SINGER 15-91 User Manual

Form 19721

íftev. €41}

INSTRUCTIONS

SINGER

Electric Sewing Machíne

(Fe G, Buiit-oi. Motorj

' i

i .!

I

i.

( >

M

RE^TRSIBLE FEED

LOCK SXnCH, FOR FAMILY USE

WitiD Renjinis?

Needier O’i.

P.TlS C!

k^pгм: ttiT

Vshi 'Mad ire

Loot for ihe

Red “S”

Tpere ere

Singer Shops in

Every City

•fííE SEKEt MAÍ®FACTüaiSÍ CG.

THE IMPORTANCE OF USING

SINGER LUBRICANTS FOR YOUR

ELECTRIC SEWING MACHINE

“The Best is the Cheapest

>>

Use Singer Oil on Machine

Knowing from many years’ experience

the great importance of using good oil,

we put up an extra quality machine oil,

in cans, especially prepared for sewing

machines.

Use Singer Lubricant on Motor

The Singer Motor Lubricant is especially

prepared for lubricating the gears and

bearings of the electric motor. This is

a pure non-flowing compound which

retains its consistency and possesses high

lubricating qualities.

PRINTED IN U. S. A.

Copyright, U. S. A., 1915, 1920,1921,1923,1924,1926,

1928, 1931,1932,1933,1935,1936,1938,1939,1940 and 1941

by The Singer Manufacturing Co.

All Rights Reserved for all Countries

19721

INSTRUCTIONS FOR USING

SINGER

ELECTRIC SEWING MACHINE

(P. G. Built-on Motor)

15-91

REVERSIBLE FEED

OSCILLATING SHUTTLE, FOR FAMILY USE

Machine 15-91

THE SINGER MANUFACTURING COMPANY

To all whom it may concern;

The placing or renewal of the name

“Singer” (Reg. U. S. Pat, Off,) or any of

the trade marks of The Singer Manufac

turing Company on any machine that has

been repaired, rebuilt, reconditioned, or

altered in any way whatsoever outside a

Singer factory or an authorized Singer

agency is forbidden.

Genuine Singer Needles should be used

in Singer Machines.

These Needles and their Containers

are marked with the

Company’s Trade Mark “SIMANCO.” 1

Needles in Containers marked

“For Singer Machines”

are not Singer made needles.

DESCRIPTION

Machine 15-91,

for family use, has an oscillating

shuttle and makes the lock stitch.

It has reverse feeding mechanism by means of

which the machine stitches as readily in a reverse

direction as it does in a forward direction.

It is especially designed for operation by elec

tricity, having an electric motor built on the back

of its arm. The motor drives the machine through

spiral gears.

It is also equipped with an electric Singerlight.

Before starting to darn or embroider, make the

simple adjustment on the machine, as instructed

on page 33.

SINGER SERVICE

Now that you have purchased your new Singer,

we do not want jn)u to feel that your relations with

us have come to an end. You are cordially invited

to visit your Singer Shop at any time for assistance

in your sewing problems. You will be most welcome.

We hope, too, that you will make the Singer Shop

your headquarters for sewing supplies and service.

Only there or through authorized bonded Singer

representatives can you secure genuine Singer oil,

needles, belts, parts, etc., so important in getting

the best results from your machine. And remember,

Dnly an authorized Singer representative should be

dlowed to touch your machine when repairs or

idjustments are required.

World-wide Singer Service has no equal. Use it!

4

Motor Can be Operated on Either Alternating

Current or Direct Current

The electric motor, which is located at the back

of the machine, can be operated on either alternat

ing current or direct current, as desired. The

standard windings of the motor are for 110 volts,

and motors can be furnished for any voltage be

tween 100 and 250.

Special motors for 32 volts direct current, and

for 50 volts alternating current and direct current,

have also been developed and arc available.

Points to Determine Before Connecting

Motor to Electric Service Line

Obtain the following information from the Elec

tric Light Company which supplies the electric

current for the circuit to which the motor is to

be connected;

1. If current is direct, what is the voltage? The

voltage must be within the range stamped on the

name plate of the motor.

2. If current is alternating, in addition to the

voltage, what is the number of cycles? The number

of cycles must be within the range stamped on the

name plate of the motor.

The voltage of any circuit and, if alternating

current, the number of cycles, can be verified by

looking at the name plate on service watt meter

installed by the local Electric Light Company.

To Connect the Machine to

Electric Service Line

Push the terminal plug at one end of the electric

cord as far as it will go on the three-pin terminal

block at the right of the machine. Attach the plug

at the other end of the cord to the nearest electric

light socket and the machine is ready for operation.

To Insure Perfect Action of the Machine

The balance wheel must always turn over toward

the operator.

Do not run the machine with the presser foot

resting on the feed without cloth under the presser

foot.

Do not mn tlie machine when both bobbin case

and needle a.rc tlii'cadi'd, unless there is material

under the presser foot.

Do not ti’3'- to help the machine by pulling the

fabric, lest you bend the needle. The machine feeds

the work without assistance.

The slide over the bobbin case should be kept

closed when the machine is in operation.

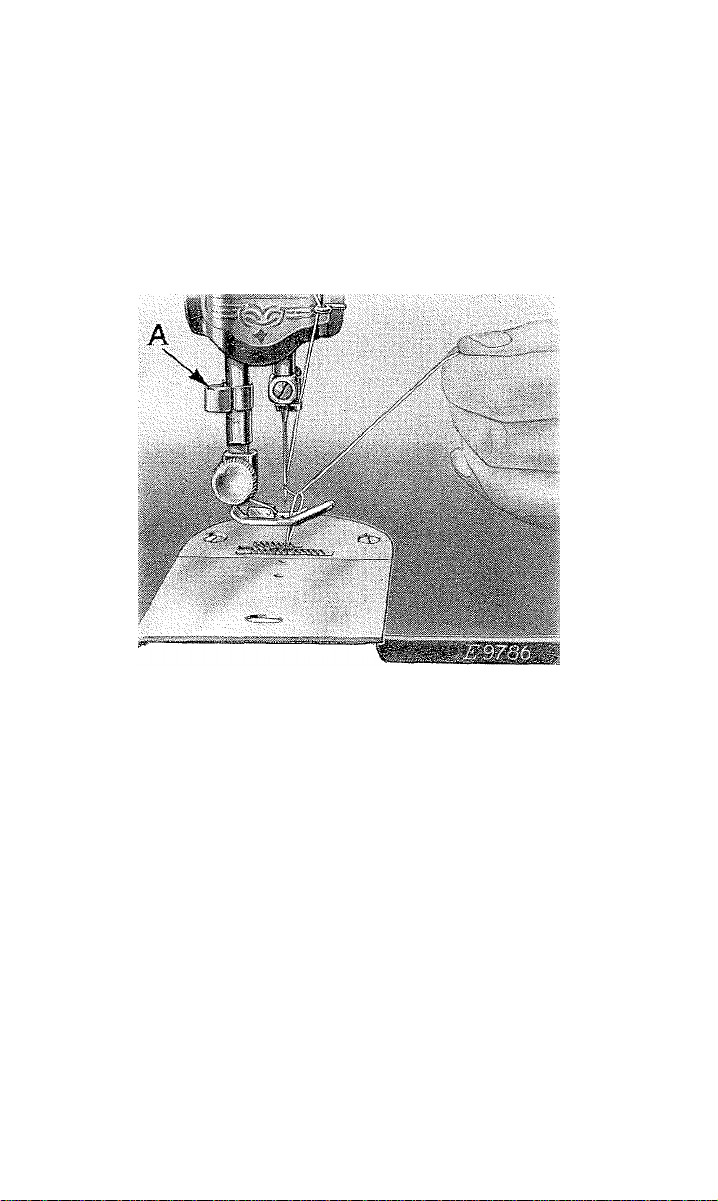

To Turn Singerlight “On” or “Off”

Reach under the machine arm and move the

switch (A, Fig. 2) to the right or left as desired.

CAUTION

When you have finished your sewing, always dis

connect the plug from the electric socket.

6

To Remove and Replace the Bulb

Do not attempt to unscrew the bulb. It is of the

bayonet and socket type and does not unscrew.

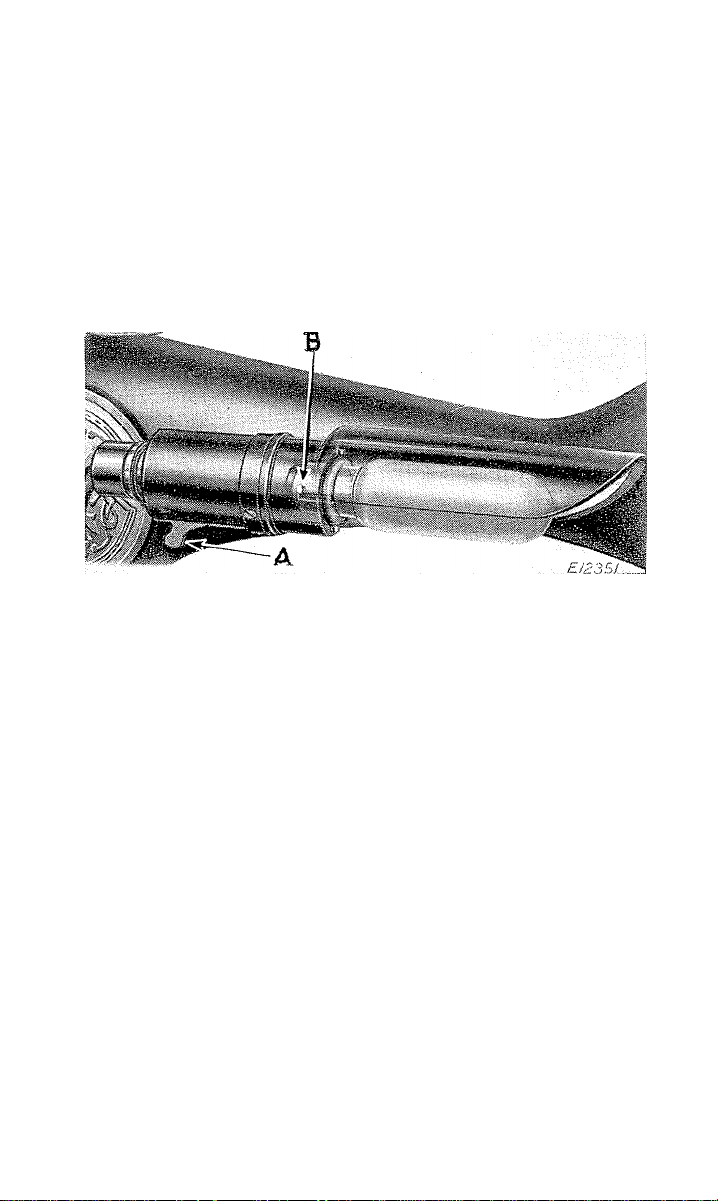

Fig. 2

To remove the bulb. Having turned the shade

slightly, hold the Singeiiight socket with one hand

and with the other hand press the bulb into the.

socket and at the same time turn the bulb over from

the machine as far as it will go, then withdraw

the bulb.

To insert a new bulb. Hold the socket with one

hand and at the same time with the other hand

press the bulb into the socket and turn it over

toward the machine until the bulb pin (B, Fig. 2)

enters the notch in the socket, then return the shade

to its normal position, as shown in Fig. 2.

To Operate the Machine

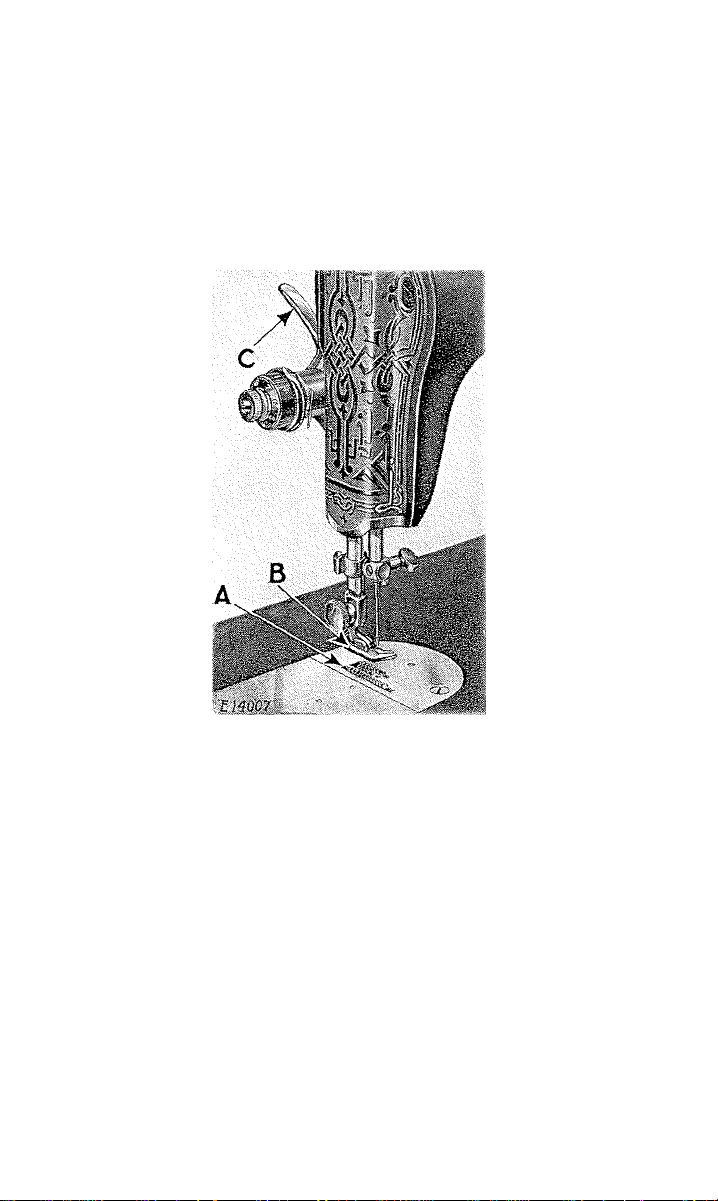

Raise the presser foot (B) by means of the presser

bar lifter (C) to prevent injury to the foot (B) and

feed (A).

Fig. 3. Front View of the ¡Machine

Place a piece of cloth under the presser foot and

let the foot down upon it.

Turn on the electric current and, if the combina

tion knee and foot controller is installed as a knee

controller, press the controller to the right, or, if the

controller is placed on the floor to be used as a foot

controller, press down on the pedal of the controller.

As the pressure on the controller is increased, the

speed of the machine is increased, the speed being

controlled entirely by the amount of pressure on the

controller. Operate the machine in this way, without

being threaded, until you have become accustomed

to guiding the material and operating the controller.

8

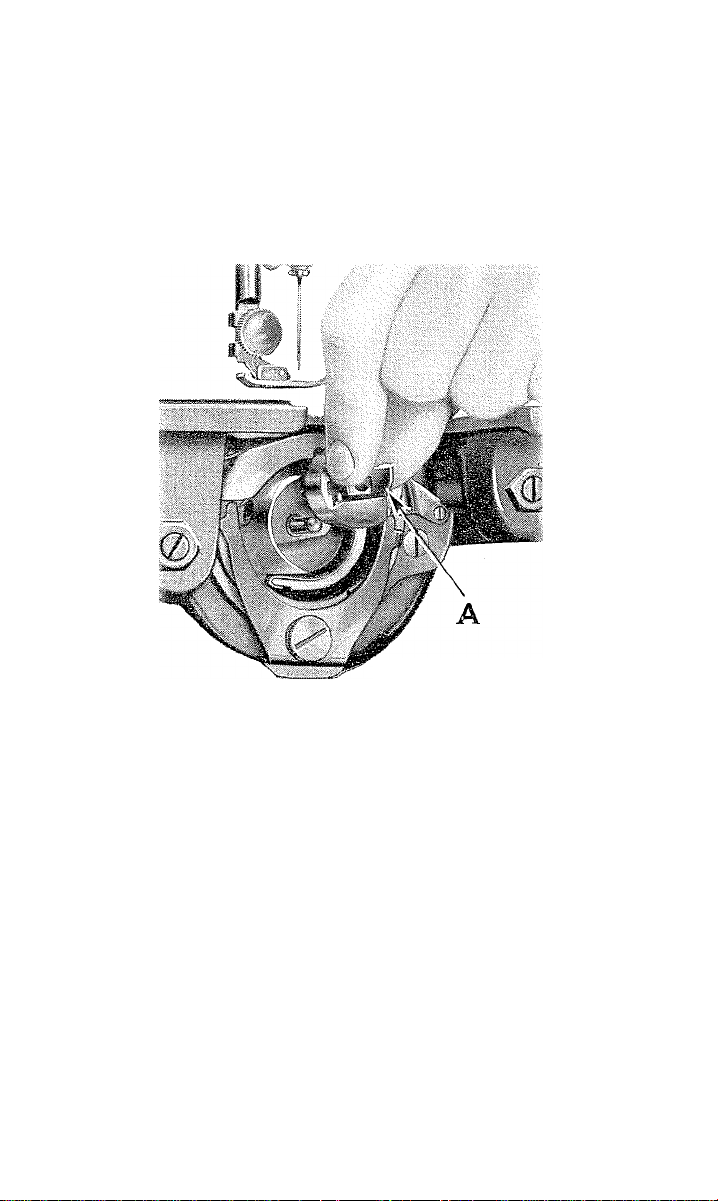

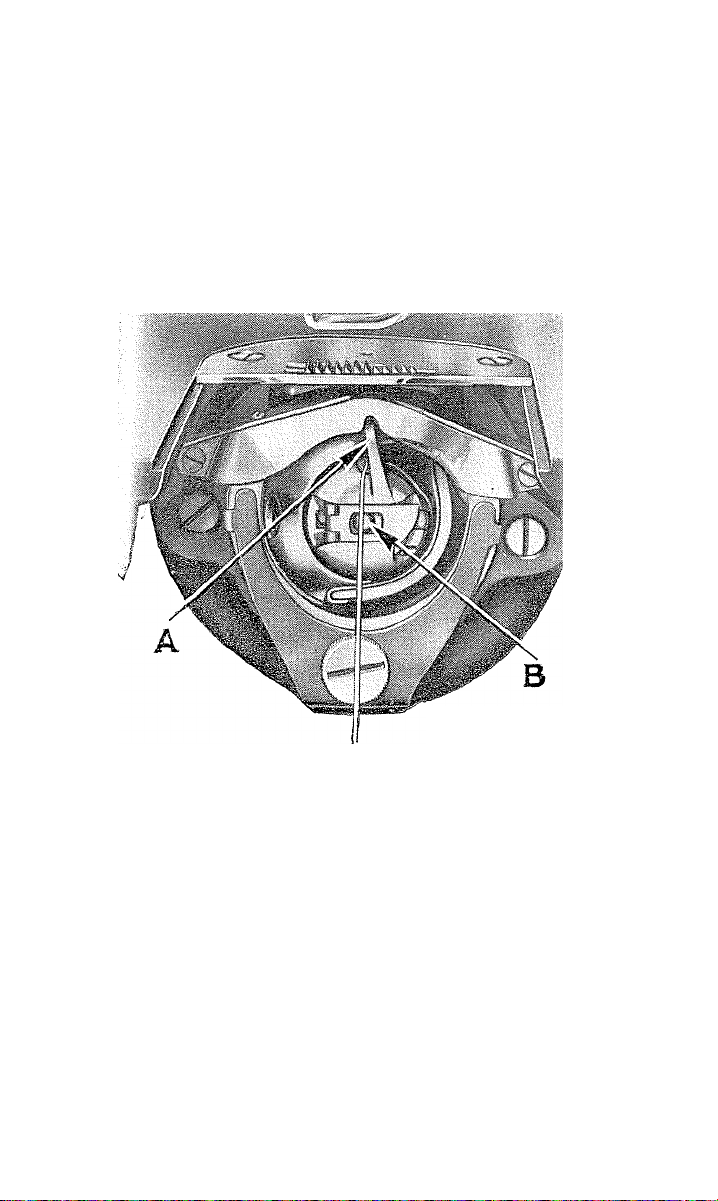

To Remove the Bobbin

Turn the balance wheel over toward you until

the thread take-up lever (5, Fig. 12) is raised to

■ 1781

Fig. 4. Removing the Bobbin Case

its higliest position. Draw to the left the slide in

the bed of the machine. Reach down with the

thumb and forefinger of the left hand, open the bob

bin case latch (A, Fig. 4) and lift out the bobbin

case. While the latch remains open, the bobbin is

retained in the bobbin case. Release the latch, turn

the open end of the bobbin case downward and the

bobbin will drop out.

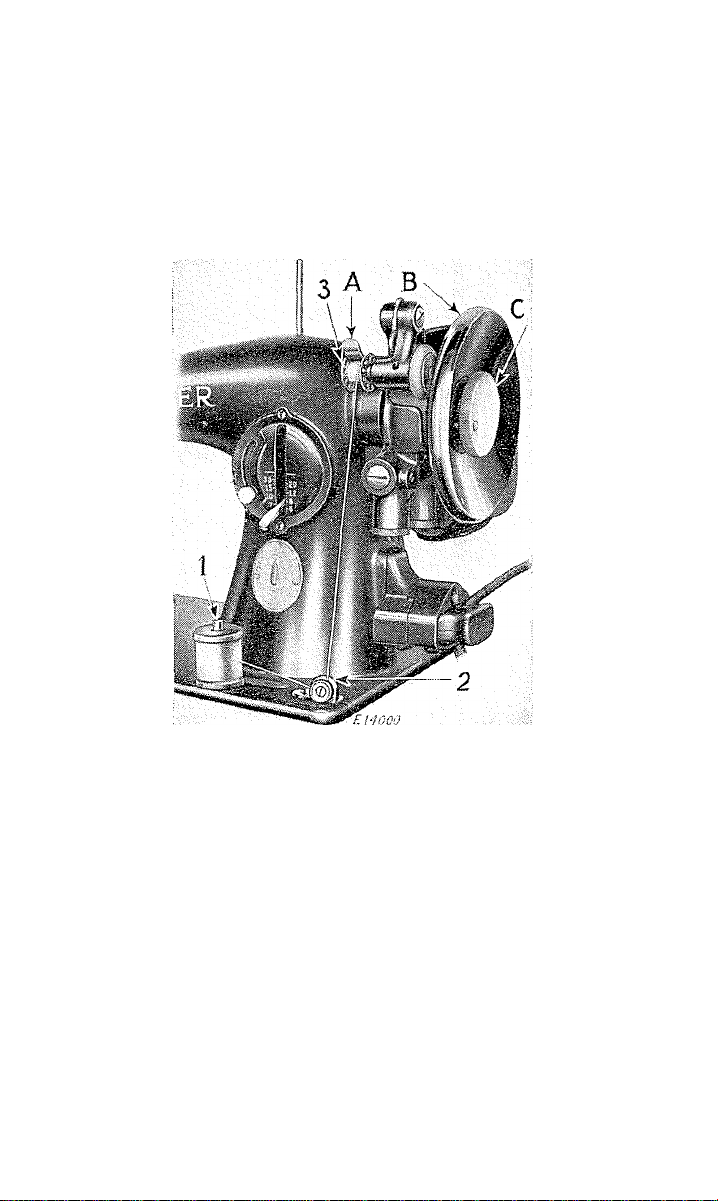

To Wind tbe Bobbin

It is necessar}’^ to understand the stop motion

(C, Fig. 5) by which the balance wheel (B, Fig. 5)

can be released when required, thus permitting the

winding of bobbins without running the stitching

mechanism.

9

Release the balance wheel by turning the stop

motion screw (C) over toward you. It is necessary

to hold the balance wheel while loosening the stop

motion screw.

Fig. 5. Wi.xdi.vg the Bobbin

Place the bobbin on the bobbin winder spindle

and pusli it up closely against the shoulder, having

the small pin in the shoulder enter the hole in the

side of the bobbin. Put the spool of thread on the

spool pin (1). Draw the thread under and between

the tension discs (2) on the bed of the machine,

then pass the thread up and through one of the holes

(3) in the left side of the bobbin, from the inside.

Press down on the bobbin and the bobbin winder

latch (A, Fig. 5) will drop down and hold the bobbin

winder pulley against the hub of the balance wheel.

Then press the knee controller or the foot controller

the same as for sewing.

10

The end of the thread must be held by hand until

a few coils are wound and should then be broken off.

When sufficient thread has been wound upon the

bobbin, the bobbin winder is automatically released

from the balance wheel.

E10P37

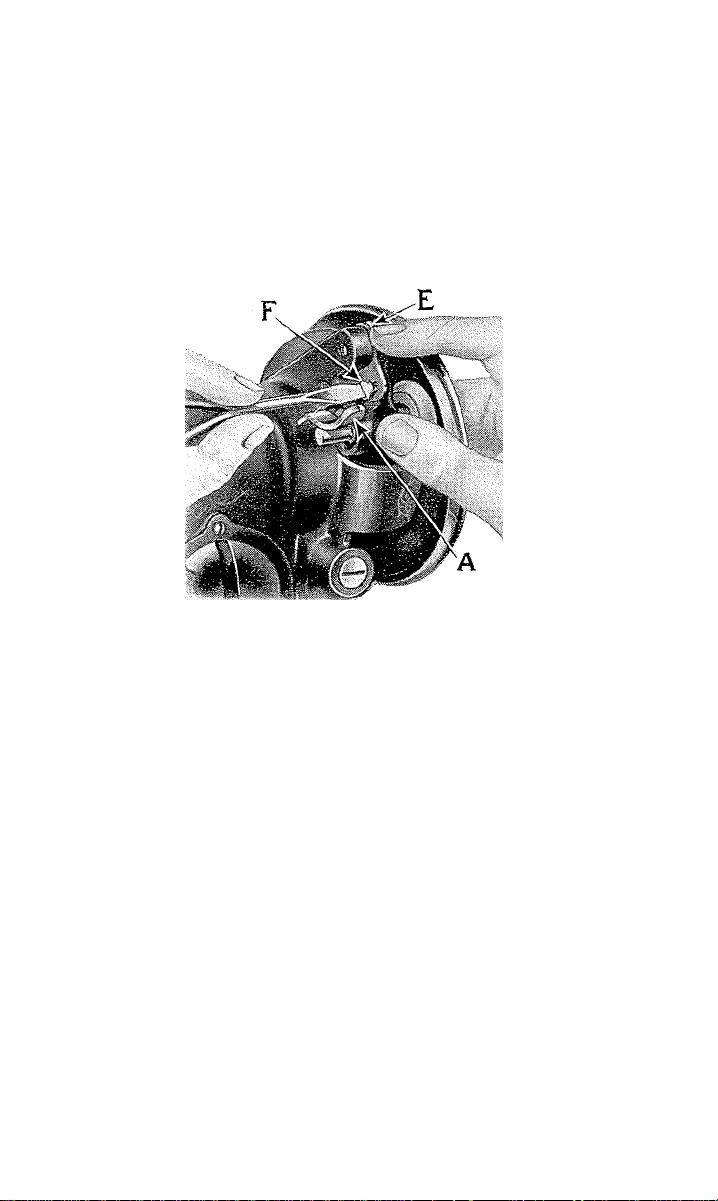

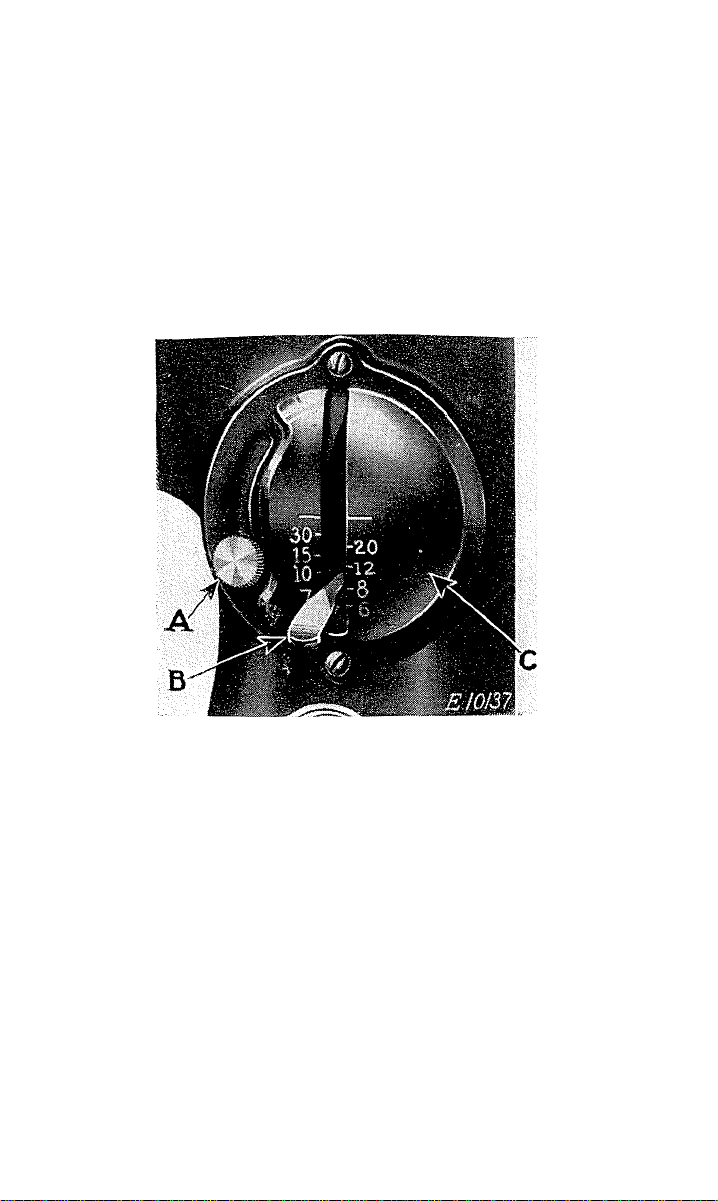

Fig. G. -\djustment of Bobbin Wi.nder

If the pressure of the bobbin winder pulley against

the hub of the balance wheel is insufficient for wind

ing the bobbin, press down the bobbin winder until

the latch (A) drops down and holds it, then loosen

the adjusting screw (F). With the forefinger, push

back the upper end of the slotted plate (E) as far

as it will go, as shown in Fig. 6, and at the same

time press the bobbin winder pulley against the hub

of the balance wheel, then tighten the adjusting

screw (F).

If the thread does not wind evenly on the bobbin,

loosen the screw which holds the tension bracket

(2, Fig. 5) in position on the bed of the machine and

slide the tension bracket to the right or left, as may

be required, then tighten the screw.

Bobbins can also be wound while the machine

is sewing.

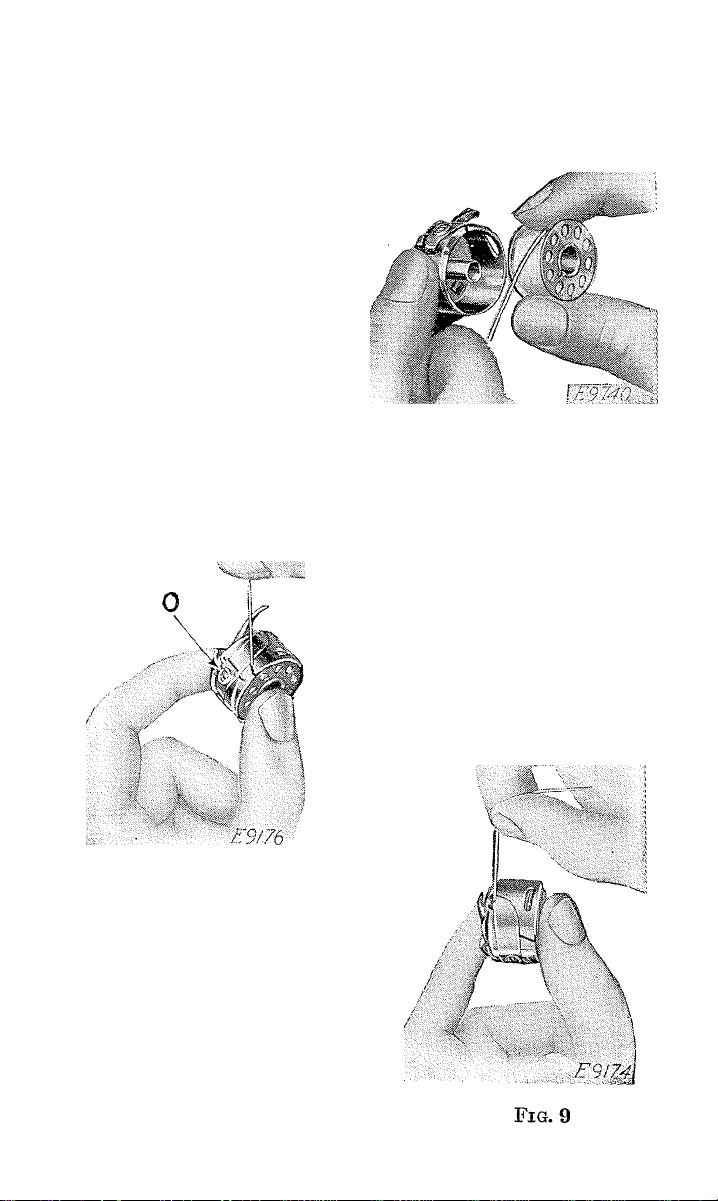

To Thread the Bobbin Case

Hold the bobbin

between the thumb

and for finger of

the right hand, with

the thread on top

drawing from right

to left, as shown in

Fig. 7.

11

Fig. 7

With the left hand

hold the bobbin case as

shown in Fig. 7, the

slot in the edge being

at the top, and place

the bobbin into the

bobbin case.

Fig. 8

Then pull the

thread into the slot

as shown in Fig. 8,

and back under the

tension spring into

the slot at the end

of the tension spring

as shown in Fig. 9.

12

To Replace the Bobbin Case

After threading, take the bobbin case b3^ the

latch, holding it between the thumb and forefinger

Fig. 10. Bobbi-x C.vse Thiie.a.ded and IIeplaced

of the left hand. Place the bobbin case on the center

stud (B, Fig. 10) of the shuttle bodj^ with the posi

tion finger (A, Fig. 10) opposite the notch at the top

of the shuttle race. Release the latch and press the

bobbin case back until the latch catches the groove

near the end of the stud. Allow about three inches

of thread to hang free from the bobbin case and

close the slide in the bed of the machine.

13

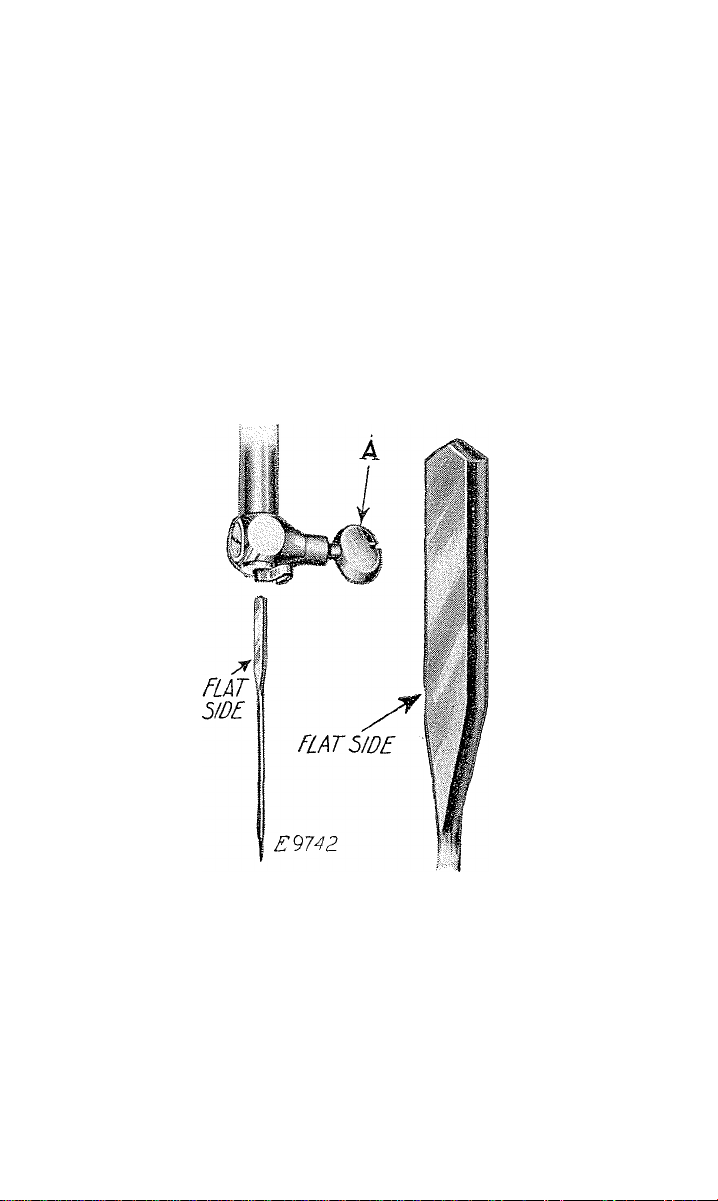

To Set the Needle

Select a needle to suit the size of thread being

used. See inside cover page at back of book.

Turn the balance wheel over toward you until

the needle bar is at its highest position, and loosen

the thumb screw (A, Fig. 11) in the' needle clamp.

Fk5. 11. Positioning of Needle

IN Needle Cl,vmi>

Have the flat side of the shank of the

needle toward the left as shown above and

put the needle up into the clamp as far as

it will go. Then tighten the thumb screw.

14

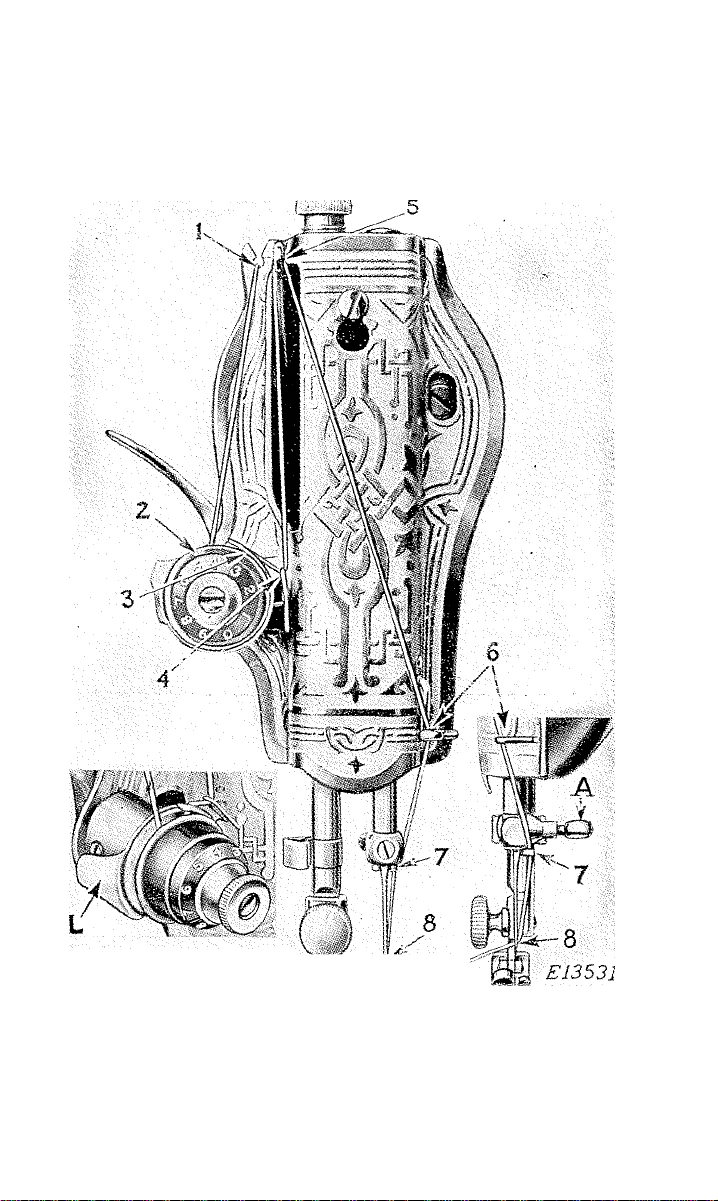

Upper Threading

(See Fig. 12)

Turn the balance wheel over toward you until

the thread take-up lever (5) is raised to its highest

position. Place the spool of thread on the spool pin

at the top of the machine and pass the thread to

the left through the thread guide (1) at the rear of

the face plate, down, under and from back to front

between the tension discs (2), the thread guard (L)

guiding the thread between the discs. (See insert in

Fig. 12). With the right hand hold the spool to pre

vent it from turning, and with the left hand draw the

thread up into the take-up spring (4) until the thread

enters the retaining fork (3), then pass the thread up

and from back to front through the hole in the thread

take-up lever (5), down through the guide (6) on the

face plate, into the guide (7) on the needle clamp and

from

right to left

through the eye (8) of the needle.

Draw about two inches of thread through the eye

of the needle with which to commence sewing.

15

Fig. 12. Upper Thre.^ding

16

To Prepare for Sewing

With the left hand hold the end of the thread,

leaving it slack from the hand to the needle. Turn

Fig. 13. Du-vwing Ur the Bobbin Thkbad

the balance wheel over toward you until the needle

moves down and then up to its highest position,

thus catching the bobbin thread. Draw up the needle

thread and the bobbin thread will come up with it

through the hole in the throat plate, as shown in

Fig. 13. Lay both threads back under the presser

foot.

To Commence Sewing

Place the material beneath the presser foot,

lower the presser foot and commence to sew.

When sewing thick material, it may be necessary

to turn the balance wheel over toward you to start

the machine. This should also be done if the machine

stops when sewing across thick seams.

17

To Remove the Work

Stop the machine with the thread take-up lever

(5, Fig. 12) at its highest position, raise the presser

foot and draw the fabric back and to the left, pass

the threads over the thread cutter (A, Fig. 13) and

pull down lightly to sever them. Leave the ends of

the threads under the presser foot.

To Turn a Corner

Stop the machine when the needle is commencing

its upward stroke. Raise the presser foot and turn

the work as desired, using the needle as a pivot,

then lower the presser foot.

To Regulate the Pressure on the Material

For ordinary family sewing, it is seldom necessary

to change the pressure on the material. If sewing

fine silk or flimsy material, lighten the pressure by

turning the thumb screw (A, Fig. 24) on the top of

the machine over to the left so that it screws up. To

increase the pressure, turn this thumb screw over to

the right so that it screws down. The pressure

should be only heavy enough to prevent the material

from rising with the needle and to enable the feed to

move the work along evenly. The heavier the ma

terial, the heavier the pressure; the lighter the

material, the lighter the pressure.

18

To Regulate the Direction of Feed

To feed the goods

from you,

push down the

stitch regulator lever (B', Fig. 14) as far as it will go.

Fig. 14, Showing TjEver for Reversing Direction

OF Feed and Regudating Length of Stitch

To feed the goods

toward you,

raise the stitch

regulator lever (B) as high as it will go.

The direction of feed can be reversed at any point

of a seam without removing the work from the

machine.

Back tacking is therefore readily accomplished

.and the fastening of the ends of seams is made easy.

19

To Regulate the Length of Stitch

The machine can be adjusted to make from 6 to

30 stitches to the inch as indicated by the numerals

on the stitch indicator plate (C, Fig. 14).

The number of stitches to the inch that the ma

chine is set to make is indicated by the number

which is in line with the upper side of the stitch

regulating lever (B, Fig. 14).

To change the length of stitch, loosen the thumb

screw (A, Fig. 14) and move it to the bottom of the

slot. Then move the stitch regulating lever (B) until

its upper side is in line with the number of the

desired length of stitch. Now move the thumb screw

(A) until the stitch regulating plate touches the

lever (B), then tighten the thumb screw (A).

The machine will now make the indicated number

of stitches to the inch in either a forward or reverse

direction, depending on whether the lever (B) is at

its lowest or highest position.

Basting

The longest stitch made by the machine. No. 6

on the stitch indicator, is found satisfactory for

basting, after loosening the tension on the needle

thread so that the stitches may be easily pulled from

the material.

Machine basting is firmer and more even than

that done by hand in addition to being much (juicker.

To Sew Flannel or Bias Seams

Use a short stitch and as light a tension as possible

on the needle thread so as to leave the thread loose

enough in the seam to allow The goods to stretch

if necessary.

Loading...

Loading...