Singer 29K171, 29K172, 29K173 Service Manual

Service

Manual

SINGER

INDUSTRIAL

PRODUCTS

USE

SINGER

OILS

and

They

Tfio

jYPE

When

stain

YYPE D —

type

insure

following

B —

an

on

fabrics,

OTHER

E —

For

stitching

required.

LUBRICANTS

freedom

longer life to sewing equipment

sre

MANUFACTURING

oilisdesired

even

MANUFACTURING

SINGER

THREAD

lubricating

fabrics

from

lubricating

tho

corroct

MACHINE

which

after a

long

MACHINE

LUBRICANT

the

needle

or

leather

fubncBnis

will

produceaminimum

period

LUBRICANTS

thread

where

trouble

for

this

OIL,

of storage,

OIL,

of

sewing

a

thread

and

wschinGi

HEAVY

HEAVY

machines

lubricant

give

GRADE

of

use:

GRADE

for

is

TYPE

GEAR

BALL BEARING LUBRICANT

F -

LUBRICANT

MOTOR

For oil lubricated motors and plain bearings in power

tables

NOTE;

1 gallon and 5 gallon cans.

This

lubrication on manufacturing sewing machines.

This

of

electric

etc.

and

All

specially

pure

ball

bearings

transmitters,

Furnished in 1

OIL

transmitters.

of the above oils ore available in 1 quart,

prepared

greaseisspecially

and

greaseisrecommended

ball

lb.

ball

bearing

and

designed

thrust

4

bearings

hangers

lb.

for

tins.

the

of

of power tables,

for

gear

lubrication

motors

and

FOREWORD

This book contains complete information covering operation and

Parts

Chart

29K172

for

and

29K173

PARTS CHART

these

machines

is

Form

adjustment

K6461

for machines 29K171,

Page

Accessories (List) 3

Adjustments

Bobbin:

Removal

Replacement

Winding

Bobbin

Bobbin

Description

DescriptionofOils

Direction

Feeding

Foreward

Hand

Height

Hints

Information

LengthofStitch

Needles:

Needle

Needle

Needle

Needle

Thread

Winder

Wheel

Adjustment:

Feeding

Needle

for

Class

Ordering

Setting

Sizes

and

Plate

Throad

Thread

Tension

of

Machines

of

Feed

Foot

Lift 13

Foot

Bar

perfect

for

and

Variety

recommended

Thread

Tofision

Twist

Operation

Operator

Relationship

Inside

12-16

11

Cover

13

5-16

INDEX

6

6

6

6

3

2

6

13

12

14

12

5

5

9

5

5

13

11

6

Page

Oiling

Operation of

the

Machine

Machine

Perfect Stitch 1^

Preparation for

Sewing

1®

Presser Bar Height,Setting 13

Presser

Pressure on Material 13

Rack

Box:

Bar

Lift 1^

Removal and Inspection 15

Removing the Work

Shuttle:

Threading

Timing

Special

Characteristics;

1®

Speed

Start

Sewing

Stitch

Stop

Tensions:

Length

Motion

Explanation

Regulation

Thread and Bobbin Thread

(Hand

for

Wheel)

Needle

^^

1^

11

Thread Twist ®

Thread Take-up Lever Regulation and

Adjustment

Threading:

Upper

Lower

Timing

(Needle)

(Bobbin)

the

Shuttle

9—10

^

3

3

^

6

DESCRIPTION

Machines

and

fabrics,

Single

Stop

Horizontal

Eccentric

Cylinder

Replaceable

Universal

Stitch

Needle,

Motion

Length:

Presser

Double

Adjustable

Two

Speed

29K171,

have

Hand

Oscillating

Adjustment

Bed.

Steel

Upper

Foot

rise

End

Needle

Thread

Machine

29K172

the

following

Lock

Stitch.

Wheel-releases

Horn.

Feed

7 to15to

during

Plate-(two

Take-up

Pulley.

and

29K173,

for

stitching

boots,

characteristics:

hand

wheel

Shuttle.

for

Shuttle

for

Stitching

the

feeding

ACCESSORIES AVAILABLE UPON ORDER

Timing.

in

inch,

depending

action

sizesofneedle

Lever.

any

1/4

from

stitching

direction

on

without

material

inch-(Maximum

holesateach

shoes,

turning

being

clearance:

end

and

other

mechanism

the

stitched

for

various

tabular

for

bobbin

work.

and

operations

3/8

inch).

sizesofneedles).

workinleather

winding.

performed.

Stands

MACHINE

Endofcylinder

for

mounting

29K171

bed is 1

Spaceatrightofneedle

Diameters

MACHINE

Endofcylinder

Spaceatright

Diameters

Large

of

of

Bobbin.

belt

29K172

of

belt

grooves

bed is

needle

grooves

the

inch

12-1/4

2-7/8

1-5/32

17-1/2

3-1/4

machines:

wide

and

inches.

inches

inches

inches.

inches

(at

additional

49732

49733

SPECIAL FEATURES

7/8

inch

deep.

and

4-7/8

wide

and

1-1/16

and

5-1/2

charge)

for

29K171

for

29K172

inches.

inches

inches.

Machine

and

deep.

(foot

29K173

power)

Machines

(foot

power)

MACHINE

Endofcylinder

Space

Diameters of belt

29K173

bed

is 1

inch

wide

and

7/8

inch

deep.

at

right

of

needle

grooves

17-1/2

• '

inches.

inches

and 5

\r:

••iches.

[

The

maximum

machines

on

material

formed.

For

stitching

is

thick

elastics,

500

being

larger pulley of

pulleyofthe

stand.

speed

stitches

work,

the

SPEED

recommended

per

stitched

patching,

put

the

machine and

minute,

and

operations

driving

for

depending

mending,

belt on

the

these

per

and

the

smaller

i'«

f.'-

! \ uj

For light work, put

of

the

machine

When

always

NOTE:

must

(counter-clockwise).

turn

If

always

and

in

operation,

over toward

fitted

turn

TO

.•7

the

the

at

end

over

OIL

siNC.tR '

belt on

larger

AAACHINE

the

the

of

machine,

toward

pulley of

hand wheel

right (clockwise).

\/w

K '

smaller

the

hand

the

1

pulley

stand.

must

wheel

operator

these

Use

See

"TYPE

inside

oils.

if !

II/-

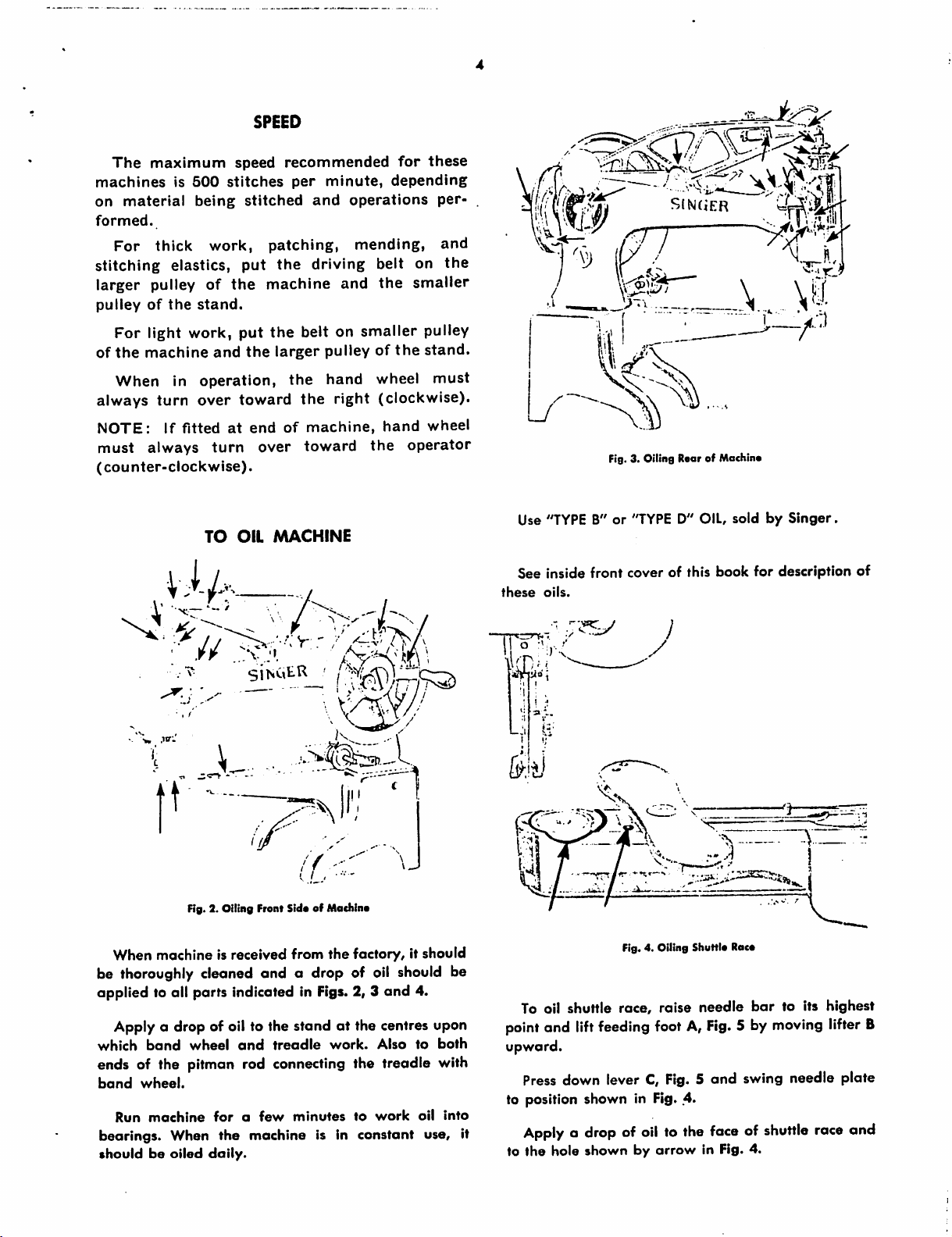

Fig.3. Oiling Rsor of Machina

B" or

"TYPE

D" OIL, sold by

front

cover

of this

book

Singer.

for

description

of

1

Fig.2. Oiling Front Sido of Mochino

When machine is received from

the

factory# It should

be thoroughly cleaned and a drop of oil should be

applied to all parts indicated in Figs. 2, 3

Apply a drop of oil to the standatthe centres upon

which

bond

wheel

and

treadle

work.

and

Also

4.

To oil shuttle

pointand liftfeeding foot A,

to

both

upward.

ends of the pitman rod connecting the treadle with

band

wheel.

Run

machine

bearings. When

shouldbeoiled

forafew

the

daily.

minutes

machine is in constant use, it

to

work

oil

into

Press down lever C, Fig. 5 and swing needle plate

to position shown in Fig. 4.

Apply

to

a drop of oil to the face of

the

hole

Fig. 4. Oiling ShuHla Roc*

race,

shownbyarrow

raise

needle

Fig.

5 by

in Fig. 4.

—

bar

shuttle

to its

moving

highest

lifter B

race and

Loading...

Loading...