Page 1

SINGER

OPERATOR'S GUIDE

MODEL 132B26

Page 2

4;

s

K

if

S;

i:

SPECIFICATIONS

SPEED:

ROTARY HOOK:

BOBBIN :

NEEDLE:

NUMBER OF NEEDLE

THREAD:

FEED MECHANISM:

STITCH LENGTH:

PRESSER BAR LIFT;

PRESSER FOOT:

WORKING SPACE:

132 B26

800 r.p.m.

ii32S

34.5(i X 15.6 mm

Cat. No. 4950 ^rlS—2

Two

Synthetic If 2-# 00

Drop feed

Maximum 8 mm

Maximum 10 mm

Flat presser foot &

roller presser foot

254 mm x 195 mm

Page 3

CONTENTS

I’lige

Setting Up the machine............................................................................................................. 2

Speed of the machine ............................................................................................................ 3

Oiling........................................................................................................................................... 4

Needle and thread....................................................................................................................5,6

Winding bobbins........................................................................................................................ 6

Inserting and removing the bobbin case and bobbin........................................................ 7

Threading the machine ............................................................................................................ 8

Preparing for sewing................................................................................................................. 8

Regulating the thread tension................................................................................................8,9

Adjusting the presser foot pressure..................................................................................... 9

Adjusting the stitch length....................................................................................................... 9

Bulge guide of sewing material ............................................................................................... 9

Gauge parts.............................................................................................................................. 10

One or three needle machine................................................................................................ 10

Piping or beading work .......................................................................................................... 10

Dummy-joint finish with knife

.............................................................................................

10

Two roller presser feet........................................................................................................... 11

Timing between the hook and needle.................................................................................. 11

Adjusting the height of the needle bar ............................................................................... 11

Adjusting the hook retainer bracket..................................................................................... 12

Adjusting the height of the feeder........................................................................................ 12

Adjusting the feed bar hinged stud....................................................................................... 12

Timing between needle and feeder........................................................................................ 13

Adjusting the up and down travel of the feeder................................................................. 13

Adjusting the height of the presser foot

...............................................................................

14

Adjusting the thread controller spring................................................................................. 14

SETTING UP THE MACHINE

Carefnllv unpack the machine from the packing case and make sure that al

small parts and accessories are removed from packing material.

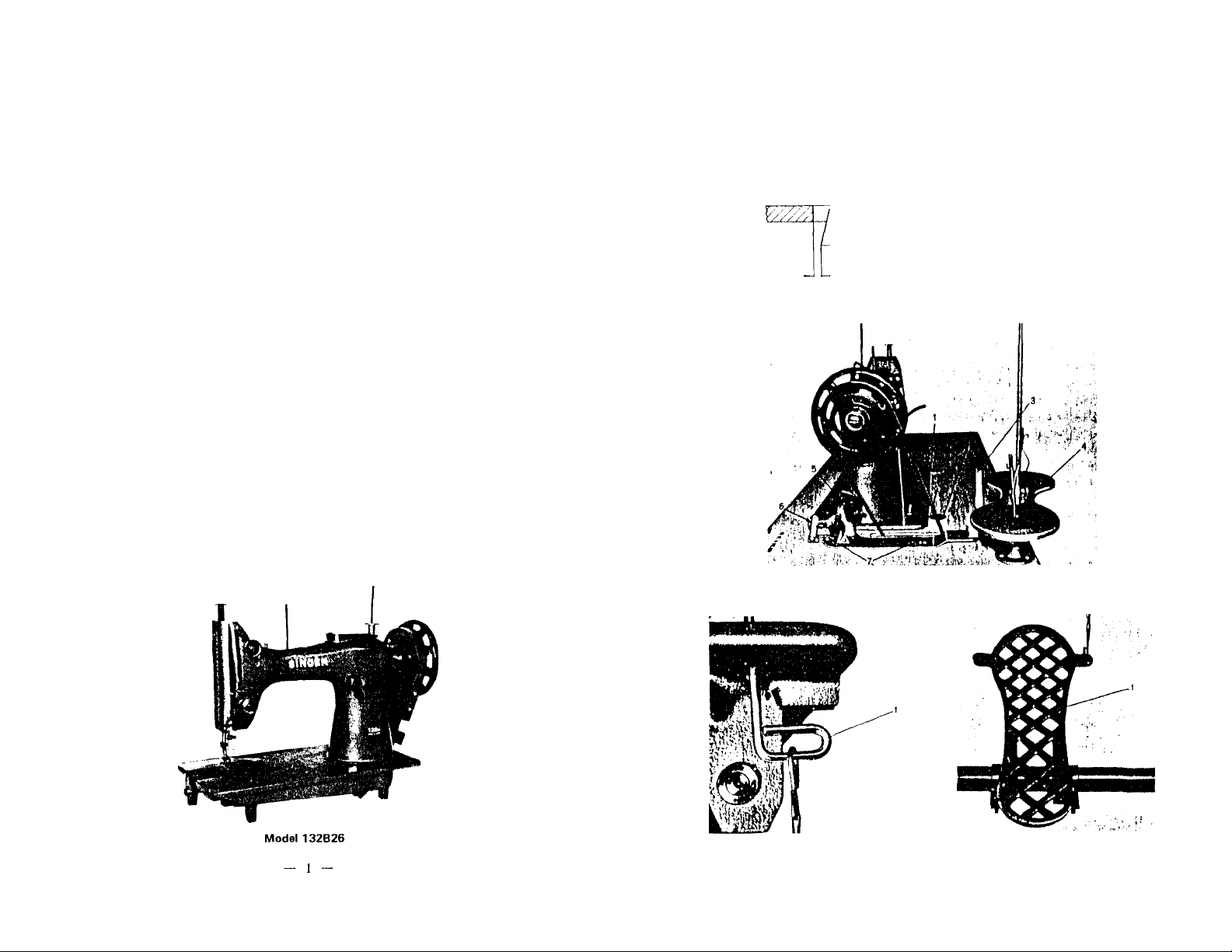

Fig. 1 To atfoch drip pan io Ihe table

Fig. 2 To Initall the machine on the table

Fig. 3 & 4 To ouemble the pedal

— 2

Page 4

Fig. 5 Th® proper angle of the pedal

OILING

Do not operate the machine, even if only for testing, unless it has been

properly oiled at every .spot requiring lubrication.

The arrows on the figures 7, 8, 9, 10 and 11 indicate these spots.

Oiling must be done at least twice daily when the machine is in continuous

operation to assure free running and durability of the operating parts.

SPEED OF THE MACHINE

The maximum speed for machines of class 132B26 is 800 stitches per minute.

Machines should be run slower than the maximum speed, until tJie parts which

are in movable contact have become glazed by their action upon each other.

— 3 —

Fig. 7

Fig. 9

Fig. 8

Fig. 10

— 4

Page 5

Fig. n

NEEDLE

The machine is set up to use Needle Cat. No. 4950 in si/e ranging lioni 18

to 29.

The thickness of tlie sewing thread, which must pass freely through the needle

eye, determines the size of the needle.

To insert the needle, turn the machine pulley toward you, until the needle

bar rise to its highest point, loosen the needle set screw (2) and put the needle

up into the needle bar as far as it will go, with the long groove of the needle,

or toward you. Then, tighten the needle set screw securely.

THREAD

Otdy left twist thread is to he used for

the needle, to test for twist, hold a length

of thread between thumbs and iiulex

fingers of your hands. Turn the thread

counterclockwise.

If it will twist tighter, it has a left .'twist.

If it unravels, it has a right twist.

The bobbin can be wound with either left or right twist thread.

WINDING BOBBINS (Figs. 2 and 15)

The bobbin winder is mounted on the table top with its pulley (5, Fig. 2)

in front of the driving belt so that the pulley will separate from the belt after

the bobbin has been wound with sufficient thread, push the bobbin on the

bobbin spindle (3 Fig. 15) as far as it will go.

Pass the thread from the thread stand downward through the eye (1, Fig. 1,5)

in the tension bracket.

Then, between and around the hack of the tension discs (2 Fig. 1,5) bring

the thread forward toward the bobbin and wind from below in clockwise direc

tion several times around the bobbin. Push bobbin winder lever (4, Fig. 15)

downward until the wheel (5) contacts the drive belt and start the machine.

After the bobbin is filled with thread, release will cause the wheel to disen

gage from the belt and winding will stop. Cut the thread and remove the

bobbin from the winder spindle.

The adjusting screw (A, Fig. 15) can be turned in or out to increase or

decrease the amount of the thread wound on the bobbin.

If the thread does not wind evenly on bobbins, loosen the screw (B, l ig 1.5)

and move the bracket to the right or left as may be required and tighten the screw.

— 5

Fig. 13

Fin. 15

Page 6

INSERTING AND REMOVING THE BOBBIN CASE AND BOBBIN

Turn the balance wheel until the needle is above the needle plate.

Push the retainer (1, Fig. 16) to the left like the figure 16, and remove the

bobbin case (2, Fig. 16).

Pull up the latch (1, Fig. 17) and lift the bobbin from the bobbin case.

To insert a full bobbin, raise the latch in center of the bobbin case, and

place the bobbin on the center post of the bobbin case.

Be sure that the thread draws out from the bobbin from left to right.

Pull the thread into the cut (4, Fig. 18) in the edge of the bobbin case, and

from you under the tension spring (5, Fig. 18). Then, pass its end from the

back through the hole (6, Fig. 18) in the bobbin case.

Finally, push down the latch to retain the bobbin in position.

Fig. 16

Fig. 17

from you

1 ,

leaving the end of the thread about 10 cm long.

PREPARING EOR SEWING

With the lelt hand hold the end

of the needle threarl, leaving it (piite

slack from the end to the needle.

Turn the hand pulley toward you

until the needle moves down and up

again to its highest position, thus

catching the under thread.

T'hen, pull the end of the needle

thread you are holding, then the

bobbin thread will be brought up

with it through the needle hole in

the needle plate.

THREADING THE MACHINE

Raise the needle bar to its highest

point, learl the thread from the hole

(I) through the thread guide (2), from

above between the retaining discs (,'i),

and from right to left around the ten

sion discs (4), over the spring (6), un

der the slack thread regulatrrr (6), up

through the guard (7), from right to

left through the hole in the take up

lever (8), down through the thread

guide (9) and the thread guide (10),

through the needle clamp hole (It),

then through the eye of the needle

— 7 —

Fig. 19

TENSION OF THE BOBBIN THREAD (Fig 18)

If it is necessary t(i alter

the tension on the bobbin

thread, slightly turn the screw

(7) to the right to increase it

or turn the screw to the left

to decrease it.

Fig. 23

I" Perfect stitching.

- Tight tension of needle thread

Loose tension of needle thread.

Fig. 24

— 8

Page 7

REGULATING THE THREAD TENSION

The thread tensions of upper thread

(a) and lower thread (b) should he

equal

1. Correct tension

2. Tight tension of needle thread

Fig. 26

3. Tight tension of bobbin thread

ADJUSTING THE TENSION OF THE UPPER THREAD

The serrated nut (fi) controls the tension of two

upper threads. To increase the tension, turn the

nut to right, or to left to decrease it.

ADJUSTING THE TENSION OF THE LOWER THREAD

Fig. 27

See the instructions for SK machines.

ADJUSTING THE PRESSER FOOT PRESSURE (Fig, 7)

The pressure of the presser foot is regulated by the screw (1).

To incrca.se the pressure, turn it to the right and to the left to decrease the pressure.

GAUGE PARTS

There are three kinds of gauge parts (needle clarttps) as 3.5 mm 4.8 mm and

7.5 mm, wliich can be changed according to your purpose, replace it to the re-

(luired size.

ONE OR THREE NEEDLE MACHINE (SKM only)

One needle machine is used for decorative coarse straight stitching.

On three needle machine, either the right or left side (two needles) make

moccasin stitch and the other needle makes decorative coarse stitching.

I hree needle machine can also be used for only the decorative coarse stitciiing

I hese stitchings can be made by replacing the re.spective presser foot, needle

clamp, needle plate, and feeder.

Fig. 29

Fig. 30

PIPING OR BEADING

Piping requires a special needle plate witli a

hole for die cord.

ADJUSTING THE STITCH LENGTH (Fig. 7)

Turn the balance wheel toward you, at the same time pressing on the feed

regulating lever (2) until it snaps into the feed driving mechanism.

Continue the pressure on the lever and turn the balance wheel either to or from

you until the travel of the feed is such as to give the required length of stitch.

THE BULGE GUIDE OF SEWING MATERIAL

Normally, edge of the guide (1)

comes to the center of the needle

plate.

To adjust this, loosen the set

screw (2) and move the guide to

ward the arrow direction.

The shape of the guide can be

varied according to the sewing

Fig. 28

purpose.

Fig. 31

DUMMY-JOINT FINISH WITH KNIFE

A knife fitted on the pres,ser foot makes dummy-joint finish on the shoe up

pers, For this work, knife and special presser foot with groove are required.

TWO ROLLER PRESSERS (SKM only)

Tie roller pressers employ ball bearings to airl

in curve stitching.

Fig. 32

10

Page 8

THE TIMING BETWEEN HOOK AND NEEDLE

Loosen the hook set screws, turn the halaiice wheel toward you until the

needle bar raises to .'1.8 iiiiii from its lowest position.

Bring the hook point (I, I'ig. .’!(i) to the renter between two needles (2) and

(.'!), then tighten the hook screws, at the same time, set the clearance between

the needle and hook point 0.1mm to 0.2 mm.

ASSEMBLING THE HOOK RETAINER BRACKET

This must be done after adjusting

the clearance between the needle and

hook.

Let the retaining spring (2) contact

sufliciently, but not to bend, with the

hook (3) without any clearance, then

tighten the screw (4) securely.

Excess contact between the two

makes unnecessary wear and noise.

Fig. 39

ADJUSTING THE HEIGHT OF THE FEEDER

Adjust the feed motion to the maximum and turn the balance wheel to raise

the feed dog to its highest position.

Loosen tite screws (I,

Fig. 41), adjust the height

of the feeder by raising or

lowering it to 1.4 mm

from the surface of the

needle plate to the feeder.

Tlicn tighten the said

screws securely.

Fig. 38

ADIUSTING THE HEIGHT OF THE NEEDLE BAR

This shotdd be made after the timing between the

needle and hook has been determined.

Turn the balance wheel toward you so as to fit

the center of the left needle to the hook point.

Loosen the screws (1, Fig. flH), adjust the needle

bar up or down so that the up|ier end of the needle

eye comes to 3.5 mm down from the book point,

at the same time, the two needles must be parallel.

Then, tighten the screw (1, Fig. .'18).

11

Fig. 41

ADIUSTING THE FEED BAR HINGED STUD

jn When the feed dog is at its highest position, if it

Lw j,; parallel with the surface of the needle plate,

loosen the stud screws (I ) and turn the stud (21 to

get it parallel, then tighten the screws.

Fig. 42

12

Page 9

TIMING BETWEEN NEEDLE AND FEEDER

The correct timing is as follows:

Adjust the feeding motion to the maximum and turn the balance wheel to

ward you, after the feed dog has finished its feeding motion and when teeth

of the feeder become equal height to the surface of the needle plate, the needle

reaches to the needle plate.

To adjust this, pull open the top cover (I), loosen three screws (3) out of

five on the feed eccentric adjusting flange coupling (2) and move the feed ec

centric adjusting flange (4) for the adjustment.

Fig. 43 Fig. 44

ADJUSTING THE UP AND DOWN TRAVEL OF THE FEEDER

The adjustment of the up and down travel of the feeder against its hack and

forth travel is made so that the teeth of the feeder rise to the highest point

at the middle position, when feeding travel is the largest.

Loosen two screws (5) and adjust it against the main shaft by moving the

feed lifting cam (6).

To make its up and down travel faster, turn the feed lifting cam toward

driving direction and to make it slower, turn the cam toward opposite direction.

Be sure to tighten screw pushing the screw against the rod (7) not to make

any clearance axialy.

ADJUSTING THE HEIGHT OF THE PRESSER FOOT

Raise the presser bar lifter (1) and so adjust the

measurement to 10 mm between the bottoiii ol

the presser foot (2) and the surface of the needle

plate (3).

To adjust this, loosen the screw (4), fit the needle

hole of the presser foot to the needle by moving the

presser bar (5) up or down, then tigliten tire screw.

Fig. 46

— 13

ADJUSTING THE THREAD CONTROLLER SPRING

(Fig, 27)

Normally, the thread controller spring (4) should hold slack of the upper

thread until the needle reaches to the goods, and it should pause.

To adjust this, loosen the screw (5) and adjust it by turning the thread take

up spring regulator (6).

To strengthen the tension of the controller spring, loosen slightly the tension

.screw stud (7) with a screw driver and turn the serrated nut to the right, to

lighten the tension, turn to the left. Then, tighten the tension screw stud.

- 14 -

Loading...

Loading...