SINGER 143G2 User Manual

SINGER

143G2,143G3

Form K6485

(Form 2646w Rev.)

(663)

USE SINGER* OILS

and LUBRICANTS

They insure freedom from lubricating trouble and give

longer life to sewing equipment

The following' are the correct lubricants for this machine:

TYPE B — MANUFACTURING MACHINE OIL, HEAVY GRADE

When an oil is desired which will produce a minimum of

stain on fabrics, even after a long period of storage, use:

TYPE D — MANUFACTURING MACHINE OIL, HEAVY GRADE

OTHER SINGER* LUBRICANTS

TYPE E — THREAD LUBRICANT

For lubricating the needle thread of sewing machines for

stitching fabrics or leather where a thread lubricant is

required.

INSTRUCTIONS

FOR USING AND ADJUSTING

SINGER

SEWING MACHINES

V

TYPE F - MOTOR OIL

For oil lubricated motors and plain bearings in power

tables and transmitters.

NOTE: All of the above oils ore available in 1 quart,

1 gallon and 5 gallon cans.

GEAR LUBRICANT

. V. This specially prepared grease is recommended for gear

r ^ . lubrication on manufacturing sewing machines.

BALL BEARING LUBRICANT

This pure grease is specially designed for the lubrication

of ball bearings and ball thrust bearings of motors and

electric transmitters, ball bearing hangers of power tables,

etc. Furnished in 1 lb. and 4 lb. tins.

I43G2 and I43G3

THE SINGER COMPANY

♦A Trademark of THE SINGER COMPANY

Alio

Amies TO

‘W

MACHMB

Printed in Great Britain

Copyright under International Copyright Union

DESCRIPTION

HIGH SPEED MACHINE 143G2 has an aluminium alloy vibrating

needle bar frame and a rotary hook, and Is Intended for overseaming and zigzag stitching on fine lingerie, general fabrics

and light weight leather. It has ball bearings on the rear end

of the arm shaft and hook driving shaft. The needle has a maxi

mum throw of 3/16 inch, vibrating both sides of a centre line.

The speed of this machine Is especially valuable In zigzag

work and long overseamlng In fine fabrics such as women's under

wear, slips, also reducing corsets, dresses, etc. It Is success

fully used In general tailoring work and the manufacture of

articles such as trousers, coats, gloves, and for certain opera

tions In the manufacture of shoes, such as attaching side and top

facings to the linings and butting canvas or felt toe pieces to

the end of the vamp.

In the manufacture of table covers, draperies, scarfs, etc.,

an ornamental effect can be produced by overseamlng a cord with

thread of a contrasting colour. The raw edges of fabric may be

overseamed by taking one stitch In the fabric and the other over

the edge.

MACHINE 143G3 Is similar to Machine 143G2 except that the

needle has a maximum throw of 5/16 Inch. It Is designed for

basting and tacking coat pads.

Speed

The maximum speed recommended for either machine Is 3000

stitches per minute, the speeds depending on the material being

sevn. The machines should be run slower than the maximum speed

at first until the parts which are In moving contact have become

glazed by their action on each other. When the machine Is In

operation, the machine pulley should turn over toward the oper

ator.

To Oil the Machine

Use "TYPE B" or "TYPE D" OIL, sold by Singer Sewing Machine

Company. For description of these oils, see Inside front cover

of this book.

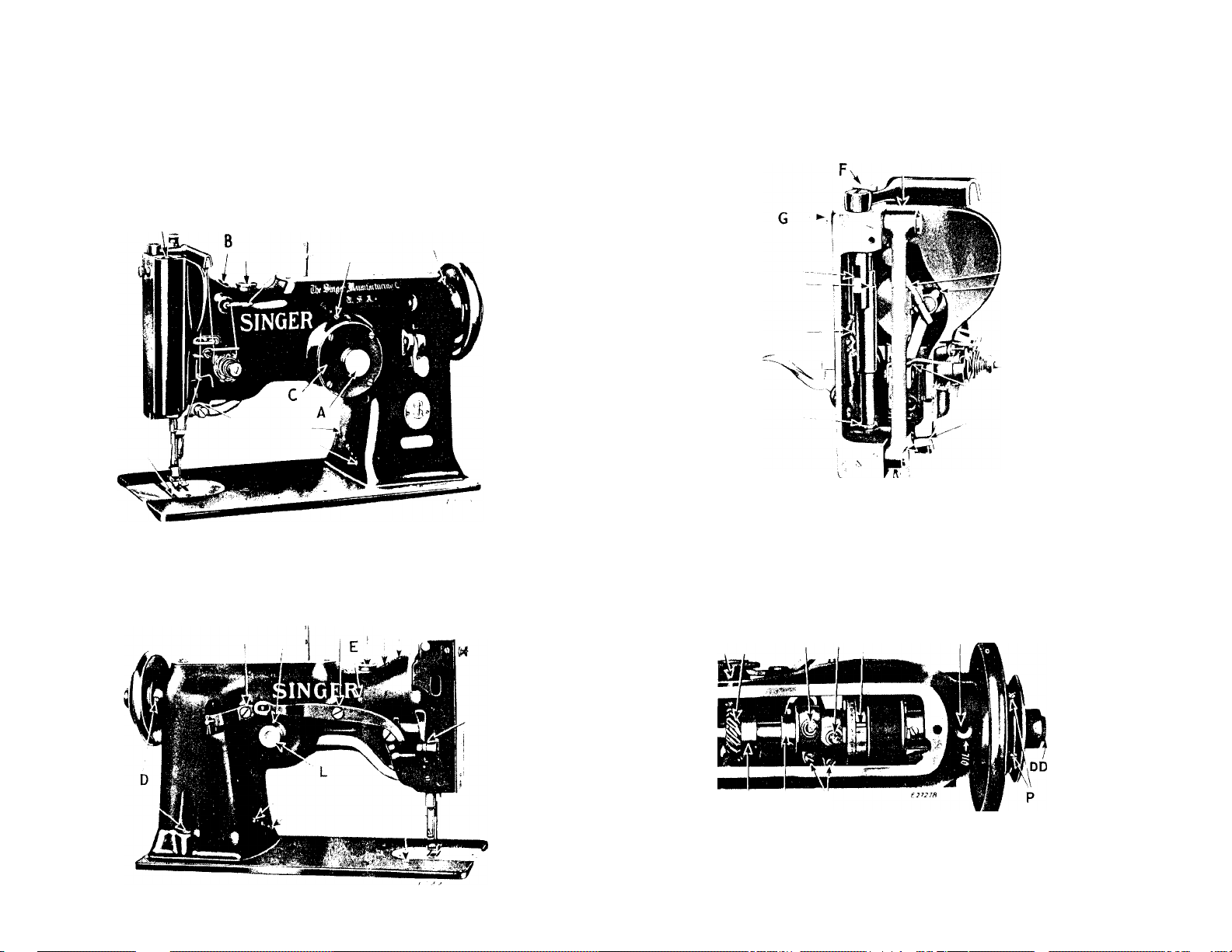

The machine should be oiled at the places designated by un

lettered arrows In Figs. 2 to 6, and when In continuous use it

should be oiled at least twice a day.

5

Remove the face plate and apply oil to the places Indicated

In Fig. 4, then replace the face plate.

О ' ■*'

Vt rf//. no

Fig. 2. Front View of Machine, Showing Oiling Points

Slip the belt off the machine pulley, turn the machine back

on Its hinges and apply oil to the points shown In Fig. 6, then

bring the machine forward Into place.

H i^a

Fig. 3. Oiling Points and Adjustments at Rear of Machine

Fig. 4. Face Plate Removed, Showing Oiling Points

Turn back the cap at the top of the machine, and apply oil to

the places shown In Fig. 5.

M N О

Fig. 5. Oiling Points and Adjustments at Top of Machine

Loading...

Loading...