Singer 211W151 Service Manual

Form

(962)

3173W

SERVICE

SINGLE

21tW151

NEEDLE

MANUAL

SINGER'

machine

LOCK

STITCH

This

and

special

of

book

requiring

"A Trodemorit of THESINGER

book

adjustment

fittings.

should

renewal.

THE

MANUFACTURING

contains

of

machine

Illustrations

be

consulted

SINGER

COMPANY

complete

MANUFACTURING

CopyrightC) 1^62 by ThoSmger MonufodurlngCompony

All Righlft

information

andalist

and

when

Copyright Undir Intcrnationol Copyright Union

RtMrv«d

of

parts,

descriptions

ordering

wndtr

Inter-AmtrUon

Copyright

covering

accessories

of

any

part

COMPANY

Union

parts

of

operation

and

in

rear

machine

Printed

In U. S. A.

Machine

precision

alls,

clothes

heavy

Stitch

tical

stitch.

rainwear,

Single

Belt

axis

Safety

and

weight

needle,

Type

driven

clutch,

conditions,

resulting

any

foreign

new

type

self

and

will

has

been

Compound

feed

and

Maximum

Presser

Hinged

Needle

Needle

automatically

ervoir

Bed,

Space

in

20-3/8

at

211W151

stitching

similar

fabrics.

301.

makes

protects

from

matter

safety

re-engage

cleared.

feed,

needle

length

bar

presser

bar

thread

face

right

DESCRIPTION

produces

on

coats,

sports

items

lock

rotary

two

stitch.

sewing

revolutions

adjustable

hook

accidental

clog

clutch

combination

feed.

of

stitch,

lift,

1/4

foot.

stroke,

1-5/16

lubricated

supplied

plate.

inches

of

long,

needle,

outerwear,

of

hook

to

from

strain.

the

hook,

will

disengage

only

after

inch.

by

with

oil

7

10-1/2

high

suits,

medium

Federal

for

suit

damage

of

5

to

inches.

felt

from

inches

speed,

over

work

on

ver

each

sewing

Should

this

area

drop

inch.

pad

res

inches.

to

it

wide

hole

as

shown.

FRONT

Fig.

Hook

bobbin

eration.

tip

machine

set

screw

in

drip

pan

EDGEOFTABLE'

2.

Knee

Lifter,

HOOK

saddle

case

raceway

To

back

A,

control

and

attach

Drip

LUBRICATION

contains

and

Fig.

3.

Pan

and

oil

in

hook

amount

loosen

oil

jar

L

EDGE

^MACHINE

JCUT-OUT

Oil

Jar

pumped

during

of

oil

control

D,

in

OF

Position

to

op

flow,

valve

Maximum

ing

on

visable

maximum

allow

time

Machine

Fasten

even.with

lifter

Assemble

strike

bracket

provide

stud

B

as

presser

hand

lever.

material

to

run

speed

for

pulley

drip

left

it

drip

pan.

necessary

to

stop

foot

speed,

being

a

new

oil

turns

SETTING

pan

end

in

so

that

action

is

Screw

SPEED

4000

stitched.

machine

for

first

to

reach

over

to

table

of

cut-out.

location

lifter

Screw

adjustment.

of

raised

drain

R.

few

UP

shown

rod

slots

knee

enough

pipe

P.

M.,depend

slower

minutes

moving

toward

with

its

Fasten

in

A

in

lifter

C

It

is

parts.

operator.

left

Fig.

does

bracket

Set

stop

as

to

trip

into

ad

than

to

end

knee

not

soon

drain

2.

Fig.

3.

Control

Return

Turn

to

ment

set

instructions

control

left

is

screw

Sawing

Valve

machine

for

less

attained,

A.

Hook

Set

valve

next.

Oil

Screw

oil.

See

to

upright

K

to

After

re-tighten

complete

Fig,

Oil

right

desired

4.

Sewing

Control

Valve

position.

for

more

adjust

control

lubricating

Hook

Screw

oil;

valve

Clea]

arouj

sewi

und

1 1

al

int

and

ot!

ng

hook

er

side

and

of

th

1

out

id

on

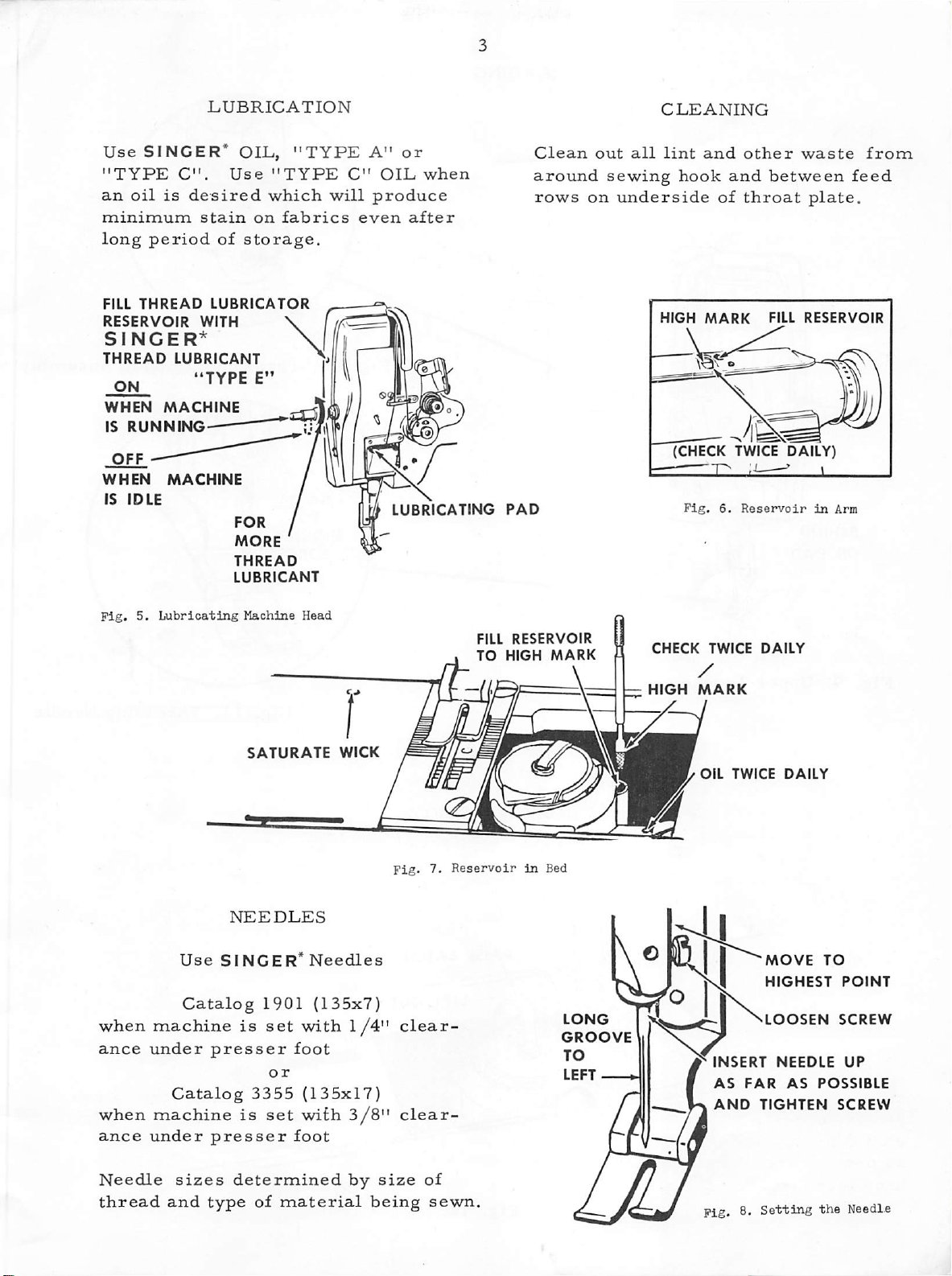

Catalog

achine

der

presser

Catalog

achine

der

presser

is

3355

is

1901

set

foot

or

set

foot

(135x7)

with1/4"

(135x17)

wilh

3/8"

I

clear-

clear-

LONG

GROOVE

TO

LF"

N

EE

AS

G

HI

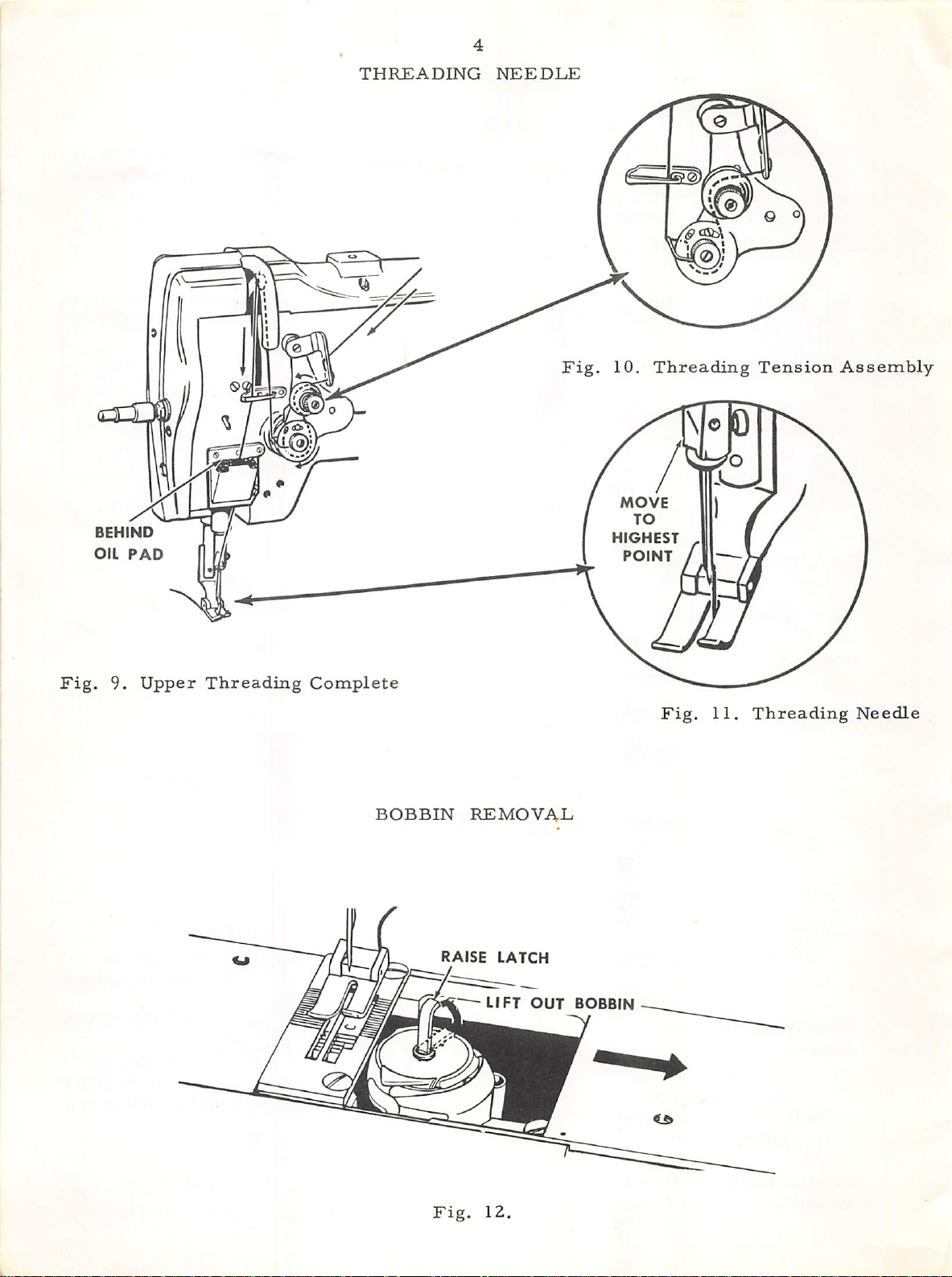

THREADING

NEEDLE

Fig.

BEHIND

OIL

9.

PAD

Upper

Threading

Complete

BOBBIN

REMOVAL

Fig.

10.

MOVE

TO

HIGHEST

POINT

Threading

Fig.

11.

Tension

Threading

Assembly

Needle

RAISE

Fig.

LATCH

LIFT

12.

OUT

BOBBIN

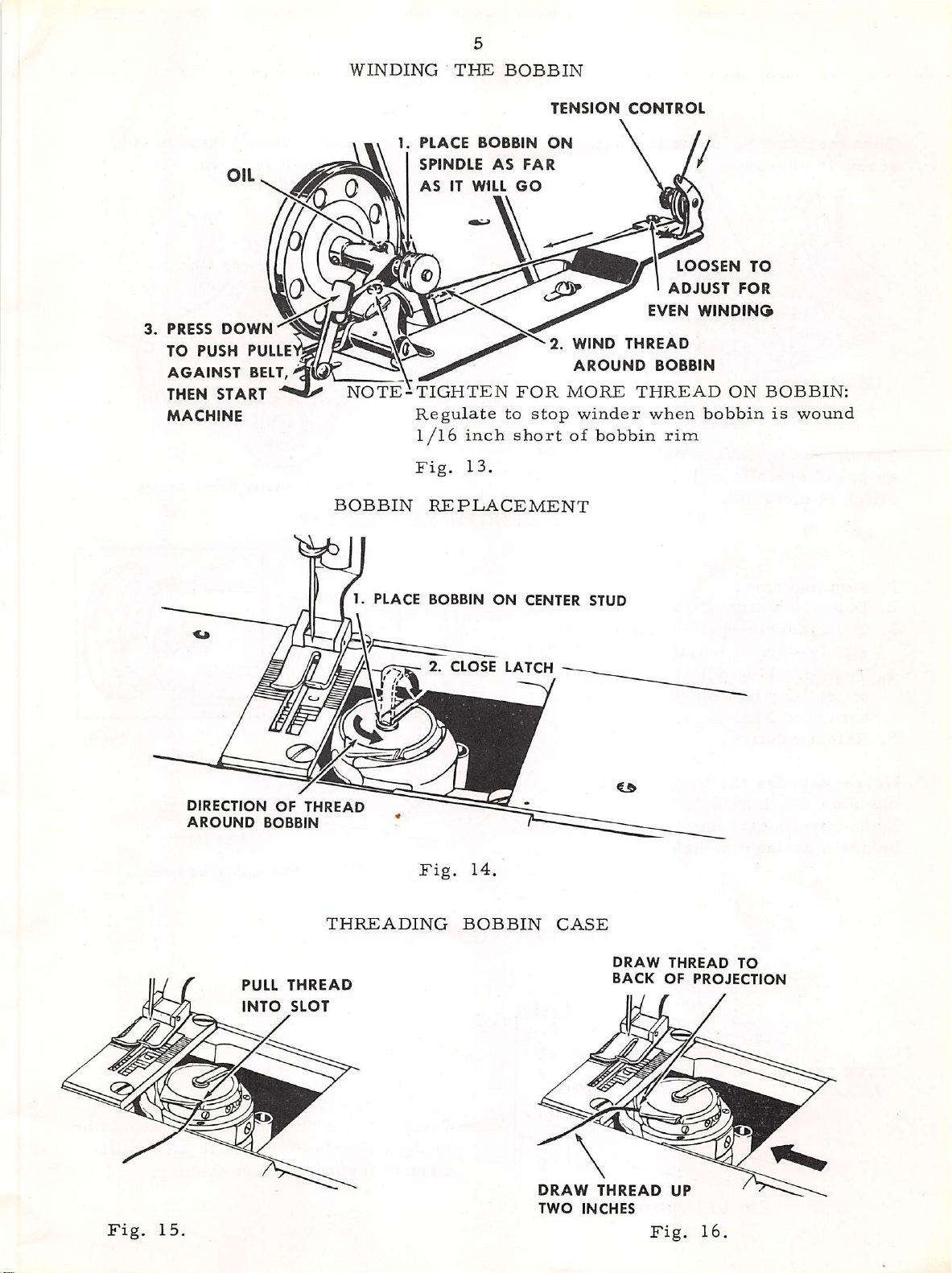

WINDING

THE

BOBBIN

3.

PRESS

TO

AGAINST

THEN

MACHINE

PUSH

START

OIL

DOWN

PULLE

BELT,

1.

NOTE-TIGHTEN

BOBBIN

PLACE

SPINDLE

AS

IT

BOBBIN

AS

WILL

\\

Regulate

1/16

Fig.

inch

13.

REPLACEMENT

FAR

GO

FOR

to

short

TENSION

ON

2.

stop

WIND

AROUND

MORE

winder

of

bobbin

CONTROL

ADJUST

EVEN

THREAD

BOBBIN

THREAD

when

rim

LOOSEN

WINDING

bobbin

ON

TO

FOR

BOBBIN:

is

wound

DIRECTION

AROUND

PULL

INTO

OF

BOBBIN

THREAD

SLOT

1.

THREAD

THREADING

PLACE

BOBBIN

2.

Fig.

CLOSE

14.

BOBBIN

ON

LATCH

CENTER

CASE

STUD

DRAW

BACK

THREAD

OF

PROJECTION

TO

Fig.

DRAW

TWO

15.

THREAD

INCHES

Fig.

UP

16

THREAD

TENSIONS

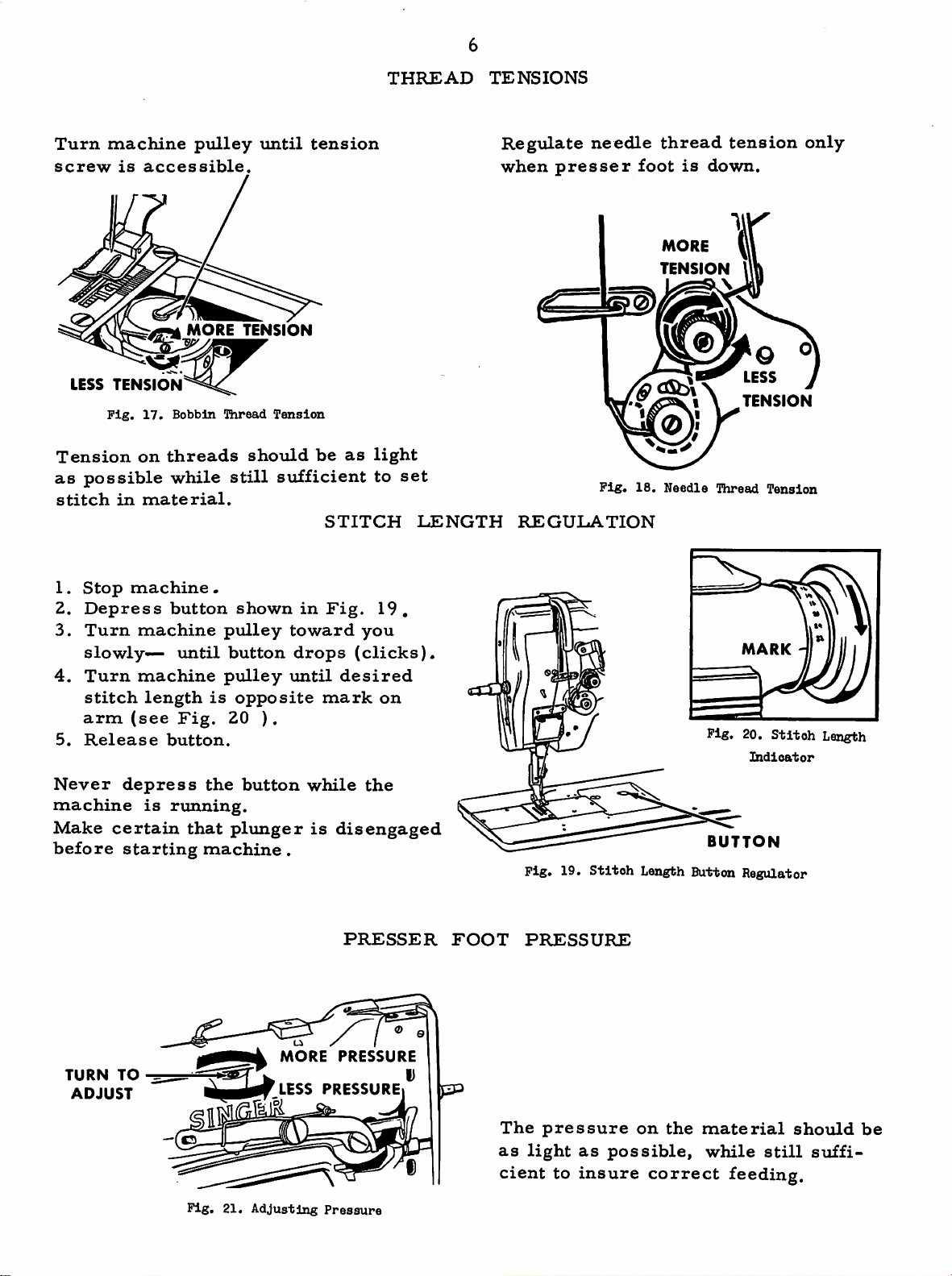

Turn

screw

LESS

Tension

as

possible

stitch

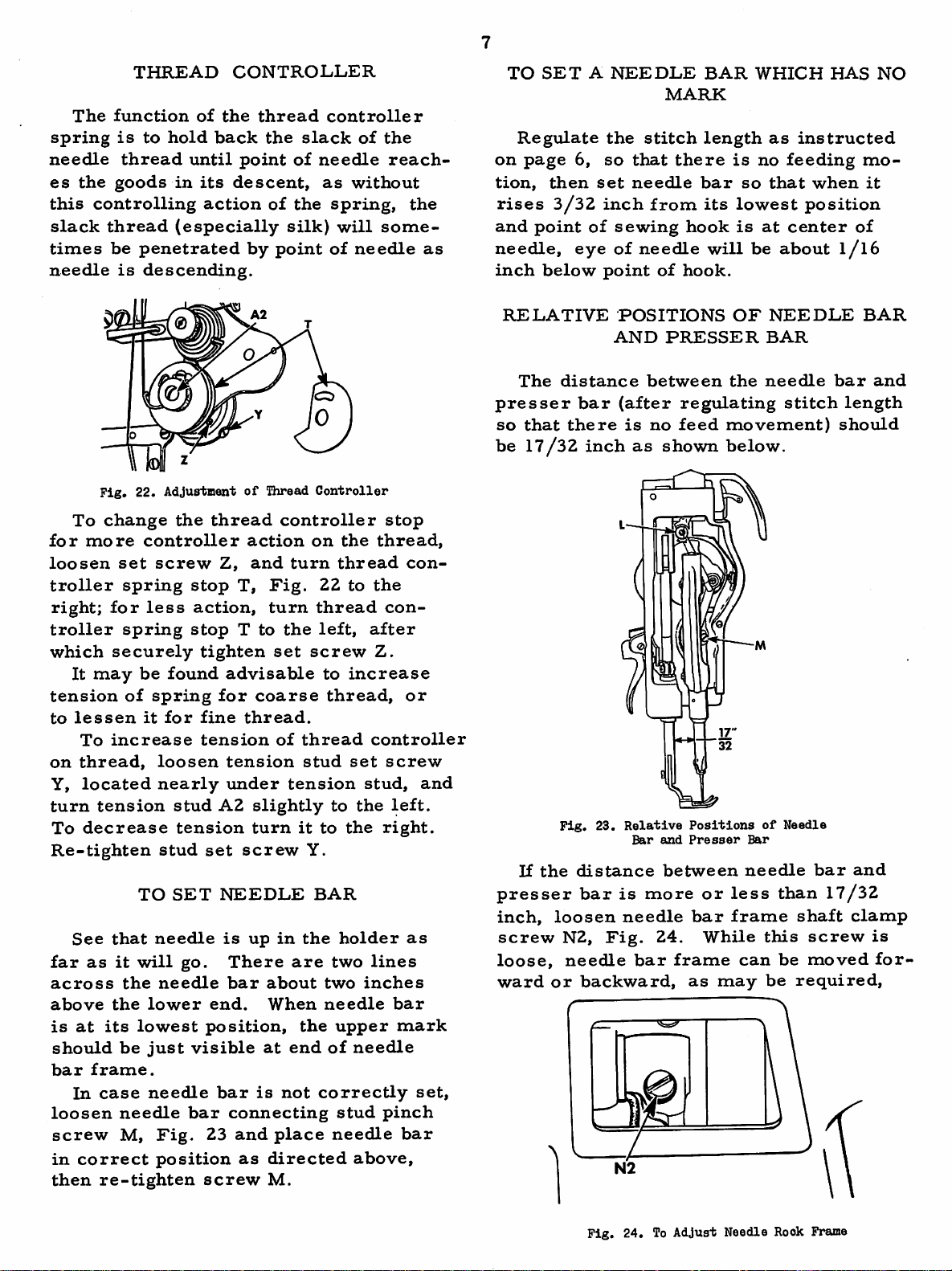

1.

Stop

2.

Depress

3.

Turn

slowly—

4.

Turn

stitch

arm

5.

Release

machine

is

accessible.

TENSION'"^^

Pig.

17.

on

in

material.

machine

pulley

MORE

ww

Bobbin

threads

while

Kiread

still

.

button

machine

machine

length

(see

button.

until

Fig.

pulley

button

pulley

is

20

until

TENSION

Tension

should

sufficient

shown

opposite

),

tension

be

STITCH

in

Fig.

toward

drops

until

mark

as

light

to

19,

you

(clicks).

desired

on

set

LENGTH

Regulate

when

presser

REGULATION

I

needle

Pig.

foot

18.

thread

is

MORE

TENSION

Needle

tension

down.

LESS

TENSION

IHiread

Pig. 20.

Indicator

O o

Tension

Stitch

only

Length

Never

machine

Make

before

TURN

ADJUST

depress

is

certain

starting

TO

the

running.

that

machine.

Pig.

21.

button

plunger

Adjusting

MORE

LESS

while

is

disengaged

PRESSER

PRESSURE

PRESSURE.

Pressure

the

BUTTON

Pig.

19.

Stitch

FOOT

D

PRESSURE

The

as

light

cient

pressure

as

to

insure

Length Button

on

the

possible,

correct

Regulator

material

while

feeding.

still

should

suffi

be

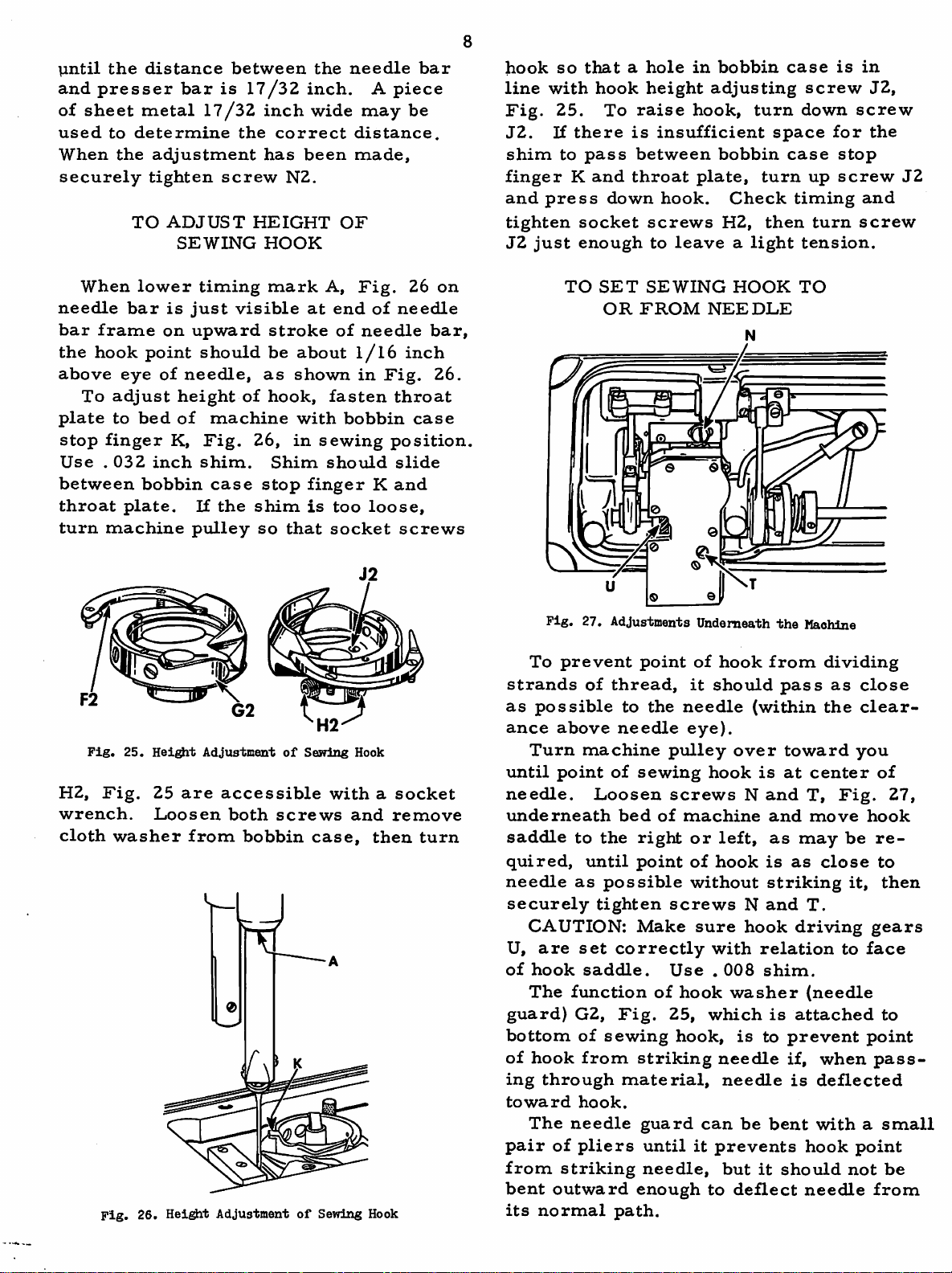

The

spring

needle

es

the

this

slack

times

needle

THREAD

function

is

to

hold

thread

goods

controlling

thread

be

penetrated

is

descending.

CONTROLLER

of

the

back

until

in

its

point

descent,

action

(especially

by

thread

the

of

point

slack

of

the

silk)

controller

of

needle

as

without

spring,

will

of

needle

the

reach

some

the

as

TO

SET

Regulate

on

page

tion,

rises

and

point

needle,

inch

below

then

3/32

A

6,

of

eye

NEEDLE

the

so

set

inch

sewing

of

point

MARK

stitch

that

needle

from

needle

of

length

there

bar

hook

hook.

BAR

its

will

WHICH

as

is

no

so

that

lowest

is

at

be

instructed

feeding

when

position

center

about

HAS

l/l6

NO

mo

it

of

Pig,

To

change

for

more

loosen

troller

right;

for

troller

which

It

securely

may

tension

to

lessen

To

increase

on

thread,

Y,

located

turn

tension

To

decrease

Re-tighten

See

that

far

as

it

across

above

is

at

the

its

should

bar

frame.

In

case

loosen

screw

in

correct

then

re-tighten

22.

AdjustmentofThread

the

controller

set

screw

spring

spring

less

stop

action,

stop

tighten

be

found

of

spring

it

for

fine

tension

loosen

nearly

stud

tension

stud

TO

SET

needle

will

go.

the

needle

lower

lowest

be

just

visible

needle

needle

M,

bar

Fig.

position

screw

thread

action

Z,

and

T,

T

advisable

for

coarse

thread.

tension

under

A2

slightly

turn

set

screw

NEEDLE

is

up

There

bar

end.

position,

bar

is

connecting

23

and

as

controller

turn

Fig.

turn

to

the

set

of

tension

it

in

are

about

When

the

at

end

not

place

directed

M.

Controller

on

thread

22

thread

left,

screw

to

thread,

thread

stud

to

to

Y.

BAR

the

two

two

needle

upper

of

correctly

stud

needle

the

thread,

to

the

after

Z.

increase

controller

set

stud,

the

the

right.

holder

lines

inches

needle

pinch

above,

stop

con

con

or

screw

left.

as

bar

mark

bar

and

set,

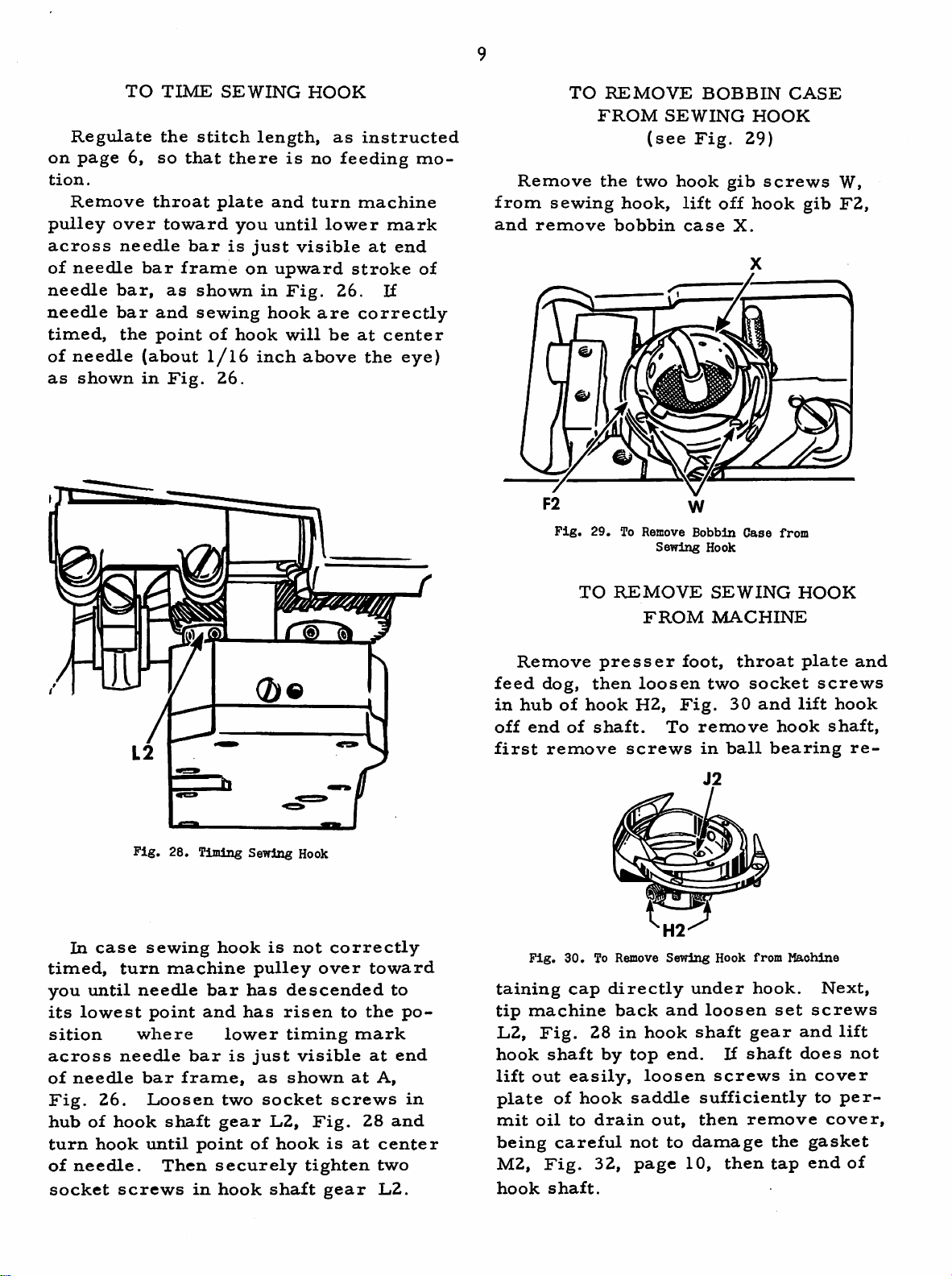

RELATIVE

The

presser

so

that

be

17/32

If

the

presser

inch,

screw

loose,

ward

distance

bar

there

inch

Fig.

distance

bar

loosen

N2,

needle

or

backward,

POSITIONS

AND

(after

is

as

23.

Relative

Bar

is

needle

Fig.

bar

1

PRESSER

between

regulating

no

feed

shown

and

between

more

24.

frame

movement)

below.

Positions

Presser

or

bar

While

as

may

OF

the

Bar

needle

less

frame

can

NEEDLE

BAR

needle

stitch

of

Needle

than

shaft

this

be

be

required.

bar

length

should

bar

17/32

screw

moved

BAR

and

and

clamp

is

for

Pig.

24.ToAdjust

Needle

Rook Frame

Vintil

and

presser

of

sheet

used

When

securely

the

to

determine

the

TO

distance

bar

metal

adjustment

tighten

ADJUST

SEWING

between

is

17/32

the

screw

17/32

inch

correct

has

HEIGHT

HOOK

N2.

the

inch.

wide

been

needle

may

distance.

made,

OF

A

bar

piece

be

hook

line

Fig.

J2.

shim

finger

and

tighten

J2

just

so

with

25.

If

to

press

that

hook

To

there

pass

K

and

down

socket

enough

a

hole

height

raise

is

insufficient

between

throat

hook.

screws

to

in

hook,

plate,

leave

bobbin

adjusting

turn

bobbin

turn

Check

H2,

then

a

light

case

down

space

case

timing

tension.

is

screw

for

stop

up

screw

turn

in

J2,

screw

the

J2

and

screw

When

needle

bar

frame

the

hook

above

To

adjust

plate

stop

Use.032

to

finger

between

throat

turn

machine

Fig.

H2,

Fig.

wrench.

cloth

washer

Fig.

lower

bar

eye

bed

bobbin

plate.

25.

26.

is

on

point

of

height

of

K,

inch

Heigjit

25

Loosen

Hei^t

timing

just

upward

should

needle,

machine

Fig.

shim.

case

If

the

pulley

Adjustment

are

accessible

from

Adjustment

visible

of

26,

shim

so

both

bobbin

mark

stroke

be

as

hook,

Shim

stop

that

of

screws

A,

Fig.

at

end

of

about

shown

1/16

in

fasten

with

bobbin

in

sewing

should

finger

is

too

socket

Seyring

Hook

withasocket

and

case,

of

Sewing

of

needle

Fig.

throat

position.

slide

K

and

loose,

remove

then

Hook

26

needle

bar,

inch

case

screws

turn

on

26.

Fig.

To

prevent

strands

as

possible

ance

above

Turn

until

point

needle.

underneath

saddle

quired,

needle

securely

CAUTION;

U,

are

of

hook

The

guard)

bottom

of

hook

ing

through

toward

The

pair

of

from

bent

its

striking

outward

normal

TO

SET

SEWING

OR

FROM

27. Adjustments Underneath

point

of

thread,

to

the

needle

machine

of

sewing

Loosen

bed

of

to

the

right

until

as

point

possible

tighten

Make

set

correctly

saddle.

function

G2,

of

sewing

from

of

Fig.

striking

NEEDLE

of

hook

it

should

needle

eye).

pulley

hook

screws

machine

or

left,

of

hook

without

screws

sure

with

Use.008

hook

25,

which

hook,

needle

material,

hook.

needle

pliers

guard

until

can

it

prevents

needle,

enough

path.

to

HOOK

N

(within

over

is

N

N

hook

washer

is

needle

be

but

it

deflect

TO

the

Machine

from

pass

toward

at

and

and

as

may

is

as

striking

and

driving

relation

shim.

is

attached

to

prevent

if,

is

bent

hook

should

needle

dividing

as

close

the

clear

you

center

T,

move

close

Fig.

be

it,

of

27,

hook

re

to

then

T.

gears

to

face

(needle

to

point

when

pass

deflected

withasmall

point

not

be

from

Regulate

on

page

tion.

Remove

pulley

across

of

needle

needle

needle

timed,

of

needle

as

shown

TO

6,

over

needle

bar,

bar

the

TIME

the

so

that

throat

toward

bar

frame

as

and

point

(about

in

Fig.

SEWING

stitch

plate

bar

shown

sewing

of

1/I6

26.

there

you

is

just

on

hook

length,

is

and

until

visible

upward

in

Fig.

hook

will

inch

HOOK

as

no

turn

lower

26.

are

be

above

instructed

feeding

machine

mark

at

stroke

If

correctly

at

center

the

end

eye)

mo

of

Remove

from

and

sewing

remove

Fig.

TO

REMOVE

FROM

the

hook,

bobbin

29.

To

(see

two

Remove

Sewing

BOBBIN

SEWING

Fig.

hook

lift

case

Bobbin

Hook

gib

off

X.

HOOK

29)

hook

Case

CASE

screws

from

gib

W,

F2,

In

timed,

you

its

lowest

sition

across

of

needle

Fig.

hub

turn

of

needle.

socket

case

until

26.

of

hook

/

Pig.

sewing

turn

needle

point

where

needle

bar

Loosen

hook

until

screws

28. Timing Sewing Hook

machine

bar

and

bar

frame,

shaft

point

Then

in

hook

gear

securely

hook

has

has

lower

is

two

is

pulley

just

as

socket

L2,

of

hook

shaft

not

descended

risen

timing

visible

shown

correctly

over

to

screws

Fig.

is

tighten

gear

c

toward

the

mark

at

at

28

at

to

po

end

A,

and

center

two

L2.

in

Remove

feed

in

hub

off

end

first

Fig.

taining

tip

machine

L2,

hook

lift

out

plate

mit

being

M2,

hook

dog,

of

of

remove

30.

cap

Fig.

shaft

of

oil

to

careful

Fig.

shaft.

TO

presser

then

hook

shaft.

To Remove

28

by

easily,

hook

drain

32,

REMOVE

FROM

loosen

H2,

screws

directly

back

in

hook

top

loosen

saddle

out,

not

page

SEWING

MACHINE

foot,

two

Fig.

To

remove

in

J2

Sewing

under

and

loosen

shaft

end.

screws

sufficiently

then

to

damage

10,

30

ball

Hook

If

then

throat

socket

and

from

hook.

gear

shaft

remove

HOOK

plate

lift

hook

bearing

Machine

set

screws

and

does

in

to

the

gasket

tap

end

and

screws

hook

shaft,

re-

Next,

lift

not

cover

per

cover,

of

10

CAUTION:

screw

in

position

plate

at

the

seat.

factory.

inganew

that

the

fits

correctly

too

high,

passage

slip

out

bobbin

To

make

washer

socket

hub,

then

appears

bottom

against

with

down

screwdriver

position

screws

To

remove

rest

bearing

of

sheet

ofavise.

moved.

the

of

hook,

bobbin

it

of

and

case

the

in

bottom

screws

turn

beneath

of

bobbin

its

H2,

metal

The

hub

for

the

hook

This

When

care

case

in

the

will

interfere

thread.

cause

when

adjustment,

H2,

hook

one

seat

and

is

attained.

Fig.

ball

with

placed

Tap

shaft

hook

adjusting

relative

position

replacing

must

stop

throat

Ifitis

damage

machine

of

bobbin

Fig.

until

of

case.

turn

until

30

in

bearing

shaft-end

across

until

is

equipped

is

finger

with

to

is

remove

30,

adjusting

the

Hold

adjusting

the

proper

hub

from

bearing

the

to

the

set

toagauge

or

be

taken

K,

plate.

the

too

low,

hook

in

operation.

case,

page9in

holes

hook

Tighten

of

hook.

hook

up

on

the

with

vertical

throat

install

to

Fig.

Ifitis

free

it

and

cloth

loosen

screw

in

the

down

screw

up

socket

two

open

is

see

may

hook

and

shaft,

pieces

jaws

re

a

31

Pig.

31,

Adjusting

Bobbin

Case

D2

Opraier

C2

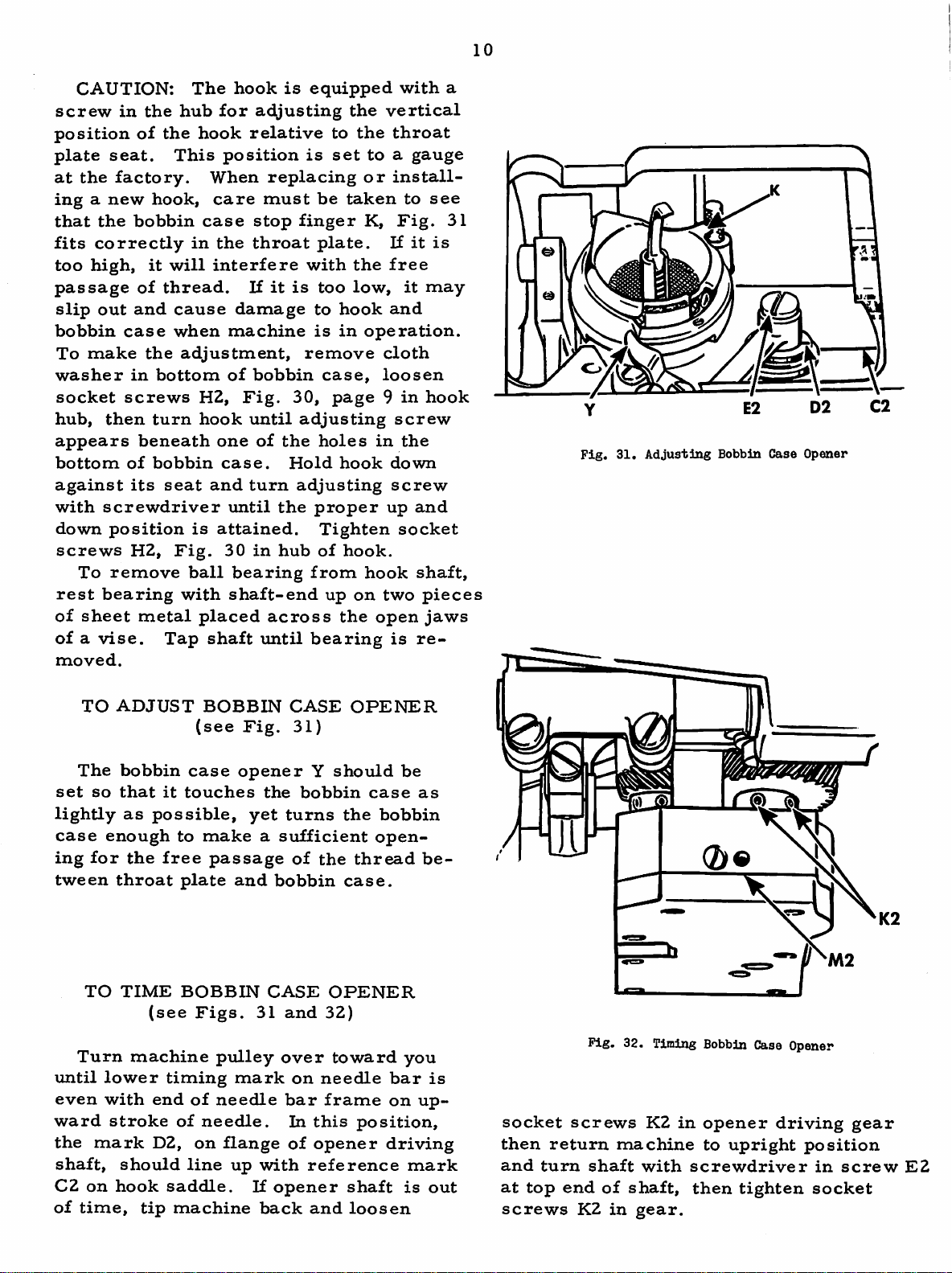

TO

The

set

lightly

case

ing

for

tween

TO

Turn

until

even

ward

the

shaft,

C2

on

of

time,

ADJUST

bobbin

so

that

enough

throat

TIME

lower

with

stroke

mark

should

hook

it

as

possible,

the

free

(see

machine

timing

end

D2,

saddle.

tip

BOBBIN

(see

case

touches

to

make

passage

plate

BOBBIN

Figs.

pulley

of

needle

of

needle.

on

flange

line

machine

Fig.

opener

the

yet

a

and

31

mark

up

with

If

back

CASE

31)

Y

bobbin

turns

sufficient

of

bobbin

CASE

and

over

on

bar

In

this

of

reference

opener

and

OPENER

should

the

the

thread

case.

OPENER

32)

toward

needle

frame

opener

shaft

loosen

be

case

bobbin

open

you

bar

on

position,

driving

mark

is

as

be

up

is

out

socket

then

and

at

top

screws

return

turn

end

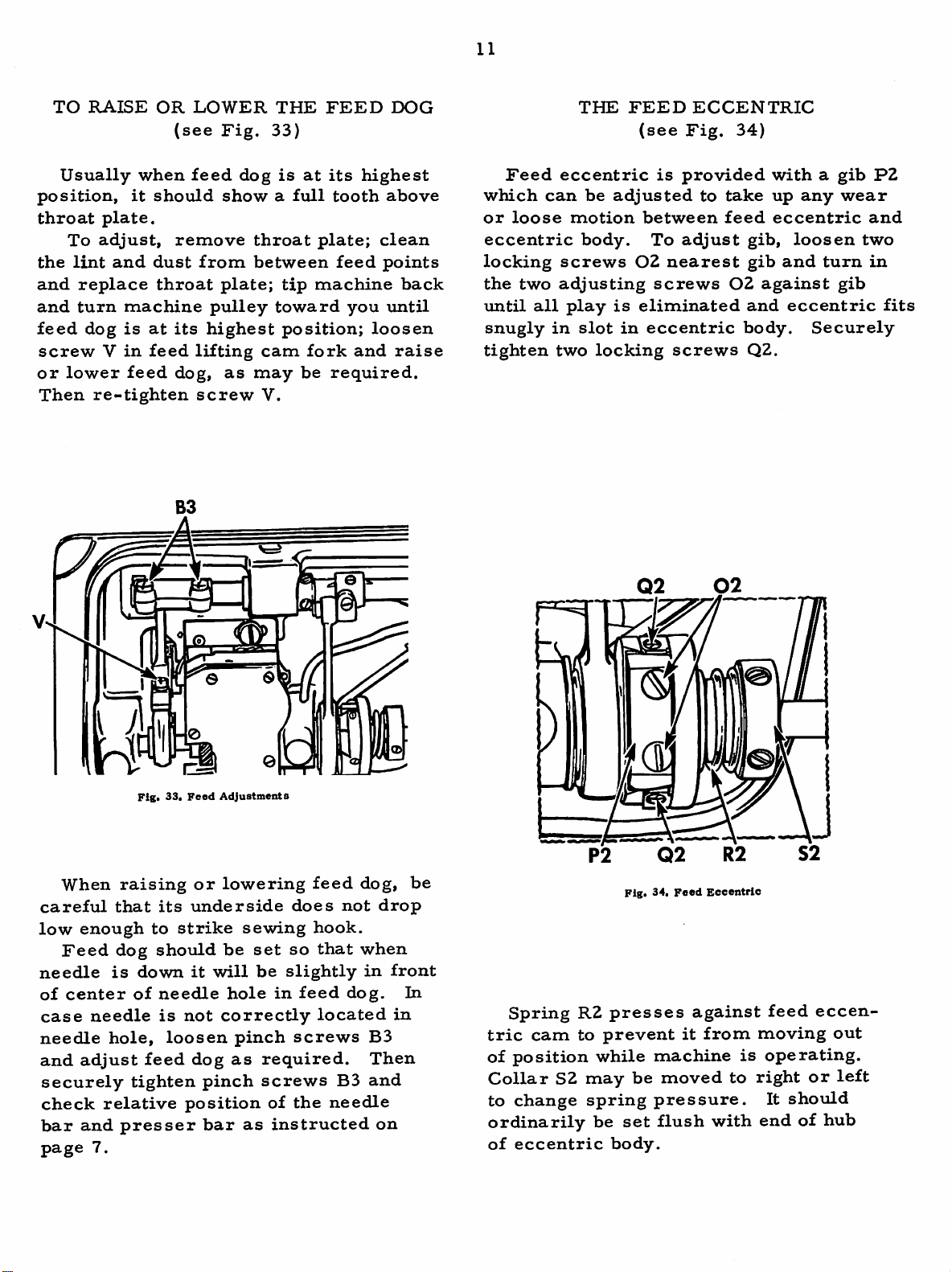

Pig.

screws

shaft

of

K2

32. Timing Bobbin Case Opener

K2

in

machine

with

shaft,

in

gear.

opener

to

upright

screwdriver

then

driving

tighten

gear

position

in

screw

socket

E2

TO

RAISE

OR

LOWER

(see

Fig.

THE

33)

FEED

DOG

11

THE

FEED

(see

ECCENTRIC

Fig.

34)

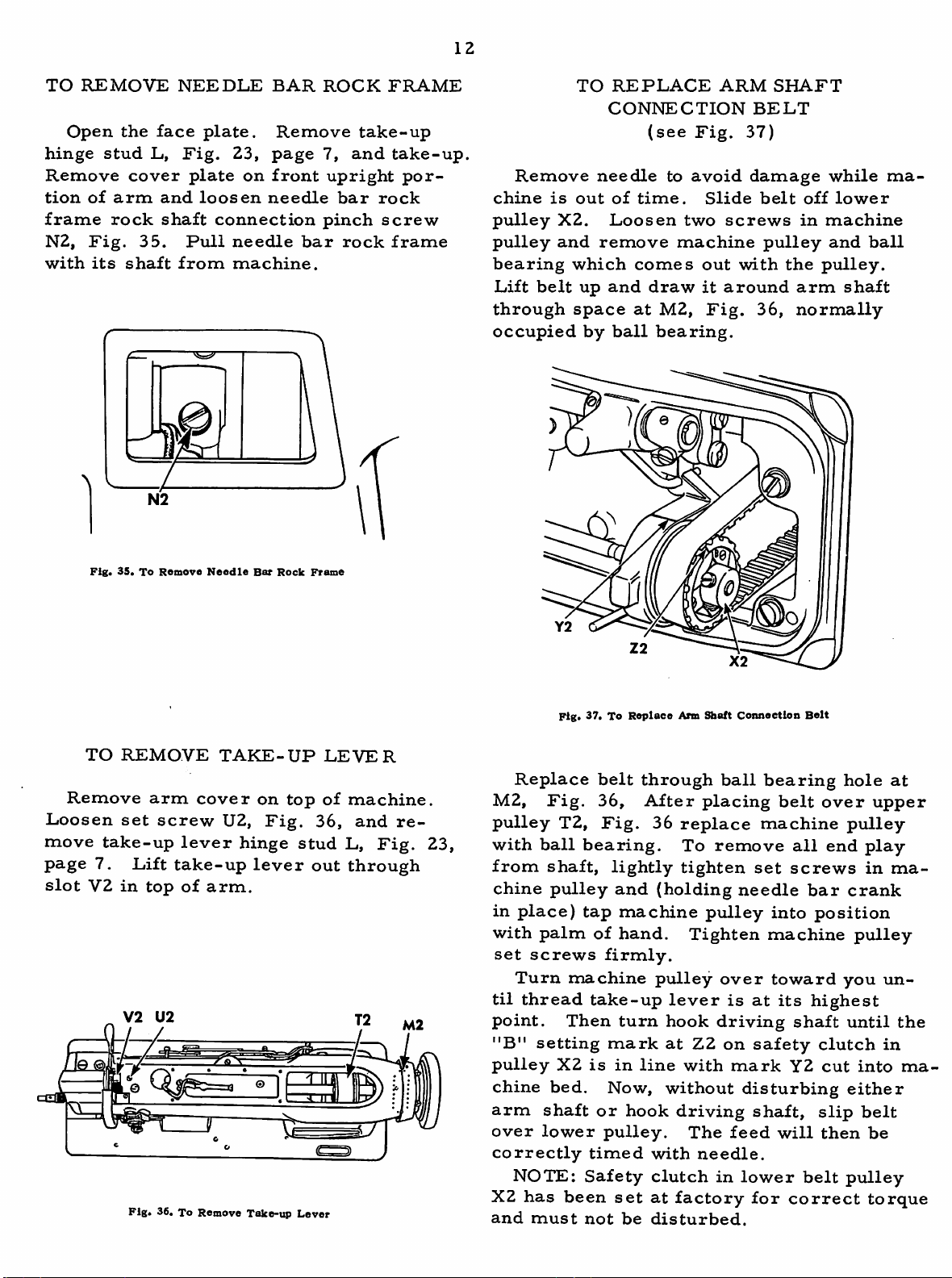

Usually

position,

throat

To

the

lint

and

replace

and

turn

feed

dog

screw

or

lower

Then

when

it

should

plate.

adjust,

and

dust

throat

machine

is

at

V

in

feed

feed

re-tighten

feed

remove

from

pulley

its

highest

lifting

dog,

screw

dog

is

showafull

throat

between

plate;

tip

toward

position;

cam

as

may

be

V.

at

its

tooth

plate;

feed

machine

fork

required.

highest

you

loosen

and

above

clean

points

back

until

raise

Feed

which

or

loose

eccentric

locking

the

two

until

all

snugly

tighten

eccentric

can

be

motion

body.

screws

adjusting

play

in

slot

two

adjusted

02

is

in

locking

Q2

is

provided

to

between

To

adjust

nearest

screws

eliminated

eccentric

screws

02

take

feed

gib,

gib

02

and

body.

Q2.

withagib

up

any

eccentric

loosen

and

turn

against

eccentric

Securely

P2

wear

and

two

in

gib

fits

When

careful

low

enough

Feed

needle

of

center

case

needle

and

needle

adjust

securely

check

bar

and

page

raising

that

dog

is

hole,

relative

presser

7.

Fig.

33.

its

to

should

down

of

needle

is

loosen

feed

tighten

Feed

Adjustments

or

lowering

underside

strike

it

will

not

correctly

dog

pinch

position

bar

sewing

be

hole

pinch

as

as

does

set

so

be

slightly

in

feed

screws

required.

screws

of

the

instructed

feed

not

hook.

that

dog.

located

B3

needle

dog,

drop

when

in

B3

Then

and

on

be

front

In

in

Spring

tric

cam

of

position

Collar

to

change

ordinarily

of

eccentric

52

P2

R2

presses

to

prevent

while

may

spring

be

body.

"Si

Q2

Flg>

34,

machine

be

pressure.

set

flush

Feed

against

it

from

moved

M

R2

Eccentric

is

to

with

S2

feed

moving

eccen

operating.

right

end

It

or

should

of

out

left

hub

TO

REMOVE

Open

hinge

Remove

tion

of

frame

N2,

Fig.

with

its

the

stud

arm

rock

L,

cover

35.

shaft

1

NEEDLE

face

and

shaft

from

plate.

Fig.

plate

loosen

connection

Pull

BAR

23,

page

on

front

needle

needle

machine.

ROCK

Remove

7,

pinch

bar

take-up

and

upright

bar

rock

FRAME

take-up.

por

rock

screw

frame

12

Remove

chine

pulley

pulley

bearing

Lift

belt

through

occupied

is

X2.

and

TO

REPLACE

CONNECTION

needle

out

of

Loosen

remove

which

up

and

space

by

ball

(see

to

time.

comes

draw

at

M2,

bearing.

ARM

Fig.

avoid

Slide

two

screws

machine

out

it

around

Fig.

SHAFT

BELT

37)

damage

belt

pulley

with

36,

while

off

in

machine

and

the

pulley.

arm

normally

ma

lower

ball

shaft

TO

Remove

Loosen

move

page

slot

V2

Fig.

35.ToRemove

REMOVE

set

take-up

7.

in

V2

Fig.

arm

screw

Lift

take-up

top

U2

36.ToRemove

Needle

cover

lever

of

arm.

Bar

TAKE-UP

on

U2,

Fig.

hinge

lever

Take-up

Rock

top

Frame

36,

stud

out

Lever

LEVER

of

machine.

and

L,

through

Fig.

re

23,

Replace

M2,

pulley

with

ball

from

chine

in

place)

with

palm

set

screws

Turn

til

thread

point.

"B"

setting

pulley

chine

arm

over

correctly

lower

NOTE:

X2

has

and

must

Flg« 37.ToReplace

belt

Fig.

T2,

36,

Fig.

bearing.

shaft,

pulley

tap

of

lightly

and

machine

hand.

firmly.

machine

take-up

Then

turn

mark

X2

is

in

bed.

shaft

Now,

or

hook

pulley.

timed

Safety

been

not

set

be

Arm Shaft

through

After

36

replace

To

tighten

(holding

pulley

lever

hook

at

line

with

without

driving

with

clutch

at

factory

disturbed.

Connection

ball

placing

remove

needle

pulley

Tighten

over

is

driving

Z2

on

mark

The

feed

needle.

in

Belt

bearing

belt

machine

all

set

screws

bar

into

position

machine

toward

at

its

highest

shaft

safety

Y2

disturbing

shaft,

will

lower

for

belt

correct

hole

over

pulley

end

crank

you

until

clutch

cut

either

slip

then

pulley

at

upper

play

in

ma

pulley

un

in

into

belt

be

torque

the

ma

13

PARTS

SINGER

2llwl5l

LIST

FOR

MACHINE

Parts

made

list

marked

at

the

opposite

withadiamond

factoary;

illustration.

these

(♦)

parts

(♦)

are

are

furnished

named

at

only

bottom

when

repairs

of

descriptive

are

Loading...

Loading...