Form

Rev.

3148w

\263)

SINGER

SERVICE

Class 269w

MANUAL

SINCLE

EEDLE

LOCK STITCH

THE SINCER MANUFACTURING COM

*A

Tradomarlt

Copyright©

All Rig

af

THE

SINGER

MANUFACTURING

COMPANY

1963 by The Singer Manufacturing Company

Copyright

Under

hts Re

.. rved under Inter-American Copyright Union

International

Copyright Union

PAN

Y

Printed

in

U.

S.

A.

TABLE

OF CONTENTS

DESCRIPTION

OPERATION •••••••••••••••••••••••••••••••.•••••••••••.••• 3-6

ADJUSTMENT ••••••••...••.•.••••.••.••••••••••••••••••• 6-10

Accessories

Adjusting Device ••...••••••••••••••••••••••••••••••••••••• 36

Arch Clamp •••••..••••••••.••.•••••.•••••• 12, 40-44, 52,

Arm

Shaft, ••••••••.•.••..••••.•••••••••••••••••••••••••••••.•

End

Barring, •••.••••••••••••••••••••••••••••••••••••••••••••••••••• 3

Buttonholes •••••..••••••••••••••••••••••••••••••• 42,

Pockets

Bell Crank ••••••••••••••••••••••••••••••••••••••••• 8, 22,

Belt Guard •••••••••••••••••••••••••••••••••••••••••••••• 18,

Belt Loop

Belt Tension ••••••••••••••••••••••••••••••••••••••••••••••••• 9

Bobbin,

Bobbin

Bobbin Thread

Bobbin

•.....................................................

Removal

Winding

Case,

Remova 1...

Replacement

Threading •••••••••••••••••••••••••••••••••••••••••••••• 5

Winder,

A.....

Bow Fas.dning

Brake Installation •••••••••••••••••••••••••••••••••••••••••

Brake Lining Care •••••••••••••••••••••••••••••••••••••••• 10

Button

Button Sewers •••••••••••••••••••••••••••••••••••••• 3, 36-38

Cam,

Clamp Lifting Mechanism ••••••••••••••••••••••••••••

Cleaning

Clearance under Clamp

Covers

Description

Driving

Clamp

..............................................

Timing

.•..•..•......

Arm,

Adiustment............................................

End

Play

Engaging

Adiu

~

~=~e~~J:

Feed

Plate

Feed

Plate

Flat

Bed

Gauge 239369

Interlocking Arm................................

Knife

Bar

OF

MACHINES ••••••••••••••••••••.••• 3

•.••••••••••.•••.•••••••••••••••••••••••••••• 58-79

Play

Removal ••••••••••••••••••••••••••••••••••• 8

••••••••••••••••••••••••••••••••••••••••••• 46,

Tacking...................................

•••.•.•••.•••.•.•••••••••••••••••••••••••••••••. 4

.••.••••••.••••••••••••••.•.••••••••••••••••••••• 5

••••••••••••••••••••••••••••••••••••••••••.•••• 24

••

••••••

••

••••••••

•••

•••••••

••••

••

••

•••••••

••••••••••••••••••••••••••••••••••••••••••

Tension..................................

•.••••.•.• •••••••••••••••••••••••••••••••••

.1ents

••••••••••••••••••••••••••••••••••••••••

.........................................

•.............••.•••.•......••.•••••.••..•.....

3, 38-52,56

•..••••••.••.••..•••••.•..••••.•••.••......•••••.•

.•................•..........•.......•.•...•..........

....•..•..........•..............•••

······•••••••••••••••••••••••

of

Machines ••••••••••••••••••••••••••••••••• 3

.•....•

................................................

Removal

Arm,

stment..........................................

rs~~Sc~;.;r•

Carrier Bar •••••••••••••••••• 12, 36, 40,

Positioning

Work

(Arm

Shaft) ••••••••••••••••••••••••• 8

......................................

•••

•••••••••••

••••••.• •••..•••••••••••.•••••.••.• 7

Plate

•••••••••••••••••••••••••••••

.............................

•••

••••

...........

o o

.......

•••• o ••••

3,

.......

.........••.......

•••••••••••••••••••••••••••••••••• 16

56

14

52

50

52

58

3,

56

24

••

32

5, 6

3,

42

10

34

3,

22

18,

36

20

28

..

31

42

56

54, 79

..•. 6, 1

26

4

5

6

8

4

3

7

9

Knife Holder •••••••••.••••.••••••.••••••.•.••.••.•••..•••••• 42

Knife

Thread

Knives,

Adiu stment •••.•.•••.•.••••••••••••.••.••••. •••••••••••• 8

Lateral

Length of Tack Adjustment •••••••••••••••••••••.•••

Lifting

Holder

...................................... 38

...•........•..............

Rock Shaft ••••••••••••••••••

Arm

....

····•••••••••••••••••••

....

...................

••••••••••••••••• 20,

•••••••••••••••••••••

18, 42

36

••••

• 1

•• 6

INSTRUCTIONS FOR ORDERING ••••••••••••.••••.•••

PARTS LIST ••••••••••••••••••••.••••••••.••.••••••.•.•• 12-79

NUMERICAL LIST •••.•••••••••••••••••••••••••••••••• 80-84

INDEX

Line

Tack •••••••••••••••••••••••••••••••••••••••••••••••••••• 3

Link

Arm

Adjustment ••••••••••••••••••••••••••••••••••••• 7

Longitudinal Rock Shaft .•••••••••••••••••••••••••• 20, 36

Lubrication and Cleaning •••••••••••••••••••••••••••••••• 4

Machine

Machine

Needle, ••••••••••••••••••••••••••••••••••••••••••

Pulley,

Driving

Pulley

•••••••••••••••••••••••••••••••.••••••••

Accessories

(loose), Packing ••••••••••••••.••••••• 4

••••••••••••••••••••••••. 7

Setting..................................................

....................................................

Sizes

Needle Bar, •••••••••••••••••••••••••••••••••••••••••••••••• 22

Height

Setting.......................................

Stroke..................................................

Needle Bar Crank ••••••••••••••••••••••••••••••••••••••••• 14

Needle Thread Tension •••••••••••••••••••••••••••••.•••• 6

Oiling

..•...•...•.•...................•........................

Oscillating

Recoil Absorbing Mechanism ••••••••••••••••••••••• 9,

Sewing

Shoe Tacking •••••••••••••••••••••••••••••••••••••••

Size

of

Shuttle, ••••••••••••••••••••••••••••••••••••••••••••••••• 24, 36

Timing

Shuttle Driver Adjustment •••••••••••••••••••••••••••••••• 7

Space

Speed

Split

Starting Lever,

Adiustments

Stop

Motion,

Installation ••••.•••.••••••.••••.•••.••.•.•••••••••••••

Stop

Motion Timing ••.••••••.••••••••••.•..•..••.•••••••••.

Tacking Adiustments

Tacking Belt Loops

Tension,

Regulation

Tension Position Guide, ••••••••••••••••••••••••••• 22, 23

Adiustment

Thread Cutter on

Thread Guide

Thread

Thread Retainers •••••••••••••••••••••••••••• 5, 28, 36, 42

Thread

Throat

Tripping Mechanism Adjustment •••••••••••••••••••••••• 8

Tripping

Timing

Twist

Uneven Winding, Correction for •••••••••••••••••••••••

"V"

Belt

Vertical Drive

Width

Shafts ••••••••••••••••••••••••••••••••••••••••• 6

Strops

...........................................

Needles

behind Needle ••••••••••••••••••••••••••••••••••••••• 3

........

Feet

............•.......•.................•....••

••••..•.•••••.•..••.....•..•.•..............••..•.

••••••••••••••••••••••••····················· ..

....•............••....••..................•........

......•....•......................•..........

••..••••.•...•...••..••.........•••.•.••.•.

Brake

.......................................

....................................•

......•..•••.•........•.••.•.•...•

••••••••••••••••••••••.••••••.••..••••.•.•••..•••••••

...••....•....•••..•...................••..•••

.............................................

Face

Plate

.....................•........•......•.....

in

9••••••••••••••••••••••••••••••••••••••••••••••••••••

Wiper...........................

Plate

••••••••••••••••••••.••••••.••••• 18, 36, 40, 42

Points,

of

Thread......................................

of

Tack Adjustment ••••••••••••••••••••••••••

.•.....•.....•.••..................

...•.•.....••..•..•••..•..•....•....••••••.•...••.

Tension Adjustment •••••••••••••••••••••••

Shaft

..........•.....•.....................

••••••••••••••••••••••••

22, 36, 44,52,

3,

4, 36, 40,

3,

3,

.

.....

••••

11

3,

14

4,

76

48,

6G'

4

4

6

3

4

26

3,

44

40, 48

4-

~---,...._

7

...

3

44

26

9

26

10

lO

1

3,

56

28

6

6

3,

18

5,

28

5

56

38-50

.

lO

4

5

•••

9

30

• 1

,

..,.

3

Machine 269w8

clothing

tions.

jus

"V"

5/32

ing, 27 covering and 3

nished

Other

similar

· ·e:t:ptions -

Machine 269w5

with

ligne

be

Machine 269w7

1/8

stitches).

and

Single

Needle,

Link

take-up.

table

oscillating

Manually

Automatic

Two-piece

belt

Needle

Clearance

Space

Bar pattern

inch wide;

Cylinder

an

varieties

to

21

stitches

Regularly fitted with button clamp for 14

buttons.

fitted

with clamp for 14

Space

Needle,

to

3/8

Needle,

is

designed

general

needle,

Catalog

groove

bar

behind

request.

Machine 269w8, with

••

behind

Catalog

Catalog

lock

1628 (68x5).

Short

shuttle.

operated

stop

and

machine pulley

2-1/4

stroke,

under clamp,

needle, 8 inches.

1/8

to

consists

bed.

Flat

of Machines

- for

stitching

(18

If

specified

needle, 7 inches.

1627 (68x3),

• for

tacking

inch long, with 18

3072 (16x100).

for barring

barring and

stitch.

beak,

thread

clutching

inches

1-9/16

5/8

5/8

inch long and

of

tying

stitches).

bed

cross

and 3

on

to

central

cutter.

device.

(tight)

outside

inches.

inch.

42

stitches

type

of

the

2 or 4

order, machine will

50

ligne

shoes,

stitches

DESCRIPTION

pockets

tacking

bobbin, ad-

and

diameter.

(12

work

plate

Class

following

hole

tying

thin

Tack

269w

stitches).

buttons.

(no tying

on

opera-

(loose);

1/16

to

stay-

fur-

are

ex-

buttons

to

50

pattern

OF

MACHINES

M

~

bar

5/32

21

Machine 269w14

21

Machine 269w17 •

cept

16

3

Machine 269w26

and

5/32

17 covering

Machine 269w38

5/32

11

and a clamp for

buttonholes.

Machine 269w39

slacks,

stitches

269w12

taclting

Bar

inch wide;

covering

Needle,

Tack

stitches

Needle,

for cam which

stitches

tying

Needle,

other

Bar

inch wide;

Needle,

Bar

inch wide;

covering and 3

Regularly

Clearance

Space

~eedle,

Line

Regularly

Needle,

operations.

pattern

and 3

Catalog

pattern

including 5

(6

stitches),

Catalog

general

pattern

and 3 tying

Catalog

pattern

behind

Catalog

sportswear,

tack

(including

Catalog

·for

barring

1/8

to

consists

tying

1628 (68x5).

•

for

tacking

1/8

to

Catalog

fitted

under

1/8

fitted

3072 (16x100).

similar

produces a tack

parallel, 1 cross-over, 6 parallel

1627 (68x3).

• for barring

barring

1/8

to

consisting

1628 (68x5).

• for barring

1/8

to

consists

tying

with

contracting

clamp,

needle,

1628 (68x5).

• for

tacking

shirts,

to

1/2

3 tying

with

1628 (68x5).

pockets

5/8

inch

of

36

stitches).

overlapping

5/8

stitches).

1/4

stitches).

7-3/4

stitches

shoes.

5/8

inch long;

to

Machine 269w5,

pockets

and

tacking

inch long

of

28

stitches

buttonholes

inch long

of

21

stitches

flat

bed

the

13/32

inch.

inches.

belt

etc.

inch long;

stitches),

flat

bed

and for

long and

(12

consists

stitches,

consisting

on

operations.

and

in

and

(7

type

cut

edges

loops

on

consists

type

work

(8

work

other

1/16

staying,

ex·

and

clothing

1/16

staying,

clothing.

1/16

staying,

plate

of

the

trousers,

of

28

plate.

to

of

of

to

to

Machine 269w9 • for barring

bows and

Bar pattern

21

stitches).

Needle,

Machine 269w11

ing

Bar

:i/32

2 covering and 3 tying

N

other

stitches

straps

on

pattern

inch wide;

eedle,

ornaments on

1/8

(7

staying,

Catalog

·for

underwear,

3/8

consists

Catalog

to 5/16 inch long;

1628 (68x5).

general

to

1628 (68x5).

buttonholes,

shoes

11

covering

barring and for

etc.

7/8

inch long and

of 42

stitches).

and

stitches

fastening

garments.

consists

and 3

1/16

(7

staying,

of

tying

sew-

to

The

chines

2000

R.

Button

designed

The

machine

the

thread

maximum

of

this

P.M.

sewing

to run

maximum

is

determined

used

Class

and

SPEED

speed

Machines 269w5

at

a maximum

efficient

recommended for

(except

speed

by

the

the

operation

the

button

speed

for any

material

performed.

sewers)

and

269w17

of

1850 R.P.M.

particular

being

all

sewn,

ma-

is

are

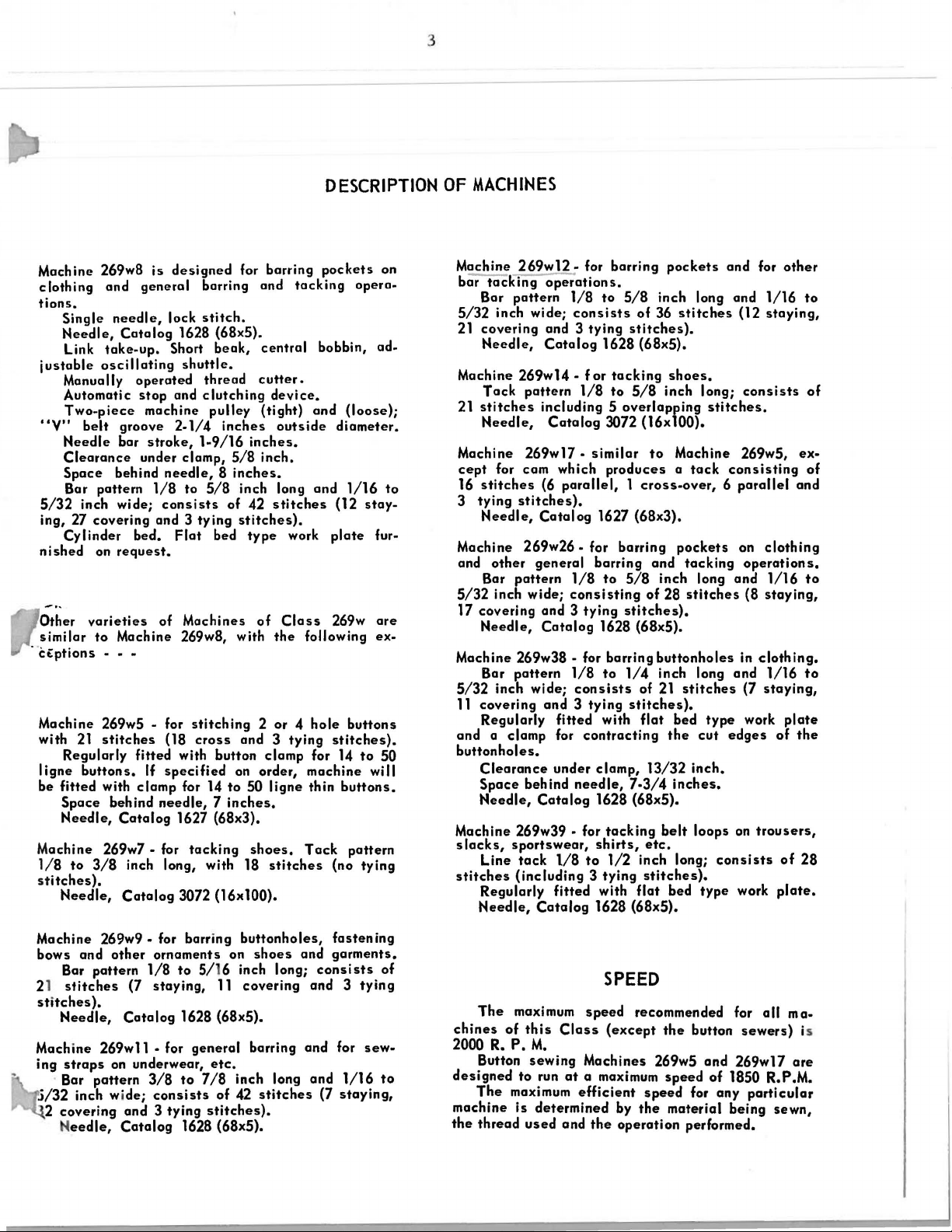

LUBRICATION

Fig.

2.

Oiling

Clean

received

Use

Use

will produce a minimum of

Apply oil

indicated

When

at

least

prevent

and oil machine thoroughly when

from

factory.

SIHGER* OIL,

"TYPE

D"

OIL when an oil

at

each of

by

the

arrows

machine

twice

daily

unnecessary

is

wear.

in

to

AND

Ports,

"TYPE

stain

the

places

in

Figs.

continuous

insure

easy

CLEANING

Front

View

B"

or

"TYPE

is

desired

on

fabrics.

on

2 and

3.

use,

running and

the

apply oil

Machine pulley (loose) should be repacked with

grease,

or

around

underside

off

come

at

Using

shears)

ho~k

Close

excess

in

contact

least

once

short

bristled

clean

area,

of throat

all

covers

oil

from

with material.

each

year.

out

brush (not

all

lint

point

or other

and between moving

plate.

after

oiling and

surfaces

of machine

of

waste

cleaning.

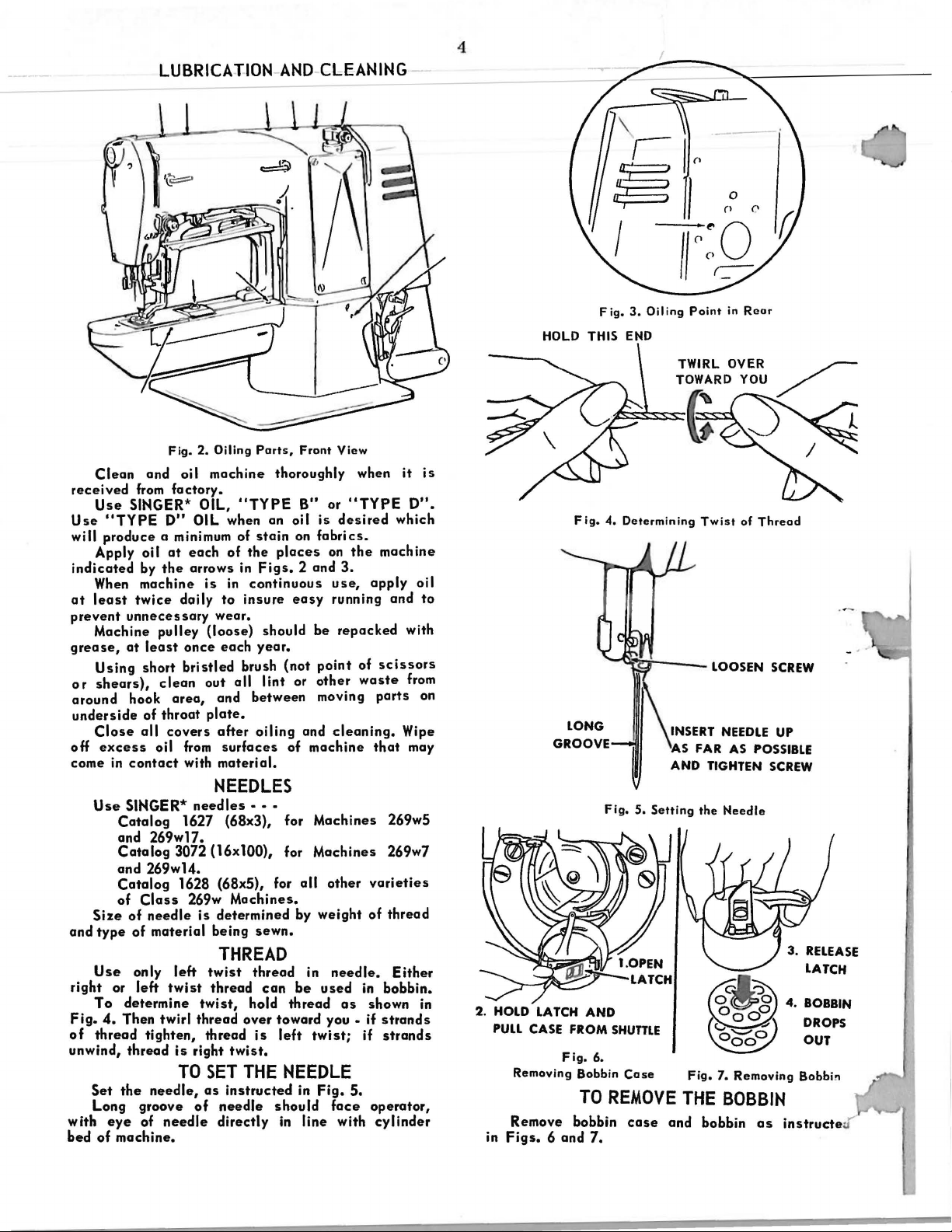

NEEDLES

Use

SIHGER*

Catalog

needles··

•

1627 (68x3), for Machines 269w5

and 269w17.

Catalog

3072 (16x100), for Machines 269w7

and 269w14.

and

Catalog

of

Size

of

type

of material being sewn.

1628 (68x5), for

Class

269w Machines.

needle

is

all

other

varieties

determined by weight of

THREAD

Use

right or

To

determine

Fig.

4. Then twirl

of

thread

unwind,

Set

the

Long groove

eye

with

bed

of

machine.

only left

left

tighten, thread

thread

needle,

of

twist

thread

is

right

TO

of

needle

twist

thread

thread

twist,

can

hold

over toward you -

is

twist.

SET

THE

as

instructed

needle

directly

in

be

used

thread

left

twist;

NEEDLE

in

Fig.

should

in

line with

needle.

in

as

if

if

5.

face

shown

operator,

it

D".

which

machine

scissors

from

parts

Wipe

that

may

thread

Either

bobbin.

strands

strands

cylinder

is

to

on

in

4

HOLD THIS

PULL

CASE FROM SHUnLE

Fig.

Removing Bobbin

Remove bobbin

in

Figs.

6 and

Fig.

TO

Fig.

4.

Fig,

6.

7.

3.

Oiling

END

Determining

~S

AND TIGHTEN SCREW

5.

Setting

Cose

REMOVE

case

and bobbin

Point

Twist

F~R

the

Fig,

THE

in

Rcor

of

Thread

AS POSSIBLE

Needle

7.

Removing

BOBBIN

as

3.

RELEASE

LATCH

4.

BOBBIN

DROPS

our

Bobbin

instructe

d"'

Fig.

B.

Winding

the

Bobbin

1.

PULL

INTO

THREAD

SLOT

5

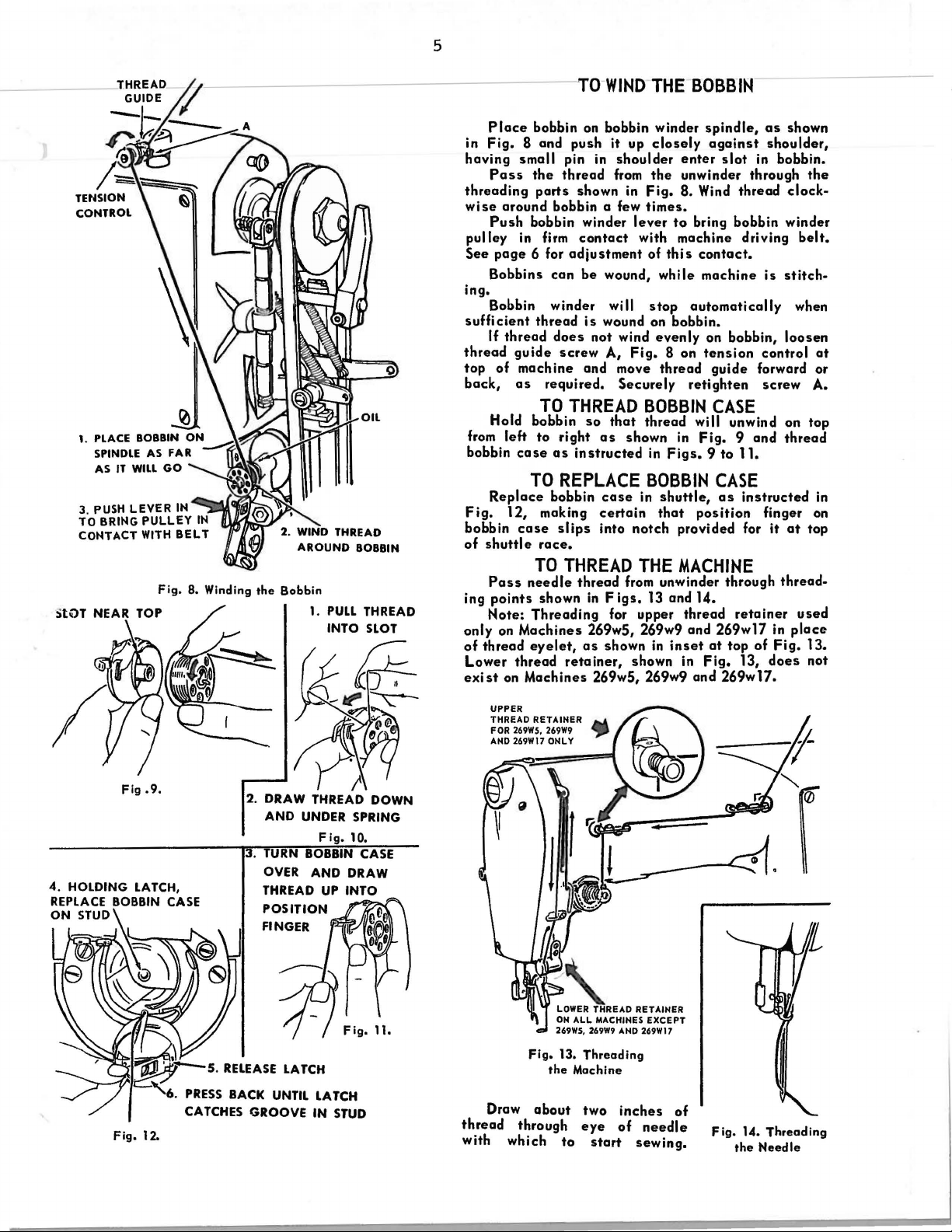

Place

in

Fig.

having

Pass

threading

wise

Push

pulley in firm

See

Bobbins

in g.

Bobbin winder

sufficient

If

thread

top

back,

Hold bobbin

from left

bobbin

Replace

Fig.

bobbin

of

shuttle

Pass

ing

points

Note:

only

of

thread

Lower

exist

-

To

WIND

THE

BOBBIN

bobbin on bobbin winder

8 and push it up

small

pin

in

the

thread

parts

shown in

around bobbin a few

bobbin winder

page

thread

guide

of

machine

as

case

TO

12,

case

needle

Threading

on

Machines

eyelet,

thread

on Machines 269w5, 269w9 and 269w17.

6 for

adjustment

can

thread

does

screw

required.

TO

THREAD

to

right

as

instructed

REPLACE

bobbin

making

slips

race.

TO

THREAD

shown

retainer,

contact

be

wound, while

is

wound on bobbin.

not

and move

so

as

case

certain

into

thread

in

269w5, 269w9 and 269w17 in

as

shown

closely

shoulder

from

the

Fig.

times.

lever

with machine driving

of

wi

II

stop

wind

evenly

A,

Fig.

Securely

BOBBIN

that

thread

shown in

in

BOBBIN

in

that

notch

THE

from unwinder through

Figs.

13 and 14.

for upper

in

shown in

spindle,

against

enter

slot

unwinder through

8.

Wind

thread

to

bring bobbin winder

this

contact.

machine

automatically

on bobbin,

8 on

tension

thread

guide

retighten

CASE

will unwind on top

Fig. 9 and

Figs.

9 to 11.

CASE

shuttle,

as

instructed

position

provided for

MACHINE

thread

inset

at

Fig.

retainer

top

13,

as

shown

shoulder,

in bobbin.

the

clock·

belt.

is

stitch·

when

loosen

control

forward or

screw

finger on

of

thread

it

at

thread-

Fig.

does

A.

top

used

place

13.

not

at

in

Fig

Fig,

.9.

12.

2. DRAW

AND

URN

OVER

THREAD

UNDER

Fig.

BOBBIN

AND

DOWN

SPRING

10.

CASE

DRAW

Fig.

Draw

thread

with which

about

through

13.

the

to

Threading

Machine

two

eye

start

inches

of

needle

sewing.

of

Fig.

14.

the

Threading

Needle

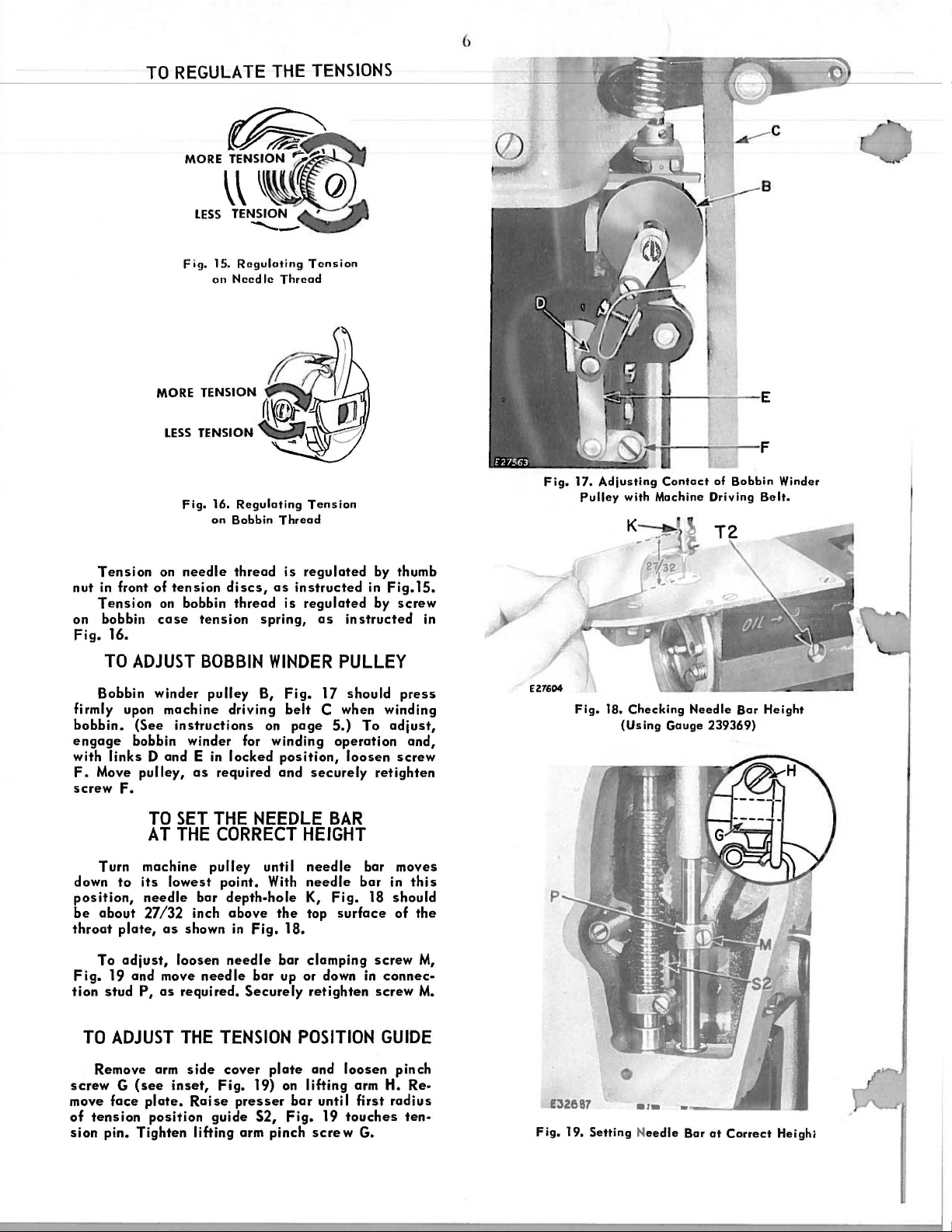

TO

REGULATE

THE

TENSIONS

Tension

in

front

nut

Tension

on bobbin

Fig.

16.

TO

ADJUST

Bobbin winder

firmly upon

bobbin.

engage

with

F.

screw

(See

bobbin winder for winding

links

Move

pulley,

F.

F ig. 15.

Fig.

on

needle

of

tension

on

bobbin

case

machine

instructions

D and E

as

Regulating

on

Needle

16.

Regulating

on

Bobbin

thread

discs,

thread

tension

BOBBIN

pulley

driving

in

locked

required

Tension

Thread

Tension

Thread

is

regulated

as

instructed

is

regulated

spring,

WINDER

B,

Fig.

belt

on

page

position,

and

securely

by

thumb

in

Fig.15.

by

screw

as

instructed

PULLEY

17

should

C when winding

5.)

operation

loosen

To

adjust,

screw

retighten

press

and,

in

Fig.

17.

Pulley

Fig.

Adjusting

with

18.

Checking

(Using

Contact

Machine

Needle

Gouge

of

Bobbin

Driving

Bar

239369)

Winder

Belt.

Height

TO

SET

THE

AT

Turn

to

its

about

plate,

To

adjust,

19

and

stud

P,

ADJUST

face

pin.

Tighten

machine

needle

27/32

plate,

position

down

position,

be

throat

Fig.

tion

TO

Remove arm

screw G (see

move

of

tension

sion

THE

CORRECT

pulley

lowest

as

move

as

inset,

point.

bar

depth-hole

inch

shown

loosen

needle

needle

required.

THE

TENSION

side

cover

Fig.

Raise

guide

lifting arm pinch

NEEDLE

until

above

in

Fig.

bar

Securely

19) on

presser

S2,

With

the

bar

up or down

plate

BAR

HEIGHT

needle

needle

K,

Fig.

top

surface

18.

clamping

retighten

POSITION

and

loosen

lifting

bar

unti I

Fig.

19

touches

screw

bar moves

bar

in

this

18

should

of

the

screw

in

connec·

screw

GUIDE

pinch

arm H. Re-

first

radius

ten-

G.

p

M,

M.

Fig,

19,

Setting Needle

Bar

at

Correct

Heigh;

Fig.

21.

Fig.

(Using

Needle

20.

Timing

Gauge

Guard

the

Shuttle

239369)

Adjustment

7

Turn

ta

dawn

in

shuttle

Insert

point

against

shuttle

TO

To

set

screw

as

wedges,

position.

To

and

move

screw

To

(reached

To

make a

over

to

nut

over

After

sary

to

needle.

feed

plate

screw

TO

machine

its

lowest

driver.

gauge

gauge.

driver.

ADJUST

adjust

adjust

U2.

shuttle

T2,

move

Tighten

needle

needle

TO

ADJUST

(ALONG

adjust

the

R.

width

through back

wider

right.

to

the

left.

adjusting

adjust

Loosen

central

ADJUST

(ACROSS

TIME

THE

pulley until

paint.

(See

pages

as

shown in

Then,

SHUTTLE

NEEDLE

in

Fig.

18,

and,

shuttle

screw

guard,

guard

in

WIDTH

of

tack,

opening

tack

(along

To

make a narrower

Tighten

width

position

socket

of

screw

with

LENGTH

SHUTTLE

Loosen

24 and

Fig.

tighten

GUARD

relation

using

race

T2.

loosen

or out

THE

loosen

the

screw

of

tack,

feed

needle.

THE

needle

pinch

25).

20,

socket

DRIVER

to

needle,

two

bushing

screw

as

required.

OF

TACK

BED)

nut

in

base

bed),

tack,

Q.

it may

plate

R,

Fig.

Tighten

OF

TACK

BED)

bar

moves

screw

350606

bring

shuttle

screw

AND

loosen

screwdrivers

to

desired

U2,

Fig.

Tighten

Q,

Fig.

of

machine).

slide

the

slide

be

neces·

in

relation

22

and

move

socket

in

21

22

nut

the

to

Fig.

22.

and

Adjusting

Positioning

Width

Feed

of

Tack

Plote

Remove

machine,

loosen

the

bed),

tack,

slide

After

sary

to

needle.

and

V2,

needle.

shown

face

plate

so

that

needle

as

nutS,

slide

nut S over

adjusting

adjust

Loosen

Fig.

Set

in

Fig.

end

left

hole.

the

cover

shown

Fig.

nut S over

position

socket

24

driving

23.

of

machine,

end

of

Tighten

in

Fig.

23.

To

to

length

and

arm

Tighten

feed

screw

plate

from

23.

Through

make a longer

to

right.

left.

Tighten

of

tack,

of

feed

plate

pinch

set

plate

feed

and

move

T,

screws

link arm

screw

feed

slot

Fig.

the

To

it

plate

V2,

is

22.

bose

the

tack

make a

nut

S.

may

be

in

relation

T,

central

parallel

Fig.

plate

1/8

inch from

of the

opening,

(across

shorter

neces·

to

Fig.

22

with

as

24.

At

to

right

£27566

Fig.

23.

Adjusting

s

Length

of

Tack

Fig,

24.

Arm

Driving

Adjustment

Arm

and

Link

8

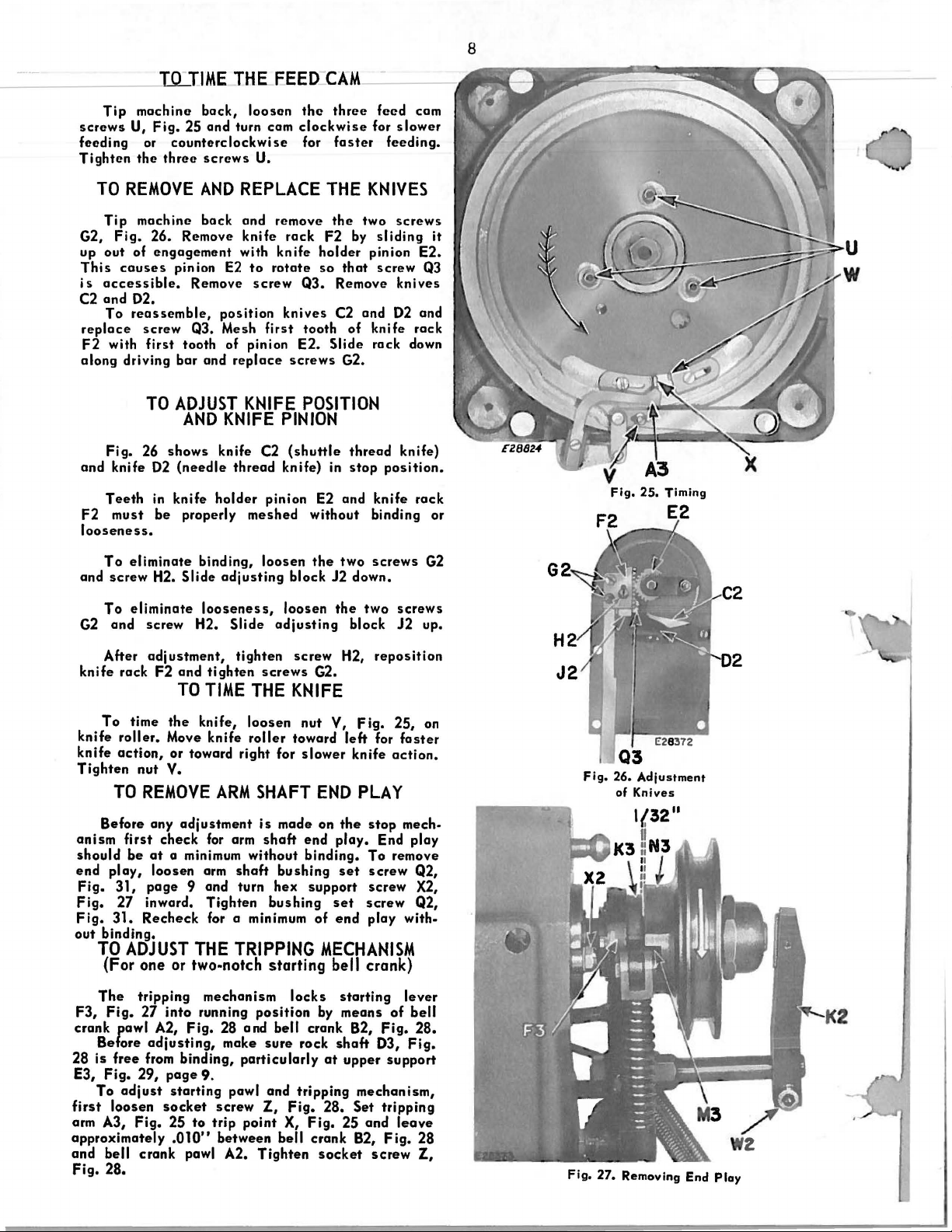

Tip

machine back,

screws

feeding or

Tighten

G2,

up out of

This

is

C2 and

replace

F2

along driving

U,

Fig.

the

TO

REMOVE

Tip

machine bock and remove

Fig.

26. Remove

engagement

causes

accessible.

02.

To

reassemble,

screw

with

first

TO

Fig.

26

and knife

F2

looseness.

Teeth

must

02

in knife

be

IQ_TIME

25 and turn cam

counterclockwise

three

pinion

tooth of pinion E2.

bar

ADJUST

AND

shows

(needle

properly

THE

screws

AND

E2

Remove

position

QJ.

Mesh

and

replace

KNIFE

knife C2

thread

holder

loosen

U.

REPLACE

knife

with knife

to

screw

KNIFE

meshed

FEED

rotate

first

CAM

the

clockwise

for

THE

rock F2

holder

so

QJ.

knives

tooth of

screws

three

faster

the

two

by

that

Remove

C2 and

Slide

G2.

feed

for

slower

feeding.

KNIVES

screws

sliding

pinion

screw

knives

02

knife

rack down

POSITION

PINION

(shuttle

knife) in

pinion E2 and knife

thread

stop

position.

without binding or

cam

E2.

QJ

and

rack

knife)

rack

it

Fig.

25.

Timing

To

eliminate

and

screw

H2.

Slide

To

eliminate

G2

and screw H2.

After

adjustment,

knife

rack

F2

and

TO

To

time

the

knife

roller.

knife

action,

Tighten

TO

Before any

anism

should

end

play,

Fig.

31,

Fig.

27 inward.

Fig.

31.

out

binding.

TO

(For one or two-notch

The

F3,

Fig.

crank

pawl A2,

Before

28

is

free

E3,

Fig.

To

adjust

first

loosen

arm A3,

approximately

and bell

Fig.

28.

Move knife

or toward right for

nut

V.

REMOVE

first

be

adjustment

check

at

a minimum

loosen arm

page

9 and turn

Recheck

ADJUST

tripping mechanism

27

into

Fig.

adjusting,

from

binding,

29,

page

starting

socket

Fig.

25

.010"

crank

pawl A2.

binding,

looseness,

tighten

TIME

knife,

for arm

Tighten

for a minimum

THE

loosen

adjusting

Slide

tighten

screws

THE

loosen

roller

ARM

SHAFT

is

shaft

without

shaft

bushing

TRIPPING

block

loosen

adjusting

screw

KNIFE

nut

toward

slower

made on

end

binding.

bushing

hex

starting

locks

running

9.

to

position

28 and bell crank B2,

make

sure

rock

particularly

pawl and

screw

trip

point

between

tripping

Z,

Fig.

X,

bell

Tighten

the

two

screws

J2

down.

the

two

block

H2,

reposition

G2.

V,

Fig.

left

for

knife

END

PLAY

the

stop

play.

End play

To

set

screw

support

of

set

end

screw

screw

play

MECHANISM

bell crank)

starting

by

at

28.

Fig.

crank

socket

means

shaft

upper

25

of

Fig.

03,

support

mechanism,

Set

tripping

and

B2,

Fig.

screw

G2

screws

J2

up.

25, on

faster

action.

mech-

remove

Q2,

X2,

Q2,

with-

lever

bell

28.

Fig.

leave

28

Z,

Fig.

Fig.

Q3

26.

of

27.

Adjustment

Knives

Removing

End

Play

9

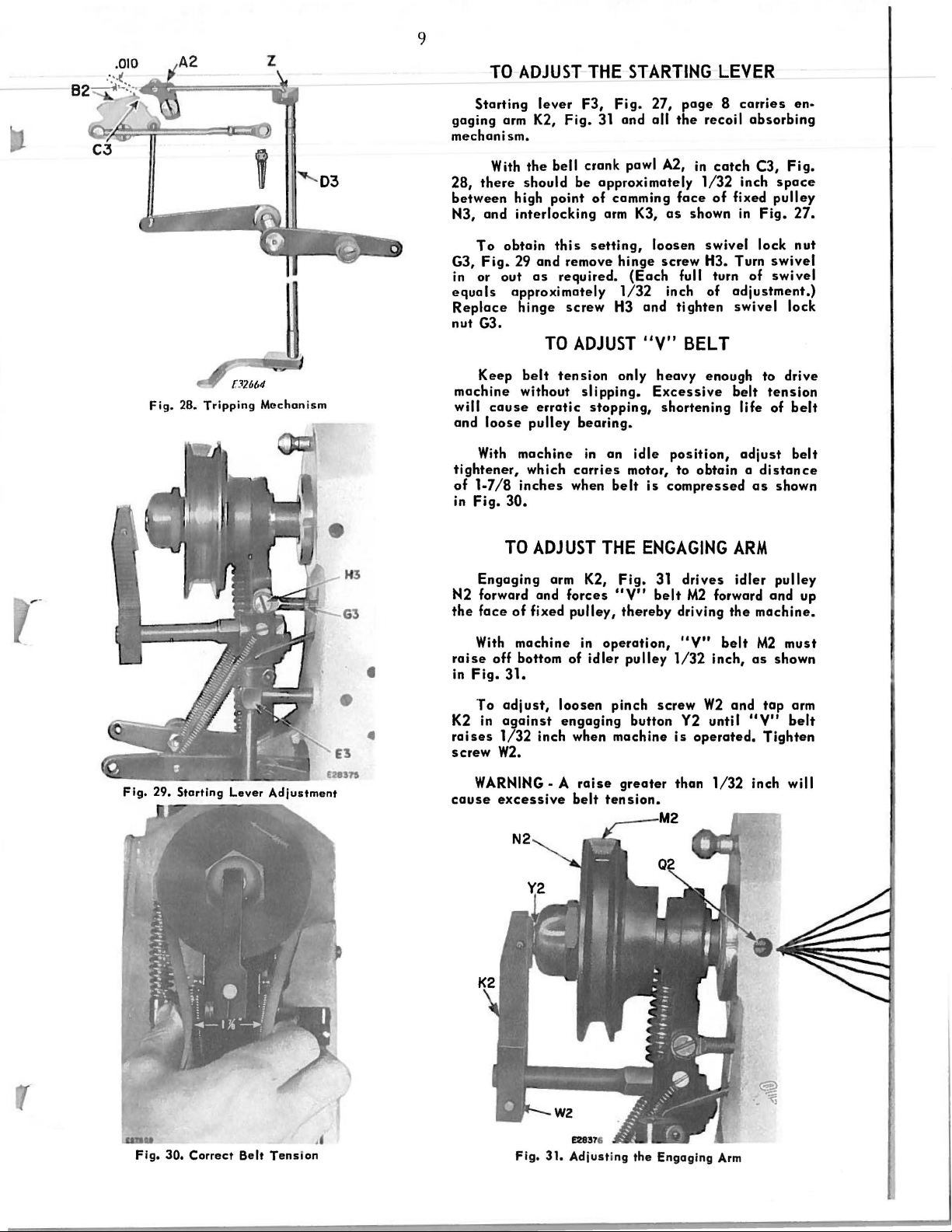

TO

ADJUST

THE

STARTING

LEVER

Fig.

28.

Tripping

Mechanism

Starting

gaging arm K2,

mechanism.

With

28,

there

between

N3, and

To

G3,

Fig.

in

or

equals

Replace

nut

G3.

lever

the

should

high

interlocking

obtain

29

and

out

as

approximately

hinge

TO

Keep

belt

machine

will

and

tightener,

of

in

Fig.

without

cause

loose

With machine

1-7/8

erratic

pulley

which

inches

30.

TO

ADJUST

F3,

Fig.

27,

Fig.

31

and

all

bell crank pawl A2,

be

approximately

point

of

camming

this

setting,

remove

required.

screw

ADJUST

tension

slipping.

stopping,

bearing.

in

carries

when

arm K3,

hinge

H3

only

an

belt

THE

as

loosen

screw

(Each

1/32

inch of

and

"V"

heavy

Excessive

shortening

idle

position,

motor, to

is

compressed

ENGAGING

page 8 carries

the

recoil

absorbing

in

catch

C3,

1/32

inch

face

of

fixed

shown

full turn

tighten

in

swivel

H3. Turn

of

adjustment.)

swivel

Fig.

lock

BELT

enough to

belt

life

adjust

obtain a distance

as

ARM

en-

Fig.

space

pulley

27.

nut

swivel

swivel

lock

drive

tension

of

belt

belt

shown

•

4

Engaging arm K2,

N2 forward and

the

face

of

fixed

With machine

raise

off bottom of

Fig.

in

K2

raises

screw

cause

31.

To

adjust,

in

against

1/32

inch when machine

W2.

WARNING· A

excessive

N2

forces

pulley,

in

operation,

idler

loosen

engaging

raise

belt

tension.

Fig.

31

drives

"V"

belt

M2

thereby

pulley

pinch

greater

driving

"V"

1/32

screw

button Y2 until

is

than

idler

forward

the

belt

inch,

W2

and

operated.

1/32

pulley

and

machine.

M2

must

as

shown

tap

arm

"V"

belt

Tighten

inch will

up

,,

Fig,

30.

Correct

Belt

Tension

Fig.

31.

!283

76

Adjusting

the

Engaging

Arm

TO

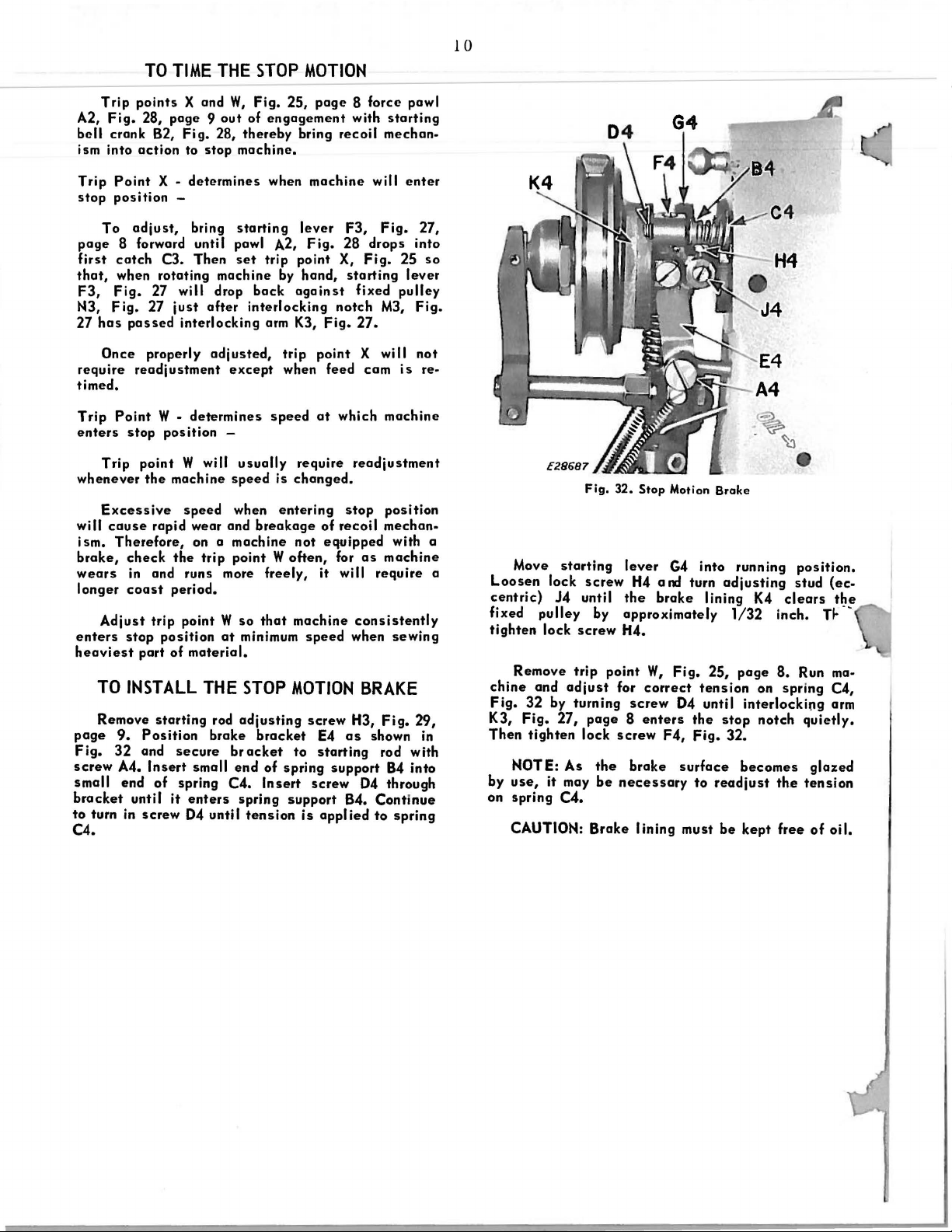

TIME

Trip

points

Fig.

A2,

bell

crank

ism into

Trip

stop

page

first

that,

F3,

N3,

27

require

timed.

Trip

enters

whenever

will

ism.

brake,

wears

longer

enters

heaviest

page

Fig.

screw

small

bracket

to

action

Point

position

To

adjust,

8 forward unti I pawl A2,

catch

when

Fig.

Fig.

has

passed

Once

readjustment

Point

stop

Trip

Excessive

cause

Therefore,

check

in

coast

Adjust

stop

TO

INSTALL

Remove

9.

32

A4.

end

until

turn in

X and

28, page 9

82,

Fig.

to

X -

determines

bring

C3.

Then

rotating

27

will

27

just

interlocking

properly

W -

determines

position

point

W will

the

machine

speed

rapid wear and

on a

the

and runs more

period.

trip

point W so

position

part

of

material.

starting

Position

and

secure

Insert

small

of

spring

it

enters

screw

04

C4.

THE

STOP

W,

Fig.

out

of

28,

thereby

stop

machine.

starting

set

machine

drop

bock

after

interlocking

adjusted,

except

usually

speed

when

breakage

machine

trip

point W often,

at

minimum

THE

STOP

rod

adjusting

brake

bracket

bracket

end

C4.

spring

until

tension

MOTION

25,

page

engagement

bring

when

machine

lever

Fig.

trip

point

by

hand,

against

arm K3,

speed

is

freely,

that

Fig.

trip

point

when feed

at

require

changed.

entering

of

not

equipped

it

machine

speed

MOTION

screw

E4

to

starting

of

spring

Insert

screw

support

is

applied

8 force pawl

with

recoil

mechan-

will

F3,

Fig.

28

drops

X,

Fig.

starting

fixed

notch

M3,

27.

X will

cam

which

readjustment

stop

recoil

mechan-

for

as

will

require

consistently

when

BRAKE

H3,

Fig.

as

shown

rod with

support

04

84.

Continue

to

starting

enter

27,

into

25

so

lever

pulley

Fig.

not

is

re-

machine

position

with a

machine

sewing

29,

in

84

into

through

spring

10

Stop

lever

H4

W,

correct

screw

brake

lining

G4

Motion

G4

and

brake

Fig.

04

F4,

surface

must

Brake

into

turn

adjusting

lining K4

25,

tension

until

the

stop

fig.

32.

to

readjust

be

running

1/32

page

interlocki{lg arm

becomes

kept

inch.

8.

on

spring

notch

the

free

position.

stud

clears

Run ma-

quietly.

glazed

tension

of

n

(ec-

the

--

C4,

oil.

04

Fig.

32.

a

Move

Loosen

centric)

fixed

tighten

Remove

chine

Fig.

K3,

Then

NOTE:

by

use,

on

spring

CAUTION:

lock

pulley

lock

and

32

by

Fig.

tighten

it

starting

screw

J4

until

by

screw

trip

point

adjust

turning

27,

page 8 enters

lock

As

the

may

be

C4.

Brake

the

approximately

H4.

for

screw

necessary

---

---

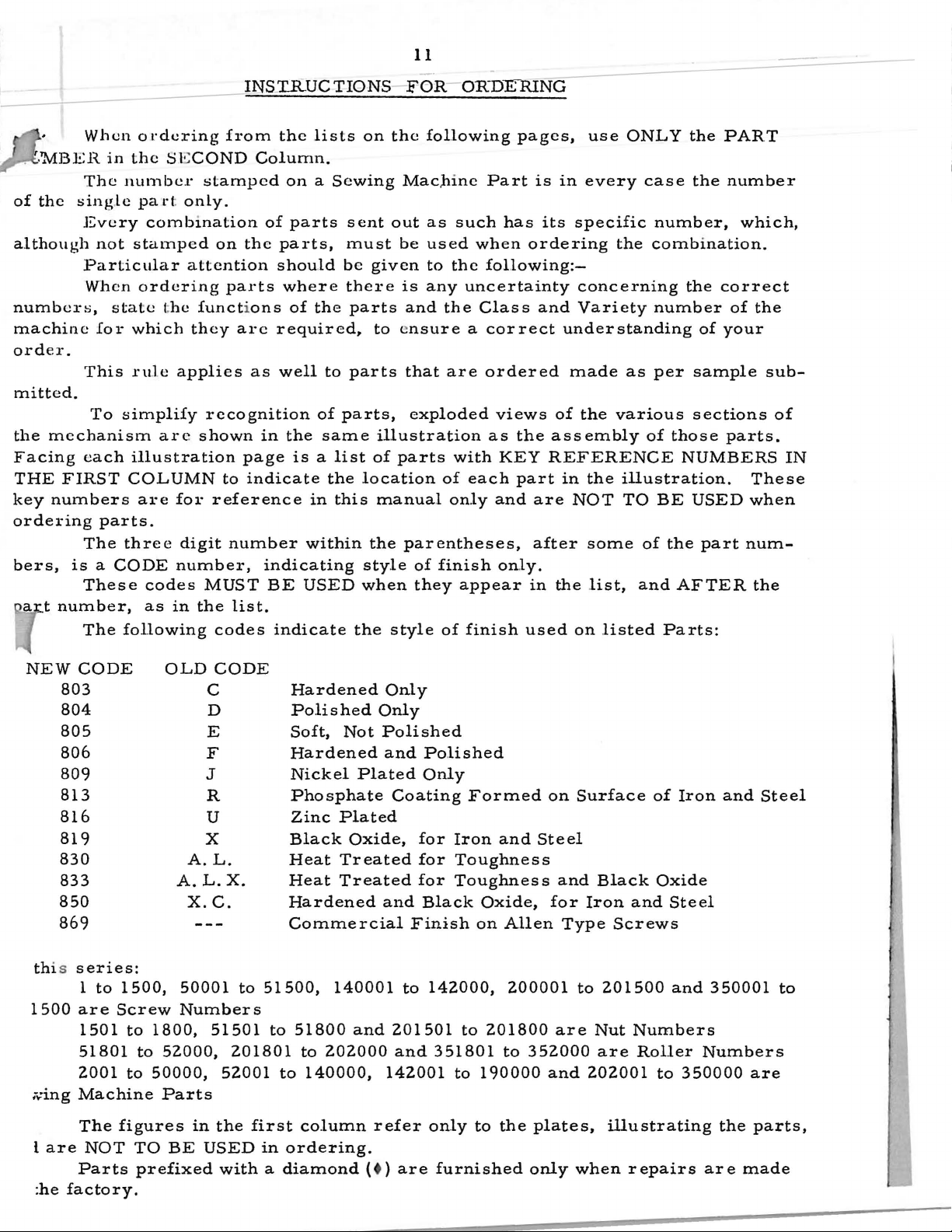

INSTRUCTIONS

11

FOR

ORDERING

---

---

.

'.MBER

of

the

although

numbers,

machine

order.

mitted.

the

mechanism

Facing

THE

key

ordering

bers,

a;r,t

FIRST

numbers

is a CODE

number,

When

in

the

The

number

sing.Lc

Every

not

stamped

Particular

Whcn

state

Lor

which

This

each

The

These

The

To

simplify

parts.

following

three

.rule

illustration

COLUMN

ordering

Sb

COND

stamped

pa

rl:

only.

combination

on

attention

ordering

the

functions

they

applies

recognition

are

shown

are

for

reference

digit

number,

codes

as

in

MUST

the

codes

from

Column.

of

the

pa1·ts

arc

as

in

page

to

indicate

number

indicating

BE

list.

the

lists

on a Sewing

parts

parts,

should

where

of

required.

well

the

is a list

indicate

be

the

to

of

parts,

same

the

in

this

within

USED

sent

must

there

parts

parts

the

on

the

Mac.hine

out

be

given

is

and

to

ensure

that

exploded

illustration

of

parts

location

manual

the

parentheses,

style

when

of

they

style

following

Part

as

such

used

to

any

when

the

following:-

uncertainty

the

Class

a

correct

are

ordered

as

with

of

each

only

finish

appear

of

finish

pages,

has

ordering

views

the

KEY

part

and

only.

used

use

is

in

every

its

specific

concerning

and

Variety

understanding

made

of

the

assembly

REFERENCE

in

the

are

NOT

after

in

the

some

list,

on

.listed

ONLY

case

number,

the

combination.

the

number

as

per

various

of

those

NUMBERS

illustration.

TO

BE

of

the

and

AFTER

Parts:

the

PART

the

number

correct

of

of

your

sample

sections

parts.

USED

part

which,

the

sub-

of

IN

These

when

num-

the

NEW

CODE

803

804

805

806

809

813

816

819

830

833

850

869

this series:

l

to

1500

are

1501

51801

2001

;,;ing

Machine

1500,

Screw

to

1800,

to

to

50000,

OLD

A.L.

A.L.X.

X.

50001

Numbers

52000,

Parts

CODE

c

D

E

F

J

R

u

X

C.

51501

201801

52001

to

Hardened

Polished

Soft,

Hardened

Nickel

Phosphate

Zinc

Black

Heat

Heat

Hardened

Commercial

51500,

to

51800

to

to

140000,

Not

Plated

Plated

Oxide,

Treated

Treated

140001

and

202000

Only

Only

Polished

and

Polished

Only

Coating

for

for

for

and

Black

Finish

to

142000,

201501

and

142001

Formed

Iron

Toughness

Toughness

Oxide,

on

to

351801

to

190000

and

Allen

200001

201800

to

352000

on

Steel

and

for

Type

are

and

Surface

Black

Iron

Screws

to

201500

Nut

are

202001

of

Iron

Oxide

and

Steel

and

Numbers

Roller

to

350000

and

Steel

350001

Numbers

are

to

The

l

are

:he

figures

NOT

Parts

factory.

TO

prefixed

BE

in

the

first

USED

in

ordering.

with a diamond

column

refer

(t )

are

only

to

furnished

the

plates,

only

illustrating

when

repairs

are

the

parts,

made

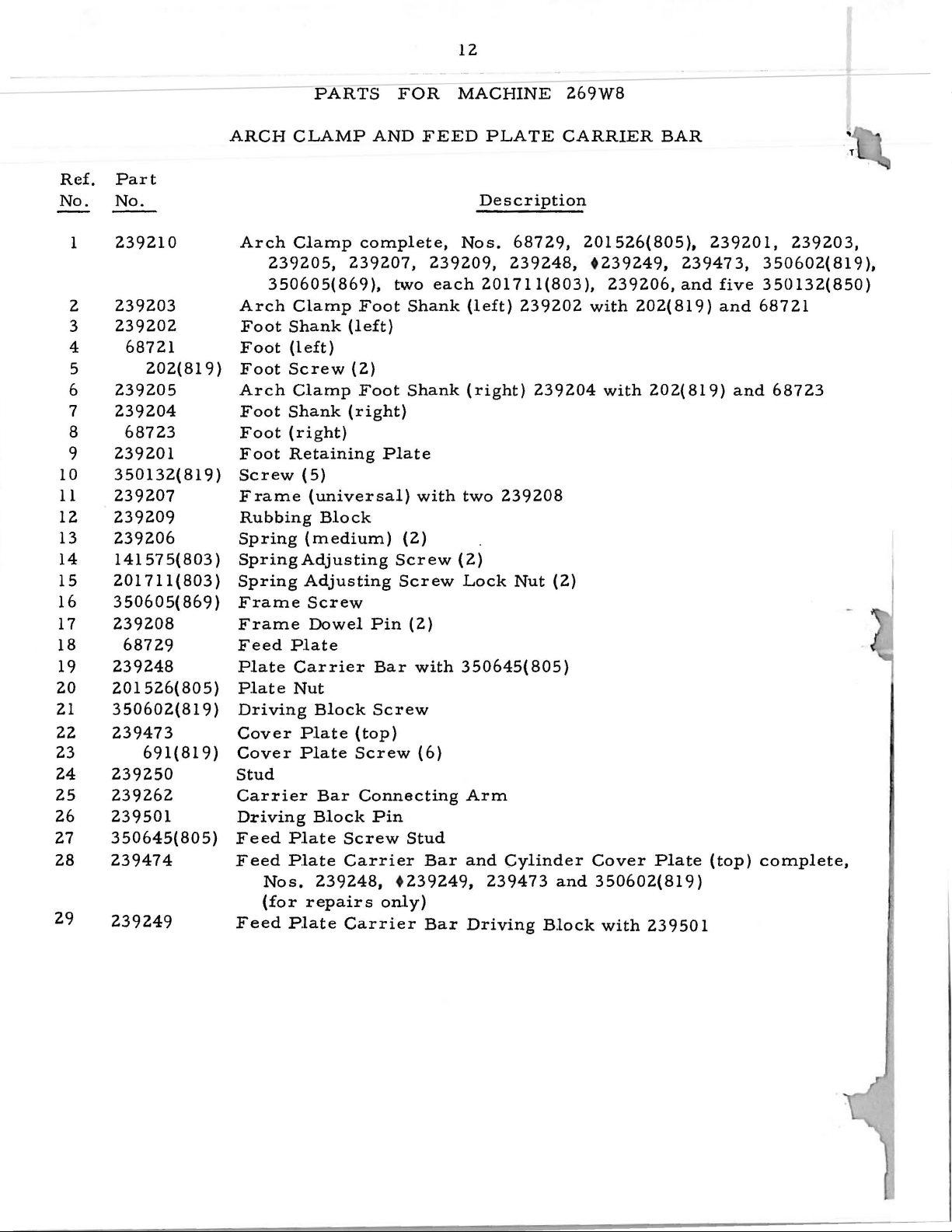

12

Ref.

No. No.

10

ll

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Part

1

239210

2

239203

239202

3

4

5

6

239205

7

239204

8

239201

9

350132(819)

239207

239209

239206

141575(803)

201711(803)

350605(869)

239208

239248

201526{805)

350602{819)

239473

239250

239262

239501

350645(805)

239474

239249

68721

68723

68729

202(819)

691(819)

PARTS

ARCH

Arch

Arch

Foot

Foot

Foot

Arch

Foot

Foot

Foot

Screw

Frame

Rubbing

Spring

SpringAdjusting

Spring

Frame

Frame

Feed

Plate

Plate

Driving

Cover

Cover

Stud

Carrier

Driving

Feed

Feed

Feed

CLAMP

Clamp

239205,

350605(869),

Clamp

Shank

(left)

Screw

Clamp

Shank

(right)

Retaining

(5)

{universal)

Block

(medium)

Adjusting

Screw

Dowel

Plate

Carrier

Nut

Block

Plate

Plate

Bar

Block

Plate

Plate

Nos.

(for

239248,

repairs

Plate

FOR

AND

complete,

239207'

two

Foot

(left)

(2)

Foot

(right)

Plate

(2)

Screw

Screw

Pin

Bar

Screw

(top)

Screw

Connecting

Pin

Screw

Carrier

+239249,

only)

Carrier

FEED

239209,

each

Shank

Shank

with

(2)

with

(6)

Stud

Bar

Bar

MACHINE

PLATE

Description

Nos.

(right)

two

(2)

Lock

350645{

Arm

and

Driving

68729,

239248,

201711(803),

(left)

239202

239204

239208

Nut

805)

Cylinder

239473

269W8

CARRIER

201526(805),

+239249,

with

(2)

Cover

and

350602(819)

Block

239206,

202(

with

with

BAR

23947

and

819)

202(

819)

Plate

239501

239201,

3,

five

and

68721

and

(top)

complete,

239203,

350602(

350132(850)

68723

819

),

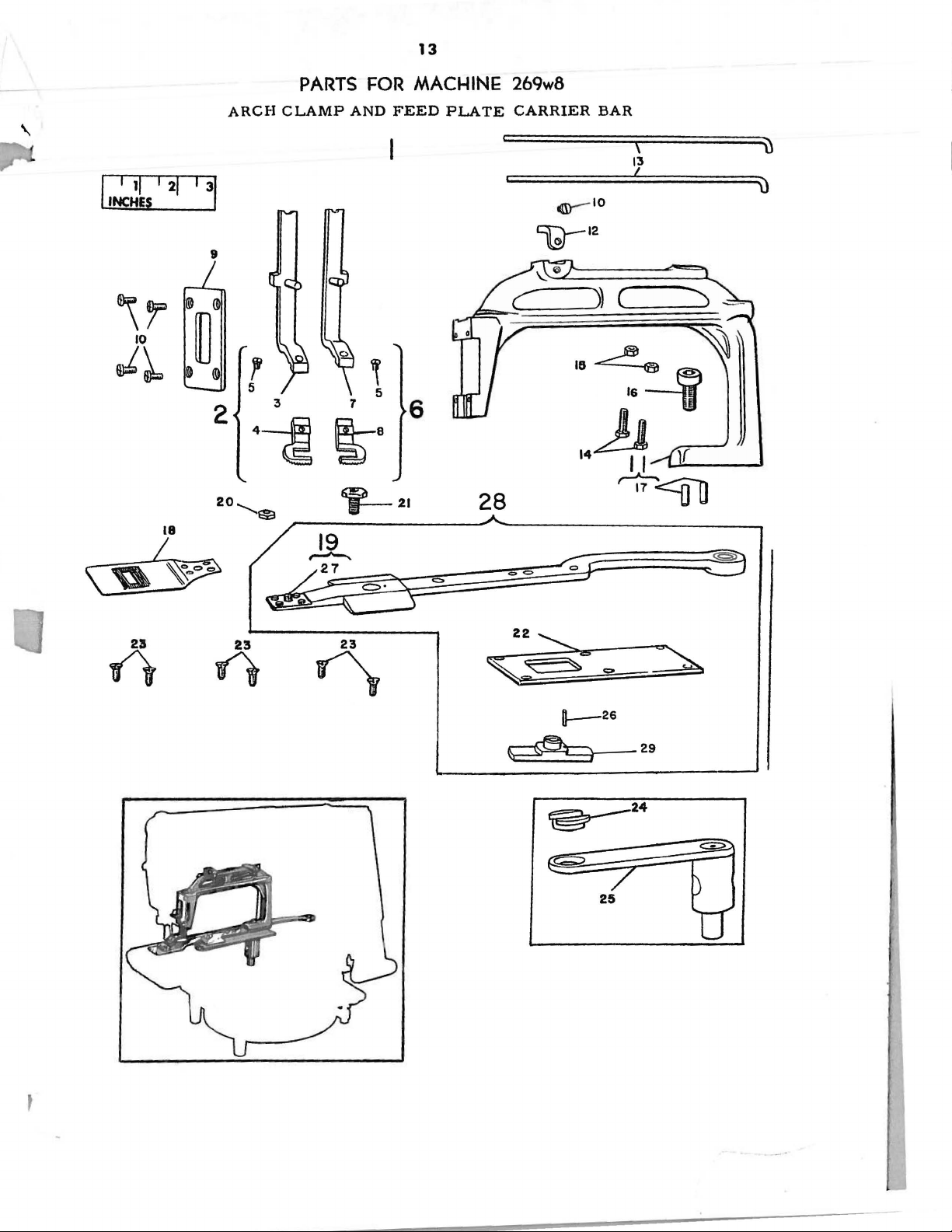

13

'

I I

11 I 21

INCHES

\r

10

J~

18

/_

I

31

9

2

PARTS

ARCH

CLAMP

5

3

'

·~

FOR

MACHINE

AND

FEED

~

5

7

6

§5-8

~21

PLATE

28

_A

269w8

CARRIER

.m--

~12

BAR

10

))

IJ

c

23

~

22~6

ll--26

~

~24

29

25

,

11

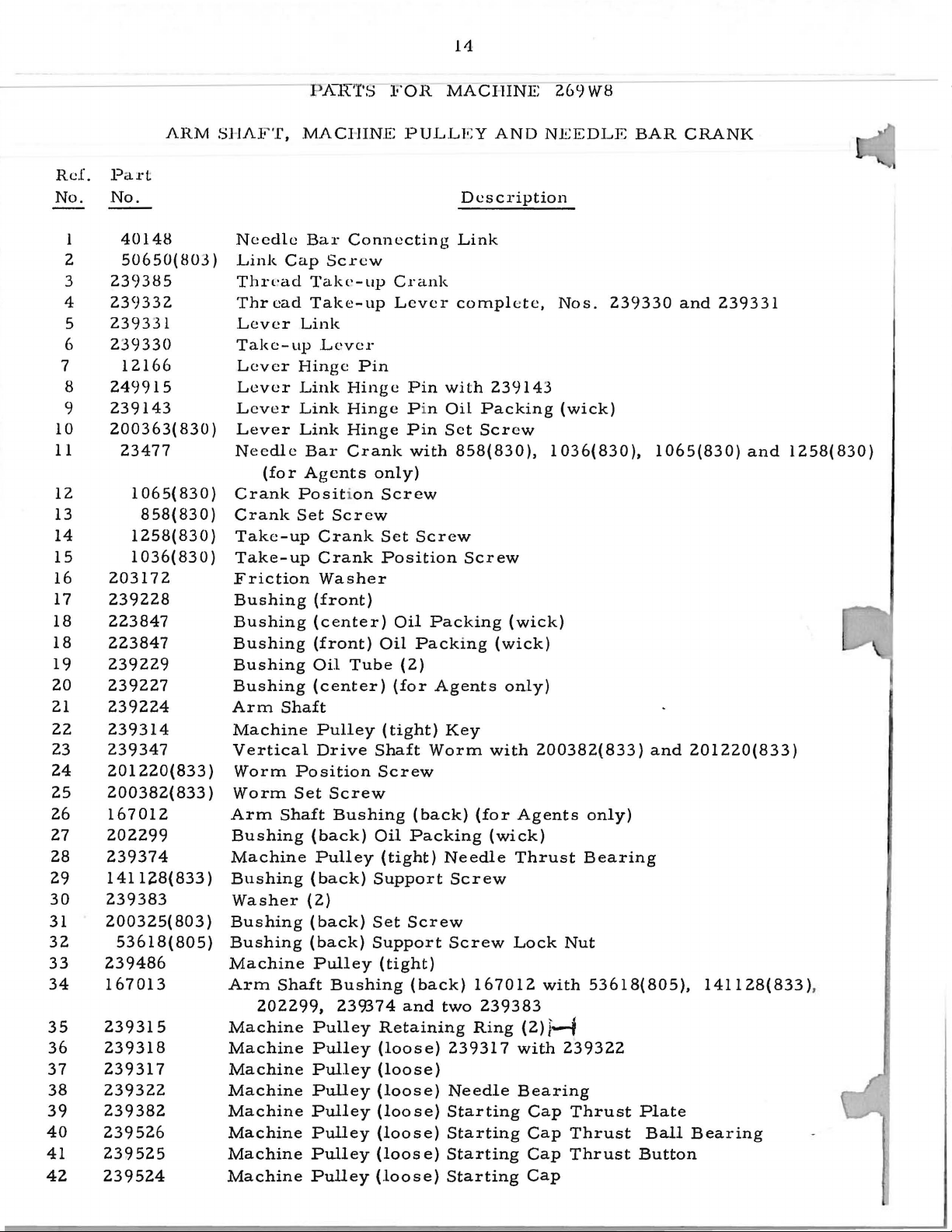

Rc.f.

No.

7

10

11

12

13

14

15

16

17

18

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

1

2

3

4

5

6

8

9

223847

239229

239227

239224

239314

239347

201

200382(833)

167012

202299

239374

l4llZ8(833)

239383

200325(803)

239486

167013

239315

239318

239317

239322

239382

239526

239525

239524

ARM

P::u-t

No.

4014H

50650(803)

2393H5

239332

239331

239330

12166

249915

239143

200363(

23477

1065(830)

8

58(

1258(830)

1036(830)

203172

239228

223847

220(833)

53618(805)

830)

83

0)

Sl1Al1 'f,

Needle

Link

Tbrl'ad

Thr

cad

Lever

Tal<c-up

Lever

Lever

Lever

Lever

Needle

(for

Crank

Crank

Take-up

Take-up

Friction

Bushing

Bushing

Bushing

Bushing

Bushing

Arm

Machine

Vertical

Worm

Worm

Arm

Bushing

Machine

Bushing

Washer

Bushing

Bushing

Machine

Arm

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Shaft

202299,

A-:R"'I'S

MACHINE

Bar

Cap

Screw

TakP-up

Take-up

Link

.L(•ver

Hinge

Link

Link

Link

Bar

Agents

Position

Set

Crank

Crank

Washer

(front)

(center)

(front)

Oil

(center)

Shaft

Pulley

Drive

Position

Set

Screw

Shaft

(back)

Pulley

(back)

(2)

(back)

(back)

Pulley

Bushing

Pulley

Pulley

Pulley

Pulley

Pulley

Pulley

Pulley

Pulley

FOR

Connecting

Pin

Hinge

Hinge

Hinge

Crank

only)

Screw

Screw

Set

Position

Oil

Tube

(tight)

Shaft

Screw

Bushing

Oil

(tight)

Support

Set

Support

(tight)

239374

Retaining

(loose)

(loose)

(loose)

(loose)

(loose)

(loose)

(loose)

MACIIINE

PULLI~,y

Description

Link

Crank

Lever

Pin

P in

Pin

Oil

(2)

(for

Screw

and

complete,

with

Oil

Set

with

858(830),

Screw

Packing

Packing

Agents

Key

Worm

(back)

Packing

Needle

Screw

Screw

(back)

two

239317

Needle

Starting

Starting

Starting

Starting

Screw

AND

239143

Packing

Screw

(wick)

(wick)

only)

with

(for

(wick)

Thrust

Lock

167012

239383

Ring

269

NEEDLE

Nos.

(wick)

1036(830),

200382(

Agents

Nut

with

(2)

H

with

239322

Bearing

Cap

Cap

Cap

Cap

WH

239330

833)

only)

Bearing

53618(805),

Thrust

Thrust

Thrust

BAR

and

1065(830)

and

Plate

Ball

Button

CRANK

239331

and

201220(833)

141128(833)

Bearing

1258(830)

,

15

-----------

BAR

CRANK

ARM

SHAFT,

PARTS

MACHINE

FOR

PULLEY

MACHINE

AND

269w8

NEEDLE

h.j

I

II

15~

21

14~

13_...e

~

i-12

___________________________________________________________________________

17

20

/

))

~1'-----JI....)CJ_,i

j

'

'

'

'

2

\._

24

r;)

..

31

34

(

lfV-27

26

[j

29

---siii()J

33

{/~0,

35

16

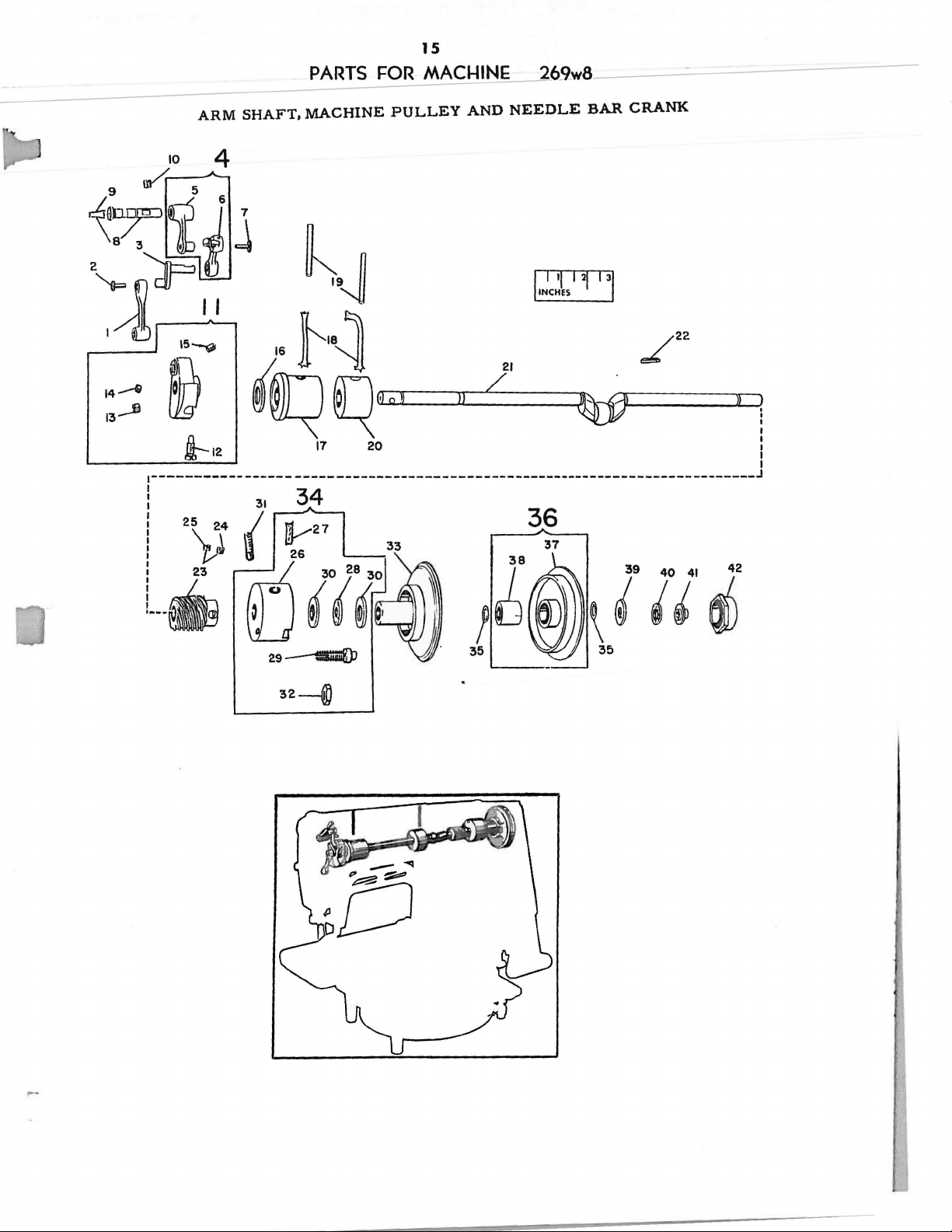

Ref.

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

35

36

37

38

39

40

41

42

Part

No.

239254

1

2

239253

239261

3

239260

4

202603

5

350132(819)

6

239284

7

201472(803)

8

200333(830)

9

239283

239550

239282

239145

239551

239552

201749(805)

239280

239279

222583

200394(803)

20197

125044

201083(803)

213484

213484

200689(803)

350447(804)

239257

239251

239252

239146

239553

24050

226(809)

12424

19448

1

035(803)

1636(805)

13275

39653

23421

908(803)

896(803)

KNIFE

Knife

Knife

Adjusting

Knife

Screw

Screw

Bushing

Bushing

Bushing

Bushing

Oscillating

Bushing

Oscillating

Slide

Crank

Crank

Crank

Slide

Oscillating

Crank

Screw

Oil

Oscillating

Hinge

Oscillating

Hinge

Hinge

Hinge

Hinge

Rod

Crank

Rod

Rod

Knife

Knife

Knife

Slide

Connection

Knife

Knife

Knife

Oscillating

Oscillating

Bar

Bar

Bar

Washer

(4)

Block

Slide

Slide

Slide

Block

Pin

Stud

Pad

Screw

Pin

Pin

Pin

Pin

Hinge

Connecting

Cap

Oil

Actuating

Bar

Bar

Block

Bar

Actuating

Actuating

PARTS

BAR

AND

239253

Block

Rack

(4)

(front-outer)

(front-inner)

(front-outer)

(front-inner)

Shaft

(back)

Shaft

complete,

Block

Block

Block

Screw

Shaft

Nut

(felt)

Rock

Nut

Rock

Oil

Packing

Oil

Hole

Set

Screw

Screw

Screw

Pad

Connection

Driving

Screw ( 2)

Connection

Shaft

Shaft

(2)

(felt)

Lever

Screw

Lever

Lever

FOR

OSCILLATING

with

Crank

Cap

Cap

Stud

Crank

Shaft

Shaft

Plug

Rod

Slide

239550

239550

MACHIN

Description

239260, 239261,

with

Set

Screw

Set

Screw

complete,

Nos.

Screw

Screw

Hinge

(wick)

(leather)

with

Screw

Stud

Block

with

Link

with

with

-E 26<JW8

SHAFT

201472(803)

Nos.

226(809),

Washer

Pin

239279

125044

Slide

213484

and

Block

and

239145

239551

three

1636(805),

1035(803),

with

two

+

239258

and

239552

and

239552

ASSEMBLIES

each

202603

24050

12424

23421

896(803)

(for

and

(for

Agents

and

and

and

19448

222583

Agents

only)

350132(81

239551

only)

+

239258

Knife

Bar

Connection

Stud

---

KNIFE

PARTS

BAR

FOR

AND

OSCILLATING

17

MACHINE

SHAFT

269w8

ASSEMBLIES

---

31

19

20

II

42

18

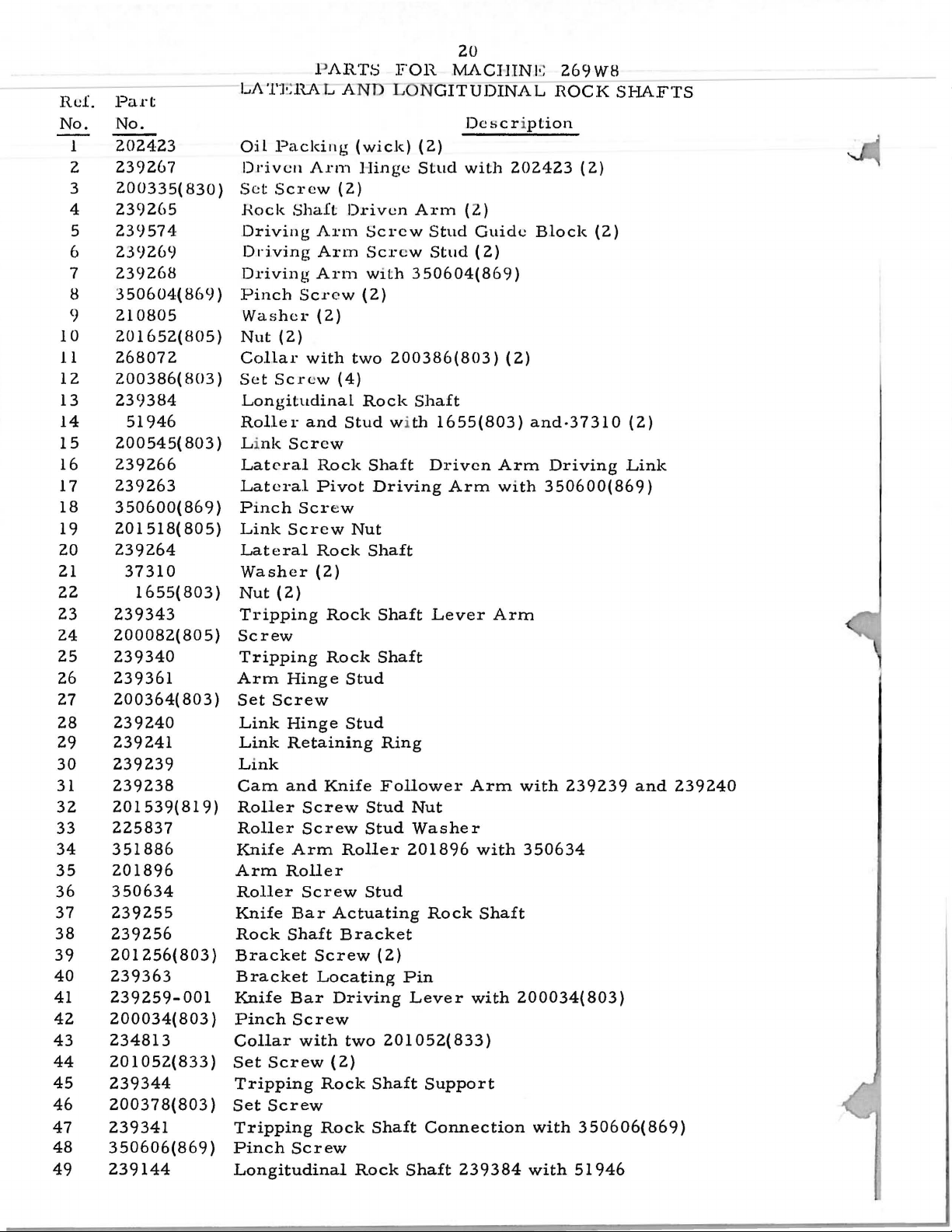

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

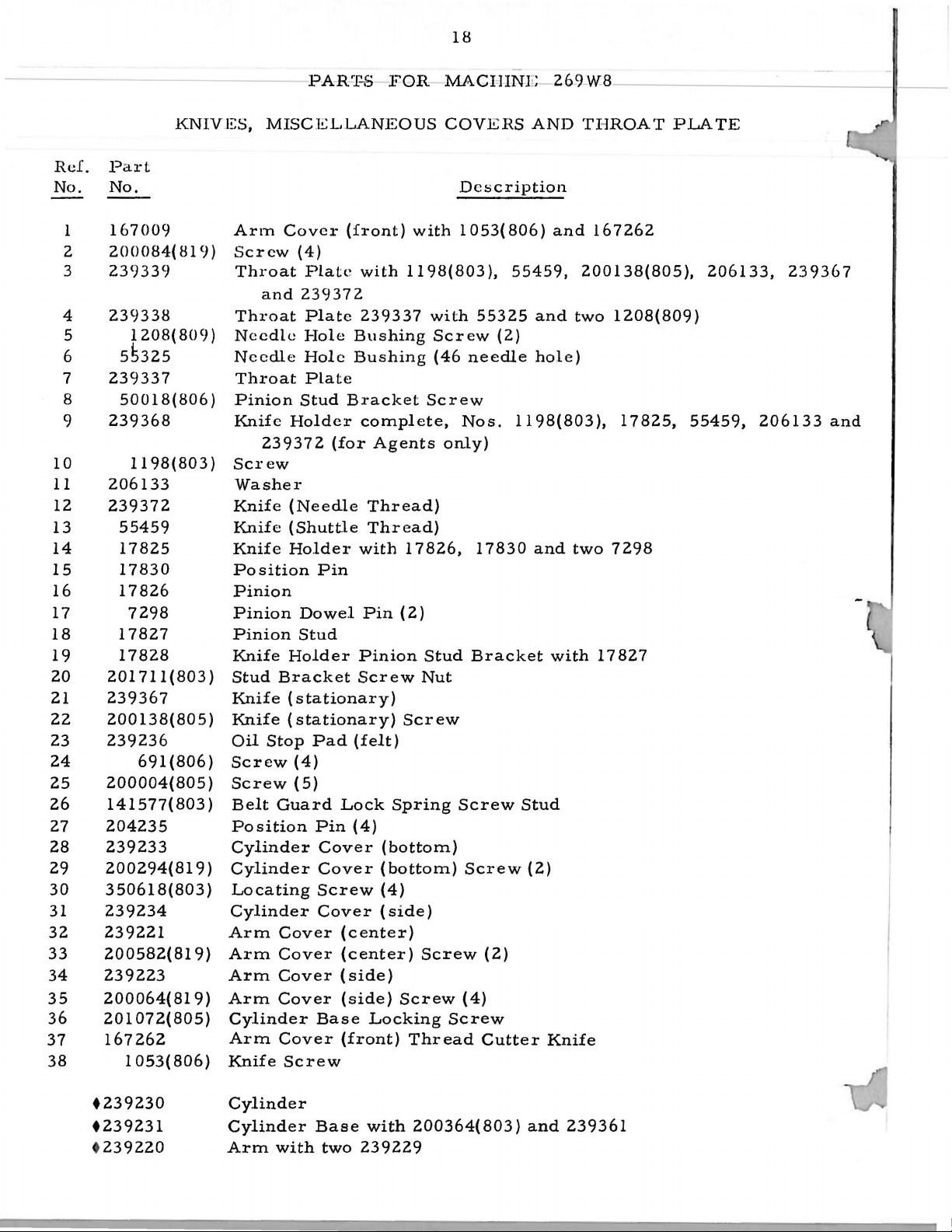

KNIVES,

P a

rt

No.

167009

200084(

23<)339

239338

1208(

IH

809)

5~325

239337

50018(806)

239368

1198(803)

206133

239372

55459

17825

17830

17826

7298

17827

17828

201711(803)

239367

200138(805)

239236

691(806)

200004(805)

141577(803)

204235

239233

200294(819)

350618(803}

239234

239221

200582(819)

239223

200064(819)

201072(805)

167262

1

053(806)

MISCELLANEOUS

Arm

9)

Screw

Throat

and

Throat

Needle

Needle

Th1·oat

Pinion

Knife

239372

Screw

Washer

Knife (Needle

Knife

Knife

Position

Pinion

Pinion

Pinion

Knife

Stud

Knife

Knife

Oil

Stop

Screw ( 4)

Screw

Belt

Position

Cylinder

Cylinder

Locating

Cylinder

Arm

Arm

Arm

Arm

Cylinder

Arm

Knife

PART-8

Cover

(4)

PlatP

239372

Plate

Hole

Hole

Plate

Stud

Holder

(for

(Shuttle

Holder

Pin

Dowel

Stud

Holder

Bracket

(stationary)

(stationary)

Pad

(5)

Guard

Cover

Cover

Cover

Cover

Cover

Screw

Lock

Pin

Cover

Cover

Screw

Cover (si

(center}

(center)

(side)

(side)

Base

(front)

FOR

(front)

with

239337

Bushing

Bushing

Bracket

complete,

Agents

Thread)

Thread)

with

Pin ( 2)

Pinion

Screw

(felt)

Spring

(4)

(bottom)

(bottom)

(4)

Locking

MACIJINJ;

COVERS

Deocription

with

1053(806)

1198(803),

with

Screw

(46

Screw

Nos.

only)

17826,

Stud

Nut

Screw

Screw

Screw

de)

Screw

Screw

Thread

(4)

Screw

55459,

55325

(2)

needle

1198(803),

17830

Bracket

(2)

Cutter

AND

and

hole)

and

Stud

(2)

269

W8

T H

and

167262

200138(805),

two

two

with

Knife

17

ROAT

1208(809)

17825,

7298

827

PLATE

206133,

55459,

239367

206133

and

+239230

+239231

+

239220

Cylinder

Cylinder

Arm

with

Base

two

with

239229

200364(803}

and

239361

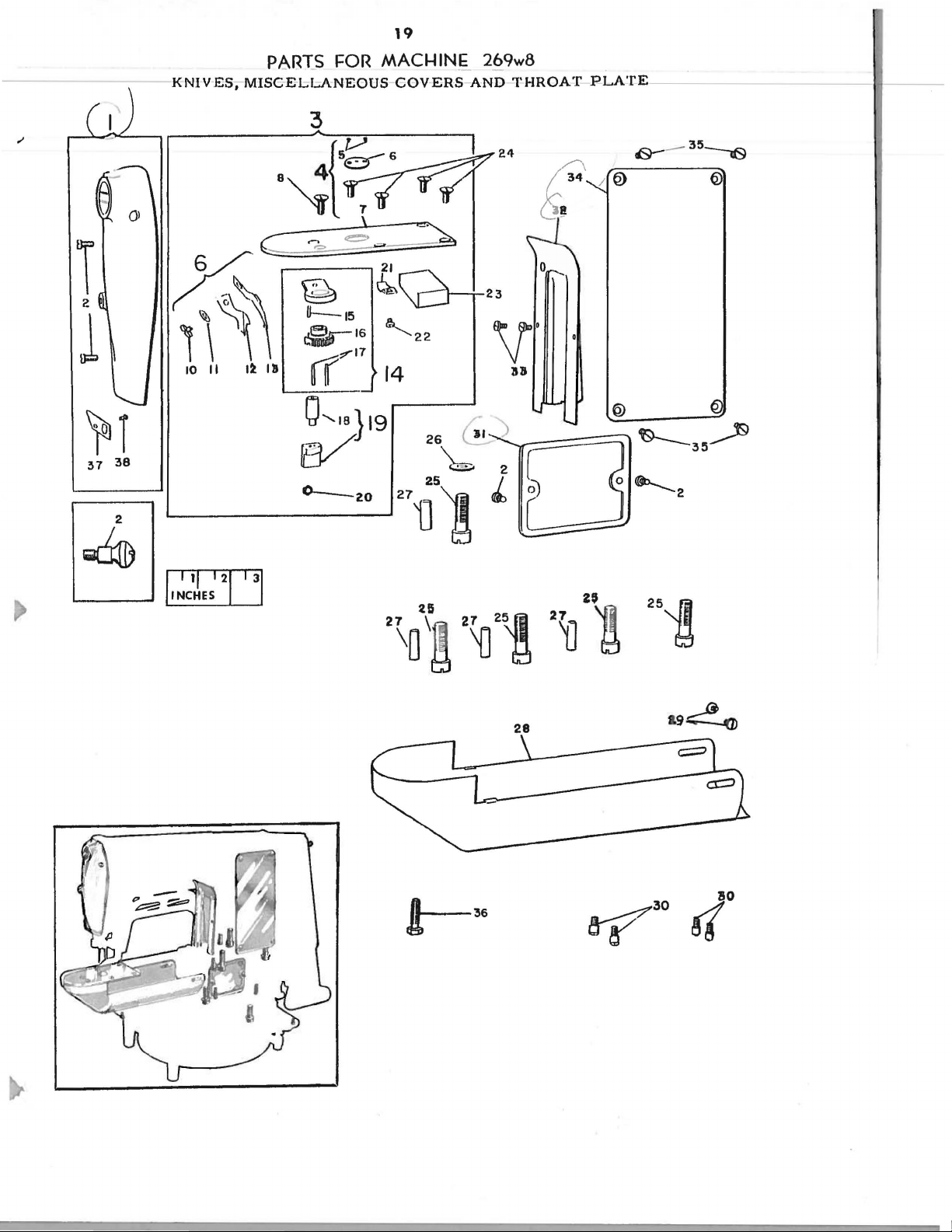

KNIVES,

01

~

10

~r

37

38

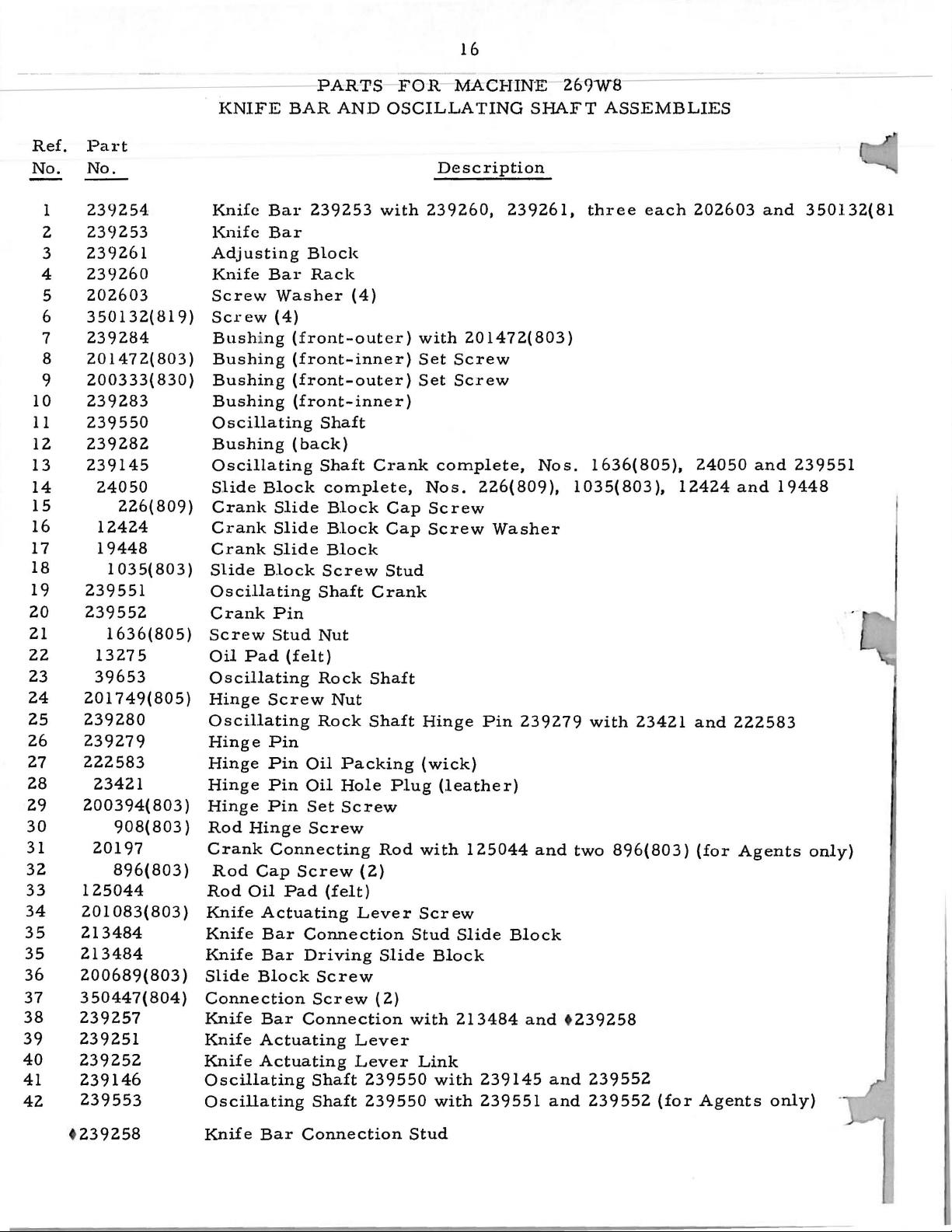

PARTS FOR MACJ-IINE 269w8

MISCELLANEOUS

II

I~

Ill

3

19

COVERS

26

k-2

5

AND

THROAT

24

0

23

PLATE

& ) D

'&--_35~

.____---J

.__

I ,, I

INCHES

I

_____

21 I 31

O--

__

z_o__,27~

_

l "~-

~2

J);---36

Rd.

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Part

1

2

3

4

5

6

7

H

9

350600(869)

201518(805)

239264

239343

200082(805)

239340

239361

200364(

239240

239241

239239

239238

201539(819)

225837

351886

201896

350634

239255

239256

201256(803)

239363

239259-001

200034(803)

234813

201052(833)

239344

200378(803)

239341

350606(869)

239144

No.

202423

239267

200335(

2392(>5

23lJ574

23lJ269

239268

350604(H6lJ)

210805

201652(805)

268072

200386(

239384

51946

200545(

239266

239263

37310

1655(803)

830)

803)

803)

803)

1

ARTS

LATJ•:RA ...... A""ND

O:il

Packing

Dri

veu

Set

Screw

Hock

Driving

Driving

Driving

Pinch

Washer

Nut

Collar

Set

Longitudinal

Roller

L i

Lat('ral

Lateral

Pinch

Link

Lateral

Washer

Nut

Tripping

Screw

Tripping

Arm

Set

Link

Link

Link

Cam

Roller

Roller

Knife

Arm

Roller

Knife

Rock

Bracket

Bracket

Knife

Pinch

Collar

Set

Tripping

Set

Tripping

Pinch

Longitudinal

Shaft

Screw ( 2)

(2)

Screw

nk

Screw

Screw

Screw

(2)

Hinge

Screw

Hinge

Retaining

and

Arm

Roller

Bar

Shaft

Bar

Screw

with

Screw

Screw

Screw

with

and

Screw

Screw

Screw

(wick)

Arm

Hinge

(2)

Driven

Artn

Arm

Arm

(2)

two

(

4)

Rock

Stud with 1655(803)

Rock

Pivot

Nut

Rock

(2)

Rock

Rock

Stud

Stud

Knife

Roller

Actuating

Bracket

Screw

Locating

Driving

two

(2)

Rock

Rock

Rock

20

FOR

L

ONGITUDINAL

Screw

Screw

with

200386(803) ( 2)

Shaft

Driving

Shaft

Shaft

Shaft

Ring

Follower

Stud

Stud

Stud

(2)

Pin

201052(833)

Shaft

Shaft

MACIIINI•,

Description

(2)

Stud

with

Arm

350604(869)

Shaft

Nut

Washer

201896

Lever

Shaft

(2)

Stud

Stud

Driven

Arm

Lever

Rock

Support

Connection

239384

202423 ( 2)

Guide

(2)

Arm

with

Arm

Arm

with

Shaft

with

269

WS

ROCK

Block

and-37310

350600(869)

with

350634

200034(803)

with 3 50606(

with

(2)

Driving

239239

51946

SHAFTS

(2)

Link

and

869)

239240

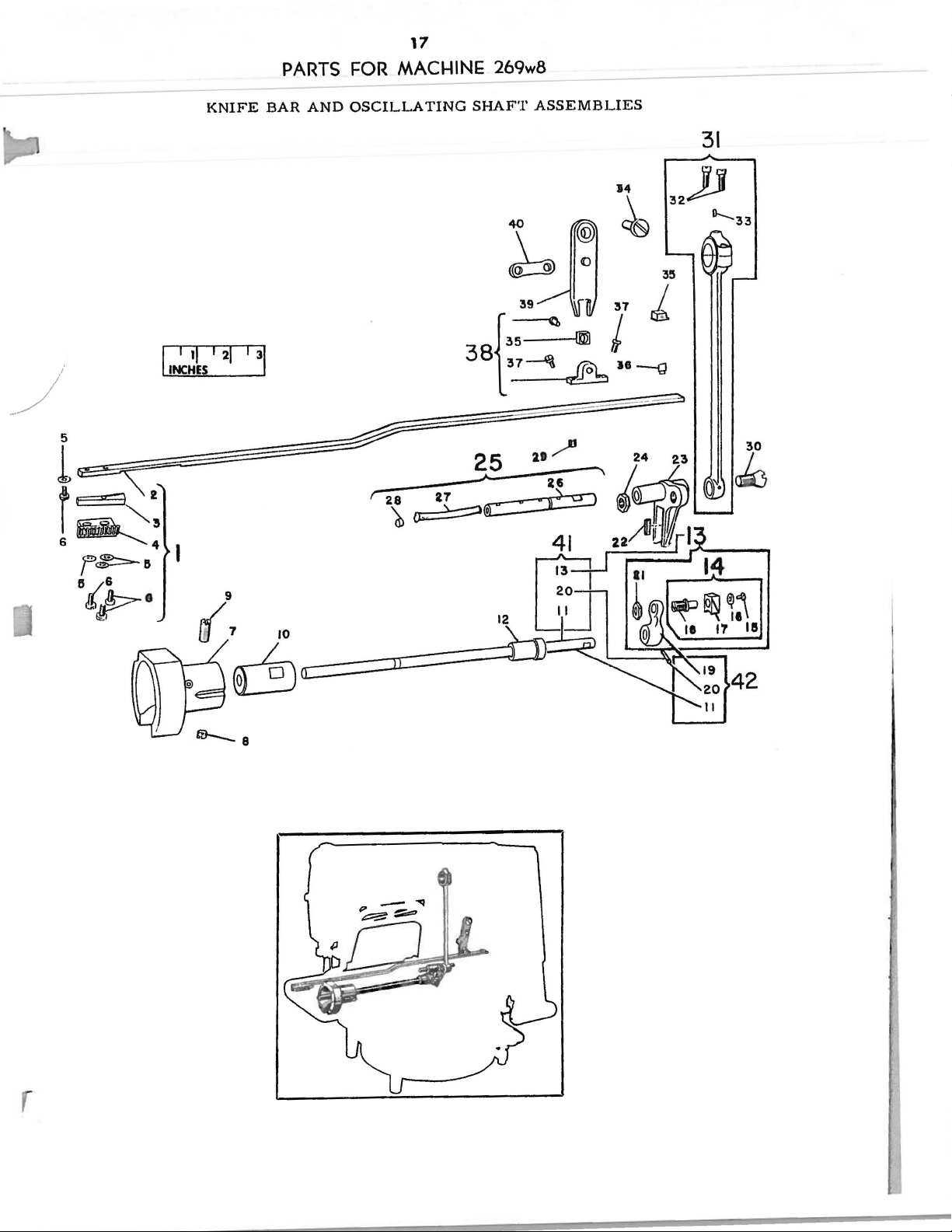

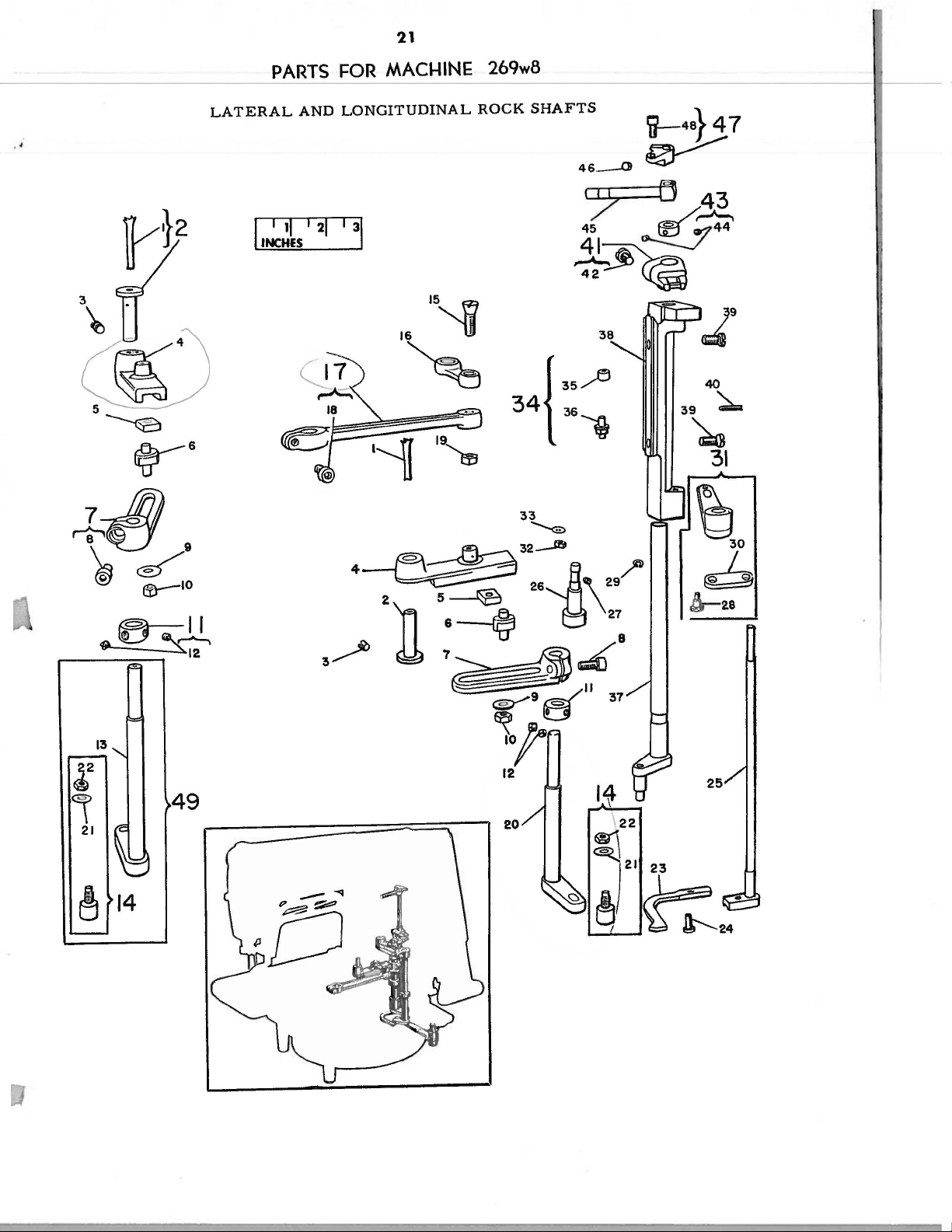

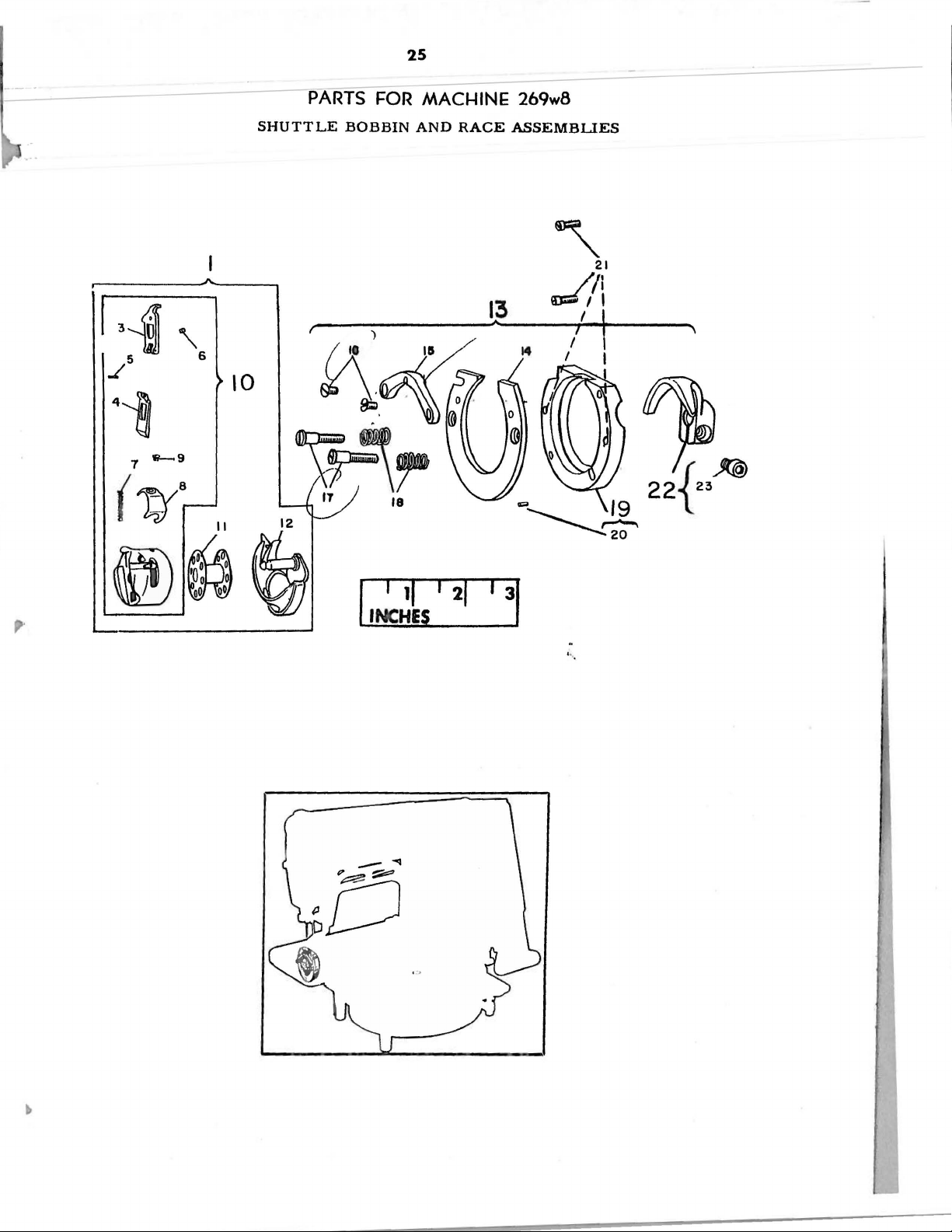

21

..

PARTS

LATERAL

I

_INCHES

I

AND

ll I 21

FOR

MACHIN~

LONGITUDINAL

I

31

.

15,

ROCK

f)

269w8

SHAFTS

46---0

I~

35~

34

19"'w

,<§::\~

4

~26~\29~

2

'r1

5~

6

--r@l

{

33

"-e

32_J&

36~

27

40

39

~

~

31

.~

~

7~~·

~96

37

'tf

12

25

22

"'-

Rd

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Part

.

No.

231.)215

1

2

200430(1330)

3

239274

3

4

23

5

6

239217

7

239327

8

23921

239515

9

200072(803)

239276

239275-001

200086(

239277

239218

239212

239211

239273

239272

239390

239376

201143(819)

200125(833)

239389

239336

141574(803)

239387

200308(803)

239388

200337(803)

239487

239216

20

167143

167144

141

239299

167154

167155

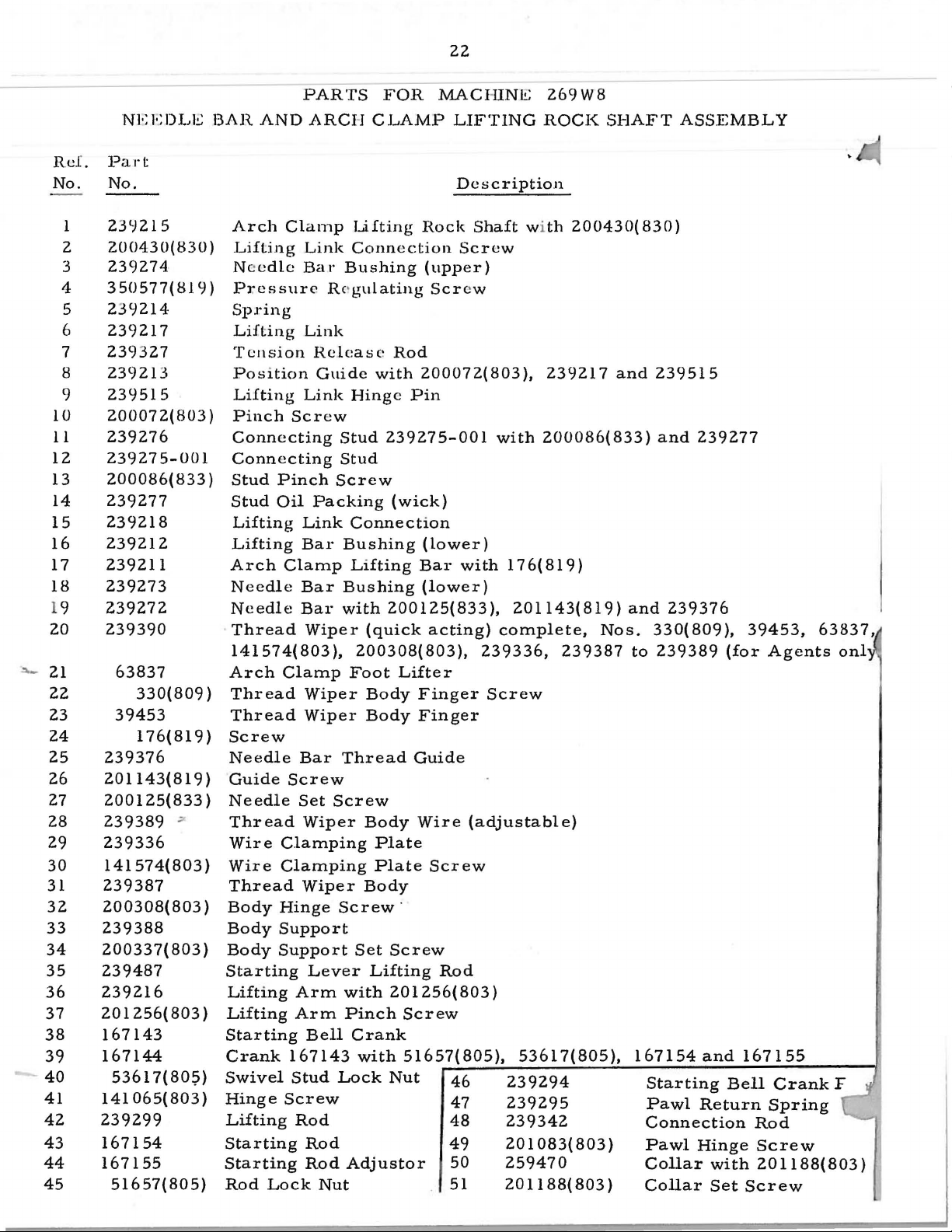

NEJo.:DLI~

50577(

9214

3

63837

330(809)

39453

17

6(

1256(

53617(80.?)

065(803)

51657(805)

BAR

819)

833)

819)

"'

803)

AND

Arch

Clamp

Lifting

Ne

edle

Pxcssur

SpJ~ing

Lifting

Tl:nsion

Position

Lifting

Pinch

Screw

Connecting

Connecting

Stud

Pinch

Stud

Oil

Lifting

Lifting

Arch

Needle

Needle

·

Thread

141574(803

Arch

Clamp

Bar

Bar

Clamp

Thread

Thread

Screw

Needle

Guide

Needle

Bar

Screw

Set

Thread

Wire

Wire

Clamping

Clamping

Thread

Body

Body

Body

Hinge

Support

Support

Starting

Lifting

Lifting

Arm

Arm

Starting

Crank

Swivel

Hinge

Lifting

167143

Stud

Screw

Rod

Starting

Starting

Rod

Lock

PARTS

ARCH

FOR

CLAMP

Lifting

Link

Bar·

Bushing

c R<·

Connection

gulating

Link

Rclcas e Rod

Guide

Link

Hinge

Stud

with

23927

Stud

Screw

Packing

Link

Bar

Bushing

(wick)

Connection

Lifting

Bushing

with

200125(833),

Wiper

),

200308(

(quick

Foot

Wiper

Wiper

Body

Body

Thread

Screw

Wiper

Body

Plate

Plate

Wiper

Body

Screw

Set

Screw

Lever

Lifting

with

20

Pinch

Bell

Crank

with

Lock

Nut

Rod

Rod

Adjustor

Nut

MACHINE

LIFTING

Description

Rock

Screw

(upper)

Scr

ew

200072(803

Pin

5-001

(lower)

Bar

with

(lower)

acting)

803

),

Lifter

Finger

Finger

Guide

Wire

(adjustable)

Screw

·

Rod

1256(

803)

Screw

51657(805),

46

47

48

49

50

51

269W8

ROCK

Shaft with

),

239217

with

200086(833)

1 7 6( 81

201143(819)

complete,

239336,

Screw

53617(805),

239294

239295

239342

201083(803)

259470

201188(803)

SHAFT

200430(830)

and

9)

and

Nos.

239387

to

167154

ASSEMBLY

239515

and

239277

239376

330(809),

239389

and

Starting

Pawl

Return

Connection

Pawl

Collar

Collar

Hinge

with

Set

39453,

(for

Agents

167155

Bell

Crank

Spring

Rod

Screw

201188(803)

Screw

63837,

onl

F

PARTS

23

FOR

MACHIN!: 269w8

NEEDLE

17

BAR

19

A

AND

ARCH

20

CLAMP

LIFTING

ROCK

50

4-1-51

35

I

11 I 21

_INCHES

I

~

34

I

31

_

SHAFT

ASSEMBLY

--.----.

\

24

.------'

26-

27

'

Needle:

Catalog

1628

(68x5)

Size

18

41~~

42~

25

'19

22~

23~

I

24

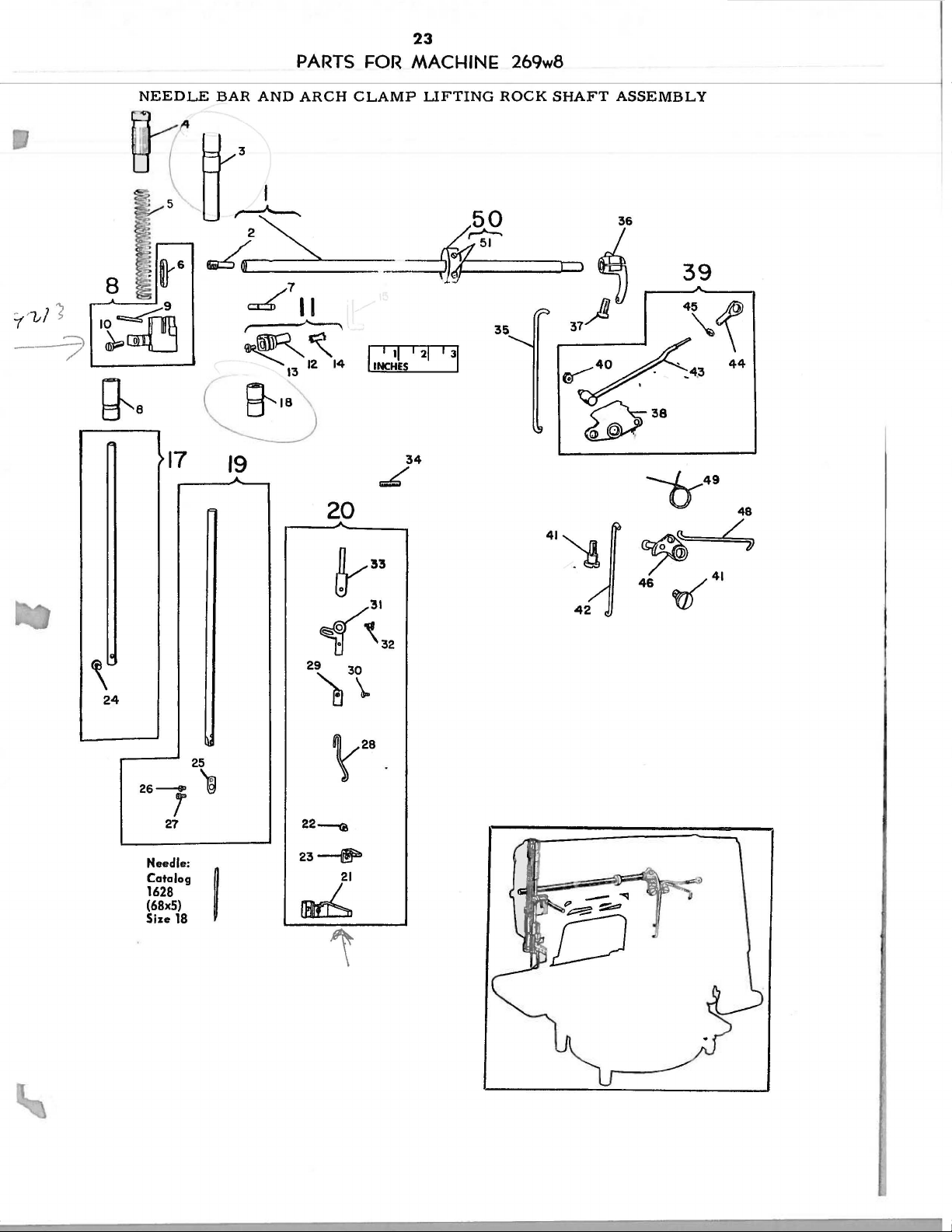

Ref.

No.

1

2 l

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Part

No.

239287

5141

15140

2973

2974

592(805)

2975

224842

591(806)

43725

23500

40028-002

239292

239290

~

2 0

1148(

51381(806)

239291

239289

239365

51403(869)

262061

350606(869)

81 9 )

ARTS

SHUTTLE

Shuttle,

Hi

nge,

1-11/16

Nos.

BOBBIN

2973,

Latch

Latch

Latch

Latch

Latch

Tension

Regulating

Shuttle

Shuttle

Shuttle

Shuttle

Race

Case

Case

Ring

Ring

Body

Body

Body

Shuttle

(central

Lever

Lever

Stop

Fulcrum

Screw

Spring

Spring

Screw

Bobbin

224842

Case

Bobbin

Body

Race

51381(806),201148(819)

complete,

Ring

Position

Position

Spring

Sp

ring1 ( 2)

with

Oiling

Screw

Driver

Plate

Plate

Screw

239365

Felt

(2)

(central

bobbin)

FOR

in.

2974

(2)

Pinch

MACHINE

AND

Description

diam.,

and

Pin

with

591(806),

Nos.

Screw

bobbin)

Screw

RACE

Nos.

15140

239285,

and

269

ASSEMBLI

23500,

592(805),

239291

with

350606(

W8

ES

40028-002

2975,

/"

239289, 239290,

869)

and

15141

two

43725

and

each

---

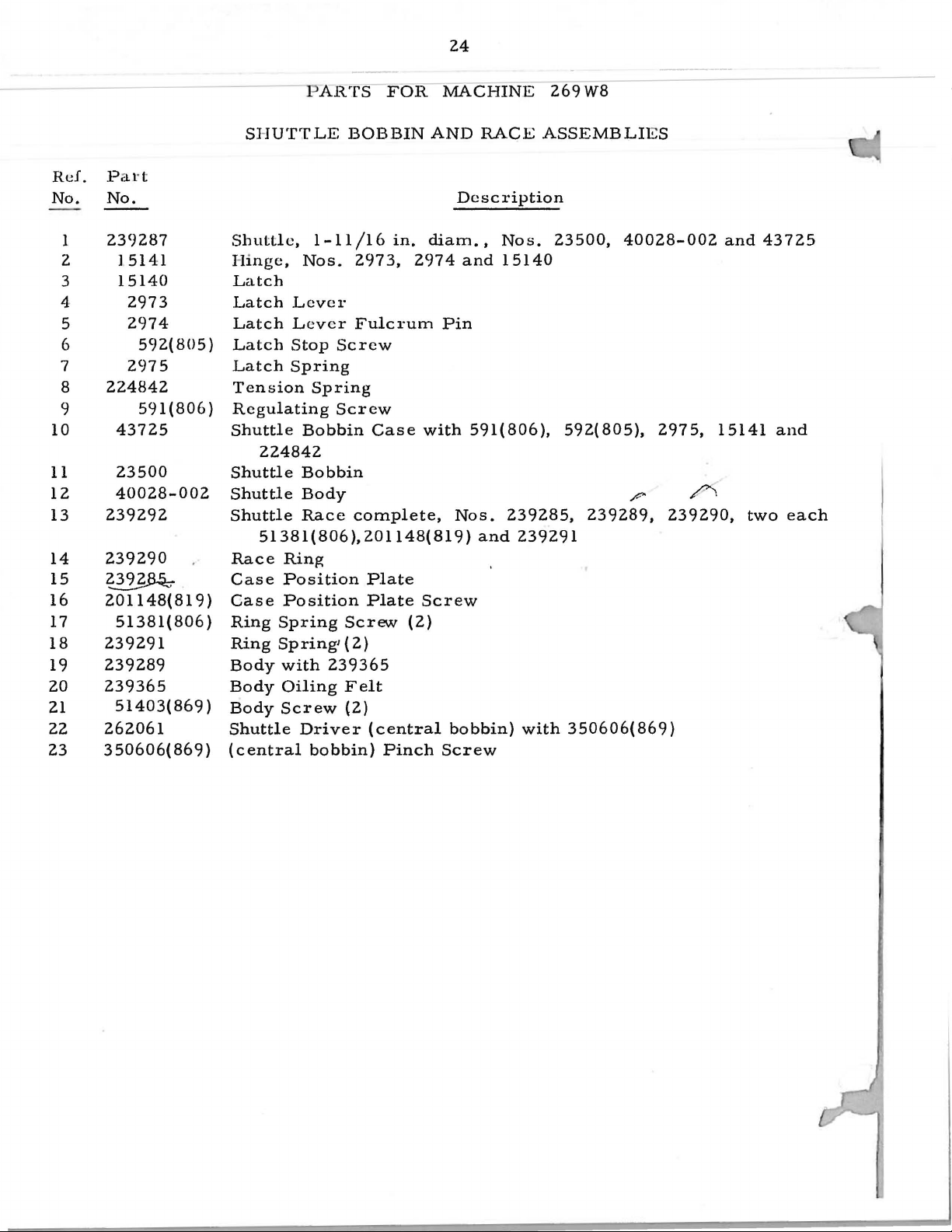

PARTS

25

---

FOR MACJ-tiNI: 269w8

·~

..15

6

"

10

4i

7

9--9

(

'tY"

SHUTTLE

12

BOBBIN

18

AND

RACE

13

,.

ASSEMBLIES

~

21

u:;(/1

1 I

I

I I

14

I

I

'

,.

~

I I

lf

INCHES

I

2f

I

31

Loading...

Loading...