Singer 270 Instruction Manual

'••••?:

•-'

.«2p7.

:-•-

-i'

}^}.

INSTRUCTIONS FOR INSTALLING AND ADJUSTING

/ ^ A-

PNEUMATIC

CLAMP

FOR

270

V3r'

LIFT

MACHINE

495069

AND

CYCLE START

•s.

il.

I

PATENT

THE

SINGER

INDUSTRIAL

s- -:' t

r

'V

H.-

MECHANIZED

CLIFTON,

Kfl.

2,764,112

COMPANY

PRODUCTS

SYSTEMS

N.J.

DIVISION

DEPARTMENT

I#*;;

.A-^-

i.

:• . • -

•.->•

PRINTED

•iAf*

•j

IN U.S.AV(10-66)

-^'1

.H- • . f r

•.yj:

i

1'

Description

coii5»letely

270

Class

terlocked

machine

movement

sei^/ing

The

raise

cycle

machine

automatically.

THE

The

air

Machines.

that

cannot

The

loiters

•vrill

SINGER

Singer

powered

the

be

foot

the

after

con5>lete

PNEUMATIC

Pneumatic Clar^)

and

air

The

cleaag

clan^)

started

control

which

clac^.

cannot

until

operates

The

the

pressure

the

CLAMP

controlled

lifting

be

raised

the

claji^)

in

second

se^dng

LIFT-CYCLE

Lift-Cycle

unit

and

starting

during

is

lowered.

two

stages.

or

final

on

the

foot

cycle

and

START

Start

designed

mechanisms

the

The

movement

control

stop

and

DEVICE

k9^069

Device 495069

specifically

are

se\7ing

first

initiates

is

the

cycle

downward

released.

clamp

so

and

the

will

is

a

for

in

the

of

the

foot

vantage

ed

in

tor.

of

the

motion

NOTE

167296

with

with

the

Another

soft

parts.

from

the

Machine on

The clajj^)

control

garments

The

inherent

reduction

advantage

action

This

******

Remove

the

pneumatic

If

the

which

can

^Tithout

that

of

of

the

Starting

machine.

cycle

clajip

it

is

be

raised

starting

are

advantage

the

amount

which

pneumatic

less

Lever

The

start

lift-cycle

installed,

or

lowered

the

difficult

inapneumatic

of

effort

is

not

so

type

wear

and,

Arm

Nut 1655

any

number

machine.

to

position

unit

and

skill

immediately

control

in

ultimately,

acd

Starting

This

properly.

of

required

apparent

relation

less

function of Tripper I67296

device.

start

must

be

is

to

in

operate

good

efficiently,

sewing

of

times

is

a

specific

this

kind

is

to

down

Lever

is

not required

condition.

by

is

of

the

the

the

time.

Arm

means

ad

reflect

opera

result

stop

Tripper

the

27O

This

is

especially

the

starting

lever

******

true

with

respect

interlocking

to

stop motion

arm (239159)•

parts

such as

the

brake and

Installation

1 -

Use

the

assembly

THE

the

ten^jlate,

present

SINCm

at

cutout

the

PMEUMATIC

included

In

the

rear

of

the

CLAMP

as

table

machine.

LIFT-CYCLE

the

last

to

facilitate

page

START

of

these

mounting

DEVICE

instructions,

the

^93069

valve

to

cylinder

enlarge

2 - Mount

cates

3 -

Mount

table

head

screws.

4 - Mount

manual.

5 -

Connect

nections

6 - Connect

marked

7 -

Fill

SIICER

the

the

valve

Belt

the

and

the

Guard Base

filter,

preferably

foot

the

tubing,

at

the

the

three

with

the

lubricator

TypeCOil

and

cylinder

239^^)

lubricator,

at

control

air

using

extending

spring.

unions on

corresponding

\d.th

or

the

assembly

the

right

any one

the

oil,

equivalent.

with

regulator

four

of

the

of

from

the

foot

control

red,

yellow

toapoint

by

means

#12X1"

assembly

of

the

pan

on

bracket

head

the

(which

screws.

underside

machine. Use two #12 X 1" pan

the

three

bottom

and

just

of

the

tubing

blue

below

methods

cylinders,

to

the

bands.

the

illustrated

ends

indicator

to

of

of

the

the

line.

dupli

the

in

con

tubing

this

Use

8 -

Mount

machine. Use two

elsewhere

9 - Make

See

ing

10-Connect

with

11-Set

poimds.

individual

the

one-shot

in

the

air

the

illustrations

procedures.

the

the

accessories.

the

main

There

requirements.

this

cylinder

unit

regulator

may

valve

-^16

manual.

to

be

on

X 1

3/4"

connections

which

an

air

pressure

some

the

underside

round head

follow

svipply

at

slight

wood

to

the

starting

for

instructions

source.

50

pounds

adjustment

of

the

screws. See

Use

the

and

of

the

table

and

and

clac^)

on

connecting

Qwlk-Change

the

air

air

spring

spring

to

the

the

illustration

lifting

cotQ)ler

pressure

pressure

rear

levers.

and

of

the

adjust

supplied

at

to

3

suit

THE

SINm

PHEUMATIC

CLAMP

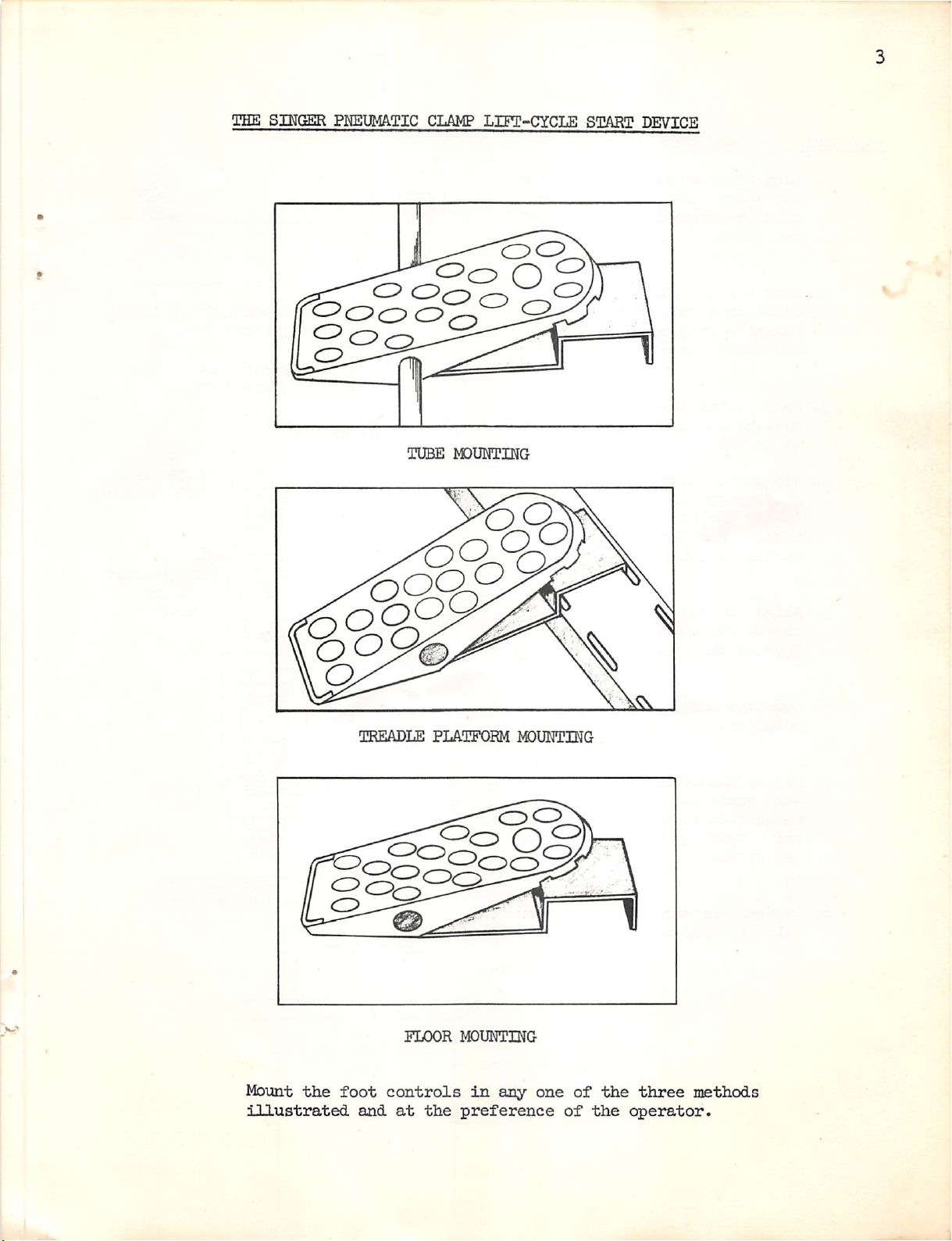

TUBE

LIFT-CYCLE

tOUKTING

START DEVICE

Moxmt

illustrated

the

TREADLE PLATFORM MDUUTING

foot

and

FLOOR

controls

at

the

MDUNTING

in

any

preference

one

of

of

the

the

three

operator.

methods

Loading...

Loading...