Page 1

Operator's

SINGER*

Guide

457U105,457U125,457U135,457U140

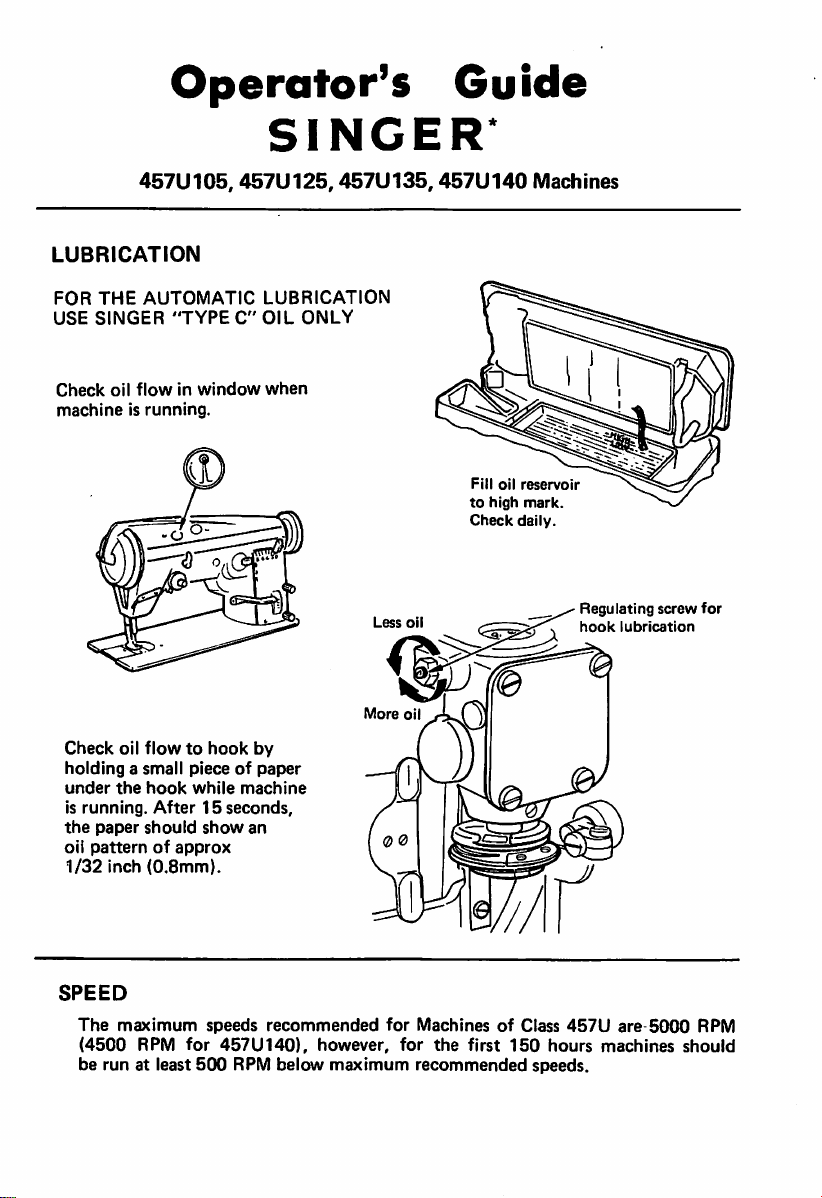

LUBRICATION

FOR

THE

USE

Check

machineisrunning.

Check

holding

under

is

running.

the

oil

1/32

AUTOMATIC

SINGER

oil

"TYPE

flowinwindow

oil

flowtohook

a small

the

hook

After15seconds,

paper

should

patternofapprox

inch

(0.8mm).

LUBRICATION

C"

OIL

when

by

pieceofpaper

while

machine

show

an

ONLY

Less

More

Machines

Fill

oil

reservoir

to

high

mark.

Check

daily.

oil

Regulating

hook

screw

lubrication

for

©

oil

SPEED

The

(4500

be

maximum

RPM

runatleast

speeds

for

500

recommended

457U140),

RPM

below

however,

maximum

©

for

MachinesofClass

for

the

first

recommended

150

457U

hours

speeds.

are

5000

machines

RPM

should

Page 2

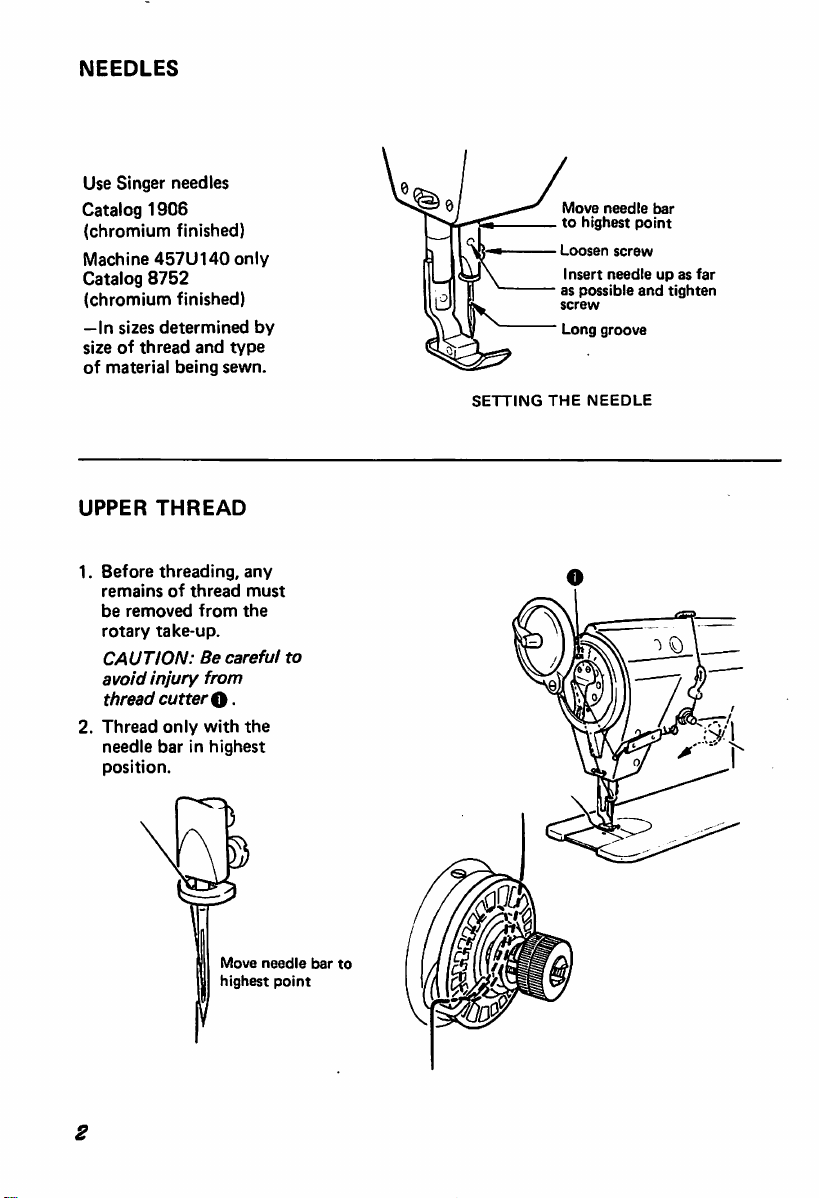

NEEDLES

Use

Singer

Catalog

1906

{chromium

Machine

Catalog

457U140

8752

(chromium

—In

sizes

determined

sizeofthread

of

material

needles

finished)

finished)

and

being

only

type

sewn.

by

SETTING

Move

to

Loosen

Insert

as

screw

Long

THE

needle

highest

screw

needleupas

possible

groove

NEEDLE

bar

point

and

far

tighten

UPPER

1.

THREAD

Before

threading,

remainsofthread

be

removed

rotary

from

take-up.

CAUTION:Becareful

avoid

injury

from

thread

cutter

2.

Thread

needle

only

with

barinhighest

position.

O •

Move

highest

any

must

the

the

needle

point

to

bar

to

Page 3

BOBBIN

REMOVAL

AND

REPLACEMENT

REMOVAL

1.

Open

latch

2.

Hold

latch

and

pull

bobbin

case

from

3.

Release

4.

Bobbin

REPLACEMENT

latch

drops

out

5. Holding latch, replace

6.

7.

bobbin

Press

catches

Release

caseonstud

latch

back

until

grooveinstud

latch

hook

BOBBIN

WINDER

Wind

around

thread

bobbin

O

Place

far as it will go

bobbinon spindleas

Press

lever

against

bobbin

Page 4

THREADING

BOBBIN

CASE

THREAD

TENSIONS

BOBBIN

THREAD

0 Pull thread

into

Use

slotO

Use

slot

Draw

and

slot

when

©when

thread

under

down

spring

o Drawthread up

Into

sewing Light-weight material.

sewing

medium-weight

NEEDLE

delivery

Lead

into

bobbin

material.

THREAD

eye

thread

slot

in

case

Tensiononthreads

be as lightas possible,

sufficienttoset

correctlyinmaterial.

4

stitch

should

while

More

Tension

Less

Tension

still

Regulate needle

tension

only

when

thread

presser

More

tension

Less

tension

footisdown.

Page 5

STITCH

LENGTH

REGULATION

457U105,457U125,457U135

MACHINES

STITCH

457U140

LENGTH

MACHINE

TILT

Loosen

MACHINE

lock

nut

REGULATION

TO

REAR

REVERSE

Turn

regulating

to

desired

FORWARD

Turn

regulating

to

desired

CHANGING

Push

lever

reverse

feeding

for

forward

FEEDING

stitch

FEEDING

stitch

TO

down

feeding.

screw

length

screw

length

REVERSE

for

and

release

FEED

Shift

connecting

To

left—longer

To

right—shorter

Tighten

RETURN

TO

SEWING

lock

nut

MACHINE

rod:

POSITION

Page 6

ZIG-ZAG

457U105

STITCH

MACHINE

Set

stitch

SETTING

hand

levertodesired

within

0-8

bight

zig-zag

range

ZIG-ZAG

NEEDLE

Set

positions

Left:

STITCH

hand

Center:

POSITIONING:

levertodesired

SETTING

457U125,457U135,457U140

457U125

Set

stitch

hand

levertodesired

within

MACHINE

457U135,457U140

Set

hand

levertodesired

stitch

within

Locking

bight

0-5

bight

0-8

bight

needle

Right:

MACHINES

screw

control

for

lever

zig-zag

range

MACHINES

zig-zag

range

Page 7

PRESSER

FOOT

PRESSURE

The

pressureonthe

lightaspossible,

ensure

correct

CLEANING

Clean

out

the

hook,

undersideofthe

hook

areaofthe

material

while

feeding.

any

lintorother

between

still

the

throat

oil

should

sufficient

feed

plate

pan.

be as

to

waste

around

rowsonthe

andinthe

pressure

More

pressure

* A

Copyright

TrademarkofTHE

©1987

All

SINGER SEWING MACHINE COMPANY

Rights

Reserved

SINGER

Throughout

COMPANY

The

World

Page 8

Form

U3150

Part

No.

543182-002

PrintedinJapan

(Rev.

990)

(Rev.

2)

Loading...

Loading...