SINGER 29K73 User Manual

s

emce

anua

and

Parts List

mi\, 29K72 and 29K73

THE SINGER MANUFACTURING COMPANY

USE SINGER" OILS

and LUBRICANTS

They insure freedom from lubricating trouble and give

longer life to sewing equipment

The following are the correct lubricants for this machine:

TYPE B — MANUFACTURING MACHINE OIL, HEAVY GRADE

When an oil is desired which will produce a minimum of

stain on fabrics, even after a long period of storage, use:

TYPE D — MANUFACTURING MACHINE OIL, HEAVY GRADE

OTHER SINGER LUBRICANTS

TYPE E —THREAD LUBRICANT

For lubricating the needle thread of sewing machines for

stitching fabrics or leather where a thread lubricant is

required.

TYPE F-MOTOR OIL

For oil lubricated motors and plain bearings in power

tables and transmitters.

NOTE: All of the above oils are available in 1 quart,

1 gallon and 5 gallon cans.

GEAR LUBRICANT

This specially prepared grease is recommended for gear

lubrication on manufacturing sewing machines.

BALL BEARING LUBRICANT

This pure grease is specially designed for the lubrication

of ball bearings and ball thrust bearings of motors and

electric transmitters, ball bearing hangers of power tables,

etc. Furnished in 1 lb. and 4 lb. tins.

Form 20870

(957)

Printed in U.S.A.

SERVICE MANUAL

AND

PARTS LIST

FOR

SINGER

29K71, 29K72 and 29K73

UNIVERSAL UPPER FEED MACHINES

SINGLE NEEDLE LOCK STITCH

THE SINGER MANUFACTURING COMPANY

Copyright © 1958 by The Singer Manufacturing Company

*A Trademark of THE SiNGER MANUFACTURING COMPANY

FOREWORD

This book contains complete information covering operation, adjustment,

and parts list, for Machines 29K71, 29K72 and 29K73. Descriptions and exploded

viev/s of all parts assemblies on pages 17 to 44 inclusive, v/ill be found helpful

when ordering any part of the machine requiring renewal.

DESCRIPTION

Machines 29K71, 29K72 and 29K73, for stitching boots, shoes, and other tubular work in leather and

fabrics, have the following characteristics:

Single Needle, Lock Stitch.

Stop Motion Hand Wheel—releases hand wheel from stitching mechanism for bobbin winding.

Horizontal Oscillating Shuttle.

Eccentric Adjustment for Shuttle Timing.

Cylinder Bed.

Replaceable Steel Horn.

Universal Upper Feed for Stitching in any direction without turning the work.

Stitch Length: 7 to 1 5 to the inch, depending on material being stitched and operations performed.

Presser Foot rise during feeding action; 1/4 inch — (Maximum clearance: 3/8 inch).

Double End Needle Plate — (two sizes of needle holes at each end for various sizes of needles).

Adjustable Thread Take-up Lever.

Two Speed Machine Pulley.

ACCESSORIES AVAILABLE UPON ORDER

(at additional charge)

Attachment for fitting Hand Wheel on front of machine (Part No. 82121).

Stand for mounting the machine

Detachable Work Table for flat stitching operations (Part No. 83739, 83740, or 83741).

Electric Transmitter S-9.

601405 or 601407 for foot power.

^601406 or 601 408 for elfectric power.

SPECIAL FEATURES

MACHINE 29K71

End of cylinder bed is 1 inch wide and 7/8 inch deep.

Space at right of needle 12-1/4 inches.

Diameters of belt grooves 2-7/8 inches and 4-7/8 inches.

MACHINE 29K72

End of cylinder bed is 1 -5/32 inches wide and 1-1/16 inches deep.

Space at right of needle 17-1/2 inches.

Diameters of belt grooves 3-1/4 inches and 5-1/2 inches.

Large Bobbin.

MACHINE 29K73

End of cylinder bed is 1 inch wide and 7/8 inch deep.

Space at right of needle 17-1/2 inches.

Diameters of belt grooves 3-1/4 inches and 5-1/2 inches.

SPEED

The maximum speed recommended for these ma

chines is 500 stitches per minute, depending on ma

terial being stitched and operations performed.

For thick work, patching, mending, and stitching

elastics, put the driving belt on the larger pulley of

the machine and the smaller pulley of the stand.

//

For light work, put the belt on smaller pulley of the

machine and the larger pulley of the stand.

When in operation, the hand wheel must always

turn over toward the operator (counter-clockwise).

NOTE: If fitted on front of machine, hand wheel must

always turn over toward the right (clockwise).

TO OIL MACHINE

/ /

//

\ \

/

Fig. 3. Oiling Rear of Machine

Use "TYPE B" or "TYPE D" OIL, sold by Singer Sew

ing Machine Company.

See inside front cover of this book for description of

these oils.

Fig. 2. Oiling Front Side of Machine

When machine is received from the factory, it should

be thoroughly cleaned and a drop of oil should be

applied to all parts indicated in Figs. 2, 3 and 4.

Apply a drop of oil to the stand at the centers upon

which band wheel and treadle work. Also to both

ends of the pitman rod connecting the treadle with

band wheel.

Run machine for a few minutes to work oil into

bearings. When the machine is in constant use, it

should be oiled daily.

Fig. 4. Oiling Shuttle Race

To oil shuttle race, raise needle bar to its highest

point and lift feeding foot A, Fig. 5 by moving lifter B

upward.

Press down lever C, Fig. 5 and swing needle plate

to position shown in Fig. 4.

Apply a drop of oil to the face of shuttle race and

to the hole shown by arrow in Fig. 4.

TO OPERATE THE MACHINE

NEEDLES

1. Raise feeding foot A, Fig. 5 by moving lifter B

upward.

2. Place both feet upon the treadle.

3. Turn top of hand wheel over toward you to

start machine. (If hand wheel is fitted on front of

machine, turn top of hand wheel from left to

right to start machine.)

4. Allow the feet to move freely with the motion

of the treadle. Continue this motion with an

alternating pressure of heel and toe until a

regular easy movement is acquired and the

hand wheel is kept in continuous rotation by use

of the feet alone.

5. When familiar with the treadle movement, and

you are able to re-start the machine without

turning the hand wheel in the wrong direction,

place a piece of material under the feeding foot.

6. Lower feeding foot by lowering lifter and oper

ate machine until you have become accustomed

to guiding the material.

Material is moved along by the feeding foot only,

and, the direction of stitching can be changed as de

sired, by turning wings. Fig.32. To make a curved line

of stitching, operate machine slowly and, without

turning work, turn the revolving wings enough to pro

duce the desired curve.

Feeding foot rises between each stitch while needle

is in the material. With needle serving as pivot, ma

terial can be turned in any direction. When desired,

the feeding foot may be fixed to work in a straight

line, in any direction, by tightening the knurled screw

A, Fig. 22.

Never turn the work or alter the direction of the

feed while the foot is pressing on the material, as this

may cause missed stitches and damage the surface

of the work.

Needles for MACHINES 29K71, 29K72 and 29K73

are of Class and Variety 29 x 3 for cloth and 29 x 4

for leather. Needles 29 x 3 are made in sizes 11, 14,

16, 17, 18, 19, 21, 22, 23, 24 and 25, Needles 29 x 4

are made in sizes 9, 11, 14, 16, 18, 19, 21, 22, 23,

24 and 25.

The above needles regularly have nickel finish but

can be supplied with chromium finish if ordered.

The size of the needle to be used should be deter

mined by the size of the thread which must pass freely

through the eye of the needle. Rough or uneven thread,

or thread which passes with difficulty through the eye

of the needle will interfere with the successful use

of the machine.

Orders for needles must specify the Quantity re

quired, the Size number, also the Class and Variety

numbers separated by an x.

The following is an example of an intelligible order:

"100 No. 16, 29 X 3 Needles", for cloth.

"100 No. 16, 29 X 4 Needles", for leather.

The best stitching results will be obtained by using

the needles sold by Singer Sewing Machine Company.

THREAD

Left twist thread should be used in the needle.

Either right or left twist thread can be used for the

bobbin.

A^

C

Í

Fig. 5. Operating Machine

1

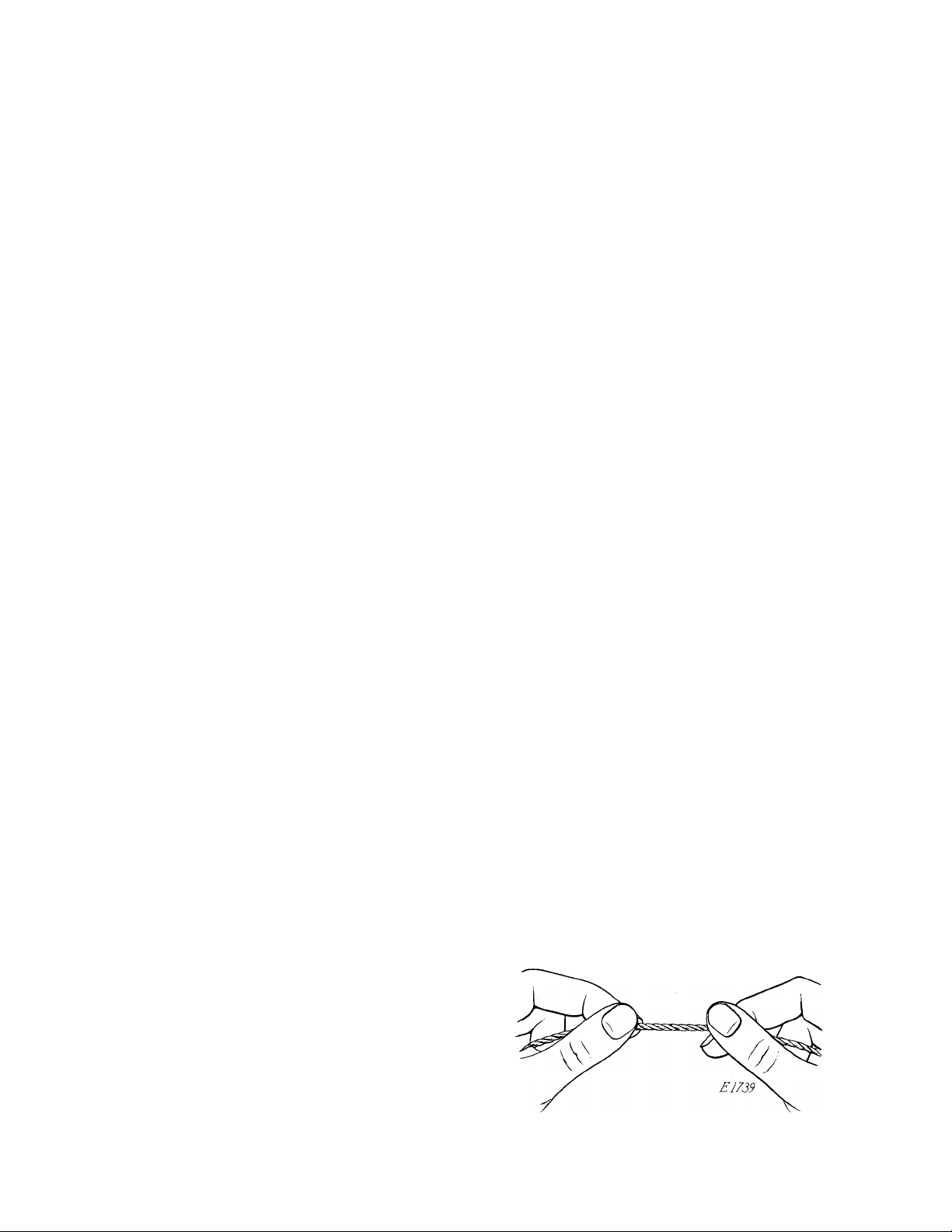

To determine the twist, hold the thread as shown.

Turn the thread over toward you between the thumb

and forefinger of the right hand; if left twist, the

strands will wind tighter. If right twist, the strands

will unwind.

Fig. 6. Determining Twist of Thread

TO REMOVE THE BOBBIN

Raise needle bar to its highest point and lift feeding

foot A, Fig. 7 by moving lifter B, Fig. 5 upward.

Press down lever C, Fig. 7 and swing needle plate

around as shown.

Turn hand wheel until point of shuttle is nearest

operator, then lift out shuttle with thumb and fore

finger.

Turn shuttle over and bobbin will drop out.

NOTE: For 29K72 machine, move bobbin retaining

spring D, Fig. 7 outward before taking out the bobbin.

f

D/

¡y

C

Fig. 8

NOTE: If hand wheel and bobbin winder are fitted

on front of machine, the slot in the side of the bobbin

must face to the outside. The top of hand wheel must

then turn over to the right (clockwise) as when sewing

to insure properly wound bobbins.

When bobbin is sufficiently full, remove it from the

spindle. Loosen thumb screw D, Fig. 9 on the winder

and move screw upward in slot until the rubber ring

is out of contact with the hand wheel, then tighten

thumb screw.

Fig. 7. Taking out th« Shuttle

TO WIND THE BOBBIN

Disengage hand wheel from operating stitching

mechanism by drawing out plunger F, Fig. 8 and

turning it slightly to left or right.

Place spool of thread on the spool pin and pass

end of thread through the center slot or hole in the

bobbin. Then press the bobbin, with slot in the side of

the bobbin facing to the left, as far as it will go,

on bobbin winder spindle.

Loosen thumb screw D, Fig. 9 on bobbin winder and

push it down until the rubber ring presses against the

rim of the hand wheel, then tighten screw.

Turn hand wheel over toward you as when sewing

and simultaneously guide the thread with the finger

as shown in Fig. 9.

Fig. 9. Winding the Bobbin

Re-engage the hand wheel v/ith the stitching me

chanism by turning plunger F, Fig. 8 slightly while

simultaneously turning the hand wheel slowly until

the plunger enters the hole in the inner disc.

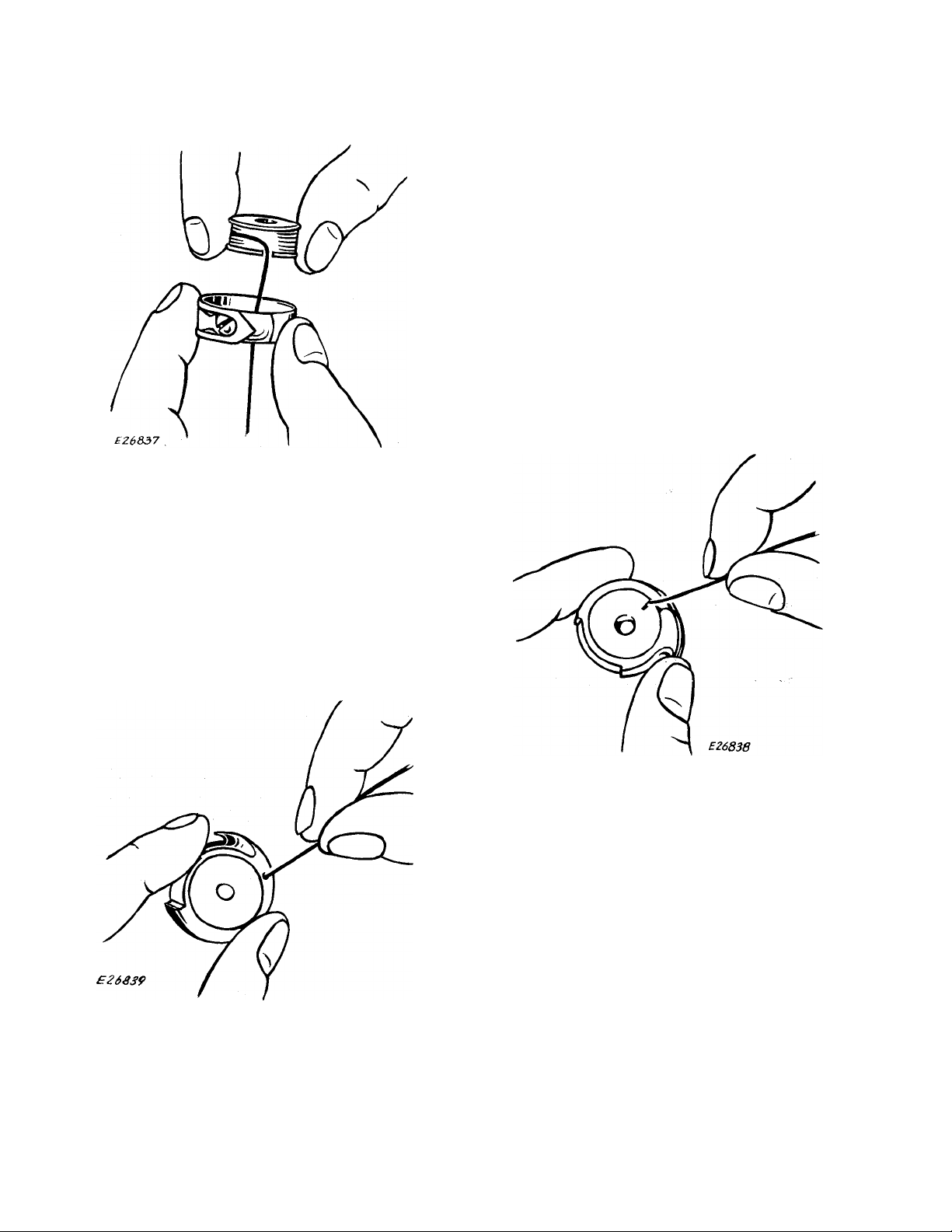

TO THREAD THE SHUTTLE FOR 29K71 AND 29K73

Hold the bobbin between the thumb and forefinger

of right hand, the slot in the edge of the bobbin being

at the bottom. Allow two or three inches of thread to

hang free.

Hold the shuttle in the left hand with the wide

opening uppermost. Let end of thread pass 'through

shuttle opening, then place bobbin into shuttle. See

Fig. 10.

Fig.lO

Turn shuttle over while holding bobbin in it and

draw the thread into the slot in the edge of the shuttle

and under the end of the tension spring. See Fig. 11.

Fig. 11

Pass the thread through delivery eye which is in

the upper edge of the shuttle. See Fig. 12.

Fig. 12

Fig. 13

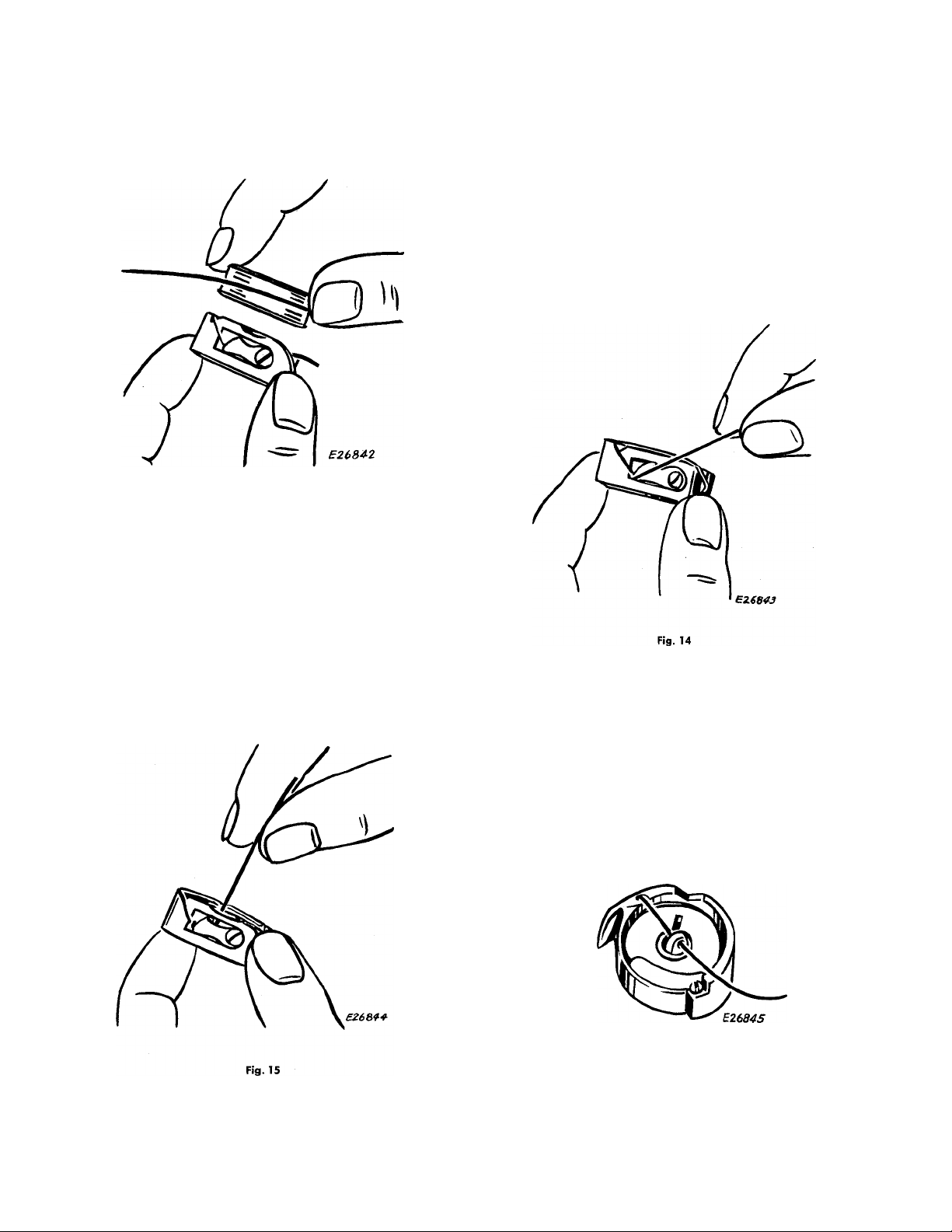

TO THREAD SHUTTLE FOR 29K72

Hold the bobbin between thumb and forefinger of

right hand with the thread leading from right to left.

Hold the shuttle in the left hand with its open end

up and its retaining spring moved outward. See

Fig. 13.

Place bobbin into shuttle and push back the re

taining spring which will hold the bobbin in the

shuttle.

With the right hand, draw the thread into the slot

in the edge of the shuttle as far as possible. See Fig. 14.

Then draw thread to the left, up, and to the right

under the spring. See Fig. 15.

Now insert end of thread up through the small hole

in the edge of the shuttle and through the eye in top

of the bobbin position post. See Fig. 16.

Fig. 16

TO REPLACE THE SHUTTLE

After threading the shuttle, turn hand wheel until

the upright part of the shuttle carrier is to the right.

Then with the point of the shuttle nearest you, and

pointing towards the right, place it into the recess

as shown in Fig. 17. With needle bar at its highest

point, press down lever C, Fig. 17 and swing back

needle plate to its sewing position.

TO THREAD NEEDLE

jy

C

Fig. 17. Replacing Shuffle

TO SET THE NEEDLE

Raise needle bar to its highest point and loosen

screw H, Fig. 18. Then insert shank of the needle up

into the needle clamp as far as it will go with long

groove of the needle to the left and its eye directly in

line with the arm of the machine. Tighten screw

Fig. 18. Loosen screw G, Fig. 18 and move the clamp

to right or left until the needle passes through the

center hole in the needle plate, then tighten screw G.

CAUTION: There are two double end needle plates

furnished with each machine. Be certain needle is

straight and corresponds to the correct needle hole

size indicated on end of needle plate.

H,

Fig. 19. Threading Needle

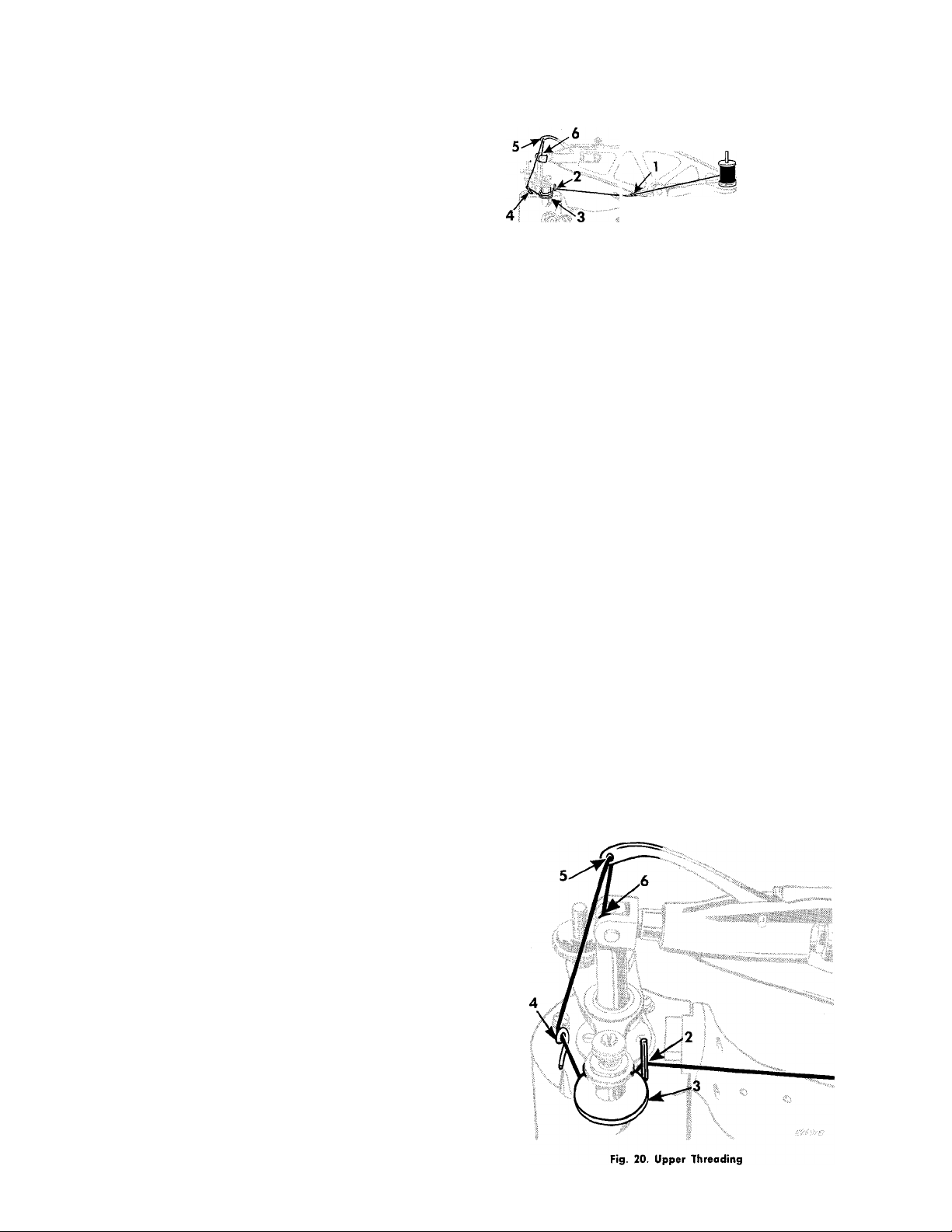

1. Place the spool of thread on the spool pin so that

thread will draw from the rear side of spool. See

Fig. 19.

2. Raise the wire guide in the oil cup on top of

the arm and pass thread under guide 1, then press

guide back into position.

3. Draw the thread around back of pin 2 which

is near the tension discs on top of the arm and from

back to front and right to left between the tension

discs 3. See Fig. 20.

4. Pass thread through wire eyelet 4.

5. Lead thread up and from front to back through

the hole 5 in the take-up lever.

6. Draw about 10 inches of thread through the

hole in take-up lever and insert the end into the slit

in the end of the threading wire supplied with the

machine. Then pass end of threading wire down

through hole

needle bar.

7. Remove thread from threading wire then with

draw threading wire. Pass the thread from left to

right through the eye of the needle 7. Draw about

three inches of thread through the eye of the needle

with which to start sewing.

6 which runs through the center of the

Fig. 18. Selling the Needle

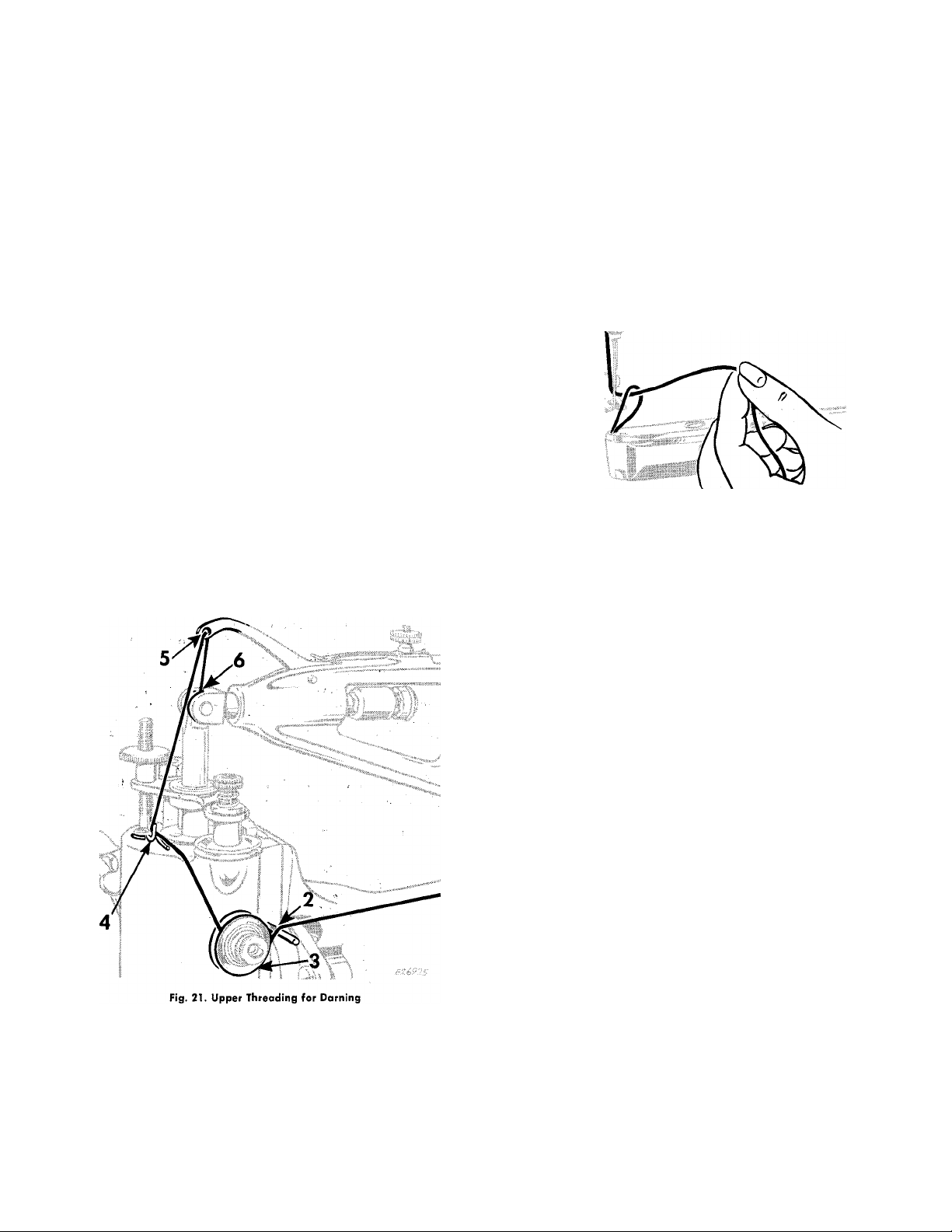

TO THREAD NEEDLE FOR DARNING

1. Place the spool of thread on the spool pin so

that thread will draw from rear side of spool.

2. Raise the wire guide in the oil cup on top of the

arm and pass thread under guide 1 then press guide

back into position. See Fig. 19.

3. Pass thread over the pin 2 near the tension

discs in front of the arm and from right to left under

and between the tension discs 3, Fig. 21.

4. Pass thread through wire eyelet 4.

5. Pass thread up and from front to back through

the hole 5 in the take-up lever.

6. Draw about 10 inches of thread through the

hole in take-up lever and insert the end into the slit

in the end of the threading wire supplied with the

machine. Then pass end of threading wire down

through hole 6 which runs through the center of the

needle bar.

7. Remove thread from threading wire then with

draw threading wire. Pass the thread from left to

right through the eye of the needle 7. Draw about

three inches of thread through the eye of the needle

with which to start darning. ,

10

Fig. 22. Drowing up Bobbin Thread

the bobbin thread; draw up the needle thread and the

bobbin thread will come up with it through the hole

in the needle plate. See Fig. 22. Lay both threads back

under the feeding foot.

TO PREPARE FOR SEWING

With the left hand hold the end of the needle thread,

leaving it slack from thé hand to the needle. Turn top

of hand wheel over toward you until the needle moves

down and up again to its highest point, thus catching

NOTE: Turn top of hand wheel over toward the

right (clockwise) if hand wheel is fitted on front of

machine.

TO START SEWING

Place the material under the feeding foot, lower the

foot and start to sew, turning the hand wheel over

toward you. (Turn hand wheel to the right if located

on front of machine.)

CAUTION: Do not try to help feeding of the work

by pulling the material as this may deflect the needle

and cause it to break. The machine feeds the work

easily without any assistance.

TO REMOVE THE WORK

Let the needle bar rest at its highest point, raise the

feeding foot, then draw the material backward about

3 inches and cut the threads close to the work. Leave

the ends of the threads under the feeding foot.

11

TENSIONS

For perfect stitching, the tension on needle and

bobbin threads must be heavy enough to pull threads

to center of material and make a firm stitch, thus:

Fig. 23. Perfect Stitch

If the tension on the needle thread is too tight, or

if that on the bobbin thread is too loose, the needle

thread will lie straight along the upper surface of

the material thus:

Fig. 24. Tight Neecile Thread Tension

If the tension on the bobbin thread is too tight, or

if that on the needle thread is too loose, the bobbin

thread will lie straight along the under side of the

material, thus:

BOBBIN THREAD TENSION

The tension on bobbin thread is regulated by the

screw in Figs. 27 and 28 on the end of the shuttle

tension spring.

To increase bobbin thread tension, gradually tighten

screw. See Fig. 27.

To decrease bobbin thread tension, gradually loosen

screw. See Fig. 28.

When bobbin thread tension has been properly

adjusted, it is seldom necessary to change it because

a correct stitch can be usually obtained by varying the

needle thread tension.

Fig. 27. Increasing Bobbin Thread Tension

Fig. 25. Loose Needle Thread Tension

NEEDLE THREAD TENSION

The tension on the needle thread is regulated by

the thumb nut near the tension discs. See Fig. 26.

To increase the needle thread tension, tighten thumb

nut.

To decrease the needle thread tension, loosen thumb

nut.

NOTE: Tension on needle thread can be tested only

when the feeding foot is down.

MORE TENSION

LESS TENSION

Fig. 28. Decreasing Bobbin Thread Tension

Fig.26. Regulating Needle Threod Tension

12

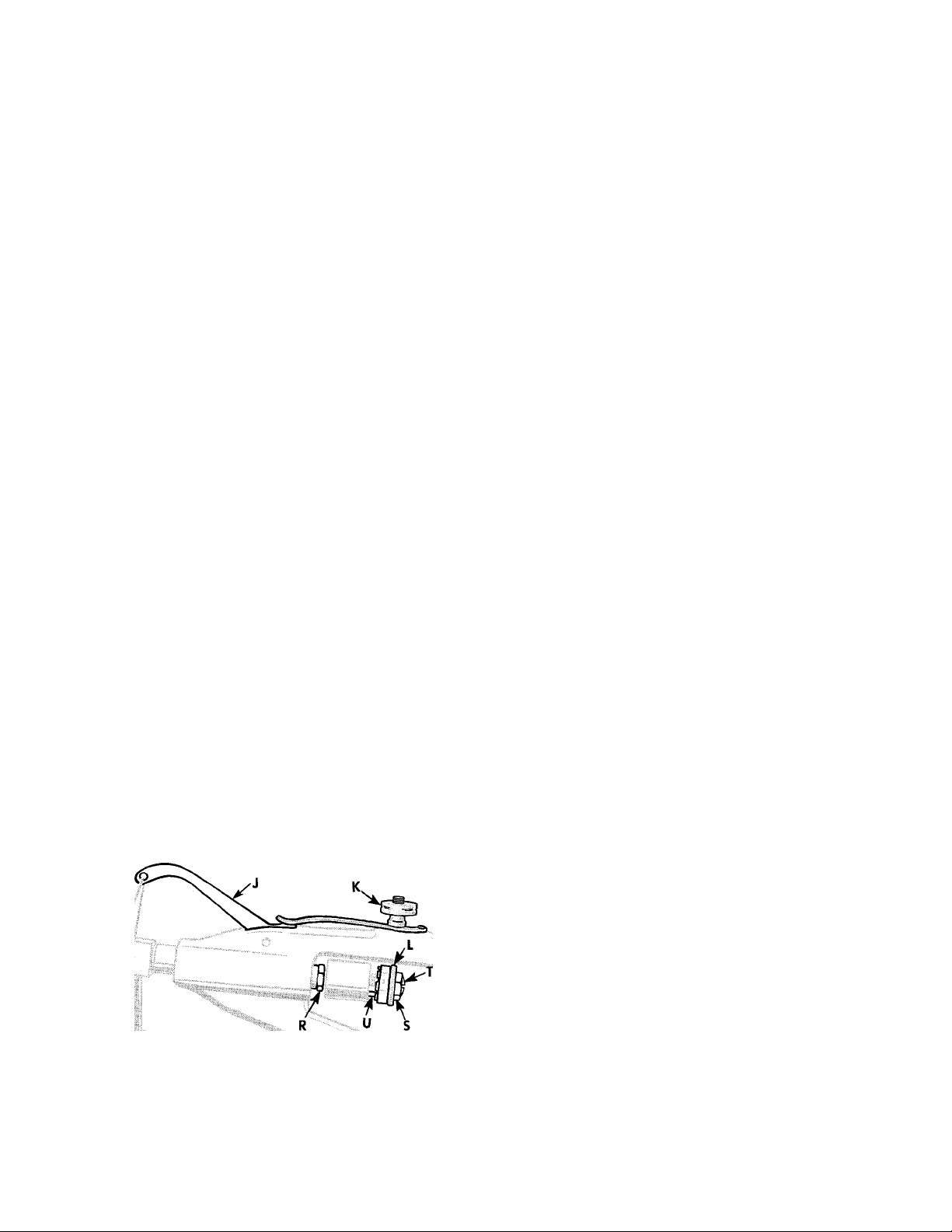

Td REGULATE THE TAKE-UP LEVER

WITH REGULATOR INDICATOR

The spring tension on take-up lever J, Fig. 29 is

adjusted by thumb nut K. The tension on this lever

should be about the same as that applied to the upper

thread by the tension discs.

When the stitch is set, at the top of the needle bar

stroke, lever J should be held down far enough by the

tension of the thread so that the take-up action will

keep the thread taut until the needle enters the work.

When sewing light weight materials with fine

thread, more take-up action may be secured by turn

ing the thumb nut K so that it screws up to decrease

the take-up spring tension. This should be done instead

of tightening the thumb nut of the tension discs.

For heavier materials and thread, the take-up ten

sion must be about the same as that applied to the

upper thread by the tension discs.

The travel of take-up lever J is regulated by means

of knurled nut L. The indicator near nut L is marked

with the figures 0 to 4. This indicator provides a useful

guide to the operator in setting the take-up movement

most suitable for the material and thread being used.

For thin materials, such as kid or box calf, turn knurled

nut L until the zero mark is opposite the small plunger U.

ADJUSTMENT OF THREAD TAKE-UP LEVER

REGULATOR INDICATOR

The range of adjustment given by the indicator,

when sent out from the factory, should suffice for all

general purposes, but, if desired, the range can be

raised or lowered by means of the adjusting screw

T, Fig. 29 at the extreme right.

To alter the range, loosen the lock nut S and, using

a screwdriver, turn the center screw T to the right to

reduce the travel of the take-up lever.

To increase the travel, turn the screw T to the left.

Wear at the tip of the center screw can also be taken

up in this manner. When the proper adjustment has

been obtained, tighten the lock nut S.

It is most important that the hexagon head nut R

be securely locked against the face of the piston.

TO CHANGE LENGTH OF STITCH

Other adjustments can be made in steps by turning

the nut to suit any thickness of material and thread

within the capacity of the machine.

NOTE: All machines sent out from the factory are

so adjusted that they will give satisfactory results on

a general range of materials. Before any adjustment

is made to the travel of the take-up lever, the needle

bar should be raised to its highest point.

Fig. 29. Regulating Tension and Travel of Take-up Lever

The length of stitch is regulated by the stitch regu

lator which is held in position by thumb screw

M, Fig. 30 at back of the feeding foot bar. Loosen

thumb screw M and move the regulator up or down

until its top is in line with the mark indicating desired

number of stitches to the inch as shown by the arrow.

Then tighten the thumb screw.

Ms.

Fig. 30. Changing Stitch Length

13

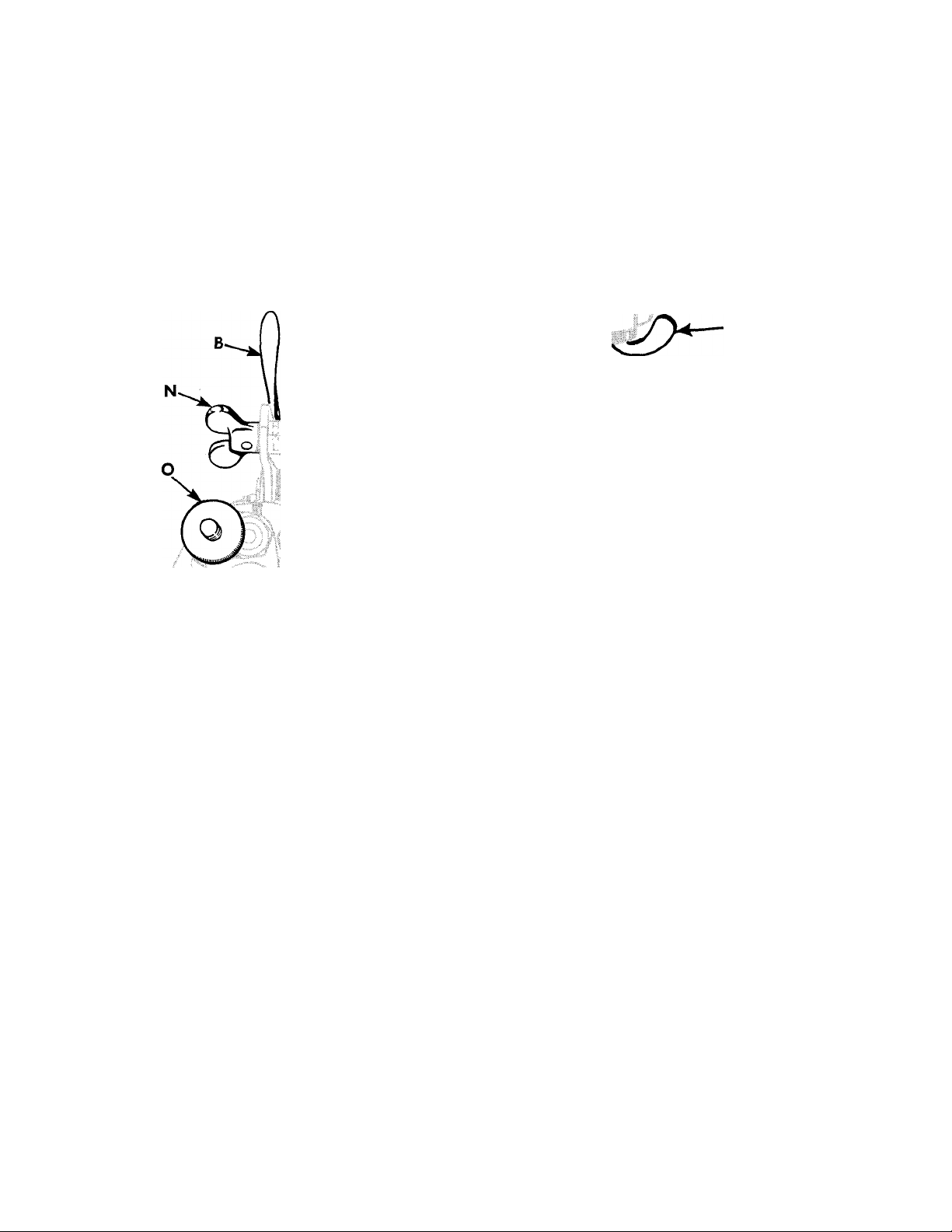

TO REGULATE PRESSURE ON THE MATERIAL

The pressure on the material is regulated by knurled

thumb nut O, Fig. 31. To increase the pressure, tighten

the thumb nut. To reduce the pressure, loosen the

thumb nut.

Heavier pressure is required for leather work than

for sewing cloth or cotton materials. The pressure

should be only heavy enough to enable the feed to

move the work along evenly.

TO CHANGE DIRECTION OF THE FEED

While stitching, the work is moved along by the

action of the feeding foot only.

The direction of the stitching can be changed as

desired by turning the foot around by means of the

two handles E, Fig. 32.

Fig. 33. Changing Feed Direction

Fig. 31. Regulating Pressure on Material

TO TURN A CORNER

Stop the machine with the needle in the work and

turn top of hand wheel over toward you until the

feeding foot rises. Then turn the work as desired,

using the needle as a pivot.

NOTE: If h and wheel is located on front of machine,

turn top of hand wheel over to the right.

TO REGULATE THE AUTOMATIC LIFT

OF THE FEEDING FOOT

While the machine is in operation, the feeding foot

rises after it has moved the work forward; then the

foot moves toward the needle and descends again

upon the fabric. It is advisable that the lift of the foot

should be only sufficient to clear the thickest part of

the work.

To adjust the lift, raise the feeding foot by means of

lifter B, Fig. 31. To increase the feeding foot lift, loosen

wing screw N and move the screw toward you. To

reduce the lift, move the screw away from you. When

the desired height of lift is obtained, tighten the wing

screw.

TO CHANGE THE NEEDLE PLATE

1. Raise the needle bar to its highest position.

2. Loosen screw Q, Fig. 33 and, by lifting upward,

remove needle plate and hinge pin P.

3. When replacing the needle plate, place flat side

of pin P toward screw Q.

4. Tighten screw Q on flat side of pin P.

à

,;S:

Fig.

33. Correct Position of Hinge Pin in Needle Plate

Loading...

Loading...