SINGER 1375A3 User Manual

INSTRUCTION MANUAL

AND

ILLUSTRATED PARTS LIST

FOR

SINGER

MACHINES

1375A1

1375A2

1375A3

THE SINGER COMPANY

CONTENTS

I . Uses and feamres

II. Main specifications

in. Cautions before operation----------------------------

IV. Installation of machine

V. Construction and Adjustments

------------------------------------------------------------------------1

----------------------------------------------------------------------1

--------------------

--------------

----------------------------------------------------------------

----------------------------------------------------- 4

2

2

VI. Lubrication and maintenance--------------------------------------------------------- 11

Vn., Trouble shooting

------

------------------------------------------------------------

11

VI. Illustrated parts list---------------------------------------------------'----------------- 15

K. Acce ssories -------------------------------------------------------------------------28

X. Table cutout drawing

-------------------------------------------------------------

29

—

----------

-----------------------------------------------------------------------

^-----------------------------------------------------------1

—, ----------------------------------------------------------------------1

-----------------------------------------------------------------2

0.

7a N -------------------------------------------------------------------------------- 11

-b-

■As -------------------------------------------------------------------------------- 15

+ , ---------------------------------------------------------------------------------------------------------29

------------------------------------------------------------

---------------------3

--------------------------------------------------------------

--------------------------------------------------------------------

----------------------------------------------------------------------------28

4

12

I - Uses and feature.

Machines of Class 1375A are used for sewing buttons especially for knitting and

clodiing industry, have features of original designed, excellent appearance and reliable

structure.

The machine has a unique system for spreader. Thread tension and looper

mechanism are reasonably designed and precisely made. In operation, the machine will

finish one sewing cycle by stepping the treadle once ,and trim thread automatically.

Model 1375A1 is for sewing four hole buttons with crossover stitches;Model

1375A2 is for sewing two or four hole buttons with parallel stitches;.And while model

1375A3 have functions both model 1375A1 and model 1375 A2 with.

1375A gitifis. itMiti!. bb

1375A1 291^^5.inj 1375A2

1375A1 ^ 1375A2

n. Main specifications.

Sewing speed: 1400rpm

Width of needle vibrating:2-4.5mm

Button clamp movement:0-4.5mm

Number of stitches per button :20stitches(16seams)

Stitch typeisingle thread chain stitch

Size of buttons :9-26mm in outside diameter

Needle type:N2852-05(#16),N2852-05(#l 8),N2852-05(#20)

Threadipolyester threads

Motor:C4132(Continuous running motor,4pole,l/3HP,220V)

Net weight of machine head:24ICg

1. ilSiiJS

2.

3. €3*?:#^

4.

1400M/^

2-4. 5 Sili:

0-4. 5 «31«: •

20 ft (16^)

5.

6.

N2852-05 (#16)

-1 -

N2852-05 (#18)

N2852-05 (#20)

7.

4)9-4)26

8.

9.

10.

C4132 (4 pole,

24 ''AJt

1/3HP, 220V)

ni.Cautions before operation.

1. Don’t hold the rear cover when transporting.

2. Never let your machine rotate in reverse direction.The correct operating direction

of the machine is clockwise as viewed form the operator.

3. When a machine is new or has been idle for several weeks,it is advisable to apply

oil to all holes,movable parts and oil felts.

■ ±,

IV. Installation of machine.

1. First assemble machine frame.

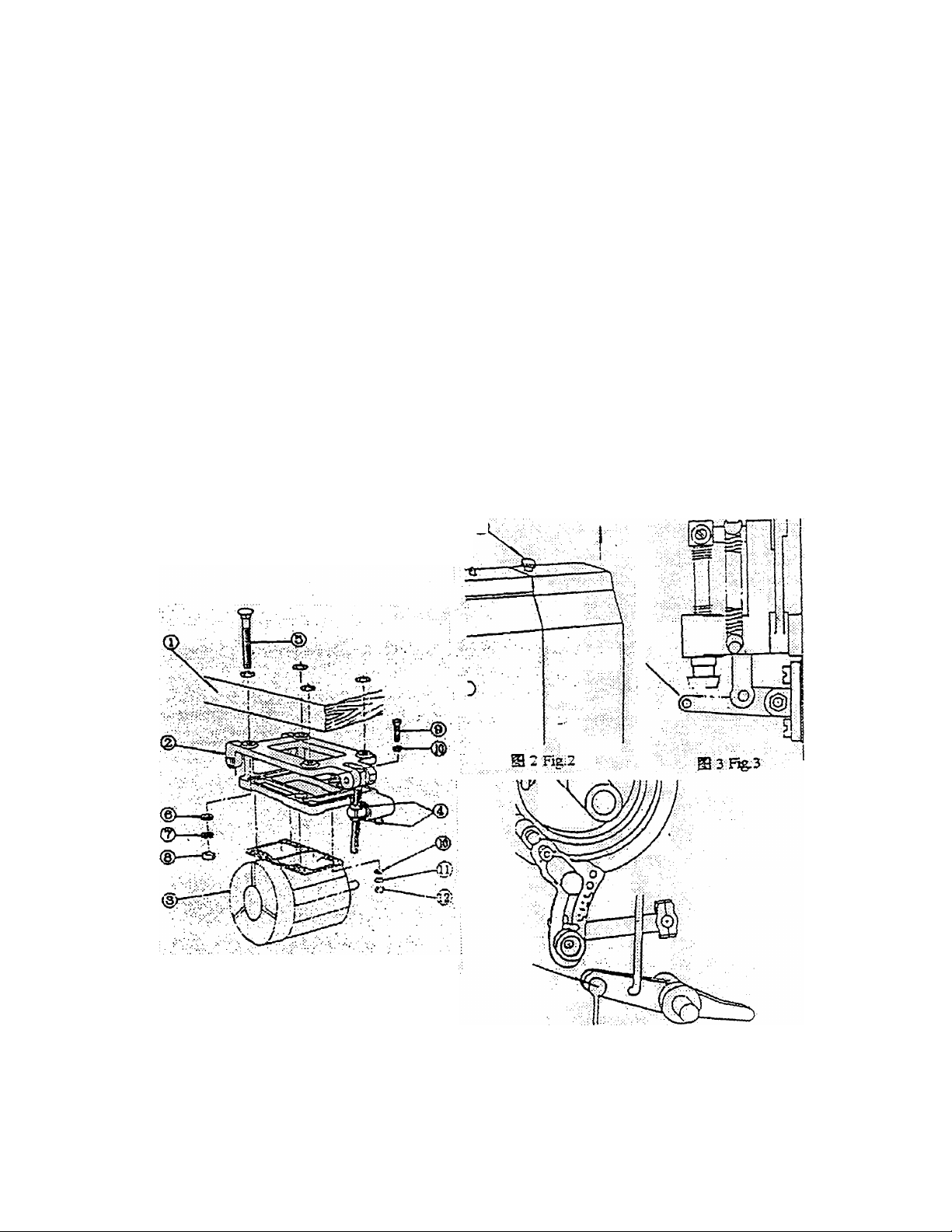

2. Fit button switch and motor to sewing machine table. To install the motor (as

shown in Fig.l), first fasten motor base (2) to sewing machine table by means of

bolts (5), flat washers(6),spring washers(7) and hexagon nuts(8),then fasten the

motor(3) to motor base (2) by means of hexagon bolts(9),flat washers( 10),spring

washers(ll) and hexagon nuts(12).

3. After completing the assembling of machine frame and table, install the machine

head. First loosen screw (1) to remove rear cover (as shown in Fig.2), then fasten the

machine head to sewing machine table by means of four long bolts.

4. To install the belt.

The belt connecting the motor with the sewing machine head should be tightened

properly. Press belt with your thumb, and adjust the belt tension by turning nut of

motor base (4 in Fig. 1) so that the belt can be depressed 2-2.5 cm with a finger.

5. To install chains.

A. To install the chain for the starting lever: remove rear cover, hitch the S shape

hook of the chain to the hole located in the front end of starting lever (as shown

in Fig.3).

B. To install the chain for the button clamp lifting rod: remove hinged cover,

connect the straight hook with chain, and hitch it to the , connecting hook on the

button clamp lifting rod (as shown in Fig.4).

button clamp lifting rod (as shown in Fig.4).

Finally, connect chains with two treadles separately. To limit movement of

treadles, treadles fastened to the floor should be inclined strongly and chains should

not be too slack. The proper adjustment will make the operator less fatigue.

1.

2. о-,

шгвтш(5).

$igiEafe±: ,74:^*19(12)

3. з^&тж^кёШ(лв 2),шт1ши

(1),

4. ^±'(#й!]йФ.

(JE® 1 Ф(4)), 2-2.5стША^Ш

¡Ж^^'Й., (С

Ш 1 FSg.1

а 4:1%4;:

3 -

5.

A: №TJsm, 3),

s JgSi^S^Se^tElFiLrt.

B: i&jiffii®^fl<isfe: njf±m%, ^f&jiwtciF±w-ji^ir(jas 4);

V. Construction and Adjustments.

1. Starting and stopping.

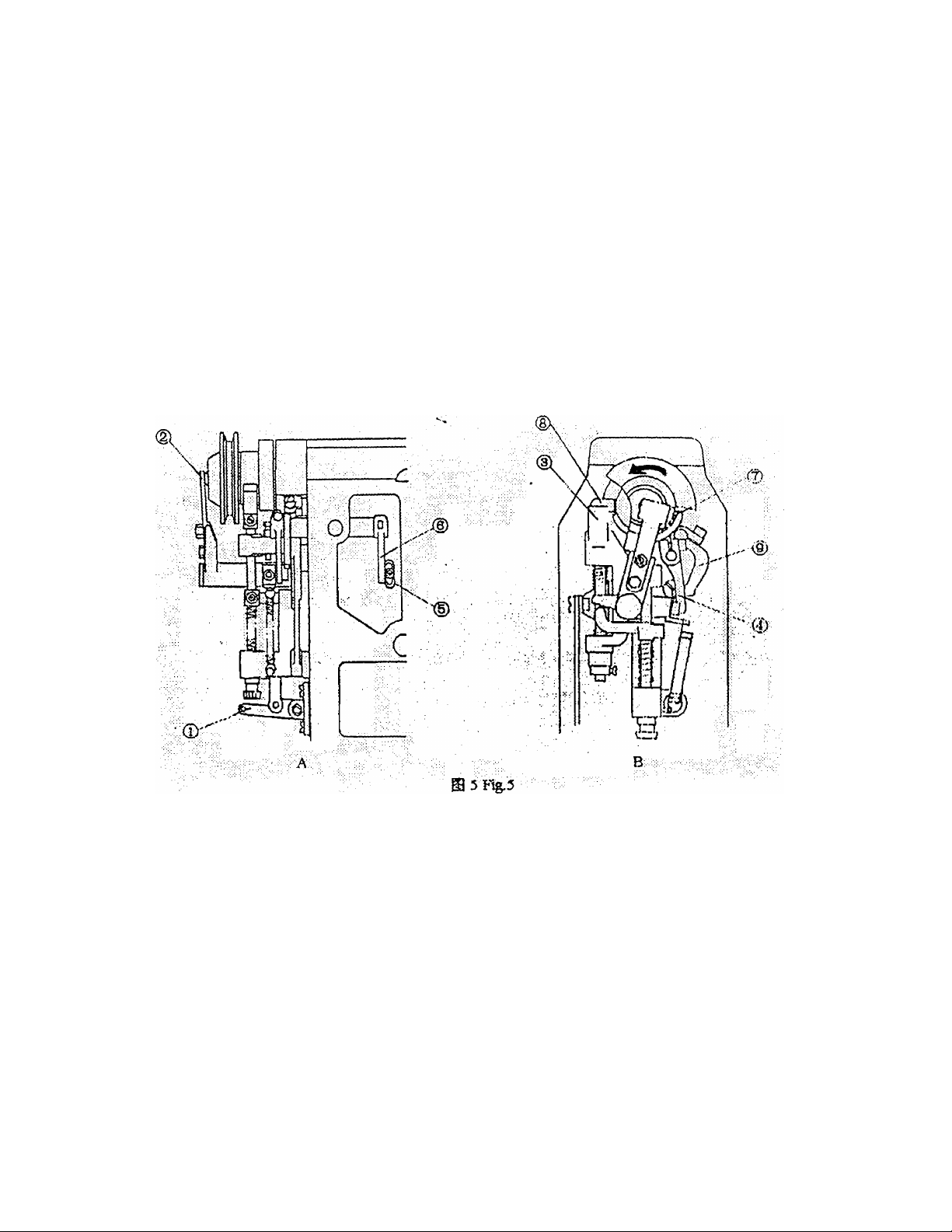

The main shaft is driven by clutch mechanism, as shown in Fig.5.Depressing

treadle allows chain to pull down the starting lever (l),and bevel of wedge(2) will

drive pulley to engage to clutch wheel and turn the main shaft .Releasing the

treadle quickly after depressing, starting bracket(3) will not be released by hook (4)

until stop block(5) on the side of worm wheel pushing out stopping lever (6) at the

end of the 19th stitch. The clutch wheel is disengaged while brake stop (7) will

move upward and apply pressure to the pulley to slow down the main shaft. As the

needle finishes the 20* stitch (the motion is now actuated by the inertia of itself

only), the speed is considerable lowered, so that enabling the stop bolt (8) plugging

into notch as a positioner.

The pressure of brake stop (7) can be adjusted to create a "soft" stop. While the

machine has been spared in use for several hours and is again to run there always

happens that the notch can not be reached while stopping. This will come back to

normal after several trials on running under no load. Therefore, there w'ill be no

need of further adjustment afterwards.

1.

(1

jv7

M 19

2. The starting safety pawl.

To avoid accident caused by careless operating, a safety device is installed at rear

of the machine. The main part of the device is starting safety pawl (9) (as shown in

-4-

mmTjB

Fig.5).

The starting safety pawl should prevent the work clamp from being lifted when

machine is in operation and should prevent machine from starting when button

clamp is raised. This will prevent needle, looper and thread trimmer from being

damaged.

2.

—JESSi'O).

BtJtJi'o

3. The relative position of needle, looper and spreader.

A. The relative position of needle and looper.

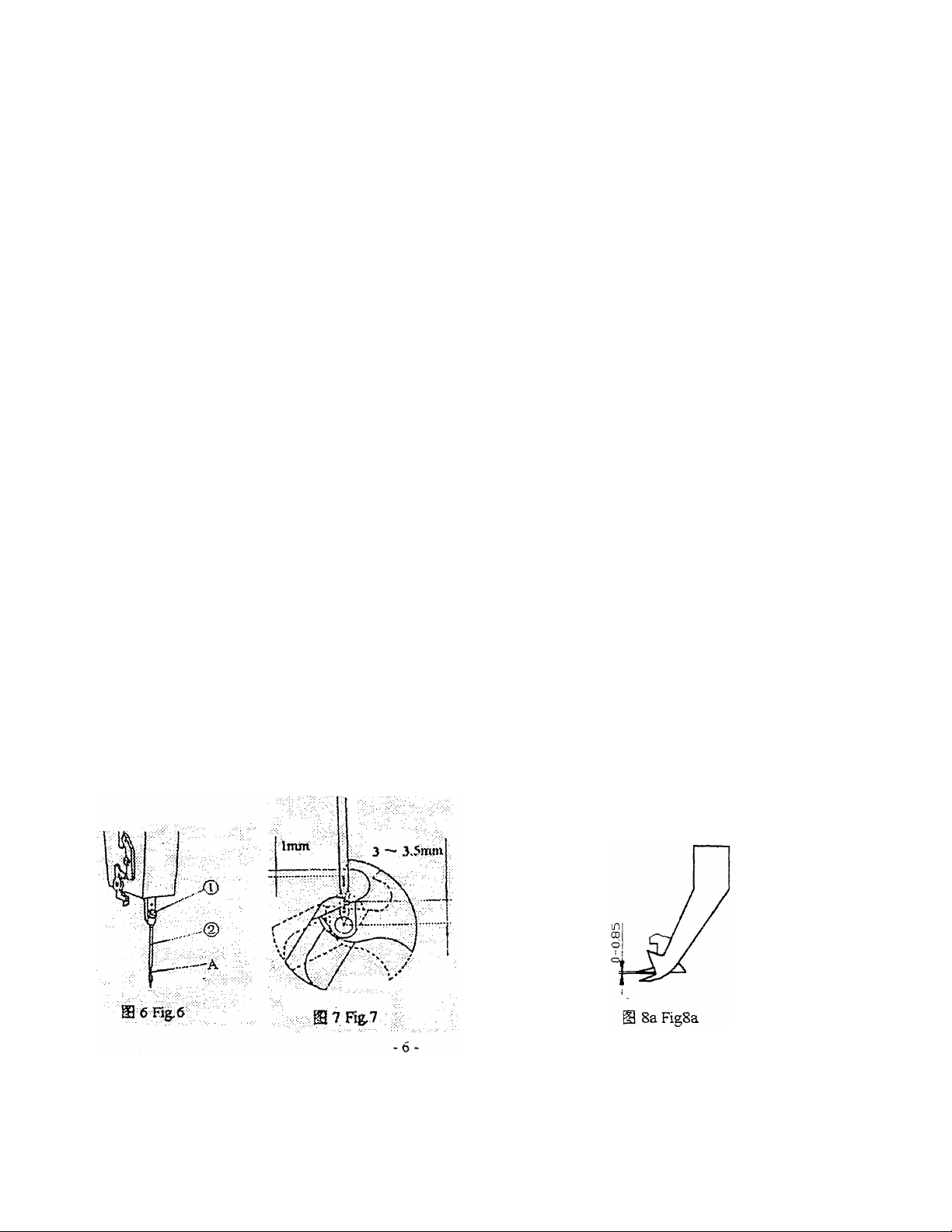

First set the needle properly, as shown in Fig.6, loosen screw (1) and insert

needle (2) up into needle bar as far as it will go with its short groove A of needle

facing away from the operator. Securely tighten needle clamping screw (1). Turn

the machine pulley until the needle bar moves down to its lowest position. When

the needle bar is in this position, needle point should be at the centre of the looper

shaft, as shown in Fig.7.Turn the machine pulley to raise the needle bar about 3-

3.5mm from the lowest position, point of looper should reach the centre line of

needle. The point of the looper should be about 1mm above the top of the needle

eye.

-5-

In the above-mentioned position, there is a very slight clearance between the

point of looper and needle. It is necessary that the needle pass 0.1-0.2mm to the

needle guard, but widiout actually rubbing against it. (see fig 8). Notice: The

clearance between needle and needle guard should be the same when the needle is

swinging right and left.

B. The relative position of needle, looper and spreader.

Turn the needle down from the highest position until needle point is in line with

the bottom of spreader. Then the spreader should be in a state of relative rest while

the needle will continue its downward stroke until the lowest position. The needle

will move upward from the lowest position to such a position where the spreader is

beginning to swing (but still in a state of rest). In such a position, the clearance

from the point of looper to fork of spreader should be 0-0.85mm.Loosen set screw'

of spreader to adjust.(see fig 8a).

3.

A:

A jtkBt:|§#ffi5g!]Sate®aW. It

3-3.5 mm, WAiftife'iiii

It Jlii 1 S it:.

B: #llt, ^lt-^tt^X6<jtS5it'aa:

gbs*-'i4a. ittBi^itii:

si5iiffi®5tsxxnsi^j®w o~o. 85 «it.

L_1

S Fig.8'

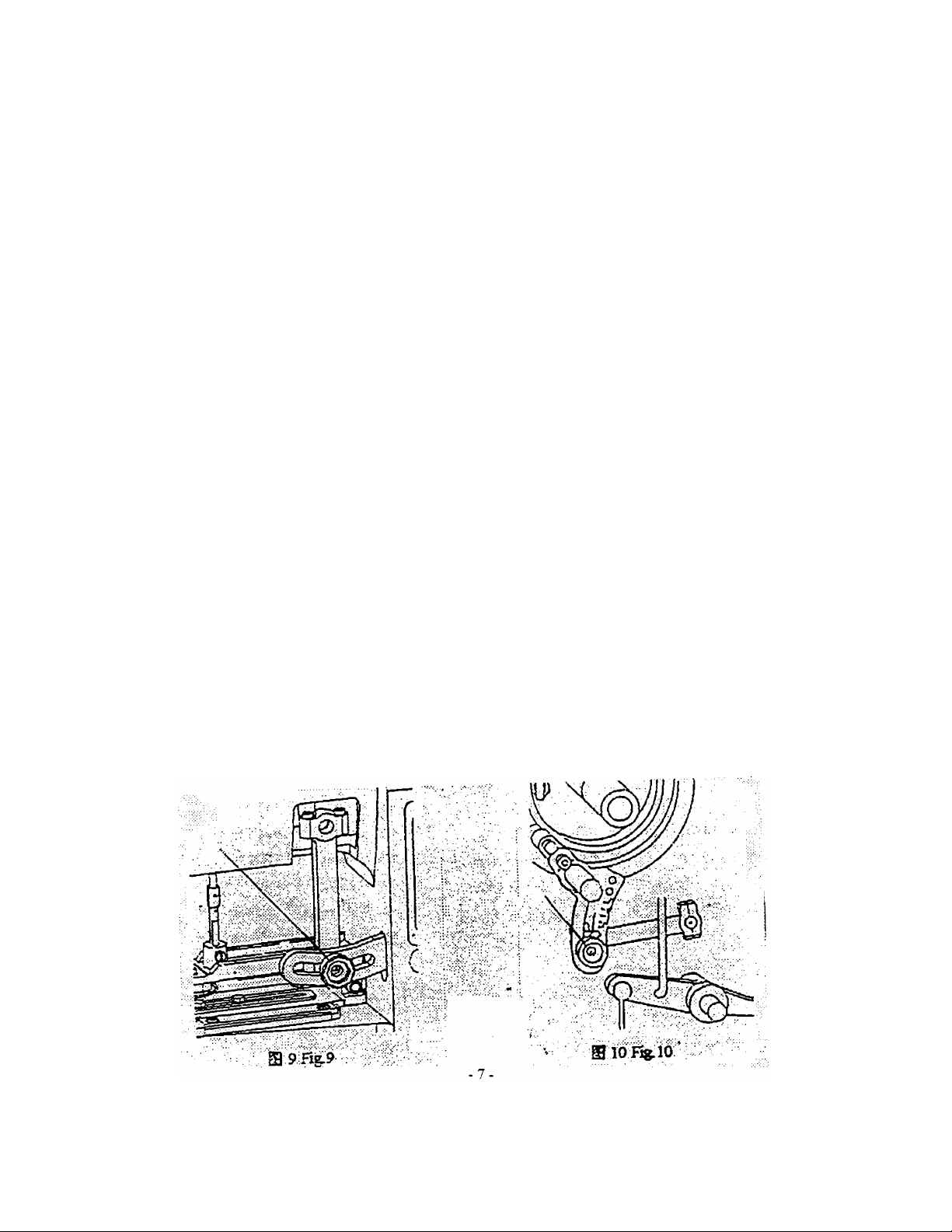

4.To adjust the needle position above button.

The needle must fall in the center of holes in the button. There are two steps to

adjust Lateral distance of buttonholes is controlled by needle vibrating crank. When

connecting rod is nioved out, lateral distance will be increased, and vice versa. As

shown in Fig.9.Longitudinal distance of buttonholes is regulated by needle crossing

crank. When its connecting link is moved downward, the longitudinal distance will

be increased, and vice versa. When the link is at its highest position, the longitudinal

distance is zero, the machine is to attach two hole buttons, as shown in Fig. 10.

If the needle can not fall in the center of holes in the button due to improperly

installed button clamp, then the button clamp must be adjusted. Loosen two hexagon

screws (1), and move the button clamp properly (as shown in Figll). Check if the

needle falls in the center of hole in feed plate before adjusting the button clamp.

The position of needle above the button is closely related to sewing performance.

Make absolutely certain when adjusting. To adjust the button clamp for the size of

button to be sewn on, choose good quality button and insert it in the clamp, pushing it

as far as it will go. When the button is correctly placed into position in the clamp,

depressing the threadle to release the button clamps. Put material under the button

clamp if it slides after falling down jfreely. Turn the main shaft slowly to bring the

needle to the centre of each hole in thé button.

When buttons of different sizes are to be sewn on one suit at the same time, the

distances from center to center of two kinds of buttons should be close. Adjusting the

button clamp in accordance with the small button, and the needle may not fall m the

center of holes in big buttons, as shown in Fig.l2.Notice: Don't let needle contact with

the hole periphery of the button.

4.

Bg€iQ. jaS lOo

W::^7L4'I'bH4*.

®X= iSliBFS'ii®iil55,?L??TMS^h

-laa^iESSi^te, itii

TFSieflEffliafS,

—?Lii.

-•fr^ie ffl [s] Bt ii A€ ia »ffl ft r: #

sli&fii, S5}£z:l4'€ft№?Li&Si®i5.

S nFig.ll

,E® 12. S.ST'gihm#i«mii»

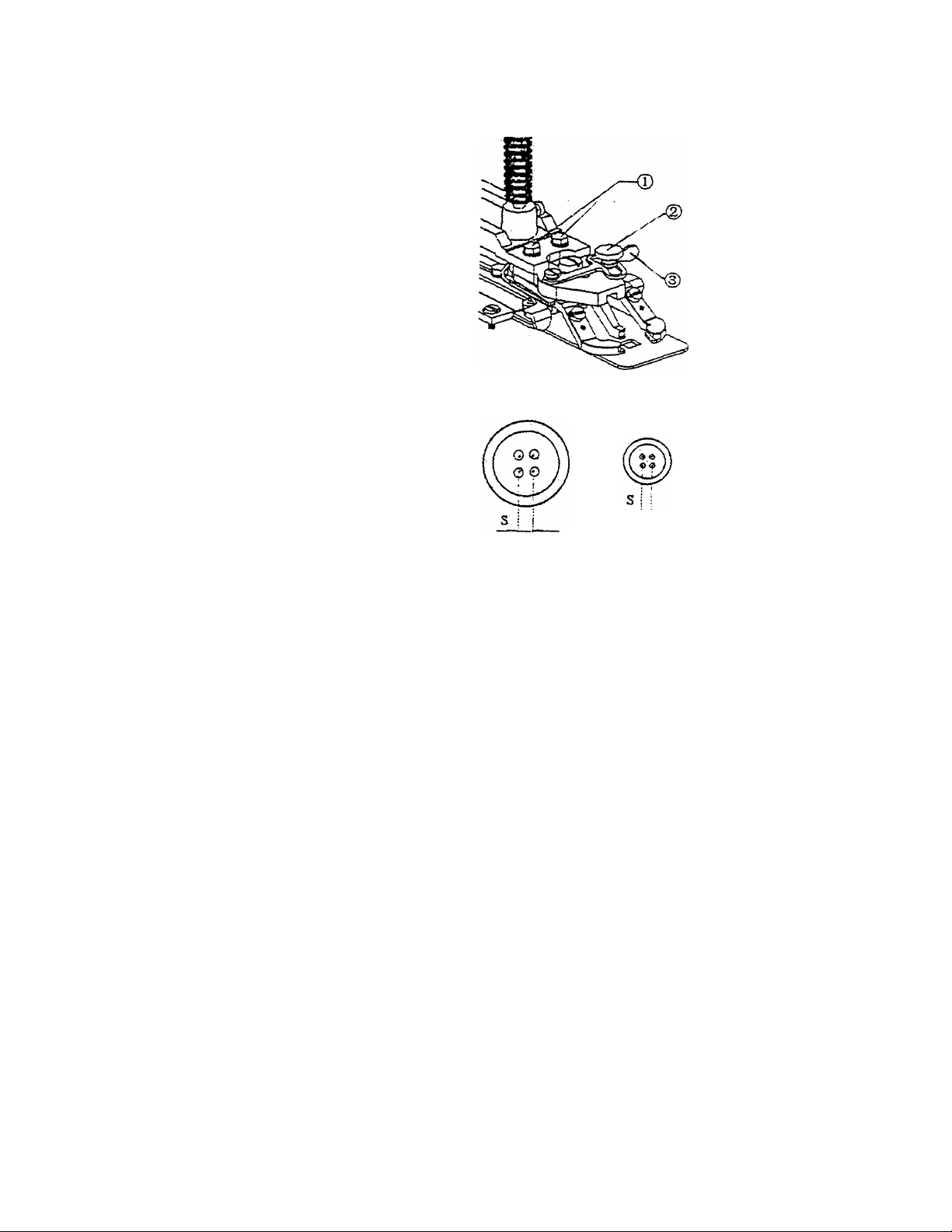

5. Adjusting button clamp (as shown in Fig.ll).

a 12 Fig. 12

The button clamp is suitable for attaching two or four or bar buttons of 9-26mm in

outside diameter.

To adjust the clamp jaws, loosen screw (2), pull back the button clamp adjusting

plate (3), and adjust the clamp jaws to the desired width, then securely tighten the

screw. The width between clamp jaws with button should be slightly smaller than

width between clamp jaws without button. It is easy for the button to be inserted or

taken out. If the opening of the clamp jaws is not wide enough, it is difficult to insert

button in and at the same time will cause unnecessary wearing of the clamp.

5. €*№iSS(JE@ 11)

*.^€^iSl:iT 9~26mm S-gfl^Higgi-ilCft.

ta □ X A №isif. ssft'siii (2), ffl€*i®(3), □ isii sj

6. Threading and thread tension discs (as shown in Fig. 13).

Thread the machine in accordance with the diagram as shown in Fig. 13.Threading

improperly will affect the sewing quality directly.

There are three thread tension discs installed at the top of the machine and each of

-8-

Loading...

Loading...