Singer 263-1 Service Manual

Form

(964)

21289

SINGER

Service Manua

MACHINE

263-1

/

*A

Tredemerlco(THE

SINGER

COMPANY

THE

Copyright Under international Copyright Union

All

Rights

SINGER

Copyright ® 1964 by The Singer Company

Reserved

under

COMPANY

Inler-Americon

Copyright

Union

Printed

In U. S. A.

COHTENTS

DESCRIPTION

INSTALLATION

LUBRICATION

OPERATOR

ADJUSTMENTS

PARTS

INFORMATION

CHART

AuxilioryThreod Toke-Up 12

Bight 9

Couses

Centrolizing Feed

Centrolizing Needle Bor 8

Cleoronce

of Troubles, Check

Dog

under

Presser

Foot

List

15

14

Description of Mochine 3

DimensionsofMochine

Bed

Federol Stitch Types 401 ond 404 3

Feed Timing 13

Feed Dog Adjustments 14

Feed

Eccentric

13

Feeding Movement 13

Feed Lifting Eccentric 13

Instollotion

Knee

Lifter

Length of Stitch 3, 7

Leveling

Feed Dog. 14

Looper Gouge Distonce .9

Looper, Needle-Avoiding

Motion

10

Looper Positioning (Front ond Reor)

from

Needle

11

Looper-Threod Retoiners 12

Looper-Threod Toke-up (Double) 3, 11

Looper-Threod Tension 6, 12

Looper-Threod

Tension

Releoser

3, 12

Looper Threoding .6

Looper

Lubricotion

Mochine

Timing 9

3,

Bose

ond Oil

Reservoir

.3, 4

INDEX

3

3

3

3

4

3

3

4

4-6

7-15

RearofBook

Mochine Pulley 3

Needle-Avoiding

Motion

10

Needle, Cotolog 2796 3, 4

Needle Setting 5

Needle Threoding 5

Needle Bor, Centrolizing 8

Needle Bor Height 10

Needle

Needle

Oil

Ports

Presser

Pressure

Puckered

Skipped

Bor

Stroke

Bor Throw 3, 8, 9

Recommended

ReorofBook

Bor Height 7

on

Moteriol

Seoms,

Stitches,

Causes

Couses

15

15

Speed

Stitch

Length 3, 7

Stitch

Types

401 ond 404 3

Toke-up, Auxiliory 12

Toke-up, Double 3, 11

Tensions

Tension

Threod Breoking,

Threod

Threod

Releoser

Couses

Recommended

Retoiners

3, 12

15

12

Threoding 5, 6

Tilting the Feed Dog 14

Trouble

Zigzog

Check

List

15

Movement .8, 9

3

4

6

n

4

6

5

TO

ALL

The

improper

(all

of which

in any way

WHOMITMAY

placing

are

duly

whatsoever

CONCERN:

or renewal of the Trademark SINGER* or any other of the Trademarks of

Registered

outside

Trademarks)

a SINGER factory or an

an any

machine

authorized

that

SINGER

has

been

agency

repaired,

is forbidden.

rebuilt,

reconditioned,oraltered

The

Singer Company

DESCRIPTION

Machine 263-1 Is o high

stitch, zig-zag machine for attaching

SPECIAL

Federal

FEATURES

Stitch

Types

401

gowns,

and

404.

slips,

panties,

One needle, one looper.

Needle, Catalog 2796.

Double iooper-threod

Tension

releaserfor

Needle bar has a throw of up to

both

sides

Lengthofstitch,

Drop

Feed.

Needle bar

Clearance

stroke,

under

Dimensions of bed: Length,

inches;

space

take-up.

looper thread and

of

centerline.

9 to 16

1-3/16

presser

at

stitches

inches..

foot,

15-3/4

right of

3/16

needle

1/8

inch. Vibrates

per

inch.

inch.

inches;

needle,

8

Automatic lubricating system delivers oil to all

principal

Oil flow window in

bearings.

direct

viewofoperation.

Head-end lubrication and oil-return system. Needle

etc.

thread.

width, 7

inches.

INSTALLATION

speed,

two thread, chain

lace

to night

bar bushings lubricated through wicks from arm

shaft

bushings.

Three plain super

Support

Rotary bed

the

shaftisgear

arm

finished

shaft.

driven.

Knee lifter integral with machine

voir.

Machine provided with

fixture mounting.

MACHINE

PULLEY

Machine pulley 146512, for

outside

diameter

inches.

must

When

always

diameter

for

belt

5/16

in operation,

turn over toward

grooveof2.9

inch

round

the

bearings

seat

for independent light

3/8

leather

base

position

and oil

and

reser

inch V-belt, has an

inches.

belt

Effective

is

2-3/8

top of the machine pulley

the

operator.

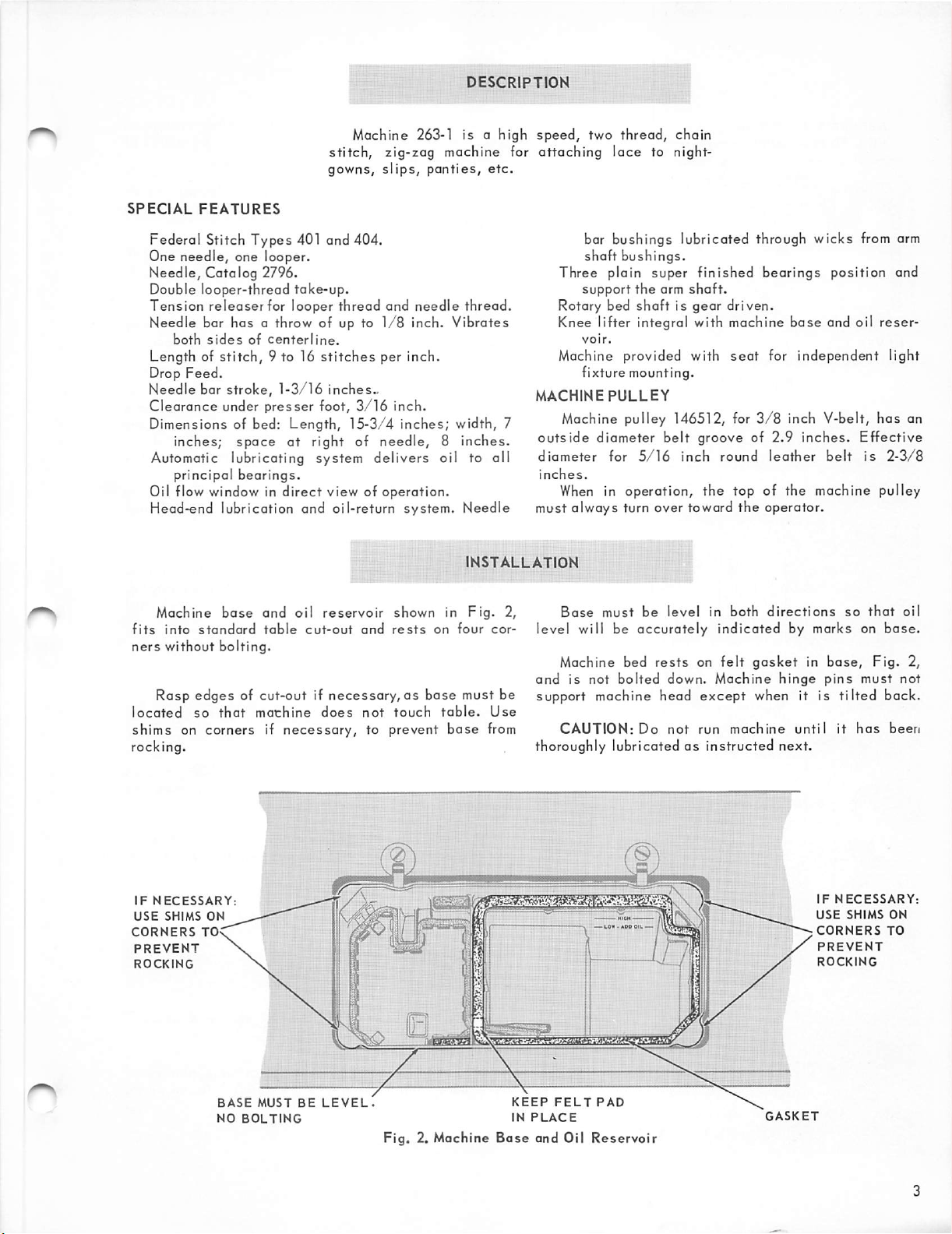

fits

ners

Machine

into

without

base

standard

bolting.

and

table

oil

cut-out

reservoir

Rasp edges of cut-out if necessary, as

located

shims on corners if

rocking.

IF

USE

CORNERS

PREVENT

ROCKING

so

NECESSARY;

SHIMS

ON

that

\

machine

necessary,

does

shown in

and

rests

not

touch

to prevent

L=

on

base

table.

Fig.

four

must be

base

Base

must

be

2,

cor

level will be

Machine bed

and

is not

bolted

level

accurately

rests

down.

support machine head

Use

from

CAUTION:

Do

not

thoroughly lubricatedasinstructed

in

indicated

on

felt

Machine

except

run

both

directions

gasket

when it is

machine

by marks on

in

base.

hinge

pins

tilted

until

it

next.

IF

NECESSARY:

USE

CORNERS

PREVENT

ROCKING

so

must

has

SHIMS

that

base.

Fig. 2,

back.

been

ON

TO

oil

not

KEEP

FELT

BASE

NO

MUST

BOLTING

BE

LEVEL.

Fig.

2. Machine

IN

Base

PLACE

and Oil

PAD

Reservoir

GASKET

liii-

IT-fSrftafl

LUBRICATION

BEFORE

FILL

NEVER

FALL

TO

ALLOW

BELOW

STARTING

HIGH

MARK

J

OIL

LOW

Fig. 3.

MACHINE:

TO

MARK

OIL

HOLDS

Lubrication

CHECK

OFTEN

RESERVOIR

1-3/4

SATURATE

WICK

PINTS

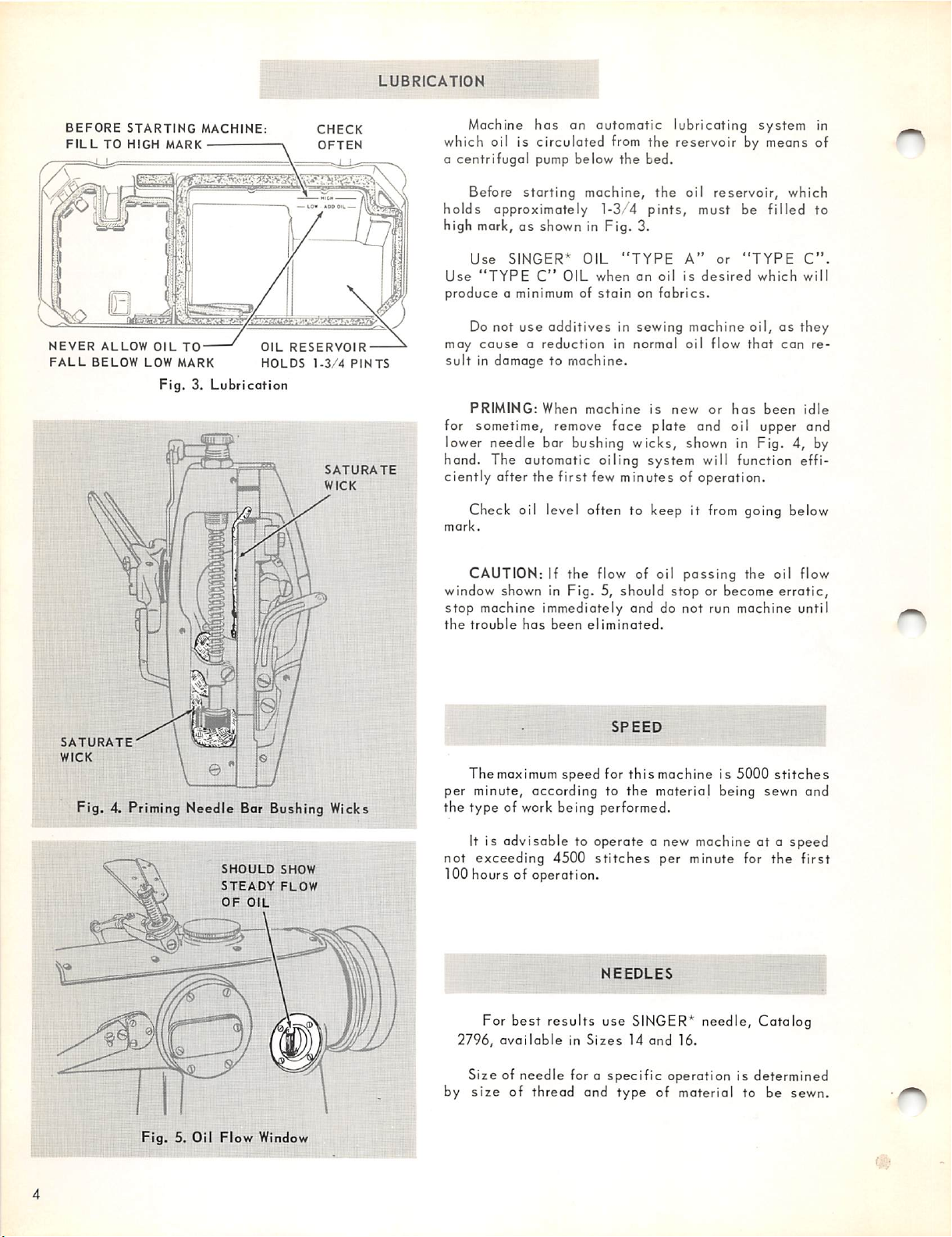

Machine

which oil is

a

centrifugal

Before

holds

has

on automatic lubricating

circulated

pump below

starting

approximately

from

the

machine,

1-3/4

the

reservoir by means of

bed.

the

oil reservoir, which

pints,

must be filled to

system

high mark, as shown in Fig. 3.

Use

SINGER*

Use

"TYPE

produce

may

sult

a minimum of

Do not

use

causeareduction

in damage to machine.

PRIMING:

for sometime, remove

C"

OIL

additives

When

OIL

when

"TYPE

on

A"

or

oilisdesired

"TYPE

stainonfabrics.

in sewing machine oil,asthey

in normal oil flow

machine

face

is

plate

new

or

has

and oil upper and

which

that

been

can

C".

will

re

idle

lower needle bor bushing wicks, shown in Fig. 4, by

hand. The automatic oiling

ciently

after

the

first

few minutes of operation.

Check oil level often to keep it

mark.

CAUTION: If

window shown in

stop

machine immediately and do not run machine until

the

trouble

has

been

the

flow of oil

Fig.5,should

eliminated.

system

will function effi

from

passing

stoporbecome

going below

the oil flow

erratic,

in

SATURATE

WICK

Fig. 4. Priming Needle Bar Bushing

SHOULD

STEADY

OF

OIL

Fig.

5. Oil

Flow

Window

SHOW

FLOW

Wtclcs

SPEED

The

maximum

per minute, according to

speed

for

this

the

material being sewn and

the type of work being performed.

It is

advisabletooperate

not

exceeding

100

hoursofoperation.

For

best

2796,

availableinSizes14and

Sizeofneedle

by

size

of thread end type of material to be sewn.

4500

results

for a

stitches

NEEDLES

use

a new machineata

SINGER*

specific

machine is

5000

stitches

speed

per minute for

needle,

16.

the

Catalog

operationisdetermined

first

HfBlfrf

•

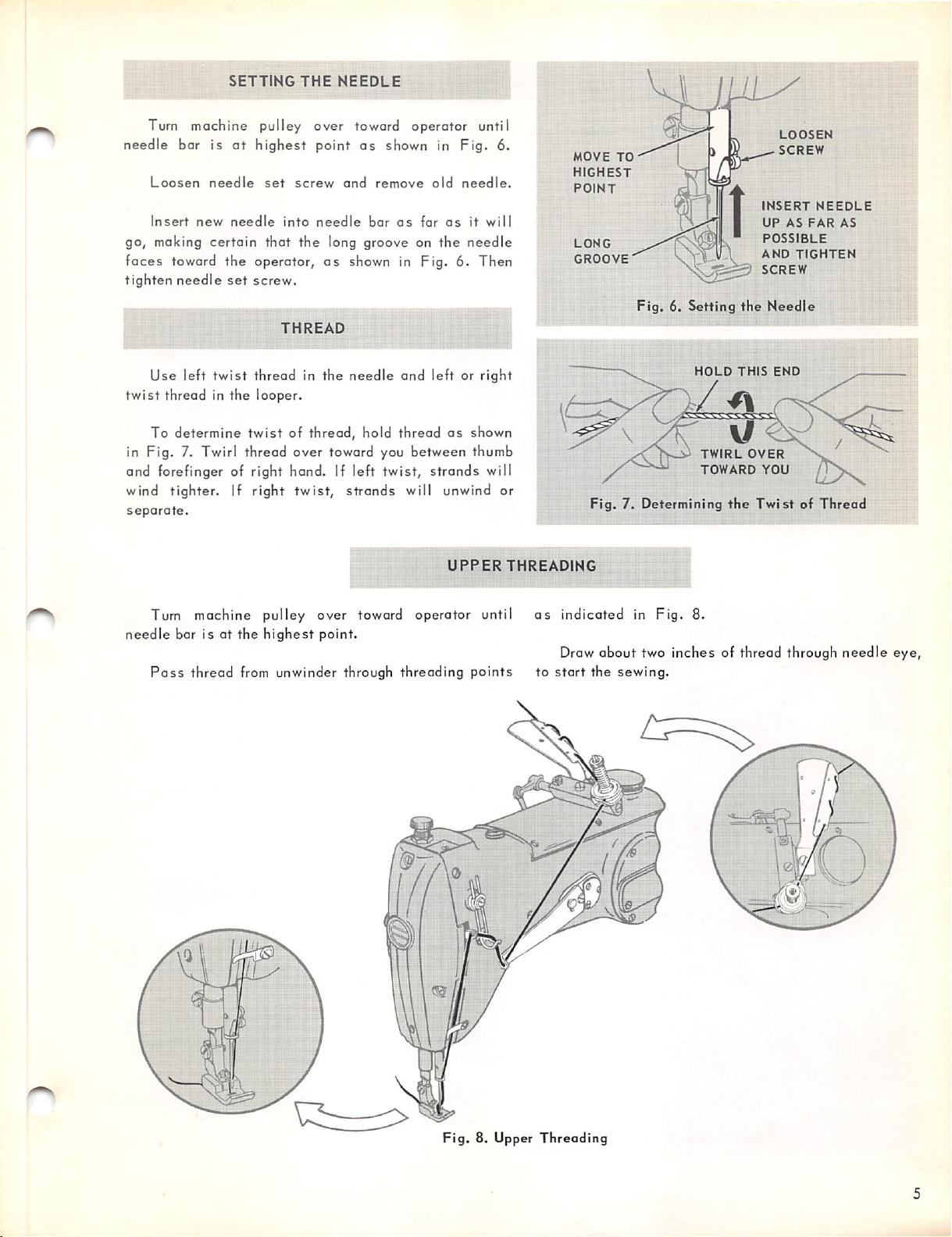

Turn

machine

needle bar is

Loosen

Insert

new

go, making

faces

toward the operator,

tighten

needle

Use left

twist

thread in the looper.

To

determine

SETTING

at

needle

needle

certain

set

screw.

twist

thread in

twistofthread,

THE

pulley

over

highest point

set

screw

into

needle

that

the

long groove on

as

THREAD

the

NEEDLE

toward

as

and

operator

shown in Fig. 6.

remove

bar

old

needle.

as

far

asitwill

the

needle

shown in Fig. 6. Then

needle

and left or right

hold

threadasshown

until

in Fig. 7. Twirl thread over toward you between thumb

and forefinger of right hand. If left twist, strands will

wind tighter. If right

separate.

twist,

strands

will unwind or

MOVE

HIGHEST

POINT

LONG

GROOVE

Fig.

TO

Fig,6.Setting

HOLD

7. Determining

TWIRL

TOWARD

the

LOOSEN

SCREW

INSERT

UP

AS

FAR

POSSIBLE

AND

TIGHTEN

SCREW

the

Needle

THIS

END

OVER

YOU

TwistofThread

NEEDLE

AS

-

Turn machine pulley over toward operator until

needle

Pass

bor is at

thread

the

highest

point.

from unwinder through threading

UPPER

points

THREADING

as

indicated in Fig. 8.

Draw

to

start

about

two inches of thread through

the sewing.

needle

eye,

Fig.

8. Upper

Threading

Loading...

Loading...