Singer 140 User Manual

0

0

00

0

Z

m

cc

z

00

z

0W

LI

mO

0)

C

L

H

-

02/01/2008

IMPORTANT

When

folowed,

Read

using

including

all

an

electrical

following:

the

instructions

(this

DANGER

An

appliance

appliance

from

never

should

the electric

WARNING

not

allow

used

this

operate

operate

of

the

and

drop

not

use

operate

not

administered.

not

unplug

shock,

byornear

appliance

electric

1.

Do

is

2.

Use

attachments

3.

Never

property,

appliance

electrical

4.

Never

ings

dust,

Never

5.

6.

Do

7.

Do

being

8.Todisconnect,

outlet.

Do

9.

ifithas

to

or

sewing

loose

or

used

to

be

children.

only

recommended

this

appliance

been

nearest

the

mechanical

appliance

the

machine

cloth.

or

insert

outdoors.

where

all

turn

pulling

by

any

SAFETY

appliance,

appliance)

reduce

To

left

unattended

be

outlet

immediately

To

reduce

a

Close

toy.

its

intended

the

by

if

it

adjustment.

with

and

into

object

(spray)

to

on

cord.

to

hasadamaged

or

any

foot

injury

as

for

dropped

authorized

aerosol

controls

safety

basic

the

the

persons:

attention

as

use

manufacturer

damaged,

or

dealer

air

openings

controller

opening.

any

products

the

oft

(“0”)

To

unplug,

INSTRUCTIONS

always

in.

before

and

burns,

when

in

this

plug,ifit

into

for

Keep

accumulation

the

used

then

plug,

should

using

shock:

unplug

Always

cleaning.

fire,

this

manual. Use

in

this

manual.

not

is

Return the

water,

examination,

ventilation

where

or

remove

not

the

appliance

working

oxygen

plug

cord.

precautions

before

risk

of

plugged

when

using

after

risk

is

necessary

described

as contained

cord

dropped

or

center

service

blocked.

free

from

are

being

position,

grasp

electric

of

or

the

this

only

repair,

open

of

lint.

from

be

is

DANGER

1.

Always

2.Donot

3.

Do

Do

not

not

unplug

reach

placeorstore

place

before relamping,

foranappliance

appliance

inordrop

into

that

water

Replace

where

or

has

it

other

fallen

can

bulb

liquid.

with

water.

into

orbepulled

fall

same

type

Unplug

15

rated

immediately.

ntoatub

watts.

or

sink.

02/01/2008

WARNING

1.

2.

3.

4

5.

6.

7,

fingers

Keep

machine

Always

not

Do

Do

not

break.

Unplug

such

as

presser

Always

lubricating,

instruction

Never

operate

may

be

away

needle.

the

use

bent

use

pull

or

the sewing

threading

foot,

etc.

unplug

or

when

manual.

blocked.

from

proper

needles.

fabric

push

machine

needle,

sewing

making

onasoft

all

moving

needle

machine

surface

plate.

while

when

changing

any

parts.

The

stitching.

making

from

the

other user

such

as

Special

wrong

It

any

needle,

electrical

servicing

a

bedorcouch

care

plate

may

adjustments

threading

is

required

can

deflect

outlet

adjustments

cause

the

bobbin,

when

where the

around

the

needle

in

the

removing

the sewing

needle

causing

needle

or

mentioned

air

to

break.

area,

changing

covers.

in

openings

it

to

the

SAVE

THESE

INSTRUCTIONS

02/01/2008

Namesofparts

and

Accessories

up

your

tray,

bobbin

bobbin

upper

up

the

presser

pressure

needle

sew

seam

a

machine

Free

case

case

thread,

bobbn

direction

foot

Stitch

thread

settings

settings

Setting

Accessory

Bobbin

winding

Removing

Inserting

Threading

Bringing

Changing sewing

Changing

Thread

Presser

Stitch

Drop

tension

foot

length,

feed

Changing

Chart

—

Fabric,

Recommended

Recommended

Starting

to

Finishing

Straight

Zigzag

stitching

stitching

Overcasting

Reinforced

Blind

Zipper

stitch

insertion

straight

hemming

Sewingonbuttons

Bidging

stitches

Buttonholes

Rolled

hem

Embroidery

Twin

needle (optional>

Quilting

Edge

guide

guide

is

(foot

(hoop

(optional>

(optional)

is

Maintenance

Performance problems

functions

their

arm

Threading

thread

width

and

(model

(model

stitching

optional)

optional>

(turning

needle

160)

140)

.

for

twin

corners)

needle

23

10

11

12

12

13

1

14

15

1

16

17

18

19

20

21

21

22

22

23—24

25

26

26

27

28

29

29

30

30

31

32

4

5

6

7

8

9

4

5

02/01/2008

2

13

/Th

3

5

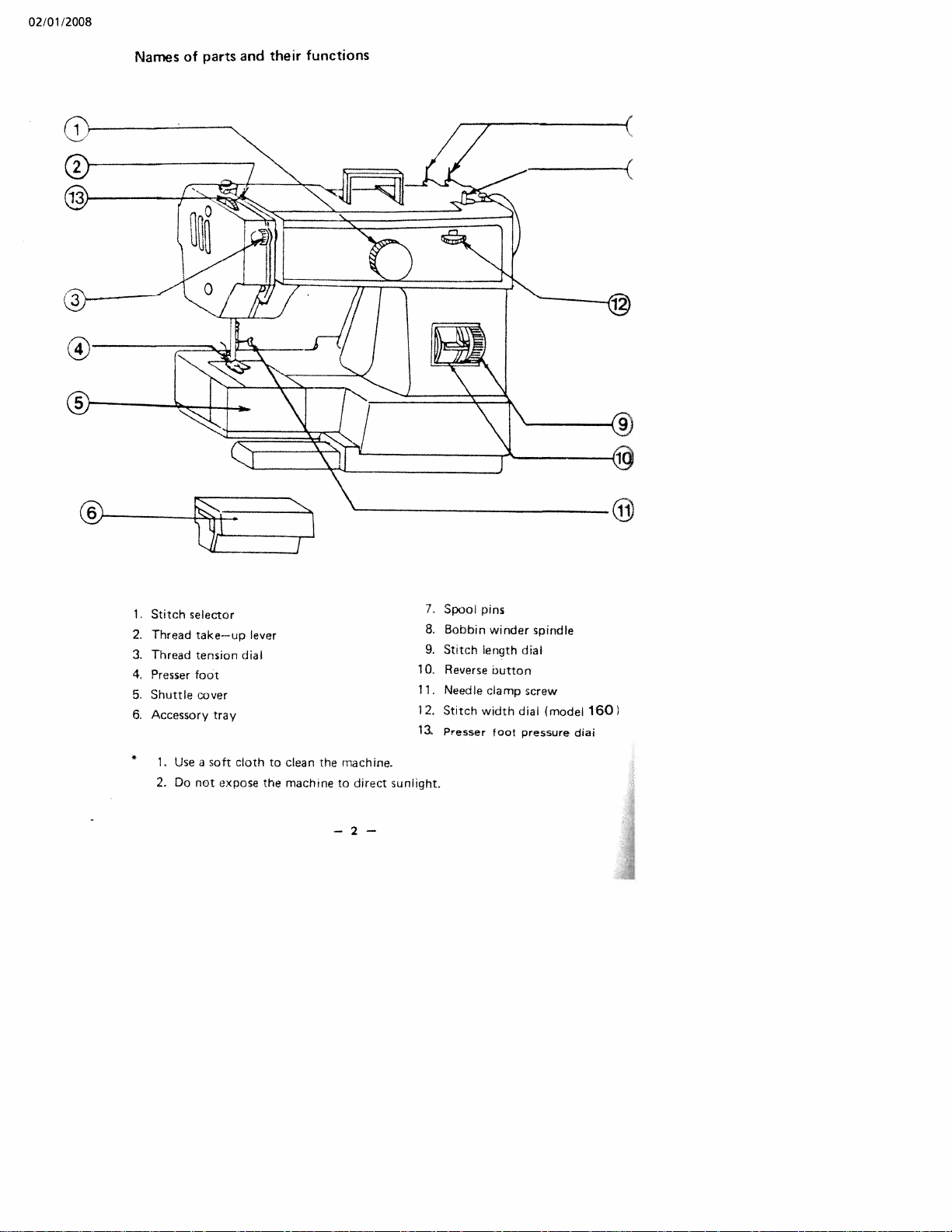

Names

of

JijIJ

parts

and

their

functions

/(

1

1

1.

Stitch

2.

Thread

3.

Thread

4.

Presser

5.

Shuttle

Accessory

6.

1.

Useasoft

Do

2

selector

take—up

tension

foot

cover

tray

not

dial

cloth

expose

lever

to

clean

the

machtnetodirect

the

machine.

—2—

10,

11

12.

ia

sunhght

7.

8.

9.

Spool

Bobbin

Stitch

Reverse

Needle

Stitch

Presser

pins

winder

length

button

clamp

width

foot

spindle

dial

screw

dial

(model

pressure

160)

dial

I

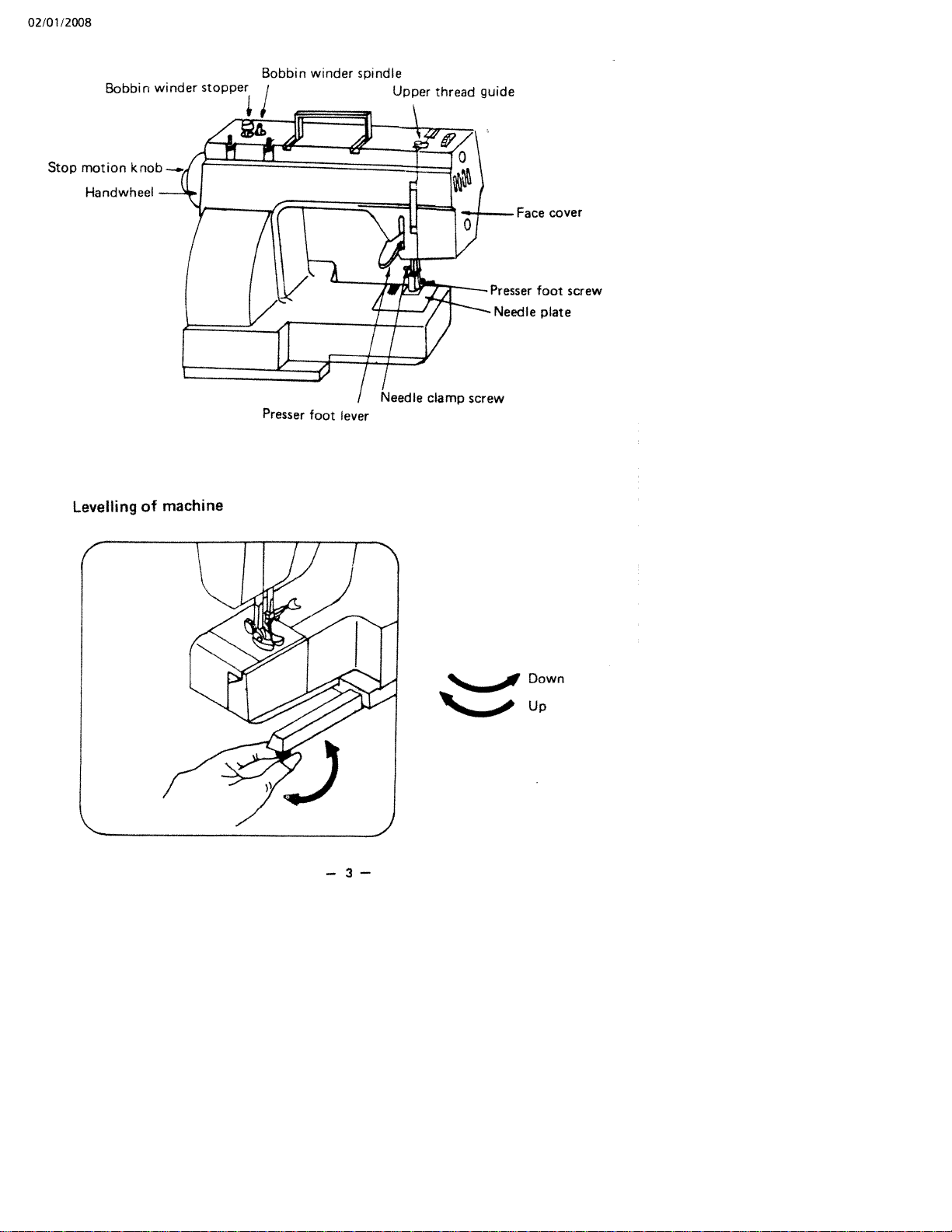

02/01/2008

Stop

Bobbin

Handwheel

Levelling

winder

of

stopper

machine

Bobbin

Presser

winder

foot

lever

spindle

Upper

thread

clamp

guide

cover

plate

screw

—3—

Down

Up

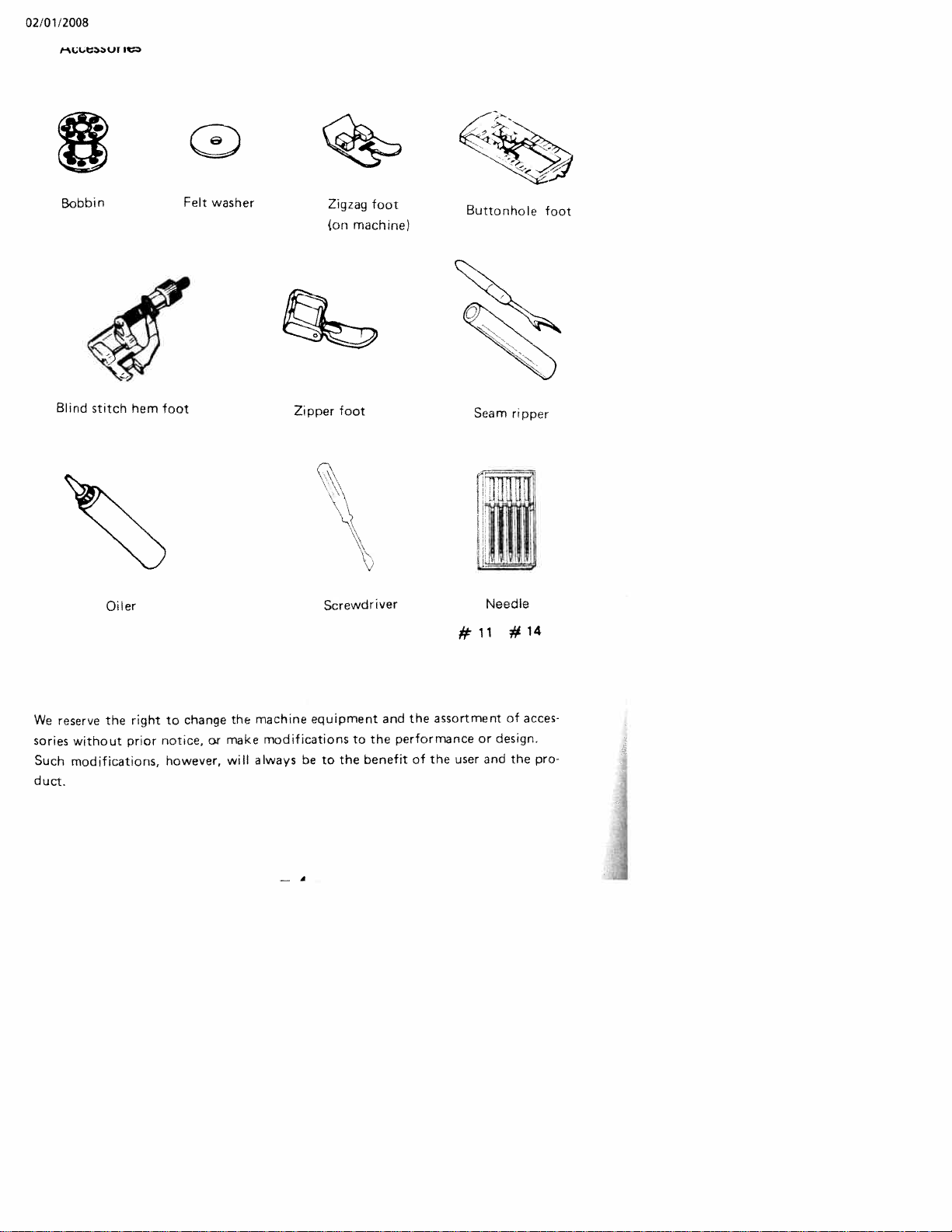

02/01/2008

Bobbin

Blind

stitch

i

hem

foot

0

Felt

washer

Zipper

Zigzag

(On

foot

toot

machine)

Buttonhole

Seam

ripper

foot

We

sories

Such

duct.

reserve

Oiler

right

the

without

modifications,

prior

change

to

notice,

however,

Tij

.1llhi

#11

user

Needle

or

and

#14

of

design.

the

acces

pro

Screwdriver

the assortment

the

to

benefit

and

performance

the

of

the

machine

the

modifications

make

or

alwaysbeto

will

equipment

—

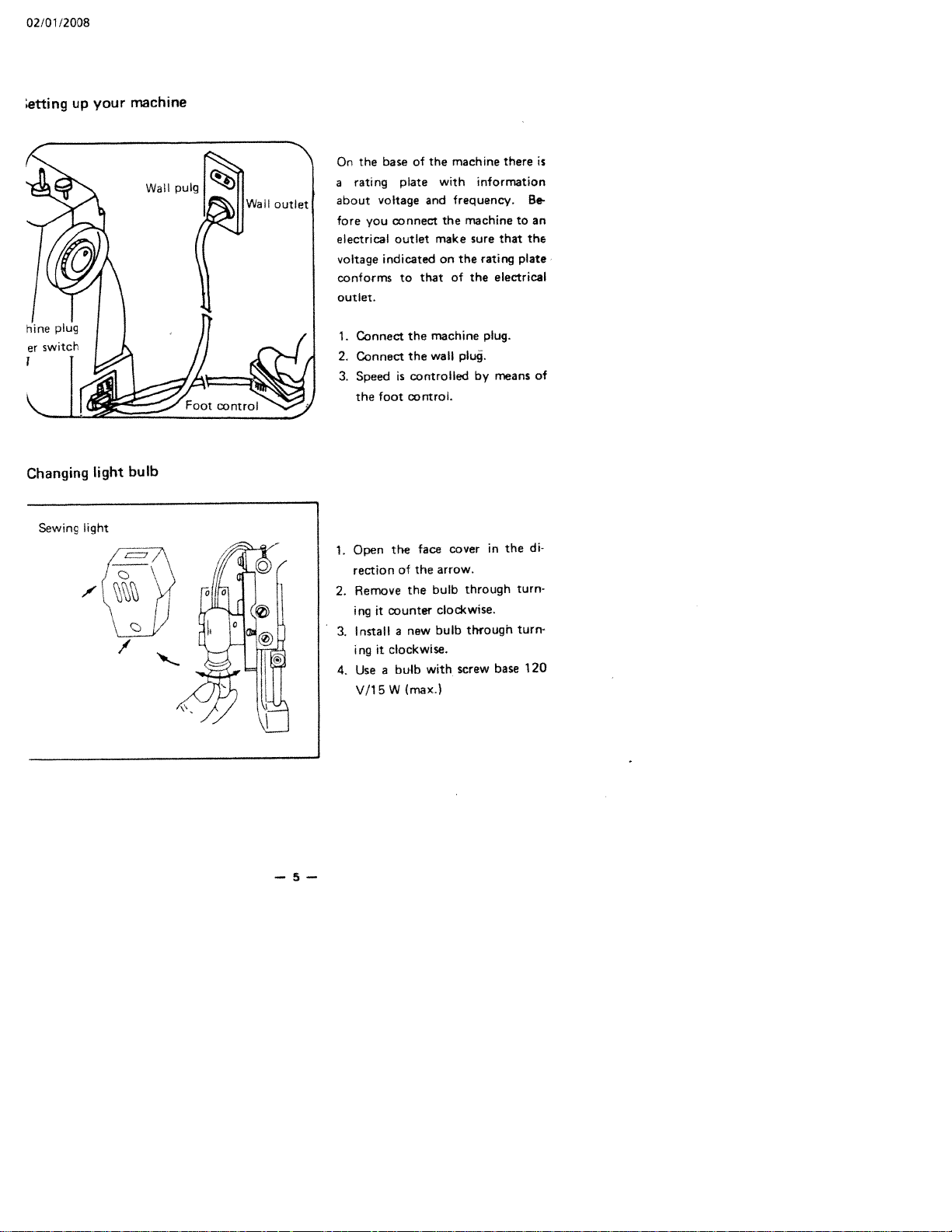

02/01/2008

etting

up

your

machine

Changing

Sewing

light

light

/

bulb

the

On

rating

a

about

fore

you

electrical

voltage

conforms

outlet.

1.

Connect

2.

Connect

3.

Speed

the

Open

1.

rection

Remove

2.

ing

Install

3.

ing

4.

Use

V/15W(max.)

base

plate

voltage

connect

outlet

indicated

to

is

foot

the

of

counter

it

a

it

clockwise.

bulb

a

the

of

with

and

the

make

on

that

the

machine

wall

the

controlled

control.

face

arrow.

the

bulb

the

clockwise.

bulb

new

with

machine

information

frequency.

machinetoan

that

sure

rating

the

electrical

the

of

plug.

plu,

means

by

in

cover

through

through

base

screw

there

the

is

Be

the

plate

of

di

turn

turn

120

—5—

02/01/2008

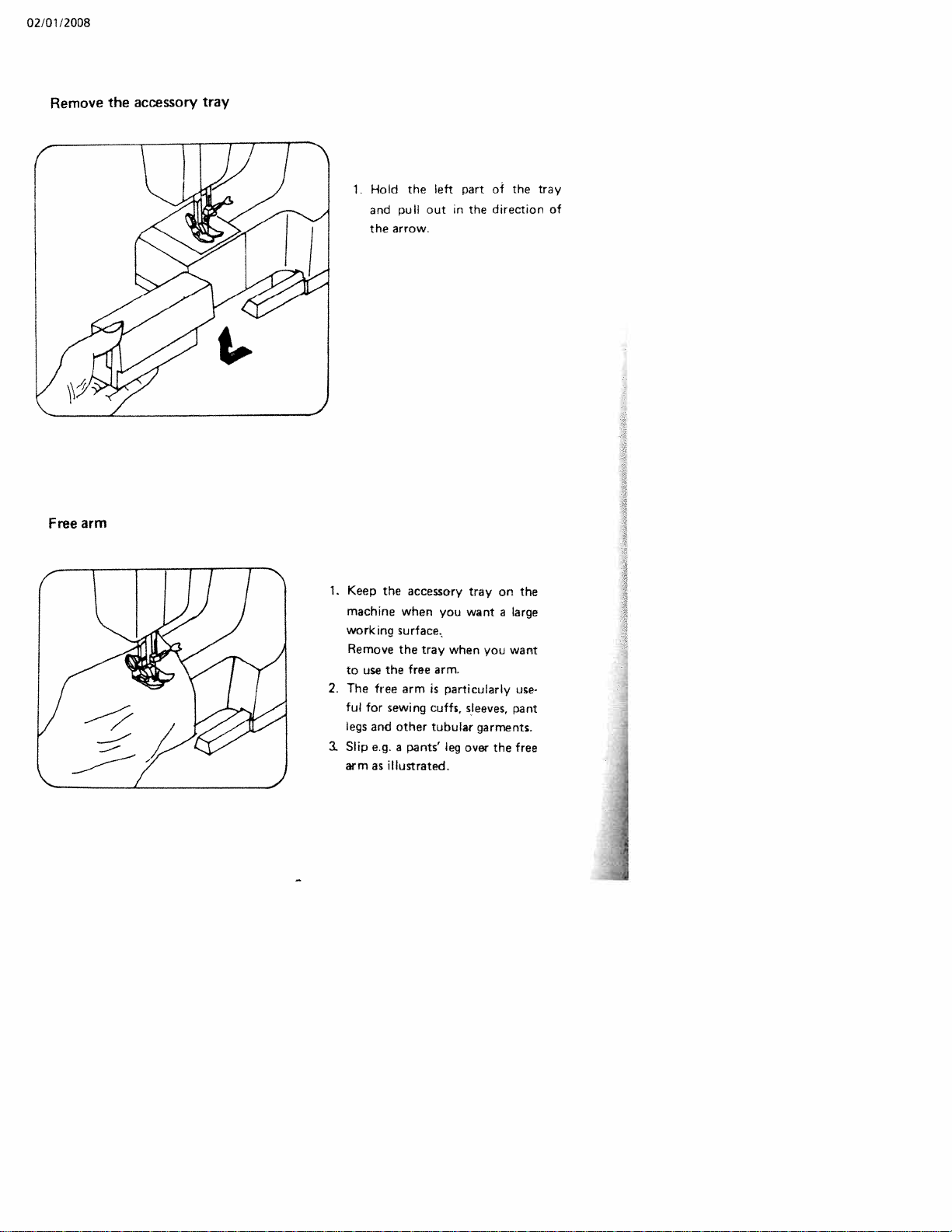

Remove

Free

arm

the

accessory

tray

the

left

Hold

1

and

pull

the

arrow.

part

outinthe

the

of

direction

tray

of

1.

2.

a

Keep

machine

working

Remove

to

use

The

ful

for

legs

and

Slip

e.g.apants’

arm

as

the

when

surface.

the

the

free

arm

sewing

other

illustrated.

accessory

you

tray

free

arm.

is

particularly

cuffs,

tubular

leg

tray

wantalarge

when

you

sleeves,

garments.

over

on the

want

pant

the

use

free

02/01/2008

stop

thread

bobbin

winder

the

winder

position.

must

arrow.

is

motion

path

is

full,

be

tightened,

spindle

When

completed,

spindle

knob.

as

the

in

ilhj

stop

rated

bobbin

its

the

the

the

knob

of

winding

bobbin

original

1

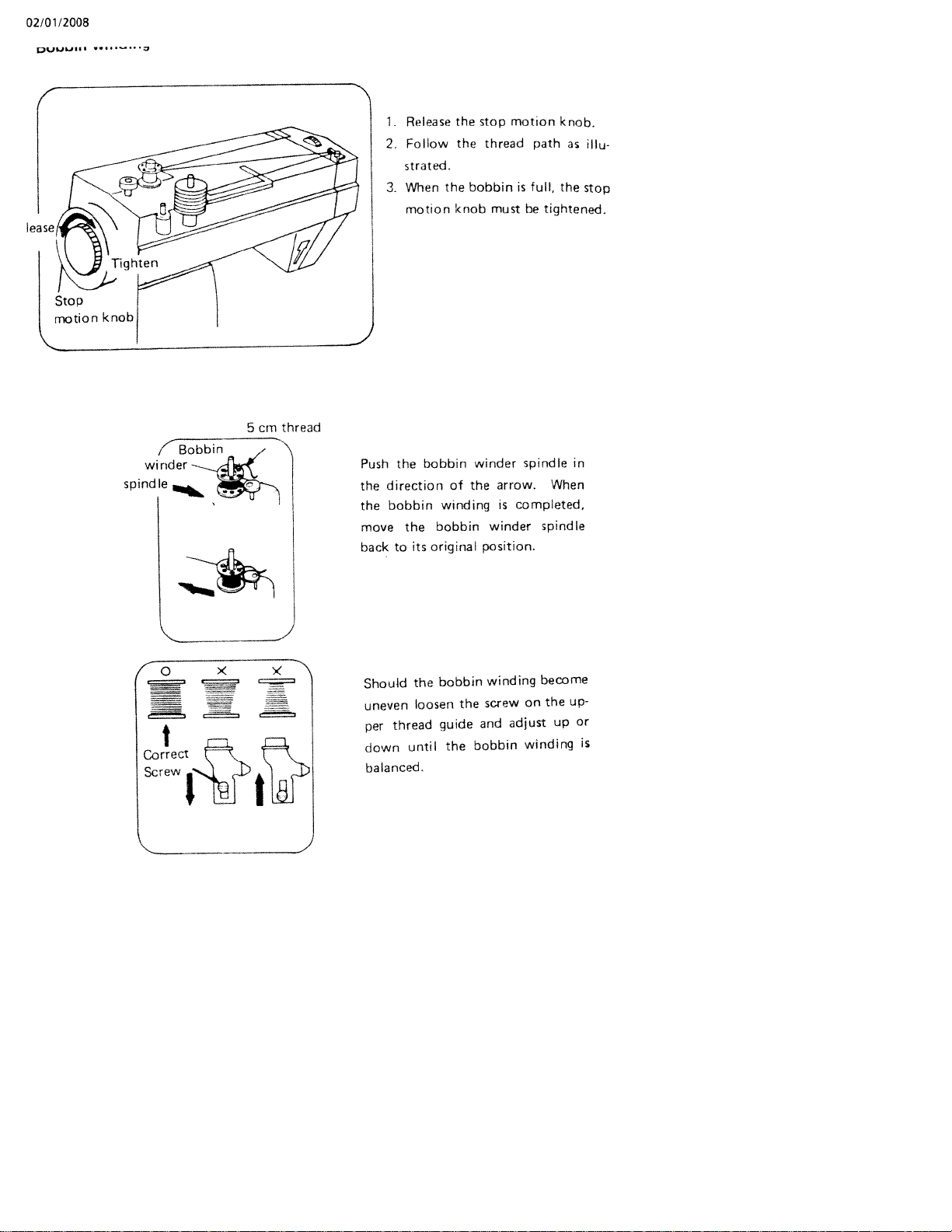

Release

2.

Follow

St

When

3.

motion

cm

thread

5

the

Push

direction

the

bobbin

the

the

move

to

back

)<,

jji

on

adjust

winding

become

the

up

up

or

is

Should

uneven

per

down

thread

until

the

loosen

bobbin

the

guide

the

winding

screw

and

bobbin

balanced,

-F

02/01/2008

Removing

the

bobbin

case

and

bobbin

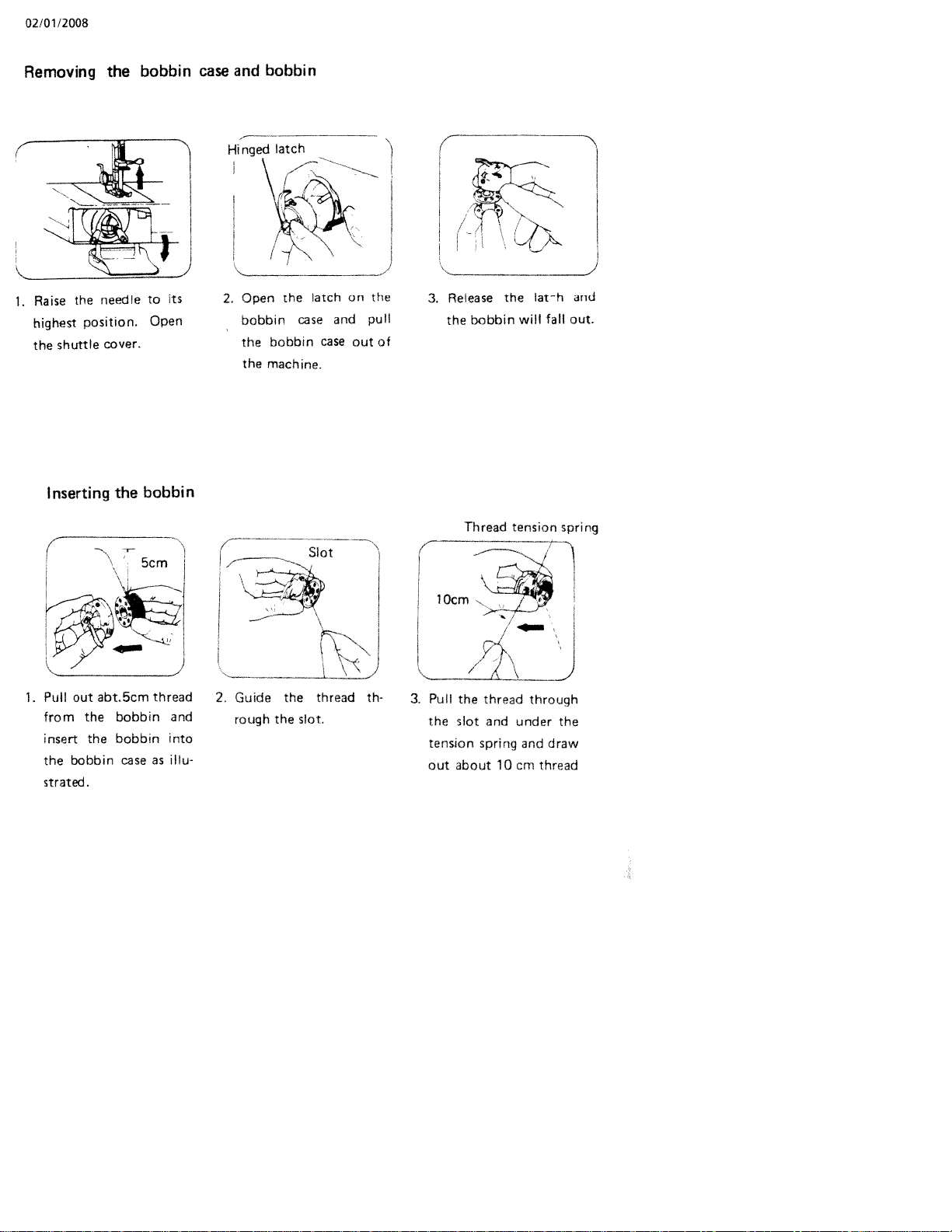

1.

Raise

highest

shuttle

the

Inserting

the

position.

needle

cover.

the

its

to

Open

bobbin

cm

Hinged

Open

2.

bobbin

the

the

latch

the

case

bobbin

machine.

latch

case

and

on

out

the

pull

1’

/1’

and

lat-h

bobbin

Thread

the

wilt

tension

fall

out.

spring

Release

3.

the

of

1.

Pull

from

insert

the

strated.

out

the

the

bobbin

abt.5cm

bobbin

bobbin

caseasiflu

thread

and

into

2.

Guide

rough

the

the

slot.

thread

th

3.

Pull

the

thread

through

the

slot

and

under

the

tension

out

about

spring

10cm

and

draw

thread

Loading...

Loading...