Page 1

INSTRUCTION MANUAL

AND

ILLUSTRATED PARTS LIST

FOR

SINGER

MACHINES

1371A1

1371A2

1371A3

THE SINGER COMPANY

Page 2

Page 3

Contents

ffiffliiiBfl

Instruction...................................................................................................................................... 1

Illustrated Parts List

1.

....................................................................................................................................42

Frame and Miscellaneous Cover Components.......................................................................................43

2.

Main Shaft Components...........................................................................................................................44

3.

Hook Driving Shaft Components........................................................................................................ 45

4.

Presser Bar Work Clamp Carrier Components...................................................................................... 46

5.

Needle Bar Frame Components...............................................................................................................47

6.

Overedging Width Adjusting Components

............................................................................................

7.

Needle Thread Trimmer Components.....................................................................................................49

8. ШтШ'Ш

Bobbin Thread Trimmer Components ■

........

.........................................................................................50

9.

Knifebar Components...............................................................................................................................51

10.

Feed Cam and Tripping Segment Components

11.

....................................................................................

Stop-Motion Components..................................................................................................................... 53

12.

Tripping Lever Components.................................................................................................................. 54

13.

Thread Tension- Components................................................................................................................55

14.

Lubrication Mechanism Components....................................................................................................56

15.

Speed Transmitter Components.............................................................................................................57

16.

Motor Pulley Components......................................................................................................................58

17.

Machine Head Accessories......................................................................................................................59

18.

Needle Safety Plate Components...........................................................................................................60

19. Ш1Ф

Accessories............................................................................................................................................. 61

20.

Table Cutout Drawing............................................................................................................................62

48

52

Page 4

INSTRUCTION MANUAL

Page 5

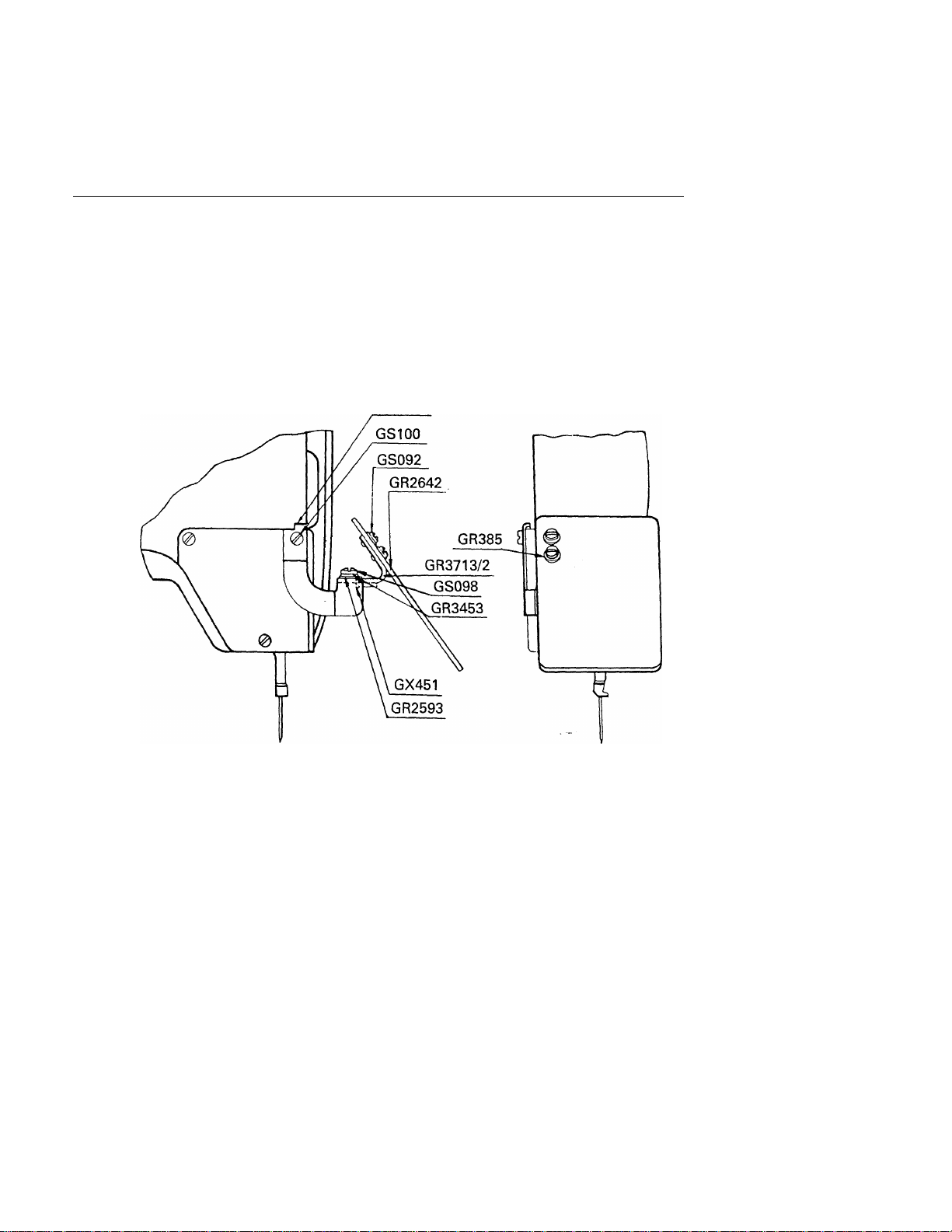

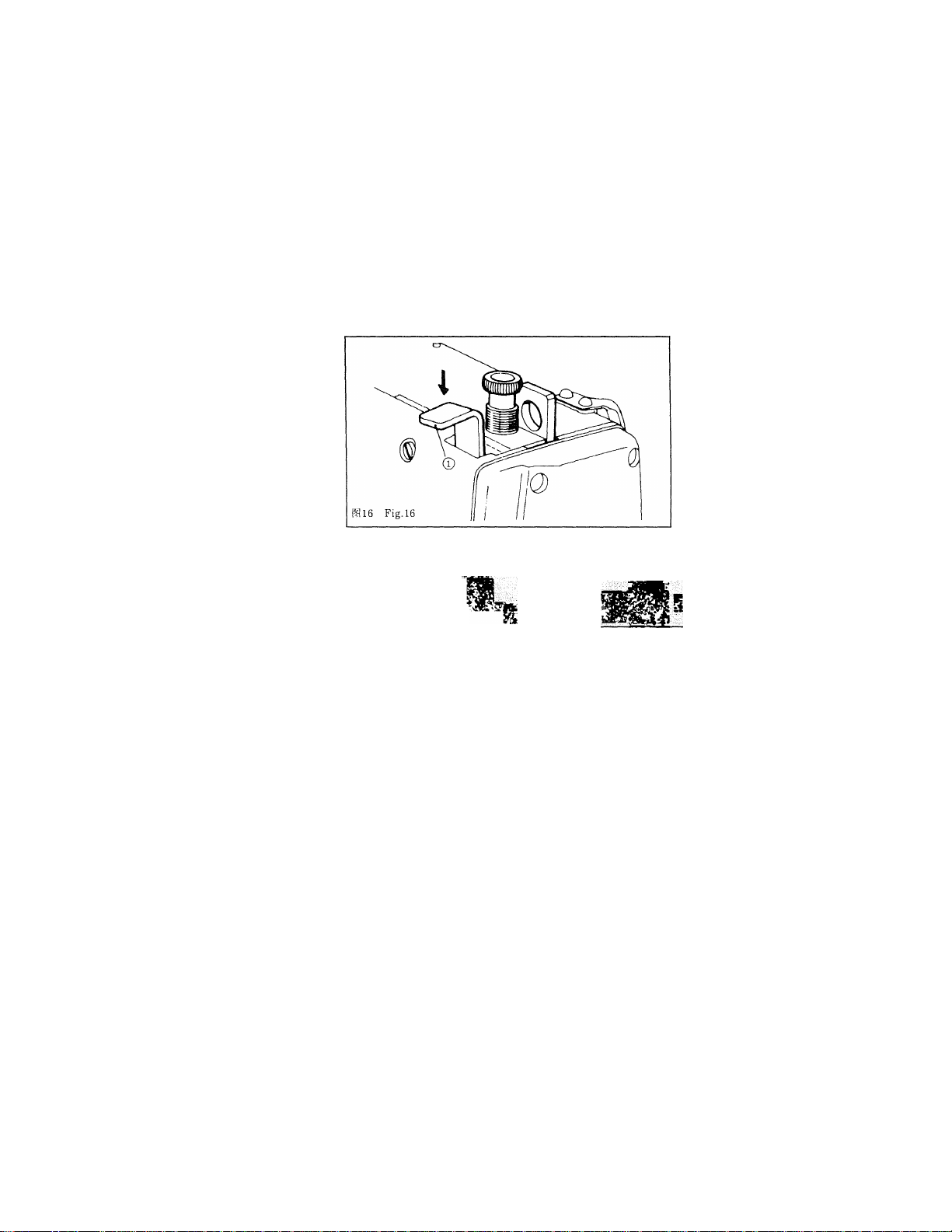

^HOW TO INSTALL THE SAFETY^ PLATE ^

a. ^®TjN^g,

Install the safety plate at the position shown in the figure by means of safety plate

installing bracket set screw.

GR3715

Page 6

INSTRUCTION FOR SET UP

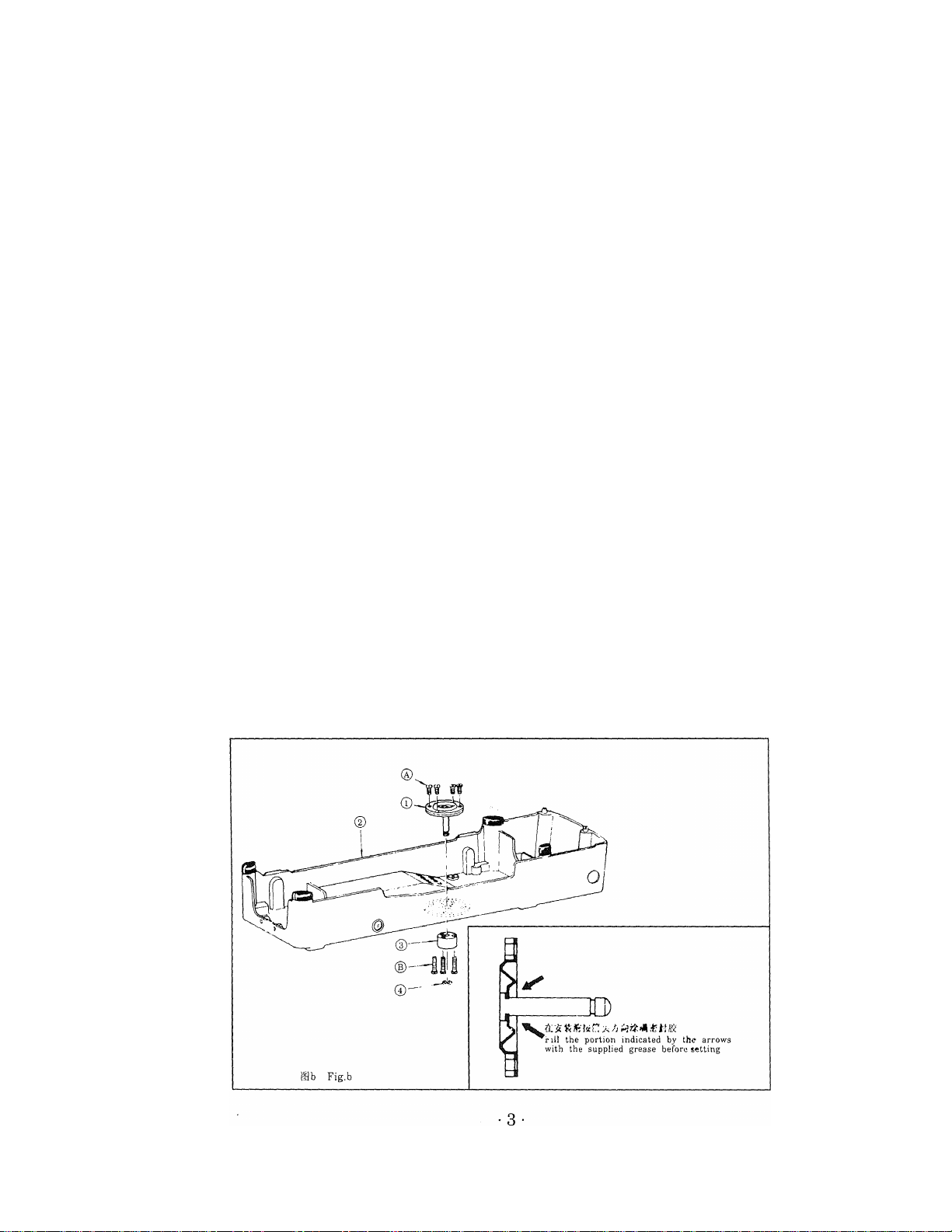

1. ##Hl^!Sa

1. Screws used for set up Pig.a

® ® ©

F zfzinSBBlEW»

2. ^iiiSS]5ffSI5ftKlSse:

fSo

2. Attaching the shifter driving pin (asm.)

1) Fully apply the supplied grease to the pin of the shifter drive pin (asm.)® and the

Ba Fig.a

rubber surface on the rear see Figure Fig.b

2) Using screw ® , fix the shifter driving pin (asm.) on machine head base ©.

3) Using screw ®, fix driving pin base ® on the rear surface of the machine head base

so that the shifter driving pin moved up and down smoothly.

4) Install snap ring ® on the shifter driving pin (asm.).

Page 7

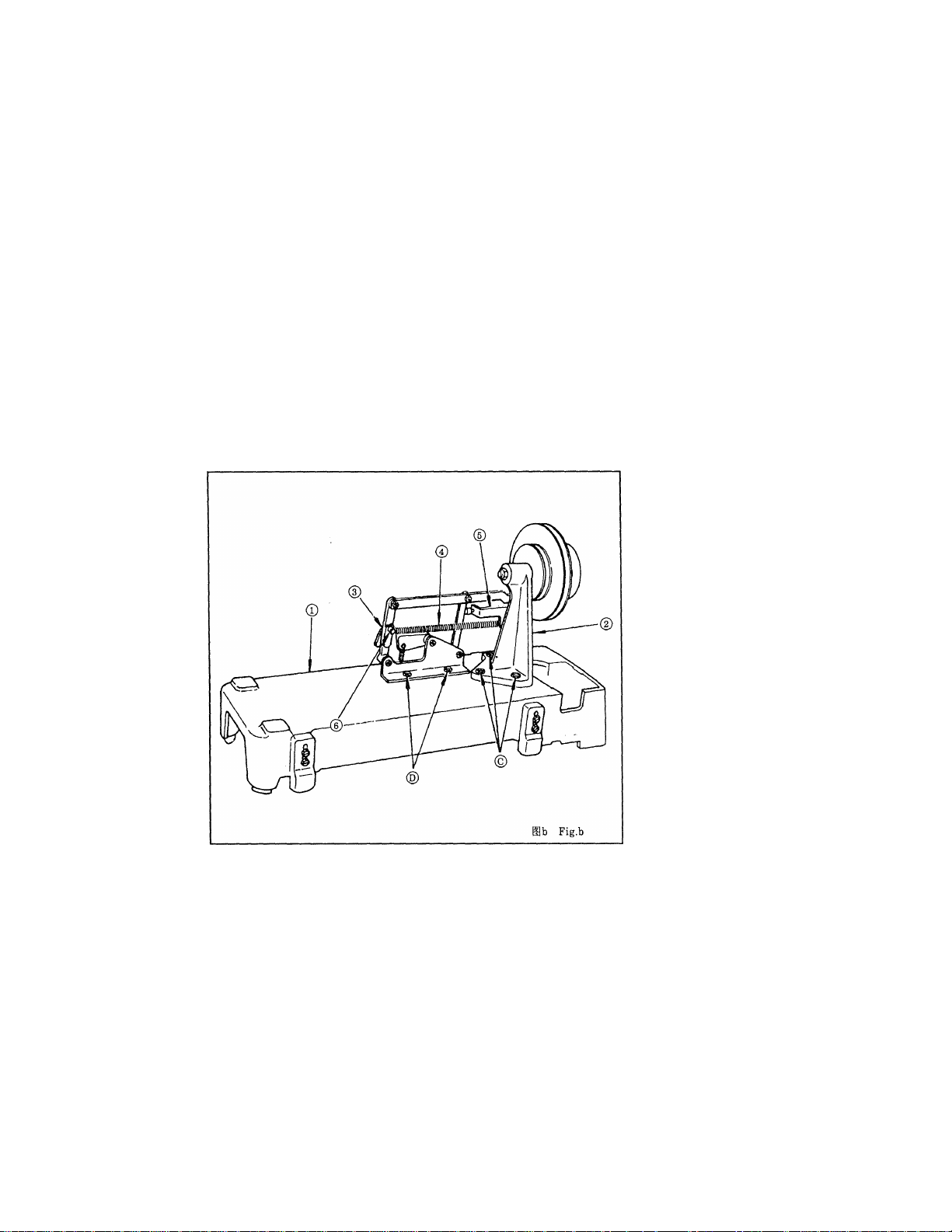

3. Sc

2)Mli4T

3 Installing transmitter (asm.) and shifter base (asm.) pig.c

1) Place machine head base ® with its rear surface facing toward you.

2) Fix transmitter (asm.) ® by screw ©

3) Fix shifter base © by screw ®

4) Attach shifter tension spring ® to shifter stopper bracket (asm.) © and shifter tension

spring bracket © of the shifter stopper base (asm.).

4. sd

4. Supplied with the reducer (asm) Fig.d

1) Fix tension pulley coupling © by hexagon screw © supplied with the reducer (asm.).

2) Install stud © and machine head base seat felt © on machine head ©.

3) Fully lubricate the shifter driving pin and the driving pin base again. Also lubricate

the end of the shifter driving pin and the head of the screw of the shifter pin bracket.

Page 8

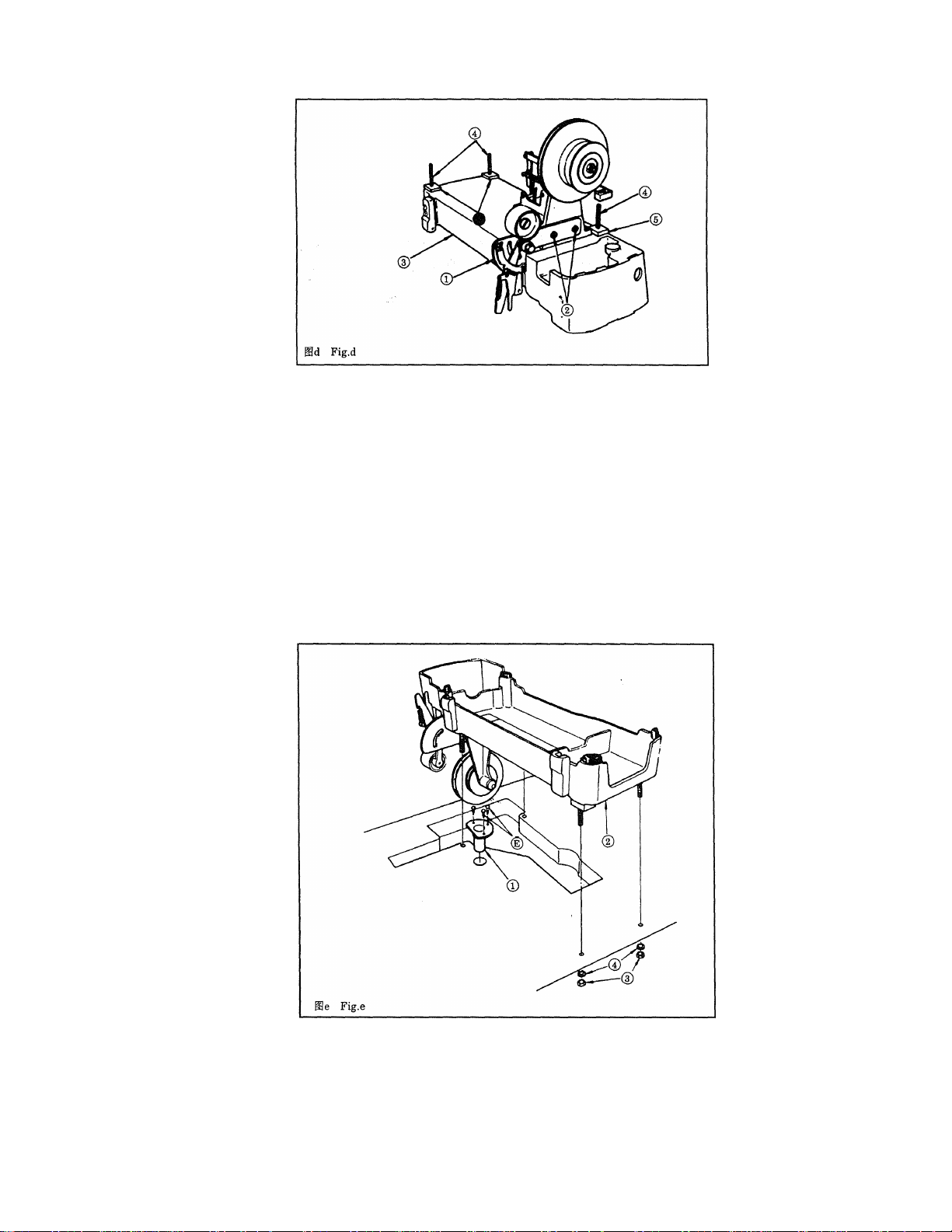

5.

mMmj i>25mwmin±o

#o

5. Installing the machine head base (asm.) Fig.e

1) Fix drain funnel Q to the drain hole (<^25) in the table by wood screw ®.

2) Placing the machine head base (asm.) on the table, fix it by tightening nut ® (flat

washer ® is used) from the bottom of the table.

Page 9

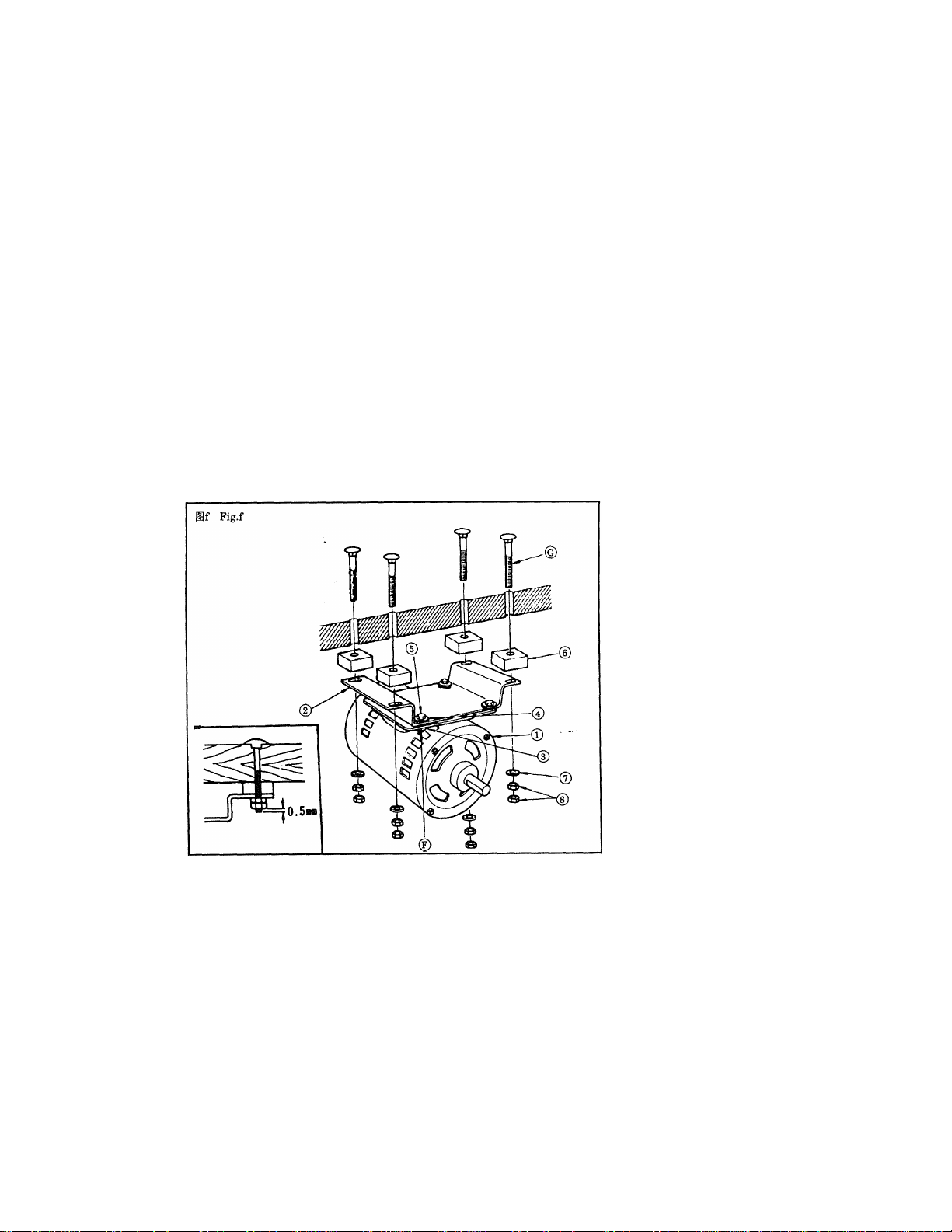

6.

itmi^, ©iit^;5&<}#HiiM;^^0.5mm(«^)o(#

6. installing the motor Fig.f

1) Install motor ® on motor base © by screw © (flat washer ®, spring washer ®, and

nut® are used).

2) Placing spacer ® between the table bottom and the motor base, fix the motor base by

installing bolt © (a flat washer ® and nut ® are used).

Tighten the nuts so that the lower nut is levelled with the end of bolt © or bolt ©

projects by 0.5 mm.

Page 10

à-''.,

yi ■ i ■'■ "i. .

rT7'rc=^l^'' *^-

i‘ '" -BSt':-

2) ÿè -^: rt ^ j]p ')È ^ tb ?f i o

CAUTIONS IN OPERATION

1) The machine should rotate counterclockwise as observed from the pulley. Take care

not to rotate the machine in the opposite direction.

2) Never start the machine before filling the machine base with lubricating oil.

3) Remove the bobbin case and the needle thread from the machine before performing the

trial operation.

4) Clean up the sewing hook and the bobbin thread trimmer every day after sewing work.

Also check the level of the lubricating oil.

5) Never bring your fingers or hair close to, or place anything on the handwheel, V-belt,

bobbin winder wheel or motor during operation. It may lead to serious personal

injuries.

6) If your machine is provided with a belt cover, finger guard and eye guard, never

operate your machine with any of them removed.

.

1. MOTOR PULLEY AND V BELT ^

Wà

2ç>omi6ï

3000$^/5h

2600$t/5h

3000$^/5->

50HZ GD370 GE137 GE137

50HZ GD370H

60HZ

60HZ

GD370HH

GE136

GD370L GE137L

GE137H

VMlÈÎiïiftiS)

GE137

GE137

GE137

Page 11

1) Motors of 370w, 4-pole are used three-phase operation. (If a 250W motor has to be used

for single-phase, operate the machine at 2600 s.p.m. or less, according to order form)

2) M-type V belts are used.

3) Refer to the following table for the motor pulleys, V belt, and sewing speed.

Sewing speed Frequency

2600 s.p.m.

3000 s.p.m.

2600 s.p.m.

3000 s.p.m.

50HZ

50HZ

60HZ

60HZ

Motor pulley Part No.

GD370 GE137

GD370H GE136

GD370L GE137L GE137

GD370HH GE137H

High speed

Vbelt

Low speed

Vbelt

GE137

GE137

GE137

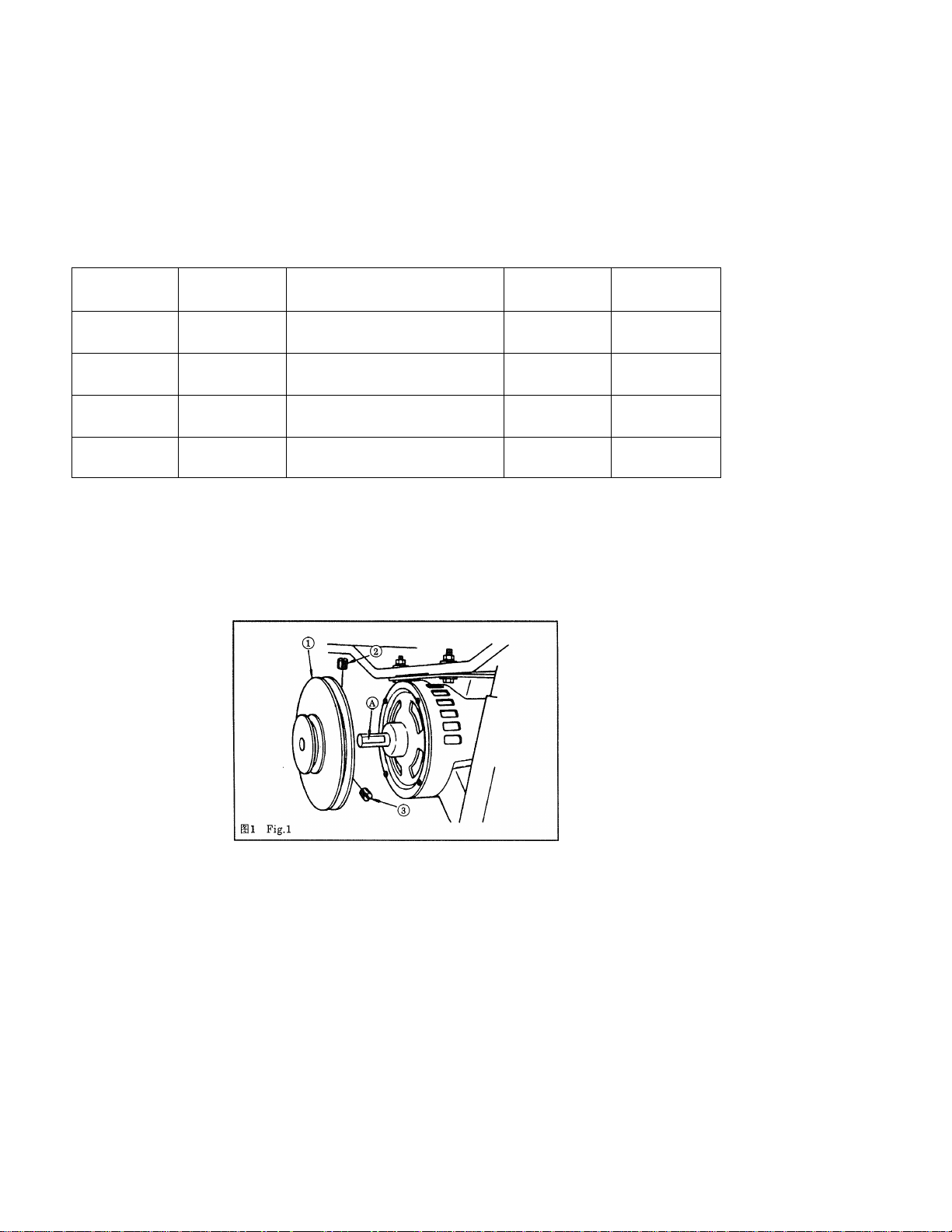

* How to install motor pulley pig.i

Place motor pulley ® into the motor shaft so that flat part ® of the motor shaft aligns

with first setscrew ©. Then securely tighten setscrews © and ®.

* ®2

BP^o

* How to install V belt pig.2

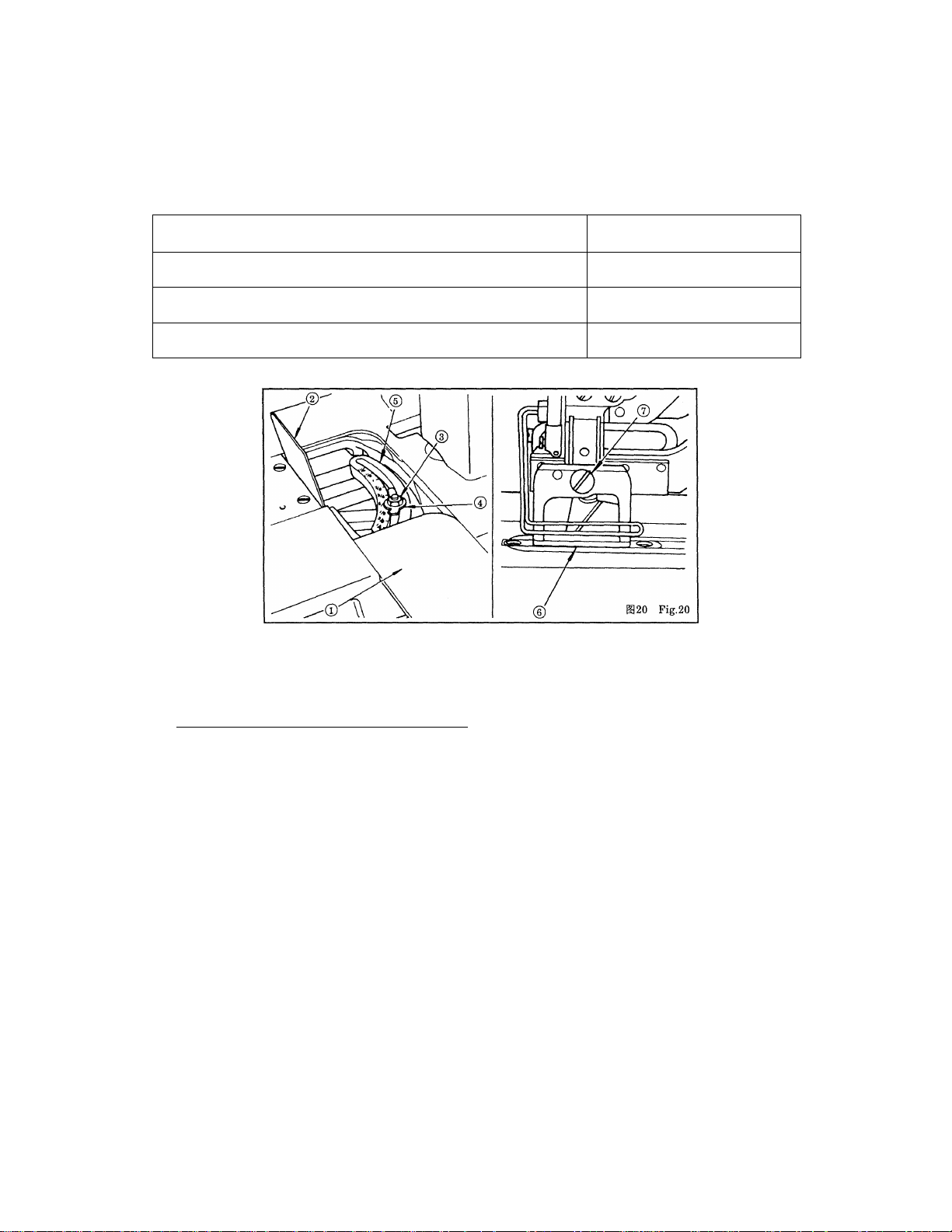

1) Mount high-speed V belt © on accelerating pulley © and the large diameters of the

motor pulley.

2) Mount low-speed V belt ® on low-speed pulley ® and the small diameters of the motor

pulley.

•8-

Page 12

3) By moving the motor from side to side, adjust the tension of V belts ® and ® so that

they give an approx. 10 mm slack when their middle portions are pushed lightly by

hand.

4) Move the motor pulley back and forth to align V belts ® and

7?

JSU«

Motor pulley

r jp, • s. ;■ «• -

A

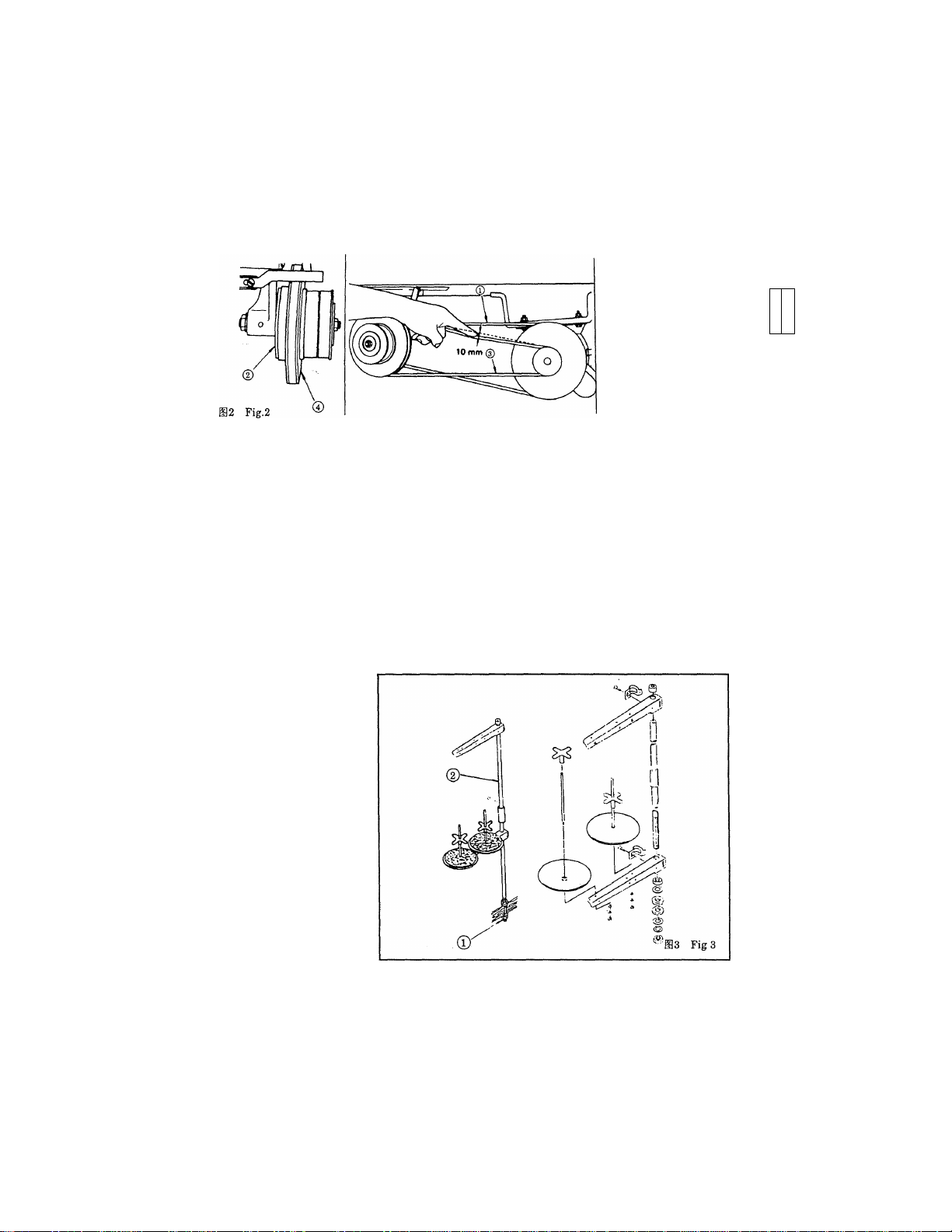

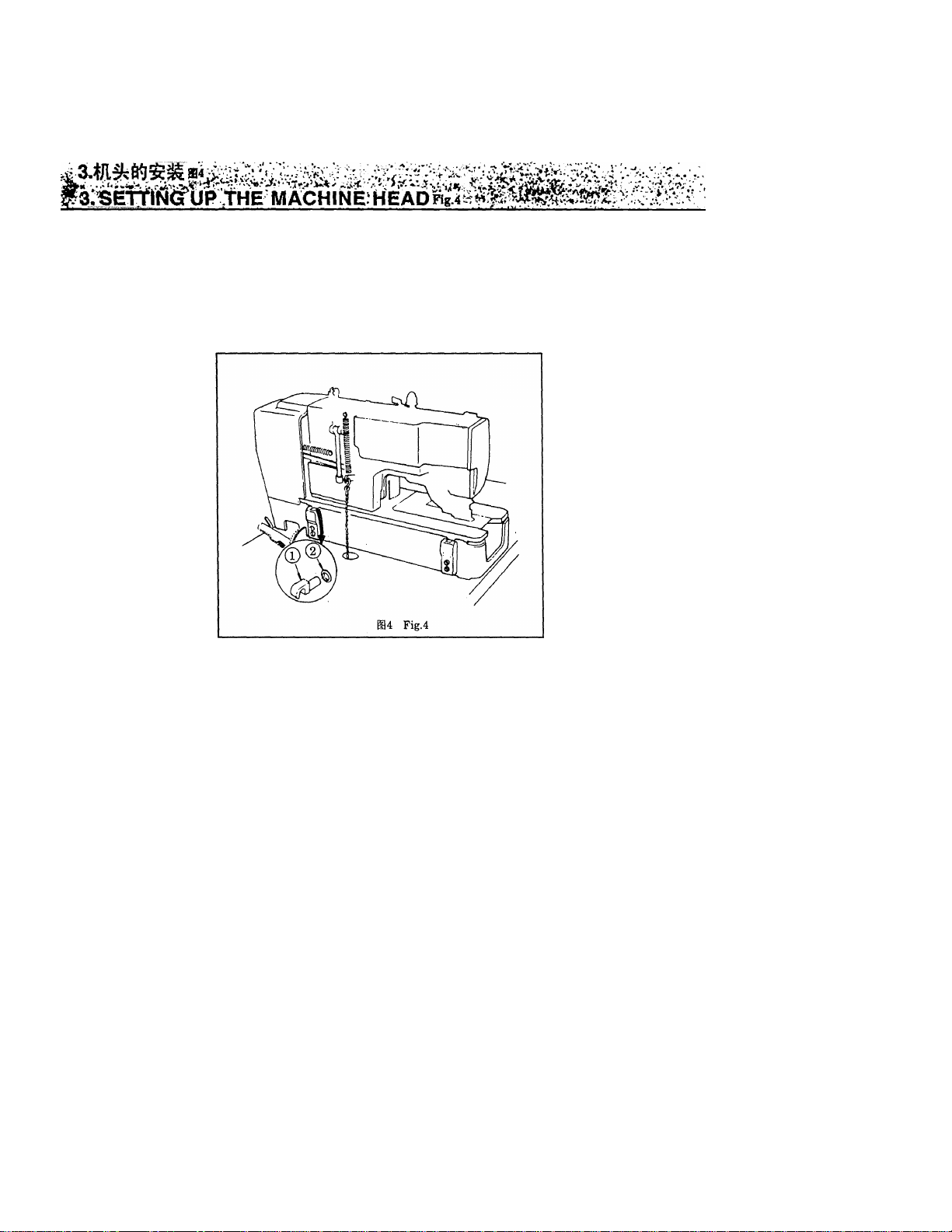

2. SETTING UP THE THREAD STAND Figs

Assemble the thread stand, and fix it in the table hole. Then tighten lock nut ® to fix the

thread stand. If ceiling wiring can be made, pass the power cable through spool rest rod

(2).

Page 13

Putting cushion ® into hinge ®, insert hinge ® into the machine head. Then, place the

machine head on the machine base.

i ; i:''A?/

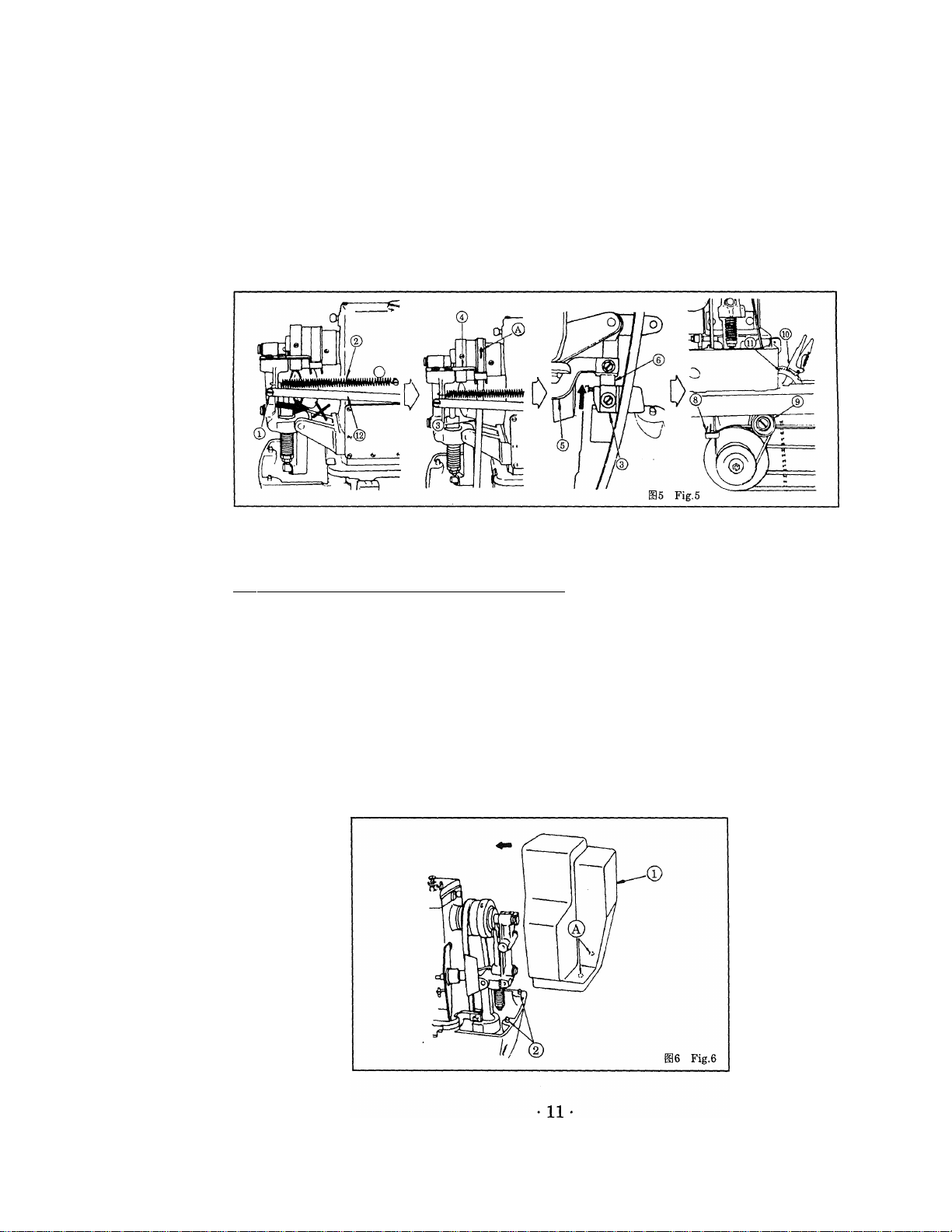

4. AtTACHiNdimE FLAT BELTFigi

siitwoin^sQsigigiih.

4)® Ain iftif ^11 c

1) Removing screw ®, remove spring @ from the suspension screw.

At this time, be careful not to push the starting link driving rod in the arrowed

direction.

2) Pass belt ® through belt shifter ® so that the belt rotates in arrow ® direction.

3) Reinstall screw ® and spring @.

4) Lift tripping lever ® in the direction, pass the belt between latch B (§) and latch A @.

10

Page 14

5) Passing belt shifter ® of the speed transmitter, attach the belt onto tension pulley d).

6) Put fixing pawl @ in the second groove from the bottom of ratchet © to provide the

belt with tension.

(NOTE) Some expansion or contraction in the belt caused by temperature or humidity

may make it rather difficult to install the belt. However, the belt will restores its

original length while in use.

5,

5. INSTÀLLÀTION/REMOVÀL OF BELT COVER Fig.6

Aligning guide pin @ with hole ® in belt cover ®, push the belt cover in the arrow

direction until it snaps.

For removal of the belt cover, bring down the belt cover in the direction opposite to the

arrow, and slide it up.

Page 15

l>l#Singer ”^ito

lUTBiiS'^iPyi o

* ®8

^zwmimo

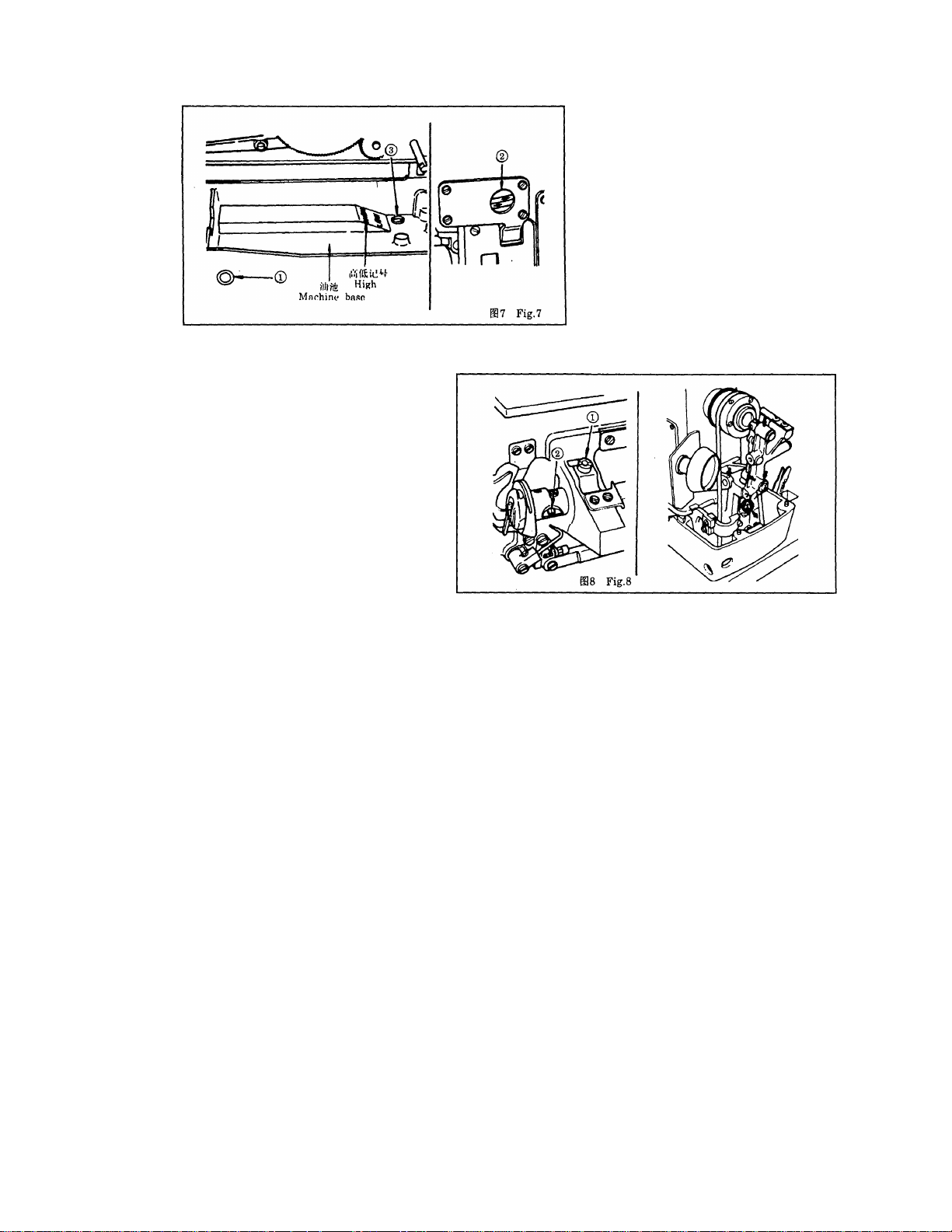

* Before starting the machine: Fig ?

1) Fill the oil reservoir of the machine base with singer oil type C up to the level indicated

by "HIGH”.

2) Supplement the oil when the oil level has lowered below the bottom line of oil gauge

3) When the machine has been properly lubricated, the oil is seen to run through the pipe

from oil sight window (D. (Low speed operation permits easier observation of the

lubricating oil.)

Drain dirty oil by loosening oil drain screw ®, and fill the oil reservoir with fresh oil.

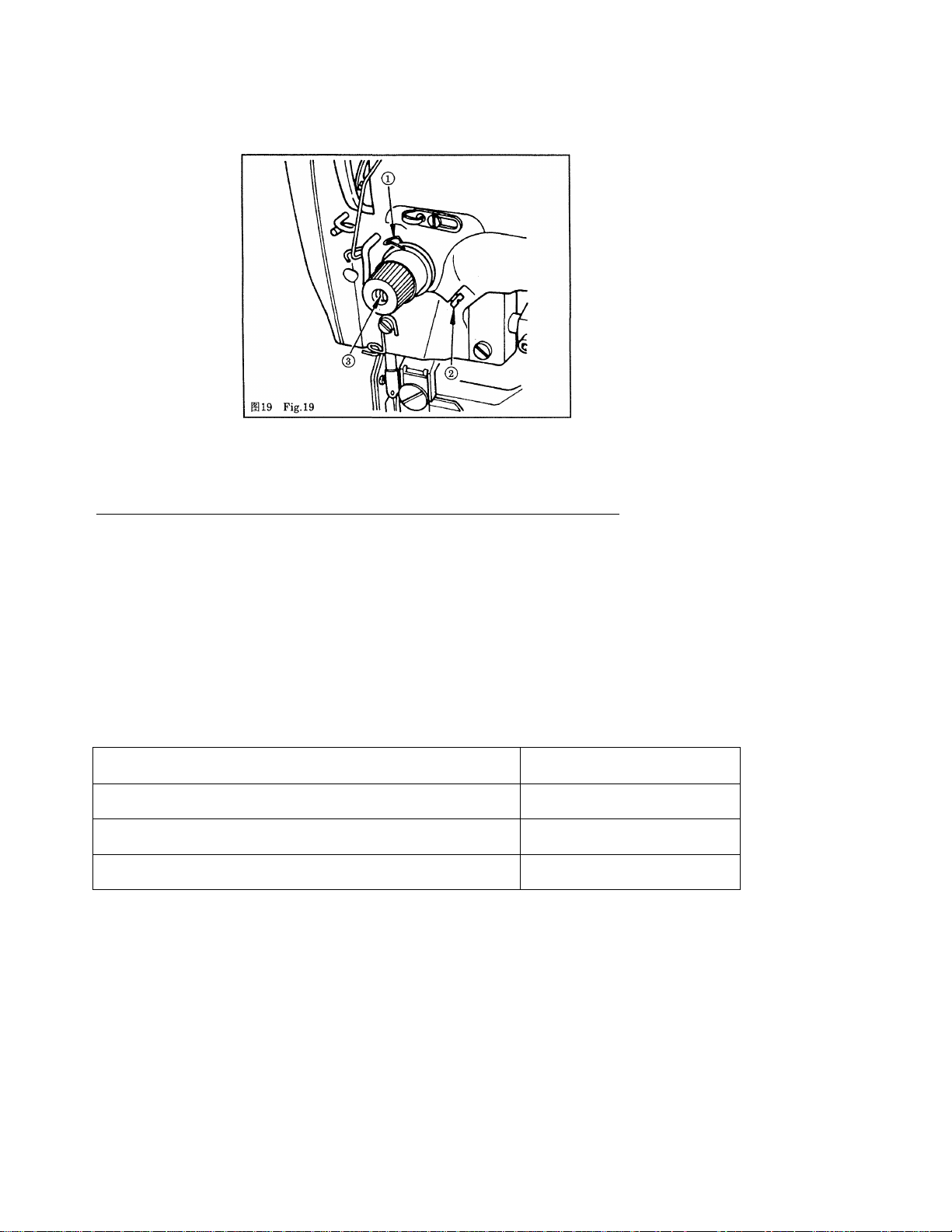

* Adjusting the lubrication for the sewing hook Fig.s

Adjust the volume of lubricating oil supplied to the sewing hook by turning oil adjusting

screws ® for rough adjustment, and (D for fine adjustment; oil volume is reduced when

turning the screws clockwise.

* Other lubricating points

1) Apply one or two drops of lubricating oil to the arrowed points once a week or every

other week.

2) Apply two or three drops of lubricating oil only to (S) point when the machine is

newly set up or has been out of use for a long time.

12

Page 16

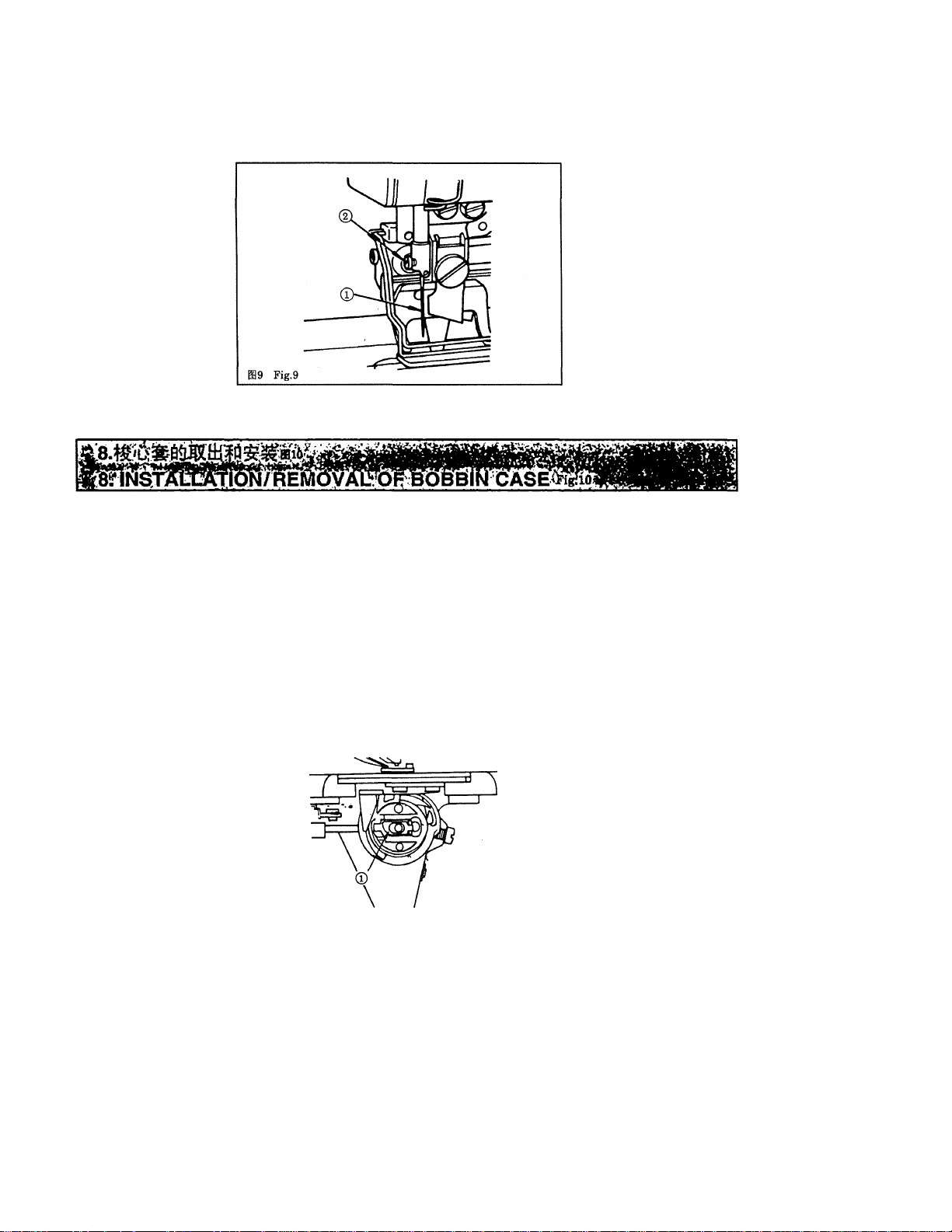

7. HOW TO INSTALL THE'NEEDLEFig.9

* *ta®Mmttftlj586iafflttSingerN-1955

ilm«o

* Turn off the motor power. Use needle cat. No. 1955-01.

1) Loosening needle setscrew ®, hold needle ® with its recessed part facing toward the

operator,

2) insert the needle fully into the needle clamping hole, and

3) securely tighten the needle setscrew.

13

Page 17

1) Lift up and hold bobbin case latch lever ® between two fingers to remove it from the

hook.A bobbin does not fall off the bobbin case while the latch lever is lifted up.

2) For installation of the bobbin case, push the bobbin case into the hook so that it is

supported by the hook shaft, and then snap in the latch lever.

SlO Fig.lO

14

Page 18

mil '■

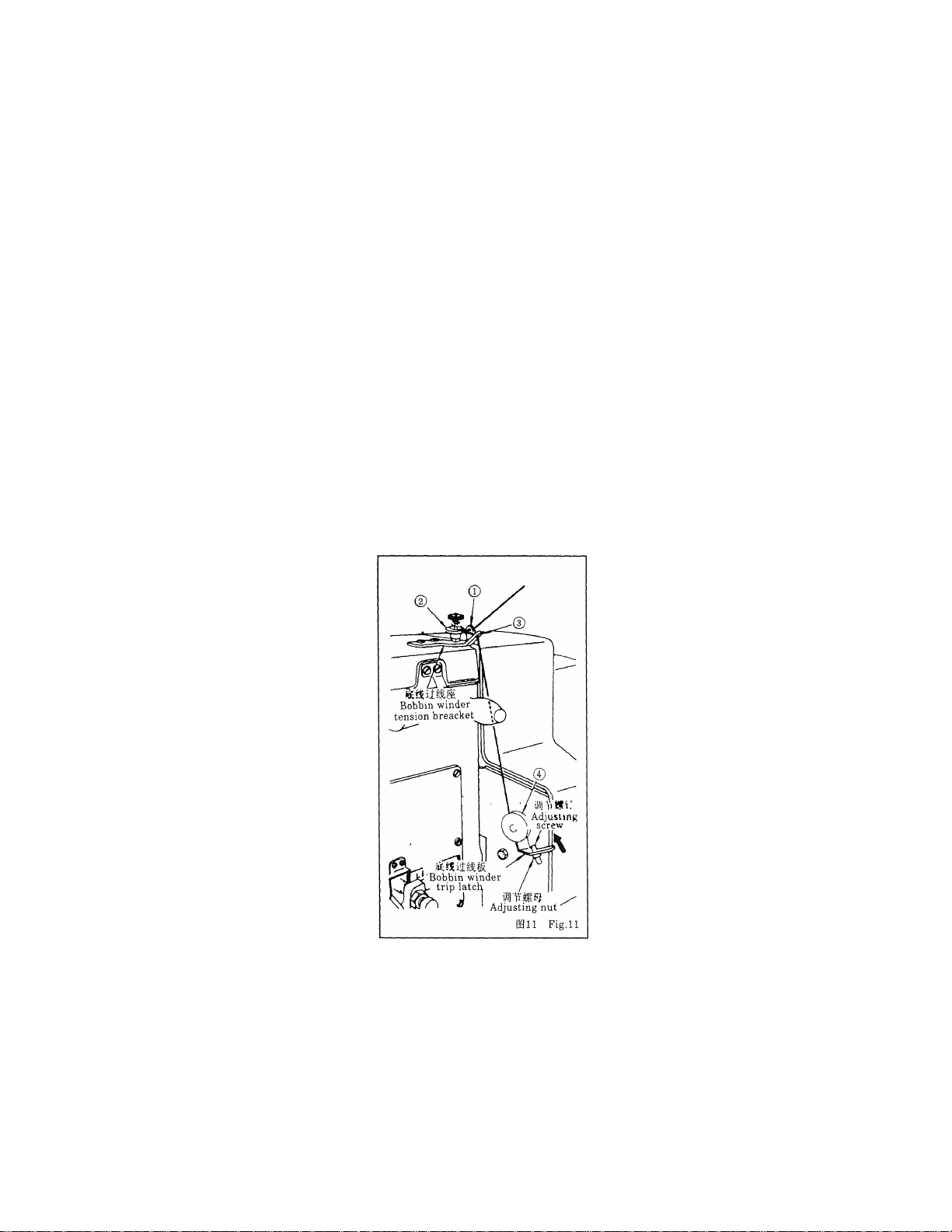

9. WINDING THE BOBBIN Fig.ii

i5iiiaiSK«Titi#, #iHT!titiiiciDgK®a*ijiTi.

5)';^m&is\¡¡¡-9m, ttjtitiiEffiiSiSisfts.

1) Fit a bobbin onto the bobbin winder shaft.

2) Take the thread from the spool and pass it through the guides in the numerical order

shown in the figure, and wind the end of the thread several turns around the bobbin.

3) Push the bobbin winder trip latch in the arrow direction, and the bobbin will be wound.

4) Loosening the adjusting nut, perform adjustment by screwing in or out the adjusting

screw so that the bobbin is wound about four-fifths full.

5) If the bobbin is wound unevenly, adjust the position of the bobbin winder tension

bracket for proper and even winding.

15

Page 19

T/i •*■__!- -

’16. AtfACi^Nil fHe BOBBiN fI^

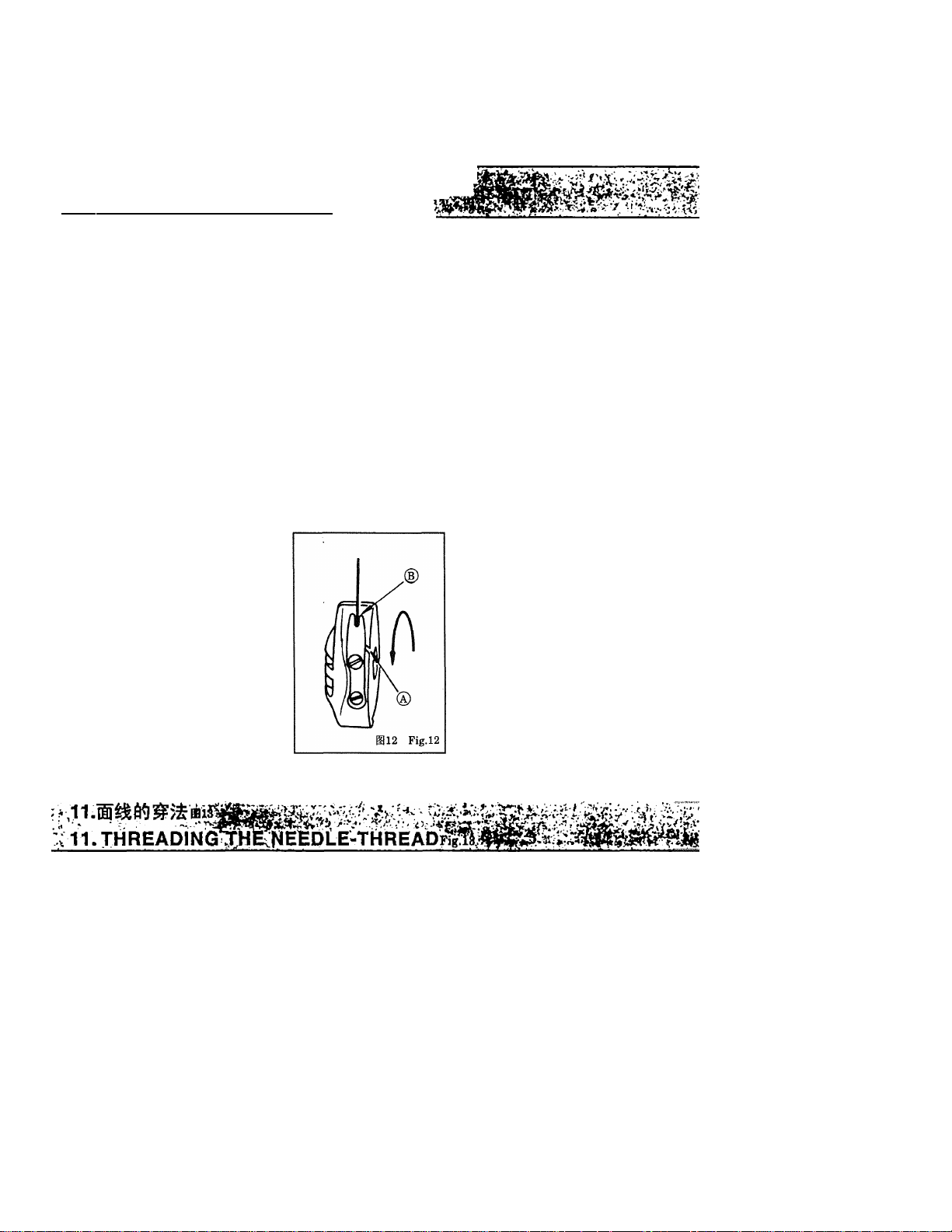

1) Hold and place a bobbin into the bobbin case so that the bobbin is wound

counterclockwise.

2) Passing the thread through thread outlet ® of the bobbin case, pull the thread, and

the thread can be drawn out from thread outlet (b),. passing under the bobbin winder

tension spring.

* Set the bobbin so that it rotates in the arrow direction when the bobbin thread is

pulled.

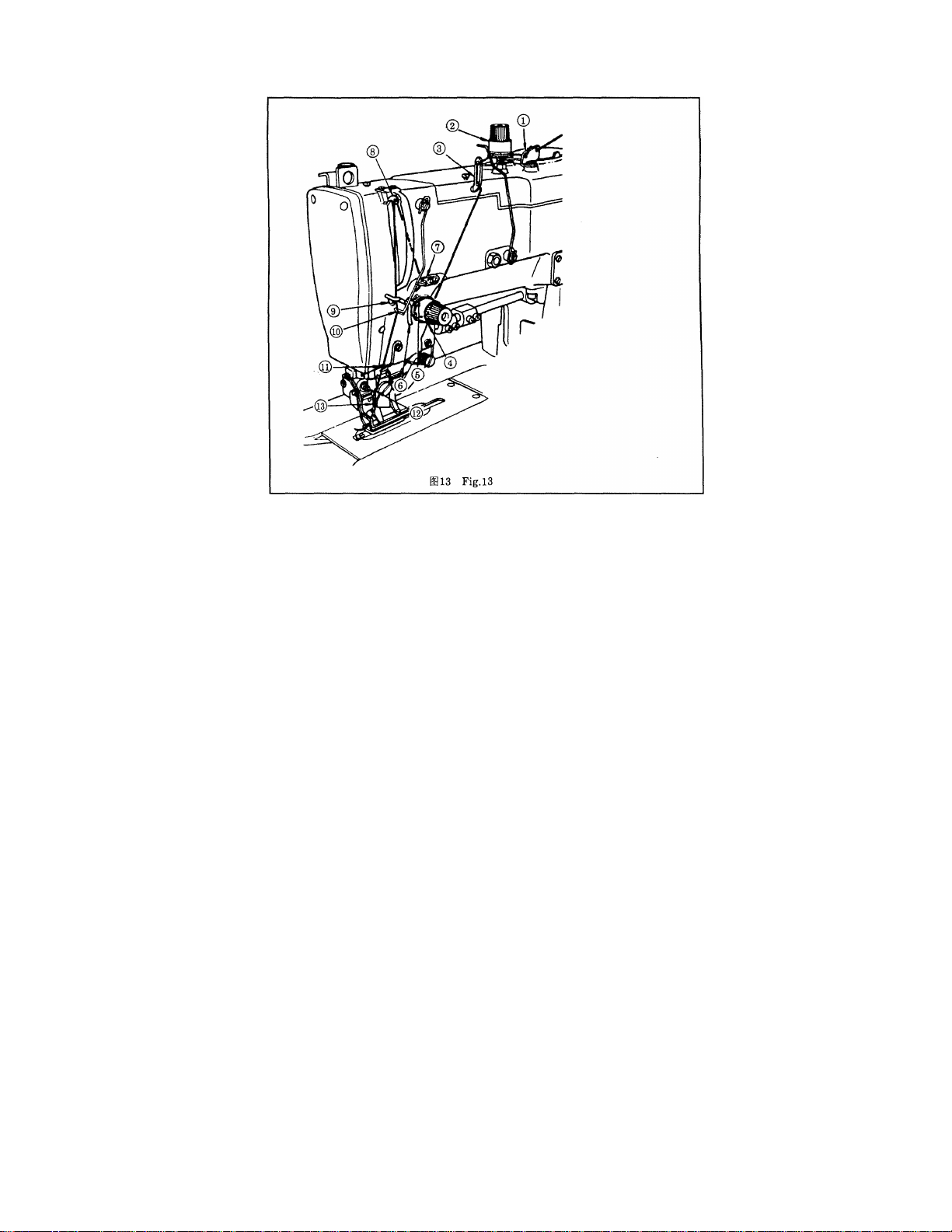

1) Pass the needle thread in the order as shown in the figures.

16

Page 20

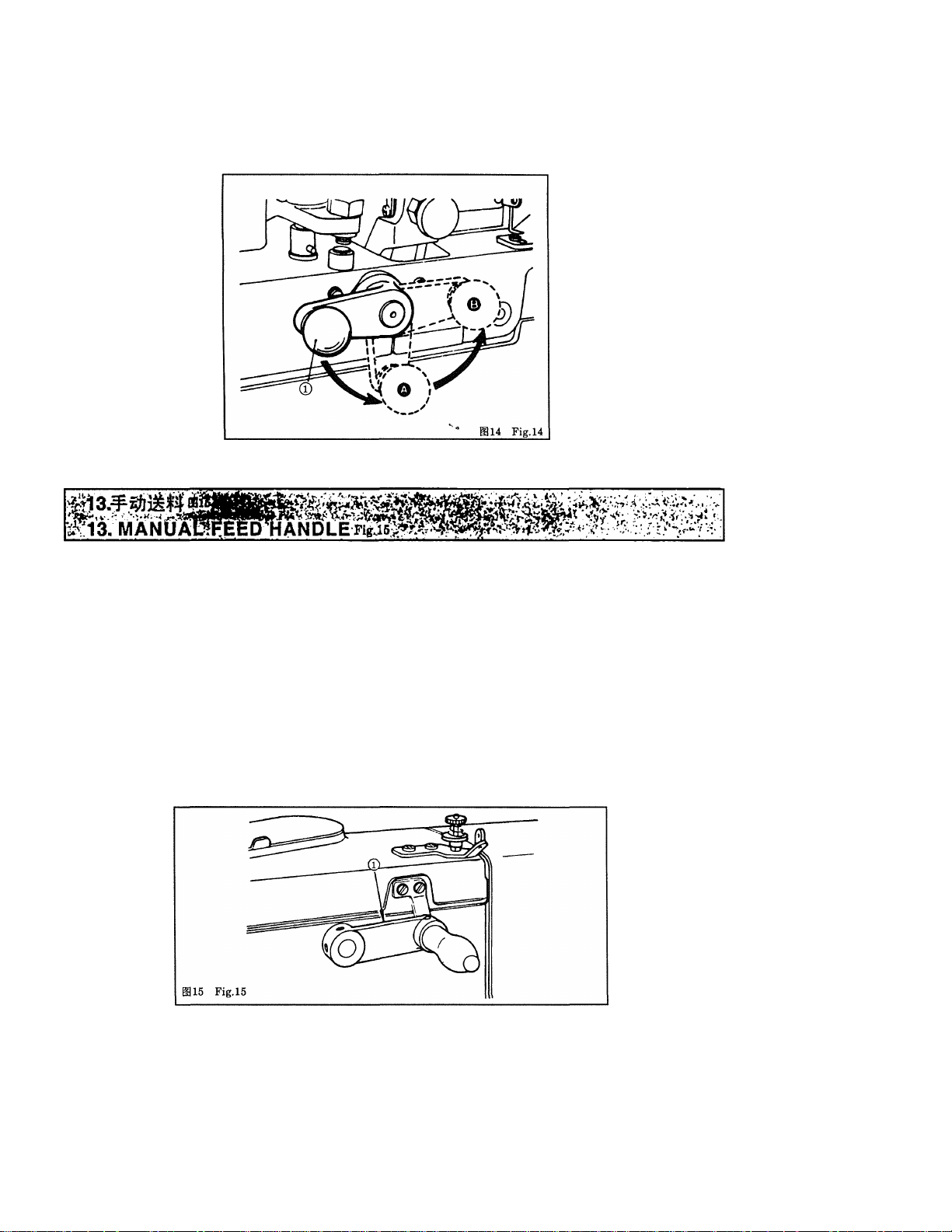

12. REDUCTION OF SEWING SPEED AND EMERGENCY STOPFigH

®^go

2)mWALBP^/^jg;3Ii5ito

*

®^go

2nmm±m9^o

* Reduction of sewing speed

1) Turn hand stop crank ® downwards to position ®, and

2) the machine will be immediately slowed down.

* Emergency stop

1) Turn the hand stop crank downwards to position ® , and further upwards to position

® and

2) the machine will stop immediately.

17

Page 21

When you want to feed fabric manually after giving an emergency stop or to resume

sewing from the point at which thread was broken, rotate manual feed handle © to

operate the cloth feeding mechanism.

(NOTE) Confirm that the needle does not stick in fabric before turning the manual feed

handle.

18

Page 22

i4.Rif±t;o7iPf BB16

14. HOW TO HOLD THE DESCENDING KNIFE Fig le

When you do not want to cut fabric after sewing because of thread breakage or some

other reasons, keep on pressing down knife stop lever ® lightly until the machine stops.

Then the knife will not descend.

BB17

15.TYPES OF STITCHESFig.i7

mmmm

iP-mmm)

This machine is capable of forming two different types of stitches, namely whip stitch and

purl stitch.

(Whip stitch)

The whip stitch is formed in zigzag showing the needle thread only on top of fabric, and

the bobbin thread on the bottom.

(Purl stitch)

When applying higher tension to the needle thread to permit it to pass straight through

fabric, the purl stitch is formed by the bobbin thread which is pulled over from both sides

to the center line.

19

Page 23

Whip stitch

Purl stitch

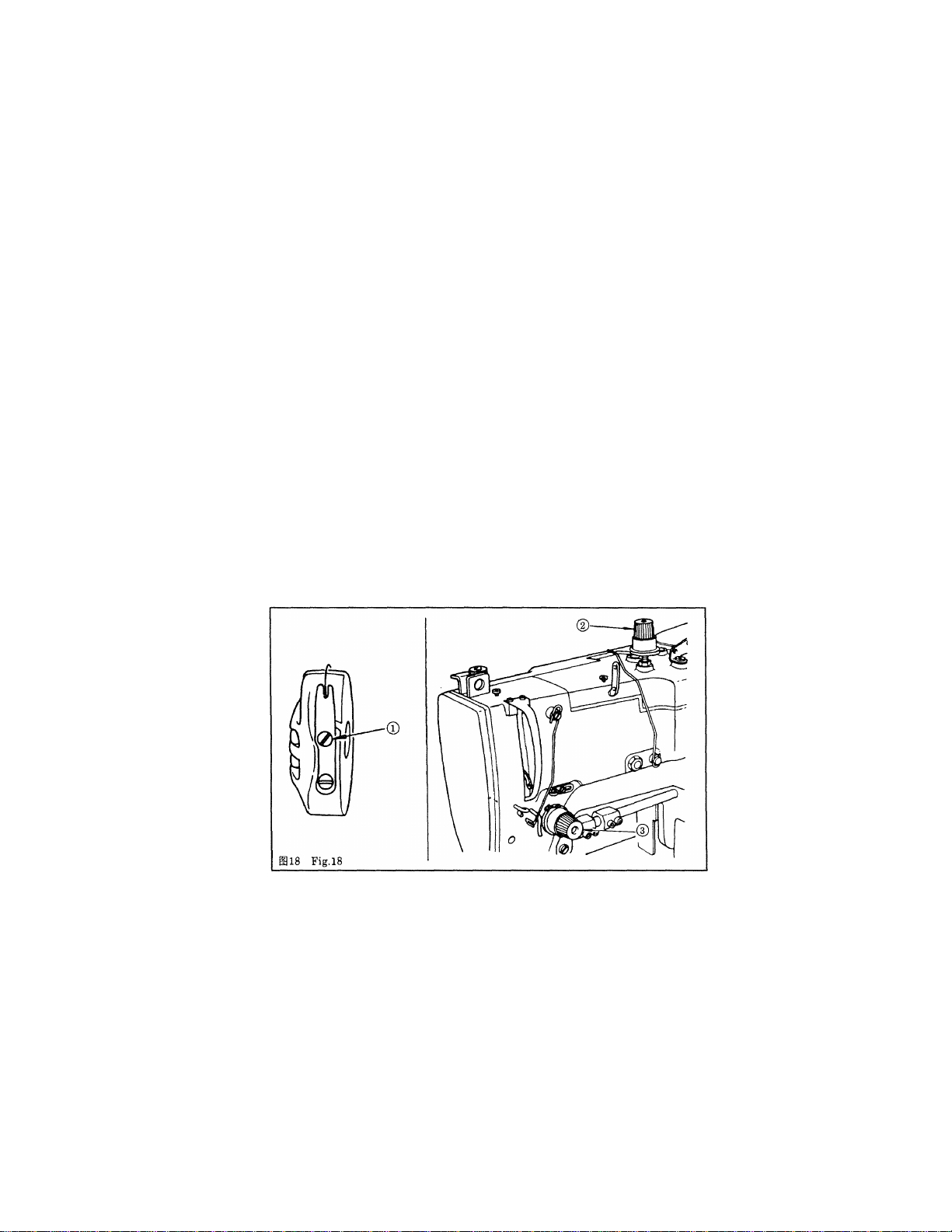

16.THREADyriNSiON Й8.18 . ^

* щшшйшт^мт^

Pallarel side seam

Bar tacking seam

ai7 Fig.l7

■ '.Л ::^’Л •

•' '■ ■ ‘ Л*'

(Ш2Ш^^-Р.ШШ)

* тшш(^шш)

тч1^т©^/>йй^йл^^шт®йш«й, тин

* Adjusting the thread tension for purl stitch:

1) Adjust the bobbin thread tension to approx. 15 to 20g by adjusting screw ® of the

bobbin case.

2) Adjust tension controller No. 1 ® for proper needle thread tension so that the bar-tack

part is formed by well-shaped whip stitches. If the tension is too low, bar tacking seam

may form thread knots on the rear face of fabric.

20

Page 24

3) Adjust tension controller No. 2 ® for proper tension of the pallarel side seams by

judging from the stitch formation.

* Adjusting the thread tension for whip stitch:

1) Adjust the bobbin thread tension to approx. 40 to 50g by adjusting screw © of the

bobbin case.

2) Exchange the adjusting springs of tension controllers No. 1© and No.2 ® each other

(the tension controller No.2 will have a weak spring).

3) Adjust tension controller No.2 ® to prevent ravelling off at the end of a seam.

4) The stitches of the parallel sides or bar-tack can be adjusted by tension controller No. 1

®.

* Adjusting the thread take-up spring (for purl stitch)

The suitable range of the stroke of thread take-up spring © is from 6 to 8mm with a

starting tension of 20 to 50g.

For adjusting the stroke of the thread take-up spring, loose screw ©, and insert a thin

screwdriver into the slit of tension post © to turn the tension post.

To adjust the tension of the thread take-up spring, insert a thin screwdriver into the slit

of tension post ® to turn it, with screw © tightened. The tension of the thread tade-up

spring increases when the tension post is turned clockwise, and decreases when turned

counterclockwise.

21

Page 25

^17.' ADJUSTING THE OVEREDOiNG LENGTHiBUnONHOLE LENGi^

2) ffi »#«?№&«# ®, fflffi ®±ff . (-iaWZI «a« 1^ «ijs

it»!®«®.

3) -nLS.m, -№№ij]m]]7pmwL№i^^.

* ffiSftSWiSffl

iiaiSMi!i@*is«w«-!5igisiKijiw«ai#.

GM344/10

GM347/10

GM348/10

1) Pull out cover ®, and raise cover ®.

2) Loosen nut ® by the spanner supplied with the machine. Set point ® to a desired

length on scale ® (this length is the same with the knife width), and then retighten

nut®.

3) Through your trial sewing, adjust the overedging length accurately to the exent that

the bar tacking seams are not cut by the knife.

l/4"~3/4"

1/4"~1"

l/4"~ 1—1/4"

22

Page 26

* Changing the work clamp check

Use work clamp check ® having the size nearly the same as that of a buttonhole length.

By removing setscrew ©, a work clamp checks can be changed together with a work

clamp check holder as a set.

GM344/10

GM347/10

GM348/10

Work clamp checkAVork clamp

check holder set Part No.

Applicable knife width

l/4"~3/4"

l/4"-l"

l/4"~ 1—1/4"

18. REPLACING THE KNIFE^g^a^

When sharpening or replacing the knife, remove it as follows:

1) Loosen setscrew ©, and remove knife © together with the washer.

2) Attach the knife to the knife holder so that the higher end of the slanted knife blade

comes down 2 to 3mm above the surface of the throat plate when the knife if brought

down to the lowest position.

(NOTE); Do not forget to install the washer when retightening the setscrew.

23

Page 27

'liTACKlNGiWIDfHyANb OVEREbGlil(^EreRENCE POSITIdNim^

№rn^mmnn^

mmn, K^siiirAiiiT®,

The needle swings from right to left with the right base line established as the reference

position.

Perform the adjustment as follows

1) To adjust stitch width ® , screw in or out screw ® , and set pointer @ to a desired

value on scale plate @. The actually sewn stitch width will be the half of the set scale

value (mm).

2) For adjustment of bar tacking width ® , screw in or out screw ®, and set pointer ® to

the value indicated by scale plate pointer @ , making the bar tacking width twice as

large as the stitch width.

24

Page 28

3) Adjust the position of right base line © by screwing in or out screw © so that it is

kept away from the cutting line of the knife. As screw © is screwed in, the right base

line moves to the left.

4) Through your trial sewing, further perform fine adjustment.

5) It is not necessary to adjust the position of left base line © since it remains

unchanged when the stitch width is changed. However, the left base line should be

moved to the left by screwing in screw @ if it is cut by the knife.

20. CHANGING .THE NUMBTER OF STITCHES

2)Bff^^^«iJWA.B.C

1371A3m±S$^H^*^,:^WG^.

..............

25

Page 29

-ia^

A 54

B

C 66

D

E

F 79

©

H

Pit 14^0

62

70

74

83

88 212

345 I

300

285 K

268

252

238

225

M

93

©

©

©

0

100

105

110

115

123

130

200

190

180

170

160

152

145

.

93f|-l^T

115#l^T

123#

* Spur gears

1) By selecting the spur gears, you can control the number of stitches as shown in the

table.

2) Alphabetical marks like A,B,C, etc,, and numerals like 123,152, etc. are both engraved

on each spur gear for identification.

3) Use a combination of gears which have the same alphabetical marks.

4) The numeral engraved on the gear installed in the rear position will represent the

fsiie©

10—12S4t

5i#:

0~2S^

26

Page 30

5) The machine head installed a couple of gears (symbol N)for 137lAl; The oter three couples

of gears (symbol G, J, L) are as accessories.

The machine head installed a couple of gears (symbol L)for 1371A2; The oter three couples

of gears (symbol J^ N) are as accessories.

The machine head installed a couple of gears (symbol H)for 1371A3; The oter four couples

of gears (symbol G, J, N) are as accessories.

Symbol No. of stitches

A 54

B

C 66

D

E

F

©

H

number of stitches provided by the combination of spur gears.

The circled alphabetical symbols in the above table show that the gears are included in

the standard accessories. All other gears are optional attachments.

* Attaching the spur gears to their shafts Fig.23

1) Push gear (D into the shaft so that it is securely fixed by the pin on gear bushing (D

located nearer to an operator.

2) For installing gear (D on the pin of rear gear bushing ® , push gear ® into the shaft

while turning it in the arrow direction.

62

70

74

79

83

88

No. of stitches Symbol

345

300

285

268

252

238

225

212

I

®

K

©

M

®

0

No. of stitches

93

100

105 180

110

115

123

130

No. of stitches

200

190

170

160

152

145

* Adjusting the low-speed cam position

Loosen setscrews (D, and adjust the position of low-speed cam (D to set clearance ® as

shown below:

Number of stitches

93 stitches or less

115 stitches or less

123 stitches

Clearance ®

10—12 mm

5 mm

0~2mm

27

Page 31

® 12mm <.

The presser bar goes up 9mm when the pedal is fully stepped down.

To adjust the pressure applied by the presser bar to fabric, turn presser spring regulator

®. When the pressure is not enough to prevent fabric from puckering, turn regulator ©

clockwise.

28

Page 32

22M

22. NEEDLE-TO-HOOK RELATION Fig25

(it

Ki A>1:.'^, fi^A0.05SA, c

i&M): uu'Jii:immf\-mw,

* Set the needle to hook relation in the following way:

1) Bring down the needle bar to the lowest point when the needle is coming down through

the center of the needle hole on the throat plate.

2) Loosen needle bar connection screw ®, and adjust the height of the needle bar.

(Setting the needle bar)

3) Insert the part 1” of timing gauge ® into the gap between the bottom end of needle

bar® and throat plate ® .

4) Retighten the needle bar connection screw to adjust the position of the sewing hook.

(Setting the hook)

5) Loosen setscrew ® of the hook sleeve by the bar spanner supplied with the machine.

6) Rotate the driving pulley in the correct direction until the needle starts to go up from

its lowest point.

7) Insert the part “2” of the timing gauge into the gap between the bottom end of the

needle bar and the throat plate, where the bottom end of the needle bar touches the

top of the part “2” of the timing gauge.

8) Align blade point © of the sewing hook with the center of needle @, and make

adjustment so that a clearance of approx. 0.5mm (1/64") is provided between the needle

and the blade point of the hook. Then, securely retighten the setscrew of the hook

sleeve.

(NOTE): If stitches are skipped, lower the needle bar by approx. 0.5mm (1/64")

from the timing gauge "1".

29

Page 33

ai26 , i; >

23. ADJUiSTING tHE BOBBIN THREAD WINDER Fig.2e

«a^aífeSSkíKSttSBí, ñTaii*K!Síi®*i)i

lío

1Í, nj.

Loosen screw @ to make adjustment so that the clearance between bobbin thread winder

pulley0and belt ©becomes approx. 1mm (3/64") when pulley © is apart from the belt.

If,however, the belt touches the pulley, adjust the tension by tension pulley ® to decrease

the deflection of the belt. And if the belt still touches the pulley, increase the clearance to

more than 1mm (3/64").

30

Page 34

24. 1^1127

24. ADJUSTING THE SPEED TRANSMITTER Fig2v

Tio

* Adjustment of the position of the belt shifter

When the hand stop crank is turned down to the low speed position, loosen screw ® and

allow the belt to move onto low-speed pulley ®, moving the position of belt shifter @.

* Adjusting the stopper screw

Perform adjustment by stopper screw @ so that belt shifter @ does not cause the belt to

come off high-speed pulley ® during high speed operation.

25.®^3? JlMi§=P №8

25. ADJUSTMENT OF THE NEEDLE THREAD TRIMMERFig28

31

Page 35

* Attaching the trimmer

Loosen setscrew ®, and adjust the height of trimmer ®. Set the height of trimmer ® as

low as possible, provided that it does not touch work clamp check ©, in order to minimize

the length of remaining thread on the needle after trimming.

* Closing timing of the needle thread trimmer

Adjust the closing timing of the needle thread trimmer so that the trimmer completely

colses when it advances farthest.

To perform the adjustment, loosen screw ®, and move needle thread trimmer driving

plate A ® back and forth. When the needle thread trimmer driving plate is moved

towards you, the closing timing is delayed with reduced amount of closing.

(NOTE) Confirm that an allowance of 0.3 to 0.5 mm is left between the blades of the

trimmer when the trimmer has completely closed.

If there is no such allowance, the trimmer would interfere with the operation of the

needle thread trimmer driving plate, preventing smooth movement of lifting lever®.

* Opening timing of the needle thread trimmer

Adjust the timing of the thread trimmer so that the trimmer begins to open gradually at a

distance of approx. 2.5 to 3mm (3/32" to 1/8") from the start.

To perform the adjustment, loosen screw @, and move needle thread trimmer driving

plate B ® back and forth. As it moves towards you, the trimmer begins to open earlier.

(NOTE); Take care not to cause the already fixed needle thread trimmer driving plate A

to get out of position.

32

Page 36

26.ADJUSTMENT OF NEEDLE THREAP TRIMMER HOLDER AND LIMITING PLATEFi«:!»

S;.(fi $ tt®ip ± ^ s ft® is I®-B)

am№isziifeJTsi.BftiizifES?®ft'f$fti!ft®i«-&9!№Ao.5a*.

Loosen setscrew and install and adjust limiting plate (D so that it comes in contact

with the blocking arm ® at the time.of slow start of the machine (when latch B ® is

engaged with latch A ©).

Needle thread trimmer holder ® should be installed in such manner that it engages with

cam @ by 0.5mm (1/64") when the needle thread trimmer opens.

33

Page 37

:27.W7lWfi №^:B3(iv , ^ ' -sS' .

27. TIMING FOR DROPPING THE KNiFE ,Fig:.30 •

t;ozi№tfB]Wmro

ifiiiio

Loosen screws ©, and move knife tripping segment @ in the direction shown by the

arrow, and the knife will drop earlier. Adjust it so that the knife drops two to three

stitches before the machine stops.

34

Page 38

28. TROUBLE, CAUSE, AND REMEDY

1. rrMH

if.ia

(2) M ''J^ Ft ?§ f n 7j

(4)Fi3#F&/7F$:£#-'7)'ll!ltiF]fi1^

(5)'a-'til/j-?i.4viE5ff]

(6)m^-;^^]l (6)ij^Fii:?lltt-

(1) ffi ^ 1? 73 JF/a f^ ^

(5ymyMr}f&m

(l)F^ JFJite^iJiS. [^ in

(2)^^7F 53i$riyiS.f^inf^

£i{

20

20

29

16

13

31

31

(3)±tijn^-7ti^^fi7££

(i)->fi '.7c-ej^;Ff;3irK7ja;7^

iL

(mrxyy. -.xtmxx

i2mmmm

(3))S^^7j7\7v

15-20^)

20

16

20

20

20

35

Page 39

4.

а)тхш=.шш±1

20

5. Ц—

т

7.

{2ШШ.Ш±1иЖХМ

аштш^^

(2)Ш=?±ШШ

(2)âi$4^îi

(2)|^л^®№йшт®, и^-ш

тхшшв.±

а)тхш-шш±1

{2УФШШ^±1 (15-20:Й) 20

а)шхштш

(2)Ш1ЕШШШ1уШ

(l)TÍffl3g^№PÍ&

31

20

20

20

16

22

29

36

Page 40

Trouble Cause Remedy Page

1. Needle thread is broken.

(1) The tension of the tension controller

No. 2 is too tight. controller No. 2

(2) The tension of the stroke of the take-up

spring is too great.

(3) Blade point of sevnng hook has bvirr orO Buff the blade point of the sewing hook,

scratches.

(4) Poor timing of the sewing hook.

(5) The thread path has scratches.

(6) The needle is too thin. O Replace by a thick needle.

2. Thread slips out of

the needle.

(1) The needle thread trimmer opens too

early.

(2) The needle thread trimmer opens when

the work clamp check is coming dovra.

(3) The whip stitch is not formed at the

start of sewing.

(4) Wrong threading.

3. Wobbling stitches

are formed in the

overedging seams.

(1) The tension disc No. 2 is too loose.

(2) The tension and stroke of the take-up

spring is not enough.

(3) Bobbin thread tension is too high.

4. Wobbling stitches

are formed at the

start of sewing.

(1) The tension disc No. 1 is too loose. O Increase the tension of the tension disc 20

(2) The position of the needle thread

trimmer is too high.

(3) The stroke of the take-up spring is too

great.

5. The needle thread

(1) The tension disc No. 1 is too loose.

at the first bar tacking comes out

(2) The bobbin thread tension is to high.

and lumps on the

bottom of cloth.

6. Stitches float over

cloth.

(1) Bobbin thread tension is not enough.

(2) Bobbin thread slips out of the thread O Properly thread the bobbin case.

path on the bobbin case.

7. Stitches are ski-

(1) The work clamp check is too large for

pped. the buttonhole.

(2) The cloth is made of light-weight O Delay the timing of the needle and the

materials.

O Decrease the tension of the tension

O Decrease the tension or the stroke of the

take-up spring.

or replate the sewing hook.

O Readjust the sewing hook's timing by the

timing gauge.

O Buff the thread path by cloth files, etc.

OMove back the needle thread trimmer

driving plate B.

OMove back the needle thread trimmer

driving plate B.

O Decrease the tension of the tension

controller No.l.

O Perform correct threading.

O Increase the tension of the tension disc

No.2.

O Readjust the take-up spring.

O Decrease the bobbin thread tension (15 to

20g for purl stitches).

No. 1 (15 to 30g),

O Lower the trimmer as low as possible.

provided it does not come in contact with

the work clamp check.

O Decrease the stroke of the take-up

spring, and increase the spring pressure.

O Increase the tension of the tension disc

No. 1.

O Decrease the bobbin thread tension (15 to

20g).

O Increase the bobbin thread tension.

O Change the work clamp check with a

smaller one.

sewing hook, (lower the needle bar by

approx. 0.5mm (1/64"))

20

20

29

16

13

31

31

20

16

20

20

20

31

20

20

20

20

16

22

29

37

Page 41

ìis: STITCHÌNG TROUBLES CAUSED BY OTHER REASONS

шт шшш жш

т^щШо

2.пттштз,^

Ж

й

(2)ЖШг^ШШт-Ш71ШШШШШ

шшш

(l)Â0fi^1ï'^3lûÿio

^шшшх.т

{2)^ШХ^к (2)mxx&^tj... 10

(3)^K3SHÄÄ^^fö

31

17

25

8

12

(Dm^JÈJ^ + vÈÂ^Æ

(2)Ш^-Ш'Ш

38

{2)ЖШШЫШХ^^Ж

(2)f^Î/|ifÎÈIâ^i)n?È 12

31

12

Page 42

(DìiTOZiP^^BÌfHKifeìfi)

34

25

16

8.«

(зтт^^ишн, штшщ-

атшшщ-

(З)ЖШШШЛЫ

13

29

31

31

39

Page 43

Trouble

Cause

Remedy Page

1. Starting pedal does

not work. (The

work clamp arm is fibrous dust.

not lifted up fiilly.)

2. Machine does not

reach the high

speed even when

the pedal is step

ped down fully.

3. A loud noise is

produced with a for small numbers of stitches.

stop-motion, or se

wing speed does

not lower at the

end of sewing.

4. Stop-motion is not (1) Stop-motion lever needs lubrication. O Lubricate the stop-motion lever.

smooth.

5. The machine does

not lubricate.

6. Knife is dropped (1) Position of the knife tripping segment is ©Adjust the position of the driving cam so

during high speed

rotation.

7. Knife is dropped

even if the needle

thread is broken.

8. Needle is broken. (1) The needle is bent. O Replace the needle.

(1) Needle plate, needle plate base or

bobbin thread trimmer is clogged wdth

(2) The needle thread trimmer is interfered

by the work clamp check or the trimer

driving plate.

(1) The hand stop crank is not in the O Correct the position of the hand stop 17

correct position.

(2) The belt shifter of the speed transmitter

has not changed to the high speed

pulley.

(1) Improper setting of the low speed cam O Readjust the setting of the low speed 25

(2) The flat belt is too loose. O Increase the belt tension by the tension

(3) The low speed V belt is too loose.

(2) The belt shifter of the speed transmitter

has not changed to the low speed pulley.

(1) Oil level in the oil reservoir is too low.

(2) Oil is not circulated.

not correct.

(2) The setting of the low speed cam for

numbers of stitches is not correct.

(1) The machine is threaded incorrectly.

(2) The needle and the hook blade touch

with each other.

(3) Needle thread trimmer hits the needle

when opening its blades.

O Tilt the machine head and clean them up.

O Readjust the installation of the trimmer.

or the position of the trimmer driving

plate.

crank.

O Lubricate the shifter driving pin.

cam.

pulley.

O Increase the tension of the V belt by the

motor.

O Readjust.the position of the belt shifter.

OFill the lubricating oil up to "HIGH"

mark.

O Apply oil to the oil return felts.

that the knife is dropped down at a

delayed timing.

O Correct the seting of the low speed cam.

O Correct the threading.

©Readjust the positions of the needle and

the sewing hook.

© Readjust the position of the trimmer.

©Adjust so that the hmiting plate and the

blocking arm touch each other at the

time of starting.

31

10

8

12

31

12

12

34

25

16

13

29

31

31

40

Page 44

30.^^

30. SPECIFICATiONS

1371A1 1371A2 1371A3

mi;3000tl75>

iSliLKiii: 6.4—19.0mm

(1/4"-3/4")

ШШШЖ

2.5—4.0

(3/32" - 5/32")

m-\-

1371A1

Application

Sewing speed

Buttonhole length

Bar-tack width

6.4—19.0mm

(1/4"-3/4")

2.5—4.0

(3/32" - 5/32")

6.4—25.4mm

(1/4" - 1")

2.5—5.0mm(3/32" - 3/16")

CAT. 1955-01

12mm(15/32")

SINGER " C " OIL

1371A2

Buttonholing for ordinary cloth, knit, etc.

Max. 3, 000 s.p.m.

6.4—25.4mm

(1/4"-1")

2.5—5.0mm(3/32" - 3/16")

6.4—31.7mm

(1/4"-W)

4

1371A3

6.4—31.7mm

(1/4" - 1^")

4

Needle

presser lift

Lubricating oil

CAT. 1955-01

12mm(15/32")

SINGER " C " OIL

41

Page 45

ILLUSTRATED PARTS LIST

42

Page 46

1

1. Frame and miscellaneous cover components

Ref.No. Part No.

GX332-S

GS0584

GQ284 A1

GQ284 A2

GQ284A3

GX333

GR3436/2

GR3438

GR3439

GS0685

GS037

GK248

GR3440

GSlOO

GK249-S

GR3441

GSlOO

GK250-S

GS0585

GR3442

GS079

GR3442

GR3443

GK251

GS079

GSlOO

GR1461

GR1463

GR3445

GR3446

GX581

GS013

GR1463

GK252

GR3447

GSlOO

GK253

GR3448

GSlOO

GK254/2

GR3450

GSlOO

GK256

GR3451

GR3452

GS0142

GS0585

GS0586

GX582

GR1461

GK257

GS0587

GR3453

GQ285

GK258

GS0588

GQ286

GR3454

GS0589

GR3455

GL15

GR3456

GR3457

GX581

GR3458

GS0590

GR3459

GR3460

GS037

GR3461/3

GS0591

GR3465

GK269

GW441

GR3466

GSlOO

GS0592

GL20

GS0593

GO480

GM343

GW442

GS0106

..............

..............

JHf№(1371Al)

H*}W1371A2)

fli}W1371A3)

ifnei±ttiT

EfiTtgir

SWJgSSS

TEWisiffiKie...

ilHhii»

KM tVIKStf

A'MhiiSU

TFWhUttlMTSin''-

..............

.............

..............

...........

.............

.............

.............

.........

............

........

......

ir

.......

.....

......

........

....

........

...........

s:«P3g*«iT

'i'. ji® 1 f fl.IE .............................................................................Rubber plug

ill ^ PU. ......................................................................................Rubber cushion

ttAPd«

iJWM*..........................................................

ilfiiiJiStttlT..................................................................................Screw 11/64-40 L=8.5

-liM ...........................................................................................Top cover

■ ..............................................................................Disc spring

iii ^^ITi iS W-

^ A .............................................................................................Rubber cushion.....................

...

...........................................................................

.....................................................................................Machine arm support rod

................

........................................................................

.....................................................................Screw 11/64-40 L=5

...........................................................................

............................................... .............................

...........................................................................

..................................................................................Side cover (a) .........................

...........................................................................

...........................................................................

..................................................................................Side cover asm.b

......................................................................................Oil sight window gasket

.....................................................................................Top cover gasket, front

....................................................................................

..................................................................................Screw 11/64-40 L=24

....................................................................................

n

...................................................................................

......................................................................................Top cover position pin

..................................................................................Rubber plug

.................................................

.....................................................................................Hinge screw D=6.35 H = 2.4

...

....................................................................

.................................................................................Thread take-up lever oil guard •

...........................................................................

■ —

...............

..............................................................^

..................................................................................Machine hinge plate

..................................................................................Pin

..................................................................................Hinge holder

......................................................................................Oil guage

J fL®-

......................................................................................'•■Bed slide

............................................................Machine base

.................................................

.......................................................................

........................................................................Nut 15/64-28-

..............................*............................................Washer

...........................................................................

.....................................................................Washer 6.2 X 13 1

...............................................................................

........................................................................

.........................................................................Oil drain cap gasket

.........................................................................Belt guard .......

.........

...............................................................

.......................................................................

...........................................................................

.....

............................................................................Ball screw..............................

................. ................................................................Nut 3/16-28

...........................................................................

..............................................................................

.

........................................................................

..........................................................................Screw 11/64-40 L=7

..............................

.........................

..................

............................

Description

’ 'Frame and miscellaneous ■ • • •

•Bed screw stud

•Model plateifor 1371A1>

"Model plate (for 1371A2>

"Model plate (for 1371A3>

"Model plate rivet.................

"Pace cover complete

"Pace plate gasket(r)

••Gaske8.............................

"Screw 1U64-40 L=18

"Screw 11/64-40 L= 10.5

"Left side cover

• 'Side cover gasket

"Screw 11/64-40 L=9

• 'Side cover (c)

' 'Side cover gasket (c)

"Screw 11/64-40 L=9

• 'Frame side cover (c)

"Screw 11/64-40 L=18

"Frame side cover gasket —

"Screw 11/64-40 L = 14

"Frame side cover gasket (c)

• 'Cushion

• 'Frame side cover ..................

"Screw 11/64-40 L=14........

"Screw 11/64-40 L=9

Rubber plug

Pin...........................................

Rubber plug

Side cover (a) .........................

Side cover (a)gasket

Screw 11/64-40 L=9

Washer

Screw 11/64-40 L=9

Top cover gasket, rear ...........

Screw 11/64-40 L= 18

Screw 11/64-40 L=12.8

Gear case cover

-. G^ar case cover plate

Screw 9/64-40 L=5

Machine base felt pad

Machine base screw stud

Washer 6.1 x 18.5 2

Screw 15/64-28 L=20.5

Screw 11/64-40 L=10.5

Screw 3/8-28 L=10

Belt guard set screw..............

Bottom guide

Screw 11/64-40 L=9

Guide Pin

Rubber bushing .......

Bed slide spring

.................

...........

...........

.........

...................

.........

.......

.........

.......

.....

...... —

.............

.........

............................

......................

.......................

..............

............................

...............

.............

...................................

..................................

........................................

.............

....................

...............................

...........

...........

...........................

......................

.............................

.......

...............

........................

............

..............

......................

............

.........................

...............

.............................

..............

..............

*...................

........................

............

.........................

..............................

—

.............................

...................

............

43

.

..

..

...

-

.......

.........

..........

..........

........

..........

......

.......

.......

.................

.

.............

.

•

Page 47

Page 48

2^±$í^

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

# -f

Part No.

GR3467

GS044

GT200

GX583

GR1261

GU210

GW212

GP170

GS0594

GS0595

GS0596

G0387

GR3468

GR3469

GS0116

GP171/2

GR3470

GR3471

GS037

GR3472

GR3473

G0482/2

GR3474

GR3475

GR3476

GS48

GR3477

GR3478

GS0597

G0485

GS04

GR3474

G0486/2

GS48

GR3479

GR3480

GZ443/2

GH580

GS0598

GS0156

GH581

GS39

GS0599

GH582/9

GX584

GS04

GR3482

GO490

GH586/3

GO270

GS09

GR3484

GR3485

GS043

2. Main shaft components

Description

......

...........

........

..............

......

...........

......

..................................................

......................................................

..........................................................Gasket

......................................................

......................................................

......................................................Screw 9/64-40 L=3.5

...........................................

............................................Retaning ring 30

...............................................

......................................................Screw 11/64-40 L = 10.5

...................................................Washer

...................................................Washer

...............................................

......................................................

...................................................Oil wick

...................................................Oil wick

......................................................

.............................................Main shaft thrust washer (C)

......................................................Main shaft thrust collar asm.-

..........................................................Screw 1/4-40 L=4.5........................................... 4

......................................................Main shaft bushing, intermediate

...............................................Screw 15/64-28 L=10.5

...............................................

nP#...............................................Bushing, front

......................................................Screw 15/64-28 L=7-

...................................................Oil wick.......................

S'J-

-h^oP#

..................................................

...........................................................

.......................................

..................-.......

tt-ffffiffiiiiT..............................................

.......................................

...........................................

..................................................

......................................................Thread take-up lever asm.

......................................................Hinge stud......................................................... 1

...............................................Screw 15/64-28 L= 10.5

...............................................Oil wick............................................................. 1

...........................................

..................................................

...........................................

...........................................

...........................................

......................................................Oil wick............................................................. 1

......................................................Screw 9/64-40 L=4............................................ 2

•Stop motion cam presser plate"*'

•Screw 11/64-40 L=6.8.....................

•Stop motion cam*

•Stop-motion cam position pin

•Bakelite segment.............................

...........................

'Stop-motion cam pin slide block*

•Stop cam pressure spring'"""""

•Driving pulley

•Screw (c)

Screw 1/4-40 L = 5

Screw 1/4-40 L=5.0

...............................................................

Main shaft thrust seal

Thrust washer a................................................ 1

Loose pulley asm.............................................. 1

Bearing retainer

.............................................................

.............................................................

Main shaft bushing, rear...............................

Oil seal.............................................................. 1

Screw 15/64-28 L=7

Oil seal-

Oil felt

.........................

Main shaft

•Counterweight

•Screw 9/32-28 L = 16'

•Screw 9/32-28 L=16’

•Needle bar crank........

Screw 1/4-40 L=6.........................................

Screw 1/4-40 L=12.......................................

Vinyl tube, white D = 6

Oil felt washer.................................................. 1

Needle bearing, B

End screw left................................................... 1

Oil wick holder

..........................

.........................................

......................................

.....................................

......................................

........................................

..............................................

...............................................

..................................

............................................................

............................................................

.........................................

....................................

.......................

.............

......................................................

...........

...............................

...................................

...................................

.............................................

................................................

.......

..........................

.........................

...................

mm

Amt.

1

3

1

1

1

2

1

1

1

1

1

1

1

3

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

44

Page 49

Page 50

3. Hook driving shaft components

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Part No.

GN200

GN201

GN202

GR3486

GS0600

G0491/7?/E^^i

GR3488

GS0601

GL48

GS0602

G0494

GR3490'T$fimrfi

GR3491 TiAfriA

GS48

G0495

GS48

G0496

GR3492

GS48

GR3493

GZ445

GR3495

G0497

GR3496 yi milf

GS0603 yi

GS0604

GR3497 yi^^....................................................Oil supply felt holder

GS062

GC201

GS0605

GR3498

GC202

GS0605

GR3499

GK260

GSOlO

G0498/2-S:iiT$Ai............................................Bushing, lower

GS0606

GZ446

GO501/2'S:iA-h^S^'i^

GS0606

GC203

GS0605

GR3498............................................................Thrust washer.................................... 1

GC204

GS0605

GR1469 ...............................Thrust coller asm.

GS0597

...........

..............................

.......

.............

.................................

.........................................

.........................

.........................

BT

...................................

^....................................

......................

.........................

.............................

^

......................................

.............................

^

......................................

.............................

.............................

.............................

Tfi

.....................................................

.................................

.....................................

.............................

.................................

.........................

.....................................

.....................................

.............................

.............................

.................................

.................................

................................

.............................

.........................................

.............................

.................................................

....................................

.............................

.................................

.................................

.....................................

.............................

........

,................................Screw 1/4-40 L = 4.5

•“•• Bobbin case positioning plate-• i 1

••••••• Screw 11/64-40 L=5..........................V 2

Description

Hook c asm

Bobbin case asm-

Bobbin ..................

Hook sleeve asm.

Oil wick asm...................................... 1

Oil adjusting screw............................ 1

Nut 9/64-40........................................ 1

Screw 1/4-40 L=7.0

Bushing asm., front

Oil wickHook driving shaft

Screw 15/64-28 L = 7......................... 1

Bushing, intermediate

Screw 15/64-28 L=7........................... 1

Bushing asm., rear............................. 1

Oil wick-

Screw 15/64-28 L = 7......................... 1

Rubber plug........................................ 1

Bobbin case asm.

Oil adjusting rubber

Bushing

Plate spring

Hook oil adjusting screwPositioning screw

Screw 15/64-28 L = 9

Pinion asm.......................................... 1

Screw 1/4-40 L = 7

Washer

Gear asm. large................................... 1

Screw 1/4-40 L=7

Washer

Oil shield

Screw 1/4-40 L = 7

Screw 15/64-28 L=11.5

Upright shaft

Bushing, upper

Screw 15/64-28 L=11.5

Pinion asm.......................................... 1

Screw 1/4-40 L = 7

Gear asm............................................. 1

Screw 1/4-40 L = 7

............

..........

............................................

............................................

...................................

.............................

...............................................

...............................................

............................................

...................................

......................................

...................................

..................

..................

.......

........ 1

•••••

...............

...........................

...........................

............................

......................

...............................

..........................

...................

........................

.........................

.............................

...............................

.............................

......................

......................

.............................

.............................

..............................

.........................

1

1

... 1

... 1

... 1

--• 1

Amt.

1

4

1

1

1

1

1

1

1

1

1

2

1

2

1

1

2

1

1

1

1

1

2

2

1

2

45

Page 51

Page 52

Ref.No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

4.Presser bar work clamp carrier components

№ ^

Part No.

GS0607

GZ447

GW443

GR3500

GS0586

GR3501

GS033

GO504

GR1306

GX585

GR3502

GR3503

GSOll

GS0608

GS0106

GR3504

GS0609

GS044

GM344/10A1 &.

GM344/10A2 Œ,

GM344/10A3 E

GR3505

GW444

GR3506

GX299

GS0610

GS045

GR3507/2A1 EWteRPft(1371Al)............................................................. Work clamp check (for 1371AD-..............................

GR3507/2A2 EiBltepP#(1371A2)............................................................. Work clamp check (for 1371A2)...............................

GR3507/2A3 EWfenP'(^(1371A3)............................................................. Work clamp check (for 1371 A3)..............................

GM345

GK261/3

GS0611

GR3511

GS090

GH588

GS0612

GZ448

GR3512

GS030

GR3513

GX587

GS0613

GR3514

GS48

GS0614

GS0615

GR3515A1 a?L'K:Æ№'lt(1371Al)--GR3515A2 a?L-fefiÎtlt(l371A2)GR3515A3 M?L-iéfiÎgtt-(l37lA3)-

GL15 m-feSiUlïÎP.#........................................

GH589/3

GH591

GS0616

GU211

GS0617

GL15

GH592

GR1510

GR3516/2

GS026

GR1299

GX122

GR3518/2

GH593

GS026

GX589

GS04

GR3520

GS0618

GW445

GS0619

GS0620

Eff.............................................................................................. Presser bar...........................................................................

Eff ............................................................................................. Presser spring......................................................................

Eff ............................................................................................ Presser bar position bracket asm.........................................

Eff ........................................................................ Screw 1/4-40 L=8...............................................................

EWï«Îè*...................................................................................... Collar...................................................................................

EWiSIÊf^..................................................................................... Connecting pin....................................................................

EÏSififèâ?

E

EW«i^5K№tHT.................................................................

EWHeft^lriSf.W........................................................................... Screw 11/64-40 L = 8.5..............................................

EPtSiiiT....................................................................................... Screw 3/32-56 L=1.9..................................................

EWiEfe........................................................................................ Work clamp carrier.......................................................

iSMSSMtenP#.............................................................................. Bracket cover

fflifLKlSiSlfFttiitffiiT.................................................................... Hinge screw D = 8.73 H = 6.0

ÎÊEWi^№ff--

ÎtEWi^WlÎfÆ

î^l4ai4iiT...........

ÎËÎÎTÈMWW

i^if-lTlÎ!s№iStî

fèEWfefeff

fêEjBHèfâwa®

ÎèEWmfâffSP#

№EPHÎfâff«JtÎWÎT-

i&EWmlfeff...................................................................................... Link............................................................................................... 1

ÎèEWjS&ffSP#

ÎÈEPÎàff............

ÎtEWtlffiS

ÎtEWttff

fâiîTÎiiT

ÎêEWtlfffeSc

........................................................................... Presser spring regulator.......................................................

...................................................................

............................................................................ Screw 11/64-40 L=12.8......................................................

................................................................................ Slide roller...........................................................................

....................................................................................

..............................................

.........................................

.........................................

.........................................

.......................................

nP#(1371Al)......................................................................... Work clamp check holder asm.(for istiad-

nP#(1371A2)........................................................................ Work clamp check holder asm.(for 1371A2)-

rP#(1371A3)

^

........................................................................

........................................................................................ Work clamp check holder........................................

.......................................................................................

...........................................................................

..............................................

.................................................................... Hinge screw D = 7.9-4 H=1.5

................................................................................. Screw 11/64-40 L = 8

......................................................................

......................................................................

........................................................................ Work clamp carrier bracket pitman-

...................................................... .............................

............................................................................ Work clamp carier bracket guide

...................................................................

......................... Work clamp check spring set pin

mi-

..

.........

......

...................

..............

...

........

.

..

.

..............

..............

...........

.

........

..............

...........

............

....

..............

Description

Presser bar guide bracket....................................................

Bracket

................................................................................

Finger guard............................

Screw 9/64-40 L=6

Screw 9/64-40 L=15 --Screw 11/64-40 L=7---Work clamp bracket---Screw 11/64-40 L=8.2-

Work clamp check holder asm.(for 137ia3)-

Work clamp check holder spring..................................

Work clamp check spring

Work clamp arm bracket asm.......................................

Screw 15/64-28 L=14

Work clamp arm slide rod-

Screw 11/64-40 L=9.5

Work clamp.........................................................................

Connecting pin---.-...........................................................

Screw 9/64-40 L=8.5.........................................................

Bearing arm.......................................................................

Screw 15/64-28 L=7.........................................................

Screw 15/64-28 L=11.0....................................................

Length regulating hinge stud.............................................

Length regulating shaft guide (for 137 lAl)Length regulating shaft guide (for 1371A2)Length regulating shaft guide (for 1371A3)-

Nut 15/64-28....................................................................

Length regulating scale asm.

Bell crank asm.-.................................................................

Screw 15/64-28 L = 15.5..................................................

Roller.................................................................................

Bell crank roller stud..........................................................

Nut 15/64-28

■ Presser bar lifting rod, long...............................................

- Snap ring 5........................................................................

■ Lever asm, front

Hinge screw D = 7.24 H = 3.3--

Split pin...............................................

Lever asm, rear....................................

Presser bar lifting rod-........................

Hinge screw D = 7.24 H = 3.3-Tripping lever hinge pinScrew 15/64-28 L=10,5

Presser bar lifting lever

Suspension screw

Presser foot lifting spring---Suspension screw

Lifting Lever stopper

...............

........................................

.................................

.....................................

...............................................................

.................................................

.................................................

................................................

...................................................................

................................................................

............................

.....................................

..........................................

.................................

.............................................

.................

..................

.................

..................

....................

.....................

.......................

................................

................................

...........................

.................

..................

..................

................... 1

................... 1

................... 1

................... 1

Amt.

2

1

1

1

1

1

1

1

1

1

1

1

■ 1

■ 1

■ 1

• 1

- 2

- 1

- 1

- 1

• 1

- 1

- 1

- 1

- 1

- 1

• 1

- 1

- 1

- 1

- 1

- 1

- 1

- 1

- 1

- 2

- 1

- 1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

2

1

1

46

Page 53

Page 54

5. Needle bar frame components

Ref.No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Part No.

GZ450/4®

GR3521

GL15

GU181

GO505/3lf?S'itr?iS^i'^

GR3522 If

GR3523

GS04

GO507

GS04

GR3524

GH595

GS091

GR3525 If $4 is ft IS

GR3526 tbIf

GS0621 If ...........................Screw 11/64-40 L=12.0

GL31 ...........................Nut 11/64-40

GS0622

GL0117

GR3527 If

GS0623 If^X^^ii^T..........................................Screw 11/64-40 L = 16.0

GT201/5ltffif

GR3528 If

GS0614 ...................................Screw 15/64-28 L=11.0

GS48

GZ452/2lf ...............................Knife driving shaft asm.

GS0614

GR1462 If

GC206

GS39

GR3530 ft"IT If

GX584 fllTIf^^f^

-GSO^

GR3531 tfUftiS.......................................

GR3532

GR3533 TtlTTfti^3^

GS0625 Ttif ...............................Screw 9/64-40 L=5.0

GR3534

GZ454

GSOlOO

GZ455

GR3535 tllTii^^

N1955-011/1IT................................................Needle #12

GS071 XHiiH..................................................Screw 1/8-44 L=4.5

GR3536 ^ITIf

GS0611

.........

.....

....................................Rubber ring

....................................Bushing, rear

BT

p ra Tt^

.................

...............................................

.....................................

.........................................

..............................................

...........................................

.......................................

.........................................

.....................................

.................................................

..............................................

.

........................Framer rock shaft crank asm., front

........................Stud'...................................................... 1

........................Nut 15/64-28........................................ 1

........................Needle bar connection slide block

........................Bushing................................................. 1

........................Oil wick................................................ 1

.............................

...............................

........................

...................................

.............................

.....................

.............................

.............................

.........................

.................................

.............................

.........................

.............................

.....................

...........

.........

.................................

.............................

.........................

.....................................Screw 11/64-40 L=8

Description Amt.

........................................

Screw 15/64-28 L=10.5

......................................

Screw 15/64-28 L=10.5

Oil felt................................................. 1

Frame rock shaft crank asm., rear

Screw 15/64-28 L= 12-....................... 1

Oil wick

Needle bar pitman

Hinge screw D = 7.94 H=8

Nut 1/4-24

Rock shaft connection guide

Needle driving gear asm................... 1

Thrust collar asm. D=9.53W=10

Screw 3/16-28 L=7

Screw 15/64-28 L=11.0

Rubber plug........................................ 1

Pinion

Screw 1/4-40 L=6

Needle bar frame................................ 1

Hinge stud

Screw 15/64-28 L=ll

Rock shaft connection guide

Oil felt................................................. 1

Oil felt retainer, lower