Page 1

(Л

z

VWWWVWWWVVVVVWVVVWWVWVWVVW' (Л

wvwwvwvwvwwwvwvwwvwwwwv ^

о

m

yWVWWWWVM

лллллмллллмл

AAWVWWWW\

Page 2

‘Copyright ® 1980 T. S. Co.

All Rights Reserved Throughout the World

Page 3

CONTENTS

Page

Chapter 1. Getting to Know Your Machine .............................................................................................................. 2

Principal Parts ......................................................................................................................................... 2

Accessories ............................................................................................................................................. 3

Chapter 2. Getting Ready to Sew ................................................................................................................. 4

Choosing and Changing Accessories ..................................................................................................... 4

Fabric Weight Table

Fabric Thread and Needle Table......................................................................................................... 8

Operating the Machine ...........................................................................................................................10

The Bobbin Thread ................................................................................................................................11

Winding the Bobbin • Removing the Bobbin Case • Threading the Bobbin Case •

Replacing the Bobbin Case • Adjusting Bobbin-Thread Tension

Threading the Machine...........................................................................................................................14

Raising the Bobbin Thread

Chapter 3. Straight Stitching ................................................................................................................................. 16

Adjusting Machine Stitch to Suit Your Fabric

Setting Selectors • Regulating Presser Foot Pressure • Adjusting Stitch Length •

Needle-Thread Tension • Bobbin-Thread Tension

Sewing a Seam ..................................................................................................................................... 18

Keeping the Seam Straight

Applications .......................................................................................................................................... 19

Zipper Insertion • Darning

Chapter 4. Basic Zig-Zag Stitching ....................................................................................................................... 20

Adjusting Machine to Suit Your Fabric ...................................................................................................20

Setting Selectors • Needle Position Selector • Stitch Width Selector •

Adjusting Needle Tension • Adjusting Stitch Length •

Adjusting Presser Foot Pressure

Satin Stitching ........................................................................................................................................22

Applications ............................................................................................................................................23

Applique'

Chapter 5. Twin-Needie Stitching ...........................................................................................................................24

Chapter 6. Performance Checkiist ..........................................................................................................................25

Chapter 7. Caring for Your Machine ....................................................................................................................... 26

index ......................................................................................................................................................................... 28

....

........................................................................................................................ 6

........................................................................................

16

Page 4

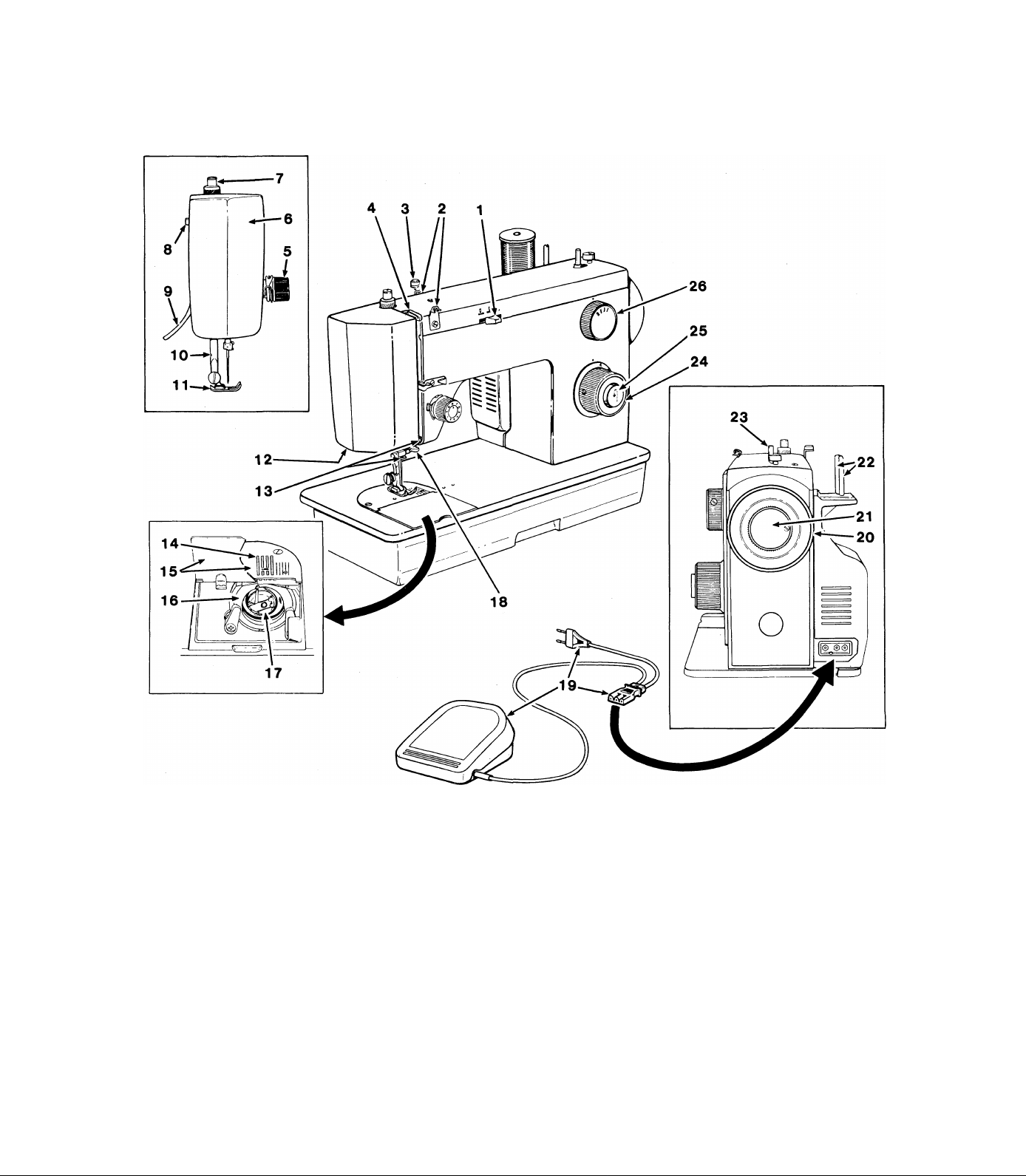

Chapter 1. Getting to Know Your Machine

principal parts

1. Needle Position Selector

2. Thread Guides

3. Bobbin Winder Tension

4. Take-up Lever

5. Needle-Thread Tension

Dial

6. Face Plate

7. Pressure Regulator

8. Sewing Light Switch

9. Presser Foot Lifter

10.

Thread Cutter

11.

General Purpose Presser

Foot

12.

Sewing Light

13.

Thread Guides

14.

Feed

15.

General Purpose Needle

Plate & Cover Plate

16.

Bobbin Case Holder

17.

Bobbin Case

18.

18. Needle Clamp

19.

Electrical Conner

Speed Controller

20.

21.

22.

23.

24.

25.

Button

26.

26. Stitch Width Seiector

Page 5

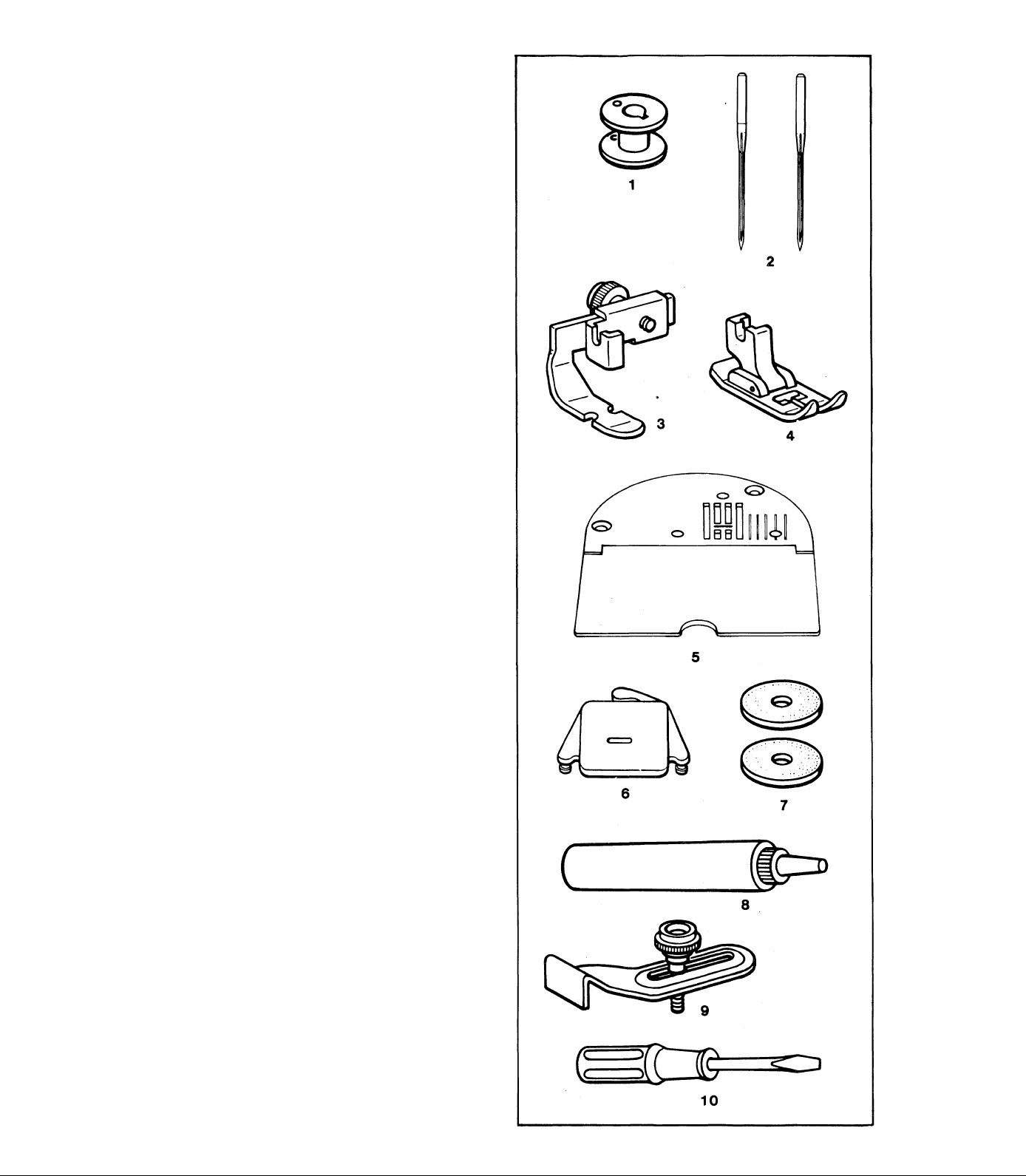

accessories

The accessories that come with your sewing

machine are designed to help you do many

kinds of sewing easily.

1. Transparent Bobbins (No. 541090)

2. Needles

• Style 2020 is used for general sewing.

• Style 2045 is used for sewing knits,

stretch fabrics and elastic.

3. Zipper Foot for inserting zippers and

stitching corded seams.

4. General Purpose Foot, on your machine

when delivered, Is used for all utility and

decorative sewing, with either straight or

zig-zag stitching.

5. General Purpose Needle Plate, on your

machine when delivered. Is used with all

presser feet.

6. Snap-in Feed Cover for darning.

7. Felt (2) to help thread unwind smoothly.

8. Tube of Oil for oiling the machine.

9. Seam Guide to help you keep seam

allowances even.

10. Screwdriver for adjusting bobbin-thread

tension.

Page 6

Chapter 2. Getting Ready to Sew

choosing and changing accessories

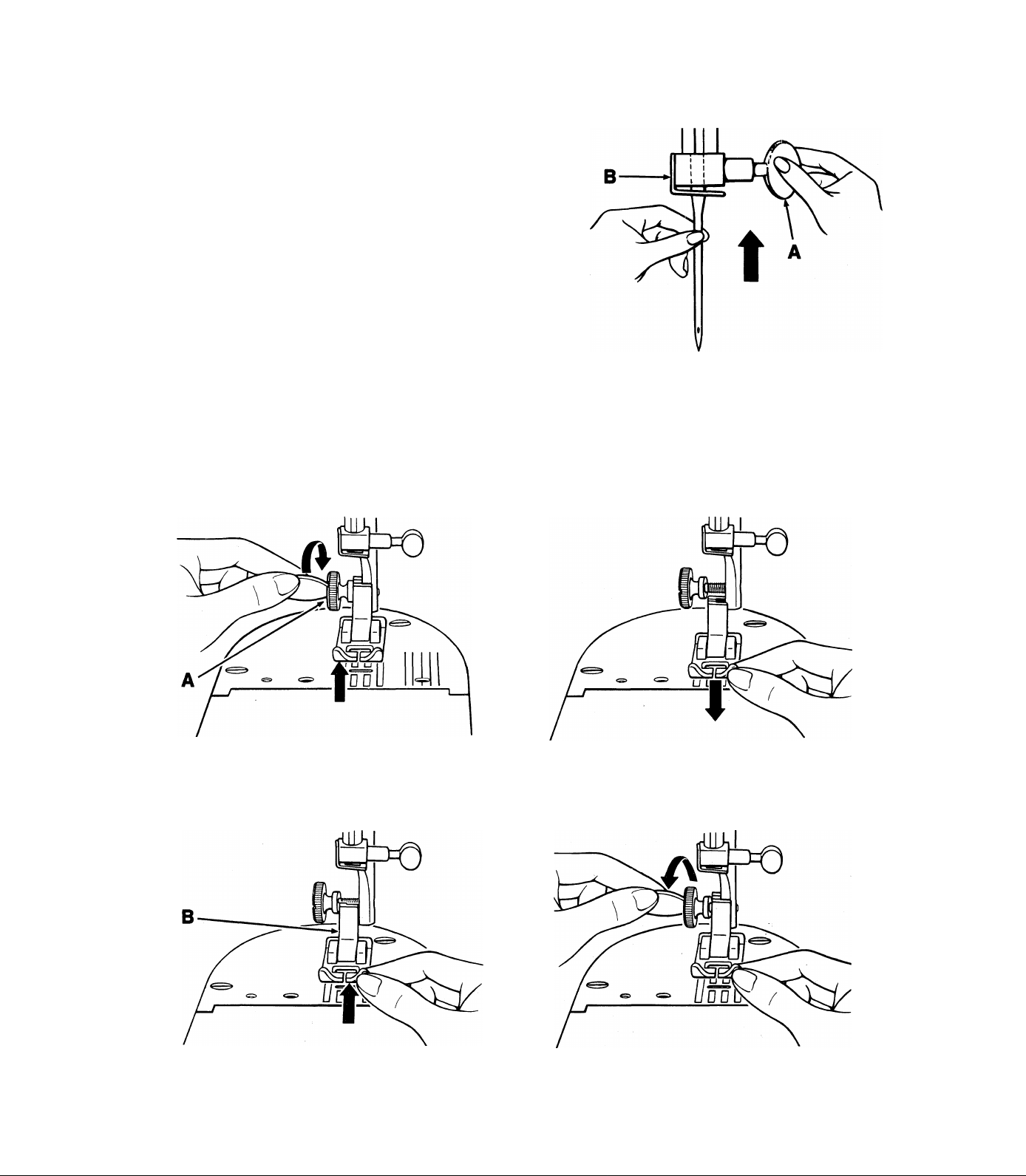

CHANGING THE NEEDLE

• Raise needle to its highest point by turning

the hand wheel toward you. Loosen needle

clamp screw A and remove the needle.

• Insert new needle up into clamp B as far as it

will go, with the flat side of the needle to the

back.

• Tighten needle clamp screw.

CHANGING PRESSER FEET

The general purpose foot is on your machine when delivered. To change to another foot, raise

needle to highest position by turning the hand wheel toward you. Raise presser foot.

To Remove and Replace Foot

1. Insert the edge of a coin in the slot of the

presser foot screw A. To loosen, turn screw

away from you.

3. Centre the new presser foot shank B under

the presser foot screw. Lift shank all the way

up.

2. When screw is fully loosened, foot will drop.

Remove presser foot by sliding it toward you.

4. Tighten presser foot screw securely with a

coin.

Page 7

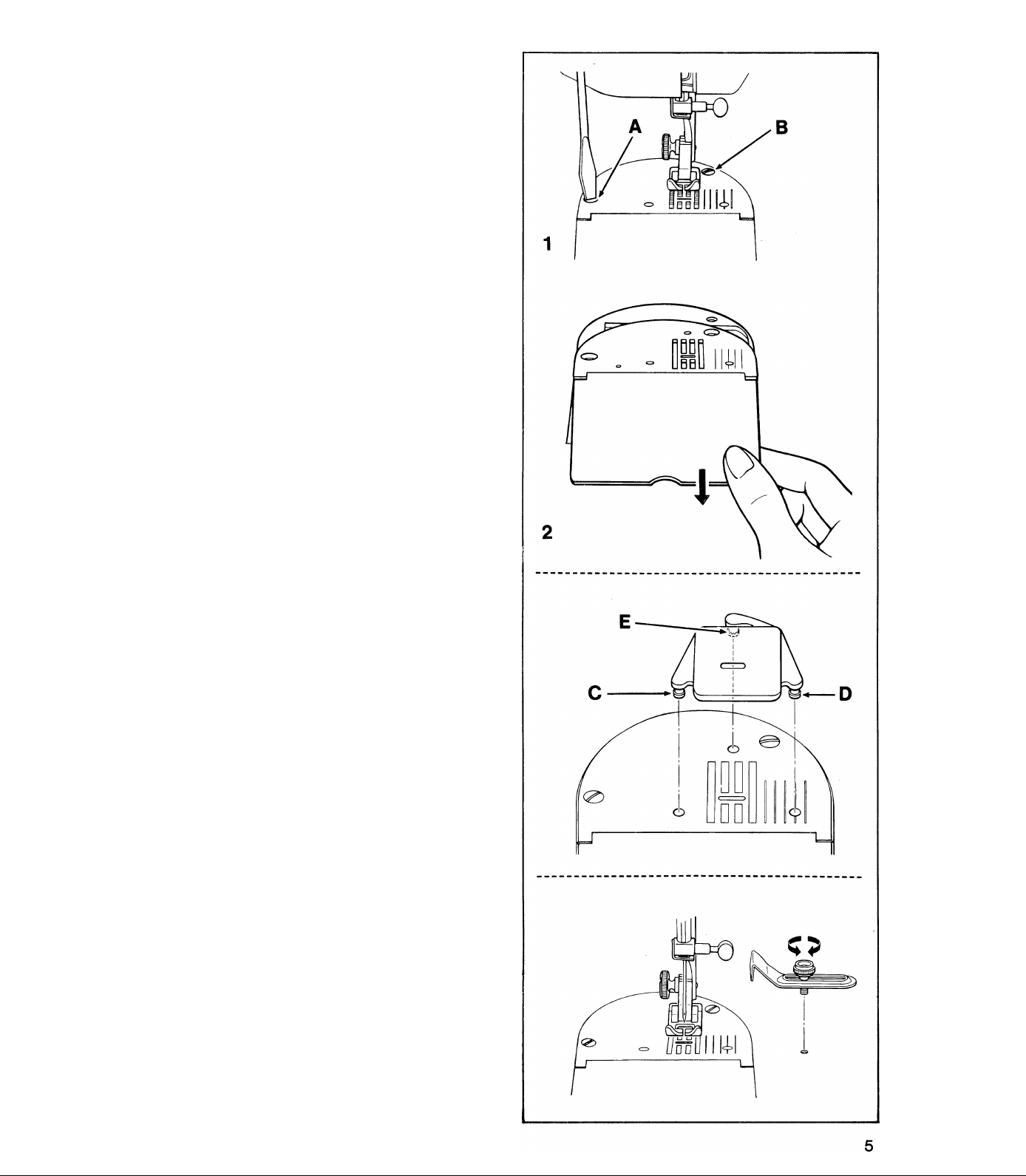

REMOVING AND REPLACING NEEDLE

PLATE AND COVER PLATE

• Raise needle to highest position and raise

presser foot.

1. Remove screws A and B using a large

screv\/drlver.

2. Remove the needle plate and cover plate by

simply guiding it toward you.

To replace needle plate and cover plate,

guide needle plate into position under the

presser foot. Replace screws A and B using

a large screwdriver and tighten securely.

ATTACHING SNAP-IN FEED COVER

• Raise needle to highest position by turning

handwheel toward you.

• Raise presser foot.

• Slide snap-in feed cover away from you over

needle plate until points C and D are posi

tioned directly over holes In needle plate as

illustrated. Snap in point C. Then push point

D toward point C until it snaps into place.

Push down on point E until it also snaps Into

place.

• To remove, lift up edges of feed cover.

ATTACHING THE SEAM GUIDE

Place screw in either hole to the right of the

needle plate; line up straight edge of guide with

the needle plate guideline for desired seam

width, and tighten screw.

Page 8

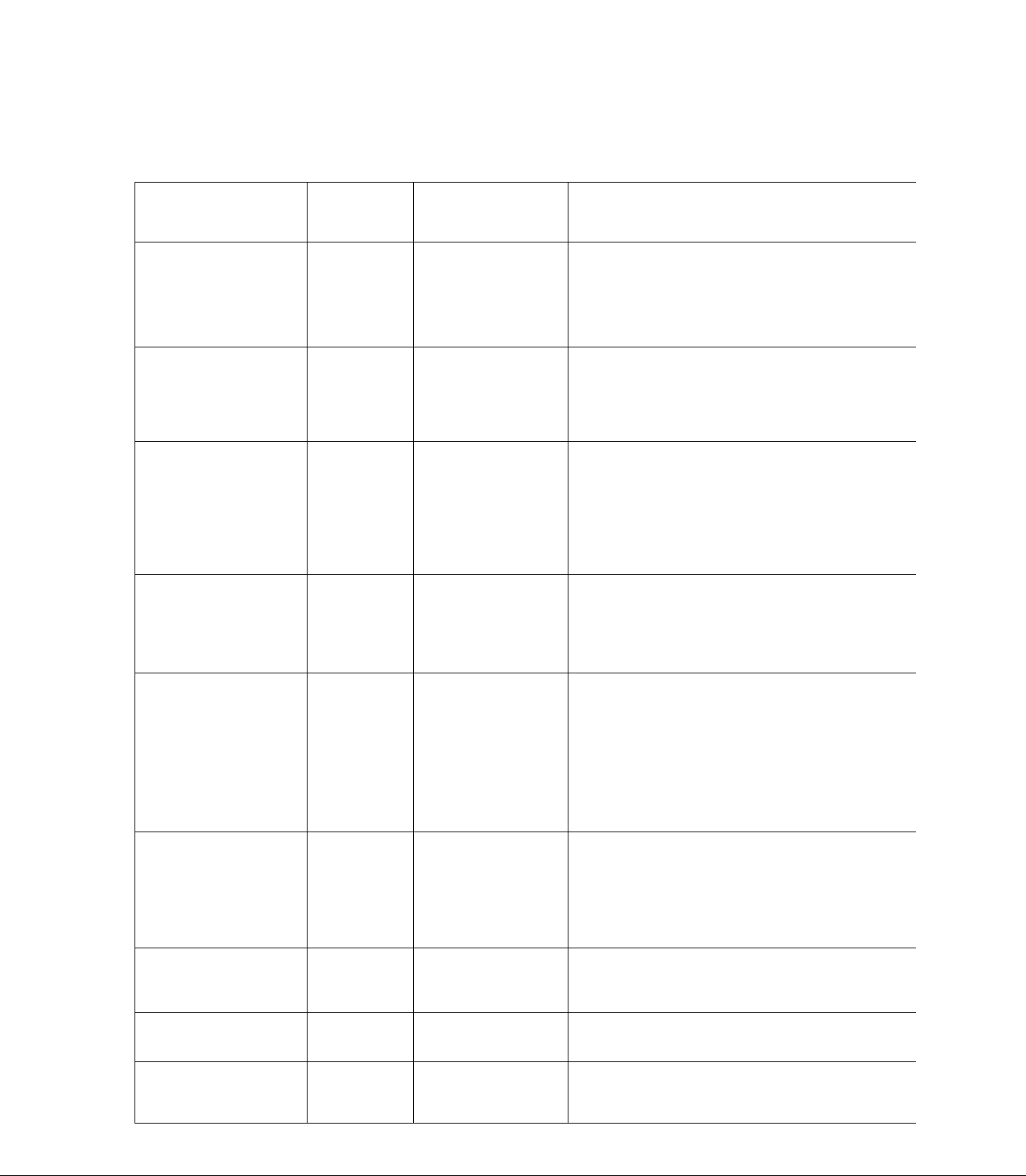

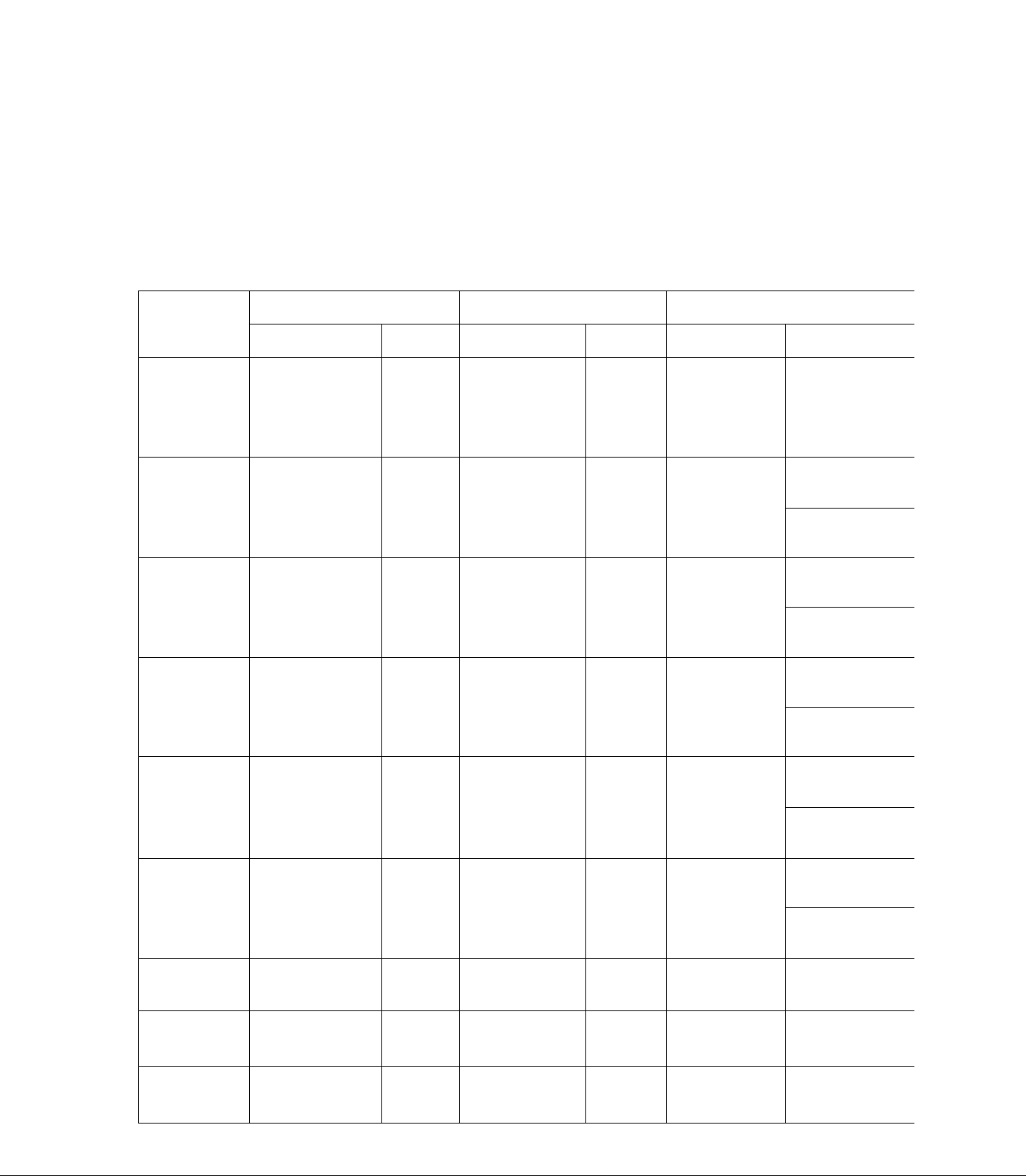

FABRIC WEIGHT TABLE

There are many types of fabric around the world, each manufactured with a specific fibre and

weight. The fabrics below have been classified according to weight to give a small sample of what

is available for purchase.

FIBRE

AND

CONSTRUCTION

FILMY

SHEER LIGHT

SILK

(Woven)

(Knit)

RAYON

(Woven)

(Knit)

COTTON

(Woven)

(Knit)

WOOL

(Woven)

(Knit)

Chiffon,

Organza,

Tulle

Tulle

Voile,

Tulle

Net, Lace, Ninon Velvet, Crepe de Chine, Shantung, Faille

Jersey

Net, Lace

Net, Lace

Velvet, Taffeta, Satin

Ciré

Challis, Organdy, Muslin, Batiste, Dimity,

Lawn, Percale, Eyelet, Gingham, Piqué,

Poplin

Jersey

Cashmere, Flannel, Mohair, Felt, Crepe

Jersey

SYNTHETIC

(Woven)

(Knit)

SYNTHETIC

BLENDS

(Woven)

(Knit)

LEATHER

PLASTIC

VINYLS

Chiffon,

Organza,

Tulle

Net, Lace, Ninon,

Crepe de Chine

Voile

Plastic Film

Crepe, Velvet, Taffeta, Satin

Raschel, Single Knit, Sweater Knit,

Bonded Knit, Tricot, Ciré

Broadcloth, Batiste, Eyelet, Gingham,

Poplin

Single Knit

Kidskin, Patent, Chamois, ImitationLeathers & Suedes, Leather, Suede

Plastic Film

Page 9

Refer to this table to determine the weight and type of fabric you will be using in order to select the

correct needle and thread combination.

For correct needle and thread combination for your fabric, refer to the Fabric, Thread and Needle

Table on the following pages.

MEDIUM HEAVY

Velvet, Crepe de Chine, Shantung,

Suiting, Brocade

Velvet, Taffeta, Satin, Crepe

Velveteen, Corduroy, Velvet, Fleece,

Velour, Terry, Chintz

Stretch Velours A, Stretch TerryA

A Usually contain some synthetic fibres also.

Suiting, Flannel, Gabardine, Felt,

Serge, Mohair

Brocade, Taffeta, Satin, Crepe

Corduroy, Denim, Ticking, Canvas,

Linen, Drapery Fabric, Burlap

Suiting, Tweed, Duffle

VERY HEAVY

Denim, Duck,

Canvas, Sailcloth,

Upholstery Fabric

Coating, Blanketing

Jersey

Velvet, Crepe, T affeta. Satin

Jacquard, Double Knit, Sweater Knit,

Bonded Knit, Tricot, Spandex, Stretch

Terry, Stretch Velour, Deep Pile, Fake

Furs

Linen Type, Poplin, Corduroy,

Gabardine

Terry Knit

Patent, Imitation-Leathers & Suedes,

Leather, Suede, Reptile

Gabardine

Double Knit, Helenca, Fake Furs

Denim, Gabardine, Drapery Fabric

Double Knit

Buckskin, Calfskin, Suede, Reptile

Upholstery Leather

Bonded Vinyl (Knit Back), Patent,

Embossed, Printed

Upholstery Vinyl

Upholstery Vinyl

Page 10

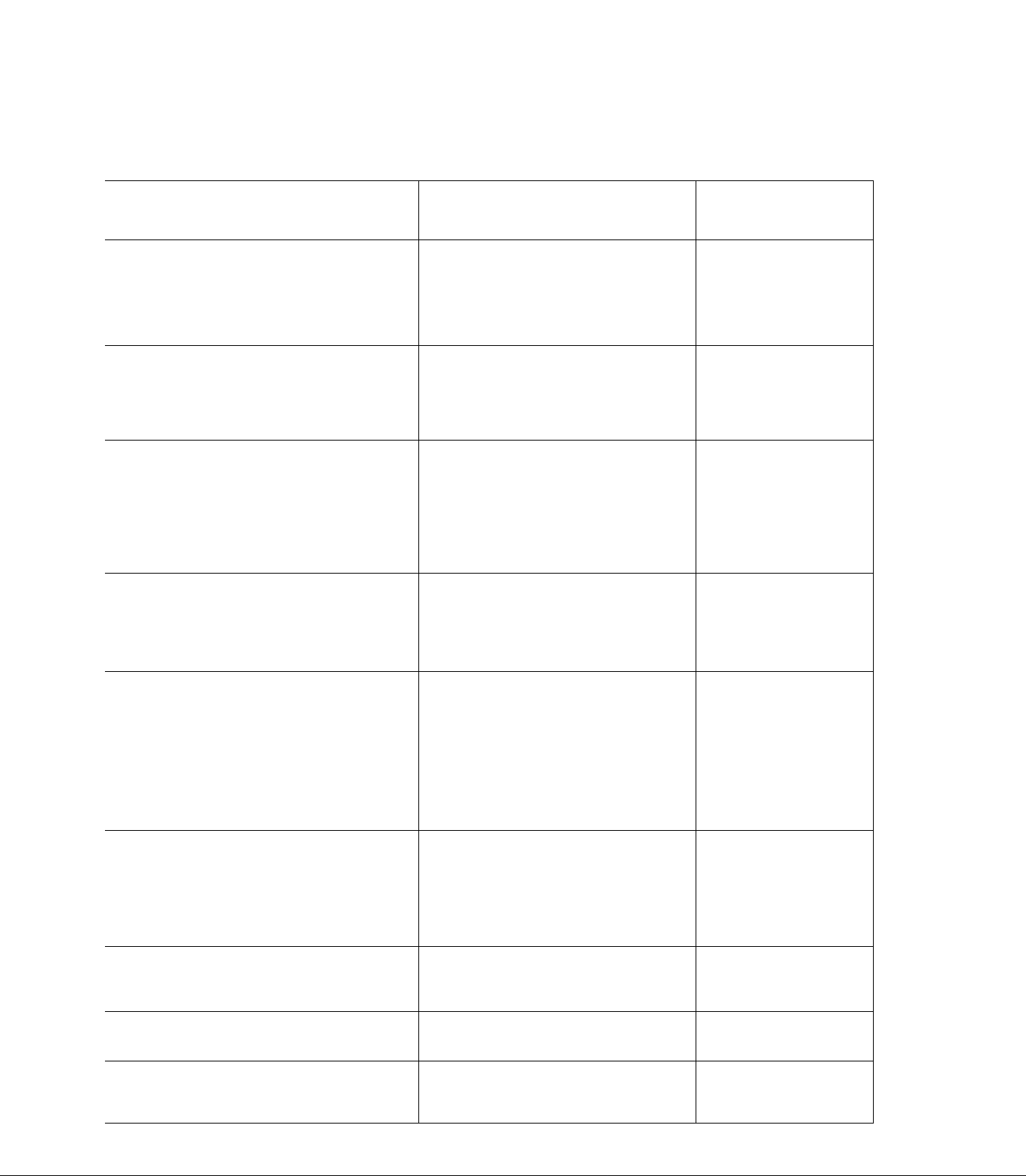

FABRIC, THREAD AND NEEDLE TABLE

Choosing the correct needle and thread for your fabric is of utmost importance. Correct choice

will make the difference in the wear and appearance of your new garment. The Fabric Weight

Table on the previous page, and the Fabric, Thread and Needle Table below are practical guides

to needle and thread selection. Refer to them before starting a sewing project. Be sure to use the

same size and type of thread In both needle and bobbin.

To select the correct needle and thread for your fabric, first refer to the Fabric Weight Table to

determine the weight and type of material you are using.

Next, refer to the Fabric, Thread and Needle Table.

TYPE

OF

FABRIC

SILK

RAYON

COTTON Fine Cotton

WOOL

THREADS NEEDLES

Fine Silk

Fine Mercerized 2020-9

Fine Silk

Fine Mercerized 2020-9

Fine Mercerized

FILMY

2020-9

SHEER

THREADS

Fine Silk

Fine Mercerized 2020-9

Fine Silk

Fine Mercerized 2020-9

Fine Cotton

Fine Mercerized 2020-9

NEEDLES

LIGHT

THREADS

Fine Silk

Fine Mercerized

Fine Silk

Fine Mercerized

Medium Cotton

Med. Mercerized

Fine Silk

Fine Mercerized

NEEDLES

2020-11

Woven

2045-11

Knit

2020-11

Woven

2045-11

Knit

2020-11

Woven

2045-11

Knit

2020-11

Woven

2045-11

Knit

SYNTHETIC Fine Synthetic

SYNTHETIC

BLENDS Fine Synthetic 2020-9

LEATHER

PLASTIC

VINYLS

2020-9

Fine Synthetic 2020-9

Fine Mercerized

Fine Synthetic

P020-9

8

2020-11

Woven

Fine Synthetic

2045-11

Knit

2020-11

Woven

Fine Synthetic

Med. Mercerized

Med. Synthetic 2032-11

Fine Mercerized

Fine Synthetic

2045-11

Knit

2020-11

Page 11

Find the fabric you are using in Type of Fabric column at left (silk, rayon, etc.). Then locate the

fabric weight column (filmy, sheer, etc.) for your fabric at top of table. Read across from Type of

Fabric column to correct weight of fabric column. There, the correct thread and needle choice for

your fabric will be found.

Example: If you are sewing a medium weight wool, find wool in Type of Fabric column. Read

across to Medium (weight) column and you will see that a medium silk or mercerized thread and a

size 2020-14 needle for woven fabric or size 2045-14 needle for knit fabric are to be used.

You should follow the recommendations in this instruction book and on the needle package for cor

rect style and size of needle for different types and weights of fabric.

MEDIUM

THREADS

Medium Silk

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Cotton

Medium Mercerized

Medium Silk

Medium Mercerized

NEEDLES

2020-11

2020-11

2020-14

Woven

2045-14

Knit

2020-14

Woven

2045-14

Knit

HEAVY

THREADS

Heavy Synthetic

Heavy Mercerized

Heavy Cotton

Heavy Mercerized

Heavy Mercerized

VERY HEAVY

NEEDLES THREADS

2020-14

Heavy Cotton

2020-16

2020-16 Heavy Mercerized

Heavy Mercerized

NEEDLES

2020-18

2020-16

Medium Synthetic

Medium Synthetic

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

2020-14

Woven

2045-14

Knit

2020-14

Woven

2045-14

Knit

2032-14

2020-11

Heavy Synthetic

Heavy Synthetic

Heavy Mercerized

Heavy Synthetic

Medium Mercerized

Medium Synthetic

2020-16

Woven

2045-16

Knit

2020-16

Woven

2045-16

Knit

2032-16

2020-14

Heavy Mercerized

Heavy Synthetic

Heavy Mercerized

Heavy Synthetic

2032-18

2020-16

Page 12

CONNECTING THE MACHINE

operating the machine

• Before plugging in your machine, be sure the

electrical information on the side of the

machine A, below the hand wheel, agrees

with the range marked on your electrical

meter.

• To turn on the machine, connect plug B to

machine and plug C to your socket outlet.

• To turn on the sewing light, press or turn

switch D as required. See illustration.

• To run the machine and control speed, press

the speed controller E with your foot. The

harder you press, the faster the machine will

sew.

CAUTION: Disconnect the power line plug from

the socket outlet when changing needles, feet or

needle plates or when leaving the machine unat

tended. This eliminates the possibility of starting

the machine by accidentally pressing the speed

controller.

IMPORTANT - Machines for Great Britain and some other countries having similar wiring standards are ship

ped from the factory without a plug for connection to the mains.

The wires in this mains lead are coloured In accordance with the following code:

Blue: Neutral (N)

Brown: Live (L)

As the colours of the wires in the mains lead of this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows:

The wire which is coloured blue must be connected to the terminal which is marked with the letter N or

coloured black.

The wire which is coloured brown must be connected to the terminal which Is marked with the letter L or

coloured red.

If a 13 amp (BS 1363) plug is used a 3 amp fuse must be fitted, or If any other type of plug Is used a 5 amp fuse

must be fitted either in the plug or adaptor or at the distribution board.

10

Page 13

the bobbin thread

Your sewing machine uses two threads to form a stitch. The upper thread comes from the spool

and is threaded through the eye of the needle. The lower thread comes from the bobbin. Wind the

bobbin before threading the machine.

• Place thread spool on left spool pin with

thread retaining slit B on top. (Break paper at

the end of spool if necessary).

• Lead thread around bobbin winder tension

disc C, as illustrated, and through small hole

in bobbin from inside out.

• Snap bobbin onto spindle and push bobbin to

right to engage bobbin winder.

Hold thread end, as shown, and start the

machine. Cut off thread end after a few coils

have been wound.

When required amount of thread has been

wound (winding will stop when bobbin is full),

stop the machine and cut connecting thread.

Push bobbin to left and remove bobbin from

spindle.

Hold hand wheel and tighten hand wheel

knob.

11

Page 14

REMOVING THE BOBBIN CASE

When you prepare to sew, wind the bobbin first,

then thread the machine.

To Remove the Bobbin Case and Bobbin —

• Turn hand wheel toward you to raise take-up

lever to its highest position.

1. Lift up cover plate A.

2. Grasp bobbin case latch B and withdraw

bobbin case.

• Release latch and bobbin will drop out of

case.

THREADING THE BOBBIN CASE

Page 15

REPLACING THE BOBBIN CASE

1. Hold bobbin case by latch, with about 7.5cm

(3 inches) of thread leading off top of case.

2. Align protruding finger A with slot B and

slide case on to stud C.

• Release the latch and push case until it

clicks into place. Allow 7.5cm (3 inches) of

thread to hang free from bobbin case.

• Close cover plate. Be sure thread does not

get caught when cover plate is closed.

ADJUSTING BOBBIN-THREAD TENSION

The bobbin-thread tension has been set at the

factory for most types of stitching. You may

wish to adjust the bobbin-thread tension when

straight stitching on fine fabrics or to balance

an open zig-zag stitch. Bobbin and needle

threads lock at the corner of each stitch when a

zig-zag stitch is balanced. To adjust the bob-

bin-thread tension, follow the procedure below

using two layers of scrap fabric.

• Raise the presser foot.

• Raise needle to highest position by turning

the hand wheel toward you.

• Open cover plate and remove the bobbin

case as instructed on page 12.

• Slowly turn screw D to the left, using the

small screwdriver in your accessory box,

until desired stitch appearance is reached.

• When stitching is completed, turn screw D to

the right, back to original position, for all

other sewing.

13

Page 16

threading the machine

• Raise the presser foot to release tension

discs and make sure needle is In highest

position.

• Place spool pin felts from accessories over

spool pins. Then place spool of thread on left

spool pin over felt, keeping spool thread re

taining slit A on top.

• Keep right hand on spool of thread to hold

firmly in place while threading machine.

• Place thread through thread guide 1, as

shown.

• Snap thread into thread guide 2.

• Pass thread through point 3.

14

• Thread the needle-thread tension 4. Slide

thread over metal plate into tension discs.

Lead thread under needle-thread tension and

tension wire by firmly pulling thread up and

over to the right.

• Pull thread to left behind point 5, guiding

thread up toward take-up lever.

• Thread take-up lever 6, as illustrated. Then

pass thread back down through point 5.

• Continue to guide thread through points 7

and 8, as shown.

• Thread needle from front to back and draw

about 10cm (4 inches) of thread through eye

of needle.

Page 17

RAISING THE BOBBIN THREAD

Now that you have wound the bobbin and threaded the needle, raise the bobbin thread

through the hole in the needle plate.

Page 18

Chapter 3. Straight Stitching

adjusting machine stitch to suit your fabric

Before you move the selectors to set your

machine for straight stitching, turn the hand

wheel toward you until the needle is above the

needle plate.

SETTING SELECTORS

• Needle Position: i. [JJ J,

• Stitch Width: f f | | [[]

• Stitch Length: 1.5-4 to suit fabric

16

REGULATING PRESSER FOOT

PRESSURE

The pressure regulator adjusts the pressure

that the presser foot exerts on the fabric. Cor

rect pressure is important because it enables

the fabric to feed smoothly and evenly, without

being marked.

The normal setting is being used when the

pressure regulator is in the middle position.

The normal setting is an all-purpose setting

that can be used for sewing a wide variety of

fabrics of different weights and textures.

Lower the foot before setting pressure

1. To increase pressure, slowly press down on

pressure regulator A until desired pressure

is reached.

2. To release pressure regulator, press down

on the round base B.

Page 19

ADJUSTING STITCH LENGTH

The stitch length dial controls the length of

stitches. The numbers around the edge of the

dial express stitch length in mm; the lower the

number, the shorter the stitch. Generally, shorter

stitches are best for lightweight fabric, longer

stitches for heavy fabric. The area from 0 to 1

is used for the adjustment of zig-zag satin

stitching (see page 22).

Setting the Dial

• Turn dial so that stitch length desired is posi

tioned under • symbol.

• To shorten stitch length, turn dial to the left

toward a lower number.

• To lengthen stitch length, turn dial to the

right toward a higher number.

For reverse stitching, depress push button lo

cated in centre of dial, hold in until reverse

stitching is completed, then release push but

ton.

NEEDLE-THREAD TENSION

Correct tension is important because too much

or too little will weaken your seams or cause

your fabric to pucker. Make a test sample with

the fabric and the thread you plan to use and

examine it. A well balanced stitch, as shown In

illustration A, will have; the needle and bobbin

threads locked between the two layers of fabric

with no loops on top or bottom and no pucker.

The tension dial regulates the degree of ten

sion on your needle thread. Set It according to

the type of thread and fabric you use. The num

bers on the dial eliminate guesswork.

If the fabric puckers B, decrease tension. If the

stitches in your test sample look loose C, in

crease needle-thread tension.

• To decrease tension, turn dial to lower num

ber.

• To increase tension, turn dial to higher num

ber.

BOBBIN-THREAD TENSION

For Information on adjusting bobbin-thread

tension, refer to page 13.

Page 20

sewing a seam

• Needle Position: JL 1_^ JL

• stitch Width; t 1 I I ill

• Stitch Length: To suit fabric

• General Purpose Needle Plate

• General Purpose Foot

1. Raise presser foot. Pull thread back under

presser foot leaving at least 10cm (4 Inches)

of thread.

2. Position needle approximately 1.3cm (1/2

inch) from fabric edge. Then lower presser

foot and backstitch almost to the edge of the

fabric for reinforcement by stitching in

reverse direction. For additional Information

on reverse stitching refer to page 17. Stitch

forward to end of seam and stop machine

before the end of stitching line. (Do not sew

beyond edge of fabric).

CAUTION: Do not pull the fabric while you are

stitching as this may deflect the needle caus

ing it to break.

3. Raise needle by turning hand wheel toward

you. Press reverse stitch push button, and

back stitch 1.3cm (1/2 inch) to reinforce

end of stitching.

4. Raise needle by turning hand wheel toward

you. Raise foot and remove fabric by drawing

it to the back and to the left. Cut threads on

thread cutter at rear of presser bar.

KEEPING THE SEAM STRAIGHT

For extra help In keeping the seam straight, you

may wish to use the seam guide. Because it

allows you to guide stitches evenly between

1.3cm (1/2 inch) and 3.2cm (1-1/4 inches)

from the fabric edge, it is particularly useful for

very narrow or very wide seams.

CAUTION: Because of the up and down move

ment of the needle, you must work carefully and

watch the sewing area when operating the

machine.

Page 21

applications

ZIPPER INSERTION

How the zipper is inserted will depend on the

type of garment and the location of the zipper.

With the adjustable zipper foot, you will find it

easy to sew an even line of stitching close to

the zipper.

The zipper foot can be used either to the left or

right of the needle, depending on where the

bulk of the garment is placed.

Adjusting the Zipper Foot

• Set machine for straight stitching.

• Attach the zipper foot as instructed on page 4.

When the zipper is to the right of the needle:

• Loosen the thumb screw at the back of the

foot, and slide the foot to the left of the nee

dle.

• Check the position of the foot by turning the

hand wheel to lower the needle into the side

notch of the foot, making sure it clears the

foot.

• Lock the foot into position by tightening the

thumb screw.

• Lower presser bar. Make sure the needle

clears the foot on all sides of the notch.

When the zipper is to the left of the needle, ad

just the foot to the right of the needle in the

same way.

DARNING WITH AN EMBROIDERY HOOP

• Needle Position: JL

• Stitch Width: ^ ^ | | [T|

• No Presser Foot

• Snap-in Feed Cover

• Embroidery Hoop Designed for Machine Use

• Position work under needle and lower presser

bar.

• Hold needle thread loosely with left hand,

turn hand wheel toward you, and draw bobbin

thread up through fabric. Hold both thread

ends and lower needle into fabric.

• Stitch across opening, moving hoop under

needle at a slight angie from lower left to up

per right. Keep lines of stitching cioseiy

spaced and even in length. When opening is

filled, cover area with crosswise lines of

stitching.

19

Page 22

Chapter 4. Basic Zig-Zag Stitching

adjusting machine stitch to suit your fabric

You can do functional as well as decorative zig

zag stitching with your sewing machine.

setting selectors

Before turning selector, make sure needle is out

of the fabric.

For plain zig-zag stitching:

• Needle Position: «L J»

• Stitch Width:

• Stitch Length: 1-4 to suit fabric

• General Purpose Needle Plate

• General Purpose Foot

NEEDLE POSITION SELECTOR

Before moving selector, make sure needle is out

of the fabric.

Most of your zig-zag stitching will be done In

centre J. needle position.

Left L and right A settings are used for special

stitch placement.

STITCH WIDTH SELECTOR

Before turning selector, make sure needle is out

of the fabric.

20

To produce a plain zig-zag or a decorative

stitch, the stitch width selector is turned from

Its straight stitch position i to any of Its other

four positions. The further you turn the selector

toward the right, the wider your stitch will be.

Page 23

ADJUSTING NEEDLE-THREAD

TENSION

Zig-zag stitching requires less needle-thread

tension than straight stitching.

Make a test sample with the fabric and thread

you plan to use so that you can adjust the ten

sion properly. The stitches should lie flat

against the fabric without causing the fabric to

pucker.

If the stitches are not flat and the fabric Is

puckered, lower the needle-thread tension by

turning the dial to a lower number.

ADJUSTING STITCH LENGTH

Any stitch length setting from 1 to 4 will give

you an open zig-zag stitch.

The higher the number, the more open, or

farther apart your stitches will be.

The area between 0 and 1 on the dial is used

for the adjustment of zig-zag satin stitching, a

series of closely spaced plain zig-zag stitches

that form a smooth, satin-like surface. (Refer to

page 22 for information on satin stitching.)

ADJUSTING PRESSER FOOT PRESSURE

See page 16 under “Straight Stitching”.

Page 24

satin stitching

When you wish to produce a satin stitch, make

a test sampie first so you can adjust stitch

iength and thread tension properiy. Soft fabric

may*require a backing to ensure a firm stitch.

Crisp organdy, iawn or a fusible interfacing are

suitable for this purpose.

Accessory and Selector Settings

• Needle Position; J« J. J.

• Stitch Width:

• Stitch Length; 0 to 1

• General Purpose Needle Plate

• General Purpose Foot

ADJUSTING STITCH LENGTH

Incorrect

• Turn stitch length selector dial to 1.

• Run the machine at a slow speed and slowly

turn stitch iength dial toward the left until

stitches are closely spaced and form a

smooth surface.

ADJUSTING NEEDLE-THREAD

TENSION

Satin stitching requires less tension than

straight stitching or open zig-zag stitching.

Furthermore, the wider the stitch, the lighter the

tension on the thread must be. Notice the

stitching on your sampie. if the fabric is

puckered, lower the needle-thread tension by

turning the tension dial to a lower number.

22

Correct

Page 25

applications

APPLIQUÉ

Appliqué adds beauty and interest to clothing and household linens. You can create your own

design, trace a simple outline from a colouring book, or use a motif cut from a printed fabric.

Fabric of similar or different textures combine equally well.

A closely spaced plain zig-zag stitch, commonly referred to as a satin stitch, is used for appliqué

work. Although you may vary stitch width to accommodate fabric weave and texture, never allow

the stitch to be too wide.

Make a test sample to help you decide which of the following methods is best for your fabric and

design.

• Needle Position: im [A] J.

• Stitch Width: To suit fabric

• Stitch Length: Between 0 and 1

• General Purpose Needle Plate

• General Purpose Foot

Preparation

• Baste appliqué design to fabric and outline

the design with a short, straight stitch.

• Remove basting and press.

Method 1 - Trimming after Stitching

• Set machine as code recommends.

• Outline the entire design with satin stitching.

• Cut away the fabric or the outer edges of the

stitching with embroidery scissors.

Method 2 - Stitching after Trimming

• Trim outside fabric edges close to straight

stitch outline of design.

• Set machine as code recommends.

• Overedge the design with satin stitching. This

step will produce a smooth, lustrous finish

that requires no additional trimming.

23

Page 26

Chapter 5. Twin-Needle Stitching

The twin-needle simultaneously produces two

parallel, closely spaced lines of pattern stitch

ing. You can stitch with either one or two col

ours of thread.

Twin-needles No. 2011 must be purchased

separately at your local Sewing Centre.

• Needle Position: .L [JJ A only

I only ^• stitch Width:

• Stitch Length: .5 - 4 to suit fabric

• General Purpose Needle Plate

• General Purpose Foot

Procedure

• Insert twin-needle.

• Thread as for single-needle stitching, except

pass thread between centre and back tension

discs A, and through left eye of needle.

• Place second spool of thread on right spool

pin and felt.

• Thread machine in usual way, except pass

thread from second spool between centre and

front tension discs B, as shown.

• Thread through remaining points, making

certain to omit the thread guide above the nee

dle and pass thread through right eye of nee

dle.

A CAUTION: Do not use a stitch width greater than what is recommended. A wider stitch will result in needle breakage.

24

Page 27

Chapter 6. Performance Checklist

Whenever sewing difficulty is encountered, review the sections of the instruction book that ex

plain the operation you are performing to make sure you are using the machine correctly. If the

problem still exists, the following checklist may help you to correct it.

If you still have difficulties, call your nearest Sewing Centre.

What To Do If:

Needle Breaks Refer to Page:

Make sure...

• Needle Is fully Inserted into needle clamp......................................................

• Needle is not being pulled to one side as fabric is removed from the machine ........................................... 18

• Presser foot or accessory Is securely fastened to presser bar.............................................................................. 4

• Fabric is not being pulled while sewing causing needle to hit needle plate

Thread Breaks

Make sure...

• Machine is properly threaded

• Needle-thread tension is not too tight .................................................................................................... 17, 21,22

• Thread is unwinding freely from spool

• Bobbin case area is free of lint and loose thread ends........................................................................................ 26

.............................................................................................................................

......

................................................................................................... 11,14

............

........................................................

........................................ 4

18

14

Machine is Noisy or Sluggish

Make sure...

• Bobbin case and feed area are free of lint and loose thread ends

Fabric Does Not Feed Properly

Make sure...

• Presser foot or accessory is correctly attached to machine................................................................................. 4

• Stitch length dial is correctly set.............................................................................................................. 17, 21,22

• Lint has not accumulated around feed ................................................................................................................ 27

Skipped Stitches

Make sure...

• Needle is correct style for machine and size for thread..................................................................................... 8, 9

• Machine is correctly threaded

• Needle Is securely fastened to needle bar .............................................................................

Fabric Puckers

Make sure...

• Needle-thread tension is not too tight ...................... ............................................................................. 17, 21,22

Needle thread breaks while winding bobbin

.....................................................

..................................... ........................

............

............................................................

............................

26, 27

14

4

Make sure...

• Machine is correctly threaded

• Thread is unwinding freely from spool

Thread does not wind onto bobbin

Make sure...

• Bobbin winder spindle is pushed to right.............................................................................................................. 11

..................

......

...................................................................................................... 11,14

................................................................................................... 11,14

25

Page 28

Chapter 7. Caring for Your Machine

CLEANING

AND OILING YOUR

MACHINE

CAUTION: Before cleaning your machine, dis-

connect power line plug from your socket outlet.

Periodically, depending on usage, clean and oil

your machine as follows, using one drop of oil

on areas indicated:

• Top Interior Areas

To clean and oil top of machine, remove top

cover. Using a large screwdriver, remove

screws A and B. Periodically, apply a drop of

oil only to areas indicated, after cleaning.

To replace top cover, align it over screwholes

A and B. Using a large screwdriver, replace

screws A and B.

• Face Plate Area

To clean and oil the front interior of machine,

swing open face plate to left. With a soft cloth

or lint brush, clean and oil points indicated by

arrows. To close face plate, simply swing it

back to right and snap it closed.

Face Plate Area

6

• Bobbin Case Holder

To clean and oil bobbin case holder:

• Tilt machine back. Remove cover, if neces

sary.

• Turn hand wheel until needle is at highest

position.

1. Remove bobbin case and open latches A

and B, as shown. For more Information on

removing and replacing bobbin case, refer to

pages 12 and 13.

2. Remove part C and part D of Bobbin Case

Holder, as shown.

3. Clean and oil areas indicated by arrows.

4. To replace bobbin case holder, insert part D

with spindle E up, as shown.

5. Then fit part C into place with flat side up, as

removed.

6. Close latches A and B over part G.

26

• Replace cover, if necessary.

Removing Bobbin Case Holder

Page 29

• Bobbin and Feed Areas

To clean bobbin and feed areas, remove nee

dle plate, as instructed on page 5. Using soft

cloth or brush, clean area as illustrated.

Replace needle plate, as instructed on page 5.

• Exterior Areas

If necessary, a mild solution of soap and

water may be used on exterior areas to

remove stubborn stains. No other cleaning

liquid or powder should be used.

CHANGING THE LIGHT BULB

CAUTION: Before changing light bulb make sure

you have disconnected power line plug from

socket outlet.

Removing Bulb

CAUTION: This machine is designed to use a 15

watt maximum bayonet base bulb only.

Replacing Bulb

• Swing open face plate to left.

• Do not attempt to unscrew the bulb.

• Press it up into the socket and at the same

time turn bulb over in direction shown to

unlock the bulb pin and guide out of socket.

• Press new bulb into socket, with bulb pins en

tering slot of socket.

• Turn it over in direction shown to lock bulb in

position.

• Swing face plate back to right and snap it

closed.

27

Page 30

Index

Accessories........................................................... 3

Applique'

Bobbin

Bobbin Case............................................. 12,13,26

Bobbin Thread

Caring for Your Machine

Cieaning the Machine

Connecting the Machine

Cover Piate ............................................... 2, 5, 12

Darning ........................................................... 19

Fabric, Thread and Needle Table

Fabric Weight Table......................................... 6, 7

Face Plate

Feed....................................................................... 2

Feed Cover Plate

Hand Wheel

Hand Wheel Knob ......................................... 2, 11

Light Bulb

Light Switch ................................................... 2, 10

Lubrication........................................................... 26

Needle.................. 2, 4, 6, 7, 14, 17, 21,22, 24

Needle, Fabric Combinations

Needie Plates

.............................................................

...................................................................

Winding

Removing

Threading....................................................... 12

Replacing

Raising .......................................................... 15

Tension

Removing and Repiacing

Attaching and Removing

Changing

Thread and Fabric Table

Thread Tension................................... 17,21,22

Thread Tension Dial .... 2, 17, 21,22, 24

Threading

Twin ............................................................... 24

Changing Plates.............................................. 5

.........................................................

.....................................................

.....................................................

.............................................

.........................................................

....................................

.................................

...........

.....................................................

......................................

..........................................................

............................................................

........................................................

...

...........................................

.............................................

......................... 10

..............................

..................

................................

............................

.........................

23

11

12

13

13, 15

13

26

26, 27

5

8, 9

2, 26

3, 5, 19

5

2

27

6,7

14, 24

8, 9

2, 3, 5

General Purpose ............................................ 3

Needle Position Selector

3

4

Setting

Operating the Machine ...................................... 10

Oiiing the Machine

Performance Checkiist ...................................... 25

Piacing Fabric under Foot

Presser Feet

Changing Feet................................................. 4

Generai Purpose Foot ............................... 3, 4

Zipper Foot................................................ 3, 19

Presser Foot Lifter.......................................... 2, 18

Pressure Adjustment

Pressure Regulator ...................................... 2 ,16

Principal Parts

Reverse Stitching

Reverse Stitching Push Button

Satin Stitching .................................................... 22

Seams

Straight

Seam Guide .................................................... 3, 18

Sewing Light............................................. 2, 10, 27

Speed Controller

Stitch Length

Selector

Stitch Width.................................................... 16, 20

Selector

Straight Stitching

Adjusting Selector.................................... 16, 17

Take-up Lever ...................................................... 2

Thread Cutter ....................................................... 2

Thread, Fabric and Needle Table

Threading the Machine

Top Cover

Twin-needle Stitching ........................................ 24

Zig-zag Stitching ........................................... 20, 21

Adjusting Selectors.................................. 20, 21

Zipper Insertion ................................................ 19

...................................................

................................................

.....................................................

..............................................

...............................................................

..........................................................

............................................

..........................................

.....................................

..............................................

........................................

...........................................................

......................

............................................

................................

....................................

.....................

2, 17, 2 1,22

..................

................................

2, 16, 20

16, 20

26

18

2, 3, 4

16, 21

2

17

2, 17

18

18

2, 10

17, 21,22

2, 16, 20

16,17

8, 9

14, 24

26

28

To ensure that you are always provided with the

most modern sewing capabilities, the Manufacturer

reserves the right to change the appearance, design

or accessories of this sewing machine when con

sidered necessary.

‘A Trademark of THE SINGER COMPANY

Page 31

Page 32

Loading...

Loading...