

........................................

...............................................

..............

...

.............

.

.

...........

36-38

39

40

40

41-44

46

46-48

49-61

62-64

56-68

6b

66

.

67-68

59-63

64-66

Your Personal Measurement Chart

Index

.............................................

66

67

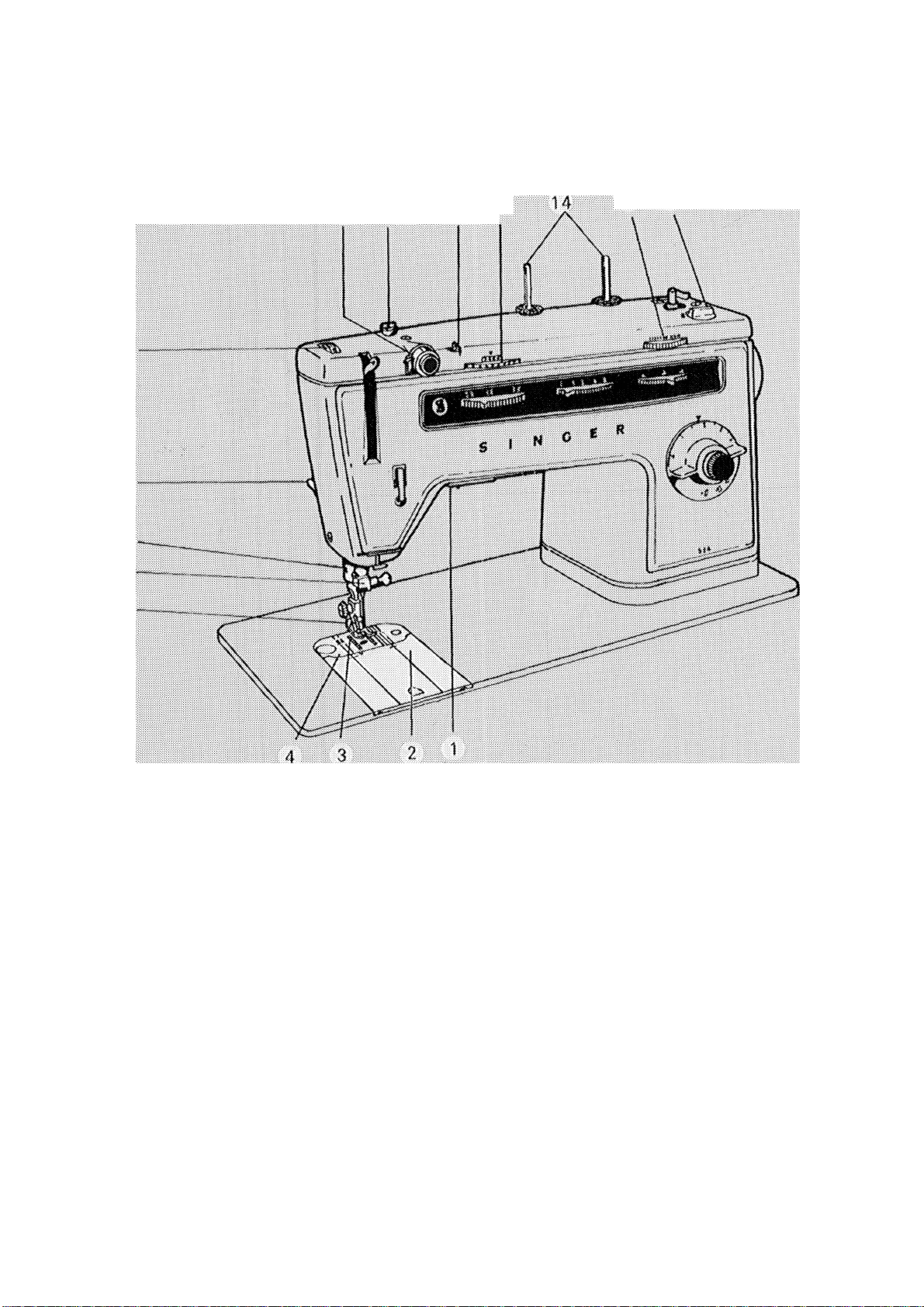

Pri nc ip al P ar ts

10 11

12 13

15 16

1. Sewing Light

2. Slide Plate

3. Peed

4. Needle Piate

5. Presser Foot

6. Needle Clamp

7: Thtèad Ciittef

8. Presser Foot Lifter

9. Pressu re Dia i

........ ................

10. Tension Discs

11. Bobbin Winder Tension

12. Thread Guide

13i Needle-iThread Tension

14. Spooi Pin and Felt

16. Dial

16. Bobbin Winder

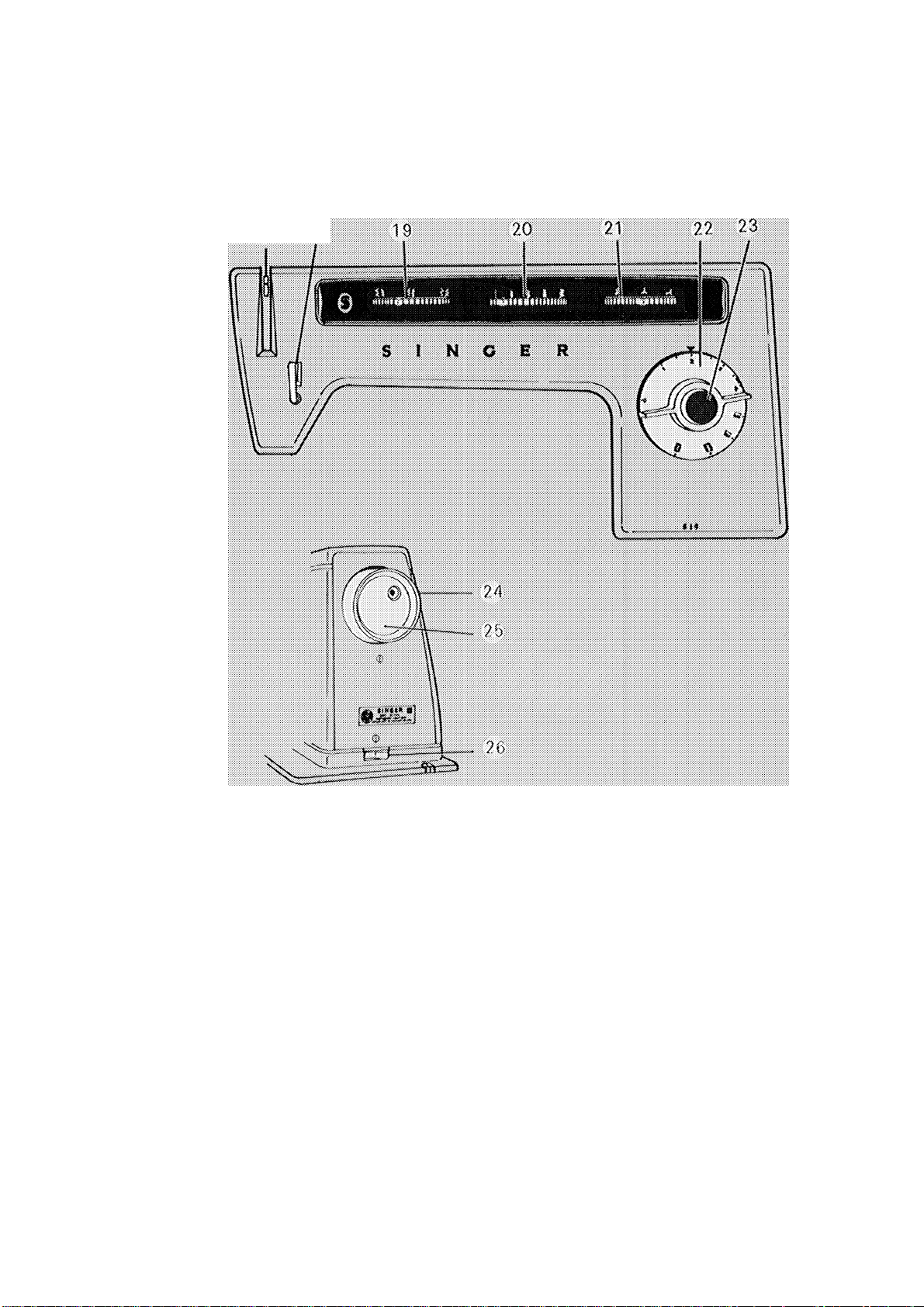

PRINCIPAL PARTS (Continued)

17 18

17, Thread Take-up Lever

18, Thread Guide

19, Pattern Selector Dial

20, Stitch Width Dial

21, Needle Position Dial

22. Stitch Length/

Buttonhole Dial

23. Reverse-Stitch Push

Button

24. Hand Wheel

28. Hand Wheel Disc

26. Power and Light Switch

■ ! -

. . . and when to use them

The accessories that come with your

sewing machine will help you to sew

with ease and comfort. They are simple

to use and place an almost limitless

variety of sewing effects at your finger

tips.

The eccessorfos shown in this instruction

book me not necessariiy furnished with

your machine. Those that are not in

cluded are avaiiahie for separate purchase

at your Singer Sewing Centre.

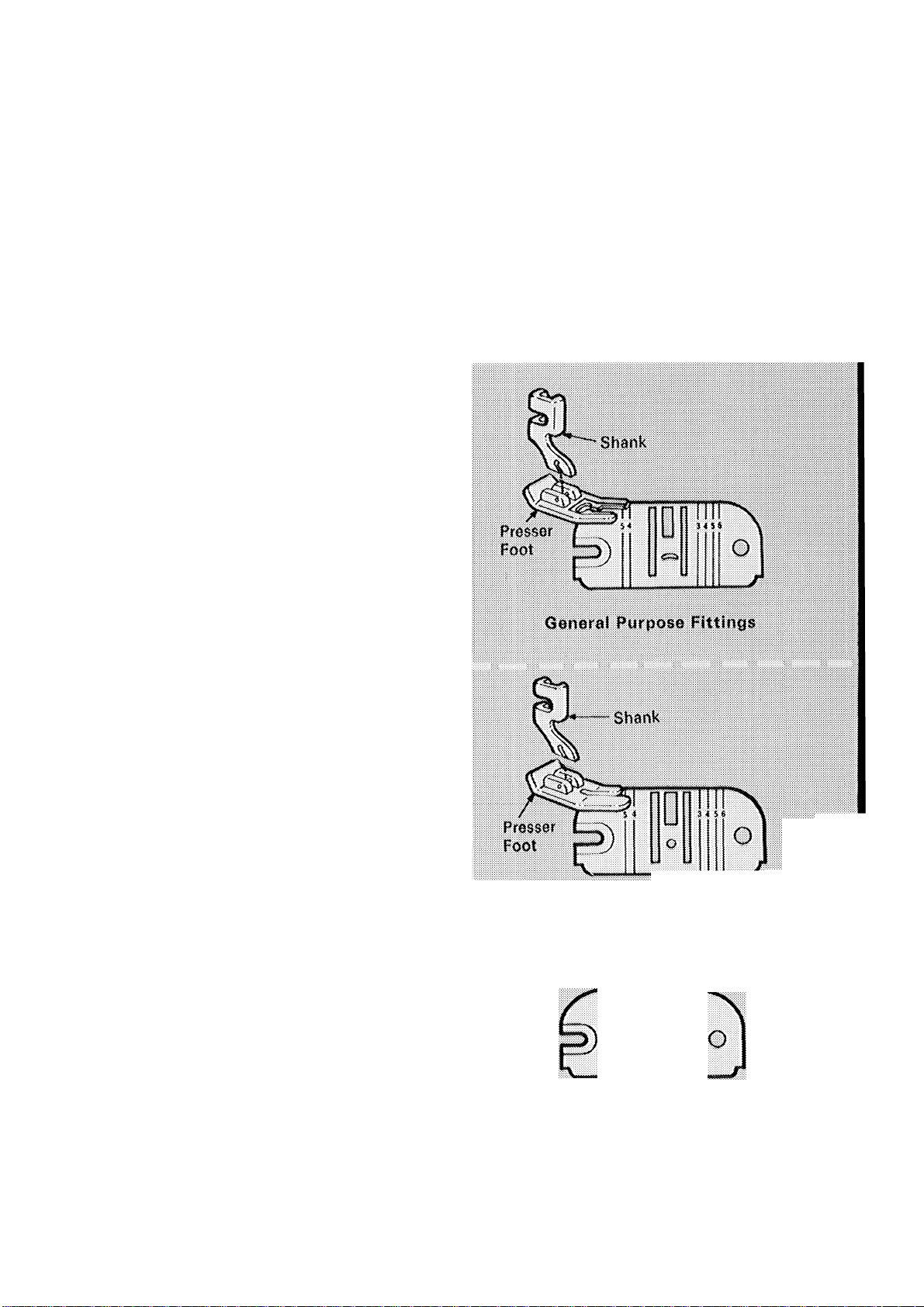

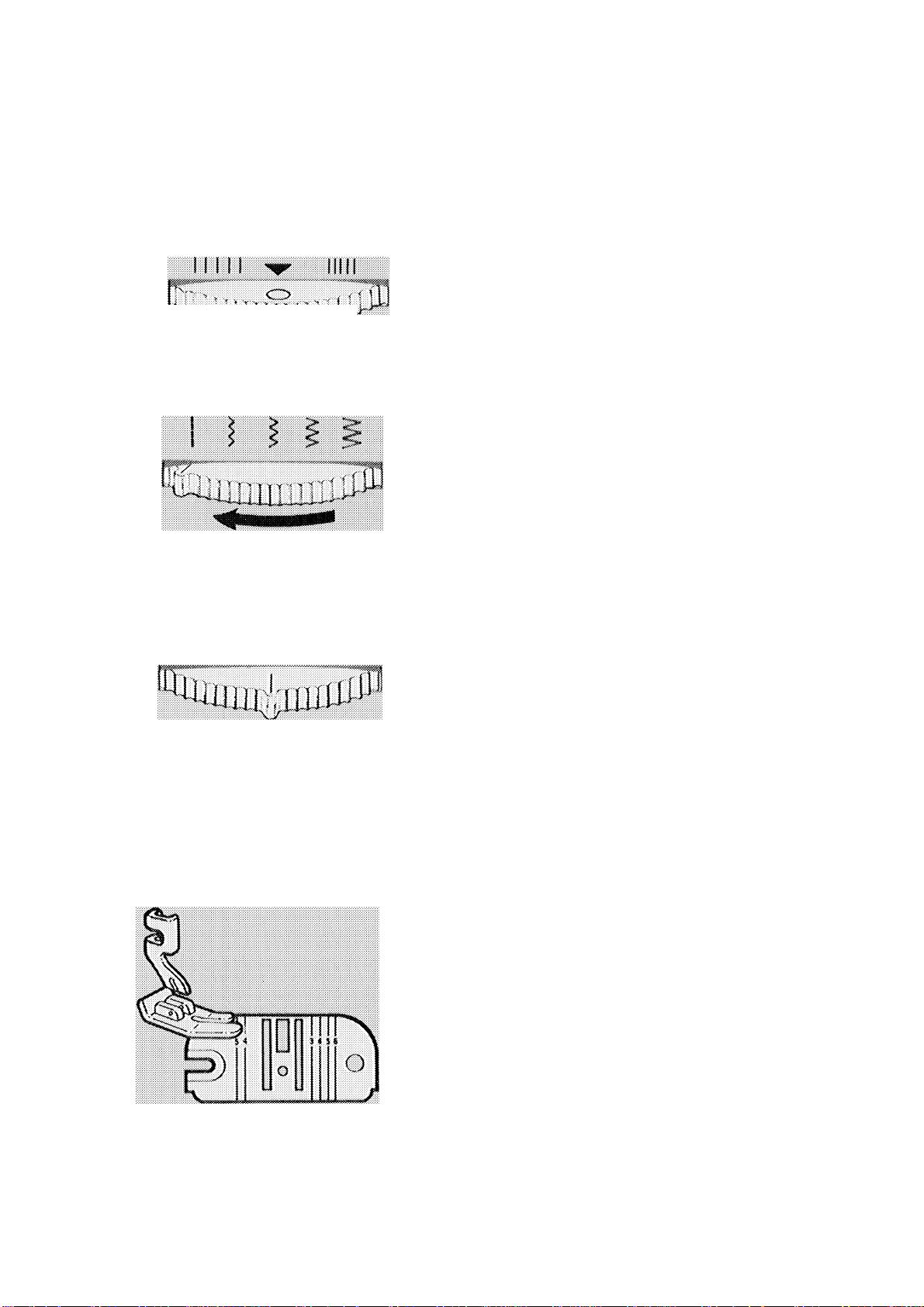

General Purpose fittings

The general purpose presser foot and

needle plate are in place on the machine

and can be used for either straight or

zig-zag stitching. These fittings must be

used when alternating between straight

stitching and any kind of zig-zag stitch

ing.

Straight Stitch Fittings

The straight stitch presser foot and

needle plate are used only with the

stitch width selector at \ and the

needle position selector at X , Use these

fittings for:

# Precision stitching of curved edges,

top stitching, edge stitching, eta

# Stitching delicate fabrics.

straight Stitch Fittings

ii—ii*******««

■iilllll

Ч1И

¡IIP

ШШ

Feed Cover Needle Plate

The feed cover needle plate is used for

free motion darning and embroidery and

for sewing on buttons. It covers the feed

so that the fabric does not move.

I

Feed Cover Needle Flate

Ö

ACCIESSORIES {Contiriuod)

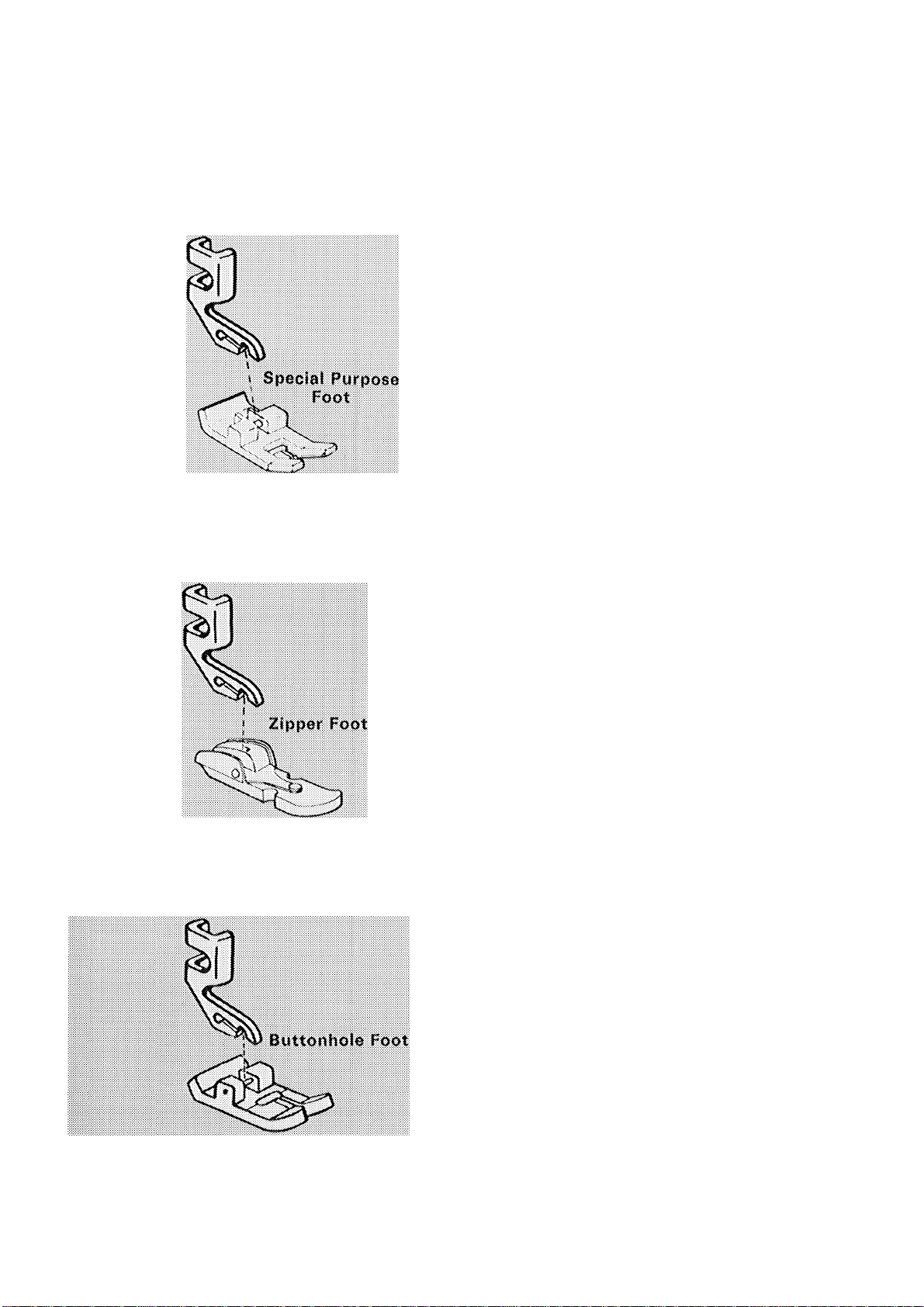

Special Purpose Foot

The special purpose foot is designed for

zig-zag stitching, buttonholing, and ap

plique, The channel on the underside

allows closely spaced zjg-zMg stitches to

feed evenly.

Zipper Foot

This foot makes it easy to place stitching

close to a raised edge. Thus, it is useful

for corded seams as well as zippoi'

insertions (page 40), The hinged foot

easily rides over pins, heavy layers of

fabric, or seams.

This foot is used to make 4-step bar tack

buttonholes. The channels on the under

side allow closely spaced zig-zag stitches

to feed freely and permit buttonholes to

be double stitched when extra strength

is needed. Guidelines on the foot simplify

buttonhole placement and make it easy

to gauge buttonhole length.

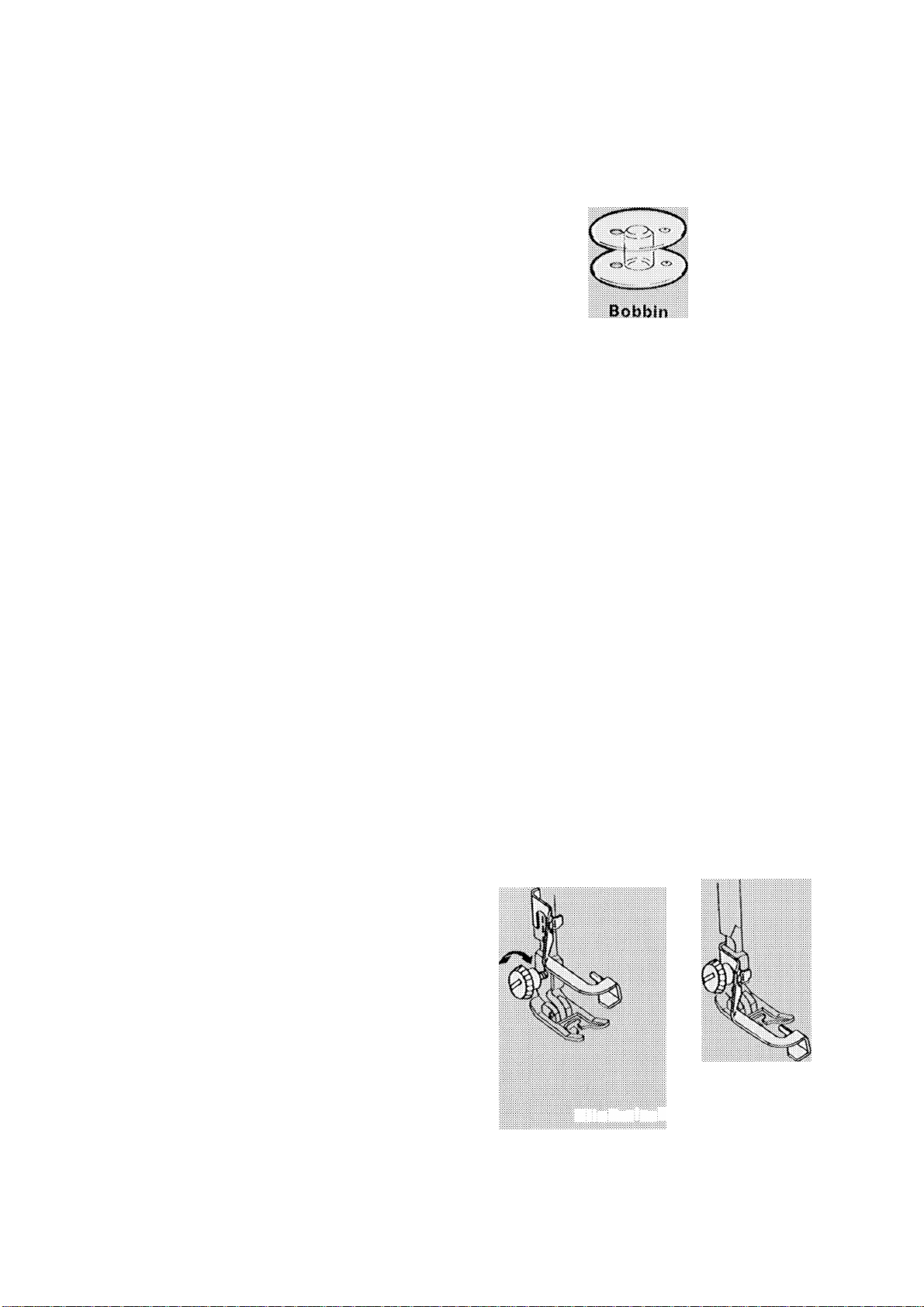

The tfanspareni bobbin shows thread

supply at a glance*

One bobbin Is in place in your machine.

Icxtra bobbins are among your acces

sories*

Needles

Regular Meedles (Catalogue 2020) for

all-purpose sewing*

Yellow-Band Needles (Catalogue

2046) for sewing knits and stretch

fabrics.

II

Twin Needle (Catalogue 2028) for

decorative twin-needle stitching.

Biindstitch Hem Guide

The biindstitch hem guide, used with the

general purpose foot, positions the hem

fold in front of the needle for biindstitch

hemming. To attach, simply loosen

presser foot screw and slip the guide

between presser foot screw and presser

foot shank. The guide is then positioned

over the left toe of the foot For biind

stitch hemming instructions, see page 46,

Regular

Noedle

(Cat. 2020)

Yellow-Band Noodle

Blindstitoh Hem Guide

Twin

Needle

(Cat* 2028)

(Cat. 2045)

ACCESSORIES (Continued)

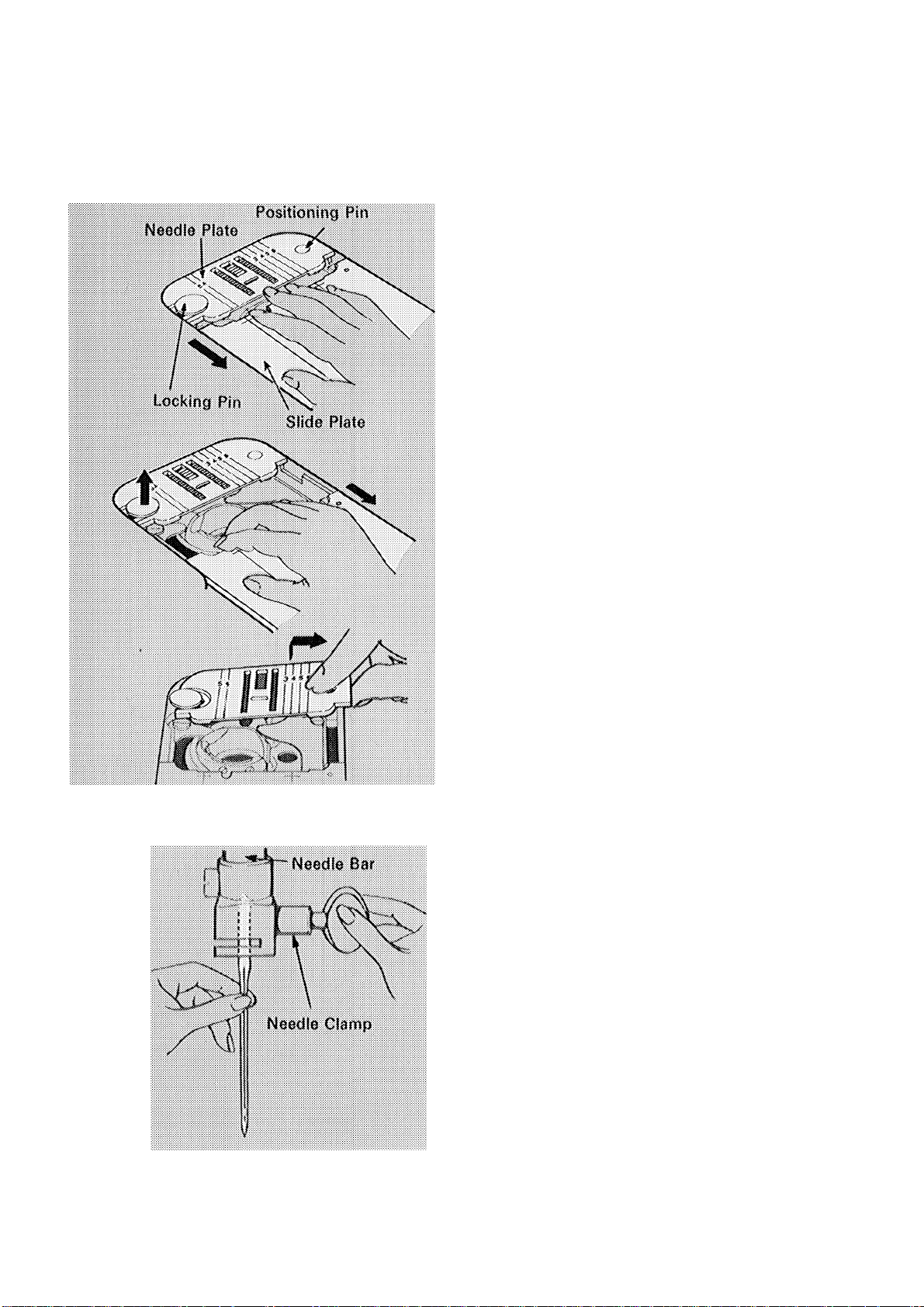

CHAN6JN<3 NEEDLE PLATl

Changing Needle Plates

1 > Raise the pressor foot.

2> Turn hand wheel toward you until the

needle is above the pressor foot>

3. Open slide plate as Illustrated until

bobbin is fully revealed

4. Place fingers on edge of slide plate

as illustrated and apply pressure to

fully open the slide plate and release

the locking pin,

5. Insert thumb under needle plate and

\mth6raw needle plate to the right to

remove.

6. Insert new needle plate under locking

pin and locate on position pin. Fully

close slide plate to lower the needle

plate locking pin and secure the

needle plate.

CHANGING THE NEEOM

a

Changing the Needle

The needle clamp has been designed so

that the needle can only be inserted one

way—the correct vv^ay, with the flat side

of the shank to the back.

1. Turn hand wheel toward you until

needle is at highest position.

2. Loosen needlC'Clamp screw and re

move needle.

3. Insert new needle in clamp with the

fiat side of the needle to the back and

the long groove toward you; push it

up as far as it will go.

4> Tighten needle clamp screw.

For regular sewing, this machine uses

SINGER needles Catalogue 2020 (15x1).

available in sizes 9. 11. 14. 16 and 18,

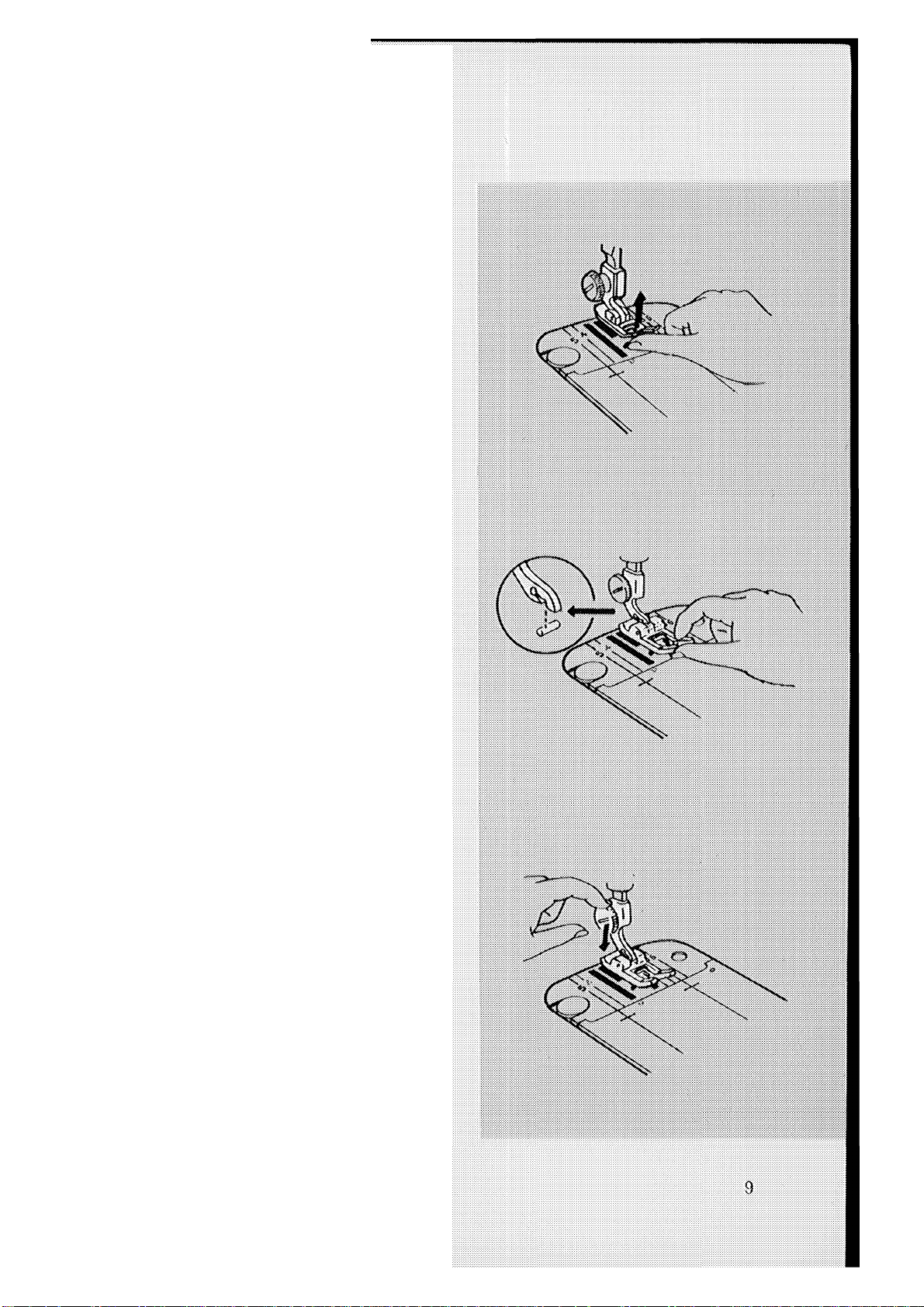

Changing Presser Feet

1. Raise the prosser foot and make sure

the needle Is at Its highest point.

2. With youf thumb under the prosser

foot and your Index finger at the back,

tilt prosser foot away from you and

remove it.

3. Centre the new pressor foot under the

shank and hold it in position,

4. Lower die presser bar so that the

front opening in the shank fits over

the pin in the presser foot.

b. Press down on the presser foot screw

until the foot snaps into place.

Ope ra ti ng y ou r se wi ng ma ch in e

Before plugging in your machine, be sure

that the voltage and number of cycles

indicated on the plate under the hand

wheel conform to your electrical power

supply. .

CAUTION: Because of the up and

down movement of (he needle, you

must work carefully and watch the

sowing area when operating the

machirm. We recommend that you

switch off the power and light before

changing needles, pressor feet and

needle plates and when leaving the

machine unattended. This eliminates

the possibility of starting the machine

by accidentally pressing the speed

controller.

■I

IIIIII!

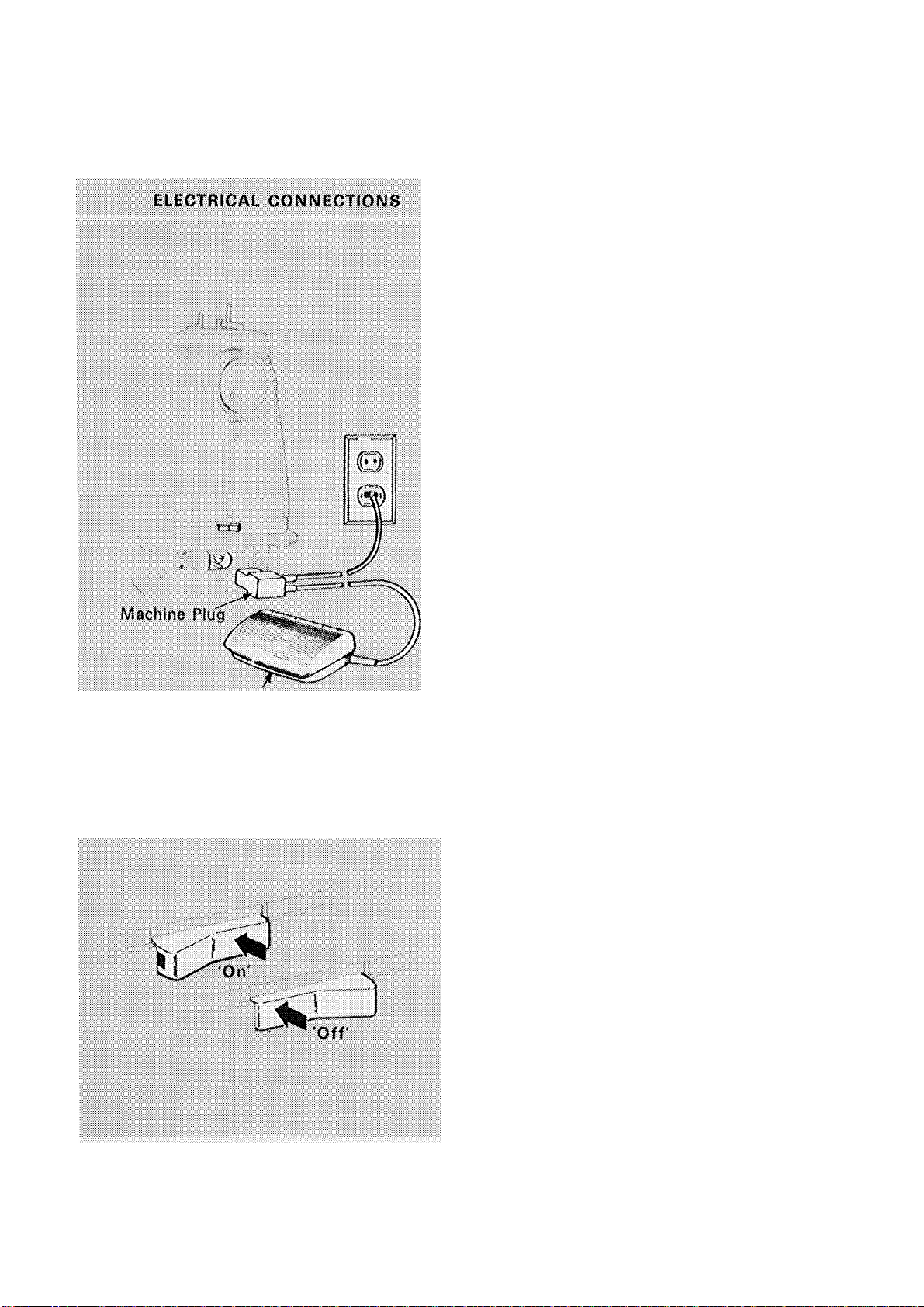

Electrical Speed ContfOllcr i

POWER AND UGHT SWITCH

ELECTRIC DRIVE

# liaise the presser foot (the higher

lifting position allows placement of

bulky fabrics).

# Place material under the presser foot

and lower presser foot.

# Insert machine plug Into the recep-'

tacle at the right end of the machine,

and connect the wall plug to the

electrical outlet. Switch on the pow-^er

and light. Start the machine by

pressing down on foot controller. The

speed of the machine is regulated by

amount of pressure on foot controller.

# Practice operating machine (without

thread) until you become accustomed

to guiding material and regulating

machine speed.

NOTE: Do not operate machine wittv

out material under presser foot

as this may damage the feed

and presser foot.

10

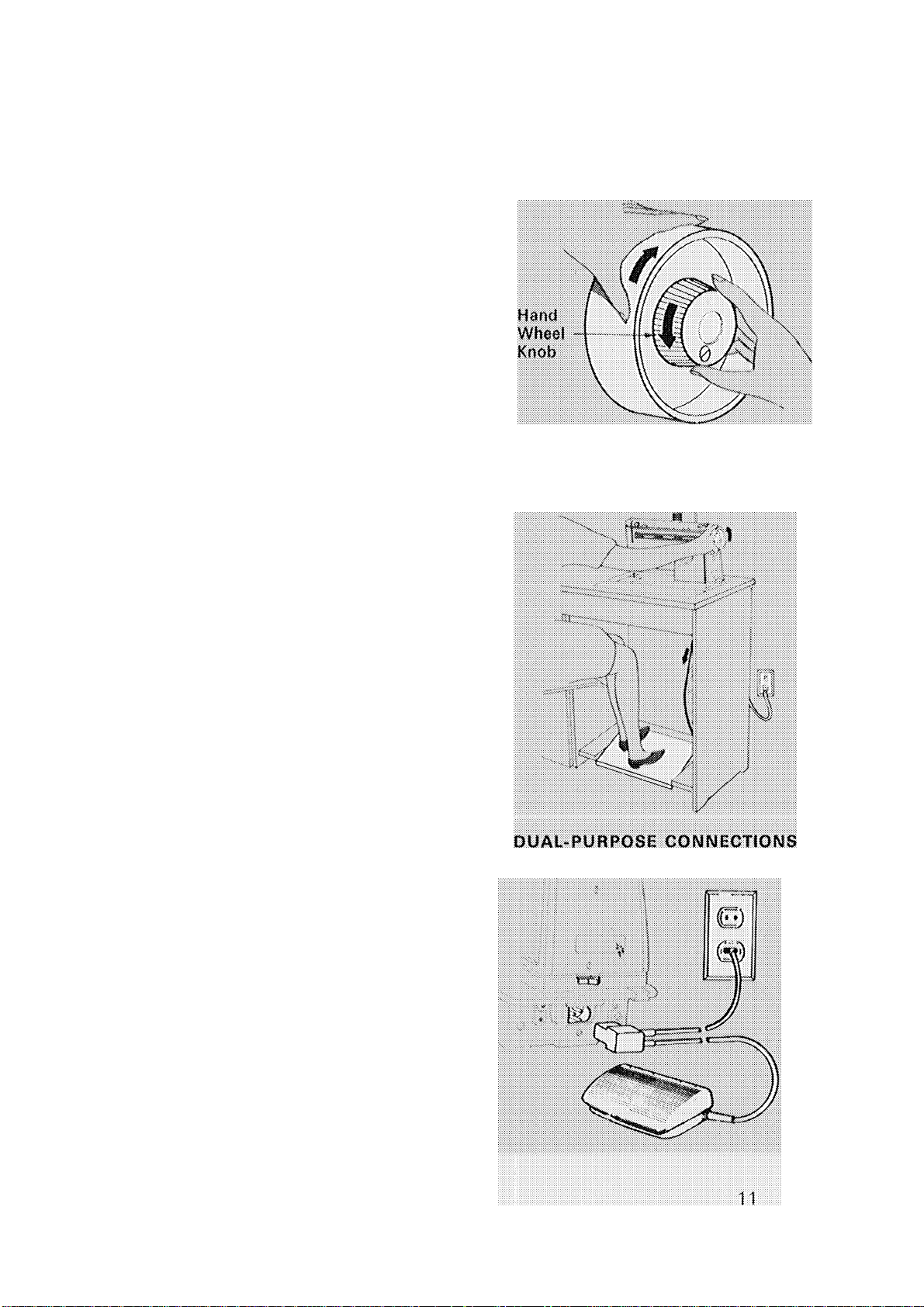

TREADLE DRIVE

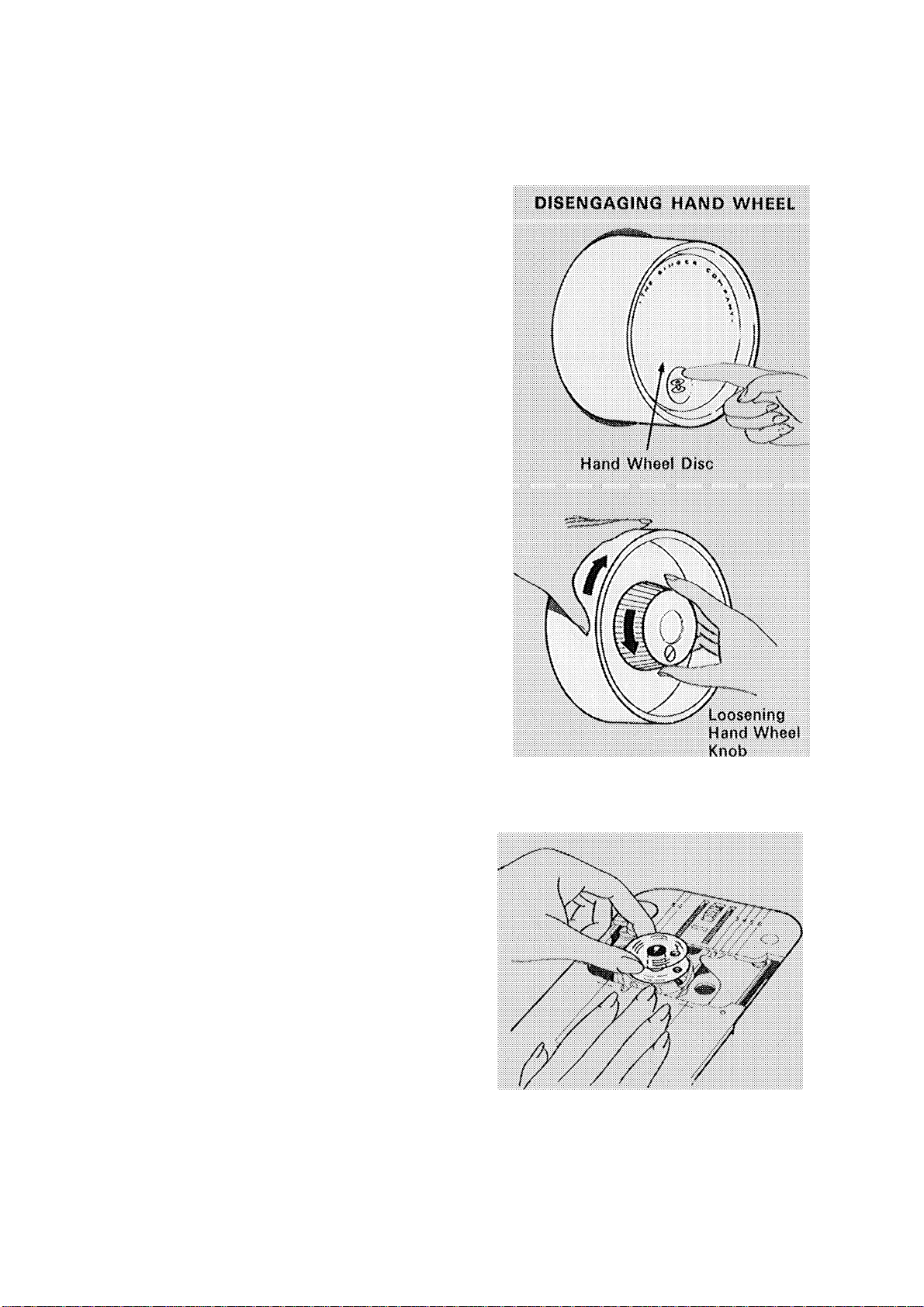

# Loosen hand wheel knob.

# Place feet on tfeadle.

# Turn hand w4ieel over toward you and

allow feet to move freely and lightly

with motion of treadle.

# Practice this motion until you are able

to redstart machine v/ith hand wheel

turning over toward you<

# Tighten hand wheel knob.

# For light, insert machine plug and

connect wall plug. Switch on light,

# Place material under presser foot and

lower the presser foot.

# Operate machine (without thread} until

you become accustomed to guiding

the material

# To disengage belt—operate treadle

and throw-off belt to the right.

# To engage belt—operate treadle with

hand wheel turning toward you and

guide belt on to band wheel

DISENGAGING HAND WHEEL

ENGAGING BELT DRIVE

NOTE; Belt tension should be only

heavy enough to keep belt

from slipping.

DUAL PURPOSE ELECTRIC/TREADLE DRtVE

Electric Drive

CAUTION: Before insermg machinem

plug and wall plug (he beh for treacHe |

drive must be disengaged as instructed |

above, 11

# Operate the machine as instructed for

electric drive on page 10.

Treadle Drive

# Disconnect rnachine/controller plug

from machine and wall plug from

electrical outlet as shown. (If light

connection is required a special light

lead must be used—please consult

your SINGER Sewing Centre.)

# Operate machine as instructed above.

FABRIC, THREAD, NEEDLE AND STITCH LEN6TH TABLE

STRAIGHT STITCHING

Uso the chart as a general guide: with the ever Increasing development of

symhetic fibres, all fabrics are not covered. We recommend as a golden rule

to use a synthetic fibre thread to sew synthetic fibre fabrics and natural

fibre thread to stitch natural fibre fabrics. Be sure to use the same size

thread In both needle and bobbin.

THREAD

TABRICS

DKUCATB—tulle, chiffon,

fine lace, silk, organdie.

SIZES

Fine mercerized

cotton.

fine synthetic

LIGHTWeiGHT-lawn.

organdie, voile, taffeta, silk.

crepe, chiffon velvet plastic

50 mercerized

cotton.

silk.

fine synthetic

SYNTHETIC KNITS AND

STRETCH FABRICS-polyester double knit nylon

60 mercerized

cotton.

silk.

tricot, jersey, bonded fabrics.fine synthetic

ciré, panné velvet, rascheL

MBmumwmmr--

50 mercerized 14 1.8-2

gingham, percale, pique. cotton.

linen, chintz, faille, satin, silk.

fine corduroy, velvet

suitings, stretch fabric.

fine synthetic.

60 cotton

NEKDŒ

SIZES

9

(Cal. 2020)

11

(Cat. 2020)

14

(Cat. 2045)

(Cat. 2020)

STITCH LSNGTH

SETTINGS

1-1.5

1.8-2

(2.8*3 for plastic)

1.6-2

MEDIUM HEAVY--»

gaberdine, tweed, sailcloth.

Heavy-duty

mercerized cotton.

16 2-2,5

(Cat- 2020)

denim, coatings, drapery 40 to 60 cotton.

fabrics, deep-pile fabrics. synthetic thread

....------

-----------------------------

............

H EAVY—overcoatings. Heavy-duty 18 2.5-3

dungaree, upholstery fabrics.mercerized cotton.

(Cat. 2020)

canvas. 24 to 40 cotton

ALL WEIGHTS-

decorative lop stitching.

Buttonhole twist t

18 2-4

(Cat 2020)

LEATHERS—suede. 60 mercerized 11. 14, 16

kidskln. lined leather.

cotton or

(Cat. 2032)

synthetic ihrmd

tUse with No, SO mercerized cotton thread or fine silk thread in bobbin.

12

2-4

you r se wi ni

THE BOBBIN THREAD

Winding the Bobbin

Always wind the bobbin before threading

the needle,

1. Raise the presser foot.

2. Turn hand wheel toward you imtil

needle is above the presser foot.

3. Disengage hand wheel by pressing

bobbin symbol (@) on hand wheel

disc.

(For treadle drive, loosen the hand

w4ieef knob.)

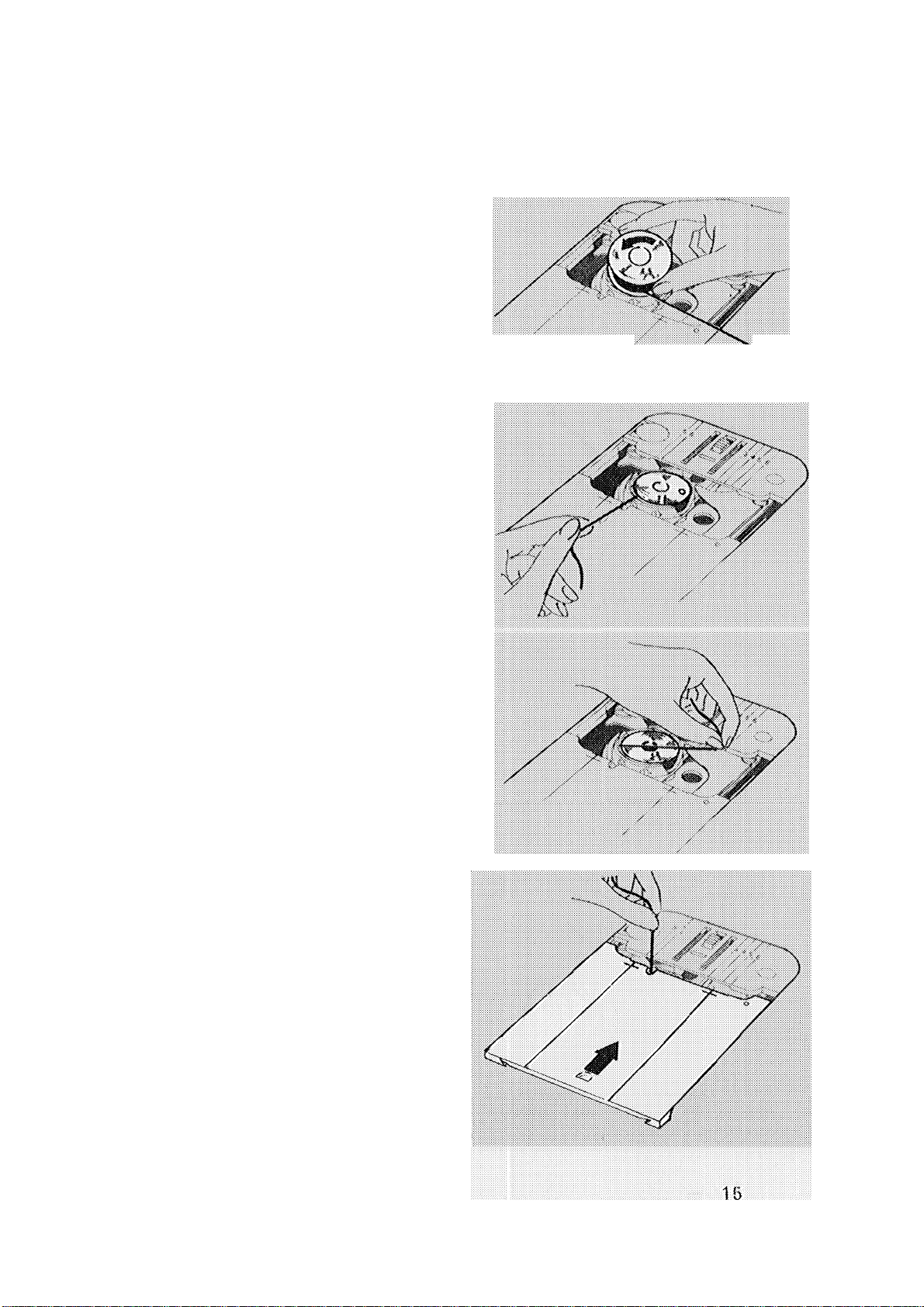

4. Open slide plate with finger pressure

as Illustrated.

6, Lift out bobbin,

6. Fully close slide plate to make sure

that needle plate is secure.

REMOVIIMG BOBBIM

13

...........................................

--------- B 0bt ■ "

................

mmmmmmmmmmmmmm

............ :

I

........^.

......

WISSS^

mmF"

BOBBIN WINDER SWITCH

ENGAGING HAND WHEEL

7. Place spool of thread on spool pin

over the spoof pin felt and lead

thread around bobbin winder tension

disc.

8. Pass thread, from the inside, through

hole in bobbin and place bobbin on

spindle.

9. Turn bobbin winderswitch clockwise

to "wind“ position, hold thread end

as shown and start the machine<

10, Cut off thread end after a few coils

have been wound on the bobbin,

11, When required amount of thread has

been wound (winding will stop when

bobbin is full), turn bobbin winder

swatch counterclockwase to “sew/“

position and cut thread.

12, Press hand wheel disc for sewing or

tighten the hand w/heel knob.

14

Threading the Bobbin Case

1. Raise the presser foot.

2, Turn hand wheel toward you until

needle is above the presser foot,

3. Open slide plate.

4, Hold bobbin so that thread unwinds in

direction shown, and insert bobbin in

bobbin case.

6, Pull thread into notch, draw it under

tension spring, and into slot.

iíiíiíSiiiíS;:

0. Draw about 10cm (4") of thread

diagonally across the bobbin.

7. Fully close slide plate with the thread

in slot between the needle plate and

slide plate. Make sure that needle

plate Is secure.

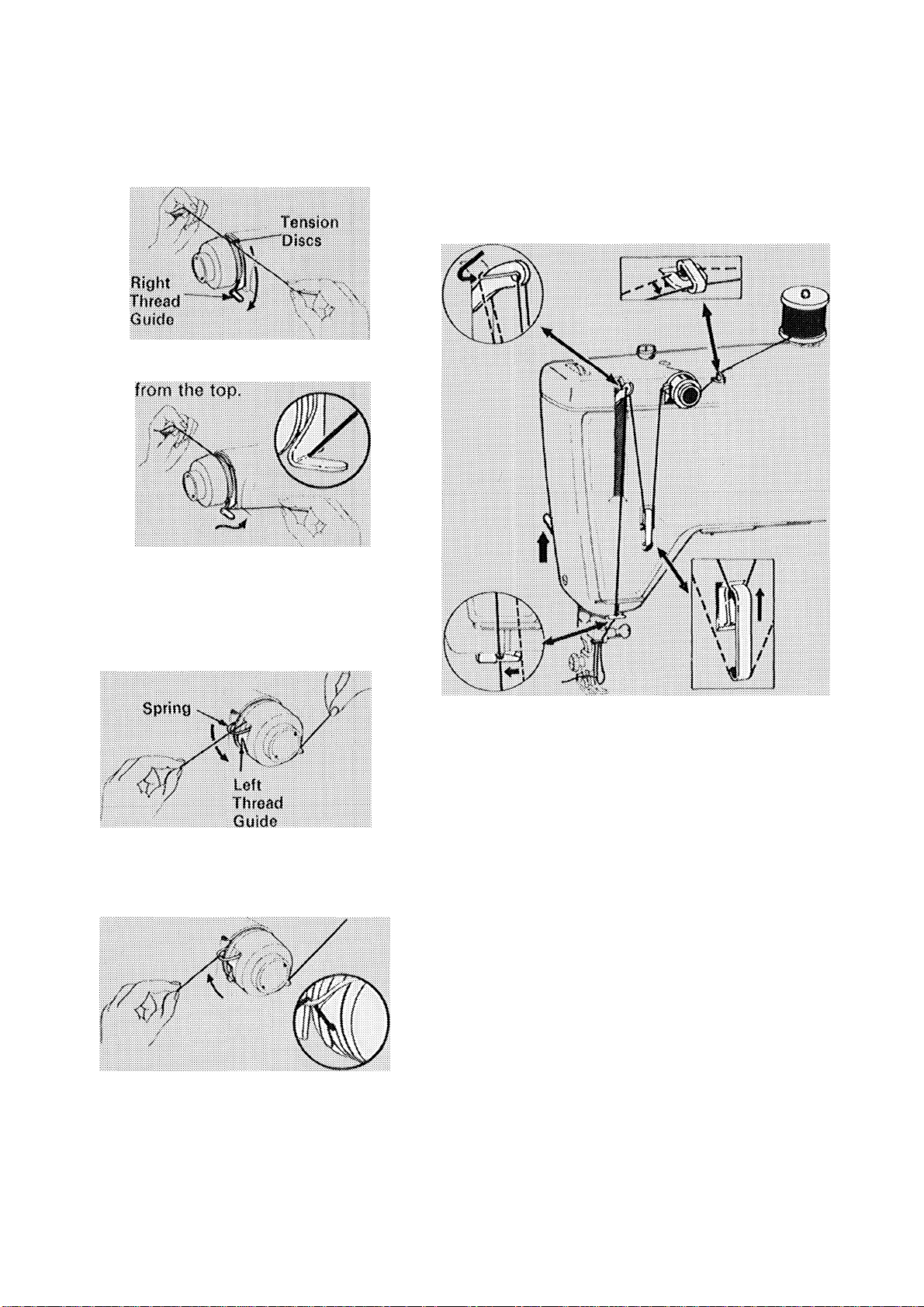

With tv>/o hands, slip Ihmad horii^onially between tension discs

THE NEEDLE THREAD

Hold thread firmly with left hand

and. with the right hand, lead the

thread down past the right throacl

guide and up to catch behind the

guide.

With left hand lead thread over

spring, pulling thread down in

direction of arrow and under guide.

Allow the gyring to return to its

normal 'up' position and continue

threading the machine.

Threading the Needle

1. Raise pressor foot to release the

tension discs and turn hand wheel to

raise the needle to its highest position,

2. Place spool of thread on spool pin

over felt and lead thread through to

points as shown, making sure to

# Thread tension discs as illustrated.

# Thread take-up lover from back to

front, guiding thread down over top

of lover and then up into eyelet.

# Thread needle from front to back

drawing about 10cm (4'0 of thread

through eye of needle.

16

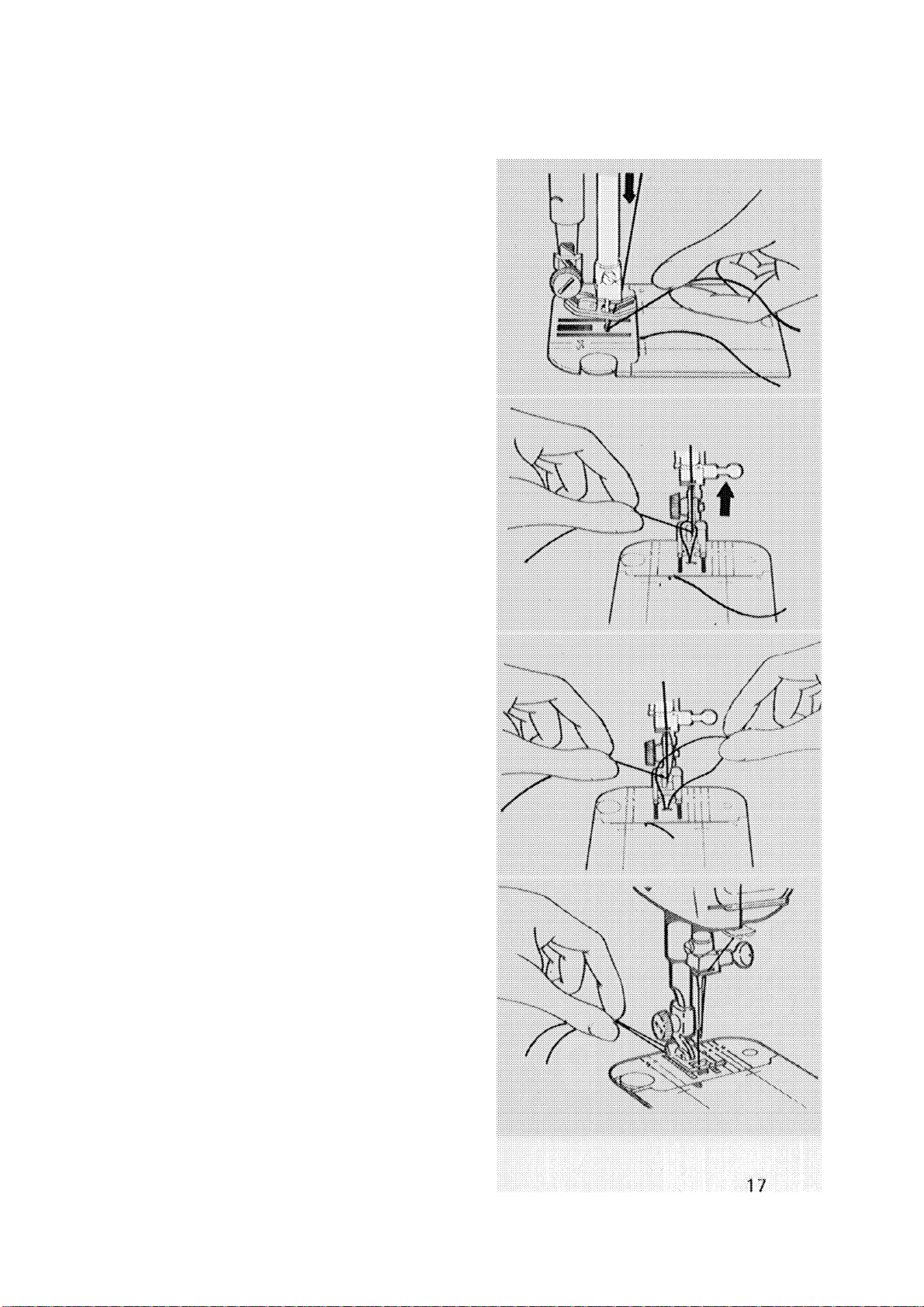

RAISING THE BOBBIN THREAD

Nov\/ that you have wound the bobbin

and threaded the needle, you will need

to raise the bobbin thread through the

needle hole in the needle plate.

1> Hold needle thread lightly with left

hand and turn hand wheel slowly

toward you so that needle enters

hole in needle plate.

2. Continue turning hand wheel and

firmly hold needle thread until needle

rises and brings up bobbin thread in

a loop.

3. Undo the loop with your fingers.

4. Place both needle and bobbin threads

under presser foot, and draw them

toward the back of the machine.

. . . You are now ready to sew

Str ai gh t st it ch in g

DIAL SETTINGS

F/exi^$tk€h Dial

Stitch Width Dial

L X

F/exhStkch Dial: 0

Stitch Width * j i 1 ^ I ^ ^

Needle Position: 5L i J 1 ?

Stitch Length; See page 19

Pressure: See page 21

Tension: See page 20

General Purpose or Straight Stitch

Presser Foot

General Purpose or Straight Stitch

Needie Plate

0^ j

SETTING NEEDLE POSITION

Before you set your sewing machine for

any kind of stitching, turn the hand wheel

tov^/ard you until the needle is above the

needle plate.

Check:

# That the Ffoxi-Stitch dial is set at 0<

# That the stitch length/buttonhoie dial

is not set at any of the four bullón-

holing positions,

Meedic Position Old

ACCESSORIES

FITTINGS

Best sewing results will be obtained if

you use the straight stitch presser foot

and needle plate (see page b). However,

the general purpose presser foot and

needle plate may also be used,

ADJUSTING FOR YOUR FABRIC

As you get ready to sew, take advantage

of the versatility of your sewing machine.

With a choice of needle si^es and three

easy-to-use selectors for stitch length,

pressure, and needle-thread tension, you

can adjust the macliine to sew perfectly

on a wide variety of fabrics. The table on

page 12 will guide you in selecting the

correct thread, needle size and stitch

length according to the vv^eight of your

fabric.

18

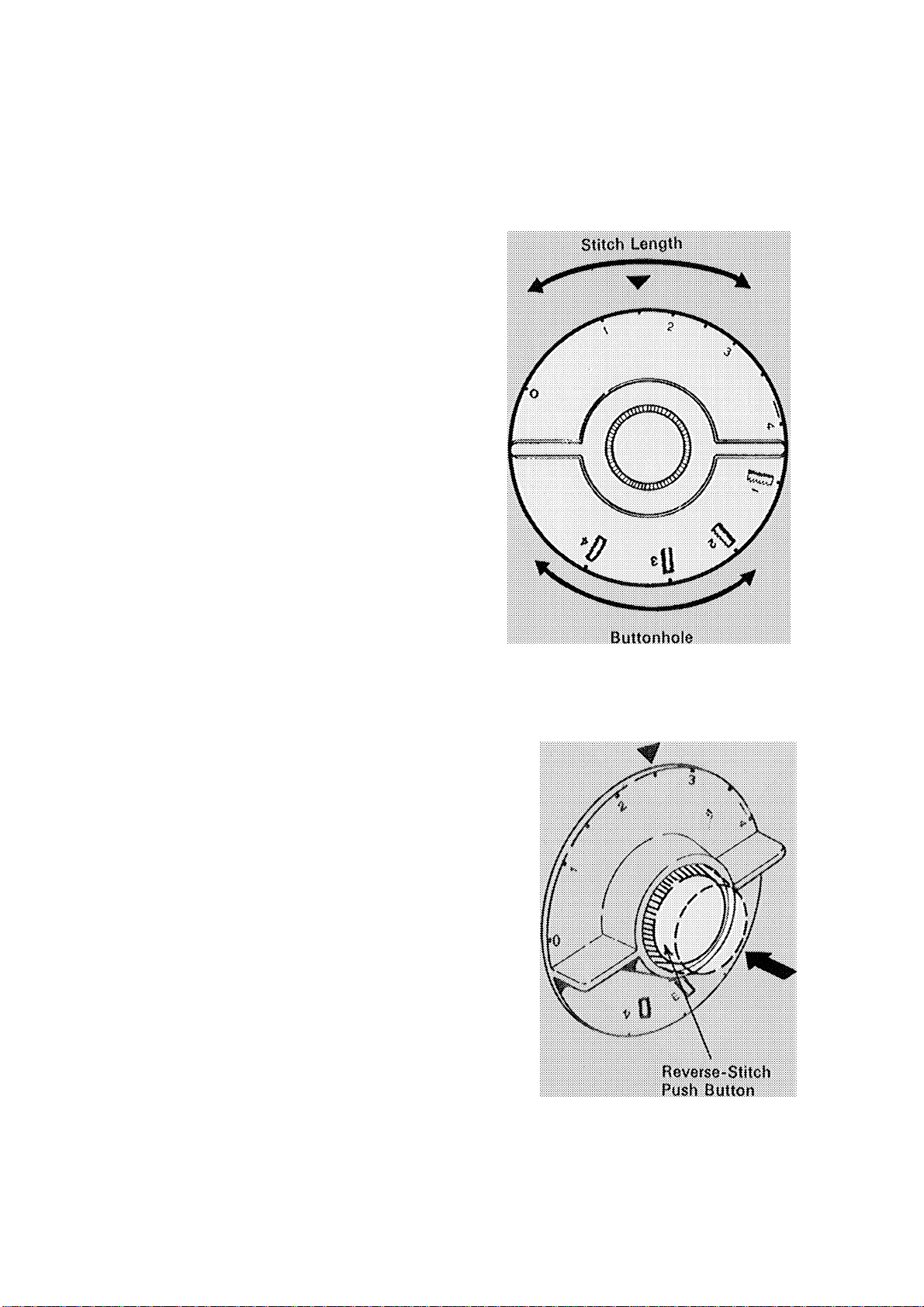

Adjusting Stitch Length

The Stitch fengtii dial controls the length

of the stitch. It is graduated from

0-4: the higher the number, the longer

the stitch>

Generally, shorter stitches are best for

lightweight fabric; longer ones for heavy

fabric. The area between 1 and 0 is used

for ^ig-:!ag satin stitching only.

Setting Selector

# Turn dial so that the stitch length

desired is positioned under the arrow

head 'W on the control panel.

#To shorten the stitch, turn dial to the

right

# To lengthen the stitch, turn dial to the

left.

STITCH lENGTH DIAL

mvBnsB STiTCHHsic

For reverse stitching, press the reversestitch push button In as far as it will go

and hold in place (the button can be

pushed in while the machine is sewing).

Release pressure on the push button to

return to forward stitching.

19

Loading...

Loading...