Page 1

Tlrm 20549

r:ev. (557)

SERVICE MANUAL

AND

PARTS LIST

FOR

SINGER

MACHINES

OF CLASS 251

SINGLE NEEDLE LOCK STITCH

AUTOMATIC OILING SYSTEM

£275Si?

CAUTION—See that the oil reservoir is filled os instructe.d on page 6 before running the machine, even to test

•A Trade Mark of THE SINGER MANUFACTURING COMPANY

the speed. Special attention is olso called, to the hook lubricating instructions on page 7.

THE SINGER MANUFACTURING COMPANY

Copyright © 1957 by The Singer Manufacturing Company

Printed in U. S. A.

Page 2

FIG. 2. X-RAY VIEW OF MACHINES OF CLASS 251

(LUBRICATING SYSTEM SHOWN IN SOLID BLACK)

FOREWORD

This book contains complete information covering operation, adjustment,

parts list, attachments and special fittings for Machines of Class 251- Descriptions

and exploded vievYS of all parts assemblies on pages 45 to 194 Inclusive, will be

found helpful when ordering any part of the machine requiring renewal.

Page 3

DESCRIPTION

Machines of Class 251 produce top quality, straight-line, single-needle, lock stitching in fabrics as fine as

ladies' lingerie or as heavy as mens' overcoating.

General Features

Federal Stitch Type #301.

High Speed (see chart on page 4). Maximum speed

dependent upon nature of work and ability of

operator.

Gear driven, lubricated. Rotary Sewing Hook on

horizontal axis makes two revolutions for each stitch.

Upper gears are spiral-bevel. Lower gears are

hypoid-bevel.

Hook Shaft mounted .160 inch forward of vertical

axis of Needle Bar for improved stitch formation.

Drop Feed guided by mounted journal bearings to

prevent side movement of Feed Dog.

Length of stitch determined by a Push-Button Stitch

Regulator on top of machine arm. Regulator includes

Locking Device to prevent changing of stitch length

during machine operation: (For maximum possible

.stitch length, see chart on page 4). Stitch Length Indi

cations on Machine Pulley are in view of operator.

Automatic Lubricating System (see X-Ray View on

opposite page). Centrifugal Pump delivers oil under

pressure from Reservoir to all principal bearings. Oil

wicks lubricate bearing surfaces in head end of ma

chine and return excess oil to Reservoir. Oil Guard

covers entire path of Take-up Lever.

Oil Flow Window, in direct view of operator, reveals

circulation of oil inside machine arm.

Machine Dimensions: Bed length 18-3/4 inches,

width 7 inches. Space at right of Needle 1 1 inches.

Machine Head is supported by Machine Base and

Oil Reservoir, designed to fit the cutout in table.

Machine Pulley 147016. Outside diameter of belt

groove 2.90 inches for 3/8 inch V-belt. Effective diam

eter for 5/16 inch round leather belt is 2-3/8 inches.

When the machine is in operation, the top of the

machine pulley must always turn over toward the

operator.

Knee Lifter, regularly furnished, is an integral part

of the Machine Base and Reservoir.

Page 4

SPECIAL CHARACTERISTICS OF

MACHINES OF CLASS 251

MACHINES (CLASS AND VARIETY)

TYPE OF

MATERIAL

MAXIMUM

SPEEDt

(R.P.M.)

MAXIMUM

STITCH

LENGTH

NEEDLE BAR

STROKE

(Inches)

251-1

Light-Weight

5000

7

per inch

1-9/64

251-2 251-3

Medium-Heavy

to Light-Weight

5000 4300

5-1/2

per inch

1-13/64 1-7/16

Heavy to

Light-Weight

5-1/2

per inch

251-3 (HEAVY)

Extra-Heavy to

Light-Weight

4300

5-1/2

per inch

1-7/16

PRESSER BAR

LIFT

(Inch)

NEEDLES:

CLASS

AND

VARIETY

SIZES

RECOM

MENDED

fDependent upon nature of material and ability of operator.

9/32

88 X 9

8, 9,10,11,12,

13, 14, 16,

17, 18, 19,

20, 21 and 22

5/16

16 X 257

8, 9, 10, 11, 12, 13,

14, 16, 17, 18, 19,

20, 21,22, 23 and

24

3/8

16 X 257

8, 9, 10, 11, 12,

13, 14, 16, 17,

18, 19, 20, 21,

22, 23 and 24

7/16

16 X 261

16, 18, 19, 21,

22 and 23

Page 5

SETTING UP

TABLE

CUT-OUT

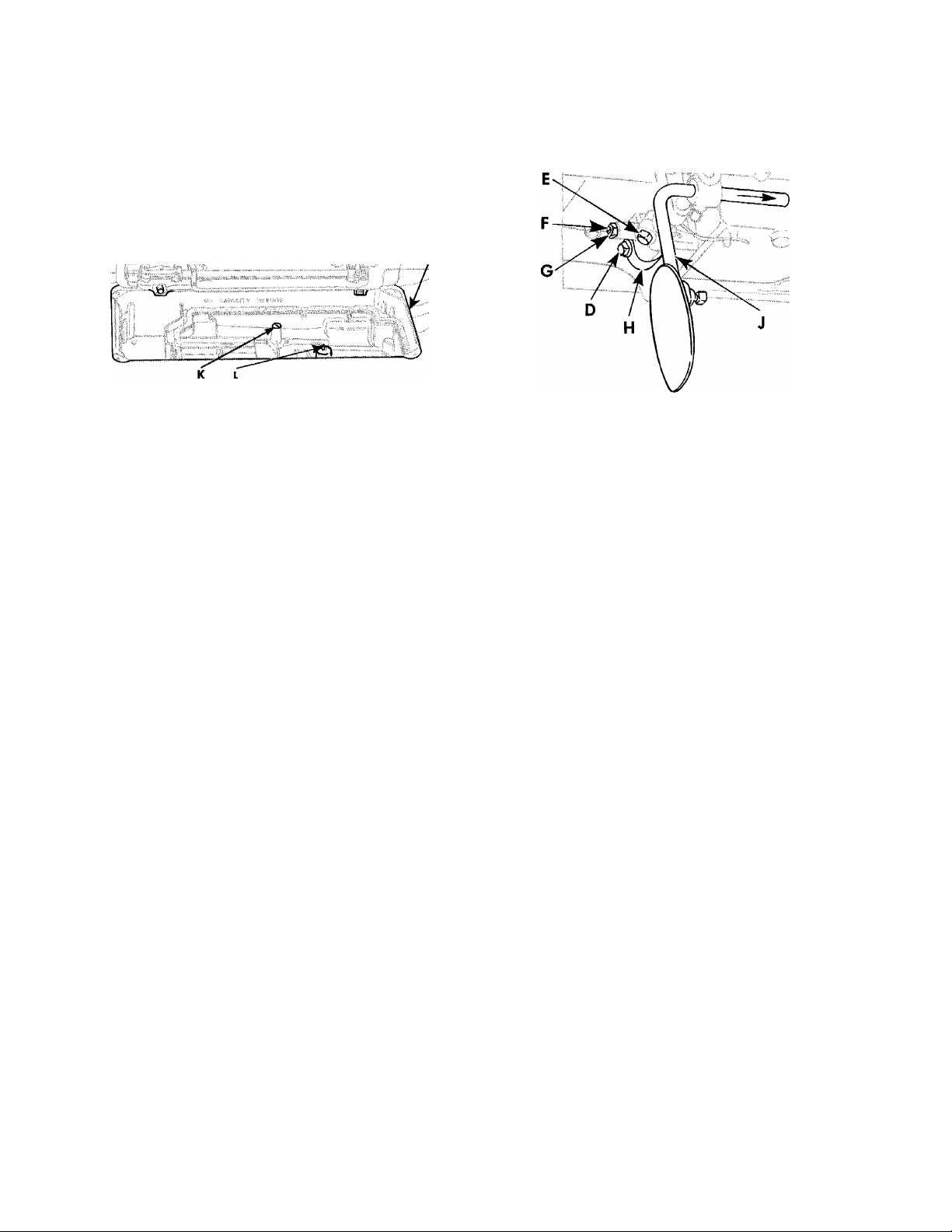

Fig. 3. Installation of Machine

on Base

When shipped, the base is held to the machine by

a single bolt through the bottom of the base. Discard

this bolt and plug the hole by inserting from inside

the base, the special cap screw K, Fig. 3, furnished

with the machine.

The base fits into a standard table cut-out, as shown

in Fig. 3 and rests on the four corners without

fastening.

Rasp the edges of the cutout, if necessary, as the

base must slide in without driving and must be located

so that the machine head does not touch the table

when it is placed on the base.

Use shims on the corners, if necessary, to prevent

the base from rocking. The base should also be level

in both directions so that the oil level will be accurately

indicated by the marks in the base.

See that the plunger L, Fig. 3 is in place inside the

base, before putting the machine on the base.

Fig. 4. Installation of Knee

Lifter on Machine Base

The machine head rests on the cork gasket in the

base and is not fastened. The machine hinges must

not support the head except when it is tilted back.

The knee lifter is shipped assembled to the base,

except for the knee plate and lever J, Fig. 4. After

the base is in position, loosen the set screws D and E,

Fig. 4 and slide the shaft forward to the position

shown in Fig. 4. Attach the knee lifter lever J. Set the

stop screw F so that there is only a little play of the

lifter before it starts to lift the presser bar, then hold

the screw and tighten lock nut G. Set the rear stop dog

H to allow the presser bar to be just raised to its limit

but not enough to permit further strain on the knee

lifter parts or to permit the action of the knee lifter

to lift the machine from its base.

CAUTION:—Before starting the machine, it must be

thoroughly oiled, in accordance with the instructions

on page 6.

The maximum speed recommended for Machines

251-4 and 251-2 is 5000 revol utions per minute and

for Machine 251-3, 4300 revolutions per minute ac

cording to the material being sewn and the type of

work being done. (See chart on opposite page.)

SPEED

It is advisable to operate these machines at a more

moderate speed the first few days, after which they

can be operated at maximum speed.

Page 6

TURN BACK MACHINE

LUBRICATION

NEVER ALLOW

OIL TO FALL

BELOW LOW MARK

Fig. 5. Oil Reservoir

FILL TO

HIGH MARK

Machines of Class 251 have an automatic lubricat

ing system in which oil is circulated by means of a

centrifugal pump from a reservoir in the base. X-Ray

view of machine on page 2 illustrates automatic cir

culation of oil in this machine.

BEFORE STARTING THE MACHINE the oil reservoir

must be filled with "TYPE A" or "TYPE C" OIL, sold

by Singer Sewing Machine Company. "TYPE C" OIL

is used when an oil is desired which will produce a

minimum of stain on fabrics, even after a long period

of storage.

Tip the machine back on its hinges and fill the oil

reservoir as instructed in Fig. 5,

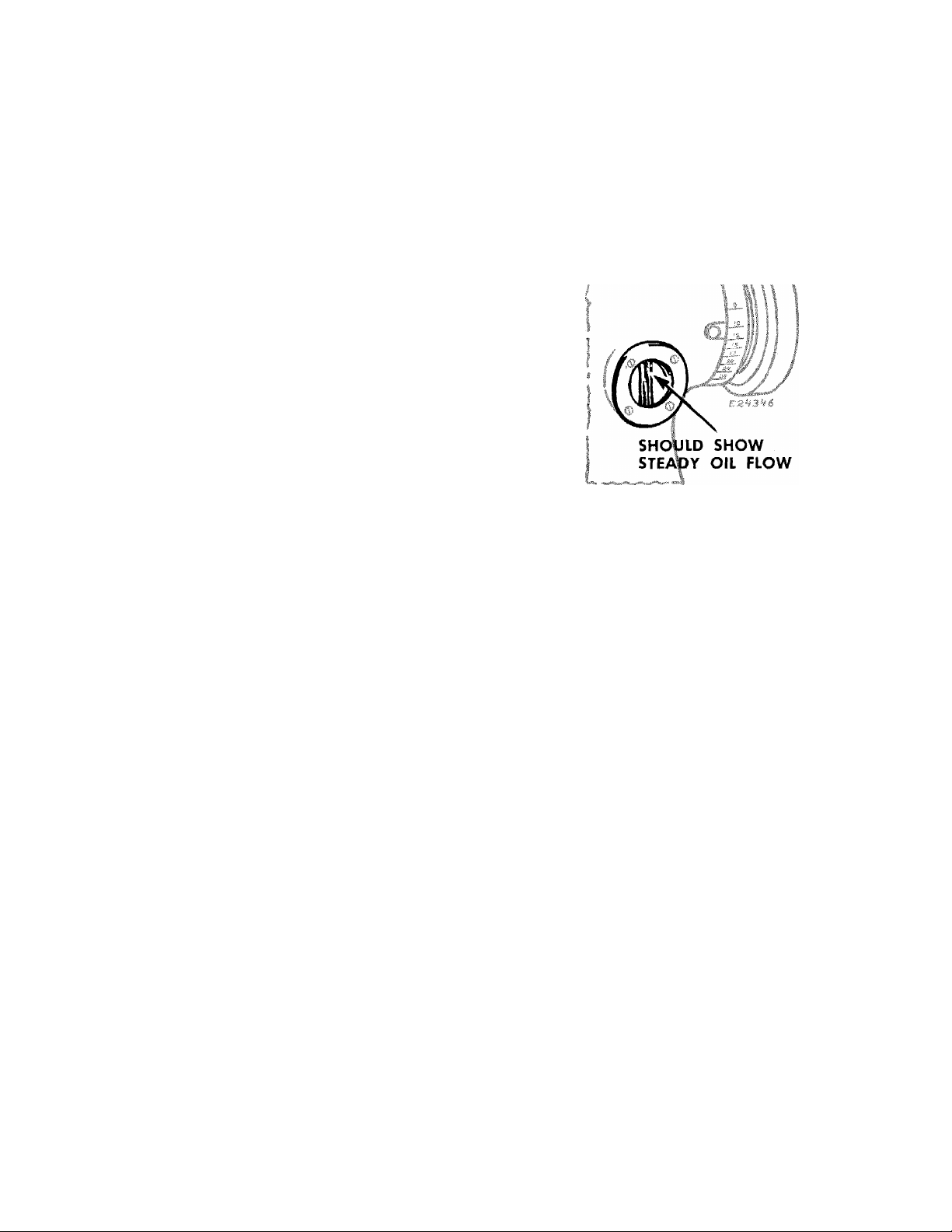

Fig. 6. Oil Flow Window

When in operation, the oil level in the reservoir

should be inspected at least twice a month or as oftei^

as necessary, to keep it from going below the LOW

mark, see Fig. 5, in the reservoir.

CAUTION: Correct lubrication is indicated by a con

tinuous stream of oil passing the oil flow window

while machine is running, as shown in Fig. 6.

Should this oil flow become erratic, STOP the ma

chine and do not run the machine again until the oil

flow has been restored.

At least twice each month check the oil level in the

reservoir.

Never allow oil level to drop below LOW mark,

shown in Fig. 5.

When a machine is NEW or has been idle for several

weeks it is advisable to remove the face plate and oil

the needle bar and take-up bearings. Oil the hook as

sembly by hand and check the oil flow, as instructed

on page 7. The automatic oiling system will function

efficiently, after the first few minutes and continue to

lubricate all bearings.

Oil your bobbin winder occasionally by applying

a few drops of oil to the oil well in bobbin winder,

as shown in Fig. 15, page 12.

See instructions, covering Oil Removing Wick As

sembly, on pages 38 to 41.

Page 7

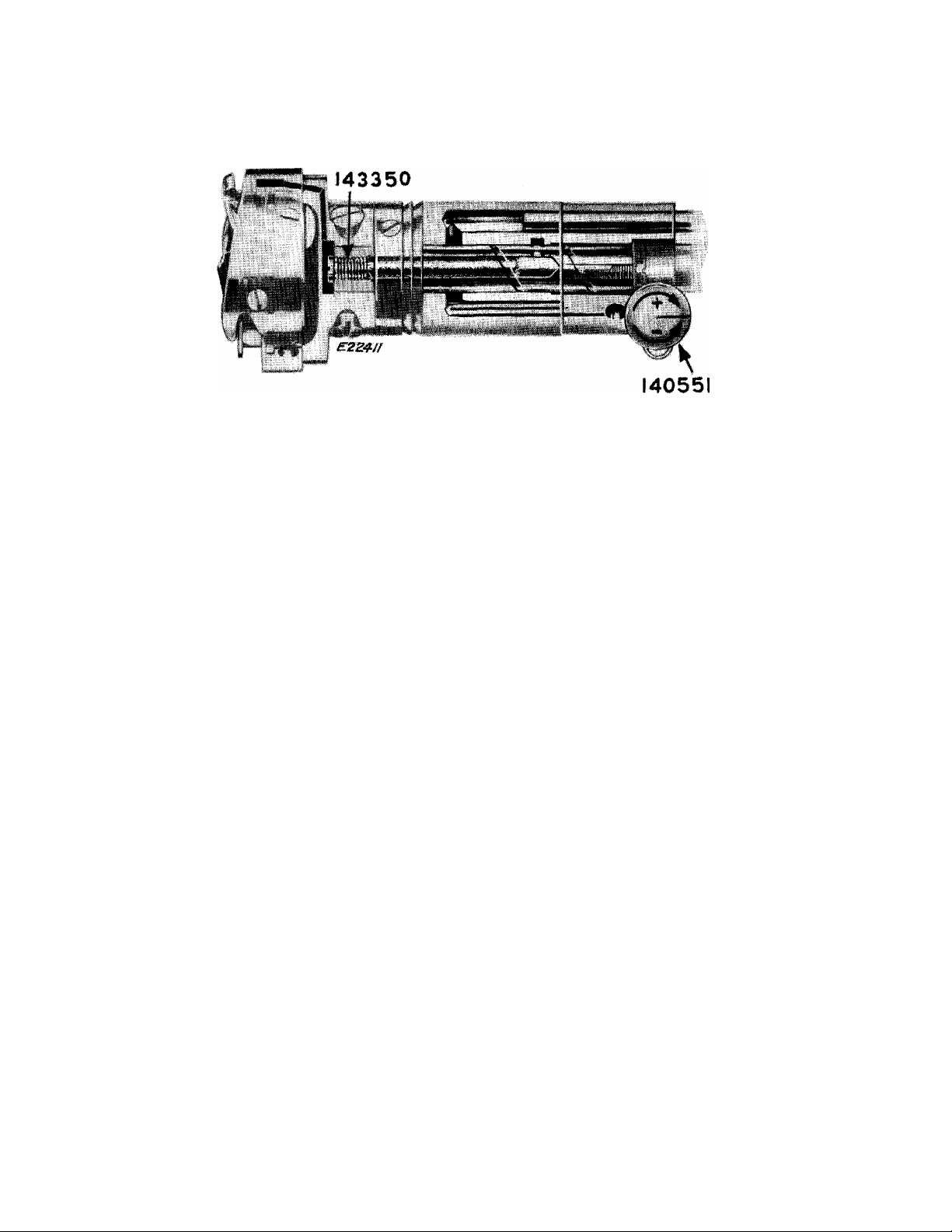

ADJUSTMENT OF ROTATING HOOK OIL FLOW REGULATOR

Fig. 7. Oil Flow Regulator in Hook Shaft Bushing

The sewing hook is automatically lubricated. The

flow of oil is controlled by Oil Flow Regulator 140551,

Fig. 7.

The Oil Flow Regulator 140551 is set at the factory

for automatic lubrication of the hook under overage

sewing conditions.

Turn Regulator Thumb Screw (see 140551, Fig. 7)

clockwise to increase the flow of oil to the hook as

indicated by the (-|-) sign under its arrow on the head

of the thumb screw.

HINTS FOR PERFECT OPERATION

If the sewing hook should become excessively warm,

it may be due to an insufficient supply of oil to the

hook (see instructions, above, for adjusting Oil Flow

Regulator).

Keep the oil level in the oil reservoir at the HIGH

mark.

Clean out any lint or other waste around the hook,

around the needle slot in the bobbin case holder

and between the feed rows on the under side of the

throat plate.

Clean out any lint or other foreign matter that may

have collected around oil return passages, particu

larly at oil return hole in rear arm shaft bushing.

Turn Regulator Thumb Screw counterclockwise to

decrease the flow, as indicated by the (~) sign under

its arrow on the head of the thumb screw.

To determine whether the oil is properly flowing

to the hook, withdraw the bed slide and hold a

piece of thin paper under the hook while the machine

runs for ten seconds. There should be a pattern of three

oil sprays on the paper; two light lines on the outside

and one heavier spray in the center. If there is no

trace of oil or an excessive amount of oil on paper,

adjust the Oil Flow Regulator, as instructed above, or

replace the oil filter 143350, Fig. 7, in the head of the

hook shaft, as instructed on page 28.

Always keep the bed slides closed when the ma

chine Is in operation.

Do not run the machine with the presser foot resting

on the feed without some fabric under the presser foot.

Do not run the machine when both bobbin case and

needle are threaded unless there is material under the

presser foot.

Do not try to aid the machine by pulling the fabric

lest you bend the needle. The machine feeds the work

without assistance.

When in operation, the top of the machine pulley

must always turn over toward the operator.

NEVER TOUCH THE STITCH REGULATOR PLUNGER

WHILE THE MACHINE IS RUNNING.

Page 8

NEEDLES

The size of the needle to be used should be deter

mined by the size of the thread which must pass

freely through the eye of the needle. Rough or uneven

thread, or thread which passes with difficulty through

the eye of the needle, will interfere with the successful

use of the machine. (See chart on page 4 to determine

Size as well as Class and Variety of needle required.)

A bent needle may cause the machine to skip

stitches, or it may make it difficult for the operator to

keep a perfectly even margin. In many cases, a run

off will take place.

A hook or burr on the needle point will result in o

finish that looks blurred and when short stitches are

used (20 to 22 per inch), some materials may be cut.

TO SET THE NEEDLE

Check needles often to make sure that defects are

not present.

Orders for needles must specify the Quantity re

quired, the Size number, also the Class and Variety

numbers, separated by an x.

The following is an example of an intelligible order;

"100 No. 16, 88 X 9 Needles."

The best stitching results will be obtained by using

needles sold by Singer Sewing Machine Company.

The above needles are regularly furnished with

nickel finish but are also available with chromium

finish if so ordered.

Turn the machine pulley over toward the operator

until the needle bar moves to its highest point.

After loosening needle set screw, insert needle UP

into needle bar AS FAR AS IT WILL GO, as instructed

in Fig, 8.

The single continuous groove of the needle MUST

face the left end of the machine, as shown in Fig. 8.

Securely tighten needle set screw.

NOTE: The needle is held in place, in Machines 251-2

and 251-3, by means of a needle clamp, instead of the

set screw in needle bar shown in Fig. 8.

MOVE TO

-^-HIGHEST '

POINT

loosen

SCREW

INSERT

NEEDLE UP

AS FAR AS

POSSIBLE

Fig. 8. Setting the Needle

(Mochine 251-1 )

Page 9

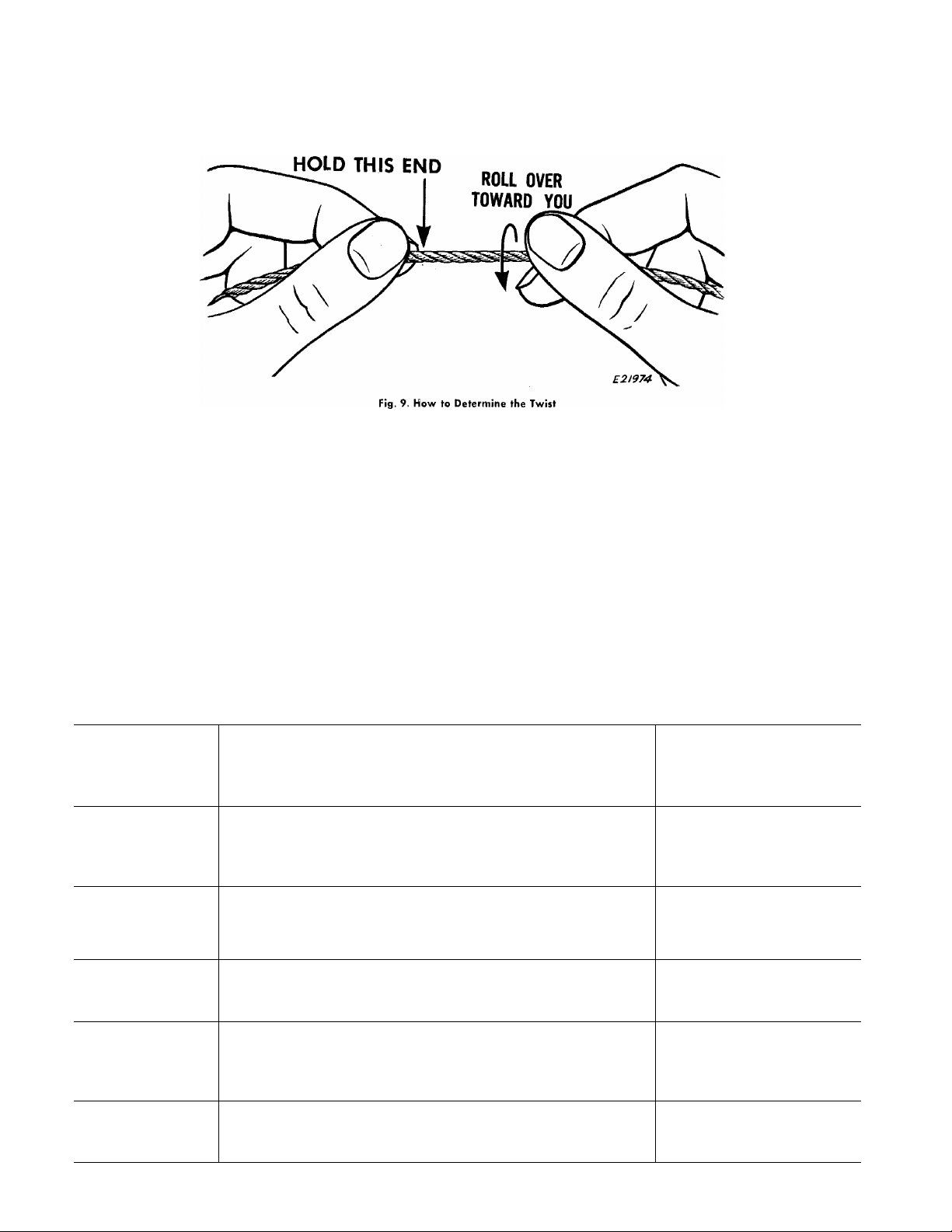

THREAD

On Machines of Class 251- use only left twist

thread in the needle. Either right or left twist thread

can be used in the bobbin.

To determine the thread twist, hold the thread as

shown in Fig. 9. Then roll the thread over toward you—

if the strands of the thread wind tighter, the thread

is left twist; if the strands unwind or separate, the

thread is right twist.

RELATIVE SIZES OF NEEDLES AND THREAD

The following sizes of needles and thread are recommended according to the class of work:

SIZES

OF

NEEDLES

8 to Shirtings, Sheetings, Calicoes, Muslins, Silks, Dress

14

16

and

17

Goods and all classes of general work with light

and medium weight fabrics.

All kinds of heavy Calicoes, light Woolen Goods,

heavy Silk, Seaming, Stitching, etc.

CLASSES OF WORK

SIZES OF

COTTON, LINEN

OR SILK

60 to 80 Cotton

A and B Silk

40 to 60 Cotton

C Silk

18 Tickings, Upholstery, Woolen Goods, Trousers, Boys' 30 to 40 Cotton

Clothing, Cloaks, etc.

19

and

20 60 to 80 Linen

21 to

24 40 to 60 Linen

Heavy Woolens, Tickings, Bags, Heavy Coats,

Trousers, Heavy Clothing generally.

Bags, Coarse Cloths and Heavy Goods.

D Silk

20 to 30 Cotton

E Silk

1 6 to 20 Cotton

Page 10

10

UPPER THREADING

Fig. 10. Upper Threading

First, turn the machine pulley over toward the oper

ator until needle is at Its highest point, then pass

the needle thread from the unwinder through the

Fig. 11. Threading the Needle

threading points in the order shown in Figs. 10 and 11.

Draw about two inches of thread through the eye

of the needle with which to start sewing.

Page 11

1. MOVE

TAKE-UP

TO HIGHEST

POINT

Fig. 12. Preparation

11

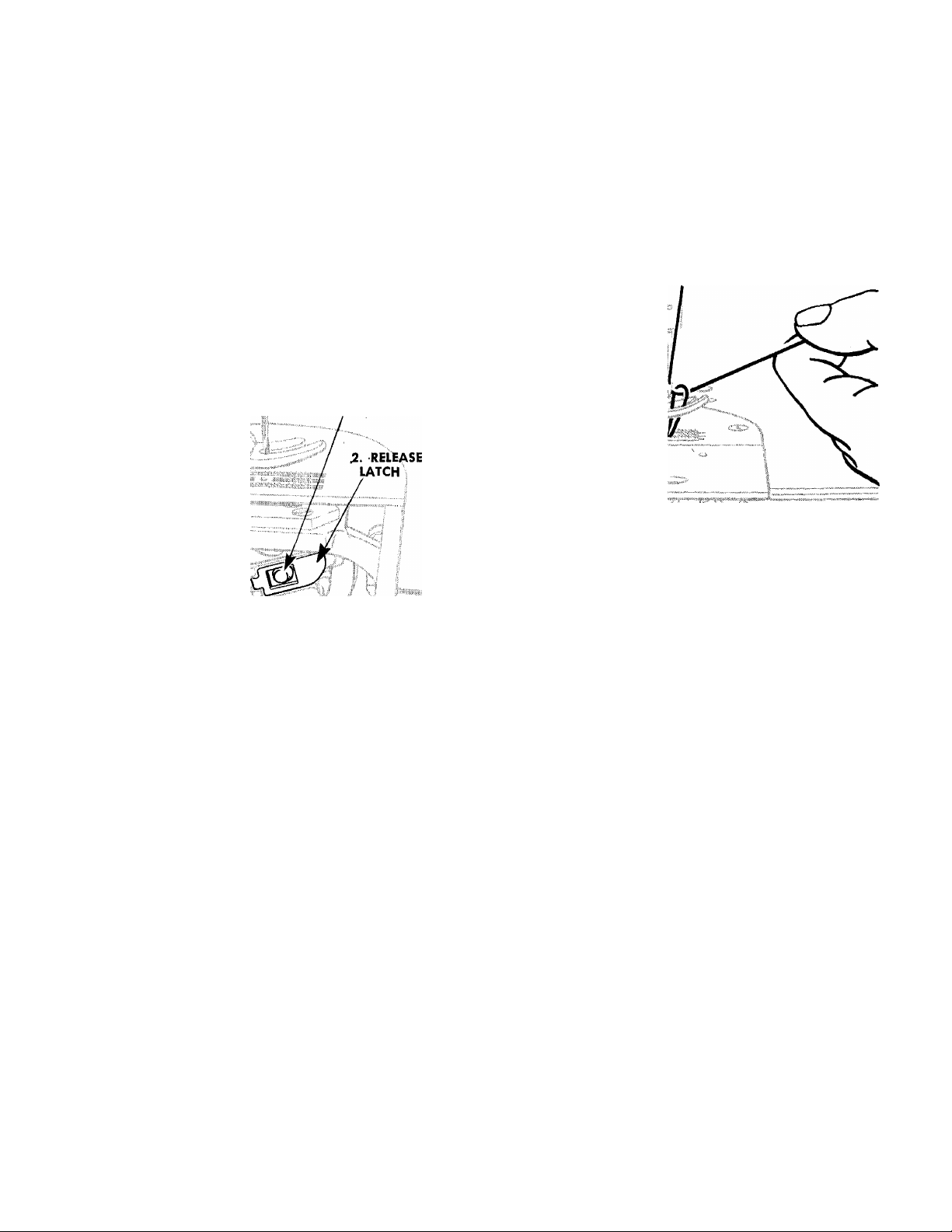

TO REMOVE THE BOBBIN

Turn machine pulley over toward operator,

until needle thread take-up lever is at highest

point, as shown in Fig. 12.

Reach beneath bed of machine with left

hand and remove bobbin, as instructed in

Figs. 13 and 14.

NOTE: While latch is kept open, bobbin will

be retained in bobbin case.

To remove bobbin from the bobbin case,

release latch and turn open end of bobbin case

downward. Bobbin will drop out, as shown

in Fig. 14.

2. OPEN

LATCH

3. HOLD LATCH

AND PULL CASE

FROM HOOK

Fig. 13. Removing Bobbin Case from Sevving Hook

4. RELEASE

LATCH \

5. BOBBIN 1

DROPS ▼

OUT

Fig. 14. Removing Bobbin

Page 12

12

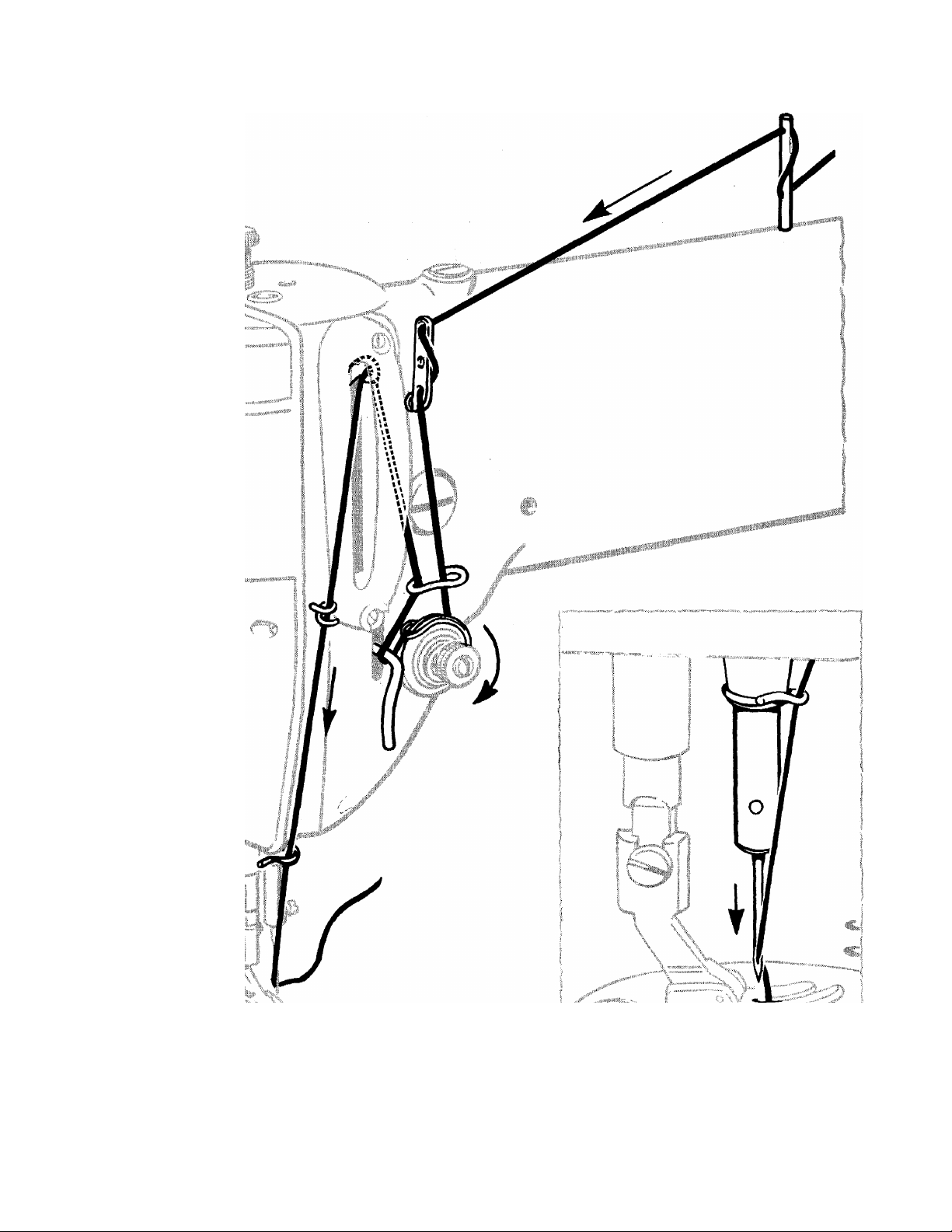

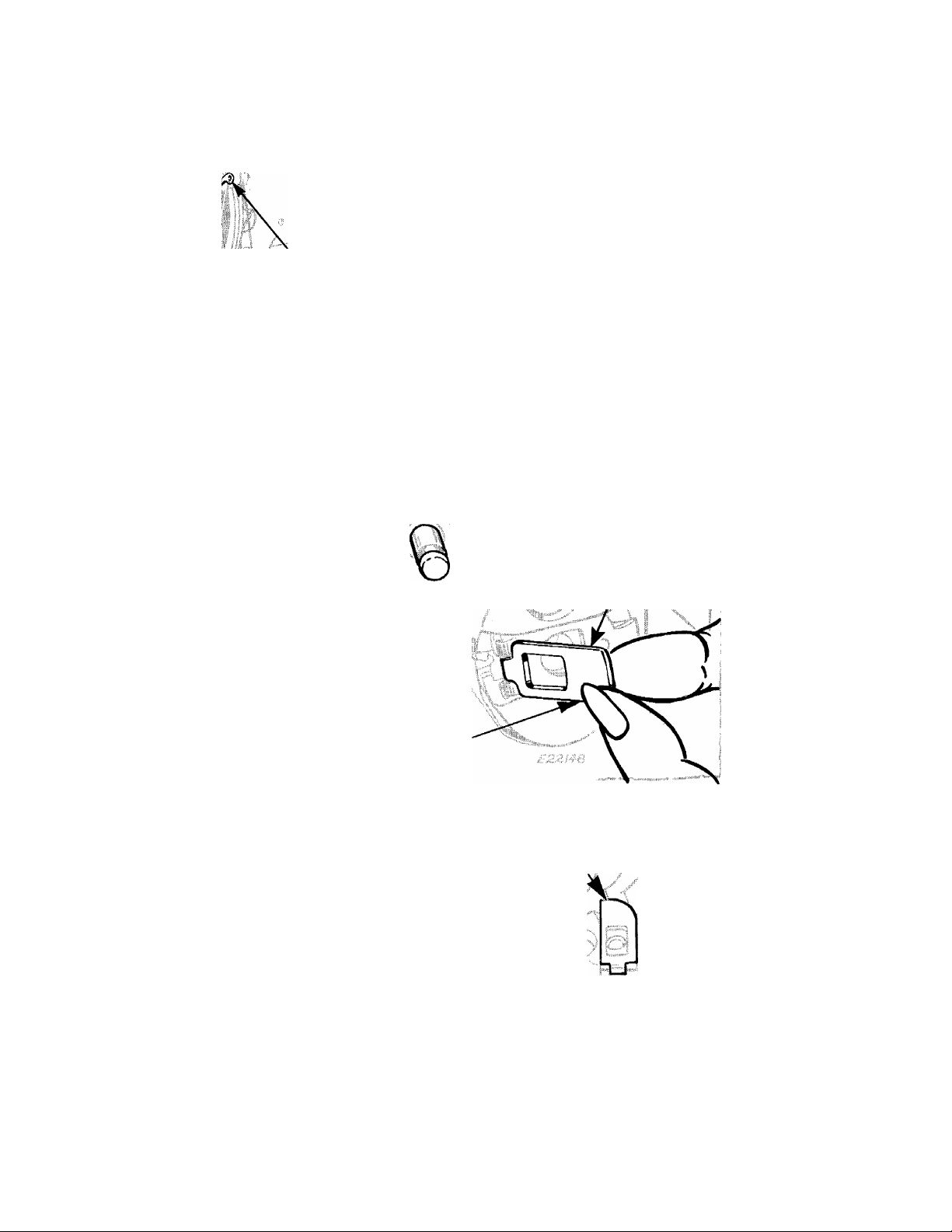

TO WIND THE BOBBIN

See Fig. 15

Fasten bobbin winder to table with its driving pulley

in front of the machine belt, as shown above, so that

bobbin winder driving pulley will make firm contact

with machine belt when thumb latch is pressed down

and pulley will be released from contact with belt

when sufficient thread has been wound upon the

bobbin.

Place bobbin on spindle, pushing it on as far as it

will go and pass thread through threading points, as

shown above.

Wind end of thread around the bobbin a few times.

Press down on thumb latch, pushing driving pulley

over against belt, as shown in Fig. 15. Start machine.

Bobbin winder will stop automatically, when the

amount of thread for which it is regulated is wound

upon the bobbin. For more thread on bobbin, turn

screw L inward; for less thread on bobbin, turn

screw L outward.

When winding a bobbin with fine thread, a light

tension should be used. Adjust the knurled nut

U, Fig. 15, to regulate the tension.

If thread winds unevenly on bobbin, loosen screw T

and move tension bracket Z to the left or right, as

required. Tighten screw T.

Bobbins can be wound while the machine is

stitching.

NOTE; Occasionally apply a few drops of oil to the

oil well, shown in Fig. 15, on top of the bobbin winder

frame.

Page 13

Hold the bobbin so that the thread will

unwind in the direction shown in Fig. 16.

13

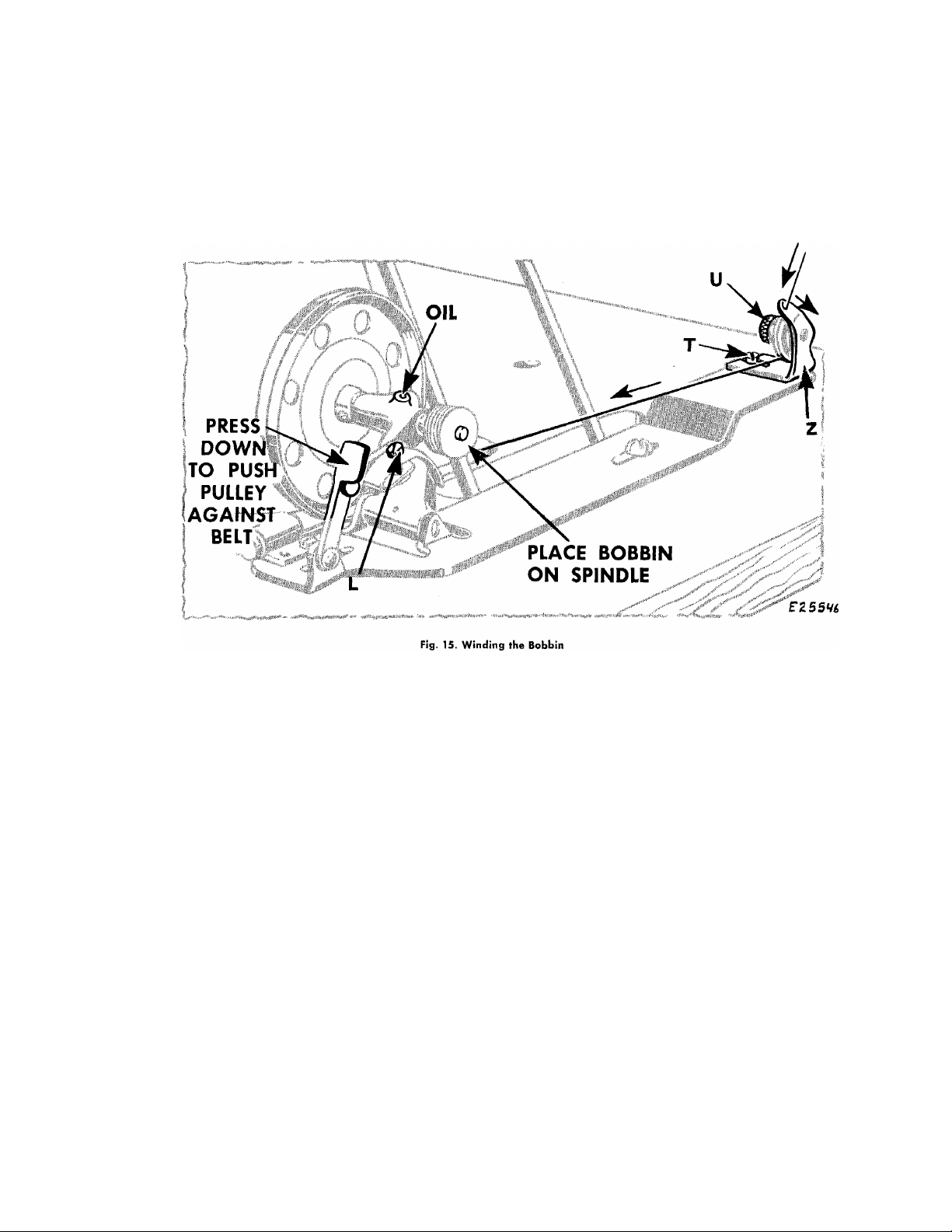

TO THREAD THE BOBBIN CASE

SLOT

NEAR

TOP

Hold the bobbin case as shown In Fig. 16

and place the bobbin into it.

/ \

I

Fig. 16. Placing Bobbin

in Bobbin Case

Pull the thread into the slot 1 and under

the tension spring 2, Fig. 17.

/

Draw the thread into the delivery eye at the

end of the tension spring, as shown in Fig. 18.

3. DRAW

THREAD

Fig. 18. Drawing the Thread

Under the Tension Spring

Page 14

14

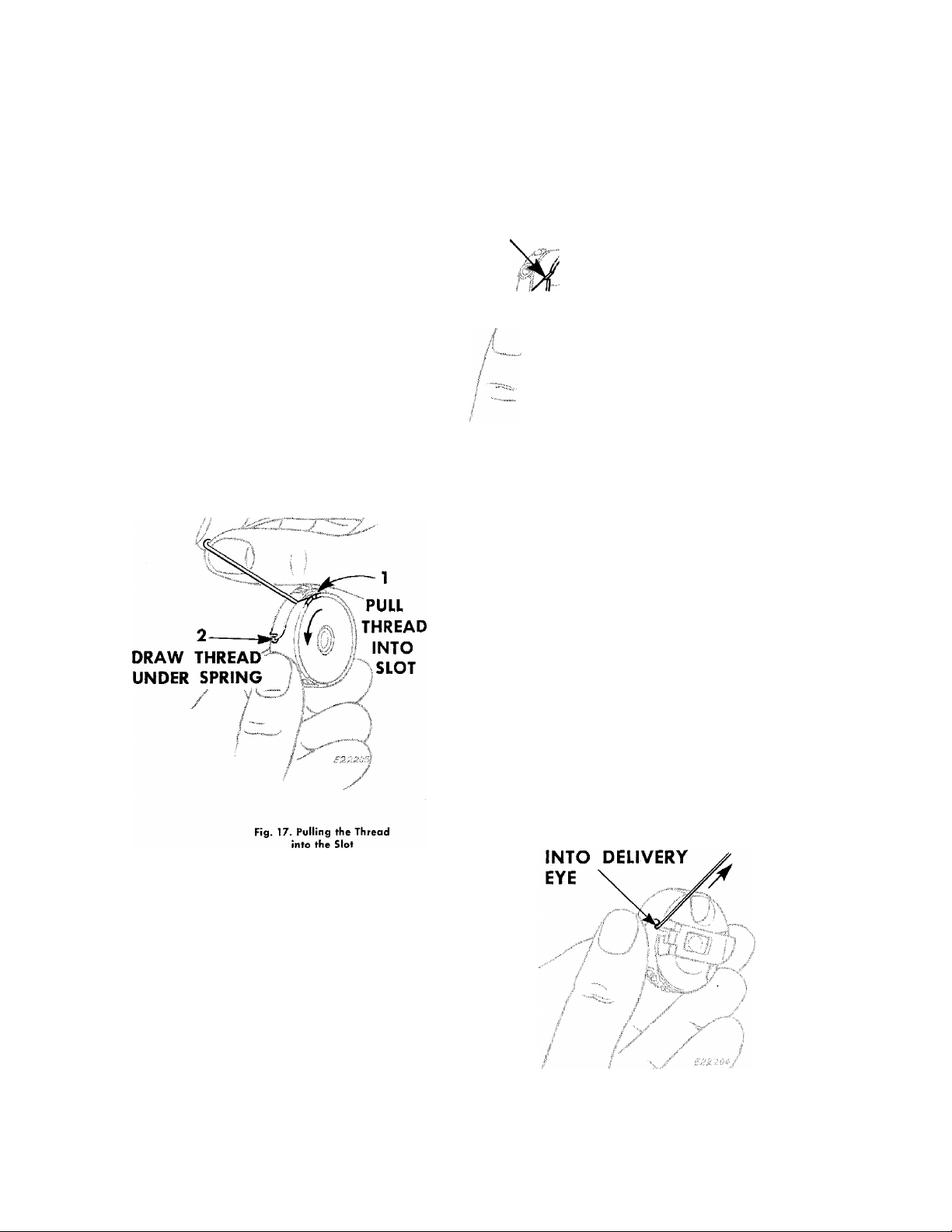

TO REPLACE THE BOBBIN CASE TO PREPARE FOR SEWING

1. REPLACE BOBBIN CASE

ON STUD

V

3. PRESS BACK

UNTIL LATCH CATCHES

GROOVE IN STUD

Fig. 19. Bobbin Case Threaded

and Replaced

After threading, take bobbin case by latch in the

left hand and place bobbin case on center stud of

bobbin case holder, as instructed in Fig. 19. Release

latch. Press bobbin case back until latch catches

groove near end of stud. Allow about two inches of

thread to hang free.

TO PREPARE FOR SEWING

Hold slack end of needle thread loosely and turn

machine pulley over toward you until needle moves

down and up again to its highest point, catching bob

bin thread. Draw up needle thread; bobbin thread

will come up with it through hole in throat plate, as

shown in Fig. 20. Lay both threads back under presser

foot.

Fig. 20. Drawing Up the Bobbin

Thread

TO START SEWING

Place material beneath the presser foot and start

to sew, turning the machine pulley over toward you.

TO REMOVE THE WORK

1. Let the thread take-up lever rest at its highest

point.

2. Raise the presser foot.

3. Draw the work toward the rear until it is clear

of the needle.

4. Cut the threads close to the goods.

Page 15

15

TENSIONS

EXPLANATION

For ordinary stitching, tension on needle and bobbin

threads should be balanced so that, if you cut straight

down through center of line of stitching and look at it

from the side, the line of stitching would appear with

needle and bobbin threads locked in center of thick

ness of material like this.

RIGHT

Fig. 21. Perfect Stitch

When there is too much tension on needle thread

or not enough on bobbin thread, needle thread can

not be pulled down into material, as required and

poor stitching results. The needle thread will lie on top

of material like this:

REGULATION

Needle Thread-

LESS

TENSION

Fig. 24. Regulating Needle

Thread Tension

First, regulate needle thread tension only when

presser foot is down.

Tension on needle thread should be ¡ust enough to

set stitch properly in material.

Having lowered presser foot, turn thumb nut at the

front of tension discs either over toward right or left,

as required. See instructions in Fig. 24.

Bobbin Thread—

WRONG

Fig. 22. Too Tight Needle Thread

Tension

When there is too much tension on bobbin thread

and not enough on needle thread, you get the reverse

of the condition shown in Fig. 22, above, but the

stitching is just as poor. The bobbin thread will lie on

bottom of material like this:

WRONG

Fig. 23. Too Loose Needle Thread

Tension

LESS

TENSION

Fig. 25. Regulating Bobbin

Thread Tension

When tension on bobbin thread has been properly

adjusted for ordinary stitching a correct stitch can

usually be obtained to suit the work in process by

varying tension on needle thread only.

For average sewing, tension on bobbin thread

should be very light.

To regulate tension on bobbin thread, remove the

bobbin case and turn screw in tension spring, as

instructed in Fig. 25.

Page 16

16

TO REGULATE THE LENGTH OF STITCH

CAUTION: DO NOT ATTEMPT TO CHANGE STITCH LENGTH WHILE MACHINE IS RUNNING.

2. TURN PULLEY

1 ;; ^ tP ;R, E S S

iPLUNGER

TOWARD YOU

SLOWLf

Fig. 26. Regulating Length of Stitch

To change the length of stitch, stop the machine-

then depress plunger, as instructed in Fig. 26, and turn

machine pulley slowly over toward you by hand until

plunger enters notch in eccentric (you will hear it click).

Then, still depressing plunger, turn machine pulley un

til number indicating the number of stitches per inch

you want is opposite mark on front of arm. Then

release plunger.

A setting of 17 stitches per inch is shown in Fig. 26

although you can set the machine to make as few as

5-1/2 stitches to the inch or as many as 30 (see chart

on page 4.)

Never depress the plunger while the machine is

running!

4. THEN fUiN

PULLEY TO DESIRED

STIfCM LiNGTM

TO PREVENT OPERATOR FROM

CHANGING STITCH LENGTH

The stitch regulator plunger (see 1 in Fig. 26) can

be removed to prevent an unauthorized person from

changing stitch length.

To remove the plunger, first remove the top cover.

Then remove the retaining ring near the tip of the

plunger, allowing the plunger to be withdrawn. The

hole in the top cover should then be filled by inserting

a plug screw 140607, which can be obtained at an

additional charge. Replace top cover.

Page 17

17

TO REGULATE THE PRESSURE ON THE MATERIAL

MORE

PRESSURE

L

------

J

LESS

PRESSURE

Fig. 27. Regulating the Pressure on the Material

The correct presser foot pressure helps feed the work

properly. You can regulate the amount of pressure by

means of the thumb screw, as shown in

The pressure on the material should be as light as

possible, while still sufficient to insure proper feeding.

NOTE:~The instructions on the following pages are for Service Representatives only.

Fig. 27.

To increase the pressure turn the thumb screw down

ward (clockwise). To reduce the pressure turn this

screw upward (counterclockwise). The pressure is

correct when the work moves steadily and smoothly

without stalling.

To insure proper timing and avoid unnecessary repetition these instructions should be followed in the order given.

Page 18

18

ТО SET THE NEEDLE BAR AT THE CORRECT HEIGHT

UPPER

TIMING

LOWEST POINT

в

NEEDLE BAR

AT

нк)!

I

м/с 25I-I

.484 inch

M/C25I-2

and 25I-3

.195 inch

UPPER

TIMING

MARK

NEEDLE BAR

vAT LOWEST

POINT

Fig. 28. Setting Needle Bar Height on Machines with Timing

Marks Aligned with UPPER Needle Bar Bushing

PREPARATION;

Remove face plate, slide plate and throat plate. See

that needle is correctly set in needle bar, as instructed

on page 8.

NOTE:

FOR MACHINES ON WHICH TIMING MARKS SHOULD

ALIGN WITH UPPER NEEDLE BAR BUSHING-

Top of bushing A, Fig. 28 must be flush with top of

casting, as shown in Fig. 28. To reset bushing, loosen

screw В and raise or lower bushing, as required.

FOR MACHINES ON WHICH TIMING MARKS SHOULD

ALIGN WITH LOWER NEEDLE BAR BUSHING-

Lower end of bushing K, Fig. 29 must be set as

shown in Fig. 29. To reset bushing, loosen screw L.

mmms

Fig. 29. Setting Needle Bar Height on Machines with Timing

Marks Aligned with LOWER Needle Bar Bushing

CHECK;

When needle bar is at its lowest point (during rota

tion of machine pulley), UPPER TIMING MARK on

needle bar should be level with lower end of bushing.

Check timing of hook as instructed on page 21.

SETTING:

Loosen clamping screw C, Figs. 28 and 29. Raise or

lower needle bar so that UPPER TIMING MARK is level

with lower end of bushing. Then securely tighten

screw C.

Replace throat plate and slide plate.

When replacing the face plate, make certain that

the screw holes in the face plate gasket are aligned

with the respective screw holes in the face plate;

avoiding injury to the gasket and consequent oil

leakage.

Page 19

19

TO SET CHECK SPRING

HEIGHT

PREPARATION:

Thread the machine.

CHECK:

HrOHER

Fig. 30. Setting Height of

Check Spring

TENSION

LOOSEN

\ /

H

/£;

Fig. 31. Adjusting Tension on

Check Spring

PREPARATION:

Thread the machine. Securely tighten set screw H,

Fig. 31. Make certain thumb nut is on stud J, Fig. 31.

Turn machine pulley over toward operator slowly.

When take-up lever begins to rise, check spring G,

Fig. 30 m akes a slight dip and a return to its higher

position. Later, as take-up lever approaches top of

stroke, check spring G should be drawn all the way

down; setting the stitch. As lever descends, check

spring G returns to rest.

SETTING;

Loosen screw H, Fig. 30. Turn stud J, Fig. 30 (at the

same time turning entire tension assembly) either over

toward left to lower check spring and decrease its

movement, or over toward right to raise check spring

and increase its movement. Securely tighten set screw

H.

NOTE:

Under certain conditions of tacking, it may be

necessary to set the check spring higher than it is

otherwise normally set.

CAUTION;

Check spring height setting must be checked each

time a different foot is applied to machine.

CHECK;

Tension on check spring G, Fig. 31, should be suffi

cient to ensure action at top speed; but still light

enough to permit itself to be drawn all the way down

(as take-up lever approaches height of stroke) before

any thread is drawn through the tension discs.

SETTING;

Using a large screwdriver in slot of stud J, turn

stud either over toward left to decrease tension or

over to right to increase it, as shown.

NOTE;

The tension on the check spring may require

different settings depending upon the size of thread

used. Heavier thread requires more tension to ensure

correct thread control.

Page 20

20

TO SET THE PRESSER BAR AT THE CORRECT HEIGHT

Fig. 32A. Required Clearance on Machines

with Latest Type Lifting Bracket

RESTING

FIRMLY

UPON

THROAT

PLATE

E27555

Fig. 32. Checking Height of

Presser Bar

PREPARATION:

Remove face plate and slide plate.

CHECK:

1. When presser foot rests firmly upon throat plate

(with feed dog below throat plate) there should

still be some clearance between guide bracket

D, Figs. 32 and 32A and lifting bracket E, as shown

in Figs 32 and 32A.

. AT

AT A

HIGHEST

POINT Î

LOWEST

PbiNT

JUST

CLEAR

E27SSÔ

Fig. 33. Setting Presser Bar

at Correct Height

SETTING:

Loosen clamping screw F, Figs. 32 and 32A. Raise

or lower guide bracket D, as required. Securely tighten

screw F.

CAUTION:

2. When presser foot is at its highest point and needle

bar is at its lowest, top of presser foot should

clear lower end of needle bar, as shown in Fig. 33.

Whenever guide bracket has been moved on presser

bar, inspect the check spring for correct setting, as

instructed on

page 19.

Page 21

21

TO TIME THE SEWING HOOK

LOWER

TIMING

MARK

LOWER

TIMING

MARK

ON

UPWARD

STROKE

Fig. 34A. Checking the Tinning of the Hook

on Machines with Tinning Marks at

Lower End of Needle Bar

I ON

UPWARD

STROKE

H

'IL

E27559

Fig. 34. Checking the Timing

of the Hook

(Viewed fronn Front)

PREPARATION:

Remove presser foot, slide plate, throat plate and

feed dog.

Remove face plate on machines on which timing

marks are on upper half of needle bar.

CHECK:

ON MACHINES ON WHICH TIMING MARKS ARE

ON UPPER HALF OF NEEDLE BAR-

When lower timing mark on needle bar is level with

lower end of upper needle bar bushing A as shown

in Fig. 34, the point of the sewing hook should be at

the center of the needle, as shown in enlarged view

in Fig. 35.

HOOK POINT

AT CENTER

OF NEEDLE

Fig. 35. Timing the Hook

(Viewed from Rear)

ON MACHINES ON WHICH TIMING MARKS ARE

ON LOWER HALF OF NEEDLE BAR-

When lower timing mark on needle bar is level

with lower end of lower needle bar bushing K as

shown in Fig. 34A, the point of the sewing hook

should be at the center of the needle, as shown in

Fig. 35.

TIMING:

Loosen two set screws L, Fig. 35 in hub of hook.

Turn hook on its shaft, as required to bring point of

hook to center of needle, as shown above.

Make certain that hub of hook is against oil-re

taining collar; then securely tighten screws L.

Page 22

...cl

'"-/ ^ " •■ .■ •

É

f®

22

TO SET THE SEWING HOOK SIDEWISE

IN RELATION TO THE NEEDLE

m:

POINT

|S3Sff

FLAT OF ,/

HOOK POINT

I'WKlEP GEARS

IN ME!

Fig. 36. Hook Point

Passing thè Needle

Fig. 37. Flat of Hook

Point Clearing the

Needle Scarf

PREPARATION;

Remove slide plate, throat plate and bobbin còse.

Seat needle correctly in needle bar, as instructed on

page 8. Time the sewing hook as instructed on page 21.

CHECK;

When point of sewing hook passes needle, clearance

between hook point M, Fig. 36 and needle should be

approximately equal to thickness of a piece of ordinary

notepaper (about .005 inch), as shown in Fig. 37.

NOTE;

Not only point of sewing hook but entire ''FLAT" of

hook point should clear scarf on needle blade.

SETTING:

Loosen screws #1 and #2 in hub of hook shaft

bevel gear P, Fig. 38.

Fig. 38. Preparation

for Setting:

Loosening Bevel Gear

CAUTION:

MAKE CERTAIN THAT THE TWO BEVEL GEARS ARE

KEPT IN MESH UNTIL SET SCREWS #1 AND #2 ARE

SECURELY RETIGHTENED.

Using a light mallet and a 1/4 inch brass drift pin,

as shown in Figs. 39 an d 40, move hook assembly

either toward or away from needle, as required.

TAP VERY LIGHTLY on drift pin to avoid injury to

hook assembly.

Securely tighten screw N, Fig. 40.

Remove all end shake from hook shaft by pushing

the hook assembly firmly against front hook shaft

bushing and, at the same time, pushing hook shaft

bevel gear P, Fig. 38 toward the hook on the shaft.

Then securely tighten screw #1, Fig. 38; then screw #2.

Loosen hook shaft bushing set screw N, Fig. 40,

page 23.

Replace bobbin case, throat plate and slide plate.

Page 23

23

m

I

loosen r DAMAGE

SET SCREW ^

III

ri-

DO NOT

HIT BRIDGE

BRASS DRIFT PIN

F'g. 39. Moving Sewing Hook Assembly

TAP

lightly

Toward the Needle

loosen

SET SCREW

N

.. ,1 M

V

f

TAP

lightly

?

/

'/4" BRASS DRIFT PIN

1

K0. IO. Mov,„3 sowing Hook Assembly A»„y

■

from the Needle

Page 24

24

TO TIME THE FEED

Before the machine leaves the factory, the feed

lifting eccentric-and-bevel-gear and the feed eccentric

are both set for average sewing conditions; having the

timing screw in each eccentric enter groove provided

for it in the arm shaft.

As the grooves in the arm shaft are not visible to

the adjuster, the machine pulley should be turned over

toward operator until feed lifting eccentric connecting

rod A2, Fig. 41 is at its lowest position. Timing screw Y,

Fig. 41 will then be on top of feed lifting eccentric-and-

bevel-gear. Loosen timing screw Y and set screw O

and, while maintaining this position of the gear, turn

arm shaft until timing screw, as it is slowly tightened,

can be felt to drop into its groove in arm shaft. Se

curely tighten timing screw Y and set screw O.

Feed eccentric timing screw Z, Fig. 41 appears im

mediately after large stop screw W, Fig. 41, when

feed eccentric is rotated over toward operator.

Feed eccentric should be set for average sewing

conditions, by having this timing screw Z exactly in

line with timing screw Y, as shown in Fig. 41. Thus,

as timing screw Z is tightened it will drop into its

groove in arm shaft which is in line with groove pro

vided for feed lifting eccentric-and-bevel-gear timing

screw Y. Securely tighten timing screw Z and the two

set screws in feed eccentric.

If for any reason, it is necessary to alter the timing

of either eccentric, timing screw should be removed

and eccentric locked in desired setting by means of

set screws only.

NOTE: Whenever the timing of the feed is changed,

sewing hook should be checked for necessary adjust

ment also, as instructed on page 21.

Page 25

TO SET THE FEED DOG AT THE CORRECT HEIGHT

FULL DEPTH REAR TEETH

nnnn

25

T

Fig. 42. Showing Feed Dog at Correct Height

When the feed dog is at Its highest position^ ap

proximately the full depth of the rear teeth of the feed

dog should project above the top surface of the

throat plate, as shoyvn in Fig. 42.

Before checking the height of the feed dog, set the

machine for the longest stitch, as instructed on page 16.

To adjust, loosen the clamping screw B2, Fig. 43

and raise or lower the feed dog (which is fastened

to the feed bar C2, Fig. 43) as required. Then securely

tighten screw B2.

THROAT PLATE

B2

THE FEED DOG ECCENTRIC STOP SCREW

The machine is prevented from making longer

stitches than a predetermined maximum by the Stop

Screw W, Fig. 44 in the feed eccentric.

Feed eccentric stop screw 140256, furnished with

Machine 251-1, permits a maximum length of seven

stitches per inch.

Stop screw 140258, for 14 stitches per inch or

shorter, can also be used.

Machines 251-2 and 251-3 are regularly fitted with

stop screw 140257 permitting a maximum length of

5-1/2 stitches per inch, but either 140256 (7 stitches

per inch) or 140258 (14 stitches per inch) can be used.

Fig. 43. Adjusting

Height of Feed Dog

Page 26

Page 27

27

INSTRUCTIONS

FOR

REMOVAL AND REPLACEMENT

OF

PRINCIPAL ASSEMBLIES

CAUTION TO MECHANICS

Machines of Class 251- are made with extreme precision in machining and

assembly, and the "Superfinish" process provides microscopically smooth bearing

surfaces. Therefore, special care should be taken not to permit any misalignment

of parts or to cause any scratches or nicks on the bearing surfaces by careless

assembly or handling of parts. Any such damage might render the machine

incapable of the long, trouble-free service for which it is designed.

Page 28

28

TO REMOVE THE SEWING HOOK

143350

Fig. 45. Removing Sewing Hook

Remove the needle, slide plate, throat plate and

bobbin case. Remove the screw D2, Fig. 45 and the

bobbin case holder position bracket E2, Fig. 45. Loosen

the two set screws X, Fig. 45 in the hub of the hook

and turn the machine pulley over toward the oper

ator until the feed bar C2 is raised to its highest point.

Turn the sewing hook until the thread guard F2, is

at the bottom, as shown in Fig. 46. Turn the bobbin

case holder G2, Fig. 46 until the notch J2 is also near

S2ZH2

F2

Fig. 46. Replacing Oil Filter

the bottom, as shown in Figs. 46 and 47. The sewing

hook can then be removed from the hook shaft.

TO REPLACE OIL FILTER 143350

While the sewing hook is off the shaft, it is advis

able to replace the oil filter 143350, Fig. 46, in the

end of the hook shaft. Unscrew the filter from the

center of the shaft at H2, Fig. 46 and replace with cl

complete new filter 143350.

Page 29

29

TO REPLACE THE SEWING HOOK

J2

E2

Fig. 47. Replacing Sewing Hook (Correct Position of Thread Guard

and Bobbin Case Holder)

When placing a new sewing hook on the shaft,

have the sewing hook thread guard F2 at the bottom

and the bobbin case holder G2 turned to the position

shown in Fig. 47, so that the hook will clear the feed

bar C2.

Place the hook in position on the shaft and turn the

bobbin case holder G2 until the notch J2 is at the top,

as shown in circular inset above. Replace the bobbin

case holder position bracket E2, making certain that

the finger K2 (see inset) enters the notch J2 at the top

of the bobbin case holder. Then securely fasten the

position finger by means of the screw D2.

Replace the needle. Time the sewing hook, as in

structed on page 21. Replace the bobbin case, throat

plate and slide plate.

Page 30

30

TO REMOVE AND REPLACE THE HOOK SHAFT

HOLD GEARS IN MESH

Fig. 48. Removing and Replacing Hook Shaft

Remove and replace the hook shaft in the follow

ing manner:—

1. Remove the sewing hook, as instructed on

page 28.

2. Mark the two lower bevel gears L2 and S4,

Fig. 48, with chalk or crayon, on one tooth of one

gear and the corresponding space for that tooth

in the other gear. This is important, as these gears

may become separated during removal of shaft.

These marks will then make it possible to obtain

the original mating position of the gears.

3. Loosen the two set screws #1 and #2 in hook

shaft bevel gear. While holding the two gears

L2 and S4 in mesh, as instructed in Fig. 48, with,

draw the old hook shaft and INSERT THE NEW

SHAFT.

NOTE: Set screw #1 is the first of the two set screws

to appear on the hub of the bevel gear S4 as the

machine pulley is turned over toward operator.

4. Replace the sewing hook, as instructed on

page 29.

Make certain that set screw #T seats over flat

on the hook shaft. Remove all end shake from

hook shaft, by pushing hook firmly against front

hook shaft bushing and, at the same time, push

ing gear S4, Fig. 48 toward the hook on the

shaft. Securely tighten first set screw #1, then

securely tighten the second screw #2.

6. Time the sewing hook as instructed on page 21.

Page 31

31

THE OIL PUMP

TO REMOVE

1. Loosen the two oil pipe clamping sleeve nuts 52,

Fig. 49.

2. Remove the four screws N2, Fig. 48.

3. Remove the screen frame, screen and oil pump

cover 02, Fig. 48.

4. Remove the locking screw 02, Fig. 49.

5. Remove the impeller P2, by turning it over toward

the RIGHT (clockwise) to loosen it, as instructed

in Fig. 49.

CAUTION:—The impeller P2 is designed to be screwed

to the shaft by means of a LEFT-HAND THREAD and

must be turned over toward the right to be loosened.

Avoid damage to this impeller, as the efficient auto

matic lubrication of the machine is dependent upon it.

6. Remove the three screws T2.

TO REPLACE

1. Place oil pump body on underside of ma

chine bed, so that position pins V2, slip into

proper holes in machine casting, as shown above.

2. Replace and securely tighten the three screws T2.

Make certain that machine turns freely as screws

are tightened.

3. Carefully replace impeller P2, turning it over

toward the LEFT to screw it on arm shaft (see

CAUTION at left).

4. Make certain that impeller P2 is not so tight that

it will bind arm shaft. Make certain also that im

peller clears both top and bottom of interior of

oil pump body, then lock it in position by means

of locking screw Q2.

5. Replace pump cover, screen and frame 02 and

four screws N2, Fig. 48. Securely tighten

screws N2.

7. Carefully pull the oil pump body off the lower

end of the upright arm shaft.

6. Replace two oil pipes in oil pump body, as shown

above, and securely tighten sleeve nuts 52.

Page 32

TO REMOVE AND REPLACE THE UPRIGHT ARM SHAFT

(See Fig. 50)

REMOVAL;

If it is found necessary to remove the upright arm

shaft K3, it should be removed in the following

manner;—

1. Remove oil pump, as instructed on page 31.

2. Follow the instructions in Steps 2 and 3 for re

moval of hook shaft on page 30 except that. In

stead of removing hook shaft, merely remove

hook shaft bevel gear S4, Fig. 48.

3. Remove arm top cover.

32

4. Remove screw L3 and oil lead M3.

5. Remove four cap screws N3.

6. Remove oil flow window cap 03, window P3,

oil flow body R3 with two gaskets Q3.

7. Mark the two bevel gears S3, with chalk or cray

on, on one tooth of one gear and the correspond

ing space between the teeth of the other gear so

that these gears may be re-assembled in their

original relative positions without difficulty, if

necessary.

8. Loosen set screws T3 in bevel gear at upper end

of upright arm shaft.

9. Make certain bevel gear at lower end of upright

arm shaft is fastened securely. Then while hold

ing upper bevel gears S3 in mesh, draw upright

arm shaft down and out of machine.

03 R3 03 P3

Fig. 50, Removing Upright Arm Shaft

2. Insert upright arm shaft up through upper bevel

gear, as shown in Fig. 50.

3. Turn shaft so that one of the two set screws T3

will bear upon the upper gear flat on the shaft

and tighten the set screws T3.

4. Replace and set hook shaft bevel gear as in

structed in Step 5 on page 30.

REPLACEMENT;

1. Before installing upright arm shaft, make certain

it has the bevel gear L2, Fig. 48 correctly fastened

at the lower end of shaft.

5. Replace oil pump, as instructed on page 31.

6. Replace oil flow window assembly, in the order

shown in Fig. 50.

7. Replace oil lead M3 and arm top cover.

Page 33

33

TO REMOVE AND REPLACE THE NEEDLE BAR

(See Fig. 51)

Remove the needle bar in the following manner:—

1. Remove needle and needle set screw (or needle

clamp).

2. Remove face plate.

3. Loosen clamping screw M.

4. Loosen screw R2 sufficiently to allow needle bar

to pass, then slip needle bar up through both

needle bar bushings and out of machine.

NOTE: If it becomes necessary to remove upper needle

bar bushing N, first remove screw R2 and take-up lever

oil guard W2. Then loosen set screw P and drive

bushing N down and out of head of machine. Use a

13/32 Inch driving pin.

Fig. 51. Removing and Replacing

Needle Bar and Presser Bar

TO REMOVE AND REPLACE THE PRESSER BAR

To remove the presser bar:-

Remove presser foot and face plate.

1.

Remove presser bar pressure regulating thumb

2.

screw, X2, w ith pressure bar guide from head

of the machine.

3. Loosen clamping screw V about one turn (just

enough to make it loose). Loosen screw A5 and

slip guide bracket T up off presser bar and out

of machine.

4. Slide presser bar up through lifting bracket U,

Fig. 51 and bushing and out of machine.

Before replacing needle bar, replace upper needle

bar bushing N, by driving it down into hole provided

for it in head of the machine. Make certain top of

bushing N is level with top of arm. Tighten set screw P.

Replace needle bar in the following manner*.—

1. Slip needle bar down through both bushings in

head of the machine. Tighten screw M.

2. Replace needle clamp and needle. See page 8.

3. Set needle bar at correct height and replace face

plate, as instructed in last paragraph on page 18.

4. Replace oil guard W2 and fasten it securely to

bushing with set screw R2.

To replace the presser bar:—

1. Slip presser bar down through lifting bracket U,

Fig. 51 and lower presser bar bushing.

2. Replace guide bracket T as shown in Fig. 51.

3. Replace presser foot.

4. Replace presser bar pressure regulating thumb

screw X2 with presser bar guide.

5. Set the presser bar at the correct height, as in

structed on page 20.

6. Tighten screw V.

7. Tighten screw A5; making sure that slack thread

regulator B5 just clears the casting. Replace face

plate, as instructed on page 18.

Page 34

34

TO REMOVE THE NEEDLE THREAD TAKE-UP

H3

DO NOT

DISTURB

DO NOT

DISTURB U2

Fig. 52. Removing Needle Thread Take-up Fig. 53. Needle Bar Crank

Remove needle thread take-up in the following man

ner:—

1. Remove face plate and arm hole plug A3, Fig. 53

from machine.

2. Remove needle bar, upper needle bar bushing,

presser bar pressure regulating thumb screw X2,

Fig. 51, page 33, and guide bracket T, Fig. 52 as

instructed on page 35.

3. Turn machine pulley as required to reach screw

Y2, Fig. 53, in needle bar crank through hole left

by removal of plug A3. Loosen set screw Y2.

4. Using wrench 146057 (through same hole) and

turning machine pulley as required, loosen the

large hexagon head clamping screw Z2, Fig. 53,

on needle bar crank.

CAUTION: DO NOT DISTURB the smaller hexagon head

position screw U2, Fig. 53, which holds the needle bar

crank at its correct position on the horizontal arm shaft.

5. Loosen small set screw B3, Fig. 52 in the rear of

the arm of the machine.

6. Insert a face plate screw E3, Fig. 52.in the tapped

hole in center of stud C3, Fig. 52 and, while hold

ing back the needle thread take-up link inside

the head at G3, Fig. 52, pull upon the screw E3

until the stud C3 is removed. Remove face plate

screw from stud.

NOTE: Extractor Tool Serial 222226 may be used in

stead of face plate screw at E3, Fig. 52, to pull hinge

stud C3.

7. Back the end of the take-up H3, Fig. 52 toward

the inside of the machine, turning the machine

pulley as required until the take-up is free of the

slot provided for it.

8. The needle thread take-up link assembly (includ

ing parts F3, G3, H3, J3, Z3 and W4) can now be

pulled free of the needle bar crank WITHOUT

DISTURBING THE NEEDLE BEARINGS WITHIN THE

THREAD TAKE-UP CRANK AT F3, Fig. 53.

NOTE: If the needle bearings at F3, Fig, 53, are acci

dentally disturbed, they must be reassembled so that

there are exactly 18 bearings in each of the two as

semblies.

Page 35

TO REPLACE THE NEEDLE THREAD TAKE-UP

Replace the needle thread take-up in the following manner:

35

1. Make sure that the wearing plate J3 is in place

and undamaged on the face of the needle bar

crank, as shown in Fig. 52.

2. Place the needle thread take-up link G3 and takeup H3 in the head of the machine so that the stud

W4, Fig. 52 in the center of the linkage slips into

the hole provided for it in the needle bar crank,

as shown in Fig. 52.

3. Slip the upper end of the take-up H3 through the

slot provided for it in the head of the machine.

4. Insert stud C3 through needle thread take-up

lever link G3 and into its hole into the machine

casting so that the flat on the stud faces the rear

of the machine. The mark D3 on the stud indicates

the position of this fiat. Fig. 52 shows the stud

with the mark D3 in the correct position. DO NOT

INSERT THE STUD TO ITS FULL DEPTH AT THIS

TIME. There should be about .010 inch to .015

inch side play of the take-up lever link G3 on the

stud, until final adjustment is made in Step 15.

5. Turn the set screw B3 inward lightly against the

flat on the stud C3. DO NOT TIGHTEN screw БЗ

until final adjustment is made in Step 15.

6. Turn machine pulley as required to make set

screw Y2 in needle bar crank accessible through

hole at A3, Fig. 53 in front of machine head.

7. Insert a screwdriver through this hole and, while

turning stud W4 by hand to find its flat, turn set

screw Y2 until it bears tightly upon the flat.

8. Turn screw Y2 back, just enough to "break It

loose."

play by pushing take-up lever H3 gently right

and left; there should be .001 to .002 inch side

shake between lever and wearing plate.

10. Move thread take-up crank inward or outward

in needle bar crank, as required, to obtain clear

ance.

11. Using wrench 146057, through same hole and

turning machine pulley as required, tighten hexa

gon head screw Z2 lightly.

12. Loosen set screw Y2.

13. Securely tighten clamping screw Z2.

14. Securely tighten set screw Y2.

15. Push hinge stud C3 fully into machine casting and

securely tighten set screw B3.

16. Turn machine pulley slowly, by hand, at least

one complete revolution; testing take-up for bind

ing, end shake and noise. If binding occurs, re

check clearance between take-up and wearing

plate J3 and between hinge stud C3 and machine,

casting.

17. Replace guide bracket T in head of machine, as

shown in Fig. 52.

18. Replace presser bar pressure regulating thumb

screw X2, Fig. 51, page 33.

19. Replace and adjust upper needle bar bushing and

needle bar with their accessories, as instructed on

pages 18 and 33.

20. Replace and securely tighten arm hole plug A3.

9. Make certain that assembly F3 is firmly against,

but does not bind, wearing plate J3. Test for side

21. Replace the face plate (see instructions at bottom

of page 18).

Page 36

TO REMOVE AND REPLACE ARM SIDE SHIELD WICK, NEEDLE BAR WICK

AND NEEDLE BAR CONNECTING STUD WICK

(See Fig. 54)

Arm side shield wick may be remdved, after re

moving face plate and two screws U3. Lift arm side

shield V3 up and out of machine.

When replacing arm side shield wick, make sure

that lower end of wick drops into oil pool beneath

needle bar crank and that the two upper wick loops

are located as close as possible to the needle bearings

at F3, Fig. 55 without touching them. Then replace and

securely tighten screws U3.

To remove needle bar wick and connecting stud

wick, move take-up lever H3, so that it does not inter

fere with removal of oil guard W2. Then remove face

plate and screw R2; lift take-up oil guard W2, with

the two wicks, up and out of machine.

36

When replacing the oil guard W2, which carries

the needle bar wick and connecting stud wick, make

sure that lower end of the stud wick drops into oil

pool behind lower needle bar bushing and that the

loop of needle bar wick is placed behind the needle

bar, as shown in Fig. 54.

TO REMOVE OIL WICK HOLDER

(See Fig. 55)

Oil wick holder includes two oil wick leaders (see

Fig. 56) and an oil wick for the needle bar link and for

the two sets of needle bearings in the thread take-up

as shown in Fig. 55. It is removed in the following

manner:—

Remove face plate, needle bar and upper needle

bar bushing from the machine, as instructed on

page 33.

Fig. 54. Arm Side Shield Wick,

Needle Bcir Wick and Connecting

Stud Wick

2. Remove upper section

structed on page 33.

3. Remove holder screw W3.

Pulling gently, draw entire oil wick holder as

sembly out of the head of the machine.

of presser bar, as in-

Fig. 55. Wick Loops for Needle

Bar Link and Thread Take-up

Page 37

37

TO INSTALL NEW OIL WICK HOLDER

WICK

NOT REACHING

Fig. 56. Replacing Oil Wick Holder

(Correct Installation)

1. Remove old oil wick holder os instructed at bot

tom of page 36.

2. Remove top arm plug Y3, Fig. 56. (Use a sharpbladed screwdriver or a small chisel to pry plug

Y3 from arm casting.)

3. Insert two oil wick leaders into arm casting, as

shown in Fig. 56, so that wick is slack over edge

Fig. 57. Incorrect

of casting at point A4, Fig. 56. This will insure

free passage of oil. Use tweezers through the

plug hole at Y3 to loop the wick and bring it

into positive contact with the arm shaft approxi

mately at the point B4 shown in Fig. 56.

Installation

pushed all the way down into the smaller hole,

without jatntning, until they touch the arm shaft, as

shown in Fig. 56.

4. When oil wick leaders are correctly installed, re

place holder screw W3, Fig. 56.

5. Adjust the three oil wick loops in holder (see

Fig. 58. Incorrect

Installation

Figs. 55 and 56), so that two of the loops come

as close as possible to, without touching, the

two sets of needle bearings F3 while the third

wick loop makes positive contact with the wick

inside the stud C3, in the needle bar link, as

shown in Fig. 55.

NOTE: DO NOT FORCE the wick leaders down too

tightly against the edge A4 of the casting, as shown

in Fig. 57, as this will decrease the flow of oil from

the arm shaft to the needle bar link and take-up

bearings.

CAUTION: If the bottom of either oil wick leader is

caught on the ledge as shown at C4, Fig. 58, no oil

can be taken up by the wick to be carried to the

needle bar link and thread take-up bearing, where

it is needed. Make sure that the oil wick leaders are

6. Securely tighten holder screw W3.

7. Replace arm top plug Y3.

Replace upper section of presser bar, upper

needle bar bushing and needle bar, as instructed

on page 33.

9. Replace face plate, as instructed in last para

graph on page 18.

Page 38

38

OIL-REMOVING WICK ASSEMBLY (HEAD END) COMPLETE T 47056

lr%

\

Fig. 59. Preparing to Remove

Oil-Removing Wick

Fig. 60. Removing Oil-Removing

Wick Assembly 147056

DESCRIPTION

Oil-removing wick assembly. Complete 147056, shown in Fig. 61 is designed to remove excess oil from the

head of the machine arm.

When filling the machine reservoir, use "TYPE A" or "TYPE C" OIL, sold by Singer Sewing Machine Company.

If inferior oil is used, absorption of the excess oil by this wick may be reduced considerably. The consequent

leakage of accumulated oil will then cause serious damage to materials being sewn. For further instructions on

oiling, see inside front cover of this book and pages 2, 6, 7 and 31.

Additional sets of the oil-removing wick, wick holder body and spring, as shown in Fig. 61, will be furnished

on order.

PREPARATION FOR REMOVAL-

(See Fig. 59)

1.

Remove face plate.

Loosen presser foot lifting lever hinge screw E4,

2.

and presser foot lifting lever link stud screw F4.

Remove head end of presser foot lifting lever G4

3.

with spring H4, from the machine arm.

Remove presser foot screw and presser foot and

4.

presser bar thumb screw X2, with upper section

of presser bar.

Remove arm side shield with wick, as instructed

5.

on page 36.

Loosen screw V and remove guide bracket T, as

6.

instructed on page 33.

Remove presser bar lifting link J4, with stud.

7.

Loosen four screws K4, in the oil removing hinge

8.

plate and cover L4.

REMOVAL-

(See Fig. 60)

1. Turn machine pulley over toward the operator,

until the needle bar crank is in the position

shown at M4.

2. Lift wick LOOP up and off lower presser bar

bushing and lift wick END out of oil pool behind

needle bar bushing, as shown In Fig. 60.

3. Simultaneously push upward against wick and

wick holder at N4, while pulling outward gently

on hinge plate and cover L4, as shown in Fig. 60,

removing hinge plate and cover with oil-remov-i

ing wick and holder body from the machine.

Page 39

39

OIL-REMOVING WICK ASSEMBLY (continued)

RELEASE SPRING

SLIP SPRING

Fig. 61. Disassembly of Oil

Removing Wick

(Showing Oil-Removing Wick)

Wick Holder Body and Spring

147108)

DISASSEMBLY-

1. Release end of spring from catch on the holder

body 04, as instructed in Fig. 61.

2. Remove hinge screw, as instructed in Fig. 61.

3. Oil-removing wick and holder N4 may then be

removed from hinge plate and cover L4, as

shown in Fig. 61.

CAUTION: Before inserting a new oil removing wick,

it must be saturated with oil.

Removing Wick (with Holder)

in Assembly 147056

ASSEMBLY-

(See Fig. 62)

1. Insert open end of holder body 04, (with new

Wick) into hinge plate and cover L4.

2. Replace and securely tighten hinge screw as in

structed in Fig. 62.

3. Slip end of spring into catch on holder body 04,

as instructed in Fig. 62.

4. Place gasket P4 on hinge plate and cover L4.

5. Align the screw holes in the gasket P4 with the

screw holes in the cover L4 and insert the four

screws K4, Fig. 66, page 41 through cover and

gasket to hold the gasket in place.

Page 40

OIL-REMOVING WICK ASSEMBLY (continued)

«

¥§ I Hi

\ ^ ‘.i- ®E'-'''5.’ Ji;

40

SLIDE

INTO

RECESS

PULL

WICK

Ip

' ‘

Bf f

iiii i

‘'X

Fig. 63. Replacing Oil-Removing

Wick and Holder in Head of Machine

REPLACEMENT-

1. Turn machine pulley over toward operator until

the needle bar crank is in the position shown at

M4, Fig. 63.

2. Fold oil-removing wick along the side of the

holder body, as shown in Fig. 63 and insert oilremovimg wick, holder and hinge plate into

head of machine.

Fig. 64. Pulling Wick into

Machine

3. Place index fìnger under wick and holder body

and simultaneously pull the oil-removing wick,

as required, sliding the hinge plate and cover L4

fully Into its recess in the head of the machine,

as shown in Fig. 64.

4. Securely tighten the four screws K4, Fig. 63.

5. Check the entire assembly to make certain that

the holder body (see 04, Figs 61 and 62) hinges

freely under the needle bar crank.

Page 41

41

OIL-REMOVING WICK ASSEMBLY (continued)

if

Ml

m

III

I

IB

il

1 .«w»« J

Fig. 65. Location of Wick

Loop and Wick End

in Machine Head

LOCATION OF WICKS-

1. Replace END of wick behind tension releasing

lever Q4 and into oil pool behind lower needle

bar bushing, os shown in Fig. 65.

2. Replace LOOP behind and then under tension re

leasing lever Q4 and out over lower presser bar

bushing, as shown in Fig. 65.

REPLACEMENT OF OTHER PARTS

1. Replace presser bar lifting link J4, Fig. 66 with

stud.

'smi

'

N-

Fig. 66. Replacement of Other

Parts in Head of Machine

3. Replace arm side shield with wick, as instructed

on page 36.

4. Replace upper half of presser bar and presser

bar thumb screw X2, Fig. 66.

5. Replace presser foot and presser foot screw.

6. Place presser foot lifting lever G4, Fig. 66 with

spring H4 on machine arm and fasten lever to

arm with hinge screw stud E4, Fig. 66.

7. Tighten screw F4, Fig. 58.

2. Replace guide bracket T, Fig. 66. (See page 33,

also.) Tighten screw V, Fig. 66.

8. Replace face plate as instructed on page 18.

Page 42

42

THE ARM SHAFT

T4

Fig. 67. Loosening the Feed Eccentric

REMOVAL-

(See Figs. 67 to 69)

1. Remove the face plate.

2. Remove the arm side shield and wick and the

thread take-up oil guard, as instructed on

page 36.

3. Remove the needle bar, upper needle bar bush

ing, presser foot and presser bar, as instructed on

page 33.

4. Remove entire thread take-up lever assembly, as

instructed on page 34.

7. Loosen the four screws in the arm top cover and

remove the arm top cover.

8. Remove the oil lead that is fastened to the casting

just beneath the arm top cover.

9. Remove the feed timing screw Y, Fig. 67 and

loosen the set screw O, Fig. 67, in the feed-liftingeccentric-and-bevel-gear, X3, Fig. 67.

10. Remove the timing screw Z and loosen set screws

in the feed eccentric U4, Fig. 67.

11. Remove arm shaft screw R4, Fig, 67 from ma

chine pulley end of arm shaft.

5. Remove the oil-removing wick, as instructed on

pages 38 and 39.

6. Set the machine at any stitch length except the

longest or the shortest (see instructions on

page 16) to prevent binding of the arm shaft

during removal and replacement.

12. Loosen the two set screws T4, Fig. 67 and remove

the machine pulley.

13. Turn the needle bar crank until it is in the position

shown at M4, Fig. 69, to prevent crank from dis

turbing the three wick loops in holder W4, Fig. 69

during removal of arm shaft.

Page 43

43

THE ARM SHAFT (continued)

Z4

X4

i

Fig. 68. Removing the Arm Shaft

REMOVAL (Continued)

CAUTION: The feed-timing-bevel-gears at S3, Fig. 68

have been lapped together at the factory and should

be kept in mesh (as instructed in Fig. 68) throughout

the removal and replacement of the arm shaft.

14. While maintaining needle bar crank M4 at posi

tion shown in Fig. 69, hold these gears in mesh

by holding the blade of a large screwdriver be

tween the arm casting and the feed eccentric U4,

as shown in Fig. 68; then push the end of the

arm shaft X4, Fig. 67 through the bushing Z4,

Fig. 67.

15. Using another shaft (or a drift pin of the same

diameter as the arm shaft on these machines),

push the arm shaft X4 further through the ma

chine (still keeping the gears at S3 in mesh).

This temporary shaft must be pushed sufficiently

far into the machine to hold the entire gear and

feed eccentric mechanism in position upon it until

the new arm shaft is installed.

W4

Fig. 69. Position of Needle Bor

Crank, During Removal of Shaft

16. Finally grasp the needle-bar-crank-end of the

arm shaft firmly at the face plate end and pull

the arm shaft straight out of the machine.

Page 44

44

THE ARM SHAFT (continued)

S3

HOLD THESE GEARS IN MESH

Fig. 70. Replacing the Arm Shaft

REPLACEMENT-

(See Fig. 70)

CAUTION: Make certain that the OIL-REMOVING

WICK ASSEMBLY is out of the machine.

1. Insert the machine-pulley-end of the arm shaft

into the arm shaft bushing at the head of the

machine arm.

2. Make certain that the needle bar crank is turned

to the position shown in Fig. 69, clearing the

three wick loops in holder W4.

3. While still holding the bevel gears at S3 in mesh,

with a screwdriver, as shown in Fig. 70, push the

arm shaft X4 straight through the machine arm,

the feed eccentric U4 and the feed-eccentric-and-

bevel-gear X3, Fig. 70. (A light tapping with the

palm of the hand, against the needle bar crank

end, may be required.)

4. Replace machine pulley so that the two set screws

T4 will locate over the two grooves V4 on the

shaft and securely tighten set screws T4.

5. Replace and tighten the arm shaft screw R4

sufficiently to remove all end play of the shaft

without binding. Test the arm shaft for freedom

in rotation.

6. Move bevel gear X3 toward machine pulley and

securely tighten feed timing screw Y.

slight backlash. If there is no backlash, loosen

timing screw Y and set screw O. Lightly tap gear

X3 away from mating gear until there is just a

slight amount of backlash. Then securely tighten

timing screw Y and the set screws in gear X3. Re

check the backlash.

8. Using a screwdriver, as shown in Fig. 70, move

feed eccentric U4 as close as possible to the con

necting rod A2, Fig. 70 and tighten the timing

screw and two set screws in eccentric U4.

9. Check the adjustment and timing of parts dis

turbed and correct where necessary, according to

the instructions on pages 18 through 25.

10. Replace the oil-removing wick assembly, as in

structed on pages 39 and 41.

11. Replace thread take-up, as instructed on page 35.

12. Replace presser bar and presser foot, as in

structed on page 33.

13. Replace the upper needle bar bushing and the

needle bar, as instructed on page 33.

14. Replace thread take-up oil guard W2, Fig. 54,

page 36.

15. Replace arms side shield and wick, as instructed

on page 36.

16. Replace the oil lead beneath the arm top cover.

7. Place the first finger of one hand on one side of

the arm shaft and the first finger of the other

hand on the other side of the arm shaft so that

both fingers contact the bevel gear (on vertical

shaft) that mates with the gear X3. Feel for

17. Replace the arm top cover and tighten its four

screws.

1 8. Replace the face plate and tighten its four screws,

as instructed on page 18.

Loading...

Loading...