Singer 270-37 Service Manual

Form

(264)

-fe'.

21290

SINGER

rs

Service

270-37

Manual

*A

TrademarkofTHE

SINGER

COMPANY

THE

Copyright Under international Copyright Union

All

Rights

SINGER

Copyright © 1964 by The Singer Company

Reserved

under

COMPANY

Inter-Americon

Copyright

Union

Printed

In U. S. A.

CONTENTS

DESCRIPTION

INSTALLATION

LUBRICATION

OPERATOR

INFORMATION

MACHINE ADJUSTMENTS 8-25

PARTS

CHART

Page

Adjustment Sequence 8

AdjustmentsonUnderside

Throat

Plate

of

23-25

Loop Pick-up Finger 24

Reel Holder Position Stop 23

Trimming Knives 23, 24

Description of Mochine 3

General

Feed

Driving

Lateral

Characteristics

Mechanism

Adjustments

Gears

Linkage 14, 15

14-17

14

Longitudinal Linkage 16, 17

Timing

Timing Longitudinal

Installation

Knife

Lateral

Actuating

and

Feed

Clamp

Feed

17

17

Lifting Adjustments 12, 13

Button Clamp Foot Lifter 13

Pull-oft Loop 13

Safety

Tension

Devices

Releaser

12

13

Thread Wiper 13

Lubrication

Doily

Care

Needle

Setting

Stitching

the

Needle.

Troubles

3

4

5

5

6

6

6

INDEX

Page

3

4

5

3-7

26

Page

Sewing Difficulties 7

Sewing Mechanism Adjustments 19, 20

Needle Bar Height 20

Hook Positioning (Longitudinal) 19

Hook Timing 19

Sewing Reel 25

Speed 5

Motion

Stop

Arm

Engaging

Starting Lever 9

Starting Lever

Tripping Linkage

Stop

Motion

Threading the Machine 6

Thread

Finger

Adjustments 9-11

Shaft

Arm

Arm

Stop 10

10

11

Broke 18

Stripper and

Retracting Adjustments 22

Plate

Follower 22

Retracting Finger 22

Stripper Finger 22

Thread Tension Adjustments 7

Tripping Points Adjustments 18

Winding Linkage Adjustments 20, 21

Pre-T

ension

21

Reel Driver Tripping Points 21

Thread Clomping Action 20

n

.9

TO

ALL

WHOMITMAY

The

improper

otherofthe

Registered

reconditioned,

factory

or an

TrademorksofThe

Trademarks)

or

authorized

CONCERN:

placingorrenewalofthe

Singer Company (all of

on ony

machine

alteredinany

SINGER

that

vroy

whatsoever

agencyisforbidden.

Trodemork

has

been

SINGER'

which

repaired,

outside

or any

ore

duly

rebuilt,

a SINGER

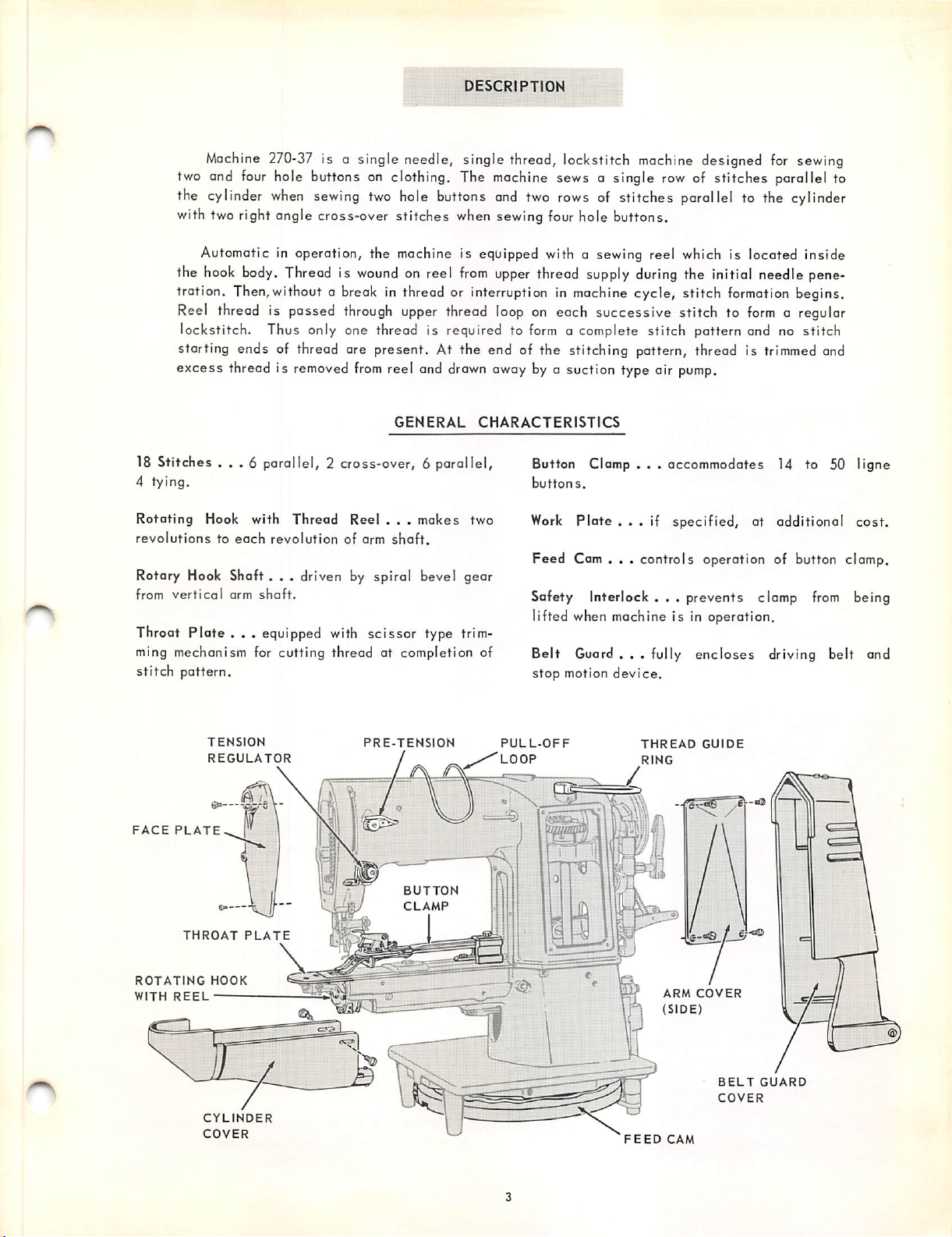

DESCRIPTION

Machine

two and

the

cylinder

with tworight angle cross-over stitches

270-37

four

hole buttons on clothing. The

when

is a single needle, single thread, lockstitch

sewing

two

hole

buttons

when

machine

and

two

sewing

sews a single

rows

of stitches parallel to the

four

hole buttons.

machine

Automatic in operation, the machine is equipped with a sewing reel which is located inside

the

hook

body.

Threadiswound

tration. Then,without a break in thread or interruptioninmachine

Reel

thread is passed

through

lockstitch. Thus only one thread is required to

on reel

upper

from

thread

upper

thread

supply

during

cycle, stitch

loop

on each successive stitch to

form

a complete stitch pattern and no stitch

starting ends of thread are present. At the end of the stitching pattern, thread is

excess thread is

18 Stitches

4 tying.

Rotating

revolutionstoeach

Rotary Hook

from

vertical

...

Hook with

Shaft,

arm

removed

from

reel and

GENERAL

drawn

CHARACTERISTICS

6 parallel, 2 cross-over, 6 parallel,

Thread

revolution

Reel

of arm

. . .

shaft.

makes

two

, . driven by spiral bevel gear

shaft.

away by a suction type air

Button Clomp . . , accommodates 14 to 50 ligne

buttons.

Work

Plate

...

if specified, at additional cost.

Feed

Cam . . . controls operation of button clamp.

Safety Interlock . . . prevents clamp

lifted when machine is in operation.

Throat Plate . . . equipped with scissor type trim

ming mechanism for cutting thread at completion of

stitch

pattern.

Belt

Guard . . . fully

stop

motion

device.

designed

row

of stitches parallel to

for

the Initial needle pene

formation

form

a regular

trimmed

pump.

encloses

driving belt and

sewing

cylinder

begins.

and

from

being

FACE

ROTATING

WITH

PLATE

THROAT

REEL

TENSION

REGULATOR

PLATE

HOOK

CYLINDER

COVER

PRE-TENSION

BUTTON

CLAMP

PULL-OFF

LOOP

THREAD

RING

r.

GUIDE

\

ARM

COVER

(SIDE)

BELT

GUARD

COVER

FEED

CAM

BELT

COVER

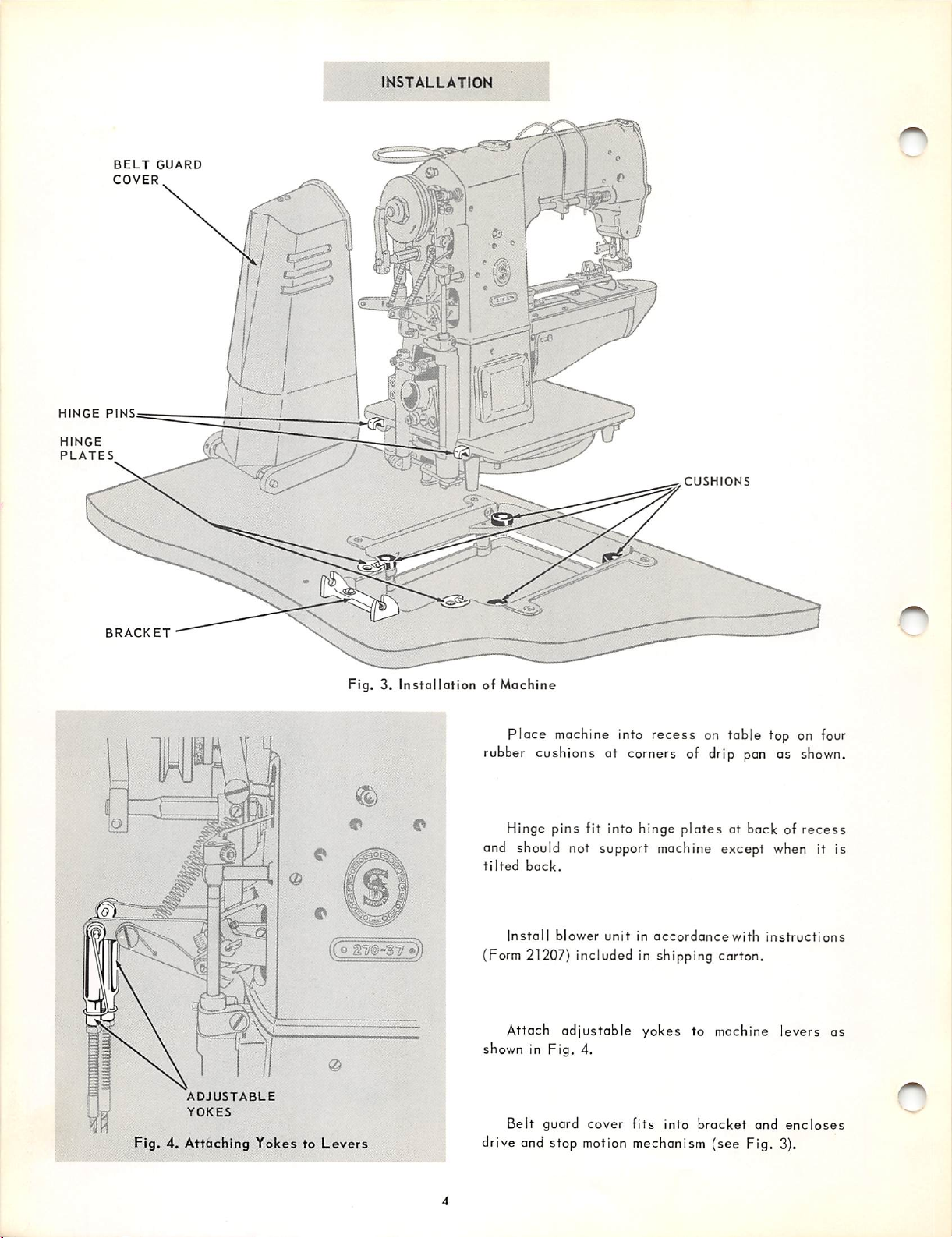

INSTALLATION

GUARD

HIHGE

HINGE

PLATES

PINS

BRACKET

Fig.3.InstallationofMachine

Place

rubber

r

cushions at corners of drip pan as

Hinge pins fit into hinge plates at back of

and should not support machine except

tilted

back.

machine into

recess

GUSH

ONS

on table top on four

when

shown.

recess

it is

(Co

Install

(Form 21207) included in shipping carton.

blower

unitinaccordancewith

Attach adjustable yokes to machine levers as

shown in Fig. 4.

ADJUSTABLE

YOKES

Fig.4.Attaching

YokestoLevers

Belt

guard cover

drive and stop

motion

fits

mechanism (see Fig. 3).

into

bracket

instructions

and

encloses

or

is

on

fabric.

Doily

For

best

"Type

desired

Core

results,

D".

"Type

use

SINGER*

Oil

"Type

D" Oil Is used when on oil

which will produce a minimum of

LUBRICATION

B"

stain

On new

machines

and

machines

Installed

after

several weeks of idleness, needle bar and take-up

linkage should be oiled by hand before using. The

residual lubricant may have congealed or dis

appeared

entirely.

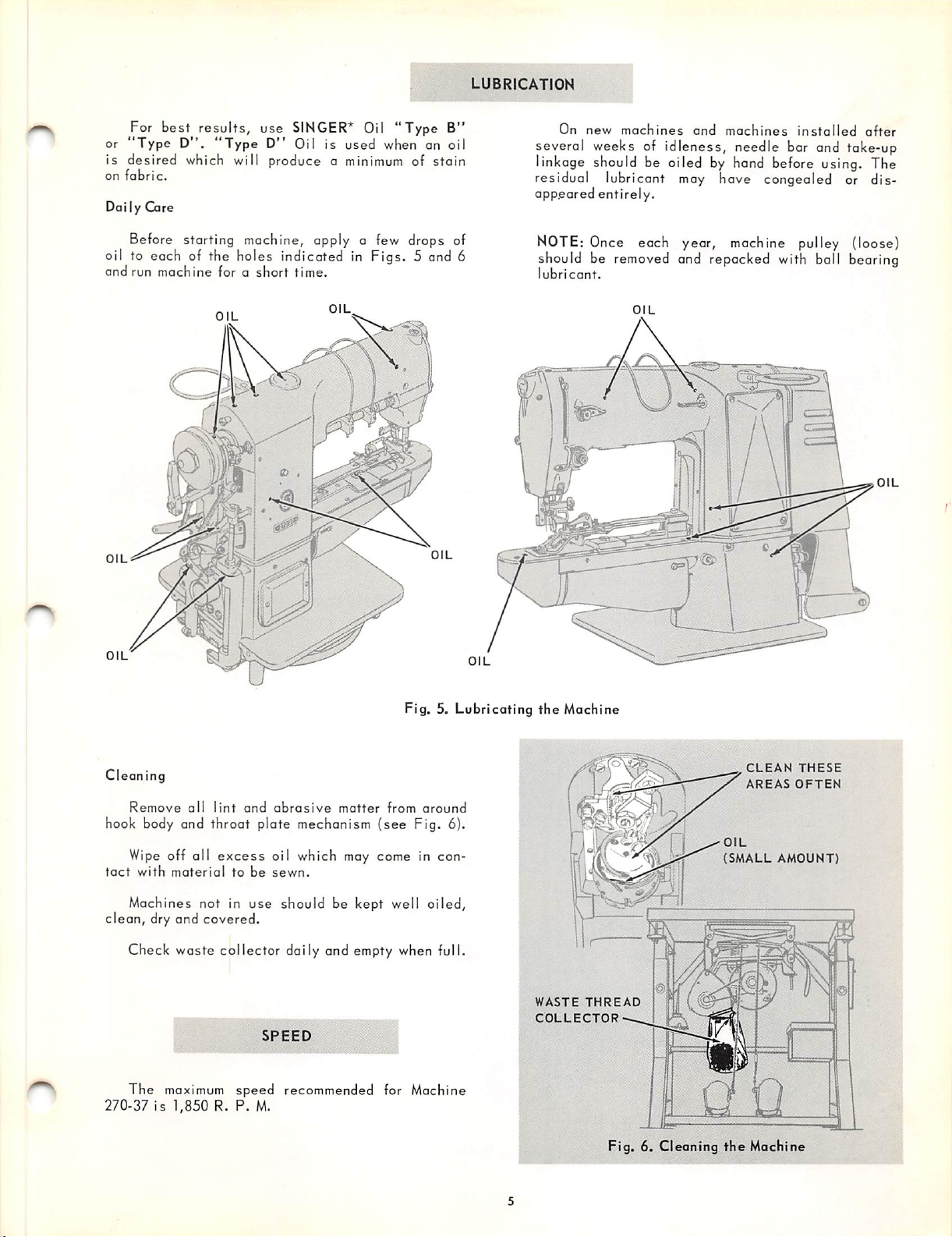

Before starting machine, apply a few drops of

oil to each of the holes indicated in Figs. 5 end 6

and

run

machine

OIL

OIL

forashort

OIL

time.

OIL

OIL

NOTE: Once each year, machine pulley (loose)

should be removed and repacked with ball bearing

lubricant.

OIL

OIL

OIL

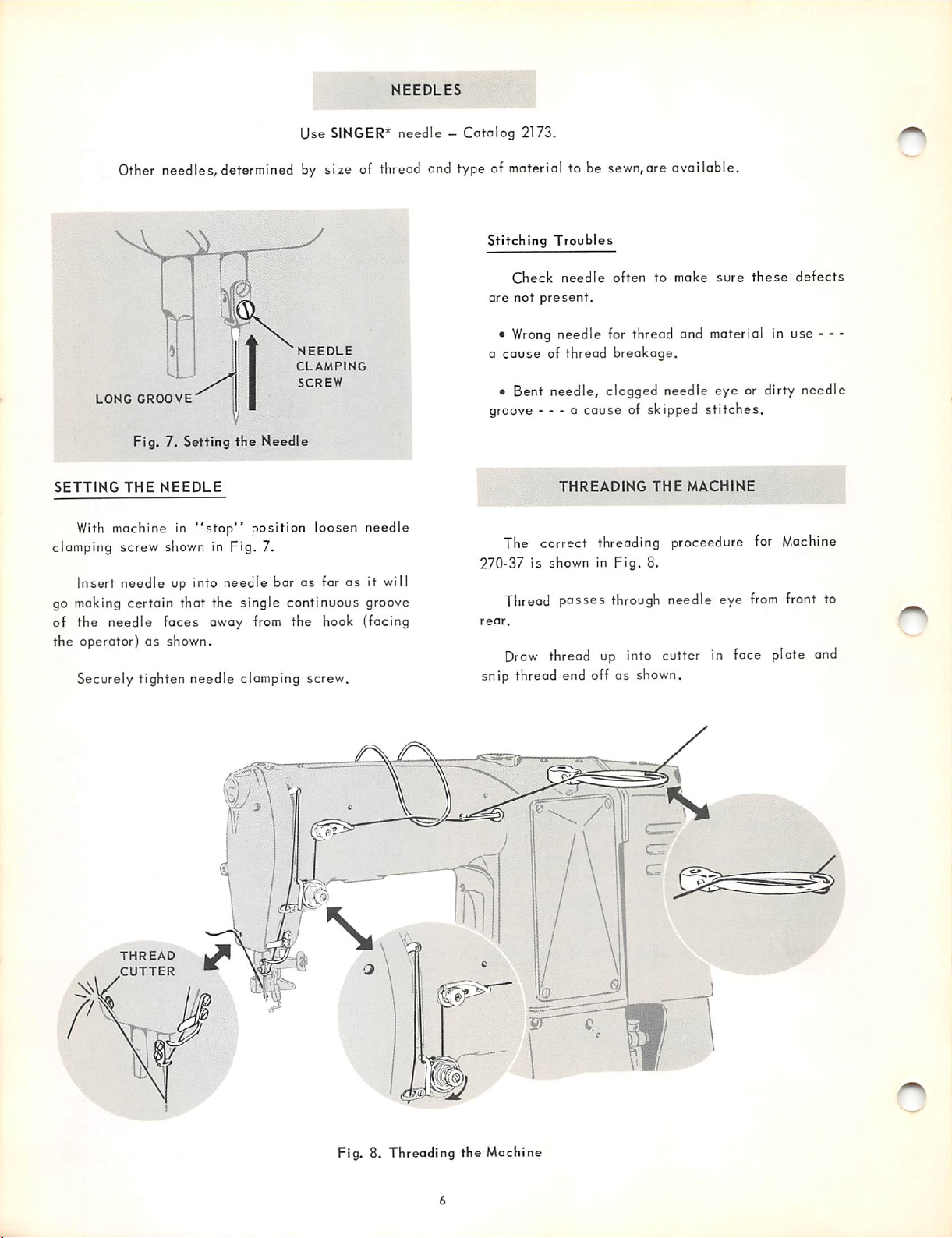

Cl

eaning

Remove

hook body and throat plate mechanism

Wipe off all

tact

with

Machines not in

all

material

lint

and

excess

tobesewn.

use

abrasive

matter

from

(see

oil which may come in con

should be kept well

clean, dry and covered.

Check waste collector daily and empty when full.

SPEED

The

maximum

270-37 is 1,850 R. P.

speed

M.

recommended for Machine

Fig. 5.

around

Fig. 6).

oiled,

Lubricating

the

Machine

WASTE

COLLECTOR

THREAD

Fig. 6. Cleaning

1

CLEAN

AREAS

OIL

(SMALL

the

Machine

THESE

OFTEN

AMOUNT)

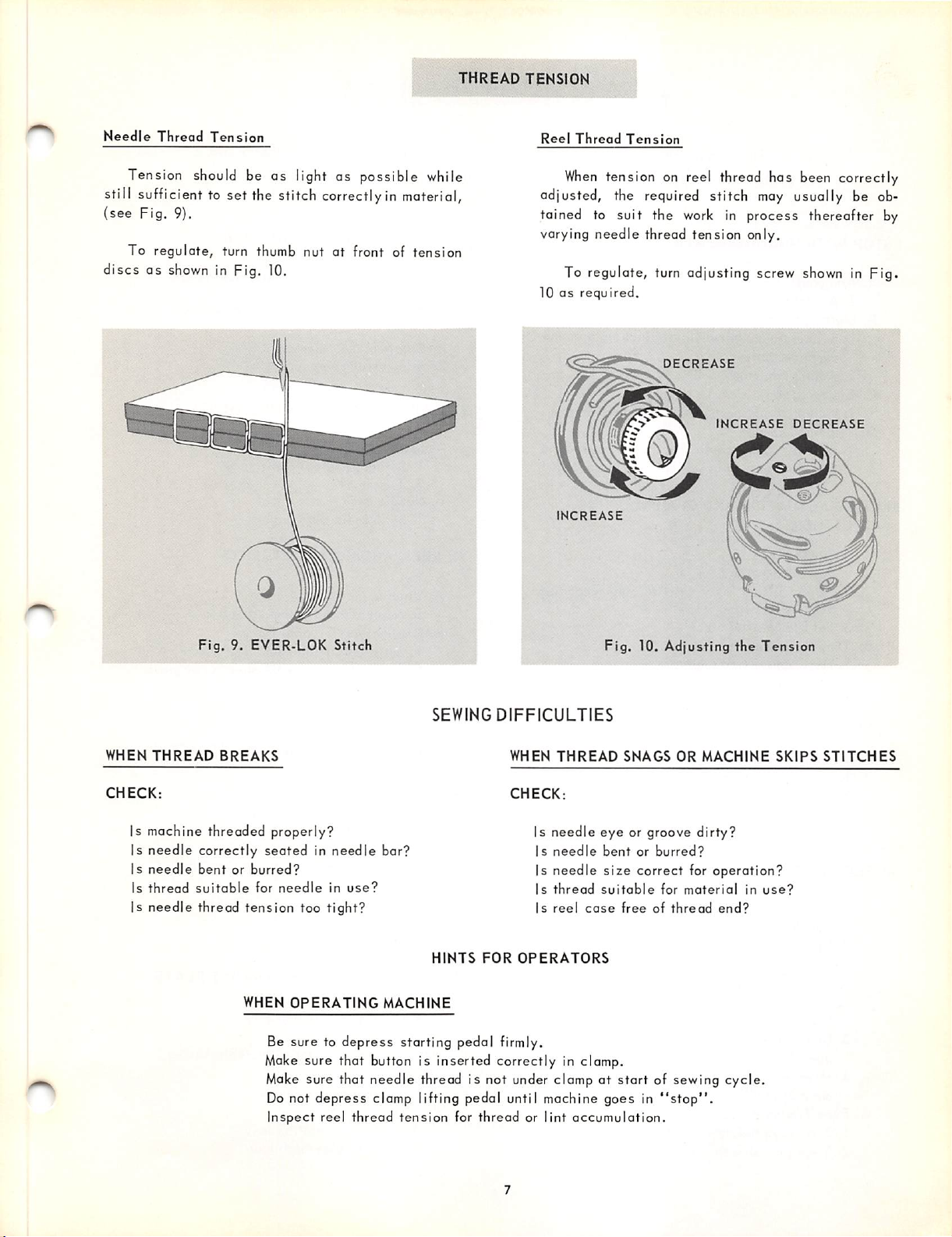

Other

needles, determined

NEEDLES

Use

SINGER*

by

size of thread and type of material to be sewn,are available.

needle—Catalog

2173.

NEEDLE

CLAMPING

SCREW

LONG

GROOVE

Fig.

SETTING

With

clamping

7. Setting

THE

NEEDLE

machine in

screw

shown in

"stop"

the

Needle

position loosen needle

Fig.

7.

Insert needle up into needle bar as far as it will

go making certain that the single continuous groove

of

the

needle

the

operator)asshown.

Securely

faces

tighten

away from the hook (facing

needle

clamping

screw.

Stitching

are

•

a

cause

Troubles

Check

not

Wrong

needle

present.

oftentomake

sure

needle for thread and material in use • - -

of thread

breakage.

these

• Bent needle, clogged needle eye or dirty needle

groove - - - a cause of skipped

THREADING

THE

The correct threading proceedure for

270-37

rear.

is shown in

Thread

Draw

passes

thread up into cutter in face plate and

Fig.

8.

through needle eye

stitches.

MACHINE

from

Machine

front to

snip thread end off as shown.

defects

THREAD

CUTTER

Fig. 8. Threading

the

Machine

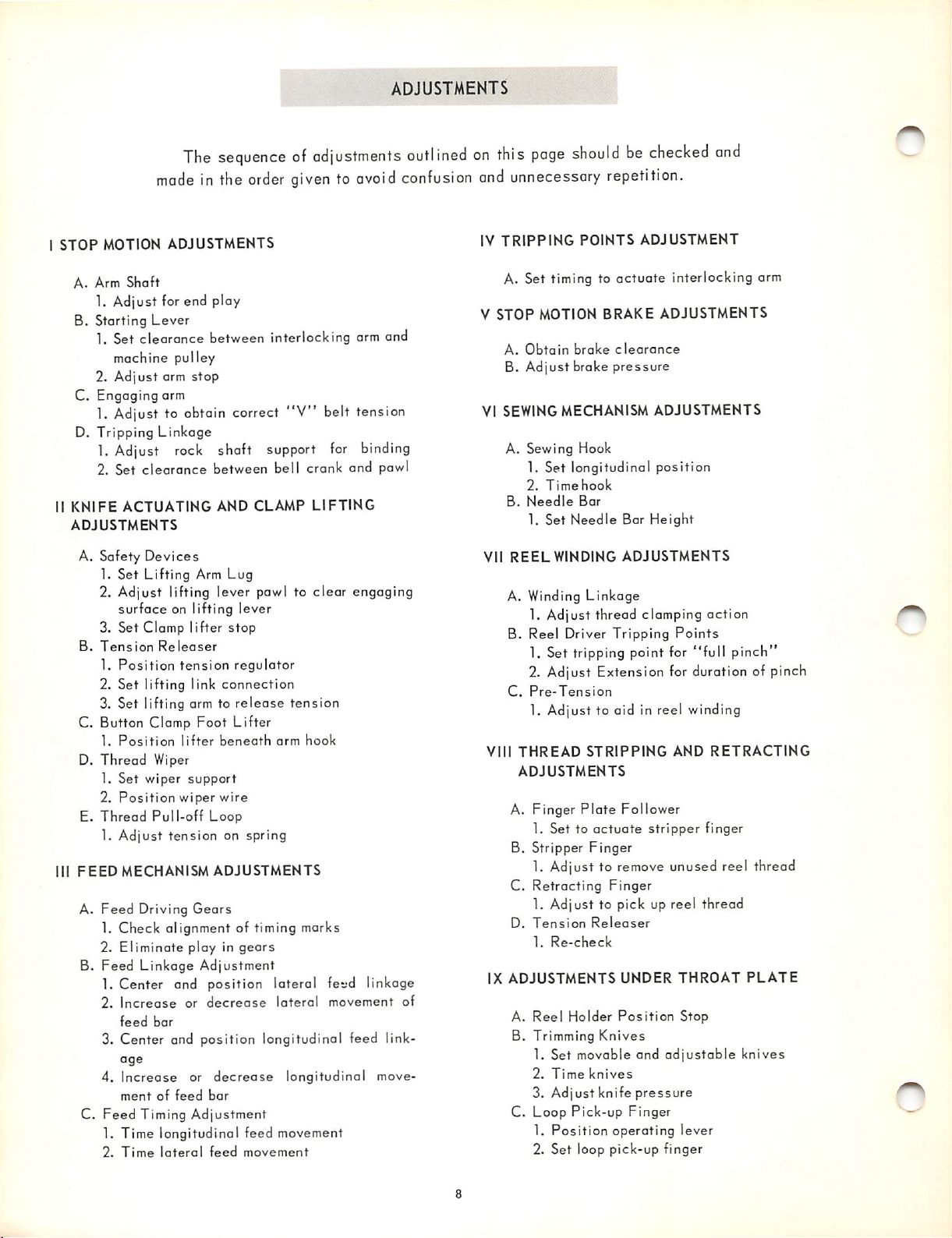

THREAD

TENSION

Needle

Thread

Tension

Tension should be

as

light as

possible

while

still sufficient to set the stitch correctlyin material,

(see

Fig.

9).

To

regulate,

discsasshown in pig. 10.

turn thumb nut at front of

tension

Reel

Thread

When

Tension

tension on reel thread has been correctly

adjusted, the required stitch may usually be ob

tained to suit the work in process thereafter by

varying

10 as required.

needle

thread

tension

only.

To regulate, turn adjusting screw

DECREASE

INCREASE

INCREASE

showninpig.

DECREASE

0

Fig.

9. EYER-LOK Stitch

WHEN

THREAD

CHECK:

BREAKS

Is machine threaded properly?

Is

Is

Is

Is

needle

needle

thread

needle

correctly

bentorburred?

suitoble

thread

seatedinneedle

for

tension

WHEN

Be sure to

Make

Make sure that

Do not

Inspect

SEWING

DIFFICULTIES

WHEN

THREAD

CHECK:

Is needle

bar?

Is

needle

Is needle

needle

in

use?

too

tight?

OPERATING

depress

HINTS

MACHINE

FOR

starting pedal firmly.

Is

thread

Is

reel

OPERATORS

sure that button is inserted correctly in clamp.

depress

reel thread

needle

clamp lifting pedal until machine goes in

thread is not under clamp at

tension

for thread or lint

Fig, 10. Adjusting

SNAGS

eye

or groove dirty?

bentorburred?

size

correct for operation?

suitable

cose

freeofthread

start

accumulation.

OR

MACHINE

for

material

of sewing

"stop".

the

end?

cycle.

Tension

in

use?

SKIPS

STITCHES

STOP

MOTION

1"he

sequenceofadjustments

madeinthe

ADJUSTMENTS

order

giventoovoid

ADJUSTMENTS

outlinedonthis

confusion

and

IV

page

unnecessary

TRIPPING

shouldbechecked

repetition.

POINTS

ADJUSTMENT

and

A.

Arm

Shaft

1. Adjust for end ploy

B. Starting

1. Set

2.

C. Engaging arm

1. Adjust to obtain correct

D.

Tripping

1. Adjust

2. Set

II

KNIFE

ADJUSTMENTS

Lever

clearance

machine pulley

Adjust

arm

stop

Linkage

rock

clearance

ACTUATING

between interlocking arm and

"V"

shaft support

between bell crank and pawl

AND

CLAMP

A. Safety Devices

1. Set

Lifting

Arm Lug

2. Adjust lifting lever pawl to clear engaging

surface

3. Set Clamp lifter

B.

Tension

1.

Position

2. Set lifting link

3. Set lifting arm to

on lifting

Releaser

tension

lever

stop

regulator

connection

release

tension

C. Button Clamp Foot Lifter

1.

D.

Position

Thread

Wiper

lifter

beneath

arm

hook

1. Set wiper support

2.

Position

E.

Thread

1.

Adjust

III

FEED

MECHANISM

A.

Feed

Pull-off

tension

Driving

wiper

wire

Loop

on

ADJUSTMENTS

Gears

spring

1. Check alignment of timing marks

2.

Eliminate

B.

Feed

Linkage

1. Center and

2.

Increase

feed

bar

play in

Adjustment

position

or

decrease

gears

lateral fevd linkage

lateral

3. Center and position longitudinal feed link

age

4.

C.

Feed

Increase

mentoffeed

Timing

or

decrease

bar

Adjustment

longitudinal move

1. Time longitudinal feed movement

2.

Time

lateral

feed

movement

belt tension

for

binding

LIFTING

movement of

A. Set timing to

V

STOP

MOTION

A.

VI

SEWING

B.

Obtain

Adjust

brake

brake

MECHANISM

A. Sewing Hook

1. Set longitudinal position

2.

Time

hook

B.

VII

Needle

1. Set

REEL

Bar

Needle

WINDING

A. Winding Linkage

1. Adjust thread clamping action

B. Reel Driver Tripping

1. Set tripping point for

2. Adjust Extension

C.

Pre-Tension

1. Adjust to aid in reel winding

VIII

THREAD

ADJUSTMENTS

A. Finger

1. Set to

B. Stripper

STRIPPING

Plate

actuate

Finger

1. Adjust to

C.

Retracting

1. Adjust to pick up reel thread

D.

Tension

1.

IX

ADJUSTMENTS

A.

Reel

B. Trimming

1. Set movable and

2.

3. Adjust knife

C.

Loop

1.

2. Set loop pick-up finger

Releaser

Re-check

Holder

Time

knives

Pick-up

Position

Knives

actuate

BRAKE

ADJUSTMENTS

clearance

pressure

ADJUSTMENTS

Bar

Height

ADJUSTMENTS

for

Follower

stripper finger

remove

Finger

UNDER

Position

operating

unused reel thread

adjustable

pressure

Finger

interlocking arm

Points

"full

pinch

duration of pinch

AND

RETRACTING

THROAT

Stop

lever

PLATE

knives