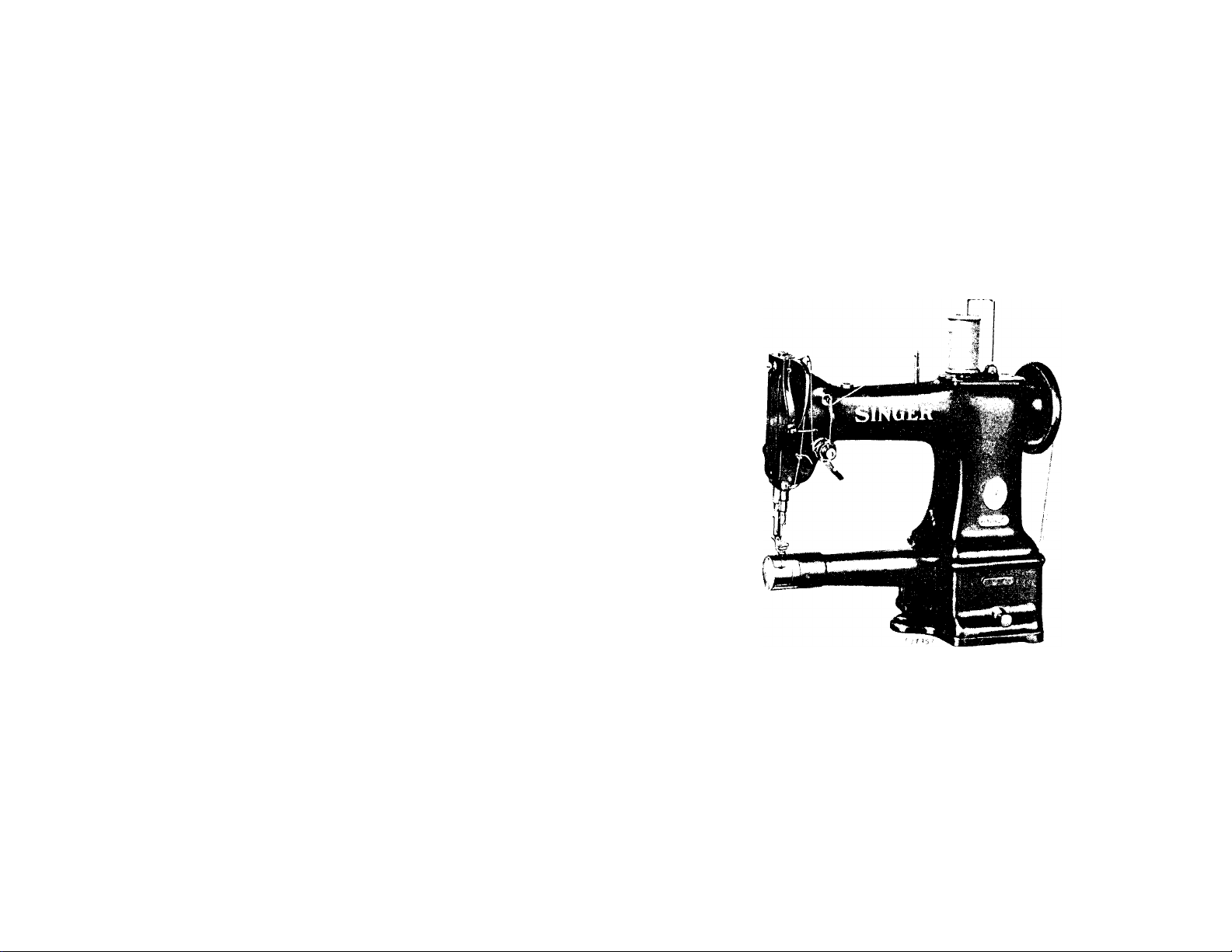

SINGER 142W25 User Manual

SINGER

142W25

USE ONLY SINGER OILS

and LUBRICANTS

They insure freedom from lubricating trouble and

give longer life to sewing equipment

“Singer Oil for High Speed Sewing Machines”

(Cloth and Leather)

For all manufacturing sewing machines excejit whore a stainless

oil is desired.

“Singer Stainless Oil for High Speed Sewing Machines”

For all mannfact\iring sewing machines where a stainless oil is

d( sired.

“Singer Motor Oil”

For oil-lubricated motors, power tables, transmitters and machin

ery in general..

“Singer Stainless Thread Lubricant”

For lubricating the needle thread of sewiiig machines for stitch

ing fabrics nr leather where a stainless thread lubricant is required.

NOTE: All of the above oils are available in I quart, S quart, t gallon

and 5 gallon cans or in 55 gallon drums, and ran also be supplied

in customer’s conlainers.

2590w

INSTRUCTIONS

FOR USING AND ADJUSTING

SIN6ER SEWIN6 MACHINE

“Singer Gear Lubricant”

T)iis Specially prcj)ared grease is rcoorninended for gear lubrica

tion on manufacturing sewing machines.

“Singer Ball Bearing Lubricant”

This i)ure grease is specially designed for the lubrication of ball

bearings and ball thrust bearings of motors and elei'tric trans

mitters, ball bearing hangers of power tables, etc.

NOTE: The above greases are furnished in lb. tubes and 1 lb.

and A lb. tins.

Copyright. U. 8. A., 1914,1915, 1922, 192.9, 1930, 1935, 1030, 1937 and 1939,

by The Singer Manufacturing Company

All Rjghta Reserved for all Countries

I42w25

FOR DARNING

THE SINGER MANUFACTURING COMPANY

To all whom it may concern:

The placing or renewal of the name “Singer” (Reg. U. S.

Pat. Off.) or any of the trade marks of The Singer Manu

facturing Company on any machine that has been repaired,

rebuilt, reconditioned, or altered in any way whatsoever

outside a Singer factory or an authorized Singer agency

is forbidden.

THE IMPORTANCE OF USING

GENUINE SINGER PARTS AND NEEDLES

IN SINGER MACHINES

The successful operation of Singer machines can only be

assured if genuine Singer parts and needles are used. Sup

plies are available at all Singer Shops for the Manufacturing

Trade and mail orders will receive prompt attention.

DESCRIPTION

MACHINE 142w25 has one needle and a rotary sewing hook and

makes the lock stitch.

It Is designed for mending and darning stockings, socks, knit

underwear, linen, curtains, etc., and Is used In laundries,

hotels, hospitals and other public or private Institutions where

darning equipment Is required.

It has a cylinder bed which enables It to conveniently darn

tubular shaped articles, the diameter of the cylinder being small

enough to accommodate a baby's sock.

When desired, the machine can be Instantly converted Into a

flat bed machine by attaching the flat work plate which will be

furnished, on order, at additional charge.

The operator can freely move the work In any direction while

darning as there Is no feeding mechanism and the presser foot

rises automatically after each stitch.

The machine can be equipped with Cylinder End Cover and

Thread Cutter complete 241230, which Is desirable when darning

socks, etc., since It permits the bobbin thread to be cut close

to the darn without removing the sock from the cylinder, thus

saving time and thread.

Speed

Genuine Singer Needles should be used

in Singer Machines.

These Needles and their Containers

are marked with the

Company’s Trade Mark “SIMANCO.” 1

Needles in Containers marked

“For Singer Machines’’

are not Singer made needles.

The maximum speed recommended for Machine 142w25 Is 2800

stitches per minute. When the machine Is in operation, the bal

ance wheel should always turn over toward the operator.

To Oil the Machine

When the machine Is received from the factory. It should be

thoroughly cleaned and oiled.

Oil should be applied to the oil holes shown by arrows In

Figs. 2 and 3 and all other places where there are parts In mov

able contact. When the machine Is In continuous use. It should

be oiled at least twice each day.

Loading...

Loading...