Page 1

Form

(546)

Printed

I936d-Revised

in

U.S.A.

LIST

OF

PARTS

Nos.

THE

/AACHINES

231-7

SINGER

MANUFACTURING

and

231-8

COMPANY

Page 2

INSTRUCTIONS

FOR

OIUN6

Remove

and

pour

mark on

check

gauge.

Pill

wheel.

Apply a few

the

ball

When

of

oil

needle

Thereafter,

replenish

Dae

ing

Machines".

oil

in

bar.

oil

the

level,

the

bearings.

the

the

the

only

the

oil

Into

gauge.

gauge

this

Run

andifnecessary,

oil

reservoir

dropsofoil

machine

topofthe

when

oil

supply

"Singer

from

arm

until

the

machine a few

at

is

first

needle

the

machineisin

about

Stainless

the

work

it

is

level

fill

the

right

to

the

three

started,

bar

guide

twiceaweek.

Oil

for

supporting

with

minutes,

to

mark on

of

the

oil

putafew

pin

over

continuous

High

Speed

the

balance

cups

drops

arm

then

for

the

use,

Sew

Copyright,

U. S. A. 1939 1940, 1941, 1942 and 1946

by The Singer Manufacturing Co.

All Rights

Reserved

for all Countries

Page 3

INDEX

Accessories

Belt

Guards

Foot

Lifter

Front

Idlers

Lap

Seam

Machine

Machine

Machine

Numerical

Obsolete

Power

Thread

Thread

Thread

Thread

Planks

Fellers

Cushions

No.

No.

Parts

Table

Unwinder

Unwinder

Unwinder

Unwinder

and

231-7

231-8

List

Accessories

Starting

of

Parts

No.

Spool

No.

Thread

150370

Rests

150695

Cone

Treadle

Holder

Parts

Page

21

21

22

23

24

25

26

7

20

29

28

26

26

27

27

28

Page 4

INSTRUCTIONS

FOR

ORDERING

Id ordering from

FIRST

column.

this

list,

use

The number stamped on a Sewing Machine

case

the

numberofthe

Every

specific

be

It

finish

A-Hardened,

A.A-Buffed

A.B-Hardened,

A.C-Brown

A.D-<}ray

combination

number,

used

when

Each

ordering

number

appears,orfor

The

letters

only,asfollows;

Polished,

and

Chromium

Polished,

Baking

Baking

A.E-Hardened, Bright

A.F-Bardened,

Chromium

A.O-Alumlllte,

A.H-Alumlllte,

Bright

Plated

Plain

Dyed

single

part

of parts sent out as such has

which,

although not

the

always

after

Eliamel

Enamel

Indicates

whatever

someofthe

Nickel

Plated

Buffed

Finish

Finish

Rumbled

Rumbled,

combination.

machine.

Plated

and

and Nickel

Nickel Plated,Bright

A.J-Pollshed, Nickel Plated and

A.K-Hardened,

A.L-Heat

B-Pollshed,

C-Hardened

C.R-Hardened

D-Polished

E-Soft,

F-Hardened

F.J-Hardened,

Q-Brlght

H-Blued

J-Nickel

K-Hardened

L-Brass

M-Qxldlzed

N-Japanned,

PsJapanned,

P.P4/rlnkle

R-Merllzed

S-Cadmium

T-Copper

T.A-Hardened, Polished,

T.B-Copper and

T.J-Copper

T.K-Hardened,

T.L-Copper

T.M-Copper

Polished, Nickel Plated and

Treated

for

Nickel

Only

and

Merllzed

Only

Not

Polished

and

Polished

Polished

Rumbled and

Plated

and

Nickel

Plated

Dull

Bright

Finish

Plated

Plated

Toughness

Plated

Only

and

Nickel

Plated

and Buffed

Nickel

Copper

Nickel

Plated

and

Nickel

Copper and

and

Brass

Plated

Plated

and

Plated

Nickel

Oxidized

and

Only

Plated

and Nickel Plated and Buffed

ONLY

only.

stamped

the

SAME

numbers

and Buffed

Chromium

Chromium

Plated

Polished

Plated

the

part

PartIsIn

on the parts,

PART

Indicate

Plated

Plated

Plated

Chromium

NUMBER

every

Its

In whatever

the

style

Rumbled

Plated

In the

must

list

of

and

Page 5

INSTRUCTIONS

U-ZlQC

Plated

V-Sllver

W-Polished

X-Black

X.C-Hardened

Y-Black

Z-Chroinlum

Plated

and

Oxide,

and

Nickel

Plated

Nickel

for

Black

Plated

Iron

CKlde,

Z.A-Hardened,Pollshed,NlckBl

Z.B-Pollshed,

Z.C-Hardened

Z.D-Polished

Z.O-Brlght

Plated

Z.J-Nlckel

Z.T-Copper

These

and

AFTER

In

The

Illustrating

Parts

repairs

Nickel

and

and

Rumbled,

and

Chromium

and

Chromium

letters

the

numberasIn

this

series:

1to1500,

are

Screw

1501to1800

1801to2000

2001to50000

190000

are

figures

Numbers

are

numbers

In

the

marked

are

withanasterisk

madeatfactory.

Plated,

Chromium

Chromium

Nickel

MUST

BE USED

50001to51500

and

and

and

Sewing

of

Electrical

the

second

parts,

FOR

ORDERING-Continued

Plated

and

Steel

for

Only

IronorSteel

Plated,Buffed

Buffed

Plated

Plated

Plated,

Plated

Bright

Plated

when

the

list.

51501

to

51801to52000

52001

Machine

to

51600

140000

Parts,

Parts.

column

and

are

NOT

(•)

and Chromluni

and

Chromium

Rumbled

they

appear

and

140001to142000

are

Nut

are

Roller

and

142001

190001

refer

onlytothe

TO BE

USEDInordering.

are

furnished

Plated

and

In

the

Numbers

Numbers

and

upward

Plated

Chromium

list;

to

plates,

only

when

Page 6

^-rta^lNGER

f

A\ACHINE

No.

231-7

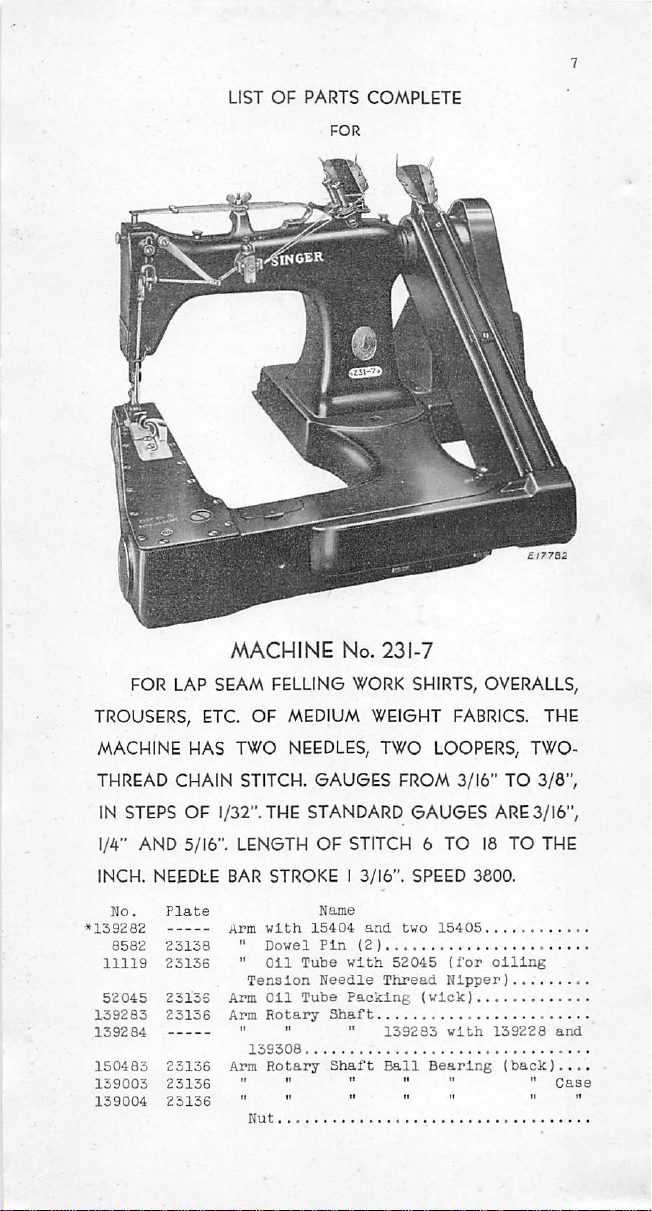

FOR LAP SEAM FELLING WORK SHIRTS,

TROUSERS,

MACHINE HAS TWO

THREAD CHAIN STITCH.

IN STEPS

1/4" AND 5/16". LENGTH

INCH. NEEDLE BAR STROKE I 3/16". SPEED

No.

•139282

8582

11119

52045

139283

139284

150485

139003

139004

ETC

OF MEDIUM WEIGHT

OF

1/32". THE STANDARD

Plate

23138

23136

23156

23136

23136

23136

23136

Arm

with

"

Dowel

"

Oil

Tension

Arm

Oil

Arm

Rotary

" " "

139308

Arm

Rotary

" " " " " "

Nut

NEEDLES,

GAUGES

OF

STITCH 6 TO 18

Name

15404

Pin

Tube

with

Needle

Tube

Packing

Shaft

Shaft

TWO LOOPERS, TWO-

FROM 3/16"TO3/8",

GAUGES

and

two

(2)

52045

Thread

(wick)

139283

Ball

FABRICS.

15405

(for

Nipper)

with

Bearing

OVERALLS,

ARE 3/16",

TO

3800.

oiling

139228

(back)....

THE

THE

,

aiui

Case

Page 7

No.

50422C

68350

131319

139005

139006

68350

131319

139007

139008

139199

139228

1149AL

51185P

139010

201254C

202253

139483

139484

51283AL

a39249

139251

139252

139253

504

^0608R

139017

50004C

139476

50608R

139017

139022

139025

139026

116E

783E

HE

Plate

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23138

23138

23138

23138

23138

23138

23097

23097

23097

23097

23097

23097

23097

23145

23145

23136

23136

23097

23136

23136

PARTS

FOR

MACHINE

Arm

Rotary

Case

Oil

Oil

Set

Rotary

Cup

Rotary

Cup

Rotary

Arm

Arm

Arm

Spacing

Arm

Rotary

Arm

Rotary

Oil

Cup

Arm

Rotary

Oil

Cup

Arm

Rotary

OilRetainer

Arm

Rotary

Oil

Retainer

Arm

Rotary

1036AL

Arm

139103

Arm

Arm

Arm

two

Arm

Screw

Arm

Flange

Arm

Balance

51283AL

Balance

in.

Balance

Bed

Bed

Bed

" " "

n n II n ii

(2)

Bed

" " " " "

and

Rotary

Rotary

Rotary

Rotary

each

Rotary

(2)

Rotary

(2)

Screw

Wheel,2in.

Wheel

"V"

Wheel

Cover

Cover

Cover

"

"

Extension

" "

"

Oil

Oil

Rotary

Drain

Gauge

" " " " "

Bed

"

" " "

mediate

)

Shaft

Screw

Shaft

Shaft

Oil

Shaft

Collar

Shaft

Shaft

Shaft

Oil

Shaft

Shaft

Shaft

Shaft

Shaft

Shaft

Shaft

201254C

Shaft

Shaft

(3)

for

belt

with

Gasket

Hole

Screw

Shaft

Name

Pad

Fad

114

round

with

Set

Screw

Plug

No.

Ball

Ball

(back)

(front)

9AL

139253

Plug

(14)

231-7

Ball

(braided

Ball

Ball

Ball

Ball

(braided

Ball

Ball

Crank

Crank

Crank

Screw....

Sprocket

and

Sprocket

Sprocket

belt

two 51283AL,

Screw

(cork)

Clamping

Screw

(2)

Screw

Ball

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

with

139199

Set

2022

pulley,

(2)

and

Bearing

cotton)

cotton)

Screw

Wheel

53

Wheel

Wheel

two

Plate

Washer

Washer

(back)

(back)

(back)

(back)

(front)..

(front)

(front)

(front)

(front)

two

with

with

50411E...

(inter

each

(2)...

with

Set

Spring

two

for

ScreW

l/2

Page 8

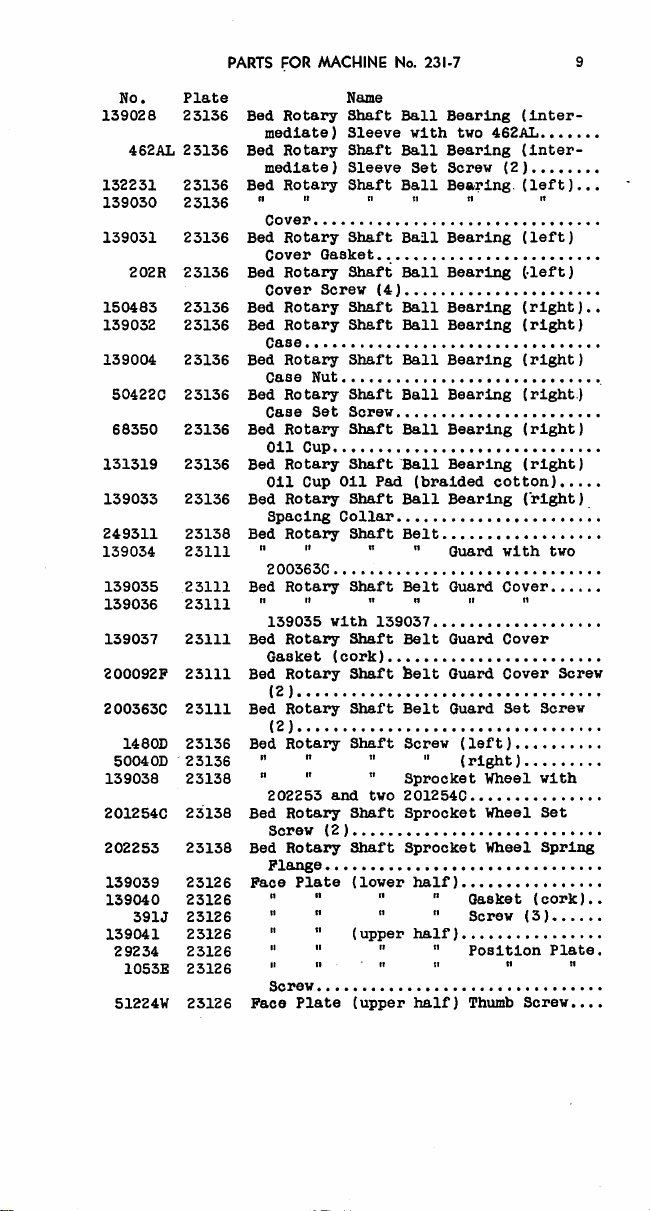

PARTS

FOR

AAACHINE

No.

231-7

No.

139028

462AL

132231

139030

139031

202R

150483

139032

139004

50422C

68350

131319

139033

249311

139034

139035

139036

139037

200092F

200363C

14801)

5004OD

139038

2012540

202253

139039

139040

139041

29234

1053E

51224W

391J

Plate

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23136

23138

23111

23111

23111

23111

23111

23111

23136

23136

23138

23138

23138

23126

23126

23126

23126

23126

23126

23126

Bed

Rotary

mediate)

Bed

Rotary

mediate)

Bed

Rotary

ti

Cover

Bed

Rotary

Cover

Bed

Rotary

Cover

Bed

Rotary

Bed

Rotary

Case

Bed

Rotary

Case

Bed

Rotary

Case

Bed

Rotary

Oil

Bed

Rotary

Oil

Bed

Rotary

Spacing

Bed

Rotary

" " " "

200363C

Bed

Rotary

139035

Bed

Rotary

Gasket

Bed

Rotary

(2)

Bed

Rotary

(2)

Bed

Rotary

" " " "

" " "

202253

Bed

Rotary

Screw

Bed

Rotary

Name

Shaft

Ball

Sleeve

Shaft

Sleeve

Shaft

n n II II II

Shaft

Gasket

Shaft

Screw

(4)

Shaft

Shaft

Shaft

Nut

Shaft

Set

Screw

Shaft

Cup

Shaft

Cup

Oil

Pad

Shaft

with

Ball

Set

Ball

Ball

Ball

Ball

Ball

Ball

Ball

Ball

Ball

(braided

Ball

Bearing

two

462AL

Bearing

Screw

(2)

Bearing.(left)..

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

Bearing

cotton)....

Bearing

Collar

Shaft

Belt

Guard

with

Shaft

Belt

Guard

Cover

with

139037

Shaft

Belt

Guard

Cover

(cork)

Shaft

feelt

Guard

Cover

Shaft

Belt

Guard

Set

Shaft

Screw

(left)

(right)

(2)

and

Shaft

Shaft

two

Sprocket

201254C

Sprocket

Sprocket

Wheel

Wheel

Wheel

Flange

Face

Plate

" " " "

" " " "

" "

" " " "

II II ' II It II II

Screw

Face

(lower

(upper

Plate

(upper

half)

half)

half)

Gasket

Screw

Position

Thumb

(inter

(inter

(left)

(-left)

(right).

(right)

(right)

(right.)

(right)

(right)

(right)

two

Screw

Screw

with

Set

Spring

(cork)..

(3)

Plate.

Screw....

Page 9

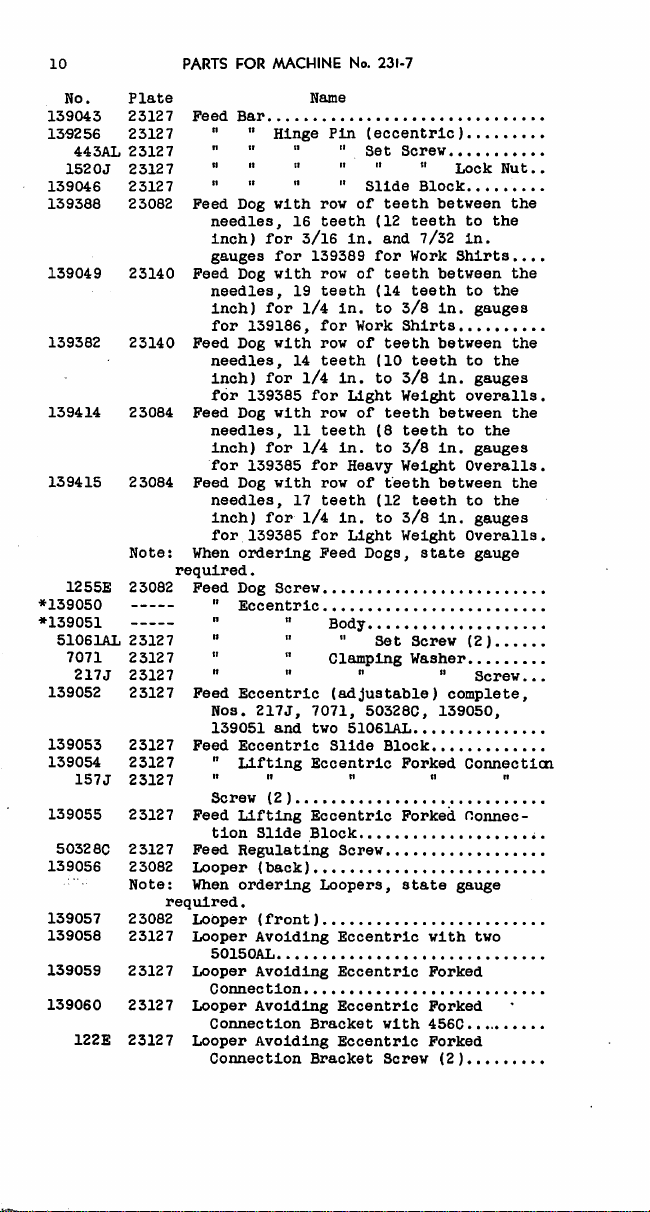

10

PARTS

FOR

MACHINE

No.

231-7

No.

139043

139256

152OJ

139048

139388

139049

139382

139414

139415

1255E

*139050

*139051

51061AL

139052

139053

139054

139055

503280

139056

139057

139058

139059

139060

443AL

7071

217J

157J

122E

Plate

23127

23127

23127

23127

23127

23082

23140

23140

23084

23084

Note:

23082

23127

23127

23127

23127

23127

23127

23127

23127

23127

23082

Note:

23082

23127

23127

23127

23127

Peed

Bar

" "

" " " "

" " " " " "

" " " "

Peed

Dog

needles,

inch)

gauges

Peed

Dog

needles,

inch)

for

139186,

Peed

Dog

needles,

inch)

for

139385

Peed

Dog

needles,

inch)

for

139385

Peed

Dog

needles,

inch)

for

139385

When

Peed

ordering

Dog

Eccentric.

required.

Hinge

with

for

for

with

for

with

for

with

for

with

for

Screw.

Name

16

3/l6

139389

19

l/4

14

1/4

for

11

l/4

for

17

l/4

for

"

" "

"

Peed

Nos.

139051

Peed

"

Screw

Peed

tion

Peed

Looper

When

required.

Looper

Looper

50150AL

Looper

Connection

Looper

Connection

Looper

Connection

" " "

Eccentric

217J,

7071,

and

(2)

Slide

two

Eccentric

Eccentric

Block

Eccentric

Lifting

Lifting

Regulating

(back)

ordering

(front)

Avoiding

Avoiding

Avoiding

Bracket

Avoiding

Bracket

Pin

(eccentric)

Set

Slide

rowofteeth

teeth

(12

in.

and

for

rowofteeth

teeth

(14

in.

to

for

Work

rowofteeth

teeth

(10

in.

to

Light

rowofteeth

teeth

(8

in.

to

Heavy

rowofteeth

teeth

(12

in.

to

Light

Peed

Dogs,

Body

Set

Clamping

(adjustable)

50328C,

51061AL

Slide

Block

Screw

Loopers,

Eccentric

Eccentric

Eccentric

with

Eccentric

Screw

Screw

Block

teeth

7/32

Work

teeth

3/8

Shirts

teeth

3/8

Weight

teeth

3/8

Weight

teeth

3/8

Weight

state

Screw

Washer

Porked

Porked

state

with

Porked

Porked

456C

Porked

Lock

between

to

in.

Shirts....

between

to

in.

gauges

between

to

in.

gauges

overalls.

between

to

in.

gauges

Overalls.

between

to

in.

gauges

Overalls.

gauge

(2)

Screw...

complete,

139050,

Connecticn

nonnec-

gauge

two

(2)

Nut..

the

the

the

the

the

the

the

the

the

the

Page 10

Ho.

139257

1324C

139055

50150AL

51485AL

139062

139083

139064

139065

1047AL

139066

175E

139069

139070

152OJ

128551

1057AL

139352

443AL

139072

1259AL

139073

139074

139075

139076

1253AL

456C

139411

139262

139264

Plate

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23127

23082

23097

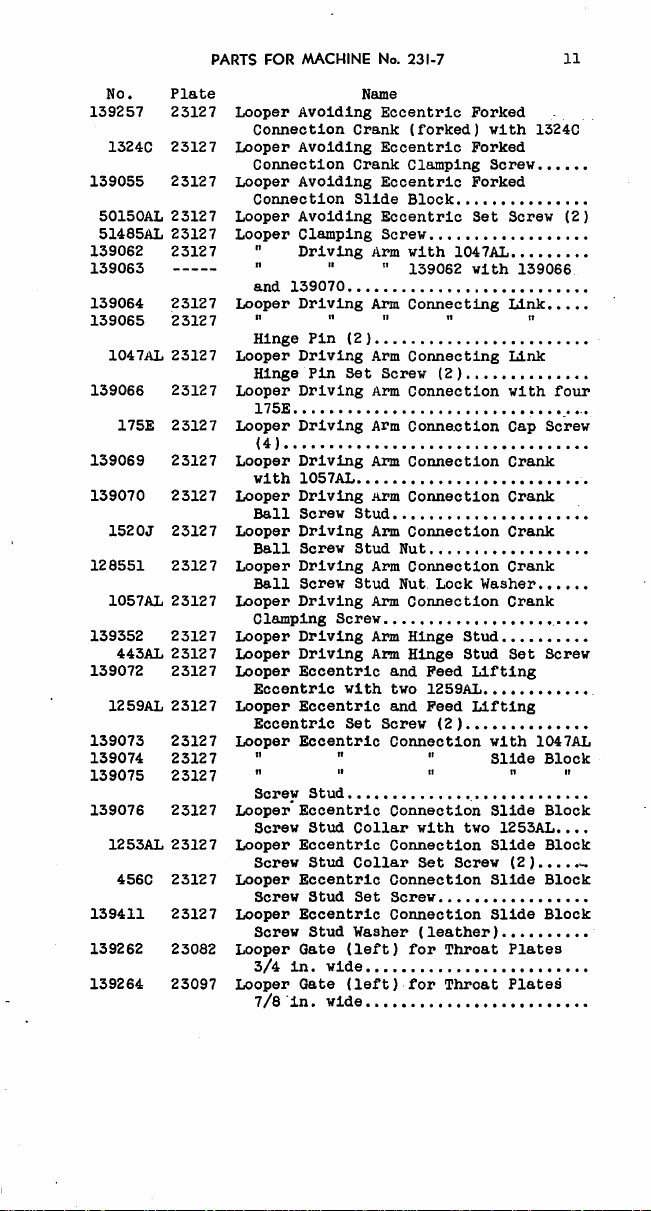

PARTS

FOR

A\ACHINE

Looper

Looper

Avoiding

Connection

Avoiding

Connection

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Looper

Avoiding

Connection

Avoiding

Clamping

"

Driving

" " "

and

139070

Driving

Hinge

Pin

Driving

Hinge

Pin

Driving

175E

Driving

(4)

Driving

with

1057AL

Driving

Ball

Screw

Driving

Ball

Screw

Driving

Ball

Screw

Driving

Clamping

Driving

Driving

Eccentric

Eccentric

Eccentric

Eccentric

Eccentric

" " "

" " " " "

Screw

Stud

Eccentric

Screw

Stud

Eccentric

Screw

Stud

Eccentric

Screw

Stud

Eccentric

Screw

Stud

Gate

3/4

In.

Gate

7/8

In.

Screw

wide

wide

Name

Crank

Crank

Slide

(2)

Set

Stud

Stud

Stud

with

Set

Collar

Collar

Set

Washer

(left)

(left)

No.

231-7

Eccentric

(forked)

Eccentric

Clamping

Eccentric

Block

Eccentric

Screw

Arm

with

139062

Arm

Connecting

Arm

Connecting

Screw

Arm

Connection

Arm

Connection

Arm

Connection

Arm

Connection

Arm

Connection

Nut

Arm

Connection

Nut

Arm

Connection

Arm

Hinge

Arm

Hinge

and

two

and

Screw

Connection

Connection

Connection

Connection

Screw

Connection

for

for

(2)

Lock

Feed

1259AL

Feed

(2)

with

Set

(leather)

Throat

Throat

1047AL

Stud

Stud

two

Screw

Forked

with

Forked

Screw

Forked

Set

with

Washer

Lifting

Lifting

with

Slide

Slide

1253AL....

Slide

Slide

Slide

Screw

139066

Link

Link

with

Cap

Crank

Crank

Crank

Crank

Crank

Set

(2)

Plates

Plates

11

1324C

(2)

four

Screw

Screw

1047AL

Block

Block

Block

Block

Block

Page 11

12 PARTS FOR /AACHINE No.

231-7

No.

139269

139271

139272

190J

139093

172E

139094

139095

435AL

139096

435AL

139097

1454E

26276

139273

206J

139099

139100

139101

1133E

139102

139103

139105

139239

1036AL

139229

139108

175E

139310

139111

139112

1057AL

Plate

23082

23097

Looper

3/4

Looper

7/8

23097

23097

23127

Looper

" " " "

"

51485AL

23127Looper

23127

23127

23127

23127

23127

23^127

23127

23127

23141

23141

23141

" "

Looper

" " " " "

Screw

Looper

" " " " "

Set

Looper

" " " "

Screw

Looper

"

" " "

Needle

Needle

Note:

23141

23141

23141

23136

23136

23136

23141

139116

When

required.

Needle

" "

" "

" " " "

139105

Needle

" " " " "

Oil

Needle

Set

Needle

Washer,

Note:

23141

23141

23141

23141

23141

23141

.012"

When

ness

Needle

" " " "

Screw

Needle

(wick)

Needle

Guide

Needle

Guide

Gate

In.

Gate

in.

Gate

Holder

Holder

Holder

Holder

Screw

Holder

Position

Thread

Bar

Bar

ordering

Bar

Bar

Pad

Bar

Screw

Bar

ordering

required.

Bar

Bar

Bar

Bar

Name

(right)

vide

(right)

wide

Retaining

with

Clamping

Shaft

Shaft

Shaft

Shaft

Pin

Guide

(hollow)

complete,

No.

Bushing

•'

Coxmecting

and

139108

Connecting

(braided

Connecting

(2)

Connecting

thicknesses,.004",

No.

Connecting

Connecting

Connecting

Connecting

Screw

(2)

for

for

Spring

172E,

Bushing

Bushing

Collar

Screw

Nos.

139100

(lower)

Link

Link

cotton)

Link

139229,

Stud

Stud

Stud

Screw

"

Link

Stud

Throat

Throat

26276

139099

state

state

Plates

Plates

Screw

and

(back)

(front)...

with

1454E.

Clamping

gauge

Set

Screw..

139102

Hinge

Hinge

Spacing

.008"

thick

with

175E...

Clamping

Oil

Pad

Slide

Slide

Set

and

with

Stud,.

Stud

and

Block.

Block

Page 12

No.

59456

139113

52146

139114

1133E

139115

59019

139118

139117

139118

139119

139195

139120

139121

139122

139123

139124

50617B

139125

139126

139127

139128

139410

38456

139130

139131

139132

139133

131749

330W

453AL

1167E

1498AL

131C

1133E

1133E

1057AL

807D

802D

Plate

23141

23141

23141

23141

23141

23141

23141

23141

23141

Note:

23082

23082

23140

23140

Note:

23141

23141

23141

23141

23138

23138

23138

23138

23138

23138

23138

23138

23138

23141

23141

23141

23141

23141

23141

23141

23118

23118

23118

23116

23118

23141

PARTS FOR

Needle

Needle

Guide

AAACHINE

Bar

Connecting

Screw

Bar

Guide

Name

Washer

" " "

braided

Needle

" " "

" "

" " " "

Bar

cotton

Guide

Thread

" " " " "

"

Clamp

When

ordering

with

No.

required

Needle

Guard,

for

" " "

gauges

Needle

Guard

for

" " "

gauges

When

gauge

required.

Needle

" " "

" "

"

Connecting

to

Oil

Presser

Presser

Screw

Presser

Hinge

Presser

ordering

Guard

Set

139125

Cup

" " " "

" " " "

" "

1057AL

Screw

Gasket

Bar

"

Bar

Bar

Screw

Bar

Needle

Holder

Screw

Cap

"

" "

Oil

Link,

and

Bushing

Lifting

Lifting

Lifting

Lifting

Spring.

No. 231-7

Stud

(2)

Oil

Pad

Oil

Pad

Set

Screw

Guide

Screw

two

1498AL

139116

3/l6

In.

7/32

In.

5/l6

In.

11/32

and

Guards,

Set

Screw

(2)

(transparent)......

Gasket

Retainer

Plug

four

(soft

Nos.

(cork)

Screw

50617B,

131C

leather)

(lower)

(upper)

Bracket

Bracket

Bracket

Lever.

Slide

(Inside)

(outside)

state

gauge

to

gauge

3/8

Screw

Hinge

Spring

Block

Washer...

gauge

9/32

In.

state

(4).

Washer.

139121

Set.Screw.

Set

Screw.

with

Clamping

Lifter....

Screw.

13

felt

In.

Page 13

14

PARTS

FOR

MACHINE

No.

-231-7

No.

131750

131751

1637J

36468

131830

131851

139218

139219

139220

139221

139222

18055

131534

18055

139223

139383

128390

131705

131706

131707

18055

131534

18055

139420

51697W

131752

42290K

139390

665J

665J

190J

Plate

23141

23141

23141

23141

23141

23082

23082

23082

23082

23082

23082

23082

23082

23082

23082

23084

23084

23084

23084

23084

23084

23084

23084

23084

23084

Note:

23082

23141

23141

23143

Presser

Presaer

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

When

required.

Presser

Pressure

Pressure

Pressure

Slack

Name

Bar

Bar

Bar

and

Bar

complete

131749

Foot

Spring

Spring

Spring

Spring

" " "

" " " " "

Nut

51697W

spring)

51697W,

" " "

" " " " "

Position

Screw

Foot

" "

" " " "

" " " " "

Hinge

Pin

Foot

Spring

Foot

" "

for

3/l6

in.

131534, 139218,

two

each

665J,

Foot

" " "

•'

Screw

" " " "

(2)

Foot

" "

" " " "

" " " "

Hinge

Pin

Foot

131749

and

Plate

(2)

Shank

Yielding

Yielding

Yielding

(triple

to

18055

Plate

Shank

Yielding

Yielding

Auxiliary

Screw

Stud

complete

to

(less

Nos.

131751

Hinge

hinged)

l/4

139220

Hinge

131752

Heel

Heel

Heel

in.

and

Heel

Heel

Stud

auxiliary

1637J,

Stud

Connection

Connection

Hinge

gauges

to

139219

Stud

Connection

Connection

Spring

Foot

for

overall

131534,

two

ordering

for

for

Foot

3/I6

each

Foot

Regulating

Regulating

131830

Regulating

131851

Thread

Yielding

(triple

in.

work

131705

665J,

Presser

Screw

Regulator

to

and

3/8

shirt

to

18055

Heel

hinged)

in.

131707,

and

Feet,

Thumb

Thumb

Thumb

Hinge

gauges,

work,

139383

128390

state

Nut

Nut

Nut

Lock

Nos.

1637J

42290K,

(2)

Pin..

complete,

Nos.

139222

(2)

Position

Pin..

complete,

Nos.

gauge

Washer

Washer

and

for

and

Page 14

No.

139300

139299

131405

1423J

131406

139275

51486C

1423J

139140

42639

59534

139276

42727

453AL

171AL

217J

430C

Plate

23143

23143

23143

23143

23143

23143

23143

23143

23118

23118

23118

23118

23118

2311b

23118

23118

23118

139278 23118

54070

2

139307

1149AL

139308

139310

1698R

13218

59456

376J

102

456C

23118

23118

2

3118

23141

23141

23136

23136

23141

23141

23141

23141

PARTS

!=0R

MACHINE

Slack

Thread

Connecting

Slack

Thread

Connecting

Slack

Thread

" " " "

with

Slack

Thread

Cap

Screw

Slack

Thread

Clamping

Slack

Thread

Connecting

Slack

Thread

Tension

Thread

Tension

Tension

Screw

Tension

Screw

Tension

Screw

Tension

Screw

Tension

" " "

(3)

Tension

Position

Tension

1423J,

139275

Tension

" " " "

" " "

171AL

(looper

Guide

(looper

(looper

(looper

Cap

(looper

Nut

(looper

Nut

(looper

(looper

(looper

51486C,

and

(needle

Regulator

Stud

Regulator

Stud

Regulator

Regulator

Regulator

Screw

Regulator

Link

Regulator

Screw

with

Position

Pin

three

" " "

with

Set

with

Set

with

Nut

Spring

Washer

13538

(needle

Screw

(needle

two

(needle

Screw

(needle

5684

(needle

(needle

(needle

456C

(2)

Tension

Tension

Tension

Tension

Tension

Tension

Tension

No.

231-7

Name

Connecting

with

453AL

Connecting

Set

Screw

Holder

Holder

Holder

Holder

Screw

thread)

with

42727

threeid)

thread)

thread)

thread)

42639

thread)'Regulating

Pin

thread)

thread)

thre^)

59534,

1392

thread)

thread)

thread)

thread)

thread)

thread)

thread)

thread)

76

Crank

Crank

Crank

Crank

Body

and

Body

Set

Regulating

Regulating

Regulating

Spring

Tension

Tension

complete,

139140,

Bracket

Disc

(4)

Nipper

Nipper

Nipper

Nipper

Hipper

Hipper

Nipper

Nipper

15

Link

Link

.

Screw

Plate

Plate

Nos.

•

Screw.

Body

Body

Cam

Cam

Stud

Stud

Stud

Stud

Page 15

16

No.

5684

139276

13538

139373

51570C

32572

54988

54071

54872

139143

154

50326C

59539

131741

59537

59538

131696

139144

139145

139146

139147

51282J

1250AL

1266AL

HOC

624AL

316C

PARTS

FOR

Plate

23141

23141

23141

23141

23118

23118

Tengion

Wearing

Tension

Plate

Tension

Plate

Tension

Nos.

139310

Tension

Thvimb

Tension

A\ACHINE

(needle

(needle

(needle

Position

(needle

1690R,

(needle

Nut(2)

(needle

(3)

and

Name

Sleeve

No.

13218,

three

231-7

thread)

Pin

thread)

thread)

Pin

thread)

thread)

thread)

59456,

139276

Nipper

Nipper

Nipper

Nipper

139307,

Regulating

Releasing

Stud

Tension

Tension

complete

Disc

(2)

23118

Tension

(needle

thread)

Releasing

Pin

(2)

23118

23118

23118

23118

23118

23118

7J

23118

23118

23118

23118

23118

23118

23136

23143

23143

23143

Tension

Tension

Tension

Tension

Tension

Tension

Tension

Tension

Tension

(needle

Shaft

(needle

Shaft

Crank

(needle

Shaft

Crank

(needle

Shaft

Crank

Screw

(needle

Shaft

Crank

(needle

Stop

Screw

(needle

Shaft

Stop

(needle

n n

50326C

(needle

(2)

with

thread)

thread)

with

thread)

Connecting

thread)

Connecting

thread)

Set

Screw

thread)

thread)

Screw

thread)

ti tt

51570C

thread)

" " " "

(large)

Tension

(small)

Tension

(double)

Thread

1266AL

Thread

(needle

(needle

(looper)

(looper)

(2)

thread)

(2)

thread)

(2)..

Take-up

Take-up

" " " "

Pin

Thread

(looper)

Take-up

624AL

Nut

Releasing

Releasing

Releasing

Link

Releasing

Link

Releasing

Releasing

Releasing

Screw

(2)

Spring

Spring

Thread

with

Cover

Cover

Hinge

Stud

(2)....

Bushing

Bushing

Guide

two

Hinge

Lock

ti

Shaft

(2)

4

Spring

23143

23136

23138

Thread

Spring

Threeui

Screw

Thread

(looper)

Screw

(looper)

Stud

(looper)

Take-up

Take-up

Take-up

Cover

Cover

Set

Lock

Position

Screw

(2).

Page 16

No.

139148

139149

139279

139280

139152

17022

139153

139154

139155

7071

139156

139157

139158

139158

139159

139160

175E

207J

665J

203J

237AL

219J

240J

22

229J

176J

202J

PARTS FOR MACHINE No. 231-7 17

Plate

23143

23143

23143

23143

23143

23143

23143

23143

23143

23143

23143

23143

23143

23143

Thread

II II " "

II II II II I'

Bracket

Thread

Bracket

7071,

139152

207J,

Thread

Bracket

Thread

Screw

Thread

Thread

Thread

Thread

Thread

(2)

Thread

Washer

Thread

(fibre)

Thread

(left)

Thread

(left)

Thread

Name

(looper)

(looper)

139279

51202J,

to

665J

(looper)

Screw

(looper)

(2)

(looper)

Guard

(looper)

Guard

(looper)

(looper)

(2)

(looper)

(looper)

(looper)

Screw

(looper)

Take-up

'

Take-up

with

219J,

139145to139149,

139157

and

and

17022

Take-up

(2)

Take-up

Take-up

Take-up

Screw

(2)

Take-up

Take-up

Take-up

Take-up

Take-up

Take-up

Stripper

Stripper

two

Stripper

Stripper

Stripper

Stripper

Stripper

Stripper

Thread

Thread

Thread

Thread

Plate

Plate

237AL,240J

each

203J,

Plate

Plate

Plate

Plate

Screw

Screw

Guard

Guide

Guide

Guide

(right)

23143

23143

23143

23143

23143

23144

9J

23144

23144

23144

23144

23144

23144

23144

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

(looper)

(right)

(looper)

(right)

(looper)

Separator

(looper)

Separator

(looper)

Separator

(looper)

It II

Screw

(looper)

II

Screw

(looper)

It

Screw

(looper)

Support

(looper)

Support

Take-up

Thread

Screw

Screw

Thread

Thread

Take-up

Washer

Take-up

Take-up

Take-up

Thread

Retainer

Retainer

It

Thread

Thread

Thread

Thread

Guide

(2)

Thread

ti

Guide

n n

(2)

Thread

11 II II «l

Thread

Thread

Screw

(lower)

Guide

Guide

Guide

II

Guide

Guide

Screw

(left)...

(right)..

Bracket..

Bracket

Bracket

It

It

Page 17

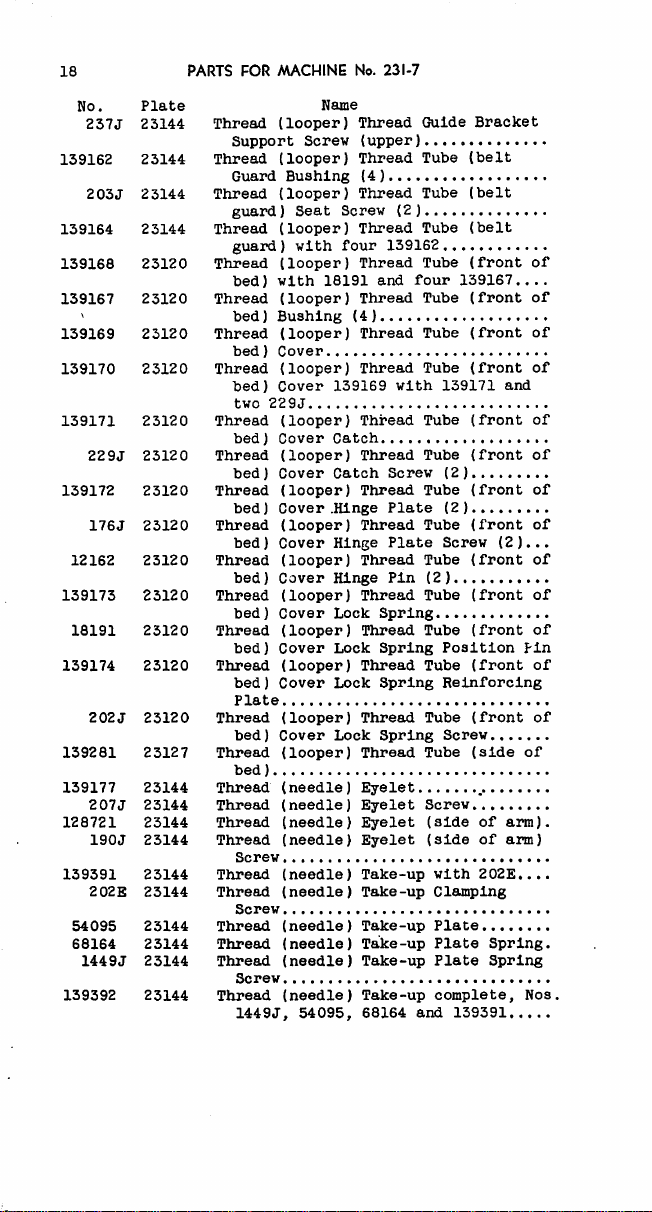

18

No.

139162

139164

139168

139167

139169

139170

139171

139172

12162

139173

18191

139174

139281

139177

128721

139391

54095

68164

1449J

139392

237J

203J

229J

176J

202J

207J

190J

202E

Plate

23144

23144

23144

23144

23120

23120

23120

23120

23120

23120

23120

23120

23120

23120

23120

23120

23120

23127

23144

23144

23144

23144

23144

23144

23144

23144

23144

23144

PARTS

Thread

Thread

Thread

Thread

Thread

Thread

Thread

FOR

Support

Guard

guard)

guard)

bed)

bed)

bed)

Thread

bed)

two229J

Thread

bed)

Thread

bed)

Thread

bed)

Thread

bed)

Thread

bed)

Thread

bed)

Thread

bed)

Thread

bed)

Plate

Thread

bed)

Thread

bed)

Thread

Thread

Thread

Thread

Screw

Thread

Thread

Screw

Thread

Thresui

Thread

Screw

Thread

1449J,

A\ACHINE

Name

(looper)

Screw

(looper)

Bushing

(looper)

Seat

(looper)

with

(looper)

with

18191

(looper)

Bushing

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

Cover

(looper)

(needle)

(needle)

(needle)

(needle)

(needle)

(needle)

(needle)

(needle)

(needle)

(needle)

54095,

No.

Screw

four

(4)

139169

Catch

Catch

.Hinge

Hinge

Hinge

Lock

Lock

Lock

Lock

231-7

Thread

(upper)

Thread

(4)

Thread

Thread

139162

Thread

and

Thread

Thread

Thread

Thread

Thread

Screw

Thread

Plate

Thread

Plate

Thread

Pin

Thread

Spring

Thread

Spring

Thread

Spring

Thread

Spring

Thread

Eyelet

Eyelet

Eyelet

Eyelet

Take-up

Take-up

Take-up

Take-up

Take-up

Take-up

68164

(2)

with

Guide

Tube

Tube

Tube

Tube

four

Tube

Tube

Tube

139171

Tube

Tube

Tube

Tube

Screw

Tube

(2)

Tube

Tube

Position

Tube

Reinforcing

Tube

Screw

Tube

Screw

(side

(side

with

Clamping

Plate

Plate

Plate

complete,

and

Bracket

(belt

(belt

(belt

(front

139167....

(front

(front

{front

(front

(front

(2)

(front

(2)

(front

(front

(front

(front

(front

(front

(side

139391

and

(2)...

of

arm).

of

arm)

202E....

Spring.

Spring

of

of

of

of

of

of

of

of

of

of

of

Pin

of

of

of

Nos,

Page 18

No.

139393

131496

139158

139158

139180

139416

139417

50318W

139186

139385

139389

*15404

15405

997J

229J

22

691P

9J

23144

23141

23141

23141

23140

23140

23082

Note;

23082

PARTS

FOR

Plate

23144 Thread

23144 Thread

23144

23144

23144

23144

23144

Clamp

Thresid

Clamp

Thread

" " " " "

Screw

Thread

" " ' " " "

Screw

Thread

"

" "

" "

Throat

gauges,

Throat

gauges,

139415

Throat

gauges,

When

gavige

required.

Throat

Trade

" "

A\ACHINE No. 231-7

Name

(needle)

(needle)

(needle)

Screw

(needle)

(2)

(needle)

(2)

(needle)

Cutter

Plate,

Plate,

Plate

ordering

Plate

Mark

for

for

for

Take-up

Thread

Thread

Thread

(knife)

Screw

for

139049

for

139382,

for

139388

Throat

Screw

Rivet

Take-up

Take-up

•'

(2)

l/4

1/4

3/l6

Plates,

(3)

(2)

(auxiliary)..

(auxiliary)

(auxiliary)

Guide

Guide

Guide

Guard

In.

to

In.

to

139414

In.

and

(left)..

(right).

Bracket.

3/8

3/8

and

7/32

state

19

In.

In.

In.

Page 19

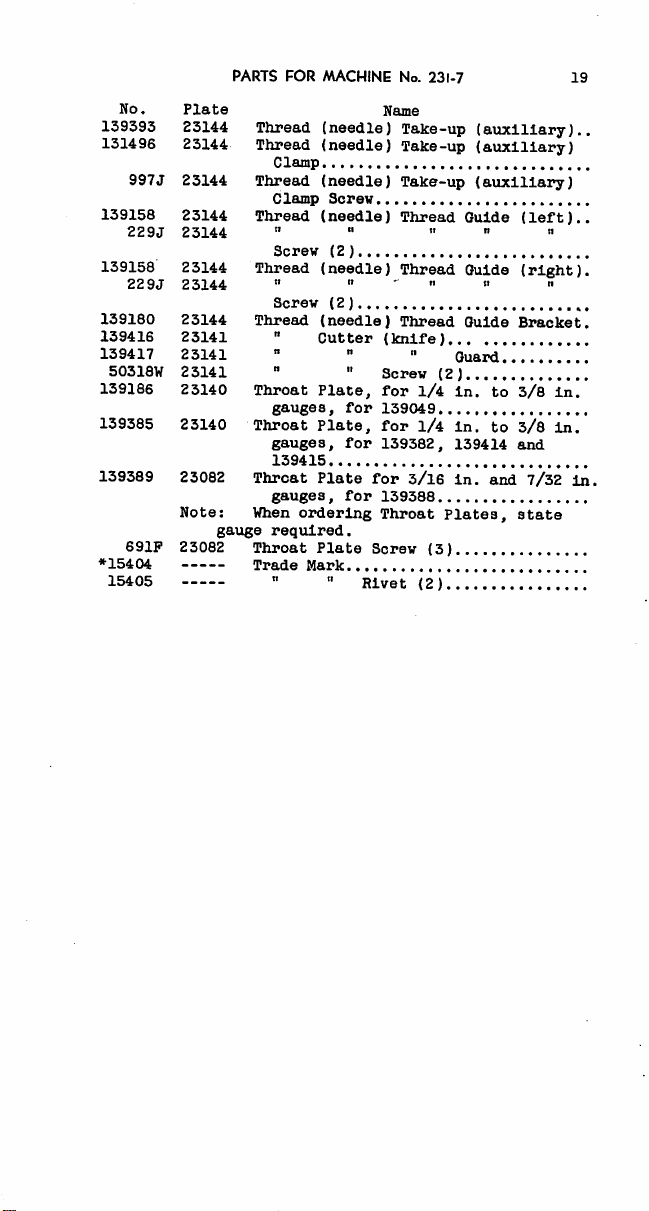

20

FOR

LAP

TROUSERS,

FABRICS.

THE

LOOPERS,

FROM

3/16"

GAUGES

6 TO18TO THE

SPEED

ARE

3600.

A^ACHINE No. 231-8

SEAM

FELLING

ETC.OFMEDIUM

MACHINE

TWO-THREAD

WORK

AND

HAS

TWO

CHAIN

SHIRTS,

STITCH.

TO3/8",INSTEPSOF1/32".

3/16",

1/4"

AND

5/16".

LENGTHOFSTITCH

INCH.

NEEDLE

BAR

OVERALLS,

MEDIUM

NEEDLES,

GAUGES

THE

STANDARD

STROKE

HEAVY

TWO

I 5/16".

No.

139374

139375

139376

139418

139377

139378

139379

1259AL

139412

Note:

Plate

23137

23139

23142

Note:

23142

23137

23142

This

Machine,

Am

Am

Arm

Balance

Needle

Needle

When

required.

Needle

Needle

Needle

Machine

with

Rotary

and

139376,

Rotary

1259AL

139199

Rotary

139103,

51283AL,

Bar

Bar

139377,

ordering

Bar

139101

Bar

set

Screw

Bar

is

the

the

following

Name

Shaft

139283

in

place

Shaft

and

in

Wheel,3in.

in

Crank

two

1149AL,

Shaft

Crank

place

in

place

(hollow)

complete,

place

No.

Bushing

Connecting

(short)

Guide,

same

of

pulley,

of

in

Nds.

of

139378

(lower)

in

place

as

exceptions;

with

of

139284

with

in

139375

139228

139483

place

139116

139100

state

Link

the

231-7

139308

1036AL,

place

with

with

of

gauge

in

place

Hinge

of

139113...

of

two

139099.

and

of

Stud

Page 20

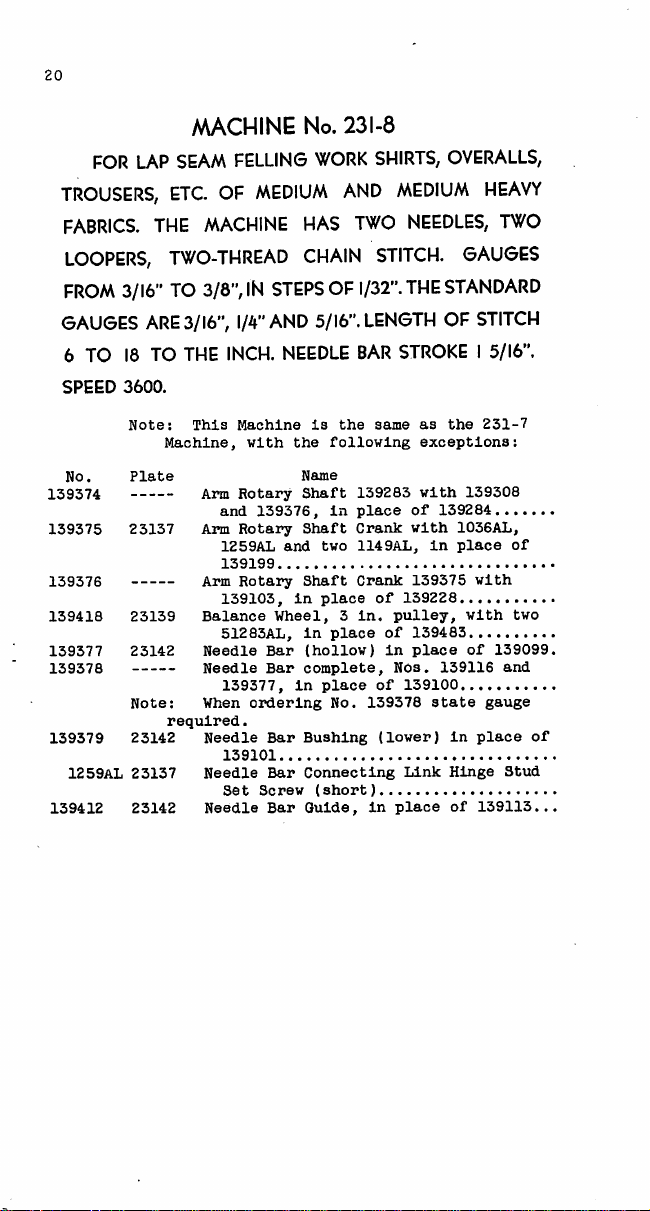

ACCESSORIES

21

No.

120344

Plate

23086

Oiler

120345 23086 "

120440

121108

120341

23535

139477

139478

139481

152004

146R

23086

23086

23086

23086

23145

23146

23145

23145

23145

Screw

Tweezers

Wrench

Belt

Belt

Belt

Belt

Belt

(copper

Spout,4l/2

Driver

" "

BELT

Bed

Applications

mounting

Universal

231-7

Bed

applications

mounting

Universal

231-6

No.9R.H.,

sion

Universal

Machine

No.

and

Stand

Extension

(2)

(curved)

GUARDS

Guard

Extension

Machine

Guard

Extension

Machine

Guard

No.

Guard

10

R.H.

S69

No.

Guard

Name

(large)

(small)

with

of

Safety

with

of

Safety

with

139476,

Safety

is

set

with

Electric

46976,

No.

Screw,

plated)

two

No.

except

the

two

No.

except

the

two wood

for

at

two

for

139337

with

in.

long

146R,

139476,

for

Machine

Power

146R,

139476,

for

Machine

Power

use

with

for

use

Power

an

oblique

wood

Series

Transmitters,

for

use

for

139477

120345.

for

for

oblique

on

Tables,

for

for

oblique

on

Tables

screws

Bed

on

Tables

screws

S39,

with

use

Singer

use

Singer

Exten

Singer

angle...

S49,

and

with

all

for

with

all

for

3/4

when

1

in.

for

Bed

139478

in.

S59

Page 21

22

No.

6439

4879

56864

56865

150212

150487

1402

15C

150488

150489

140215C

46681

60502

150216

445C

150490

150491

FOOT

Plate

23123

Note:

23123

23123

23123

23123

23123

23123

23123

23123

23123

23123

23123

23123

23123

LIFTER

AND

TREADLE

FOR

INDIVIDUAL

Foot

Lifter

with

When

required.

Foot

Starting

Starting

Starting

Starting

Starting

Starting

Starting

56864

ordering

Lifter

" " "

" " " "

" "

Treadle

" "

" "

" " "

140215C

Treadle

(2)

with

F.H.

Treadle

" " " "

two

wood

(2)

Treadle

445C

Treadle

Screw

(2)

Treadle

and

complete,

150216,

60502

150487

STARTINS

PARTS

MOTORS

Name

Chain,

and

56865

No.

6439,

Chain

Connecting

Hook

Treadle

with

Set

Shaft

Shaft

Shaft

screws

Shaft

Shaft

Spacing

Foot

Lifter

Nos.

4879,

to

36

Screw

150490

in.

state

(large)

(small)

two

Arm

Arm

Bracket

1

Collar

Collar

6439,

to

140215C

(2)

with

Set

in.

Collar

Treadle

and

45

in.,

length

Link

two

Screw

(2)....

46681

No.

with

Set

150212,

two

14

two

No.

27639

69337

2

150208

23250

80223

762

362C

FOOT

Plate

23123

23123

23123

23123

23123

23123

23123

LIFTER

FOR

AND

STARTING

UNIVERSAL

Treadle

3620

Treadle

Screw

Treadle

Washer

Treadle

SAFETY

Pitman

tl

11 II

n II 11 11 II

(2)

Pitman

(2

Pitman

11

)

Pitman

Name

TREADLE

POWER

Rod

tl

tl

Rod

Rod

Rod

(lower)

(upper)

(upper)

(upper)

Clamp

TABLE

"

with

PARTS

Collar

Collar

Spring

361C....

with

Set

Page 22

FOOT

LIFTER AND STARTING TREADLE PARTS

23

No.

361C

69338

150497

FOOT

No.

27639 23089

80223

36IC

60626

150498

No.

135060

135061

135062

135063

Plate

23123

23123

23123

Treadle

Treadle

27639,

2762

Starting

Pitman

150491

Name

Pitman

Pitman

69337,

and

complete,

Rod

complete,

80223,

Foot

Clamp

Lifter

Nos.

150208

69338

LIFTER AND STARTING TREADLE PARTS

FOR

LOW

SHAFT

POWER

TABLE

FOR

UNDER

DRIVER

NO.

150499

Plate

23089

23089

23089

23089

Plate

Treadle

" " "

" " " "Set

Treadle

and

Starting

Pitman

150491

FRONT

Front

wide, 46

1500,

mitters,

Transmitter

Front

wide,

1900

for

Iron

Front

wide,461/2

1700

Universal

Front

wide,

Electric

Transmitter

Name

Pitman

Pitman

two

27639

and

Rod

Rod

Foot

complete,

PLANKS

Name

Plank,15/8

1/2

1900

Plank,15/8

48

and

Electric

legs)

Plank,15/8

Electric

Plank,15/8

48

In.

and

for

Universal

Tables

In.

long,

2900

Electric

Transmitter

In.

Transmitters,

Electric

In.

long,

Transmitters,

Tables

(2)

Clamp

complete,

Lifter

Nos.

In.

long,

2900

In.

In.

long,

In.

60626

thick,

Electric

thick,

for

thick,

Transmitter

thick,

for

(cast

Screw

Nos.

23250,

and

Treadle

with

Treadle

with

and

36IC

Screw.....

Nos.

with

and

19

Series

Trans

19

1500,

In.

In.

for

Electric

Series

Transmitters,

Tables

19

for

In.

Series

for

Tables

19

Electric

Iron

In.

1700

legs)..

Series

for

two

80223

(cast

Page 23

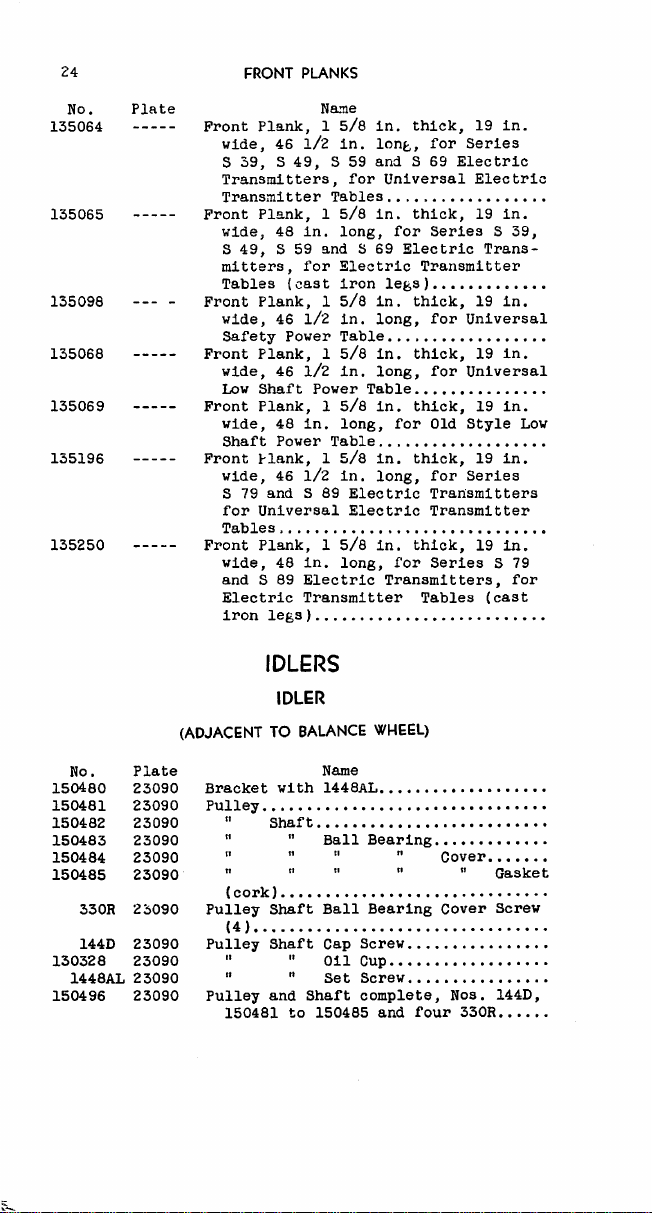

24

FRONT

PLANKS

No.

135064

135065

135098

135068

135069

135196

135250

Plate

Front

Plank,15/8

wide,

S

39,S49,S59

Transmitters,

Transmitter

Front

Plank,15/8

wide,

S

49,S59

mitters,

Tables

Front

Plank,15/8

wide,

Safety

Front

Plank,15/8

wide,

Low

Shaft

Front

Plank,15/8

wide,

Shaft

Front

Plank,15/8

wide,

S79andS89

for

Universal

Tables

Front

Plank,15/8

wide,

andS89

Electric

Iron

(ADJACENTTOBALANCE

46

l/2

48

In.

for

(cast

46

l/2

Power

46

1/2

Power

48

In.

Power

46

1/2

48

In.

Electric

Transmitter

legs)

IDLERS

IDLER

Name

In.

for

Tables

long,

andS69

Electric

Iron

In.

Table

In.

Table

long,

Table

In.

Electric

Electric

long,

WHEEL)

in.

thick,

lonfc,

for

andS69

Universal

In.

thick,

for

Series

Electric

Transmitter

legs)...

In.

thick

long,

for

In.

thick

long,

for

In.

thick

for

Old

In.

thick

long,

for

Transmitters

Transmitter

In.

thick,

for

Series

Transmitters,

Tables

19

Series

Electric

Electric

19

Trans

19

Universal

19

Universal

19

Style

19

Series

19

(cast

In.

In.

S

In.

In.

In.

In.

In.

S 79

39,

Low

for

No.

150480

150481

150482

150483

150484

150485

130328

1448AL

150496

330R

144D

Plate

23090

23090

23090

23090

23090

23090

23090

23090

23090

23090

23090

Bracket

with

Name

1448AL

Pulley

Shaft

" "

" " " "

" " " " "

(cork)

Pulley

(4)

Pulley

" "

" "

Pulley

150481

Shaft

Shaft

and

to

Ball

Ball

Cap

Oil

Set

Shaft

150485

Bearing

Bearing

Screw

Cup

Screw

complete,

and

four

Cover

Cover

Nos.

330R

Gasket

Screw

144D,

Page 24

IDLER

25

No.

150486

51183R

No.

150528

150481

150482

150483

150484

150485

330R

150529

692C

150530

692C

150531

3560

144D

168C

150496

150532

150533

Plate

23090

23090

Idler

Idler

150496

complete,

Screw

and

Name

two

(2)

Nos.

51183R

130328,

IDLER

FOR

UNDER

THE

TABLE

FOR SINGER UNIVERSAL SAFETY POWER TABLE

Plate

23090

23090

23090

23090

23090

23090

Idler

Ba&e

"

Pulley

" "

Idler

Pulley

n ti It ti ti ft

with

Name

(2)

Shai't

Shaft

3560

(2)

Ball

Ball

Bearing

Bearing

Gasket(cork](2}

Idler

23090

23090

23090

23090

23090

23090

23090

23090

23090

23090

23090

23090

Pulley

Screw

Idler

Pulley

168C

Idler

Pulley

Clamping

Idler

Pulley

168C

Idler

Pulley

Clamping

Idler

Pulley

" " " " "

Screw

Idler

Pulley

" " "

Idler

Pulley

144D,

(2)

Idler

complete,

two

150496

1

1/4

Idler

Giiard

No.9R.H.

(8)

and

and

150481

in.

Shaft

Shaft

692C

Shaft

Screw

Shaft

692C

Shaft

Screw

Shaft

Shaft

and

and

No. 12

with

for

to

Shaft

Nos.

three

two

150532

Ball

Bracket

Bracket

Bracket

Bracket

Bracket

Cap

Set

150485

150528

P.H

wood

Bearing

(lower)

(lower)

(upper)

(upper)

Shaft

Screw

Screw

complete,

and

wood

screws

150480,

(2)

(2)

four

to

150531,

screws

(2)

Cover..

Cover

with

with

Set

Nos.

330R

3/4

in.

No.

121628

121629

Plate

23091

23091

LAP

Lap

Lap

Seam

for

Seam

Lower

and

SEAM

medivim

Scroll

medium

FELLERS

Name

Peller

weight

Peller

heavy

(adjustable)

material

on

Shank

and

two

weight

with

662AL

on

for

material

Shank,

Yielding

medium

Page 25

26

LAP

SEAM

FELLERS

No.

121449

1443B

139366

662aL

No.

139190

139191

51069R

51581R

2807

14

No.

150862

150867

150863

6R

Plate

23091

23091

23091

Plate

23086

23086

23086

23086

23086

23086

POWER

Plate

Note:

state

Lap

Seam

" " "

" " "

" " "

MACHINE

Machine

"

rubber)

Machine

51581R

Machine

tl

Washer

Machine

table

TABLE

Power

Table

of

Electric

Nos.

150491

Power

Table

Safety

150497

Power

Table

Low

Shaft

or

139478

When

ordering

Machine

Name

Feller

Clamping

Screw

Slide

Spring

CUSHIONS

Name

Cushion

(rovmd

Mounting

(2)

Mounting

(2)

Mounting

it

(2)

Screw,

(2)

for

ACCESSORIES

Name

Accessories,

Accessories,

Power

Accessories,

Power

and

for

Transmitter

or

Tables,

150486

Nos.

which

139477

Plate..,

(2)

Screw

rubber)

Cushion

Cushion

Cushion

(moulded

Bolt

Bolt

II fl II

mounting

for

139478,

150486

Nos.

for

Tables,

150862

required,

machine

Power

for

139481,

Nos.

or

(2),

(2

)....

with

Nut

all

styles

Tables,

and

Universal

Universal

139477

150863,

(2).

to

and

150364

150365

THREAD

23092

23092

THREAD

UNWINDER

FOR

Base

with

Rod

UNWINDERS

NO.

FOUR

CONES

two

4370.

150370

Page 26

No.

150366

19020

150367

51082R

51581R

150368

150369

150370

437C

164J

178J

Plate

23092

23092

23092

23092

23092

23092

23092

23092

23092

23092

THREAD

Rod

Thread

Set

Screw

Cone

UNWINDER

Name

(2)

Holder

" " "

" " " "

51581R

Thread

Thread

"

"

cones,

150365,

Cone

Holder

"

Steady

Guide

Screw

Unwinder

Nos.

178J,

150367, 150369,

screws11/2

each

164J,

19020,

Screw

Support

Support

Wire

complete,

In.

No.16P.H.

(4)

51082R,

150366

(4)

Washer

Screw

(4)

for

three

and

Screw

Inverted

150364,

27

(4)...

with

Nut..

wood

and

four

150368..

No.

15064

150203

150649

178J

178J

150662

No.

150364

150653

437C

150647

150203

150649

178J

178J

150369

7 2

THREAD

FOR

Plate

3092

23092

23092

23092

23092

23092

Plate

23135

23135

23135

23135

23135

23135

23135

23135

23135

FOR

USE

IN

PLACEOFCONES

USE

WITH

Spool

" "

" "

" " "

" "

Spool

Nos.

150203and

THREAD

Base

Rod

"

Spool

Thread

UNWINDER

WHEN

SPOOLS

THREAD

Rest

with

Cushion

Rod

Set

Rests

178J,

UNWINDER

FOR

FOUR

with

two

Set

Screw

Rest

with

Cushion

Rod

Set

Guide

SPOOL

OF

UNWINDER

Name

178J

Set

Screw

complete

150649

150647

NO.

SPOOLS

Name

437C

(2)

178J

"

Set

Screw

RESTS

ARE

USE

THREAD

NO.

(4)

(felt)

Screw

(4)

(for

and

150695

(4)

(felt)

Screw

(4)

four

150370

(4)

four

(4)

spools)

each

Page 27

28

THREAD

UNWINDER

No.

178J

150695

No.

150366

164J

19020

150367

51082R

515B1R

150368

150696

Plate

23135

23135

THREAD

FOR

FOR

Plate

23135

23135

23135

23135

23135

23135

23135

Thread

Thread

UNWINDER

USE

WHEN

USE

WITH

Thread

Thread

Thread

OBSOLETE

150369,

three

P.H.

CONES

SPOOLS

THREAD

51581R

" "

cones)

each

Name

Guide

Screw

Unwinder

150649, 150653,

wood

screws1l/2

and

four

THREAD

ARE

USEINPLACE

OF

THREAD

UNWINDER

Name

Cone

Holder

Cone

Holder

Steedy

Cone

Holder

Nos.

164J,

51082R,

19020,

PARTS

complete,

each

150203

CONE

NO.

(4)..

Screw

Support

Support

Wire

complete

150366

HOLDER

150695

"

"

(4)

150367

Nos.

two

in.

and

OF

(4)

Washer

Screw

Screw

and

(for

and

150364,

ITSJ,

No.

150647

(4)...

150368

16

with

Nut..

four

four

No.

139337

139398

139217

Plate

Bed

Extension,

Belt

Guard

Individual

Power

seded

Belt

Guard

No.9R.H.

sal

Safety

by

139481,

Table

by

Name

use

with

Motors

for

139477,

with

for

Power

not

139476

two

146R,

and

Low

231-7

Machine,

not

two wood

use

interchangeable.

with

Table,

screws

Singer

superseded

interchangeable

for

Shaft

use

with

super

3/4

Univer

in.

Page 28

NUMERICAL

LIST

^5*V-

S '

OF

•

PARTS

Page 29

29

No,

HOC

116E

122

131C

14

4D

146R

14

6R

157J

164

1680

17LH.L

172E

175E

175E

175E

176J

17SJ

178J

178J

178J

190J

190J

190J

202R

202J

202J

Plate

23118

23138

E

23127

23138

23090

23145

23086

23127

J

23092

23090

23143

23127

23127

23141

23143

23144

23120

23092

23092

23092

23097

23082

23144

23136

23144

23120

NUMERICAL

Tension

Crank

Arm

Screw

Looper

Oil

Idler

Belt

Machine

Peed

Thread

Idler

Slack

Looper

Looper

Needle

Thread

Thread

Thread

Thread

Thread

Thread

Looper

Presser

Thread

Bed

Thread

Thread

Avoiding

Connection

Cup

139126

Pulley

Guard

and

139478

Table

Lifting

tion

Screw

Unwinder

Screw

Pulley

150529

Thread

Clamping

Holder

Driving

for

139066

Bar

Screw

(looper)

Bracket

(looper)

Screw

(looper)

bed)

Cover

Unwinder

150370

Unwinder

Screw

Unwinder

for

150647

Gate

(needle)

Screw

Rotary

Cover

(looper)

Support

(looper)

bed)

Cover

LIST

Name

(needle

Connecting

(3)

Bracket

Body

Cap

(4)

Shaft

Screw,

(2)

Screw

for

(2)

Eccentric

(2)

for

150370

Shaft

and

150530

Regulator

Screw

(4)

Connecting

for

139108

Screw

Hinge

and

150695

for

150662

(4)

Retaining

Foot

Screw

Shaft

Screw

Screw

Lock

OF

thread)

Link

Eccentric

Retainer

Cap

for

Mounting

Thread

for

Clamping

Arm

Take-up

(2)

Thread

Thread

Thread

Spool

Spool

Eyelet

Ball

(4)

Thread

(lower)

Thread

Spring

PARTS

Releasing

Hinge

Screw

Screw

139398,

Forked

Cone

and

150696

Set

Screw

(2)

Holder

131405

Screw

Connection

Stud

Stripper

Guide

Tube

Plate

Screw

Guide

Rest

and

150695

Rest

Spring

(side

Bearing

Guide

Tube

Forked

(2)

Screw

Machine

Holder

Clamping

(front

Rod

Set

Screw

Screw

for

139477

Connec

(4)

for

Crank

for

Cap

Bracket

(2)

Screw

Set

Screw,

Screw

of

(left)

Bracket

(front

Shaft

(2)

for

150496

to

139093

Screw

Plate

of

for

Arm)

of

Page 30

30

NUMERICAL

LISTOFPARTS

No.

202E

203J

203J

206J

207J

207J

217J

217J

219J

22

22

22

22

22

237AL

237J

24

316C

330W

330R

3560

36IC

362C

376J

391J

430C

435AL

435AL

437C

443AL

443AL

Plate

23144

23143

23144

23141

23143

Thread

for

Thread

for

Thread

Seat

Looper

Thread

(needle)

139391

(looper)

139280(

(looper)

Screw

Thread

(looper)

Screw

23144

23127

23143

23143

Thread

Peed

for

Slack

Thread

(needle)

Eccentric

139052

Thread

(looper)

(right)

9J

23144

9J

23144

9J

23120

9J

23144

Thread

Screw

Thread

Screw

Thread

bed)

Thread

(looper)

(looper)

(looper)

Cover

(needle)

Screw

9J

23144

23143

23144

Thread

Screw

Thread

(left)

Thread

(needle)

(looper)

(looper)

Support

OJ

23143

23118

23141

23090

Thread

tor

Tension

Stop

Needle

Idler

(looper)

Thread

Screw

Bar

Pulley

Screw

23090

23089

23123

Idler

Screw

Treadle

8022

Treadle

Pulley

3

Screw

23118

23126

23118

23127

23127

23092

23127

23127

Tension

Pace

Tension

Looper

Screw

Looper

Screw

Thread

150364

Peed

Looper

Plate

Holder

Holder

Unwinder

Bar

Driving

for

Screw

(2)

(2)

(2)

(2)

Screw

Screw

(needle

Thread

for

for

Pitman

Pitman

for

(needle

(lower

(looper

(2)

Hinge

Name

2)

(2)

Guide

139280

Clamping

Regulator

Catch

for

Retainer

Shaft

150498

Shaft

150528

Rod

Rod

2762

Shaft

Shaft

Pin

Arm

Take-up

Take-up

Thread

Take-up

(2)

Eyelet

Take-up

for

Thread

Thread

Thread

Screw

Thread

Thread

Take-up

139280

Thread

(upper)

Take-up

thread)

Guide

Ball

(4)

Bracket

Clamp

(upper)

(2)

thread)

half)

thread)

Bushing

Bushing

Rod

Set