Singer 299U110, 299U123, 299U130 Service Manual

SERVICE

MANUAL

299U110,

AND

PARTS

SINGER

MACHINES

299U123

FOR

LIST

and

299U130

* A

Machine

Trademark

of

299U130

THE

SINGER

COMPANY

.4

INDEX

Page

MACHINES

DESCRIPTION

AUXILIARY FEED MECHANISM

BUTTONHOLES

CAUTION

299U110

OF MACHINES

To Change

To Reduce

Eyelet-end

Never Use

Proper

To

Use

Reface

To Regulate

To Replace

AND

299U130

the

Style

the

Number

Buttonholes

Excessive

of

Cutting

Steel

the

the

Buttonhole

Cutting

Pressure

LOOPERS^

Alignment

To

Assemble

To

Remove

of

Looper

and

the

Replace

To Replace and Time

To Replace and Time

LOOP

To Time

RETAINERS

the

Looper

To Replace and Adjust

To Replace and

To Time

MATERIAL

To

the

Determine

are

Cut

Adjust

Loop

the

Before

NEEDLE

To

Set

the

Needle 10

NEEDLE

VIBRATING

To

Align

To

Regulate

To

Regulate the

MECHANISM

the

Needle

the

Cutting

Width

OILING

OPERATIONOFMACHINE

Machine

Machine

PATTERN

To

RAPID

FEED

To

SAFETY

SAFETY

LOCK

LOCKONMACHINE

299U110

299U130

WHEEL

Remove

and Replace

MECHANISM

Remove

and

ON

MACHINE

Replace

SETTINGUPMACHINES

SPEED

of

Buttonhole

of

Stitches

Pressure

on

at

the

Eye End

Cutting

Blocks

Block

on

the

Cutting

Cutting

Driving

Needle and Looper Frame

Bracket

the

Looper Frame

Non-threaded

Threaded

Driving

Left

Right

Retainer

Proper

Sewing

Material

Crank

Hand

Hand

Driving

Looper

Looper

Loop

Loop

to

Retainer

Retainer

Crank

Use

Space 27

of

Bight "

the

the

Pattern

Clutch

Wheel

Rollers

299UH0

299U130

of

Knife

Knife

Lock

for

Buttonholes

Straight

!!!!!.*!!!!!

and

which

!

.•!..*!!!!*.!

**

-

4

45

_

21

22

-

22

23

20

23

-

35

36

-

37

38

-

36

37

-

39

40

39

38

39

40

-

45

48

_

30

31

-

31

32

-

29

30

-

27

28

28

-

32

33

29

28

33

10

9 . iq

26

26

27

23-25

14 _

16

ig

21

33-34

35

g

q

o

g

8

- 2 -

TENSIONS

To

To

Adjust

Adjust

the

the

Delaying

To

Regulate

THREAD AND

THREAD BREAKING OR

THREADING

To

To

To

THROAT

To

WORK

CLAMPS

Adjustment

Adjustment

Adjustment

Adjustment

To

To

CORD

Thread

Thread

Thread

PLATE

Adjust

Machine

Machine

Adjust

Regulate

the

the

the

Needle

of

of

of

of

299U110

299U130

Clamp

Work Clamps - 299U130 41

To

Regulate

Work Clamps - 299U110 40

To Remove

To Remove

and

the

Automatic

Automatic

Mechanism

the

Tensions

SKIPPING

Cord

Looper

Needle

Guard

Clamp

Clanqp

Clamping

Work

Clamp

Closing

the

Amount

the

Amount

Replace

Work Clamp

Looper

Needle

OF

and

Locking

Opening

Pressure

Spreading

Mechanism

of

of

the

Plates

Ihread

Thread

Tension

Tension

Releaser

Release

44 -

STITCHES

48-49

12-13

11 - 12

Throat

Plate

Mechanism 42

and

Spreader

Releasing

Mechanism 43

Mechanism

41 - 42

Spread

Stretch

Work Clamp

of

of

the

the

Carrier

Material

Material

Held

Held

in

in

the

the

Page

44

45

20

10

10

29

42

43

43

42

19

MACHINE

DESCRIPTION

NEEDLE

SPEED

THREAD

THREADING

TRINWER

PARTS

PARTS,

PARTS, SPECIAL FOR

PARTS, SPECIAL FOR

ACCESSORIES

FITTINGS

NUMERICAL PARTS

299U123

AND

To

Thread

To

Hiread

DEVICE

Lower

To

Adjust

To

Adjust

To

Adjust

To

Adjust

To

Adjust

LIST

COMPLETE

OF MACHINE SO -

CORD

the

the

Trimmer

the

the

the

the

the

FOR

LIST

Cord

Needle

Adjustment

Cord

Pull-back

Looper

Needle

Needle

Under

MACHINE

MACHINE

MACHINE

Thread

Thread

Thread

Thread

and

299U130

299U110

299U123

Pull-off

Pull-off

Waste

Cord

51

51

51

51

52

51

-

52

53

55 -

56

56

56

Loop Remover 55

Trimmer

53-54

58-113

114-119

120-125

132

-

139

126

-

131

140-151

- 3 -

MACHINES

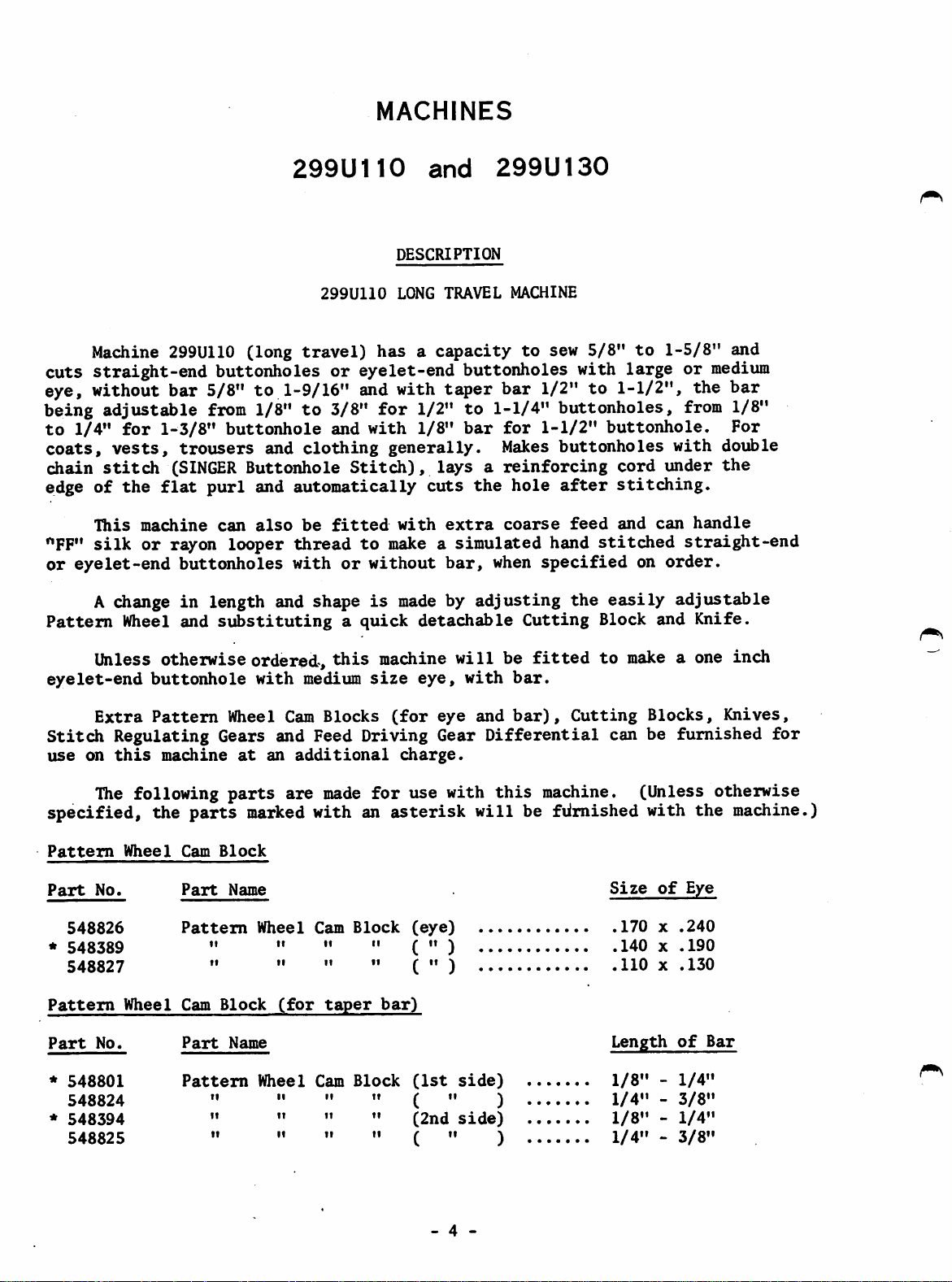

Machine

cuts

straight-end

eye, without

being

to

coats,

chain

edge

"FF"

or

adjustable

1/4"

for

vests,

stitch

of

the

This

silk

eye

let-end

machine

or

A change

Pattern

Wheel and

299U110

(long

buttonholes

bar

5/8"

from 1/8"

1-3/8"

(SINGER

flat

buttonhole

trousers

Buttonhole

purl

can

rayon looper

buttonholes

in

length

substituting

299U110

299UII0

travel)

or

eyelet-end

to

1-9/16" and with

to

3/8"

and

and

clothing

Stitch),

and

automatically

also

be

fitted

thread

with

and shape

or

a

to

quick

and

DESCRIPTION

LONG

TRAVEL MACHINE

hasacapacity

buttonholes

taper

for

1/2"

to

with

1/8"

bar

generally.

laysareinforcing

cuts

the

with

extra

makeasimulated

without

is

bar,

made

by

detachable

adjusting

299U130

to

sew

bar

1/2"

1-1/4"

for

Makes

coarse

when

buttonholes,

1-1/2"

buttonholes

hole

after

hand

specified

Cutting

5/8"

with

to

buttonhole.

feed

stitched

the

easily

Block and

to

1-5/8"

large

or

1-1/2",

from 1/8"

with

cord

under

stitching.

and

can

straight-end

on

order.

adjustable

and

medium

the

bar

For

double

the

handle

Knife.

Unless otherwise ordered,

eyelet-end

Extra

Stitch

use

on

The

specified,

Pattern

Part

No.

548826

*

548389

548827

Pattern

Part

No.

*

548801

548824

*

548394

548825

buttonhole

Pattern

Regulating

this

machine

following

the

parts

Wheel

Wheel

Cam

Part

Pattern

Cam

Part

Pattern

" " " " ( " )

" " " " ( " )

" •' " " ( " )

" " " "

" " " " ( " )

this

with

medium

Wheel

Cam

Blocks

Gears and Feed

at

an

additional

parts

are

made

marked with an

Block

Name

Wheel Cam

Block

Name

(for

Wheel

taper

Cam

machine

size

(for

Driving

for

asterisk

Block

bar)

Block

eye,

eye

Gear

charge.

use with

(eye)

(1st

(2nd

will

be

with

bar.

and

bar).

Differential

this

will

side)

side)

fitted

to

Cutting

can be

make

Blocks,

a one inch

Knives,

furnished

machine. (Unless otherwise

be

fiimished

with

Size

of

170x.240

140X.190

110X.130

Length

1/8"

1/4"

1/8"

1/4"

of

-

-

-

-

the

Eye

1/4"

3/8"

1/4"

3/8"

machine.)

Bar

for

- 4 -

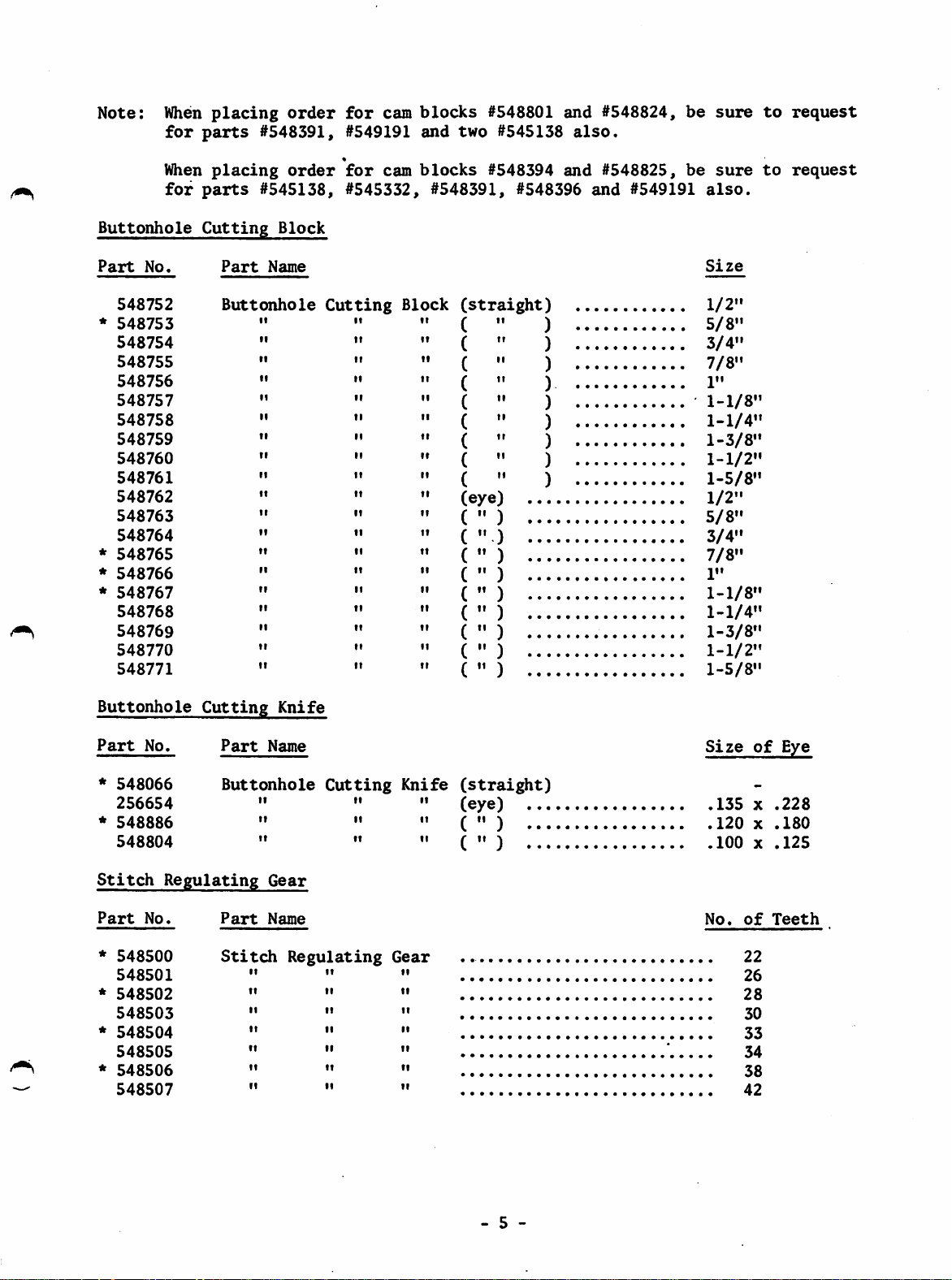

Note:

When

for

When

for

placing

parts

placing

parts

order

#548391,

order

#545138,

for

cam

blocks

#549191

%

for

cam

and

blocks

two

#545332, #548391,

#548801

#545138

#548394

#548396

and

also.

and

#548824,

#548825,

and

#549191

be

be

sure

sure

also.

to

to

request

request

Buttonhole

Part

No.

548752

548753

548754

548755

548756

548757

548758

548759

548760

548761

548762

548763

548764

548765

548766

548767

548768

548769

548770

548771

Cutting

Part

Buttonhole

Block

Name

Cutting

Block

straight)

" }

" )

" )

" )

" )

" )

" )

" )

eye)

" )

•• )

" )

" )

)

)

)

)

)

Size

1/2"

)

5/8"

3/4"

7/8"

1"

1-1/8"

1-1/4"

1-3/8"

1-1/2"

1-5/8"

1/2"

5/8"

3/4"

7/8"

1"

1-1/8"

1-1/4"

1-3/8"

1-1/2"

1-5/8"

Buttonhole

Part

No.

*

548066

256654

*

548886

548804

Stitch

Part

No.

548500

548501

548502

548503

548504

548505

548506

548507

Cutting

Part

Buttonhole

Regulating

Part

Stitch

Knife

Name

Cutting

" " "

It

Knife

M

Gear

Name

Regulating

Gear

II

(straight)

(eye)

( " )

( " )

...

Size

of

135

X

120X.180

100X.125

No.

of

22

26

28

30

33

34

38

42

Eye

.228

Teeth

- 5 -

Feed

Part

Driving

No.

Gear

Part

Differential

Name

No.

of

Teeth

548714

548715

548716

548717

548718

548719

548720

548721

548722

Note:

To

differential

Straight

cam

the

When

can

Machine 299U130

cuts

straight-eiid

eye,

without

adjustable

1/4"

for

coats,

vests,

Feed

obtain

a

buttonholes

block

wheel

from

rings.

preferred,

haveasquare

bar

5/8"

from

1/8"

1-3/8"

buttonhole

trousers

Driving

Gear

simulated

#548716,

the

pattern

the

eyelet-end

bar

(long

travel)

buttonholes

to

1-19/32"

to

3/8"

and

and

clothing

Differential

hand

#548718,

with

taper

made on

299U130

or

eyelet-end

for

with

stitched

wheel

Machine

LONG

has

and

1/2"

1/8"

generally.

buttonhole,

#548719

bar

and

and

can

fitting

buttonholes

269W39.

TRAVEL

a

capacity

buttonholes

with

bar

to

1-1/4"

bar

for

#548721.

be

made by

the

produced

MACHINE

to

sew

1/2"

to

buttonholes,

1-1/2"

18

21

22

32

33

34

35

37

38

(2)

use

feed

driving

removing

bar

cam

the

blocks

on Machine 299U110

5/8"

to

1-5/8"

with

1-1/2",

buttonhole.

large

the

from

or

bar

1/8"

gear

eye

to

and

medium

being

to

For

The machine

the

buttonhole

with

"FF"

end

cord

double

under

This

silk

or

A change

Pattern

Unless

eyelet-end

Extra

Stitch

for

use

The

specified,

machine.)

chain

the

machine

or

rayon

eyelet-end

in

Wheel and

otherwise

buttonhole

Pattern

Regulating

on

this

following

the

parts

is

intended

being

automatically

stitch

edge

of

the

can

also

looper

buttonholes

length

siibstituting

and

ordered,

without

Wheel

Gears and Feed

machine

at

parts

marked

for

(SINGER

flat

be

fitted

thread

with

shape

bar

Cam

Blocks

an

additional

are

made

with

making

cut

buttonholes

before

Buttonhole

purl.

with

to

makeasimulated

or

without

is

made by

a

quick

this

machine

for

detachable

sack

(for

Driving

for

use

an

asterisk

Stitch)

extra

bar,

adjusting

will

coats.

eye

and

Gear

charge.

with

will

in

stitching.

and

coarse

hand

when

Cutting

be

fitted

bar).

Differential

this

machine.

be

furnished

closely

Makes

woven

buttonholes

laysareinforcing

feed

the

Cutting

and

stitched

specified

easily

Block

to

make a

can be

can

handle

straight-

on

adjustable

and

Knife.

Blocks,

furnished

(Unless

with

the

fabrics,

order.

one

inch

Knife,

otherwise

- 6 -

Pattern

Part

No.

Wheel

Cam

Part

Block

Name

Size

of

Eye

548826

*

548389

548887

548827

Pattern

Part

No.

548392

548393

548802

548395

Note:

Buttonhole

Part

No.

548752

548753

548754

548755

548756

548757

548758

548759

548760

548761

548762

548763

548764

548765

548766

548767

548768

548769

548770

548771

Wheel

When

request

When

request

Cutting

Pattern

" " " " ( " ) 110 X

Cam

Block

Part

Pattern

" " " " ( " )

" " " "

" " " " ( " )

placing

for

placing

for

Part

Name

Buttonhole

Wheel Cam

Name

Wheel Cam

order

parts

order

parts

Block

Cutting

(for

taper

for

#548391,

for

#545138,

Block

Block

cam

cam

Block

(eye)

" C " )

" C " )

bar)

(1st

(2nd

blocks

#548392 and #548393, be

#549191

blocks

#548802 and #548395, be

#545332,

straight)

eye)

" )

" )

" )

" )

side)

side)

and

two

#545138

#548391, #548396

" )

" )

" )

)

" )

" )

" )

" )

)

)

)

)

)

)

.170

Length

1/8"

1/4"

1/8"

1/4"

also.

and

Size

1/2"

5/8"

3/4"

7/8"

1"

1-1/8"

1-1/4"

1-3/8"

1-1/2"

1-5/8"

1/2"

5/8"

3/4"

7/8"

1"

1-1/8"

1-1/4"

1-3/8"

1-1/2"

1-5/8"

x

.240

140X.190

126X.160

.130

of

-

1/4"

-

3/8"

-

1/4"

-

3/8"

sure

to

sure

to

#549191

Bar

also.

Buttonhole

Part

No.

*

548066

548065

*

256654

548886

Cutting

Part

Buttonhole

Knife

Name

Cutting

II II II ( " )

> " " (eye)

Knife

(straight)

II II II ( " )

- 7 -

....

Size

.140

.135

.120

of

X

X

X

Eye

.260

.228

.180

Stitch

Part

*

548500

548501

*

548502

548503

*

548504

548505

*

548506

548507

Feed

Part

*

548714

548715

548716

*

548717

548718

548719

548720

548721

*

548722

Regulating

No.

Driving

No.

Part

Stitch

Gear

Part

Feed

Gear

Name

Regulating

Differential

Name

Driving

Gear

Gear

Differential

No.

No.

of

22

26

28

30

33

34

38

42

of

18

21

22

32

33

34

35

37

38

Teeth

Teeth

(2)

Note:

holes,

as

shown

to

the

fasten

ports

set

machine on

To

obtain

differential

Straight

eye

to

the

When

299U130

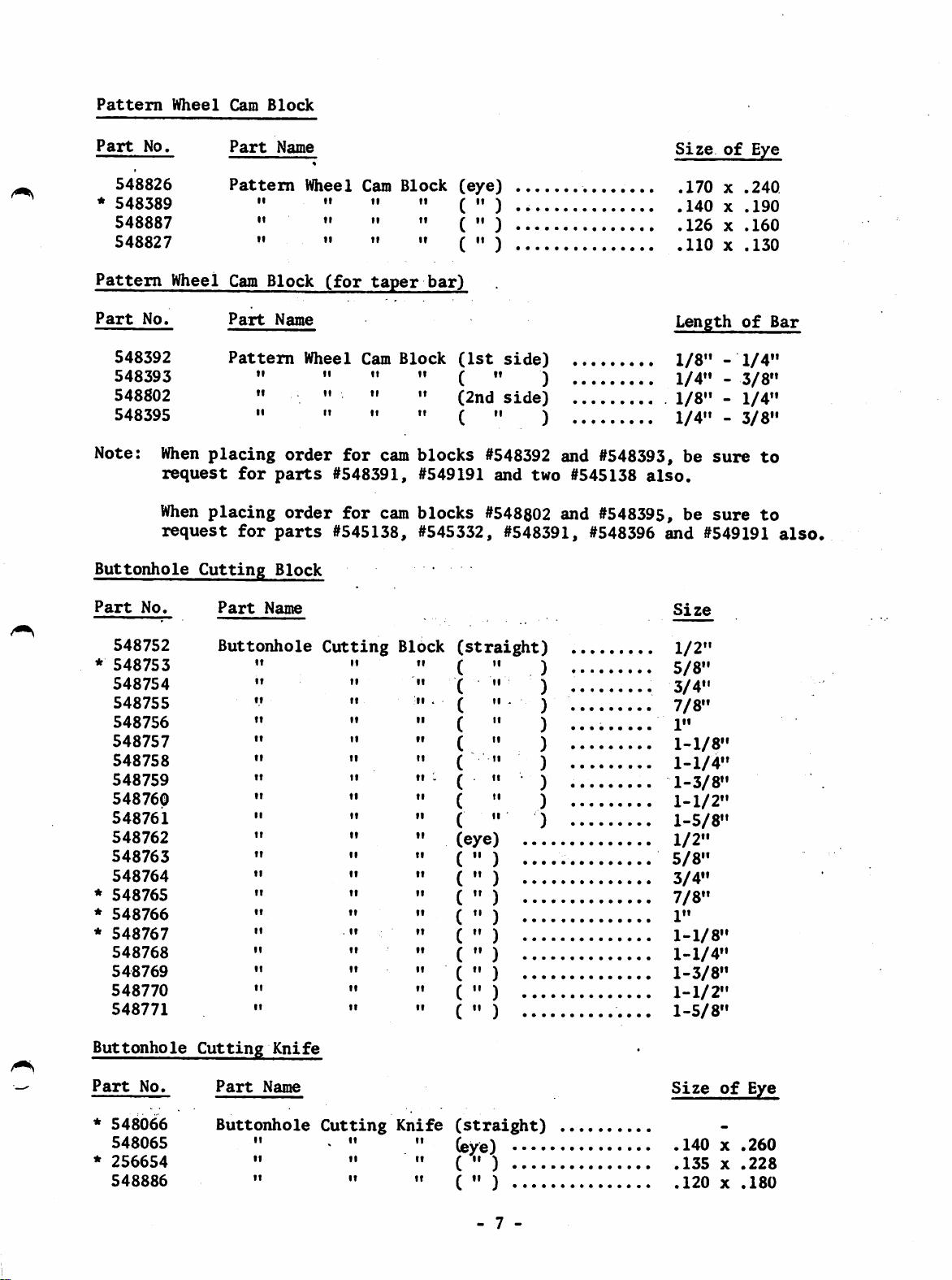

Spot

and

oil

in

Bolt

the

underside

motor

Fasten

to

the

a

buttonholes

cam

block

pattern

preferred,

can

drill

hole

and

Fig.

2.

driving

of

in

position.

the

two

table

the

simulated

hand

#548716, #548718,

with

taper

from

the

pattern

wheel

haveasquare

all

belt

the

eyelet-end

bolt

holes,

rings.

To

bar

Set

attachment

table,

machine

as

shown

then

sup

and

siq)port.

stitched

buttonhole«

#548719

bar

and

can be

wheel and

buttonholes

#548721.

made

fitting

produced on Machine

made on machine 269W39.

Up

the

Machine

use

feed

by removing

the

bar

30

i

holts

driving

the

cam

blocks

32

drill

Htchint

Stgport

Oil

Onp

Pm

thru.S

gear

holes

Fig.

2

Layout

- 8 -

for

Setting

Up

the

Machine

are

as

The

speeds

follows:

recommended

for

the

shafts

Speed

in

Machines

299U110

and

299U130

Buttonhole

Stop

the

arm

Care

is

driven

cutting

The

correct

a

speed

of

the

minute.

To

is

locked

lever

(45,

provided

other

preventing

making

the

to

(38,

to

it

from

end

To

end

slip

Fig.

start

will

under

Cutting

Motion

shaft

ataspeed

must

therefore,

ataspeed

shaft

(43,

speed

indicator

rapid

prevent

prevent

feed

See

Fig.

out

of

Fig.

on

the pattern

to

engage

the

cutter

accidental

26)

accidental

adjustments,

of

the

safety

under

be

13)

the

machine.

necessary

the

the

so

starting

Shaft

- 950

of

Fig.

of

the

at

the

crank

13.

operation

follow

with

to

the

lever

safety

that

it

When

to

Shaft

950

11)

shaft

Safety

- 200

to

of

from 1900

be

taken

to

ataspeed

stop

motion

gear

end

should

1000

1000

Lock

functioning

by means

the

outside

wheel

shaft

the

cutting

function.

Safety

Lock

starting

machine can

(45,

Fig.

lever

cannot

unlock

lever

(45),

engage

finished

the

before

to

215

revolutions

to

to

see

revolutions

of

shaft

of

the

be

about

on

Machine

of

of

having

diameter

(148,

starting

on

Machine

of

the

be

locked

13)

thus

with

threading,

machine

the

revolutions

2000

revolutions

that

the

200

to

should

rapid

feed

1310

the

cutter

the

Fig.

26)

lever

machine

out

causing

holding

the

by

swinging

machine

per

minute.

stop

per

minute and

215

revolutions

be

ascertained

crank

to

1380

299U110

during

end

of

of

the

causing the

arm

299U130

when

of

operation

the

safety

up

the

starting

oiling

can

be

per

minute.

per

motion

shaft.

revolutions

sewing,

the

cutting

safety

(39,

Fig.

threading,

starting

lever

or

making

the

safety

started

(This

minute.)

shaft

the

per

by

The

cam

(153,

lat^

10),

by

lifting

latch

lever

arm

adjustments,

latch

in

will

drive

(Fig.

buttonhole

minute.

placing

speed

per

the

cutter

safety

Fig.

on

the

thus

oiling

or

up

(44,

Fig.

trip

(39,

Fig.

out

operation.

13)

26)

13)

13)

Also,

cutter

Needles

Catalog

1411

1413

1424

1430

is

No.

to

prevent

locked

for

Class

Variety

out

Machine

142

142

142

142

accidental

of

and

X 1

X 5

X 8

X 6

operation

299U

are

Description

for

Cloth

for

Cloth

for

Leather

for

Khaki

functioning

the

same

Needles

of

the

following

Style

- 9 -

as

of

M

M

DIA

SP

the

of

SET

SET

W

the

299U110

Class

Point

cutter

during

machine.

and

Variety

15, 17,

13,

14,

12,

20,

19,

18,

17,

18,

17,

sewing,

Sizes

15,

21,

19

19,

the

Nos.:

18

16

22

21

The

the

thread

successful

is

used,

size

of

which must

use

of

or

if

it

the

the

passes

needle

pass

machine

with

to

be

freely

will

difficulty

used

should

through

be

interfered

be

the

eye

through

determined

of

the

with

if

the

eye

by

needle.

rough

of

the

the

size

The

or

uneven

needle.

of

thread

Orders

the

Catalog

For

"100

The

by

Singer

Stitch

and

materials

garment.

indicates

before

in

the

Either

When

used

in

with

A

for

number

example

Size

best

Sewing

a

If

that

sewing.

depth

stitching

the

silk

needles

...

17,

stitching

Machine

buttonhole

in

the

the

stitches

the

The

stitch

right

looper

in

the

...

Catalog

To

Determine

Buttonholes

same

material

thicker

from

or

left

buttonholes

than

needle.

must

specify

#1413

results

Company.

in

the

layers

(or

is

the

the

twist

in

the

(142X5)

will

the

Proper

which

material

and

purl)

not

suitable

material

buttonhole

Thread

thread

with

needle,

the

quantity

be

obtained

are

to

positions

pulls

is,

slit.

and

may

silk

for

Needles."

Materials

Cut

Before

be

tested,

that

off

the

for

buttonholes

the

Cord

be

used

thread,

example:

required,

in

using

to

Sewing

they

edge

wider

in

a

heavier

useBsilk

Use

using

of

the

the

the

for

will

the

bight

needle

the

needles

the

occupy

slit

which

thread

size,

same

are

should

and

in

also

sold

lining

in

it

cut

looper.

should

the

^

a

be

be

looper

When

is

recommended.

than

in

the

the

buttonhole.

For

the

Loosen

^ into the

its

eye

parallel

the

set

screw

Pass

the

hole

from back

thread

threading

pull

through

(2),

pull-off

the

thread

the

stitching

needle.

cord,

the

clamp

(154).

the

thread

from back

to

front

wire

furnished

eye

buttonholes

Harder

set

finish

This

will

medium

size

screw (154, Fig. 20)

as far as

or

in

line

from

the

to

front

through

(8) and

the

(9),

with

with

thread

facilitate

buttonhole

To

it

will

with

To

unwinder

holes

down

the

through), and pass

of

the

needle.

cotton

should

Set

the

go

with

the

bed

Thread

(See

the

Fig.

down

and on

right

(4), (5),

through

machine up

the

thread

the

cord

Needle

in

of

the

thread,

always

formation

will

the

its

the

Needle

3)

through

between

(6) and

needle

into

from back

regular

be

used

of

give

the

needle clamp and

long

groove

machine, then firmly

the

hole

the

tension

(7),

bar

(10)

the

needle

to

buttonhole

in

the

looper

perfect

best

stitches

results.

put

to the rear

(1),

through

discs

under

bar

front

the

(inserting

from below

or

thread

in

the

needle

and

tighten

(3),

needle

the

to

toward you

-

10

-

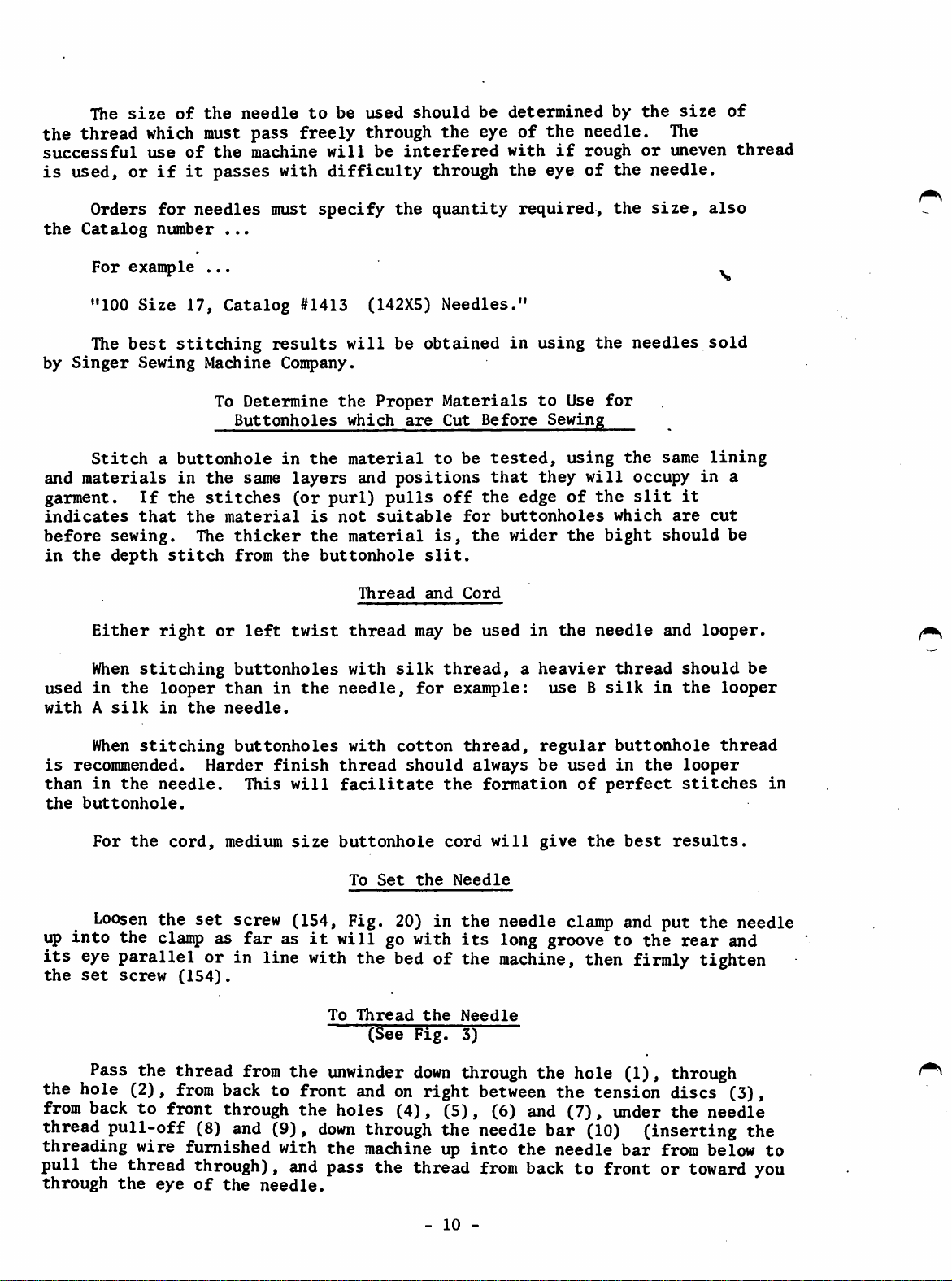

188

189

178

Fig.

179

3

To

187

186

Threading

Thread

the

the

Looper

Needle

plates

Unhook

(13

and

the

two

14,

springs

Fig,

7),.

(11

then

2f>

and

12,

Fig.

draw

the

front

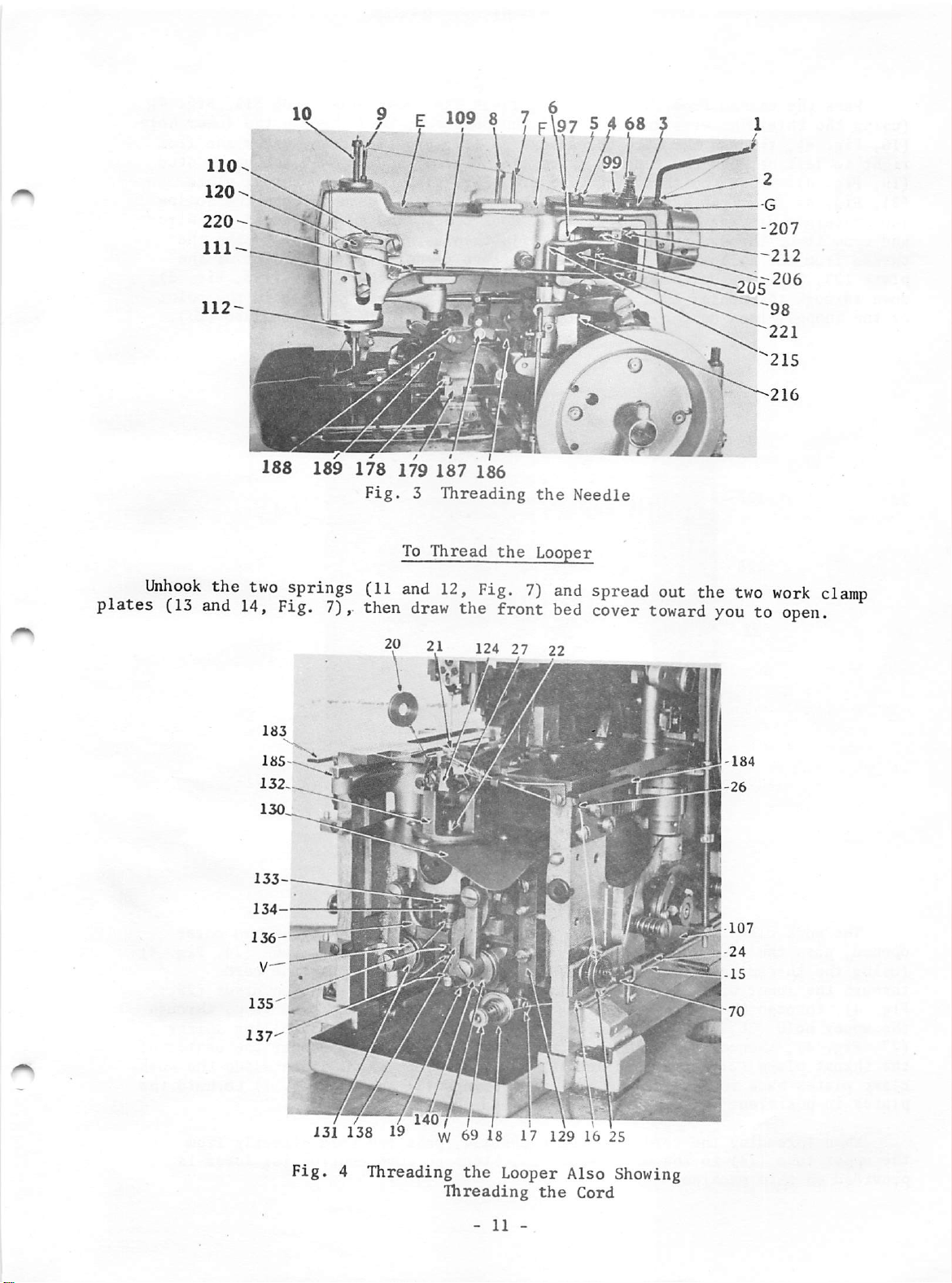

21 124 27 22

7)

and

bed

spread

cover

out

the

toward

two

you

to

work

open.

clamp

131 138 19 ^ 69 18 17 129 16 25

Fig.

4 Threading

the

Looper Also

Threading

the

Showing

Cord

(using

(16,

right

(19,

(21,

loop

and

thread

plate

down

of

the

Pass

the

Fig.

to

Fig.

Fig.

retainer

draw

from

(23,

through

looper,

the

thread

threading

4),

left

4).

4)

and

it

up

the

Fig.

the

through

between

Pass

right

driving

through

hollow

5),

center

then

from

wire

the

the

the

bar

up

up

the

furnished

wire

tension

threading

hand

loop

(22,

the

hollow

bar

(22,

through

hole

through

unwinder

thread

wire

retainer

Fig.

bar

Fig.

the

in

the

the

for

discs

4).

slot

looper

large

through

eyelet

(20,

(22),

S)

the

(18,

(124,

Hook

left

in

the

needle

the

purpose),

(17,

Fig.

Fig.

Fig.

the

then

using

to

right

heel

and

up

hole

lower

Fig.

4)

and

4)

between

thread

of

through

brass

then

4),

up

4) down

on

the

through

the

the

in

the

tube

through

down,

tweezers,

over

the

through

the

the

under

the

throat

end

looper

hole

throat

(15,

the

of

slot

(123,

in

plate

lower

and

guide

plate

the

the

pass

of

the

Fig.

from

stud

hollow

wire

the

the

Fig.

point

(21).

4)

hole

S),

Fig.

5

The work clamp

opened,

(using

through

Fig.

4),

the

upper

(27,

Fig.

the

throat

clanq)

plates

When

the

tq)per

provided

pass

the

the

through

plates

in

on

the

threading

lower

hole

4),

(26,

thence

plate

back

position.

threading

tube

(24)

this

plates

cord

from

wire

wire

the

upper

Fig.

from

(21),

into

Also

the

to

machine.

furnished

thread

4),

back

the

place

close

cord

the

Threading

To

Thread

having

the

wire

up

cord

unwinder

eyelet,

thread

through

to

leading

and

hook

the

been

for

front

front

spread

through

the

under

eyelet

the

through

toward

the

on Machine 299U110,

upper

hole

(26)

-

the

the

Cord

outward

purpose),

and

adjacent

hole

springs

bed

cover.

since

12

-

Looper

the

between

in

the

the

the

operator.

(11

pass

no

and

upper

then

to

cord

small

and

the

cord

the

front

brass

pass

the

tension

the

cord

controlling

hole

near

Then

12,

Fig.

cord

directly

controlling

tube

.the

bed

(24,

cord

discs

tube,

the

slide

7)

lever

to

cover

Fig.

(25,

through

spring

center

the

hold

from

is

4)

of

work

the

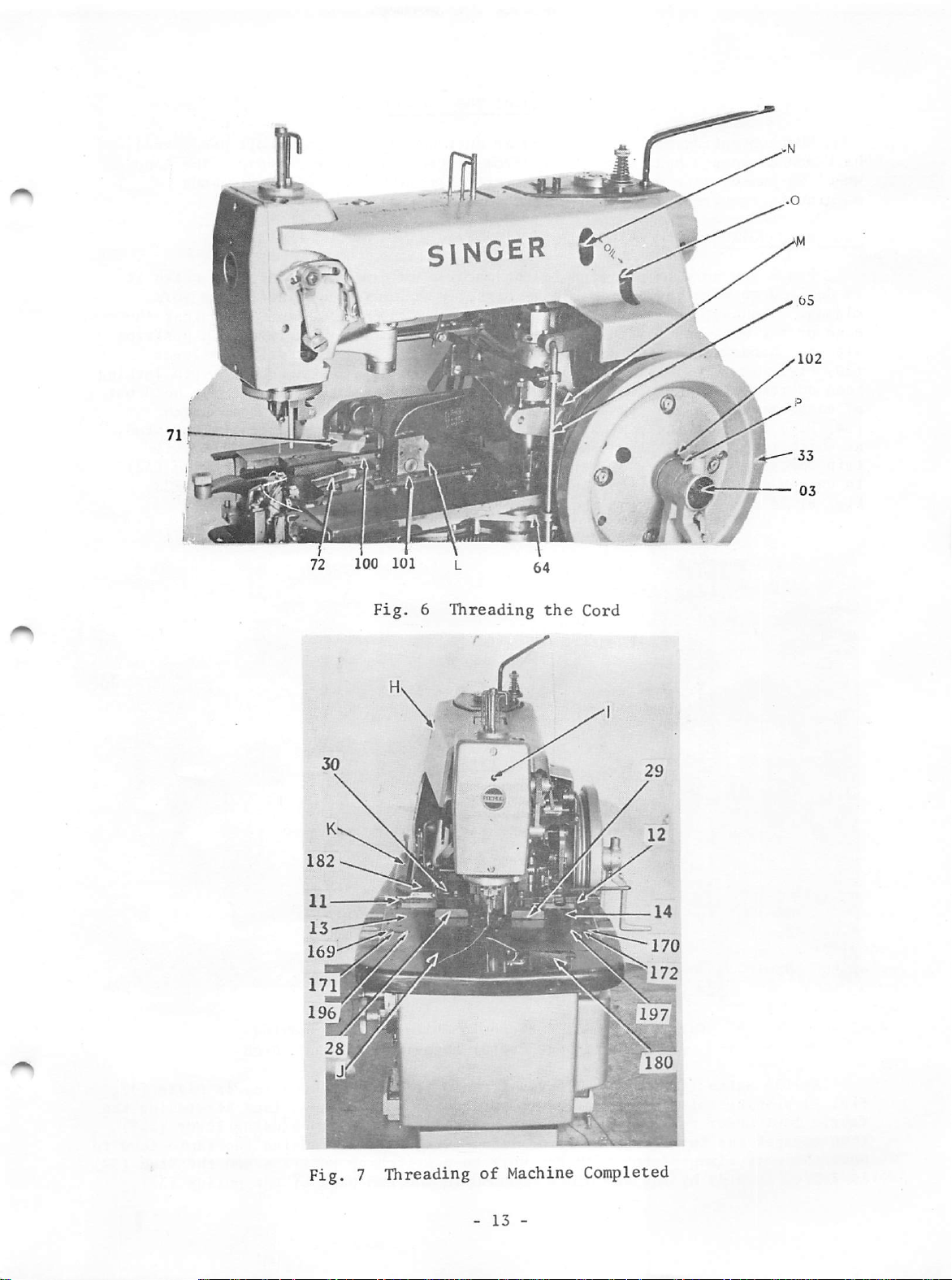

Y

ZOO

Fig.

SINGER

>

101

L

6

Threading

' l-id

*

¥

J-

I

1

li^

the

Cord

Fig.

7 Threading

of

Machine Completed

When

back and

wheel

is

machine

operating

disengage

pushed

is

required

machine

hand wiicel

into

engagement

to

be

)cration

for

shaft

turned

regular

from

with

by hand

of

tiie

buttonhole

vortical

vertical

to

Machine

shaft

make

stitching,

shaft

bevel

bevel

gear

adjustments.

pull

gear.

only

hand wheel

The hand

when

Machine

Place

is

desired

clamps.

edge

of

with

head

of

the

(30,

Fig.

on

engagement

(34,

Fig.

at

which

trip

the

to

engage

Fig.

8)

2i)ilUllU

the

work

to

make

the

Then

set

the

tiie work and

hands and

7).

rear

of

8)

until

time

lever

the

to

be depressed and

This

clamp

with

the

(35,

cam

at

will

the

the

tripping

path

in

position

buttonhole

two work

fasten

the

trip

closing

cam

cam

Fig.

8),

in

67

them

same

path

path

cam

pulley

the

61

,34

.228

^35

—32

^40

in

the

is

position

in

position.

time

press

the

latch

stud

lifting

in

is

block

(33),

(32,

the

in

work clamps

machine

directly

gauges

down

(31,

Fig.

pulley

the

correct

on

the

the

latch

causing

so

that

under

Fig.

8).

(33,

inside

to

the

(28 and

Hold

on

the

the

finger

8) from engagement

The

stud

Fig.

position

face

(34) and

the

clamp

be lowered upon

the

portion

opening

29,

work

Fig.

in

7)

firmly

starting

will

then

8) by lug on

to

receive

of

pulley

allowing

closing

the

in

the

against

(33)

the

lever

work.

which

in

lever

with

be

latch

tlie

stud

it

work

the

position

locking

held

stud,

will

(32)

(228,

out

Fig.

8 View

Buttonhole

As

the

latcii (223, Fig. 8)

this

Fig. 8) pushing

fabric

taut

under the clamps.

lever

then engages the rapid feed

move

tlie

work

is

forced inward, by the

clamp

plates with the

cam

—43

of

moves

forward

The

starting

block

-41

Buttonhole

223

193

Cutter

Cutter

to

spread the

Kngaging

forward

it

work

stud on the end

Pulley

Stud

engages

clamps, thus

of

clamp

Showing

and

Latch

the

spreader

closing

plate

stretching

lever

latch (224, Fig. 8) causing the rapid feed to

work

mounted

to a stitciiing position

in

the

cam

-

14

-

path

and

the stud

of

tlic pulley (33),

(47,

the

(228)

(32)

under

(31)

stitcliing

plate

causing

stop

the

stud

in

the

locking

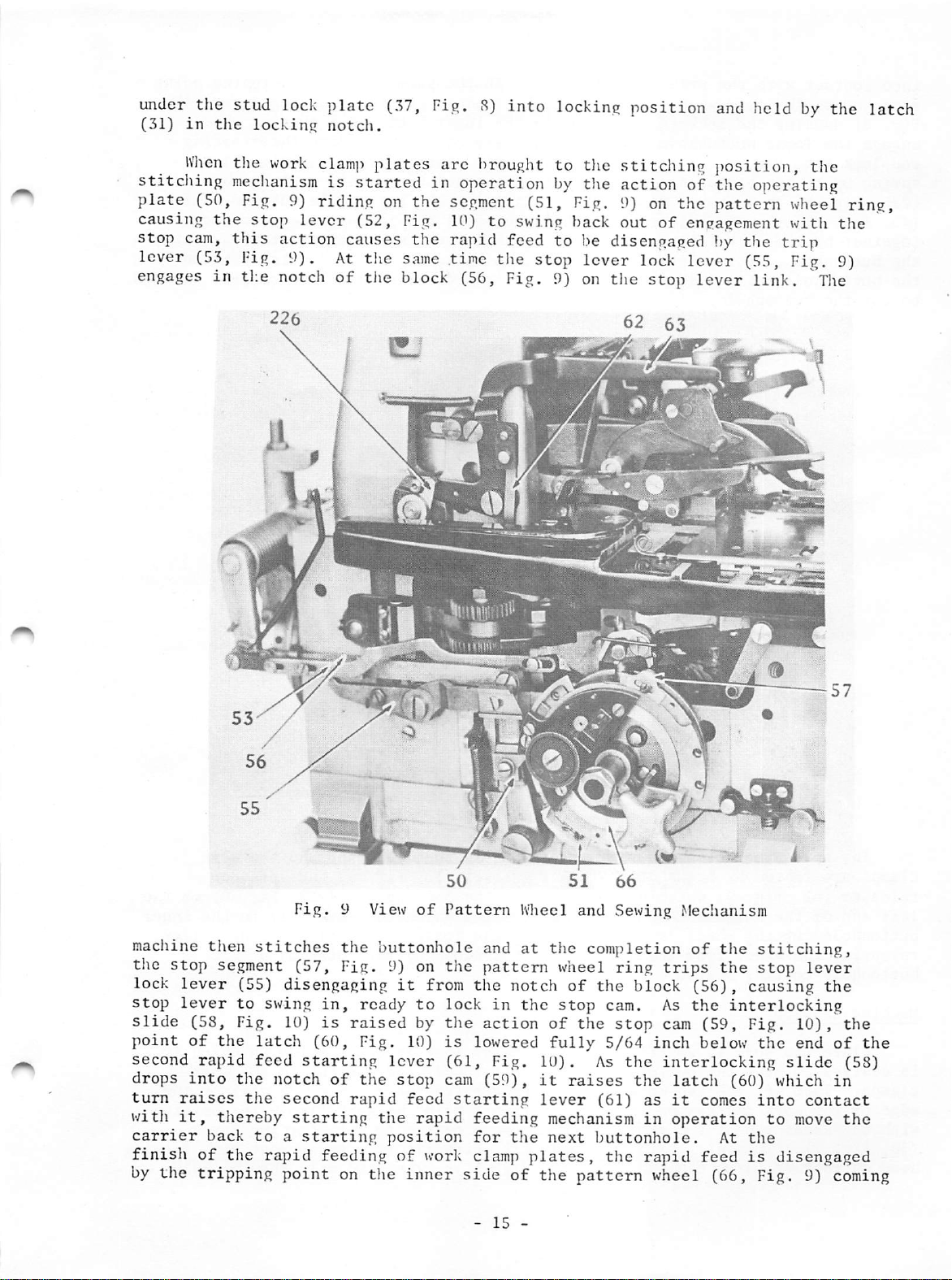

When

the

mechanism

(50, Fig. 9)

the

stop

cam,

this

lever (53, Fig.

engages

in

tl:e notch

lock

work

lever

action

9).

plate

notch.

clain]i

is

riding

(37,

plates

started

on the segment (51, Fig. 9) on the

(52,

causes

At

tiie

of

tlie block (56,

Fit*.

8)

into

are

brought

in operation by the

Fig.

10)

to

swing hack out

the

rapid

same

time the stop

feed to be disengaged by

Fig.

locking

to

the

stitching

action

lever

9) on tlie

62

position

and held by

i)osition,

the

of the operating

pattern

of

engagement witii

the

wheel

trip

lock lever (55, Fig. 9)

stop

63

lever

link.

Tlie

the

the

latch

ring,

machine

the

stop

lock

stop

slide

point

second

drops

turn

raises

with

it,

carrier

finisli

by

the

then

lever

lever

(58,

of

rapid

into

back

of

tripping

stitches

segment

(55)

to

swing

Fig.

the

latch

feed

the

the

thereby

to

the

rapid

Fig.

9 View

the

(57,

Fig.

disengaging

in,

10)

is

(60,

starting

notch

second

starting

a

starting

feeding

point

of

on tlie

buttonhole

9) on

ready

raised

Fig.

lever

the

stop

rapid

the

position

of

50

of

Pattern

the

it

from

to

lock

by

the

10)

is

(61,

cam

feed

starting

rapid

work clamp

inner

and

pattern

the

in

action

lowered

Fig.

(59),

feeding

for

side

-

15

notch

the

of

hlieel

at

the

wheel

the

stop

of

fully

10).

it

lever

mechanism

next

plates,

the

-

5^

66

and Sewing Meciianism

completion

ring

trips

of

the

block

cam.

the

5/64

As

raises

(61) as

buttonhole.

the

pattern

stop

the

the

in

rapid

As

cam

inch

interlocking

latch

it

operation

wheel

of

the

the

(56),

the

interlocking

(59,

below

(60)

comes

At

feed

(66,

stitcliing,

stop

causing

Fig.

10),

the

end

slide

which

into

to

move

the

is

disengaged

Fig.

lever

the

the

of

the

(58)

in

contact

the

9) coming

into

contact

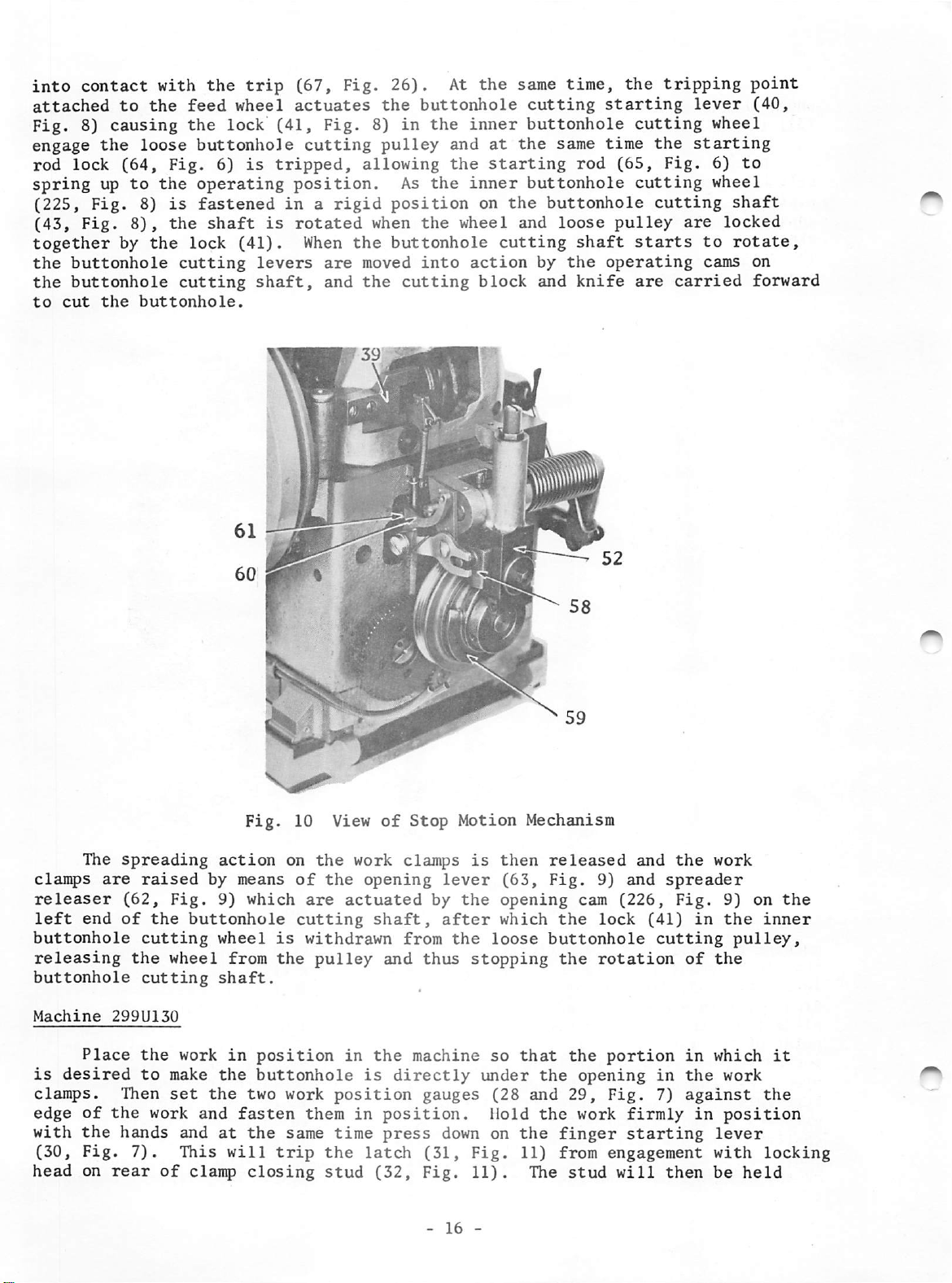

attached

Fig.

8)

engage

rod

lock

spring

(225,

(43,

Fig.

together

the

buttonhole

the

buttonhole

to

cut

to

causing

the

(64,

up

Fig.

by

the

with

the

loose

Fig.

to

the

8)

is

8),

the

the

buttonhole.

the

feed

wheel

the

lock

buttonhole

6)

operating

fastened

shaft

lock

cutting

cutting

trip

is

(41).

levers

shaft,

(67,

actuates

(41,

cutting

tripped,

position.

in

is

rotated

When

Fig.

a

are

and

Fig.

allowing

rigid

the

moved

the

26).

the

buttonhole

8)

in

pulley

As

position

when

the

buttonhole

into

cutting

the

the

At

inner

and

the

inner

wheel

action

the

at

starting

on

the

cutting

block

same

time,

cutting

buttonhole

the

same

rod

buttonhole

buttonhole

and

loose

shaft

by

the

and

knife

the

tripping

starting

cutting

time

(65,

the

Fig.

cutting

cutting

pulley

starts

operating

are

lever

wheel

starting

6)

wheel

are

to

cams on

carried

point

(40,

to

shaft

locked

rotate,

forward

The

clamps

releaser

left

buttonhole

are

end

releasing

buttonhole

Machine

Place

is

desired

clamps.

edge

of

with

the

(30,

Fig.

head

on

spreading

raised

(62,

of

the

cutting

the

cutting

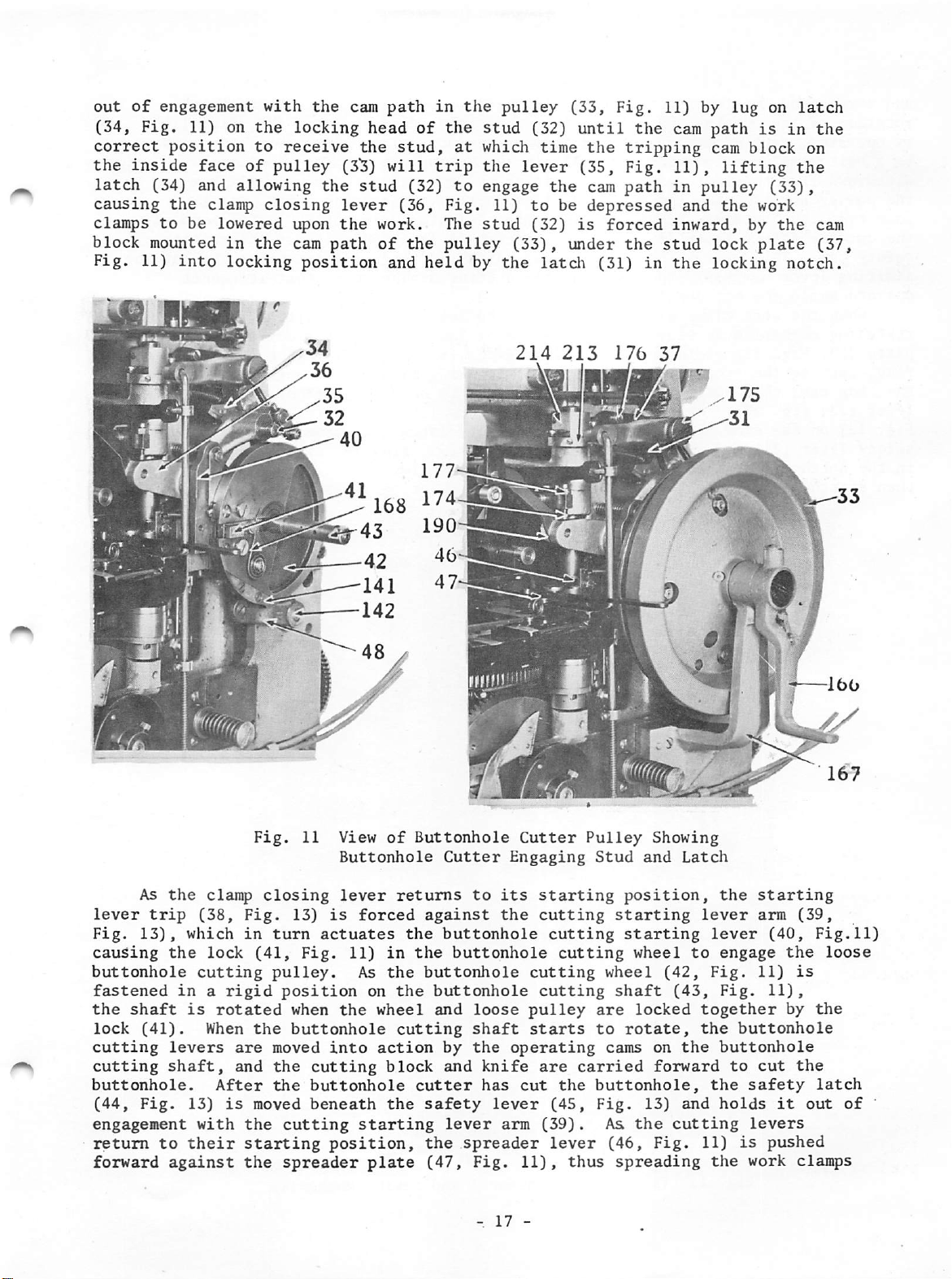

299U130

the

to

Then

the

work

hands

7).

rear

of

by

Fig,

buttonhole

wheel

work

make

set

the

and

and

This

clamp

Fig.

action

means

9)

wheel

from

shaft.

in

the

fasten

at

will

10 View

on

of

which

are

cutting

is

withdrawn

the

position

buttonhole

two

work

them

the

same

trip

closing

the

the

actuated

pulley

in

position

time

the

stud

of

work

opening

shaft,

and

the

is

in

position.

press

latch

(32,

Stop

clamps

by

after

from

thus

machine

directly

gauges

down

(31,

Fig.

-

Motion

is

lever

the

the

stopping

Fig.

11).

16

Mechanism

then

opening

which

loose

so

under

(28

Hold

on

(63,

that

the

released

Fig.

cam

the

buttonhole

the

the

the

opening

and

29,

the

work

finger

9}

rotation

11) from engagement

The

stud

-

and

(226,

lock

portion

Fig.

firmly

starting

will

and

(41)

cutting

in

7)

the

spreader

Fig.

then

work

9) on

in

the

of

the

in

which

the

work

against

in

position

lever

with

be

the

inner

pulley,

it

the

locking

held

out

of

(34,

correct

the

inside

latch

causing

clamps

block

Fig.

engagement

Fig.

11) on

position

face

(34) and

the

to

be

mounted

11)

into

of

allowing

clamp

lowered

in

locking

with

the

to

receive

pulley

closing

the

the

locking

the

upon

cam

path

position

cam

head

the

(3*3)

stud

lever

the

work. The

of

path

stud,

will

(36,

the

and

of

(32)

held

177

in

the

at

trip

to

Fig.

pulley

the

stud

which

the

engage

stud

by

pulley

lever

11)

(33),

the

214

(33,

(32)

until

time

the

(35,

the

cam

to

be

depressed

(32)

is

under

lately (31)

213

Fig.

the

tripping

Fig.

path

forced

the

in

176

11) by

cam

11),

in

and

inward,

stud

the

37

"

lug

path

cam

lifting

pulley

the

lock

locking

/175

on

is

block

(33),

work

by

plate

latch

in

on

the

the

notch.

the

cam

(37,

As

the

lever

Fig.

causing

buttonhole

fastened

the

lock

cutting

cutting

buttonhole.

(44,

trip

13),

the

shaft

(41).

levers

shaft,

Fig.

engagement

return

forward

to

against

clamp

(38,

Fig.

which

inarigid

is

13)

their

lock

cutting

rotated

When

are

and

After

is

with

in

the

starting

the

Fig.

closing

turn

(41,

pulley.

position

the

moved

the

the

moved

cutting

spreader

11 View

Buttonhole

lever

13)

is

actuates

Fig.

11)

when

the

buttonhole

into

cutting

buttonhole

beneath

position,

fl68

43

42

141

of

returns

forced

in

As

the

on

the

wheel

cutting

action

block

the

starting

plate

174

190

^*0

47

Buttonhole

Cutter

against

the

buttonhole

the

buttonhole

buttonhole

buttonhole

and

by

and

cutter

safety

lever

the

spreader

(47,

to

loose

shaft

the

knife

has

lever

Fig.

Cutter

Engaging

its

starting

the

cutting

cutting

cutting

pulley

starts

operating

are

cut

arm

(39).

11),

Pulley

cutting

cutting

carried

the

(45,

lever

thus

Showing

Stud

and

position,

starting

starting

wheel

wheel

shaft

are

locked

to

rotate,

cams on

forward

buttonhole,

Fig.

13)

As

the

(46,

Fig.

spreading

Latch

to

(42,

(43,

together

the

the

and

cutting

the

lever

lever

engage

Fig.

Fig.

buttonhole

buttonhole

to

the

safety

holds

11)

is

the

work

starting

arm

(40,

11)

11),

cut

it

levers

pushed

(39,

Fig.11)

the

is

by

the

the

latch

out

clamps

loose

of

-

17

-

Loading...

Loading...